The Investigation into the Tribological Impact of Alternative Fuels on Engines Based on Acoustic Emission

Abstract

:1. Introduction

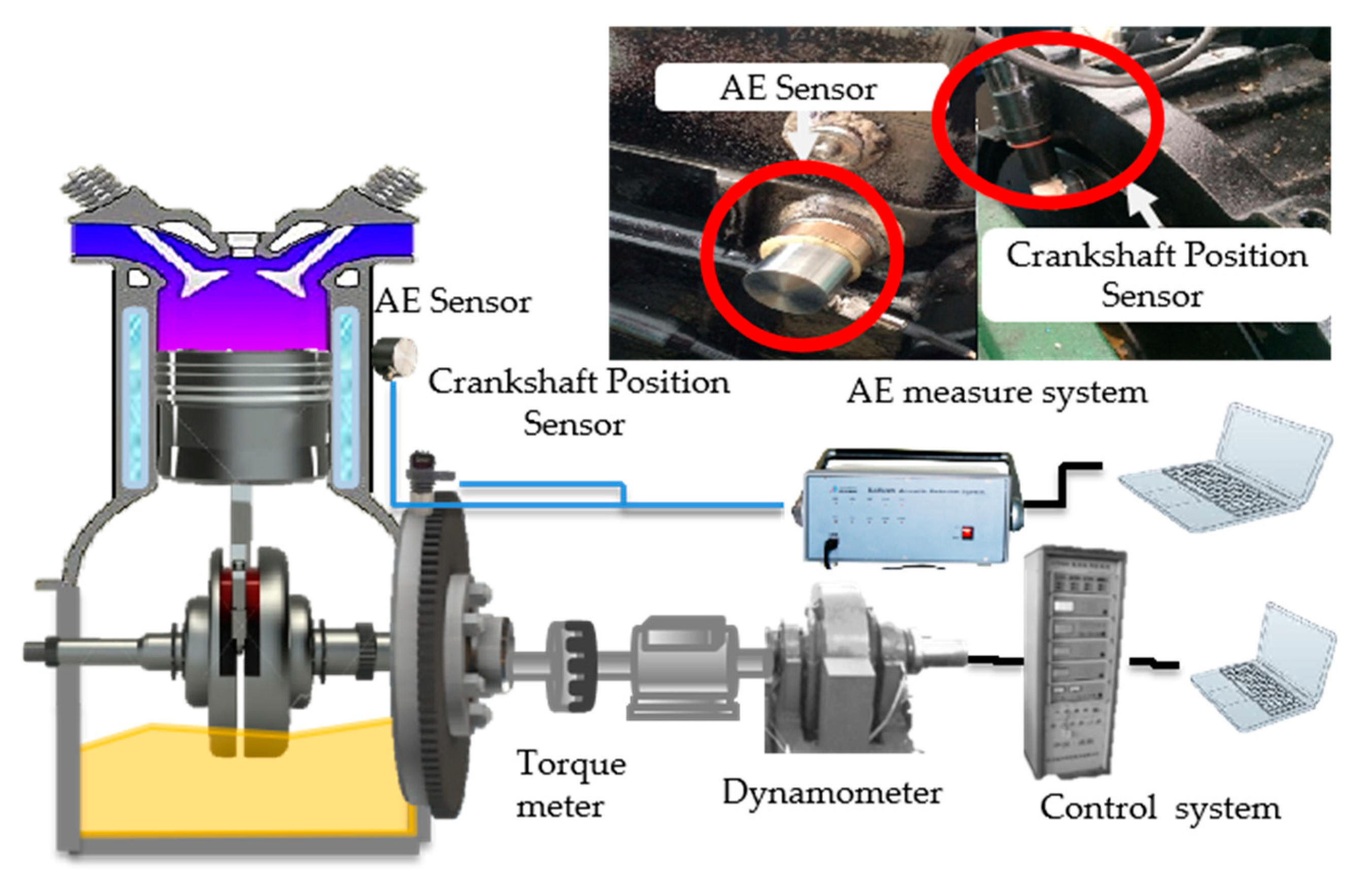

