Techno-Economic Assessment of Coal-Fired Power Unit Decarbonization Retrofit with KP-FHR Small Modular Reactors

Abstract

1. Introduction

1.1. Coal Power Sector in Poland

1.2. Options for Decarbonizing Polish Supercritical Coal-Fired Power Units

- integrating coal-fired units with Carbon Capture and Storage (CCS) installations;

- replacing coal boilers with bio-energy based boilers (and possibly additional integration with CCS installations, which may lead to obtaining negative CO2 emissions by the units [10]);

- retrofitting coal boilers with a nuclear reactor or nuclear reactors system, or, potentially high-temperature deep-drill geothermal heat sources.

1.3. Development of SMR Technology

1.4. Kairos Power KP-FHR

- a primary heat transport system where FLiBe salt (LiF/BeF2) is used as heat carrier;

- an intermediate heat transport system where solar salt (NaNO3/KNO3) is used as a heat carrier.

- the possibility of matching the thermal power of the reactor or reactors system and the heat demand of the steam turbine unit,

- the possibility of obtaining the live steam and reheated steam temperatures required by the steam turbine unit.

2. Methods

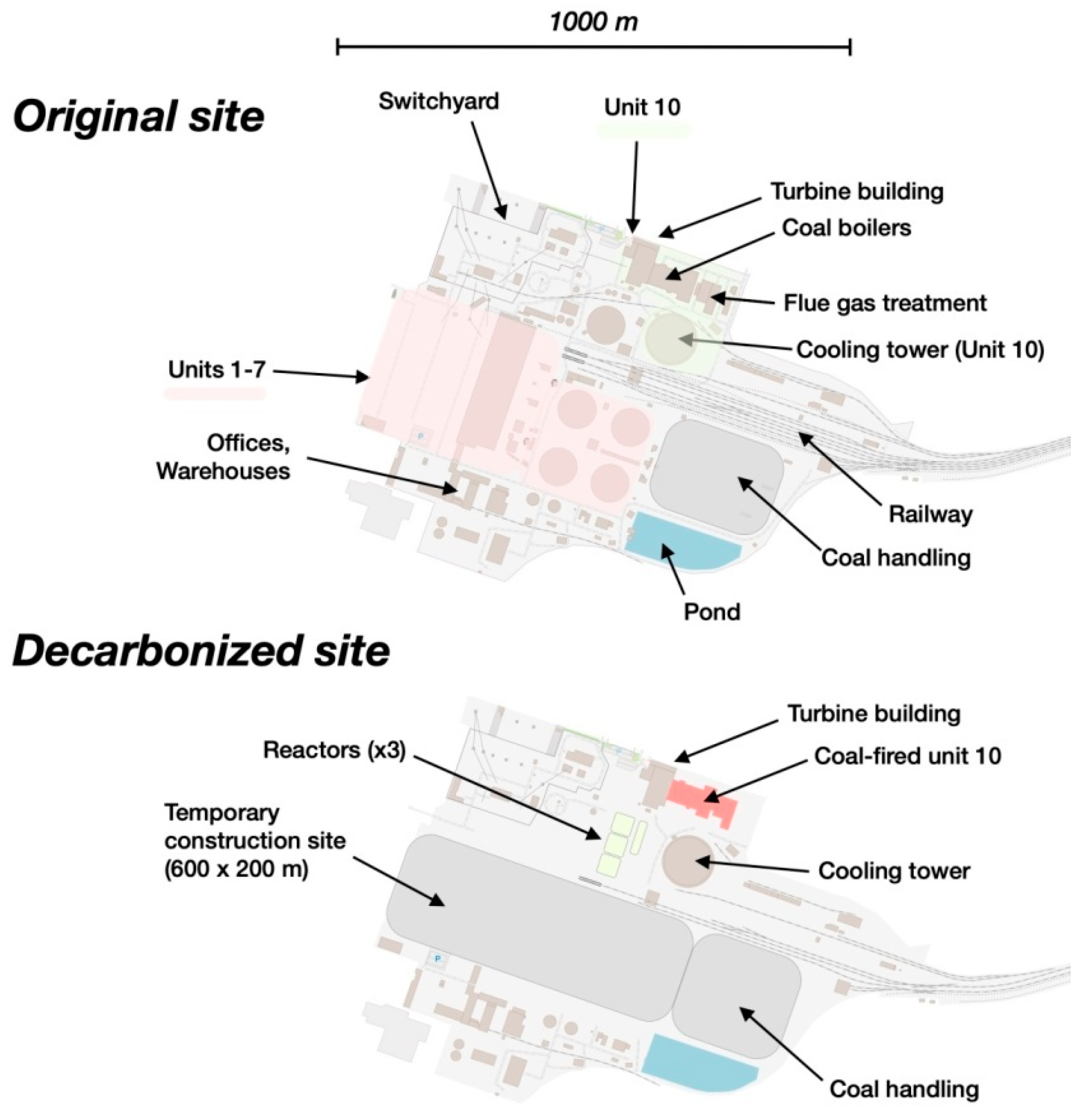

2.1. Case Study Selection

2.1.1. Criteria for the Reference Coal-Fired Power Unit Selection

- TC1: technical condition of the coal-fired unit and expected remaining lifetime;

- TC2: the operating parameters of the feedwater and steam in the coal-fired unit (at the inlet and at the outlet of the boiler) matching the operating parameters of the nuclear reactor, replacing the coal boiler;

- TC3: the thermal efficiency of the steam turbine unit, which determines the efficiency of primary energy conversion;

- TC4: the thermal power capacity of the coal boiler which determines the number of reactor units required for the nuclear retrofit;

- TC5: the physical arrangement of the power plant, deciding on the construction schedule and the possibility of carrying out and completing the reactor construction and retrofit process in parallel with continuous operation of the coal-fired unit.

