Virtual Digital Substation Test System and Interoperability Assessments

Abstract

1. Introduction

2. Substation Protection, Automation, and Control System Architecture Design

- No single activity on the Main 1 protection system (MP1) shall affect the Main 2 protection system (MP2);

- No single failure shall result in the loss of control of more than one bay;

- Fault clearance time shall at least achieve the level of performance of conventional bays.

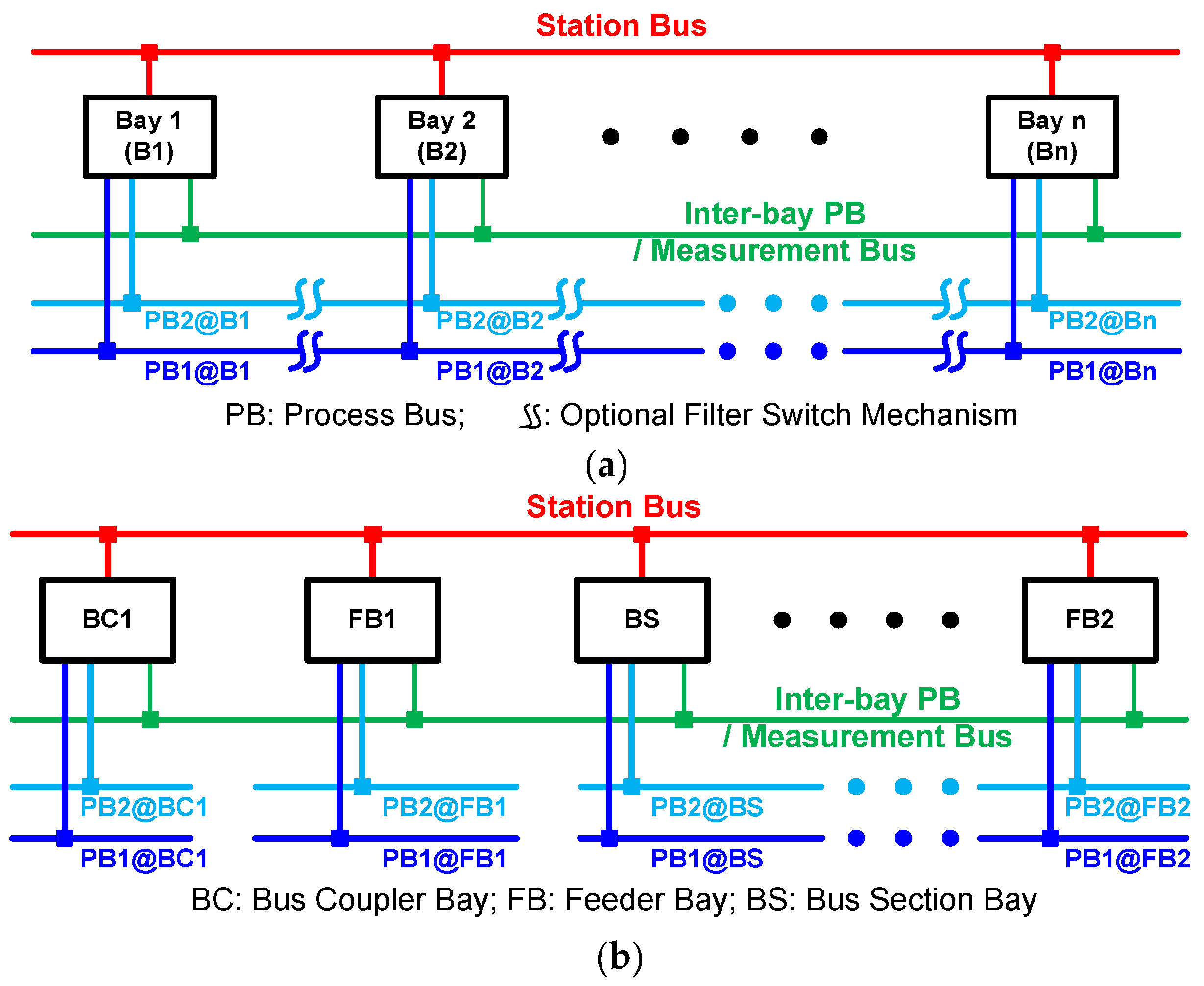

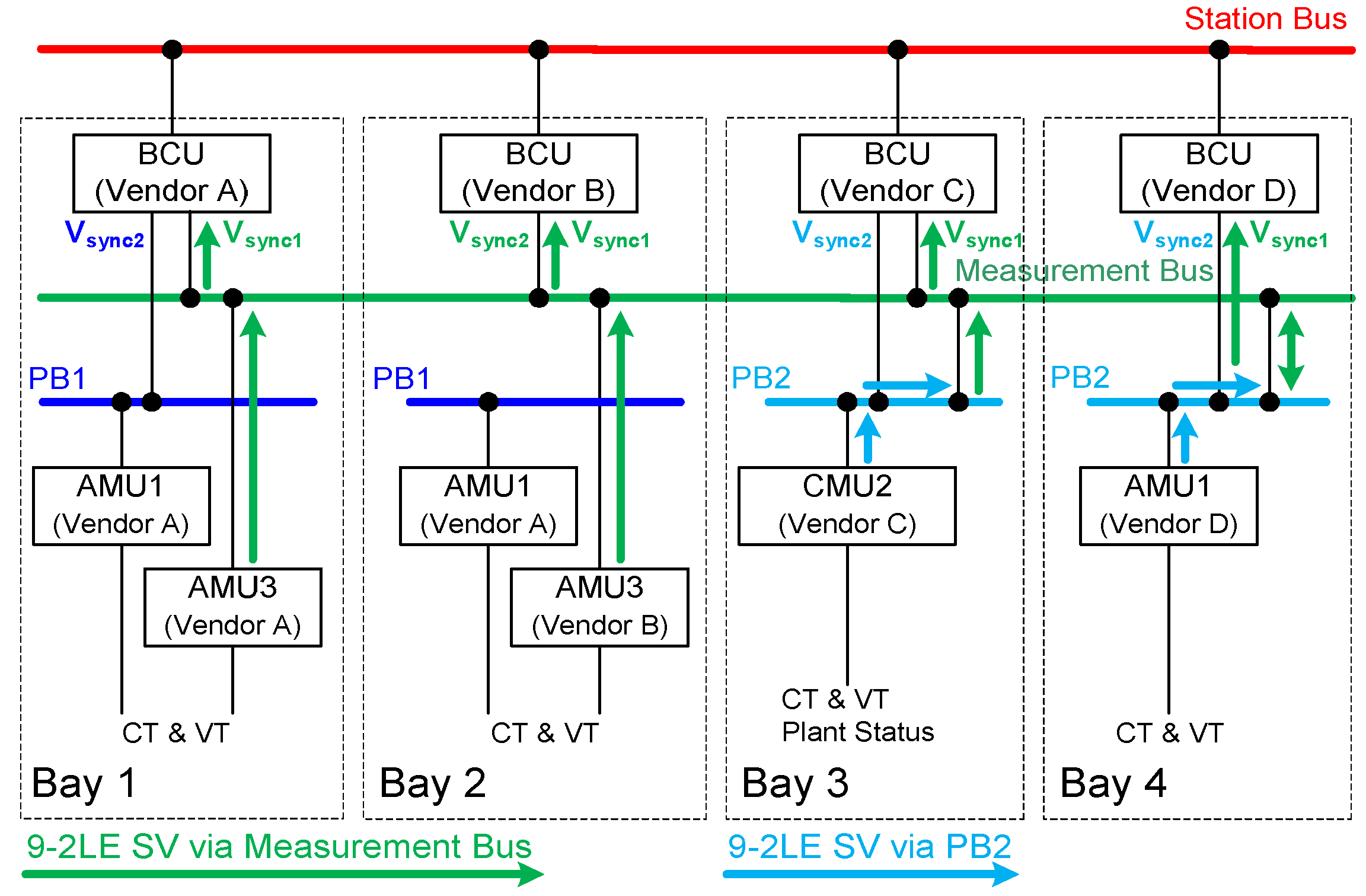

2.1. Parallel Process Buses

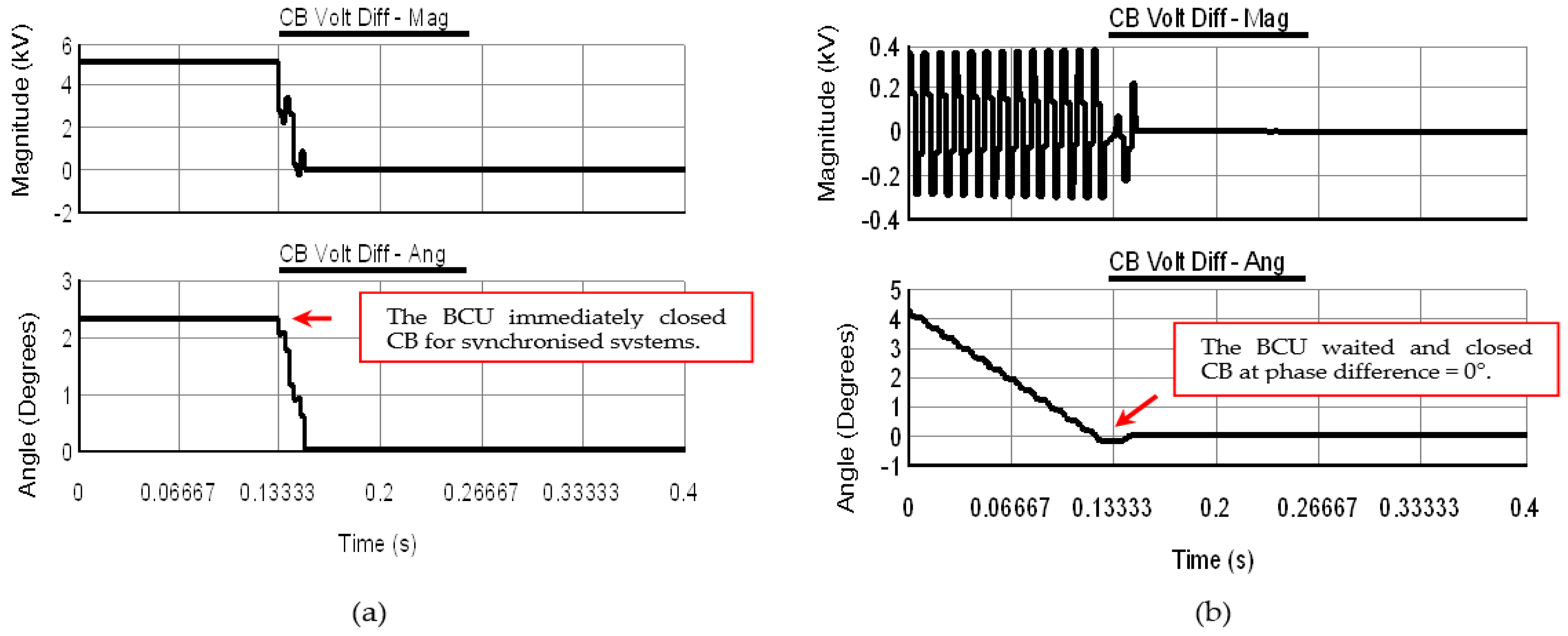

2.2. Measurement Bus for High-Accuracy Metering and Synchronising

2.3. Standard Bay Solutions

2.4. Station Bus Network for Substation Automation and Control

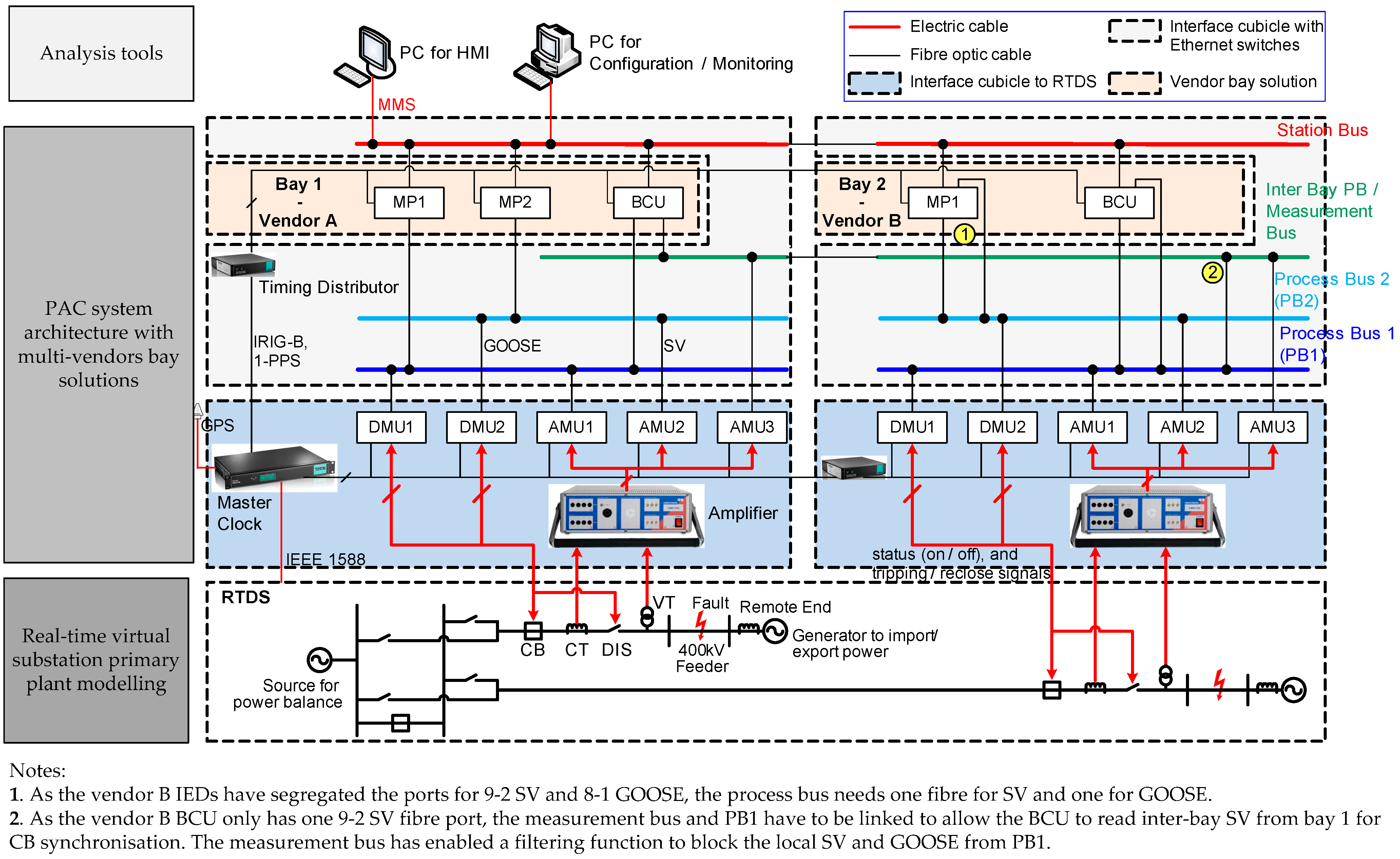

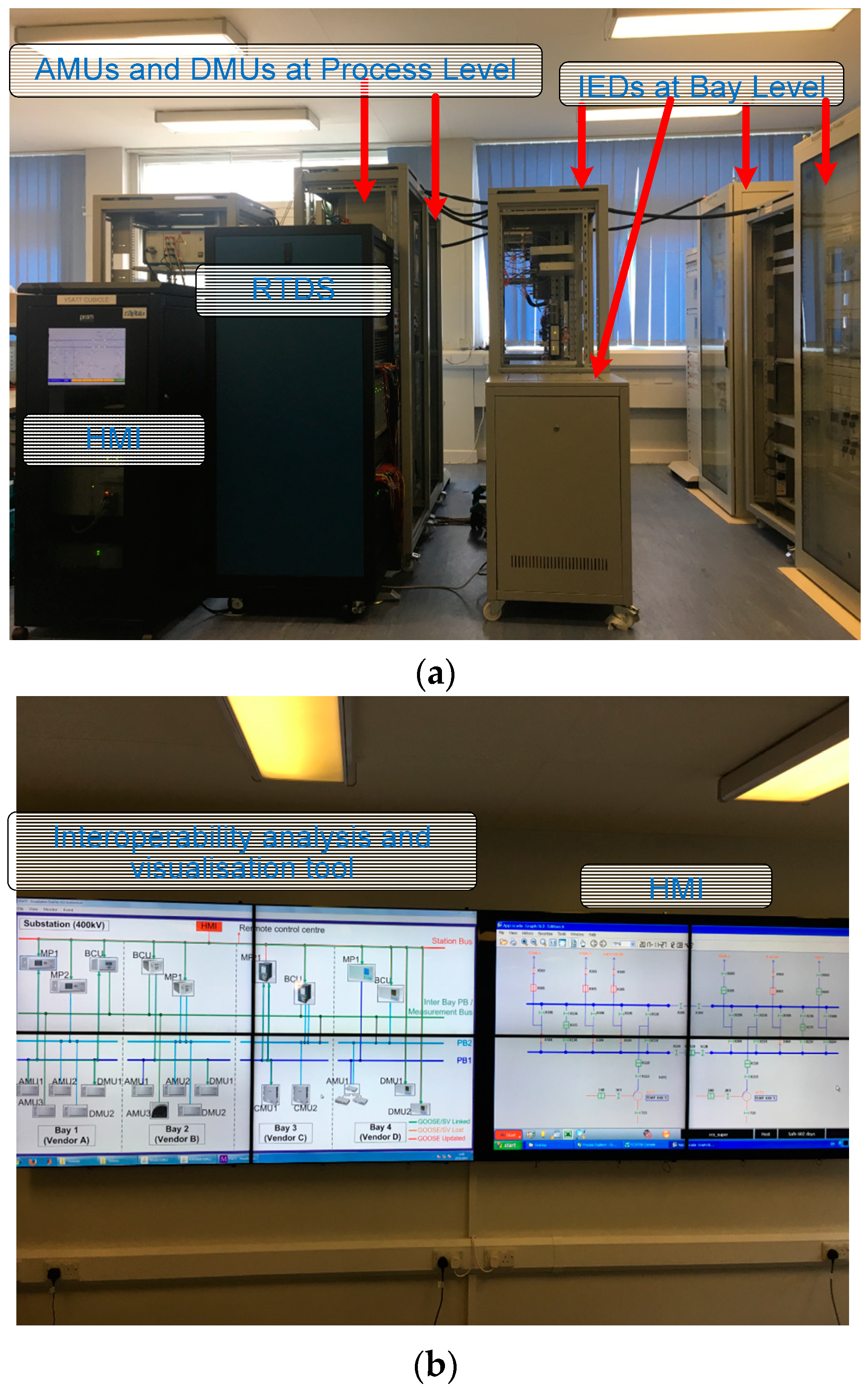

3. RTDS-Based Virtual Digital Substation Test System

