Performance Study and Optimization Design of High-Speed Amorphous Alloy Induction Motor

Abstract

1. Introduction

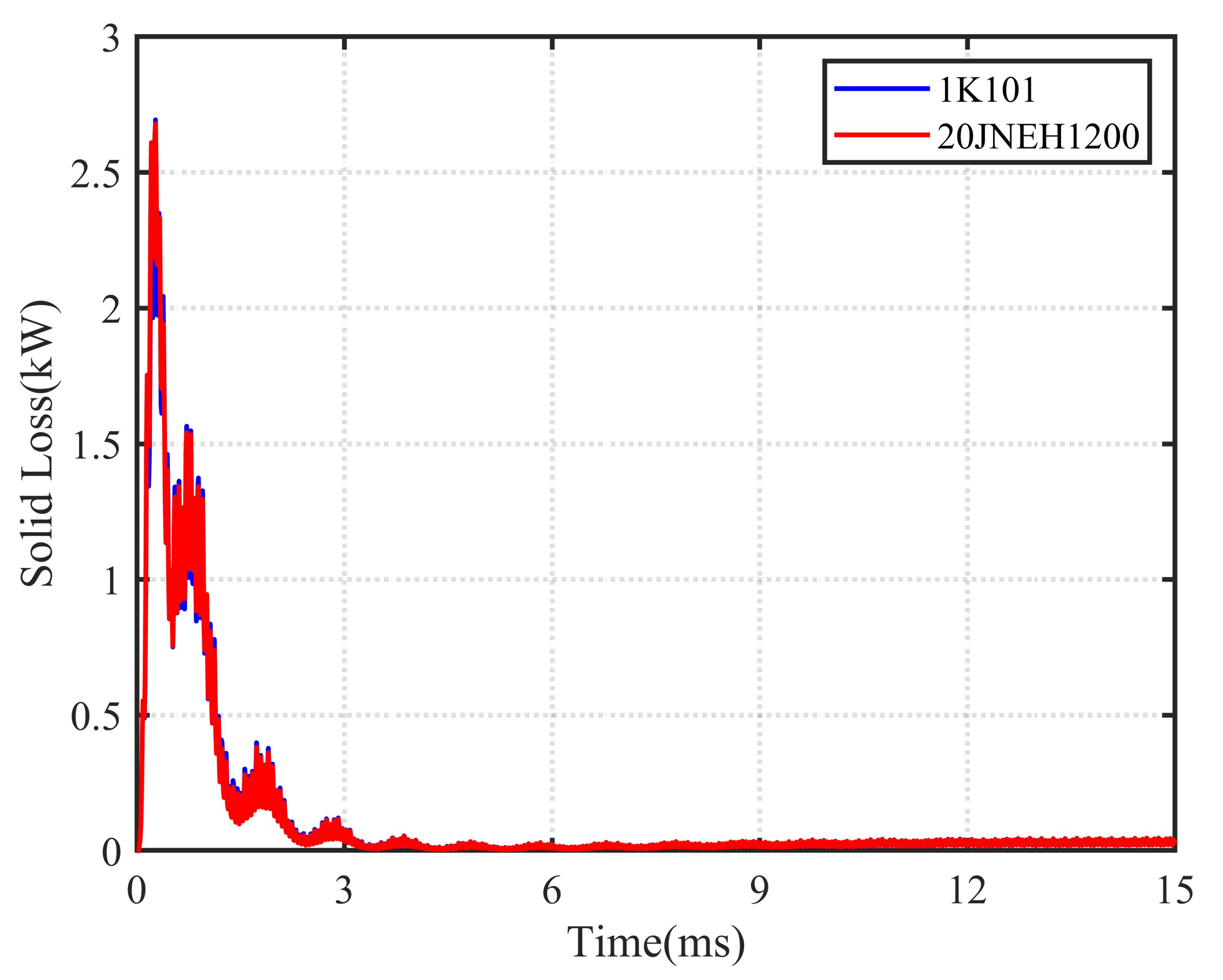

2. Loss Analysis and Material Comparison