2.1.2. Reference Coal-Fired Power Unit

2.2. Modeling and Design

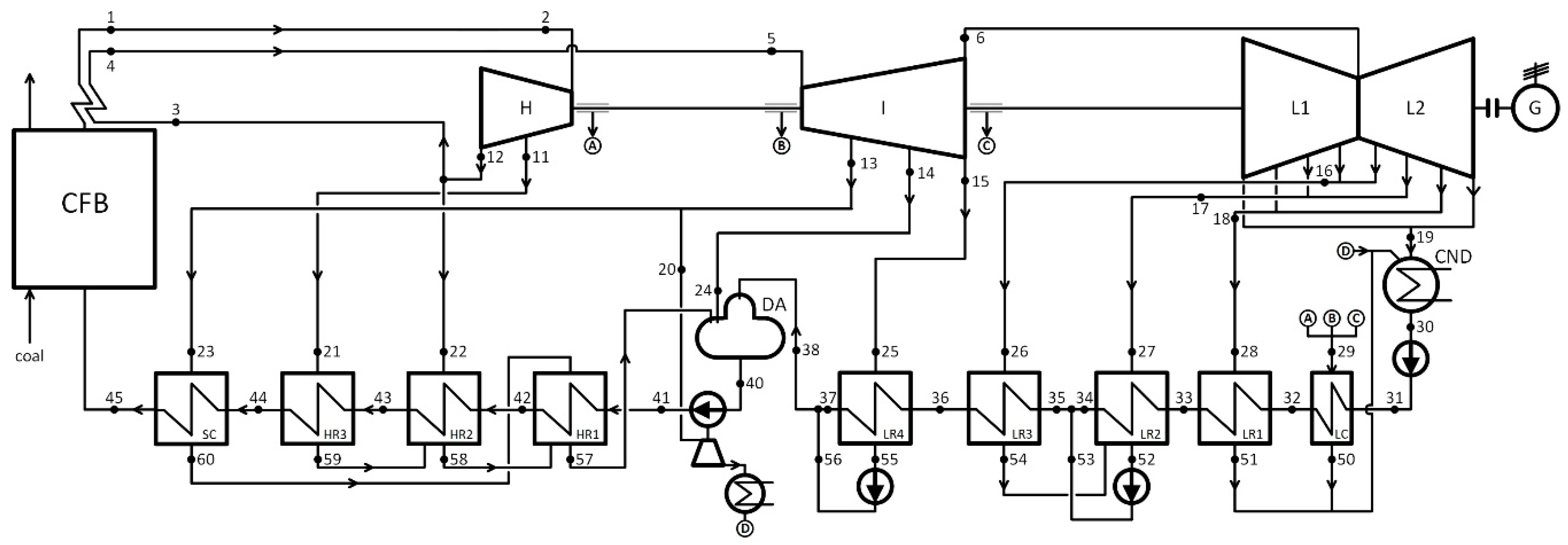

2.2.1. Model of Reference Coal-Fired Unit

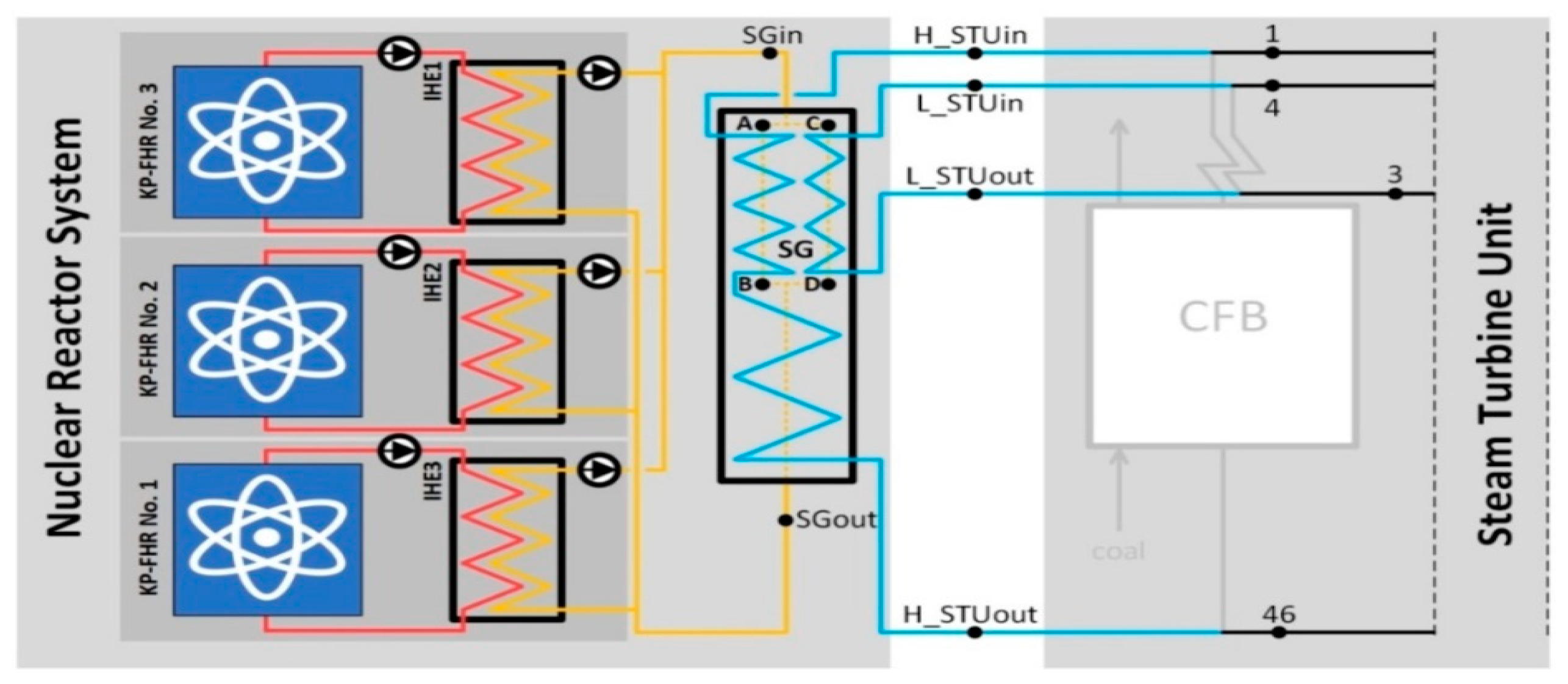

2.2.2. Steam Cycle Integration

2.3. Economic Assessment

2.3.1. Assessment Indicators

2.3.2. Assumptions

Lifetime

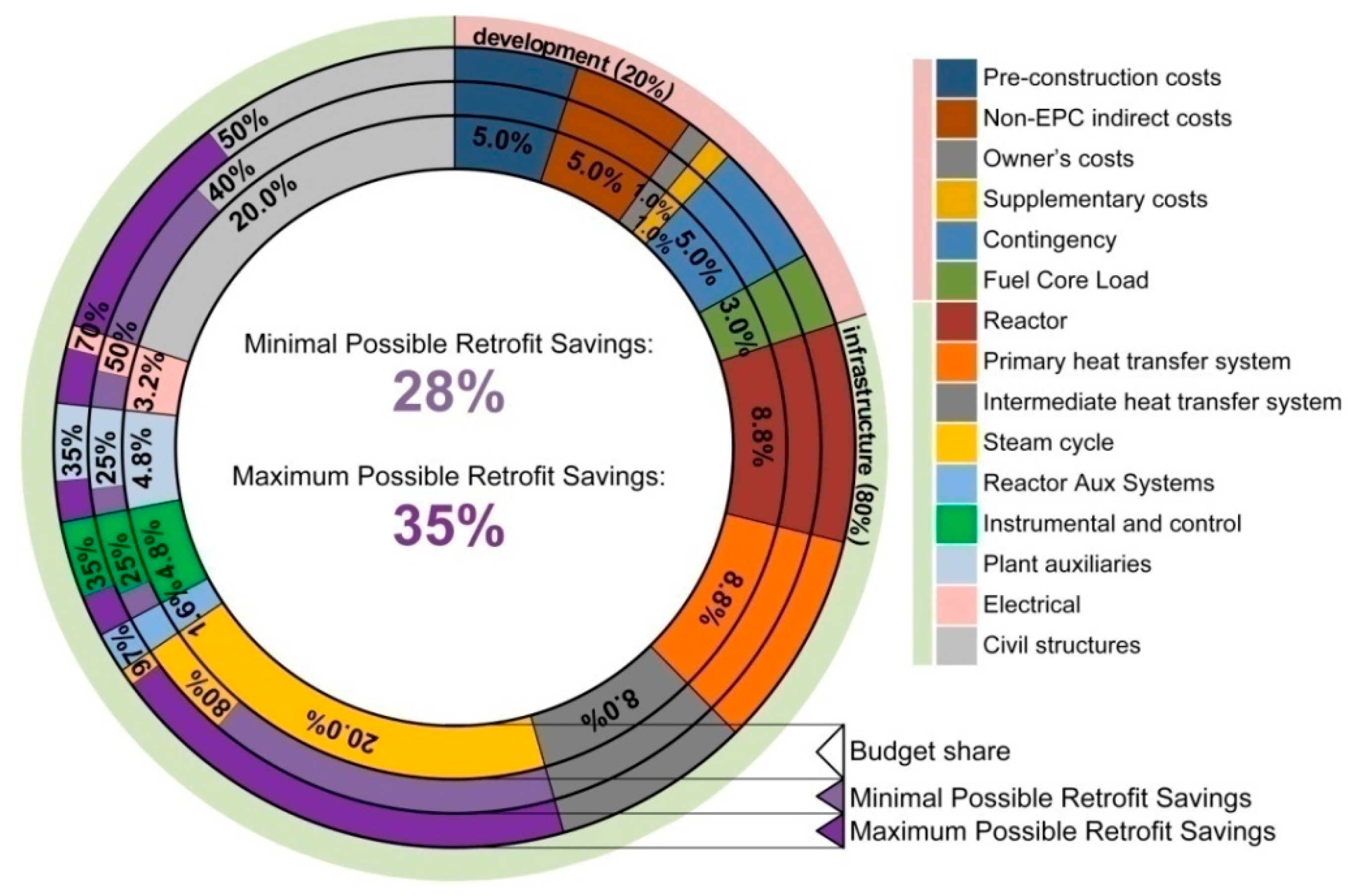

Capital Costs

Operation and Maintenance (O&M) Costs

3. Results