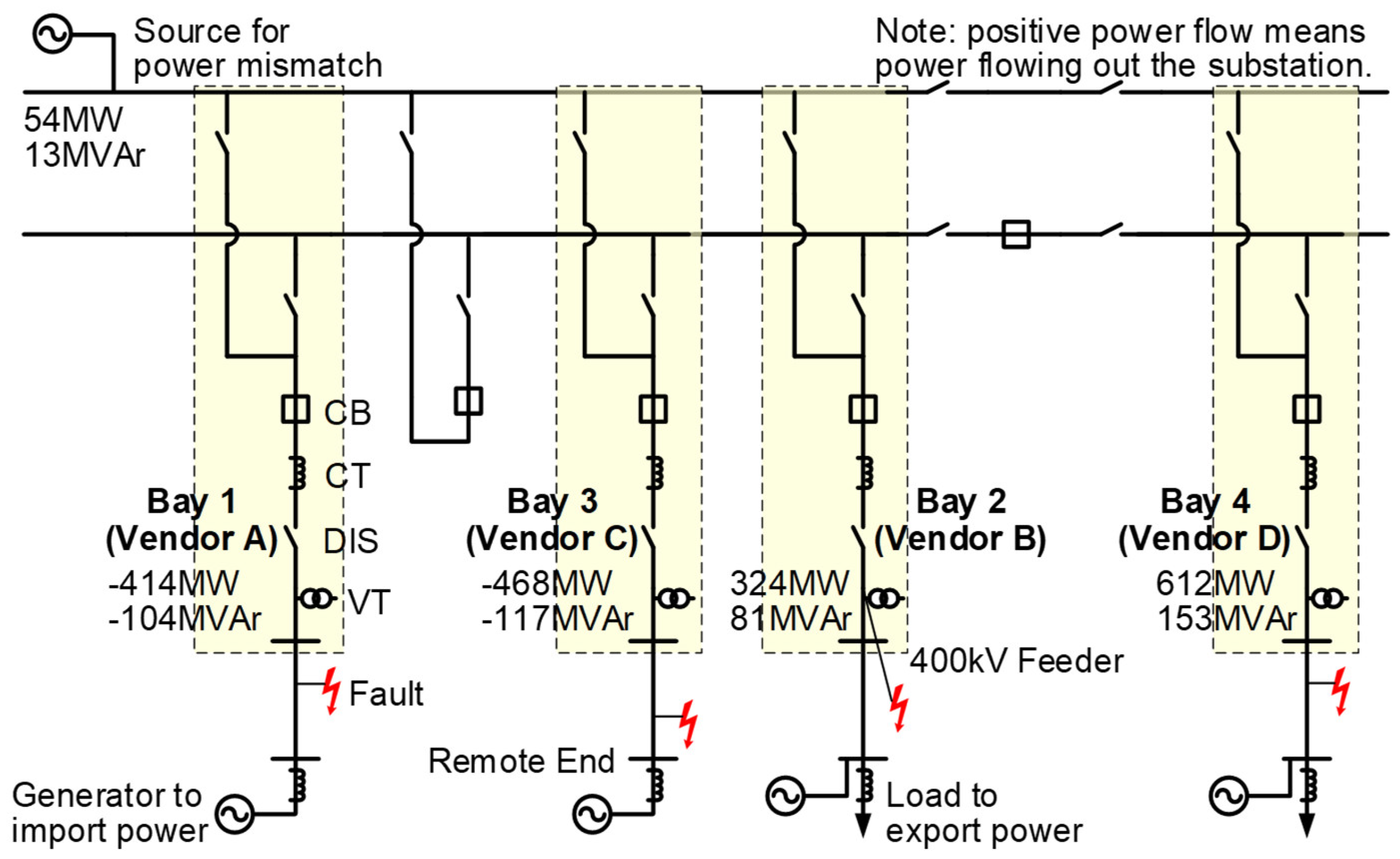

3.1. Real-Time Virtual Substation Modelling for Power Plant Using an RTDS

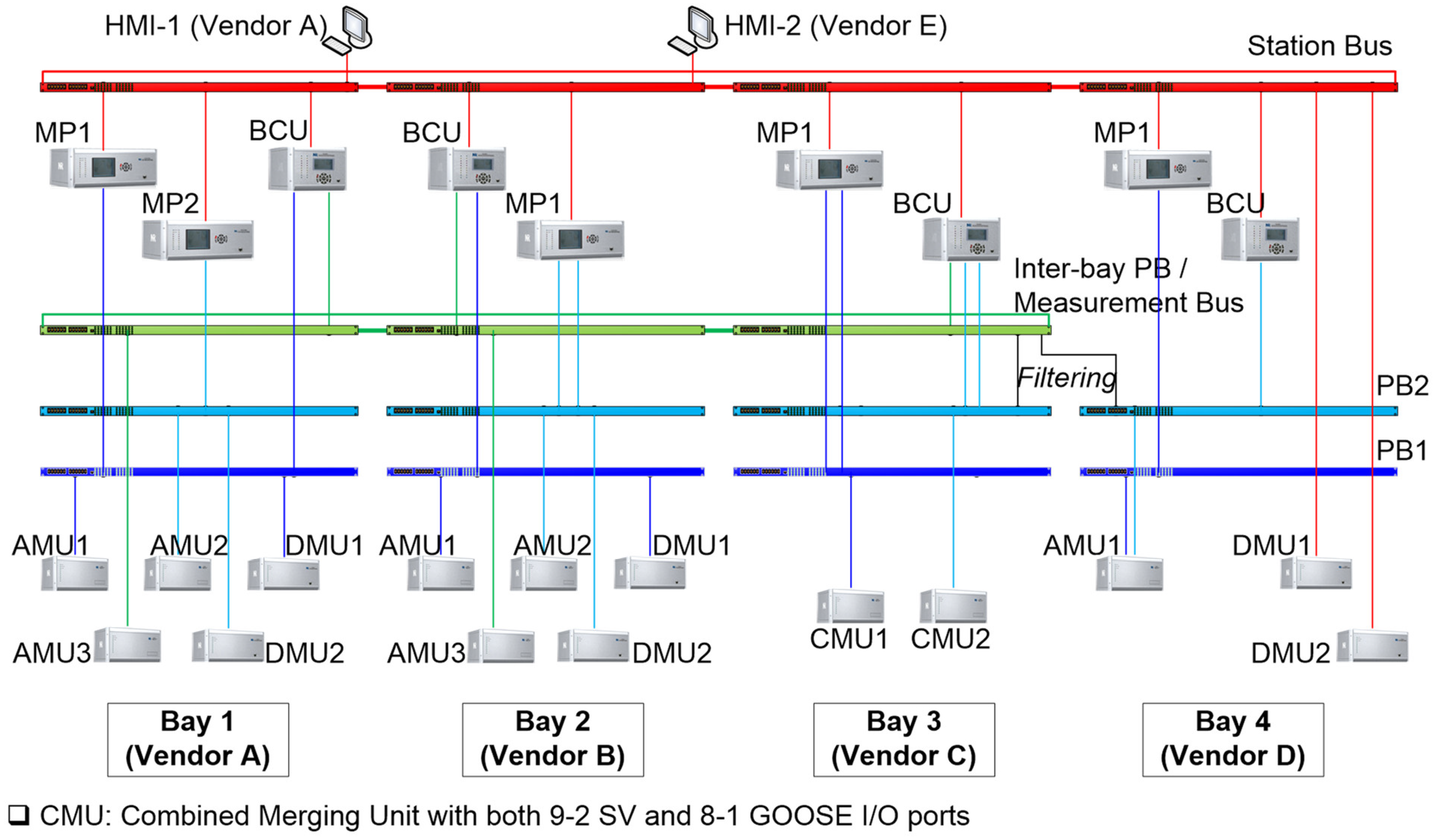

3.2. PAC System with Multivendor Bay Solutions

3.3. Visualisation Tool

- Green—SV/GOOSE being received;

- Yellow—SV/GOOSE was received but now becomes lost;

- Red—GOOSE data being updated, e.g., trip signal ON in a fault event (see Section 5).

4. System Integration with SCL

4.1. Bay-Solution Approach with Two Stages Bay SCLs

- The system integrator produces a system specification description (SSD) file according to a single-line diagram (SLD) and functional requirements from the utility;

- Each vendor preconfigures its bay by generating an SCD file, i.e., stage 1. A bay SCD file includes the project-specific instantiated IED description (IID) file of each device in the bay. An IID file contains the predefined data sets and control blocks for SV, GOOSE, and MMS messages, as well as SV/GOOSE mappings within the bay;

- The integrator imports all bay SCD files, i.e., stage 2, into a system integration tool to generate a site SCD file. The site SCD file should include inter-bay GOOSE mappings for distributed applications. The integrator will also configure the HMI with MMS reporting and control functions;

- With the site SCD file, each bay vendor reconfigures its bay to receive inter-bay GOOSE if needed.