2.1. Loss Analysis

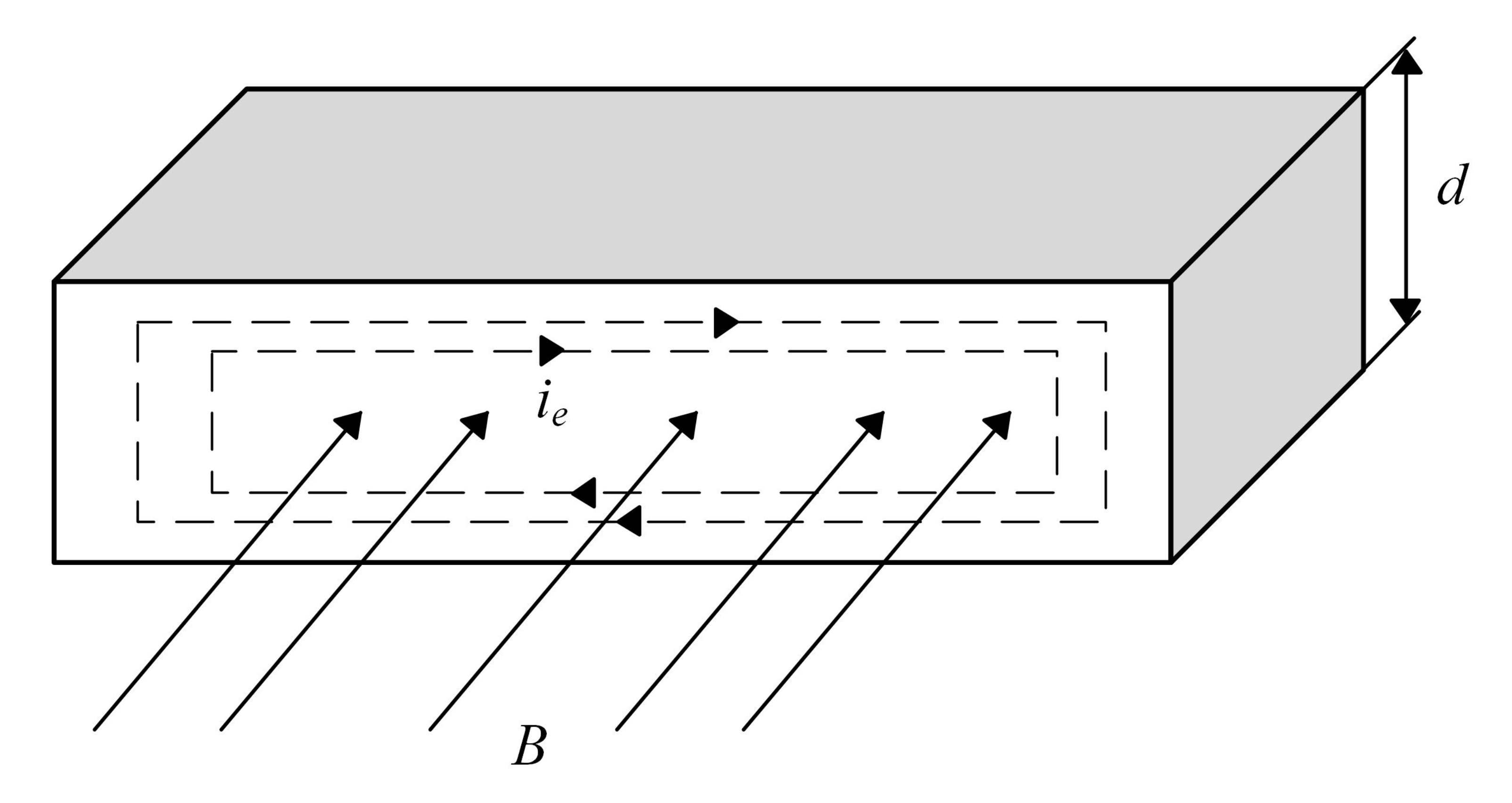

2.1.1. Copper Loss

2.1.2. Core Loss

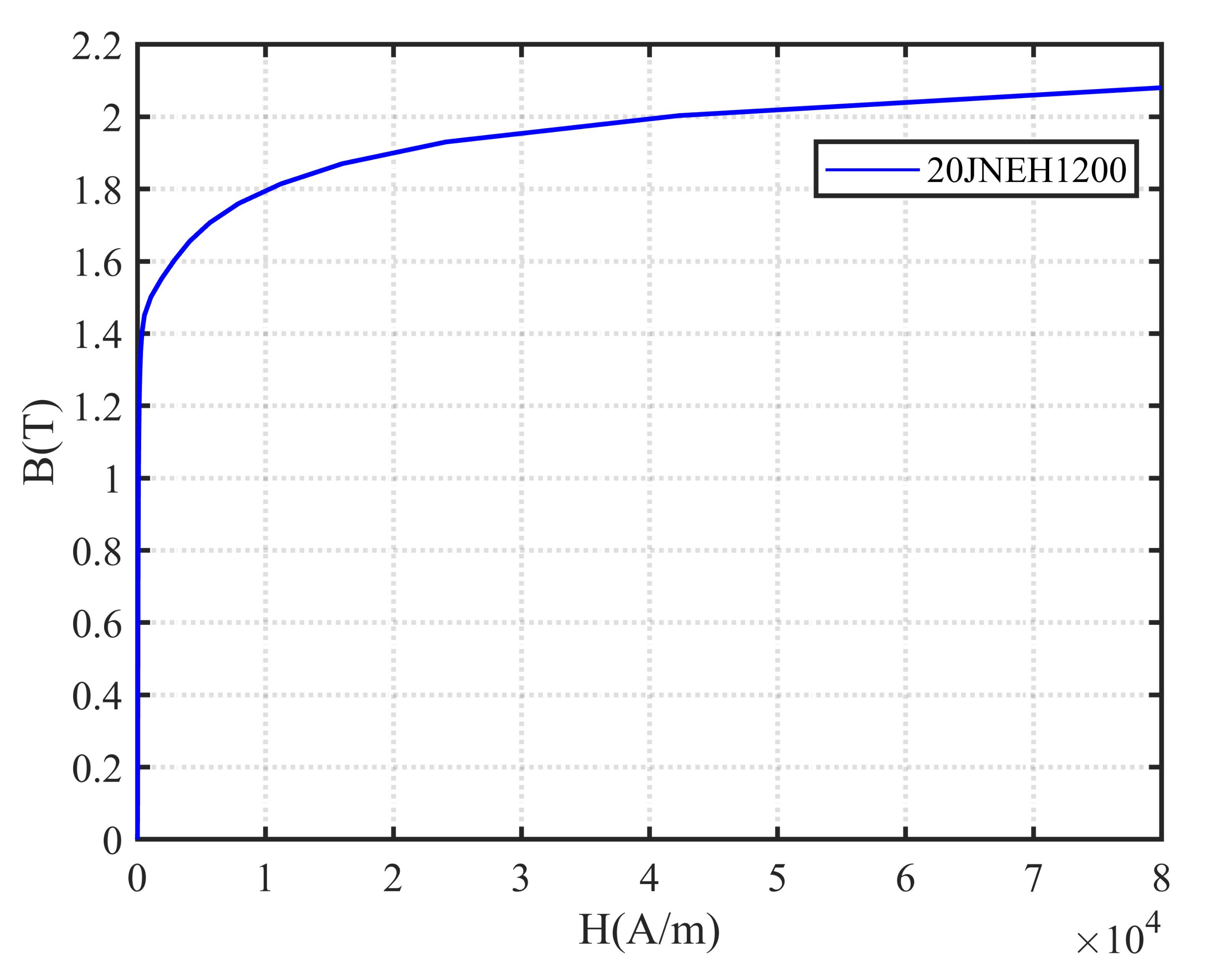

2.2. Material Characteristics Comparison