2. AE Signal Acquisition

2.1. Engine Test Rig and Test Conditions

2.2. Test Procedure

3. AE Signal Process

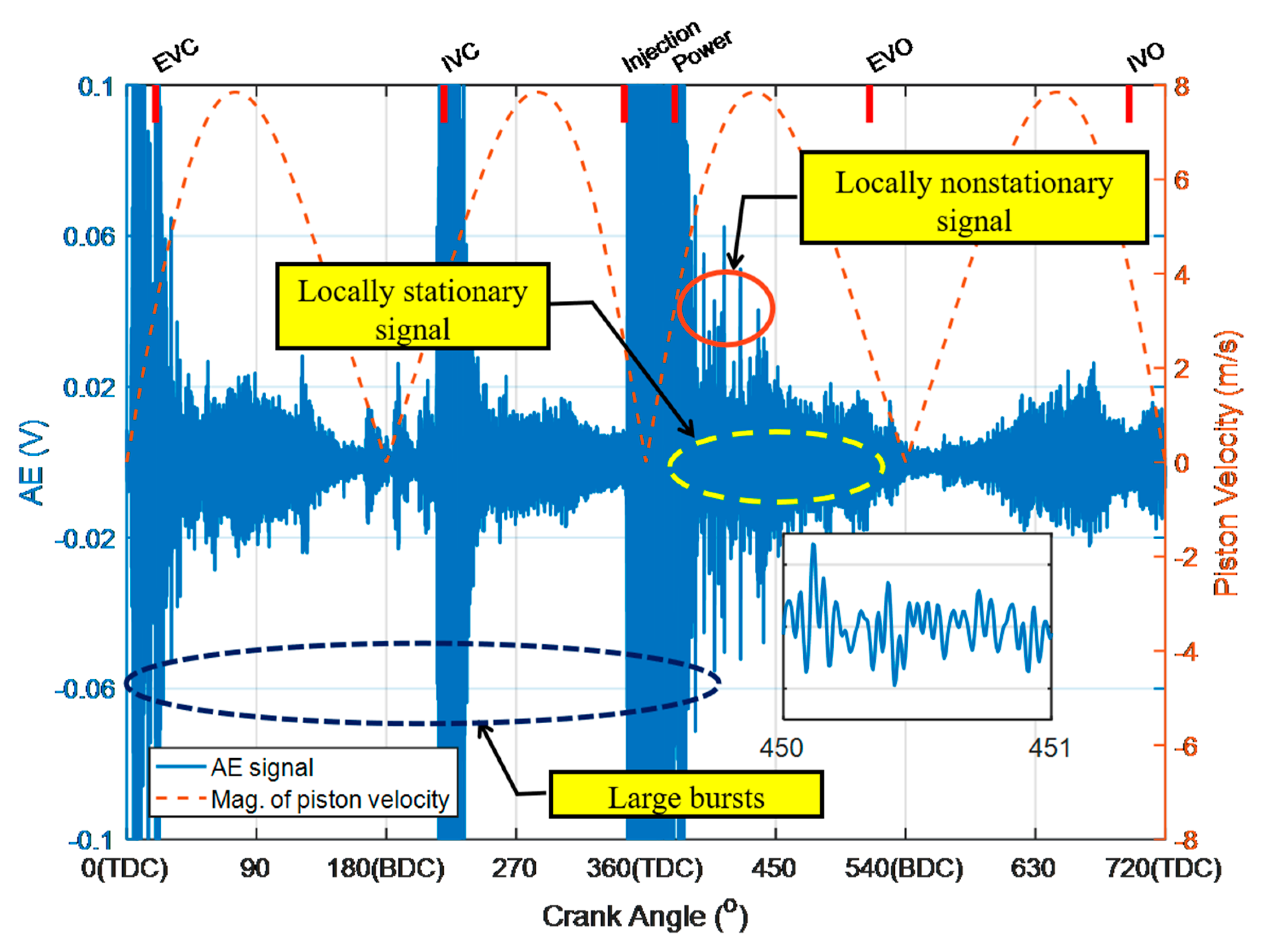

3.1. AE Signals