4.2. Integration Challenges

4.2.1. Information Modelling

4.2.2. Tool Compatibility Issues

5. Interoperability Test Cases

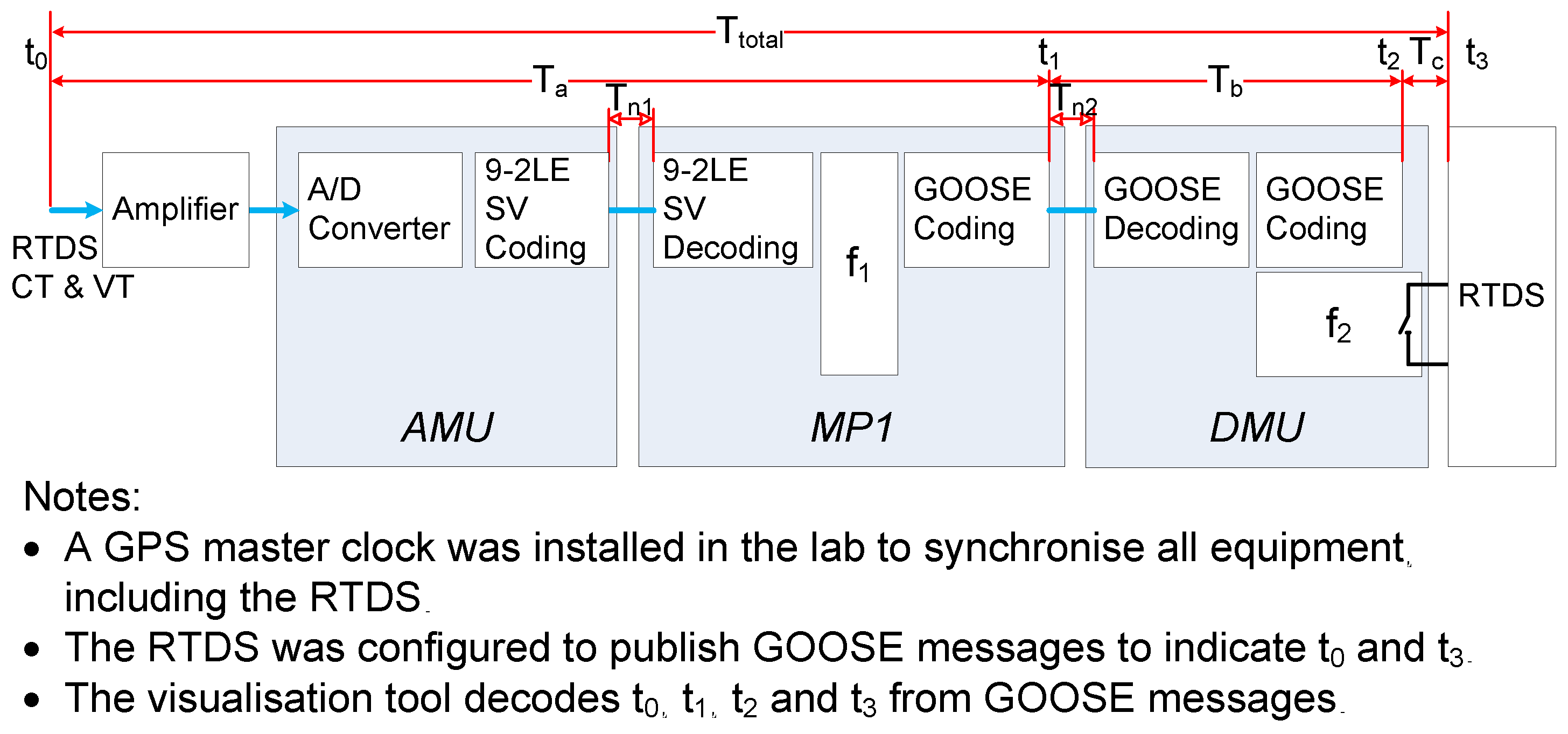

5.1. Process Bus Interoperability

5.2. Measurement Bus Interoperability

5.3. Station Bus Interoperability

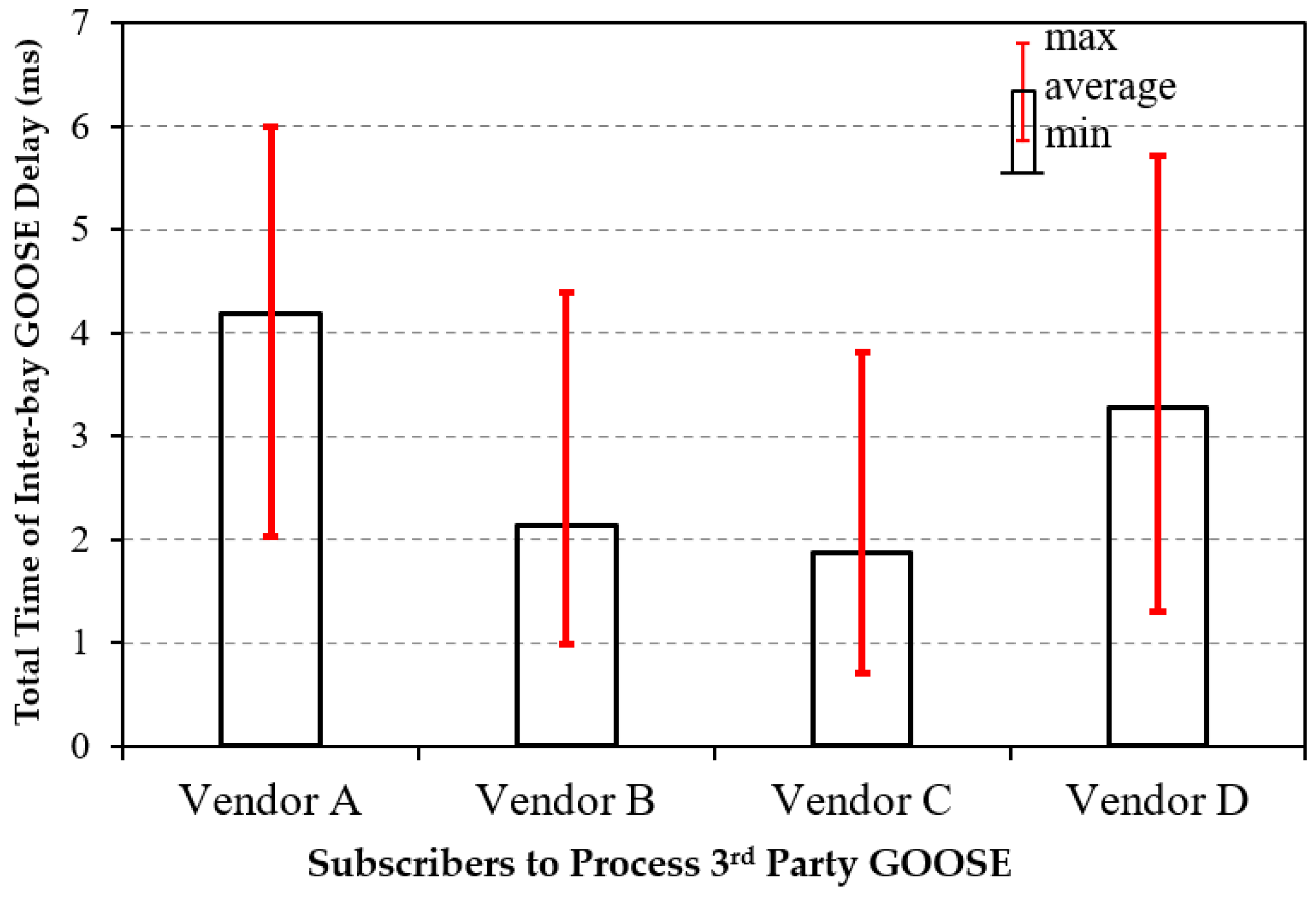

5.3.1. Inter-Bay GOOSE Interoperability via CB Failure Testing

- IED communication processing time to decode and encode GOOSE;

- IED internal logic processing time to map the incoming GOOSE to a back trip;

- Station bus network delay.

5.3.2. MMS Interoperability via HMI Monitoring and Control

- Vendor A HMI has interoperability issues when importing SCD files from third parties. To successfully build an IEC 61850 database, the system integrator needs to manually modify some parts of the SCD files as per the proprietary HMI configurator requirements;

- Vendor E HMI has challenges to configure the HMI database to initialise MMS reporting services on IEDs. The HMI will not issue a “Start Reporting” command to an IED which defines all report control blocks (RCBs) under a common “root logical device (LD)” rather than the source LD containing signals to be reported. This problem was addressed at the HMI database side by creating a dummy IEC 61,850 signal/variable coming from the root LD.