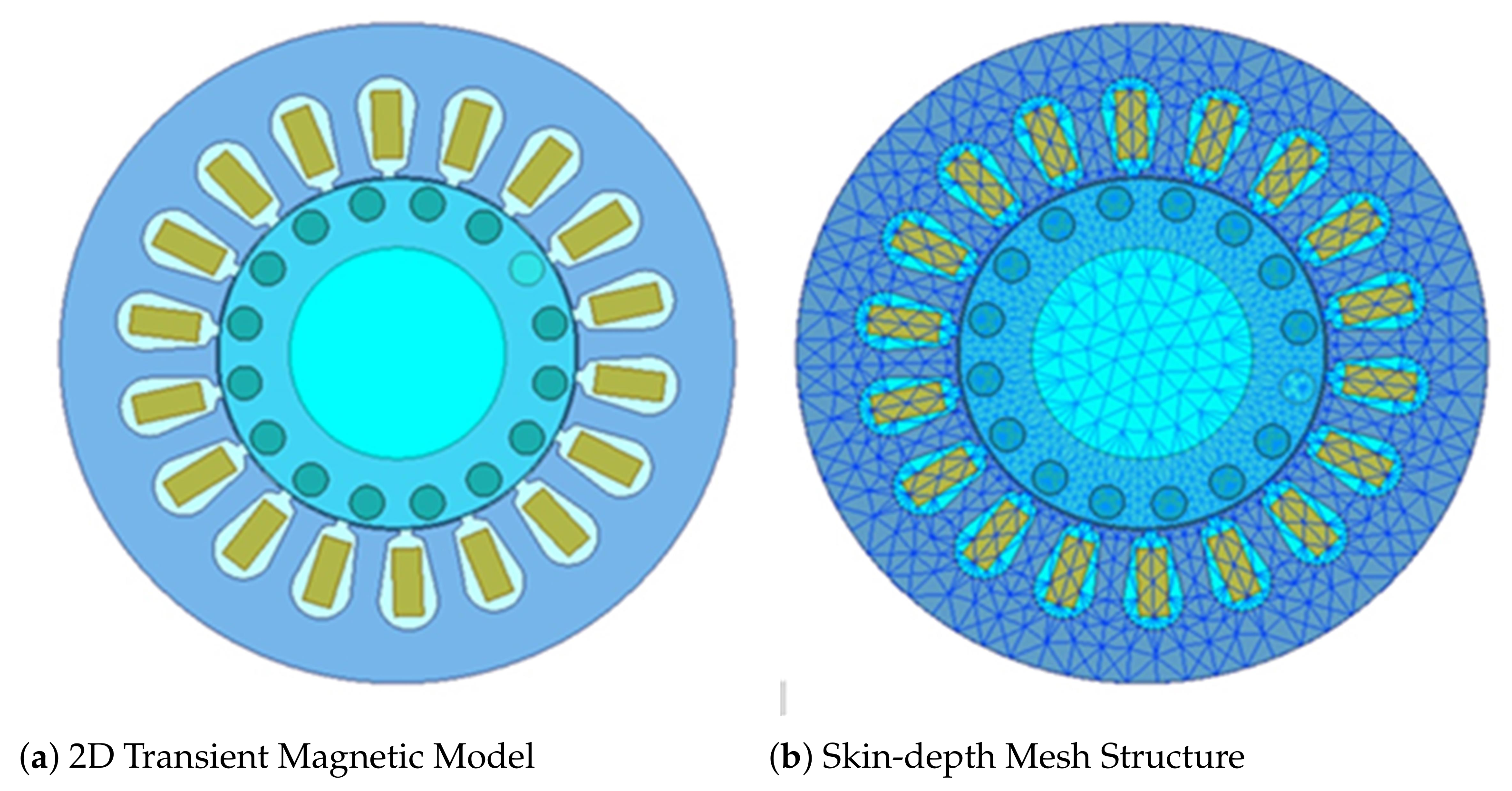

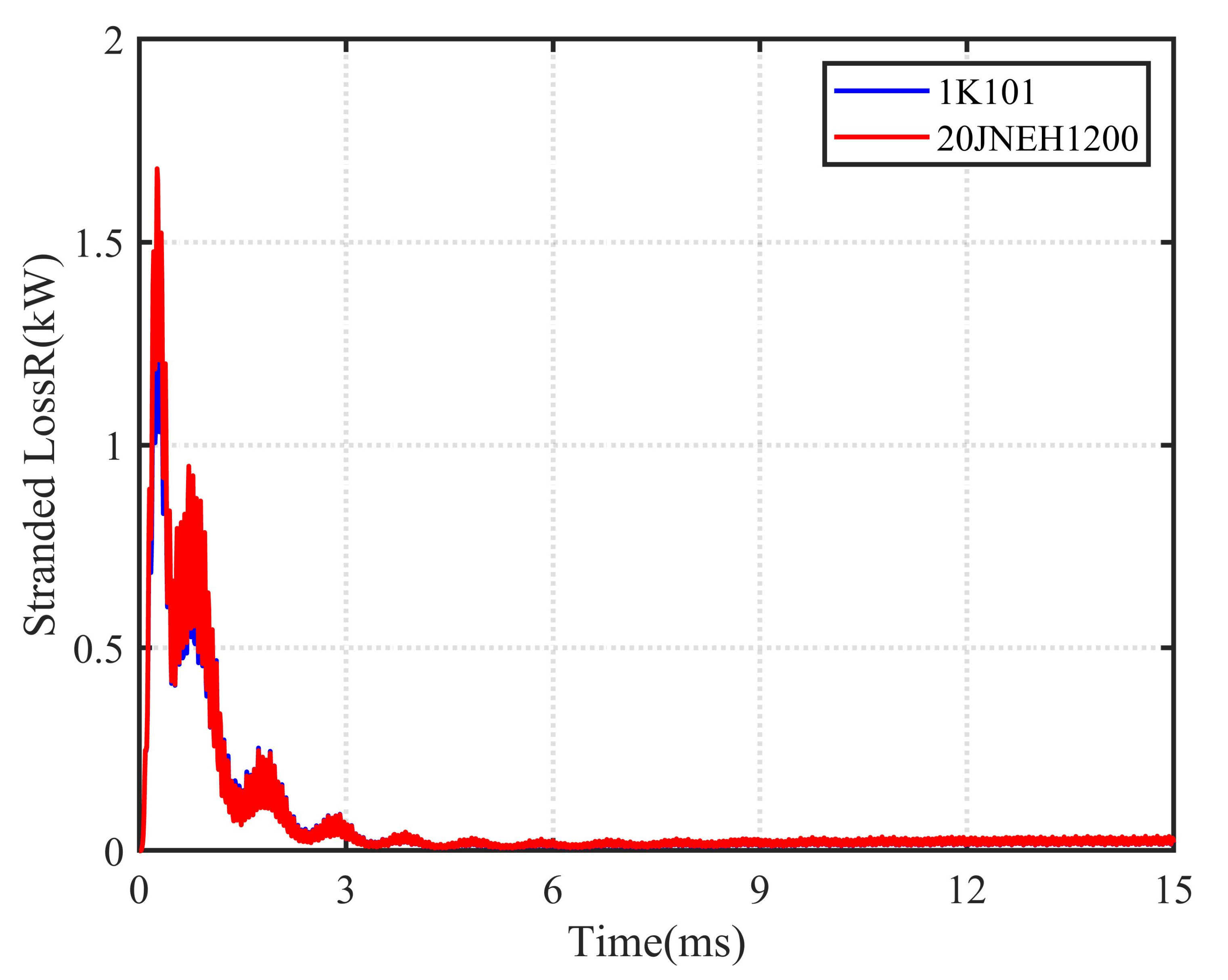

2.3. Comparison of Motor Loss and Performance with Stator Core of Different Materials

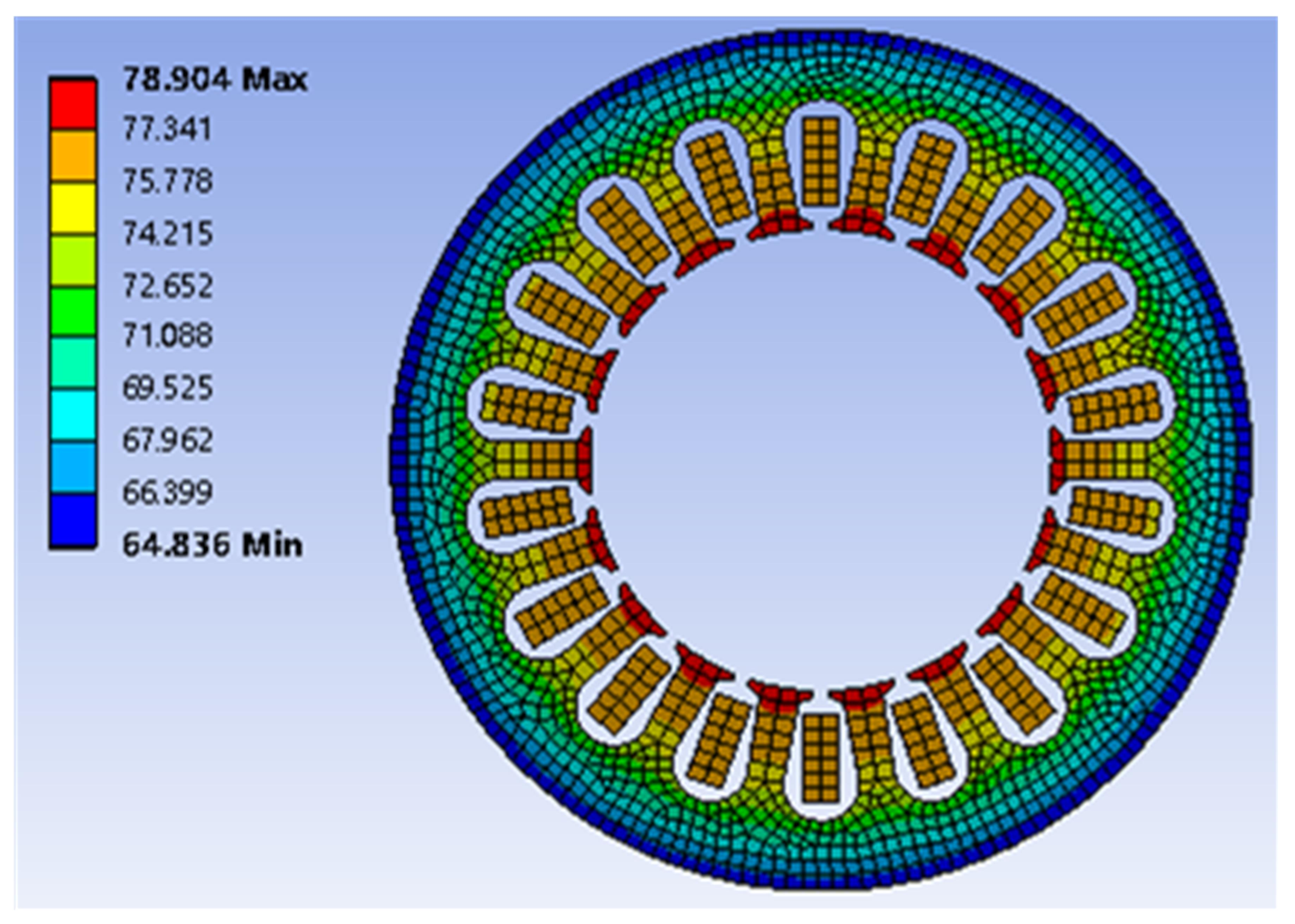