3.1. Technical and Energy Performance Assessment Results

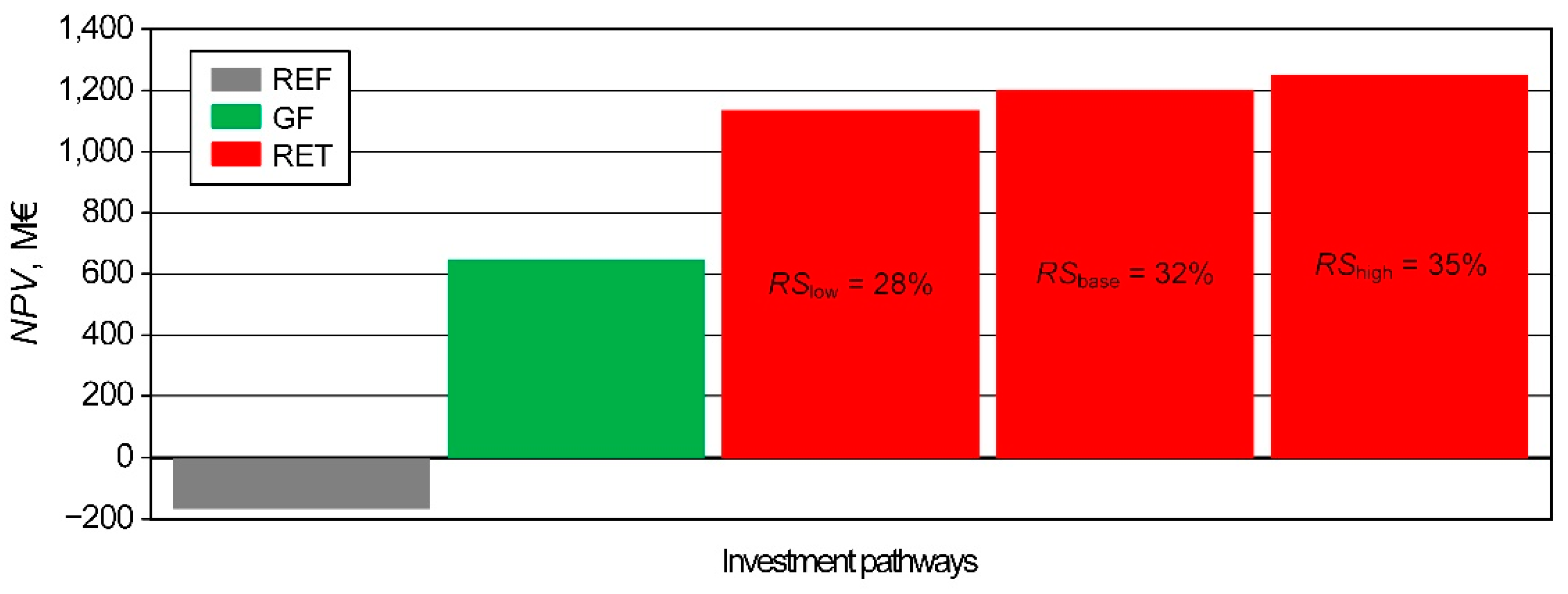

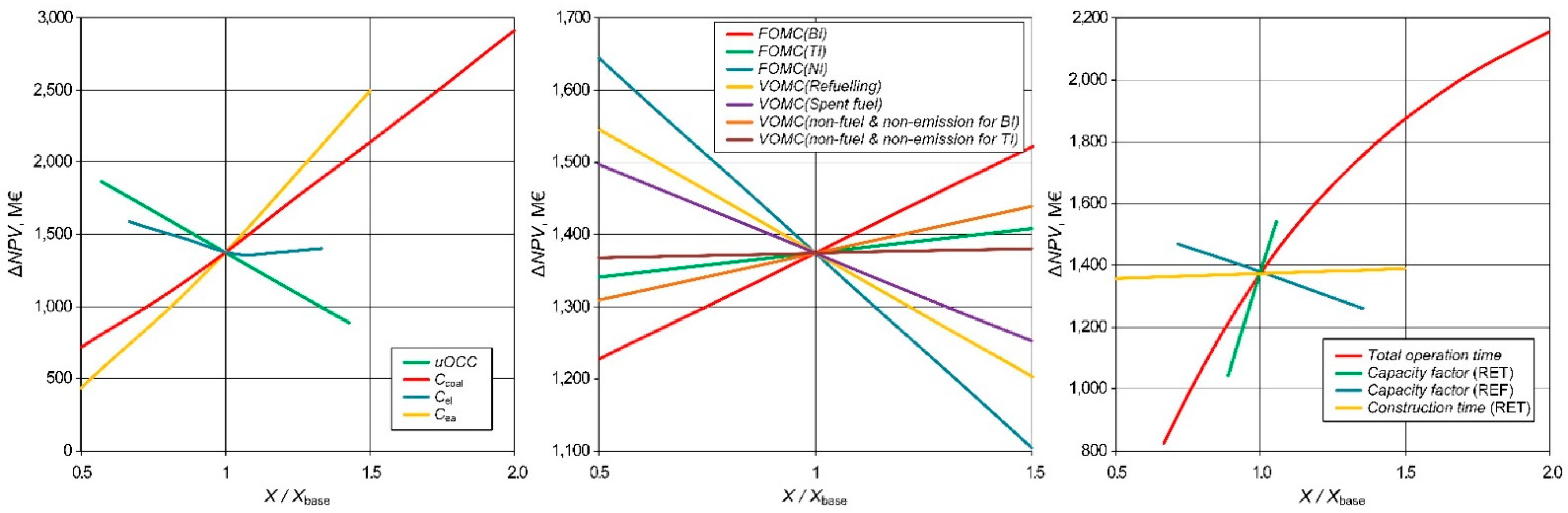

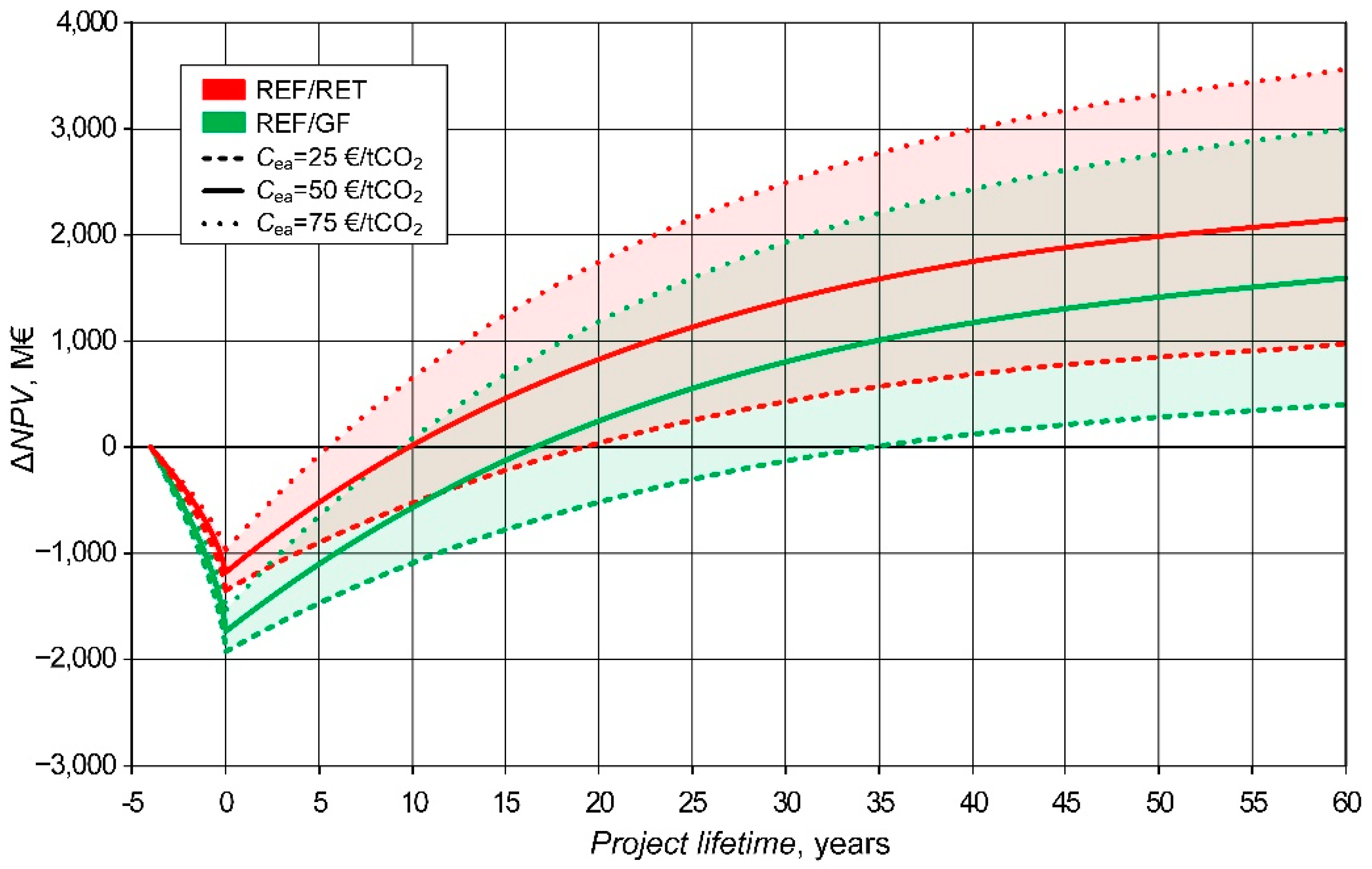

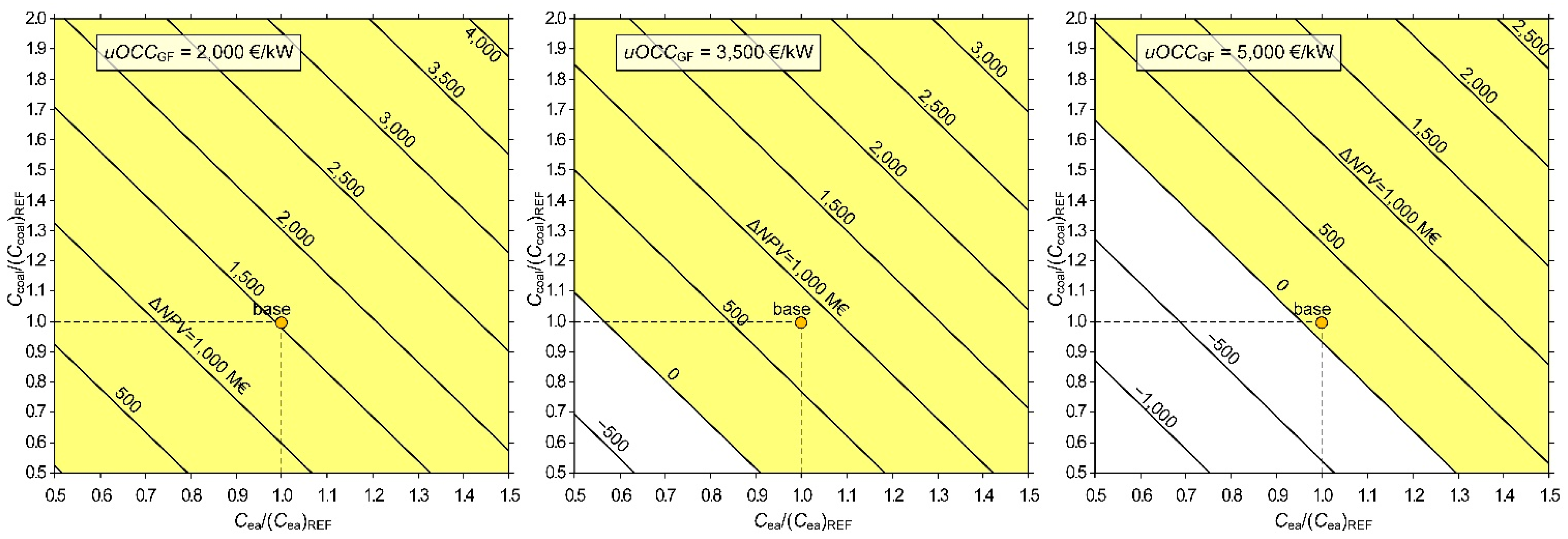

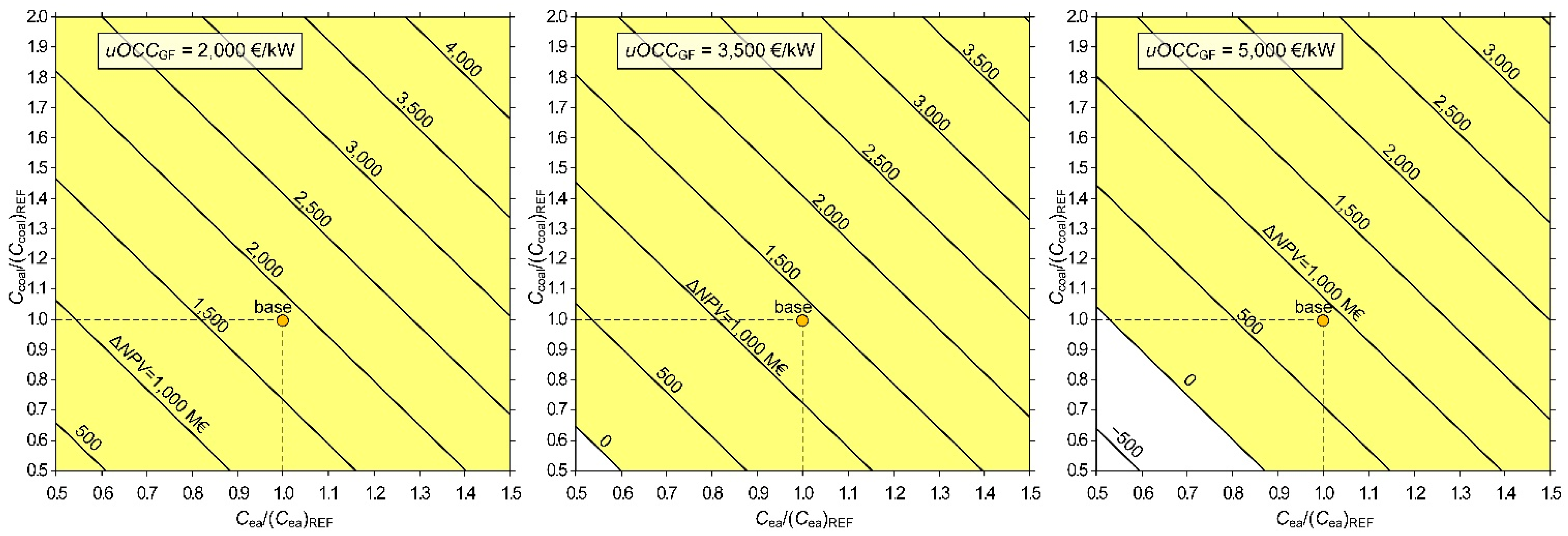

3.2. Economic Assessment Results

4. Discussion and Summary

- Technical dialog with SMRs vendors, engineering companies active in energy sector and power plant operators should be started as soon as possible to assess the detailed technical feasibility of retrofits at preselected locations.

- The decisions regarding the retrofit should be made within this decade, due to the aging of the assets and planned decommissioning.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Qvist, S.; Gładysz, P.; Bartela, Ł.; Sowiżdżał, A. Retrofit decarbonization of coal power plants—A case study for Poland. Energies 2021, 14, 120. [Google Scholar] [CrossRef]

- PSE. Summary of Quantitative Data on the Functioning of the RB IN 2019. Available online: https://www.pse.pl/dane-systemowe/funkcjonowanie-rb/raporty-roczne-z-funkcjonowania-rb-za-rok/raporty-za-rok-2019 (accessed on 5 April 2021).

- Installed Power. Report of Polish Energy Regulatory Office. Available online: https://www.ure.gov.pl/pl/oze/potencjal-krajowy-oze/5753,Moc-zainstalowana-MW.html (accessed on 5 April 2021).