6. Discussions

6.1. SCL Configuration—At Tool Level

6.2. Protocol Implementation—At Device Level

- ▪

- The use of “SmpSynch” to represent local or global synchronisation for 9-2 SV messages;

- ▪

- Failed subscriptions to the fixed-length encoded GOOSE as defined in IEC 61850-8-1;

- ▪

- IEDs from some vendors cannot publish GOOSE with data qualities, resulting in issues for test mode.

6.3. Information Modelling

6.4. Performance and Application Limitations

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, X.; Lee, W.J.; Pan, X. Modernizing substation automation systems: Adopting IEC Standard 61850 for modeling and communication. IEEE Ind. Appl. Mag. 2017, 23, 42–49. [Google Scholar]

- Manbachi, M.; Sadu, A.; Farhangi, H.; Monti, A.; Palizban, A.; Ponci, F.; Arzanpour, S. Real-time co-simulation platform for smart grid Volt-VAR optimization using IEC 61850. IEEE Trans. Ind. Inform. 2016, 12, 1392–1402. [Google Scholar]

- Almas, M.S.; Vanfretti, L. A hybrid synchrophasor and GOOSE-based power system synchronization scheme. IEEE Access 2016, 4, 4659–4668. [Google Scholar]

- Etherden, N.; Vyatkin, V.; Bollen, M.H.J. Virtual power plant for grid services using IEC 61850. IEEE Trans. Ind. Inform. 2016, 12, 437–447. [Google Scholar] [CrossRef]

- Mazur, D.C.; Entzminger, R.A.; Kay, J.A. Enhancing traditional process SCADA and historians for industrial and commercial power systems with energy (via IEC 61850). IEEE Trans. Ind. Appl. 2016, 52, 76–82. [Google Scholar] [CrossRef]

- Yang, L.; Crossley, P.A.; An, W.; Chatfield, R.; Wright, J. Design and performance testing of a multivendor IEC61850-9-2 process bus based protection scheme. IEEE Trans. Smart Grid 2014, 5, 1159–1164. [Google Scholar] [CrossRef]

- Jamborsalamati, P.; Sadu, A.; Ponci, F.; Monti, A. A flexible HiL testing platform for performance evaluation of IEC 61850-based protection schemes. In Proceedings of the 2016 IEEE Power and Energy Society General Meeting, Boston, MA, USA, 17–21 July 2016. [Google Scholar]

- Liu, Z.; Hoidalen, H.K. An adaptive inverse time overcurrent relay model implementation for real time simulation and hardware-in-the-loop testing. In Proceedings of the 13th IET International Conference on Development in Power System Protection (DPSP), Edinburgh, UK, 7–10 March 2016. [Google Scholar]

- Otani, T.; Hagiwara, F.; Matsumoto, S.; Kuroi, K.; Katayama, S.; Ogiyama, T. Requirements for IEC 61850 in terms of Logical Node design and engineering tool compatibility. In Proceedings of the CIGRE Session 2014, Paris, France, 24–29 August 2014. [Google Scholar]

- Ridwan, M.I.; Miswan, N.S.; Shokri, M.S.M.; Noran, M.N.; Lajim, R.M.; Awang, H.N. Interoperability in smart grid using IEC 61850 standard: A power utility prospect. In Proceedings of the 2014 IEEE Innovative Smart Grid Technologies-Asia (ISGT ASIA), Kuala Lumpur, Thailand, 20–23 May 2014. [Google Scholar]

- Yang, M.-T.; Gu, J.-C.; Lin, P.-C.; Huang, Y.-L.; Huang, C.-W.; Guan, J.-L. Interoperability and performance analysis of IEC61850 based substation protection system. Int. J. Electr. Robot. Electron. Commun. Eng. 2013, 7, 497–504. [Google Scholar]

- Eshpeter, A. Resolving the challenges of multiple vendor 61850 implementations. In Proceedings of the 2016 IEEE PES Transmission and Distribution Conference and Exposition (T&D), Dallas, TX, USA, 3–5 May 2016. [Google Scholar]

- Koshiishi, K.; Kaneda, K.; Watabe, Y. Interoperability experience with IEC 61850-based substation automation systems. In Proceedings of the 2012 IEEE PES Transmission and Distribution Conference and Exposition (T&D), Orlando, FL, USA, 7–10 May 2012. [Google Scholar]

- Manassero, G.; Pellini, E.L.; Senger, E.C.; Nakagomi, R.M. IEC61850-based Systems-functional testing and interoperability issues. IEEE Trans. Ind. Inform. 2013, 9, 1436–1444. [Google Scholar] [CrossRef]

- Anombem, U.; Li, H.; Crossley, P.; An, W.; Zhang, R.; Mctaggart, C. Performance testing and assessment of Merging Units using IEC61850. In Proceedings of the 2011 International Conference on Advanced Power System Automation and Protection (APAP), Beijing, China, 16–20 October 2011. [Google Scholar]

- Chen, X.; Guo, H.; Crossley, P. Performance testing of IEC 61850 based architecture for UK National Grid standardised substation automation solutions. In Proceedings of the 2015 IEEE Power & Energy Society General Meeting, Denver, CO, USA, 26–30 July 2015. [Google Scholar]

- Chen, X.; Guo, H.; Crossley, P. Interoperability performance assessment of multivendor IEC61850 process bus. IEEE Trans. Power Deliv. 2016, 31, 1934–1944. [Google Scholar] [CrossRef]

- Ingram, D.M.E.; Schaub, P.; Taylor, R.R.; Campbell, D.A. System-level tests of transformer differential protection using an IEC 61850 process bus. IEEE Trans. Power Deliv. 2014, 29, 1382–1389. [Google Scholar] [CrossRef]

- Chen, L.; Charton, T.; Li, H.; Zhang, R. Virtual site acceptance test platform for IEC 61850 based substations with multi-vendor bay solutions. J. Eng. 2018, 2018. [Google Scholar] [CrossRef]

- Anombem, U.; Li, H.; Crossley, P.; Zhang, R.; McTaggart, C. Process bus architectures for substation automation with life cycle cost consideration. In Proceedings of the 10th IET International Conference on Developments in Power System Protection (DPSP), Manchester, UK, 29 March–1 April 2010. [Google Scholar]

- Charton, T.; Chen, L.; Li, H.; Zhang, R. Virtual Site Acceptance Testing and Training Facility (VSATT) for digital substation solutions. In Proceedings of the CIGRE Study Committee B5 Colloquium, Auckland, New Zealand, 11–15 September 2017. [Google Scholar]

- Brand, K.P. IEC 61850 as backbone for smart PAC systems. CSEE J. Power Energy Syst. 2016, 2, 15–22. [Google Scholar] [CrossRef]

- RTDS Technologies Inc. The RTDS Simulator-the World’s Benchmark for Real-Time Power System Simulation. Available online: https://www.rtds.com/ (accessed on 19 April 2021).