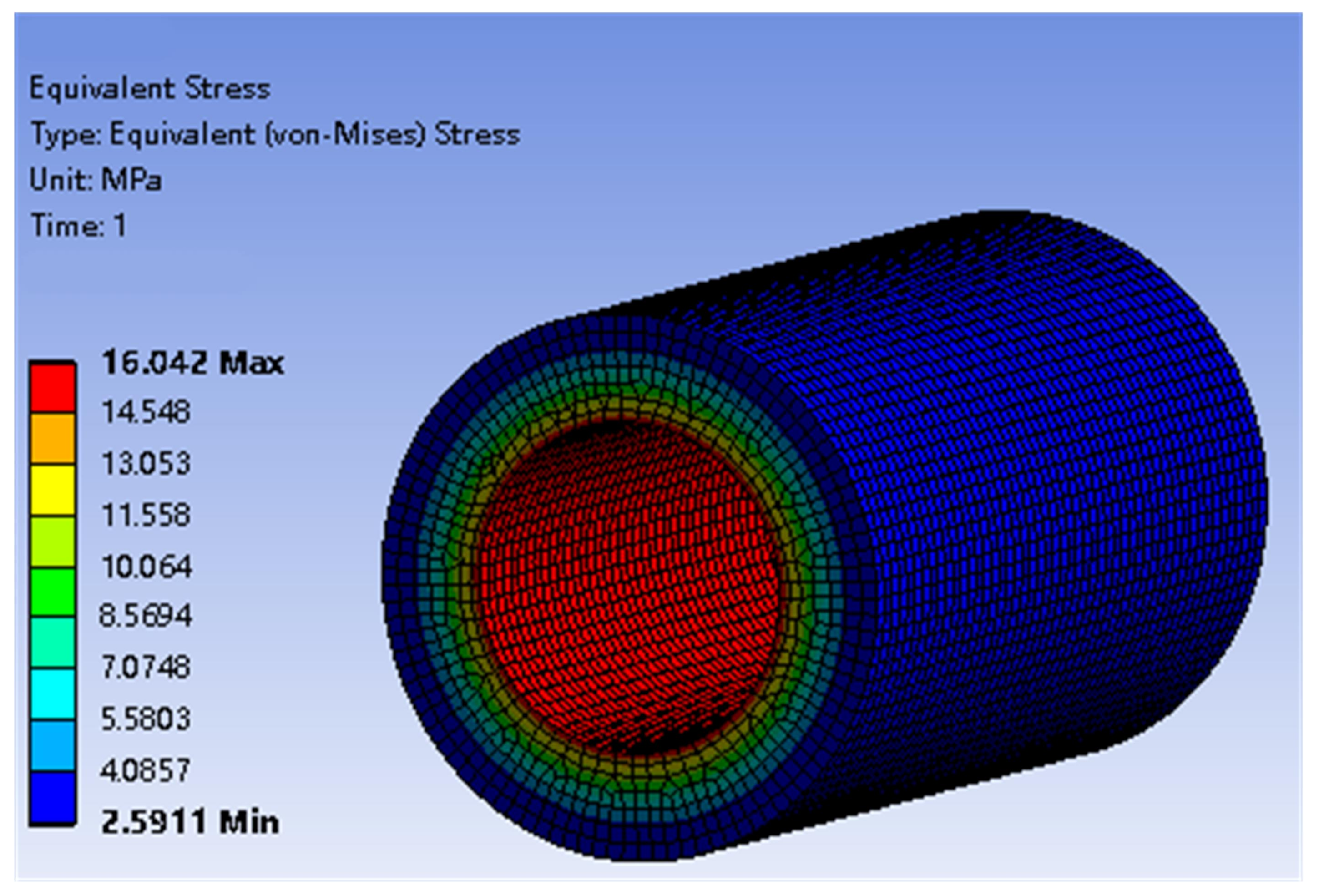

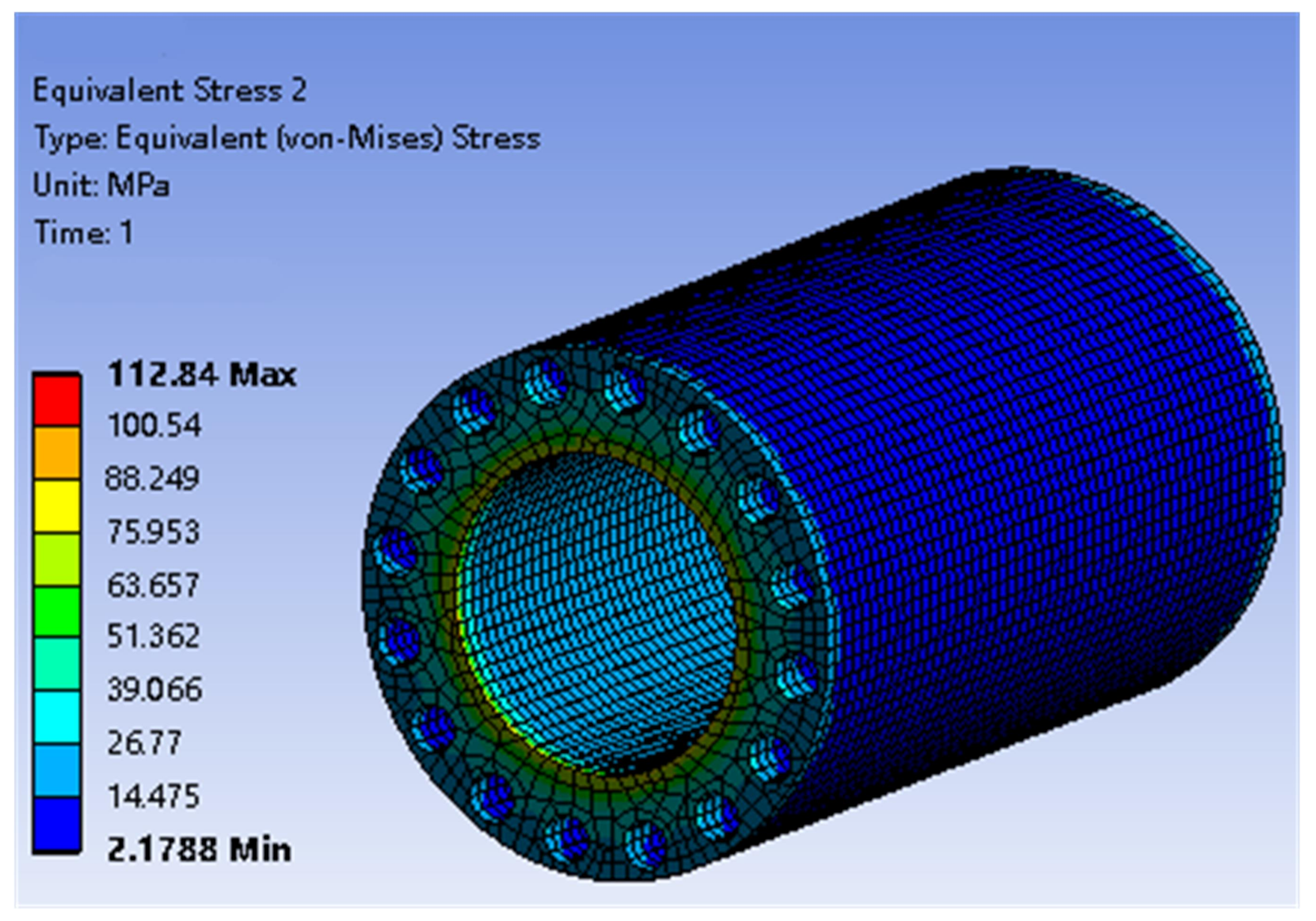

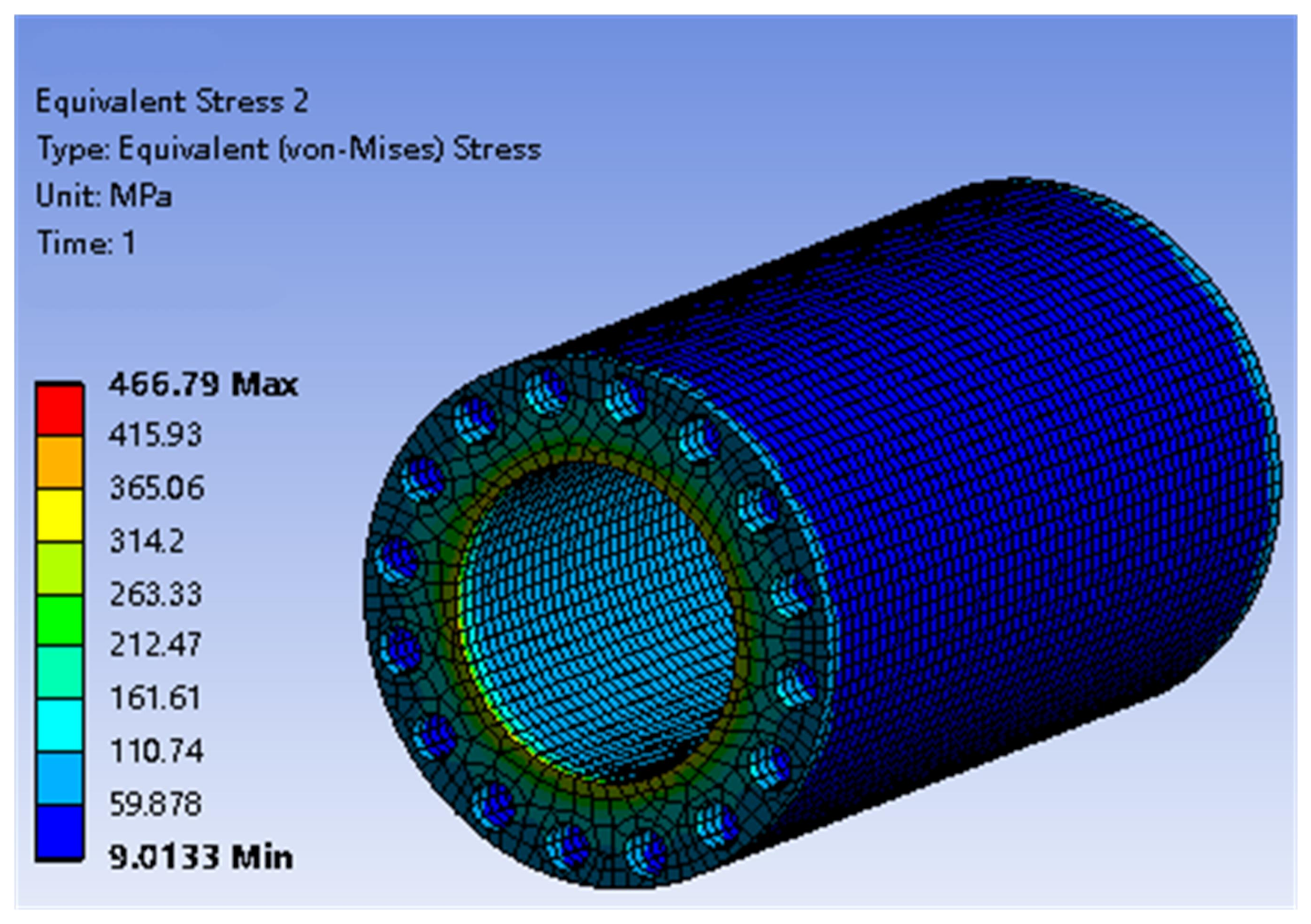

3. Mechanical Stress Analysis and Comparison of Rotor Structures