- Bartela, Ł.; Milewski, J. Directions for improving the flexibility of coal-fired units in an era of increasing potential of renewable energy sources. In Power Engineering. Advences and Challenges, Part A: Thermal, Hydro and Nuclear Power; Badescu, V., Lazaroiu, G.C., Barelli., L., Eds.; CRC Press, Taylor and Francis Group: Boca Raton, FL, USA, 2018; pp. 29–44. [Google Scholar]

- Intergovernmental Panel on Climate Change. Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels; IPCC: Geneva, Switzerland, 2018. [Google Scholar]

- Gosgortekhnadzor of Russia. Model Guidelines for Inspection of Metal and Prolongation of the Service Life of Main Components of Boilers, Turbines, and Piping Systems of Thermal Power Stations; Gosgortekhnadzor: Moscow, Russia, 2003. [Google Scholar]

- Aminov, R.Z.; Shkret, A.F.; Garievskii, M.V. Estimation of lifespan and economy parameters of steam-turbine power units in thermal power plants using varying regimes. Therm. Eng. 2016, 63, 551–557. [Google Scholar] [CrossRef]

- Krieg, T. Substations in the Power System of the Future; CIGRE Study Committee B3-Substations, ELECRAMA: Bangalore, India, 2014. [Google Scholar]

- Rusin, A.; Bieniek, M. Maintenance planning of power plant elements based on avoided risk value. Energy 2017, 134, 672–680. [Google Scholar] [CrossRef]

- Schakel, W.; Meerman, H.; Talaei, A.; Ramírez, A.; Faaij, A. Comparative life cycle assessment of biomass co-firing plants with carbon capture and storage. Appl. Energy 2014, 131, 441–467. [Google Scholar] [CrossRef]

- European Commission Joint Research Centre (JRC). Technical Assessment of NUCLEAR Energy with Respect to the ‘Do No Significant Harm’ Criteria of Regulation (EU) 2020/852 (‘Taxonomy Regulation’); JRC: Ispra, Italy, 2020. [Google Scholar]

- International Atomic Energy Agency. Power Reactor Information System (PRIS); IAEA: Vienna, Austria, 2020. [Google Scholar]

- NuScale Power, LLC. Methodology for Establishing the Technical Basis for Plume Exposure Emergency Planning Zones at NuScale Small Modular Reactor Plant Sites; Revision 1, TR-0915- 17772; NuScale: Tigerd, OR, USA, 2018. [Google Scholar]

- A Cost Competitive Nuclear Power Solution. Available online: https://www.nuscalepower.com/benefits/cost-competitive (accessed on 5 April 2021).

- McDonald, C.F. Power conversion system considerations for a high efficiency small modular nuclear gas turbine combined cycle power plant concept (NGTCC). Appl. Therm. Eng. 2014, 73, 80–101. [Google Scholar] [CrossRef]

- Xu, C.; Li, Y.; Jin, M.; Kong, F.; Gao, S.; Zhou, T.; Bai, Y. Preliminary design and analysis on the cogeneration system for Small Modular Lead-cooled Fast Reactor. Appl. Therm. Eng. 2020, 174, 115302. [Google Scholar] [CrossRef]

- Blandford, E.; Brumback, K.; Fick, L.; Gerardi, C.; Haugh, B.; Hillstrom, E.; Johnson, K.; Peterson, P.F.; Rubio, F.; Sarikurt, F.S.; et al. Kairos power thermal hydraulics research and development. Nucl. Eng. Des. 2020, 364, 110636. [Google Scholar] [CrossRef]

- Blandford, E. Commercializing the FHR: From IRP to Kairos Power. Kairos Power. 2018. Available online: http://www.crmp.gatech.edu/wp-content/uploads/2019/01/0900-Ed-Blandford-Commercializing-the-FHR-From-IRP-to-Kairos-Power.pdf (accessed on 5 April 2021).

- Wiatros-Motyka, M. The Łagisza Power Plant: The World’s First Supercritical CFB. Cornerstone 2016, 4, 57–60. [Google Scholar]

- F-Chart Software LLC. Engineering Equation Solver (EES) Professional, Version 11. Available online: http://fchartsoftware.com/ees/ (accessed on 20 April 2021).

- Mignacca, B.; Locatelli, G. Economics and finance of Small Modular Reactors: A systematic review and research agenda. Renew. Sustain. Energy Rev. 2020, 118, 109519. [Google Scholar] [CrossRef]

- Nuclear Regulatory Commission. NRC Issues Subsequent Renewed Licenses for Turkey Point Reactors; US NRC: Rockville, MD, USA, 2019.

- Boldon, L.; Sabharwall, P.; Painter, C.; Liu, L. An overview of small modular reactors: Status of global development, potential design advantages, and methods for economic assessment. Int. J. Energy Environ. Econ. 2014, 22, 437–459. [Google Scholar]

- Ingersoll, E.; Gogan, K.; Herter, J.; Foss, A. The ETI Nuclear Cost Drivers Project Full Technical Report; Energy Systems Catapult: Birmingham, UK, 3 September 2020. [Google Scholar]

- Hampe, J.; Madlener, R. Economic feasibility of high-temperature reactors for industrial cogeneration: An investor’s perspective. J. Nucl. Sci. Technol. 2016, 53, 1–19. [Google Scholar] [CrossRef]

- Scully Capital Services Inc. Business Case for Small Modular Reactors; Report on Findings to the U.S. Department of Energy Office of Nuclear Energy: Washington, DC, USA, 2014.

- Pannier, C.; Skoda, R. Comparison of Small Modular Reactor and Large Nuclear Reactor fuel cost. Energy Power Eng. 2014, 6. [Google Scholar] [CrossRef]

- Swedish Nuclear Waste Fund, Annual Report 2020. Available online: http://www.karnavfallsfonden.se/download/18.5903daa61784af90c4619b3c/1616593059594/Annual%20report%202020.pdf (accessed on 20 April 2021).

- Parsons Brinckerhoff. Quantitative Analysis and Initial Business Case—Establishing Anuclear Power Plant and Systems in South Australia; WSP: Quebec City, QC, Canada, 2016. [Google Scholar]

- Central Electricity Generating Board. Station Planning and Design: Incorporating Modern Power System Practice; British Electricity International: London, UK, 1993. [Google Scholar]

- Gibowicz, S.J.; Droste, Z. The Belchatow, Poland, Earthquakes of 1979 and 1980 induced by surface mining. Eng. Geol. 1981, 17, 257–271. [Google Scholar] [CrossRef]

- Lacomte, T.; de la Fuente, J.F.F.; Neuwahl, F.; Canova, M.; Pinasseau, A.; Jankov, I.; Thomas, B.; Serge, R. Best Available Techniques (BAT) reference document for large combustion plants. Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control). JRC Sci. Policy Rep. 2017, 12, 851–861. [Google Scholar] [CrossRef]

- Bachmann, T.M.; van der Kamp, J. Environmental cost-benefit analysis and the EU (European Union) Industrial Emissions Directive: Exploring the societal efficiency of a DeNOx retrofit at a coal-fired power plant. Energy 2014, 68, 125–139. [Google Scholar] [CrossRef]

- Data & Statistics—IEA. Available online: https://www.iea.org/data-and-statistics?country=POLAND&fuel=CO2emissions&indicator=CO2emissionsbyenergysource (accessed on 5 April 2021).