- Guise, L.; Huon, G.; Lhuillier, P.; Haecker, M.; Brunner, C. IEC 61850 interoperability at information level. A challenge for all market players. In Proceedings of the CIGRE Session 2014, Paris, France, 24–29 August 2014. [Google Scholar]

| Parameter | Descriptions |

|---|---|

| Ta | Protection response time = t1 − t0. |

| Tb | Process bus transfer time = t2 − t1. |

| Tc | DMU output delay = t3 − t2. |

| t0 | The time when the RTDS generates a fault and is stamped by the RTDS. |

| t1 | The time when MP1 publishes the GOOSE trip. Time stamped by MP1. |

| t2 | The time when the DMU publishes the acknowledgement (via GOOSE) of receiving the trip signal. Time stamped by the DMU. |

| t3 | The time when the RTDS receives a binary output from the DMU and is stamped by the RTDS. |

| Tn1, Tn2 | Network transmission delays of PBs. |

| f1 | Protection function enabled in MP1, e.g., distance protection. |

| f2 | Function that converts incoming signals to Binary Output (BO) signals |

| Fault Type | Zone | Trip Reception Time (ms) | ||

|---|---|---|---|---|

| Average | Standard Deviation | Maximum | ||

| ABC-to-ground (25% of feeder) | Zone 1 | 23.8 | 1.340 | 27.4 |

| ABC-to-ground (50% of feeder) | Zone 1 | 26.4 | 1.504 | 29.4 |

| ABC-to-ground (100% of feeder) | Zone 2 | 223.7 | 1.185 | 226.3 |

| NO | IED | GOOSE Signal | Time Stamp | Pre-Value | Post-Value |

|---|---|---|---|---|---|

| 1 | RTDS | CTRL/OUT_GGIO6/Ind.stVal (Fault Injected—Bay 2) | 12:12:03.499299943 UTC | 0 | 1 |

| 2 | BAY2_MP1 | CtlCB1/CB1PTRC1/Tr.general (Protection Trip) | 12:12:03.513999998 UTC | 0 | 1 |

| 3 | BAY2_DMU2 | RPIT/ProtInGGIO1/Ind2.stVal (Trip Received) | 12:12:03.516993343 UTC | 0 | 1 |

| 4 | RTDS | CTRL/OUT_GGIO7/Ind.stVal (RTDS Trip Received—BAY 2) | 12:12:03.521949946 UTC | 0 | 1 |

| 5 | BAY2_DMU2 | RPIT/XCBR1/Pos.stVal (CB Position) | 12:12:03.576992571 UTC | 80 (On) | 40 (Off) |

| NO | IED | GOOSE Signal | Time Stamp | Pre-Value | Post-Value |

|---|---|---|---|---|---|

| 1 | RTDS | CTRL/OUT_GGIO2/Ind.stVal (Fault Injected—Bay 1) | 12:21:37.386099934 UTC | 0 | 1 |

| 2 | BAY1_MP1 | PROT/PTRC1/Tr.general (Protection Trip) | 12:21:37.404000043 UTC | 0 | 1 |

| 3 | BAY1_BCU | PROT/RBRF1/OpEx.general (CB Failure Trip) | 12:21:37.611999988 UTC | 0 | 1 |

| 4 | BAY3_BCU | Ln1_ExternalTrip1/EXT_PSCH1/Op.general(Back Trip—BAY 3) | 12:21:37.613273024 UTC | 0 | 1 |

| 5 | BAY2_BCU | System/GosGGIO2/Ind1.stVal (Back Trip—BAY 2) | 12:21:37.613999962 UTC | 0 | 1 |

| 6 | BAY4_DMU1 | MON/SP16GAPC1/Ind15.stVal (Back Trip—BAY 4) | 12:21:37.615294635 UTC | 0 | 1 |

| Item in SCL | Descriptions |

|---|---|

| <ExtRef> | This element shows the IED inputs (e.g., GOOSE) from external devices. Different SCL tools may have variations in defining <ExtRef> at different locations in SCL files. |

| intAddr | This element defines the data attribute where an external input is linked. However, the naming format is not specifically defined in the IEC61850-6 standard. |

| srcLDInst & srcCBName | These elements define the LD instance containing the source control block and the name of the source control block, respectively. However, some SCL tools have not implemented these parameters. |

| appID | This is an application identifier for a GOOSE control block. Some SCL tools will change the appID into their default format when importing 3rd party files. |

| <ServerAt> | This can be used to reference an existing server containing GOOSE and report control blocks. It may not be recognised by some SCL tools, resulting in failed subscriptions. |

| smvID & APPID | These two parameters are used to identify an SV stream. Some vendor tools have a specific format or value range. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Li, H.; Charton, T.; Zhang, R. Virtual Digital Substation Test System and Interoperability Assessments. Energies 2021, 14, 2337. https://doi.org/10.3390/en14082337

Chen L, Li H, Charton T, Zhang R. Virtual Digital Substation Test System and Interoperability Assessments. Energies. 2021; 14(8):2337. https://doi.org/10.3390/en14082337

Chicago/Turabian StyleChen, Linwei, Haiyu Li, Thomas Charton, and Ray Zhang. 2021. "Virtual Digital Substation Test System and Interoperability Assessments" Energies 14, no. 8: 2337. https://doi.org/10.3390/en14082337

APA StyleChen, L., Li, H., Charton, T., & Zhang, R. (2021). Virtual Digital Substation Test System and Interoperability Assessments. Energies, 14(8), 2337. https://doi.org/10.3390/en14082337