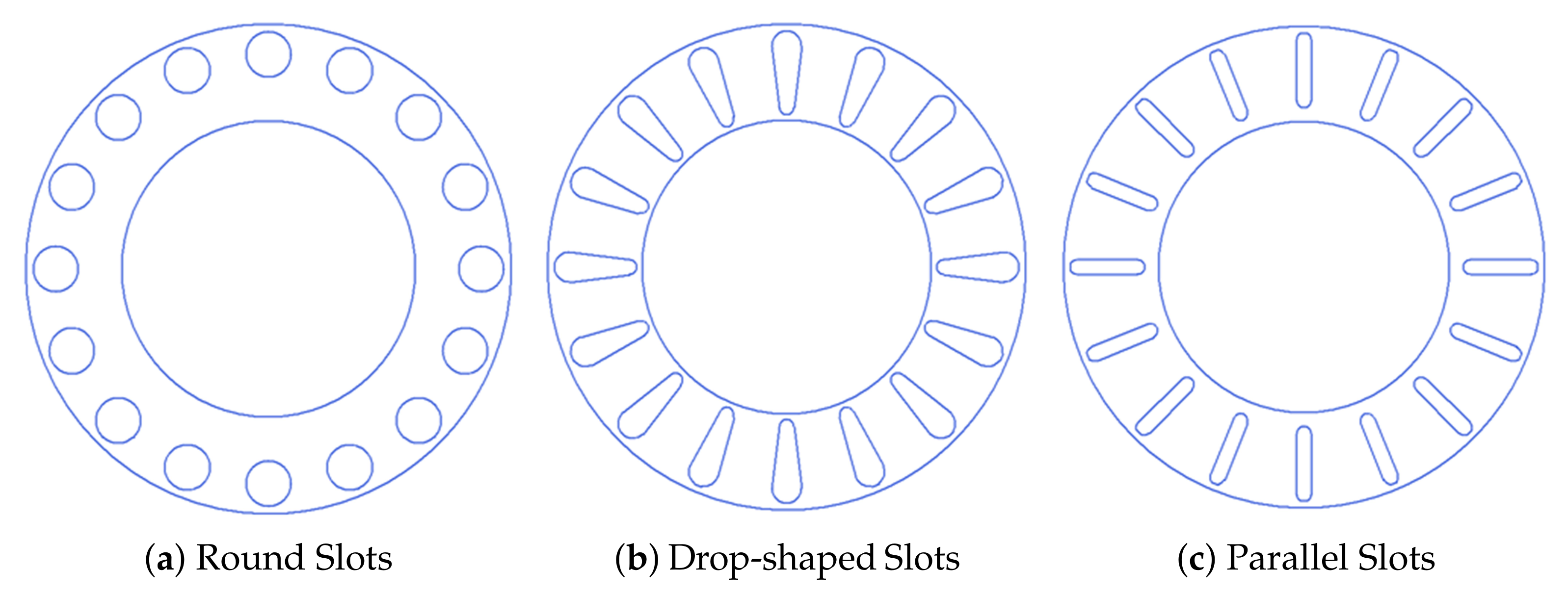

3.1. Types of Rotor Structures

3.2. Mechanical Stress Analysis

3.3. Mechanical Stress Comparison of Different Rotor Structures

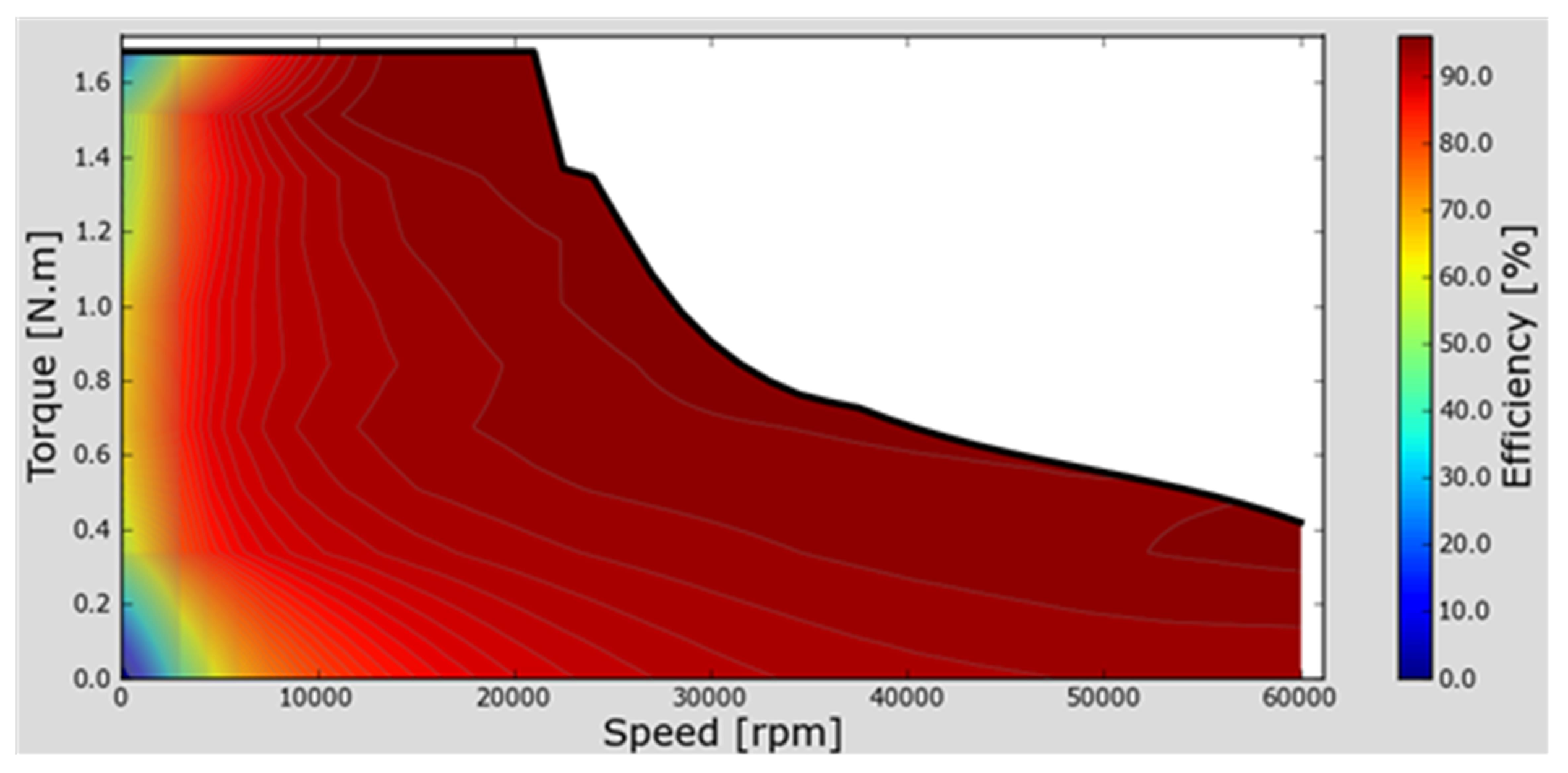