- Hong, S.; Bradshaw, C.J.A.; Brook, B.W. Global zero-carbon energy pathways using viable mixes of nuclear and renewables. Appl. Energy 2015, 143, 451–459. [Google Scholar] [CrossRef]

- Nuclear Energy Agency. Small Modular Reactors: Challenges and Opportunities. Nuclear Technology Development and Economics; Nuclear Energy Agency: Warsaw, Poland, 2021. [Google Scholar]

- Sandia National Labs. Solar Power Tower Design Basis Document; Sandia National Labs: Albuquerque, NM, USA, 2001.

| Unit | Capacity, MW | Net Efficiency, % | Live/Reheated Steam Temp., °C/°C | Date of Commissioning | Fuel |

|---|---|---|---|---|---|

| Pątnów 2 B9 | 474 | 41.0 | 544/568 | 2.2008 | Lignite coal |

| Łagisza B10 | 460 | 42.8 | 560/580 | 6.2009 | Hard coal |

| Bełchatów B14 | 858 | 42.0 | 554/582 | 10.2011 | Lignite coal |

| Kozienice 2 B11 | 1075 | 45.6 | 603/621 | 12.2017 | Hard coal |

| Opole B5 | 905 | 45.6 | 600/610 | 5.2019 | Hard coal |

| Opole B6 | 905 | 45.6 | 600/611 | 10.2019 | Hard coal |

| Jaworzno 2 B7 | 910 | 45.9 | 600/620 | 11.2020 (planned) | Hard coal |

| Turów B11 | 496 | 43.0 | 565/600 | 11.2020 (planned) | Lignite coal |

| Parameters | Value |

|---|---|

| Total thermal power, MW | 320 * |

| Auxiliary power, MW | 3 |

| LiF/BeF2: | |

| Flow rate, kg/s | 1200–1400 |

| Pressure, MPa | <0.2 |

| Temperature, °C | 650/550 |

| NaNO3/KNO3 (solar salt): | |

| Flow rate, kg/s | 2080 |

| Temperature (in/out), kg/s | 500/600 |

| Parameter | Value | Unit |

|---|---|---|

| Live steam flow | 361 | kg/s |

| Live steam temperature (at CFB outlet/at ST inlet) | 563/560 | °C/°C |

| Reheated steam temperature (at CFB outlet/at ST inlet) | 583/580 | °C/°C |

| Live steam pressure (at ST inlet) | 27.50 | MPa |

| Reheated steam pressure (at ST inlet) | 4.95 | MPa |

| Deaerator operating pressure | 1.15 | MPa |

| Condenser operating pressure | 0.005 | MPa |

| Feed water temperature | 290 | °C |

| Internal efficiency of HP ST stage—points 2–12 | 89 | % |

| Internal efficiency of IP ST stage groups—points 5–15 | 92 | % |

| Internal efficiency of LP ST stage groups—points 6–18 | 90 | % |

| Internal efficiency of LP ST stage groups—points 18–19 | 85 | % |

| Pressure drop of working medium in steam boiler | 11 | % |

| Pressure drop of steam in reheater | 6 | % |

| Pressure drop in live steam pipes | 1 | % |

| Pressure drop in reheated steam pipes | 1 | % |

| Pressure drop in pipes of steam fed to FWHs and steam coolers | 1 | % |

| Pressure drop of water in FWHs and steam cooler | 1 | % |

| Pressure drop of hot medium in FWHs and steam cooler | 1 | % |

| Specific flow fraction of steam leaks | 0.5 | % |

| Temperature increase in LP FHWs (LR1-LR4) | 30 | K |

| Terminal temperature differences for all FWHs | 3 | K |

| Temperature increase in steam cooler | 5 | K |

| Subcooling of the condensate leaving the HP FWHs | 10 | K |

| CFB thermal efficiency | 94.0 | % |

| Generator efficiency | 98.8 | % |

| Mechanical losses (0.1% of reference gross power capacity) | 0.46 | MW |

| Internal efficiency of pumps | 85.0 | % |

| Efficiency of FWHs and steam coolers | 99.5 | % |

| Boiler island auxiliary power | 12.60 | MW |

| Other auxiliary power (1.5% of reference gross power capacity) | 6.9 | MW |

| Parameter | References | Model | Model Error |

|---|---|---|---|

| Gross power capacity | 460.0 MW | 459.60 MW | 0.087% |

| Net power capacity | 439.0 MW | 439.47 MW | 0.107% |

| Chemical energy flux | - | 1018.2 MW | - |

| Boiler heat output | - | 957.1 MW | - |

| Unit fuel consumption per net production | - | 8340.8 kJ/kWh | - |

| Gross efficiency | 45.00% | 45.14% | 0.311% |

| Net efficiency | 42.80% | 43.16% | - |

| Steam cycle thermal efficiency | - | 48.02% | - |

| Steam turbine cycle auxiliary power (only the pumps auxiliary powers are included) | - | 0.64 MW | - |

| Auxiliary power of boiler island | 12.60 MW | 12.60 MW | - |

| Other auxiliary power | - | 6.89 MW | - |

| Auxiliary power index | - | 4.38% | - |

| Parameter | Symbol | Investment Pathway | References | ||

|---|---|---|---|---|---|

| GF (Nuclear Greenfield) | RET (Nuclear Retrofit) | REF (W/O Investment) | |||

| Lifetime | |||||

| Construction time, years | CT | 4 | 4 | - | [24] |

| Capacity factor, 12% | CF | 90 | 90 | 70 | [25], * |

| Total operation time assumed for the NPV analysis, years | TOT | 30 | 30 | 30 | |

| Capital costs | |||||

| Unit overnight capital cost (GF investment type), €/kW | uOCCGF | 3500 | 3500 | - | [24] |

| Retrofit savings, % | RS | - | 32 | - | [1] |

| Interest rates on construction loan, % | 5 | 5 | - | [24] | |

| Variable O&M costs | |||||

| Refuelling costs, €/MWh | uVOMC (RC) | 7 | 7 | - | [26,27] |

| Spent nuclear fuel costs, €/MWh | uVOMC (SFC) | 5 | 5 | - | [28,29] |

| Coal price, €/GJ | - | - | 3.2 | * | |

| Electricity price, €/MWh | 75 | 75 | 75 | * | |

| CO2 emission allowance price (), €/tCO2 | - | - | 50 | * | |

| Non-fuel and non-emission costs for boiler island, €/MWh | uVOMC (nnBI) | - | - | 2.25 | * |

| Non-fuel and non-emission costs for turbine island, €/MWh | uVOMC (nnTI) | 1.20 | 1.50 | 1.50 | * |