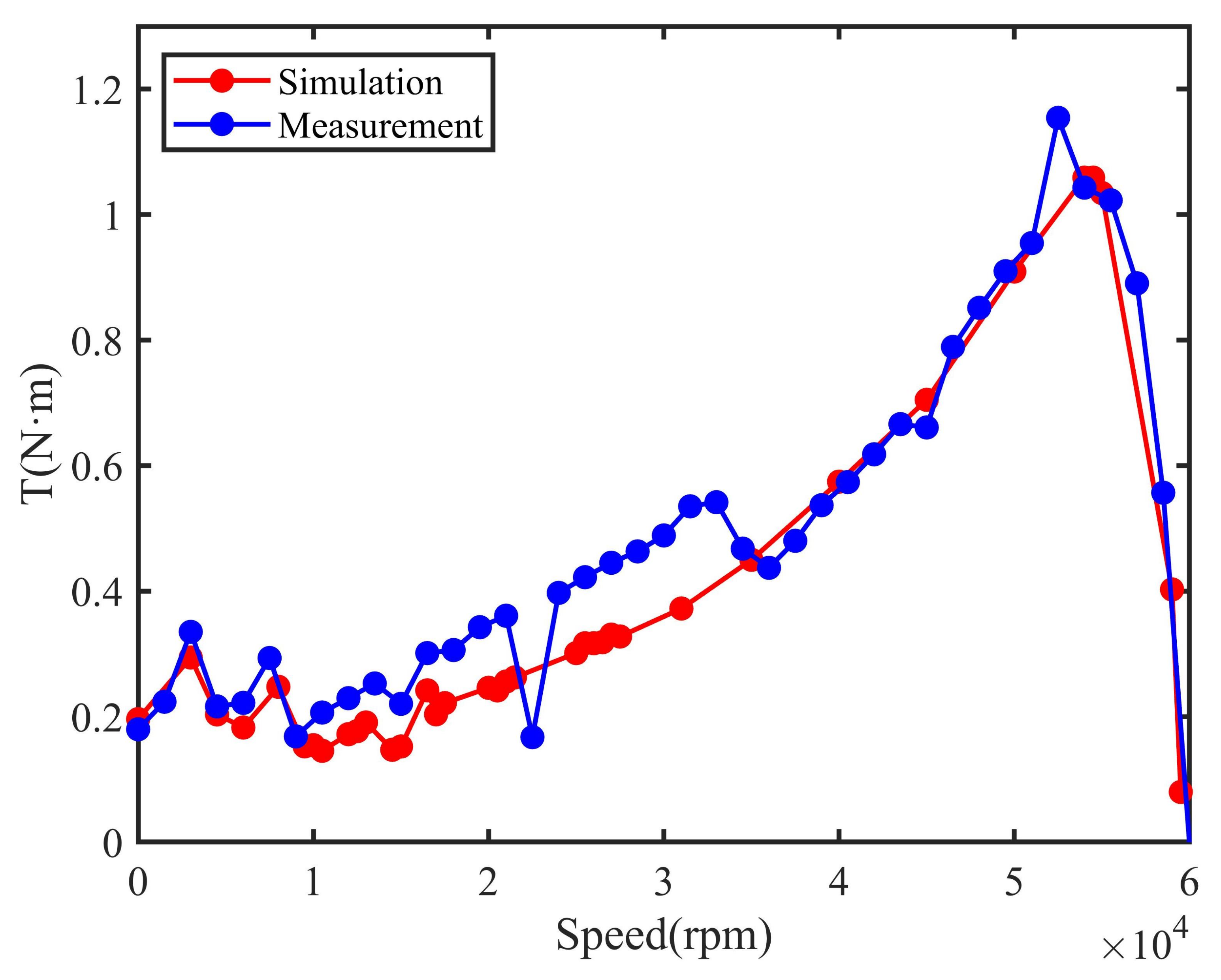

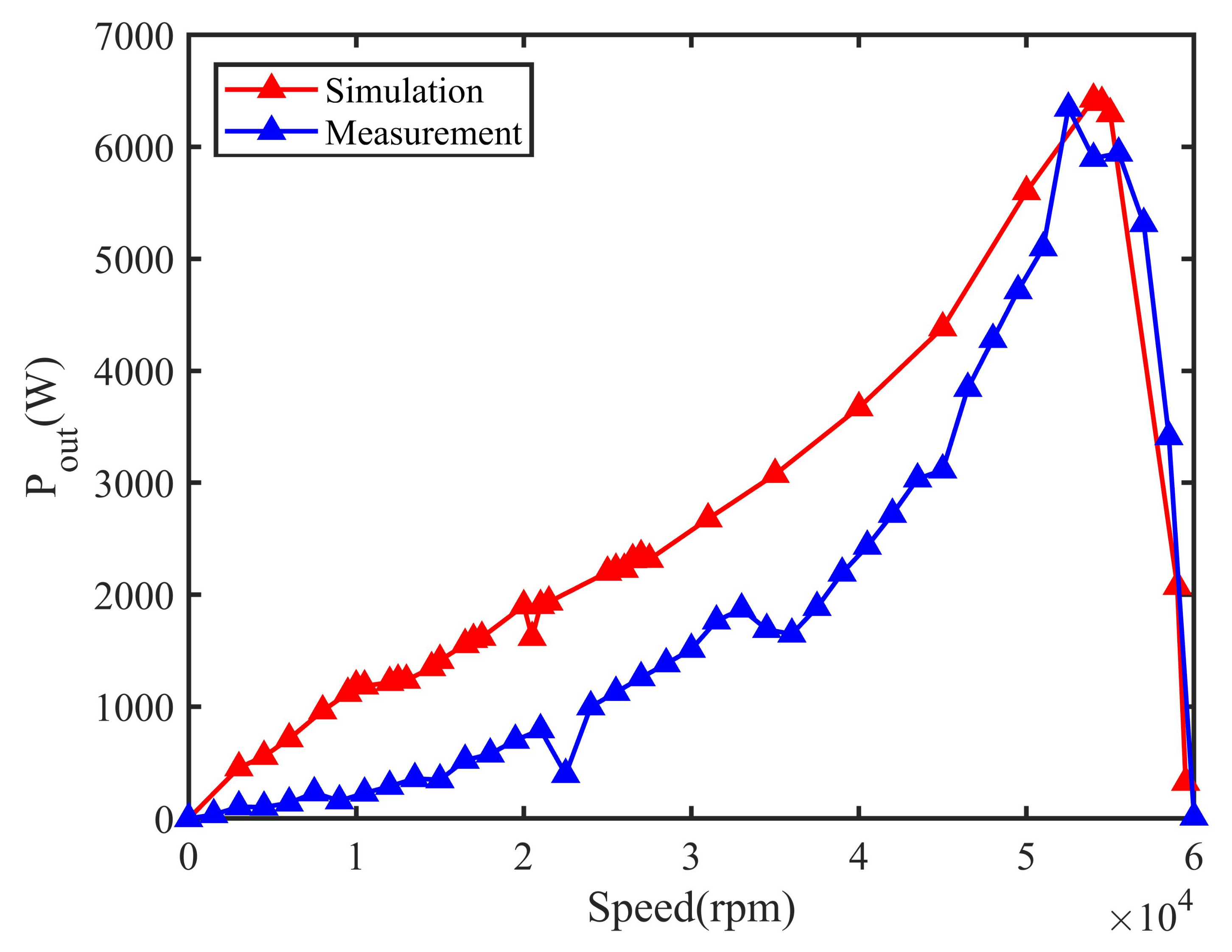

4. Prototyping and Performance Test

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CNC | Computer Numerical Control |

| AA | Amorphous Alloy |

| CNY | Chinese Yuan |

| SVPWM | Space Vector Pulse Width Modulation |

| MTPA | Maximum Torque Per Ampere |

Appendix A

| Number | Speed | Torque | Input Power | Output Power | Efficiency |

|---|---|---|---|---|---|

| (rpm) | (N·m) | (W) | (W) | (%) | |

| 1 | 0 | 0.196019 | 2997.55 | 0 | 0 |

| 2 | 3000 | 0.294189 | 3067.07 | 453.93 | 14.8 |

| 3 | 4500 | 0.203523 | 3066.85 | 555.64 | 18.12 |

| 4 | 6000 | 0.182651 | 3127.15 | 712.76 | 22.79 |

| 5 | 8000 | 0.247552 | 3162.71 | 962.43 | 30.43 |

| 6 | 9500 | 0.152614 | 3145.89 | 1119.08 | 35.57 |

| 7 | 10,000 | 0.154452 | 3167.13 | 1185.33 | 37.43 |

| 8 | 10,500 | 0.145520 | 3193.01 | 1184.60 | 37.10 |

| 9 | 12,000 | 0.172023 | 3219.63 | 1216.31 | 37.78 |

| 10 | 12,500 | 0.176870 | 3254.01 | 1236.48 | 38.00 |

| 11 | 13,000 | 0.190634 | 3269.80 | 1235.60 | 37.79 |

| 12 | 14,500 | 0.147138 | 3248.90 | 1348.29 | 41.50 |

| 13 | 15,000 | 0.152417 | 3168.05 | 1413.40 | 45.18 |

| 14 | 16,500 | 0.241848 | 3417.87 | 1554.51 | 45.48 |

| 15 | 17,000 | 0.203657 | 3386.30 | 1599.85 | 47.24 |

| 16 | 17,500 | 0.221533 | 3425.06 | 1618.80 | 47.26 |

| 17 | 20,000 | 0.245917 | 3541.61 | 1901.36 | 53.69 |

| 18 | 20,500 | 0.241755 | 3425.06 | 1618.68 | 47.26 |

| 19 | 21,000 | 0.255911 | 3612.02 | 1903.25 | 52.69 |

| 20 | 21,500 | 0.262509 | 3604.54 | 1934.29 | 53.66 |

| 21 | 25,000 | 0.301267 | 3826.45 | 2201.47 | 57.53 |

| 22 | 25,500 | 0.316899 | 3885.19 | 2227.16 | 58.01 |

| 23 | 26,000 | 0.316899 | 3885.19 | 2227.16 | 57.32 |

| 24 | 26,500 | 0.318622 | 3927.73 | 2313.31 | 58.90 |

| 25 | 27,000 | 0.330644 | 3945.88 | 2348.45 | 59.52 |

| 26 | 27,500 | 0.327650 | 3975.60 | 2315.79 | 58.25 |

| 27 | 31,000 | 0.372236 | 4209.22 | 2677.48 | 63.61 |

| 28 | 35,000 | 0.449925 | 4583.75 | 3074.66 | 67.08 |

| 29 | 40,000 | 0.574427 | 5203.65 | 3670.32 | 70.53 |

| 30 | 45,000 | 0.704867 | 5848.09 | 4384.27 | 74.97 |

| 31 | 50,000 | 0.909315 | 6934.04 | 5600.73 | 80.77 |

| 32 | 54,000 | 1.058910 | 7343.48 | 6427.44 | 87.53 |

| 33 | 54,500 | 1.058910 | 7231.88 | 6397.59 | 88.46 |

| 34 | 55,000 | 1.034429 | 7042.91 | 6297.01 | 89.41 |

| 35 | 59,000 | 0.402674 | 2197.68 | 2074.34 | 94.39 |

| 36 | 59,500 | 0.079928 | 513.41 | 323.78 | 63.06 |

| Number | Speed (rpm) | Torque (N·m) | Input Power (W) | Output Power (W) | Efficiency (%) |

|---|---|---|---|---|---|

| 1 | 0 | 0.179860 | 3808.74 | 0 | 0 |

| 2 | 1500 | 0.223726 | 3867.88 | 35.14 | 1.24 |

| 3 | 3000 | 0.335093 | 3911.09 | 105.27 | 3.65 |

| 4 | 4500 | 0.216263 | 3935.97 | 101.91 | 3.52 |

| 5 | 6000 | 0.221909 | 3947.89 | 139.43 | 4.75 |

| 6 | 7500 | 0.293345 | 3879.64 | 230.39 | 7.67 |

| 7 | 9000 | 0.168453 | 3934.51 | 158.76 | 5.41 |

| 8 | 10,500 | 0.206529 | 4015.59 | 227.09 | 7.50 |

| 9 | 12,000 | 0.229392 | 4074.94 | 288.26 | 9.35 |

| 10 | 13,500 | 0.252820 | 4122.88 | 357.42 | 11.34 |

| 11 | 15,000 | 0.220382 | 3991.31 | 346.18 | 11.35 |

| 12 | 16,500 | 0.301273 | 4229.42 | 520.56 | 15.79 |

| 13 | 18,000 | 0.306130 | 4305.29 | 577.04 | 17.29 |

| 14 | 19,500 | 0.342538 | 4349.30 | 699.48 | 20.28 |

| 15 | 21,000 | 0.360786 | 4412.97 | 793.41 | 22.50 |

| 16 | 22,500 | 0.167253 | 4404.97 | 394.08 | 12.67 |

| 17 | 24,000 | 0.397220 | 4550.06 | 998.32 | 27.04 |

| 18 | 25,500 | 0.422175 | 4651.79 | 1127.36 | 29.69 |

| 19 | 27,000 | 0.445176 | 4719.14 | 1258.71 | 32.24 |

| 20 | 28,500 | 0.463302 | 4802.57 | 1382.73 | 34.53 |

| 21 | 30,000 | 2.228737 | 3829.72 | 7001.78 | 72.11 |

| 22 | 31,500 | 0.535167 | 5001.22 | 1765.34 | 40.82 |

| 23 | 33,000 | 0.541701 | 5115.64 | 1871.99 | 42.39 |

| 24 | 34,500 | 0.467698 | 5289.97 | 1689.71 | 40.29 |

| 25 | 36,000 | 0.437137 | 5412.87 | 1647.97 | 39.71 |

| 26 | 37,500 | 0.480183 | 5471.30 | 1885.67 | 42.85 |

| 27 | 39,000 | 0.536936 | 5708.00 | 2192.89 | 47.16 |

| 28 | 40,500 | 0.573760 | 5881.07 | 2433.40 | 50.10 |

| 29 | 42,000 | 0.618045 | 6074.37 | 2718.31 | 53.28 |

| 30 | 43,500 | 0.666158 | 6297.36 | 3034.56 | 56.58 |

| 31 | 45,000 | 0.660873 | 6563.94 | 3114.29 | 58.42 |

| 32 | 46,500 | 0.789207 | 6778.41 | 3843.02 | 63.82 |

| 33 | 48,000 | 0.851525 | 7031.28 | 4280.23 | 67.41 |

| 34 | 49,500 | 0.909824 | 7266.67 | 4716.19 | 70.93 |

| 35 | 51,000 | 0.954736 | 7482.60 | 5098.97 | 74.29 |

| 36 | 52,500 | 1.154322 | 7758.21 | 6346.21 | 80.39 |

| 37 | 54,000 | 1.042989 | 7506.11 | 5897.96 | 82.35 |

| 38 | 55,500 | 1.022872 | 7044.18 | 5944.87 | 86.52 |

| 39 | 57,000 | 0.890487 | 5908.61 | 5315.34 | 90.76 |

| 40 | 58,500 | 0.556827 | 3559.67 | 3411.18 | 95.17 |

| 41 | 60,000 | −0.003362 | 21.13 | 12.78 | 67.65 |

References

- Jung, E.; Yoo, H.; Sul, S.K.; Choi, H.S.; Choi, Y.Y. Nine-Phase Permanent Magnet Motor Drive System for Ultra High-Speed Elevator. In Proceedings of the 2009 IEEE Energy Conversion Congress and Exposition, San Jose, CA, USA, 20–24 September 2009; pp. 1841–1846. [Google Scholar]

- Wen, J.S.; Wang, C.H.; Chang, Y.D.; Teng, C.C. Intelligent control of high-speed sensorless brushless DC motor for intelligent automobiles. In Proceedings of the 2008 IEEE International Conference on Systems, Man and Cybernetics, Singapore, 12–15 October 2008; pp. 3394–3398. [Google Scholar]

- Pyrhonen, J.; Nerg, J.; Kurronen, P.; Lauber, U. High-Speed High-Output Solid-Rotor Induction-Motor Technology for Gas Compression. IEEE Trans. Ind. Electron. 2010, 57, 272–280. [Google Scholar] [CrossRef]

- Liu, X.; Du, J.; Liang, D. Analysis and speed ripple mitigation of a space vector pulse width modulation-based permanent magnet synchronous motor with a particle swarm optimization algorithm. Energies 2016, 9, 923. [Google Scholar] [CrossRef]

- Yu, Y.N.; Liang, D.L.; Liu, X. Optimal Design of the Rotor Structure of a HSPMSM Based on Analytic Calculation of Eddy Current Losses. Energies 2017, 10, 551. [Google Scholar] [CrossRef]