| Fixed O&M costs, €/MW/y | uFOMC | 100,000 | 104,000 | 50,000 | [24], * |

| Boiler island, €/MW/y | uFOMC (BI) | - | - | 30,000 | * |

| Turbine island, €/MW/y | uFOMC (TI) | 16,000 | 20,000 | 20,000 | * |

| Nuclear Island, €/MW/y | uFOMC (NI) | 84,000 | 84,000 | - | [24] |

| Others | |||||

| Discount rate, % | 6 | 6 | 6 | * | |

| Annual inflation rate, % | 2 | 2 | 2 | ||

| Tax rate, % | 19 | 19 | 19 | ||

| Parameter | Range of Values * | |

|---|---|---|

| Low Value | High Value | |

| Unit overnight capital cost (GF investment type), €/kW | 2000 (0.571) | 5000 (1.429) |

| Coal price, €/GJ | 1.6 (0.5) | 6.4 (2.0) |

| Electricity price, €/MWh | 50 (0.667) | 100 (1.333) |

| CO2 emission allowance price, €/tCO2 | 25 (0.5) | 75 (1.5) |

| Fixed O&M costs for boiler island, €/MW/y | 15,000 (0.5) | 45,000 (1.5) |

| Fixed O&M costs for turbine island, €/MW/y | GF:8000 (0.5) RET:10,000 (0.5) | GF:24,000 (1.5) RET:30,000 (1.5) |

| Fixed O&M costs for nuclear island, €/MW/y | 42,000 (0.5) | 126,000 (1.5) |

| Variable O&M costs for retrofit case (refuelling), €/MWh | 3.5(0.5) | 10.5(1.5) |

| Variable O&M costs for retrofit case (spent fuel), €/MWh | 2.5 (0.5) | 7.5 (1.5) |

| Variable O&M costs for boiler island (non-fuel and non-emission), €/MWh | 1.125 (0.5) | 3.375 (1.5) |

| Variable O&M costs for turbine island (non-fuel and non-emission), €/MWh | GF:0.6 (0.5) RET:0.75 (0.5) | GF:1.8 (1.5) RET:2.25 (1.5) |

| Construction time, years | 2 (0.5) | 6 (1.5) |

| Project lifetime, years | 20 (0.667) | 60 (2.0) |

| Capacity factor for retrofit case, % | 80(0.889) | 95 (1.056) |

| Capacity factor for reference case, % | 50 (0.714) | 95 (1.357) |

| REF | RET | Relative Change, % | |||

|---|---|---|---|---|---|

| Salt | SGin | m, kg/s | - | 6240.0 | - |

| t, °C | - | 600.0 | - | ||

| A | m, kg/s | - | 3955.2 | - | |

| t, °C | - | 600.0 | - | ||

| B | m, kg/s | - | 3955.2 | - | |

| t, °C | - | 540.5 | - | ||

| C | m, kg/s | - | 2284.8 | - | |

| t, °C | - | 600.0 | - | ||

| D | m, kg/s | - | 2284.8 | - | |

| t, °C | - | 540.5 | - | ||

| SGout | m, kg/s | - | 6240.0 | - | |

| t, °C | - | 500.0 | - | ||

| Steam/Water | H_STUin | m, kg/s | 361.0 | 358.0 | 0.8 |

| t, °C | 290.0 | 290.0 | 0.0 | ||

| p, kPa | 31,212.0 | 30,952.6 | 0.8 | ||

| H_STUout | m, kg/s | 361.0 | 358.0 | 0.8 | |

| t, °C | 563.0 | 563.0 | 0.0 | ||

| p, kPa | 27,778.0 | 27,547.8 | 0.8 | ||

| L_STUin | m, kg/s | 309.0 | 306.6 | 0.8 | |

| t, °C | 311.6 | 311.8 | 0.1 | ||

| p, kPa | 5319.0 | 5278.5 | 0.8 | ||

| L_STUout | m, kg/s | 309.0 | 306.6 | 0.8 | |

| t, °C | 583.0 | 583.0 | 0.0 | ||

| p, kPa | 5000.0 | 4961.8 | 0.8 | ||

| REF | RET | ||

|---|---|---|---|

| Gross power | Nelg, MW | 459.60 | 456.06 |

| Net power | Neln, MW | 439.47 | 439.58 |

| Auxiliary power of STU | Naux_STU, MW | 0.64 | 0.64 |

| Auxiliary power of boiler island | Naux_BI, MW | 12.60 | - |

| Other auxiliary power | Naux_Ot, MW | 6.89 | 6.84 |

| Auxiliary power of NR | Naux_NR, MW | - | 9.00 |

| Gross thermal efficiency of STU | ηt_STU, % | 48.02 | 48.02 |

| Thermal power of HHECFB/HHESG | QHHE, MW | 747.95 | 742.62 |

| Thermal power of LHECFB/LHESG | QLHE, MW | 209.16 | 207.07 |

| Pathway of Investment | |||||||

|---|---|---|---|---|---|---|---|

| GF | RET | ||||||

| Cea, €/tCO2 | Cea, €/tCO2 | ||||||

| 25 | 50 | 75 | 25 | 50 | 75 | ||

| Cel, €/MWh | 50 | 33 | 14 | 8 | 18 | 8 | 4 |

| 75 | 35 | 17 | 10 | 19 | 10 | 6 | |

| 100 | 33 | 17 | 12 | 19 | 11 | 8 | |

| Ccoal, €/GJ | 1.6 | >60 | 26 | 9 | 41 | 15 | 14 |

| 3.2 | 35 | 17 | 10 | 19 | 10 | 6 | |

| 6.4 | 13 | 8 | 6 | 8 | 5 | 3 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartela, Ł.; Gładysz, P.; Andreades, C.; Qvist, S.; Zdeb, J. Techno-Economic Assessment of Coal-Fired Power Unit Decarbonization Retrofit with KP-FHR Small Modular Reactors. Energies 2021, 14, 2557. https://doi.org/10.3390/en14092557

Bartela Ł, Gładysz P, Andreades C, Qvist S, Zdeb J. Techno-Economic Assessment of Coal-Fired Power Unit Decarbonization Retrofit with KP-FHR Small Modular Reactors. Energies. 2021; 14(9):2557. https://doi.org/10.3390/en14092557

Chicago/Turabian StyleBartela, Łukasz, Paweł Gładysz, Charalampos Andreades, Staffan Qvist, and Janusz Zdeb. 2021. "Techno-Economic Assessment of Coal-Fired Power Unit Decarbonization Retrofit with KP-FHR Small Modular Reactors" Energies 14, no. 9: 2557. https://doi.org/10.3390/en14092557

APA StyleBartela, Ł., Gładysz, P., Andreades, C., Qvist, S., & Zdeb, J. (2021). Techno-Economic Assessment of Coal-Fired Power Unit Decarbonization Retrofit with KP-FHR Small Modular Reactors. Energies, 14(9), 2557. https://doi.org/10.3390/en14092557