- Tenconi, A.; Vaschetto, S.; Vigliani, A. Electrical Machines for High-Speed Applications: Design Considerations and Tradeoffs. IEEE Trans. Ind. Electron. 2014, 61, 3022–3029. [Google Scholar] [CrossRef]

- Fan, T.; Li, Q.; Wen, X. Development of a High Power Density Motor Made of Amorphous Alloy Cores. IEEE Trans. Ind. Electron. 2014, 61, 4510–4518. [Google Scholar] [CrossRef]

- Chen, P.; Chen, J.; Liao, Y.; Zhang, C.; Du, J. Vibration and Noise of High Speed Amorphous Alloy Permanent Magnet Synchronous Motor. In Proceedings of the 2018 21st International Conference on Electrical Machines and Systems (ICEMS), Jeju, Korea, 7–10 October 2018; pp. 318–322. [Google Scholar]

- Chai, F.; Li, Z.; Chen, L.; Pei, Y. Effect of Cutting and Slot Opening on Amorphous Alloy Core for High-Speed Switched Reluctance Motor. IEEE Trans. Magn. 2021, 57, 1–5. [Google Scholar] [CrossRef]

- Okamoto, S.; Denis, N.; Kato, Y.; Ieki, M.; Fujisaki, K. Core Loss Reduction of an Interior Permanent-Magnet Synchronous Motor Using Amorphous Stator Core. IEEE Trans. Ind. Appl. 2016, 52, 2261–2268. [Google Scholar] [CrossRef]

- Kolano, R.; Krykowski, K.; Kolano-burian, A.; Polak, M.; Szynowski, J.; Zackiewicz, P. Amorphous Soft Magnetic Materials for the Stator of a Novel High-Speed PMBLDC Motor. IEEE Trans. Magn. 2013, 49, 1367–1371. [Google Scholar] [CrossRef]

- Dems, M.; Komeza, K. Performance Characteristics of a High-Speed Energy-Saving Induction Motor With an Amorphous Stator Core. IEEE Trans. Ind. Electron. 2014, 61, 3046–3055. [Google Scholar] [CrossRef]

- McGuiness, D.T.; Gulbahce, M.O.; Kocabas, D.A. A performance comparison of different rotor types for high-speed induction motors. In Proceedings of the 2015 9th International Conference on Electrical and Electronics Engineering (ELECO), Bursa, Turkey, 26–28 November 2015; pp. 584–589. [Google Scholar]

- Dong, A.G.; Du, B.Y.; Jin, C.N.; Shi, D.L. Effect of different inner rotor structures on characteristics of a new energy-storage slip-clutch motor. In Proceedings of the 2016 19th International Conference on Electrical Machines and Systems (ICEMS), Chiba, Japan, 13–16 November 2016; pp. 1–5. [Google Scholar]

- Liu, C.; Zhu, J.; Wang, Y.; Guo, Y.; Lei, G. Comparison of Claw-Pole Machines With Different Rotor Structures. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar]

- Chai, F.; Li, Z.; Ou, J.; Yu, Y. Torque analysis of high-speed switched reluctance motor with amorphous alloy core. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; pp. 2464–2468. [Google Scholar]

- Yang, W.; Huang, C.; Zhang, Q. Optimization of Squirrel-Cage Rotor for Amorphous Asynchronous Motor. In Proceedings of the 2019 Chinese Automation Congress (CAC), Hangzhou, China, 22–24 November 2019; pp. 2107–2110. [Google Scholar]

- Enokizono, M.; Shimoji, H.; Horibe, T. Loss evaluation of induction motor by using magnetic hysteresis E&S/sup 2/ model. IEEE Trans. Magn. 2002, 38, 2379–2381. [Google Scholar]

- Bertotti, G. General properties of power losses in soft ferromagnetic materials. IEEE Trans. Magn. 1988, 24, 621–630. [Google Scholar] [CrossRef]

- Tao, D.J.; Zhou, K.L.; Lv, F.; Dou, Q.P.; Wu, J.X.; Sun, Y.T.; Zou, J.B. Magnetic Field Characteristics and Stator Core Losses of High-Speed Permanent Magnet Synchronous Motors. Energies 2020, 13, 535. [Google Scholar] [CrossRef]

- Wan, Y.; Cui, S.M.; Wu, S.P.; Song, L.W. Electromagnetic Design and Losses Analysis of a High-Speed Permanent Magnet Synchronous Motor with Toroidal Windings for Pulsed Alternator. Energies 2018, 11, 562. [Google Scholar] [CrossRef]

- Chen, S.F.; Han, Y.F.; Ma, Z.X.; Chen, G.Z.; Xu, S.; Si, J.K. Influence Analysis of Structural Parameters on the Performance of 120° Phase Belts Toroidal Winding Solid Rotor Induction Motor. Energies 2020, 13, 5387. [Google Scholar] [CrossRef]

- Huynh, T.A.; Hsieh, M.F. Performance analysis of permanent magnet motors for electric vehicles (EV) traction considering driving cycles. Energies 2018, 11, 1385. [Google Scholar] [CrossRef]

- Gundabattini, E.; Mystkowski, A.; Idzkowski, A.; Raja, R.S.; Solomon, D.G. Thermal Mapping of a High-Speed Electric Motor Used for Traction Applications and Analysis of Various Cooling Methods—A Review. Energies 2021, 14, 1472. [Google Scholar] [CrossRef]

- Zhou, F.Z.; Shen, J.X.; Wang, K. Influence of rotor structure on rotor eddy-current loss in high-speed permanent magnet brushless DC motors. J. Zhejiang Univ. Sci. 2008, 9, 102–106. [Google Scholar]

- Du, G.H.; Huang, N.; Mi, X.F.; Zhang, L. Comprehensive Analysis of High-speed Induction Motor With Different Laminated Rotor Structures. Micromotors 2017, 5, 2–5. [Google Scholar]

| Properties | 1K101 | 20JNEH1200 | Units |

|---|---|---|---|

| Thickness | 0.025 | 0.2 | mm |

| Coercivity | 4 | 30 | A/m |

| Resistivity | 130 | 0.45 | µΩ·cm |

| Saturation magnetization | 1.56 | 1.62 | T |

| Core loss (50 Hz, 1.35 T) | <0.2 | <0.8 | W/kg |

| Parameter | Value | Units |

|---|---|---|

| Rated power | 2 | kW |

| Rated voltage | 220 | V |

| Rated speed | 59,000 | rpm |

| Numbers of phases | 3 | / |

| Numbers of slots | 18 | / |

| Numbers of poles | 2 | / |

| Stator outer diameter | 60 | mm |

| Stator outer diameter | 32.2 | mm |

| Type | Core Loss | Copper Loss | Units | |||

|---|---|---|---|---|---|---|

| Hysteresis | Eddy Current | Excess | Stator | Rotor | ||

| Silicon steel motor | 19.79 | 34.35 | 8.21 | 28.92 | 23.46 | W |

| AA motor | 1.85 | 24.27 | 0.70 | 28.77 | 22.67 | W |

| Type | Total Loss (W) | Efficiency (%) | Power Factor | Torque (N·m) |

|---|---|---|---|---|

| Silicon steel motor | 200.6 | 91.1 | 0.831 | 0.27 |

| AA motor | 119.4 | 94.3 | 0.847 | 0.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Z.; Yi, H.; Xu, J.; Xie, K.; Qi, Y.; Ren, S.; Wang, H. Performance Study and Optimization Design of High-Speed Amorphous Alloy Induction Motor. Energies 2021, 14, 2468. https://doi.org/10.3390/en14092468

Fan Z, Yi H, Xu J, Xie K, Qi Y, Ren S, Wang H. Performance Study and Optimization Design of High-Speed Amorphous Alloy Induction Motor. Energies. 2021; 14(9):2468. https://doi.org/10.3390/en14092468

Chicago/Turabian StyleFan, Zeyang, Hong Yi, Jian Xu, Kun Xie, Yue Qi, Sailin Ren, and Hongdong Wang. 2021. "Performance Study and Optimization Design of High-Speed Amorphous Alloy Induction Motor" Energies 14, no. 9: 2468. https://doi.org/10.3390/en14092468

APA StyleFan, Z., Yi, H., Xu, J., Xie, K., Qi, Y., Ren, S., & Wang, H. (2021). Performance Study and Optimization Design of High-Speed Amorphous Alloy Induction Motor. Energies, 14(9), 2468. https://doi.org/10.3390/en14092468