3.2. Wavelet Packet Transform

3.3. Adaptive AE-WP Algorithm for Tribological Behaviors

3.3.1. Adaptive Threshold–AE Based on FAS

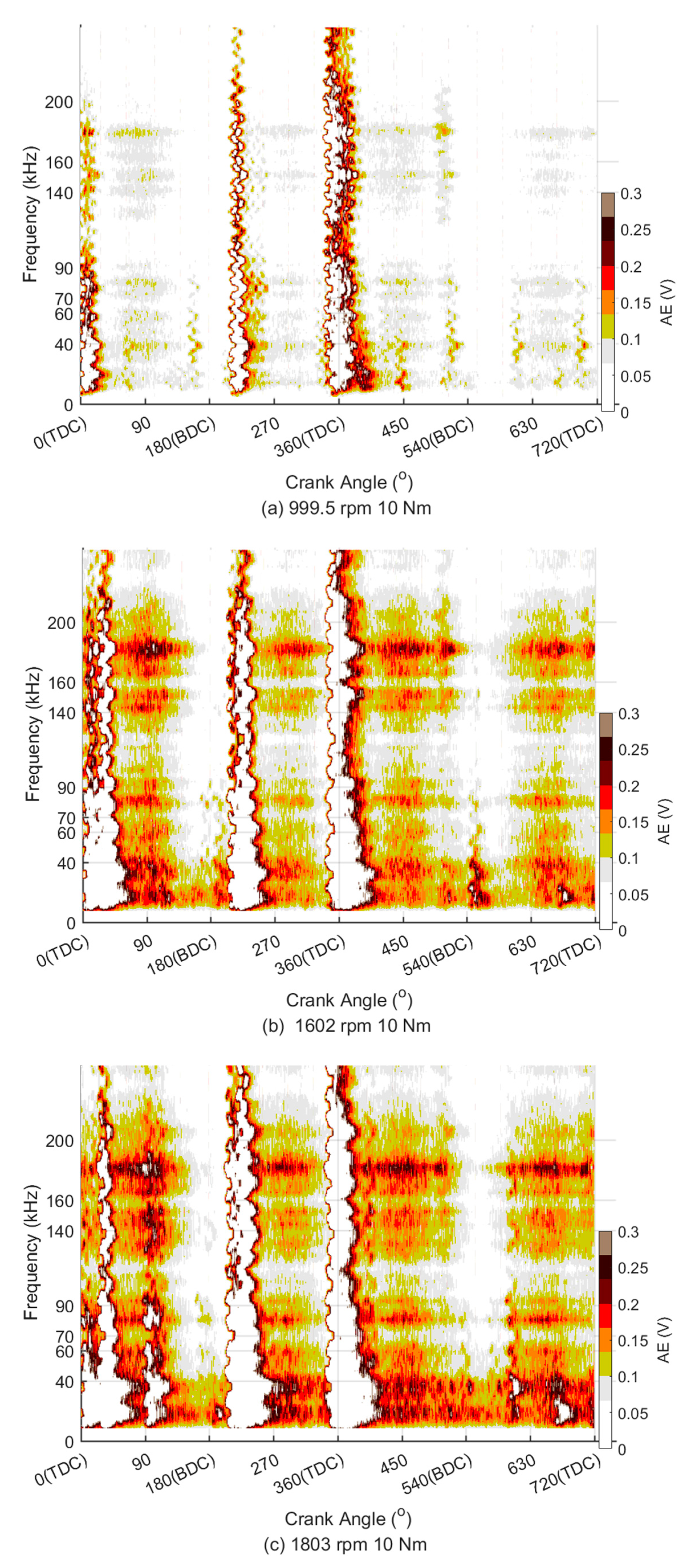

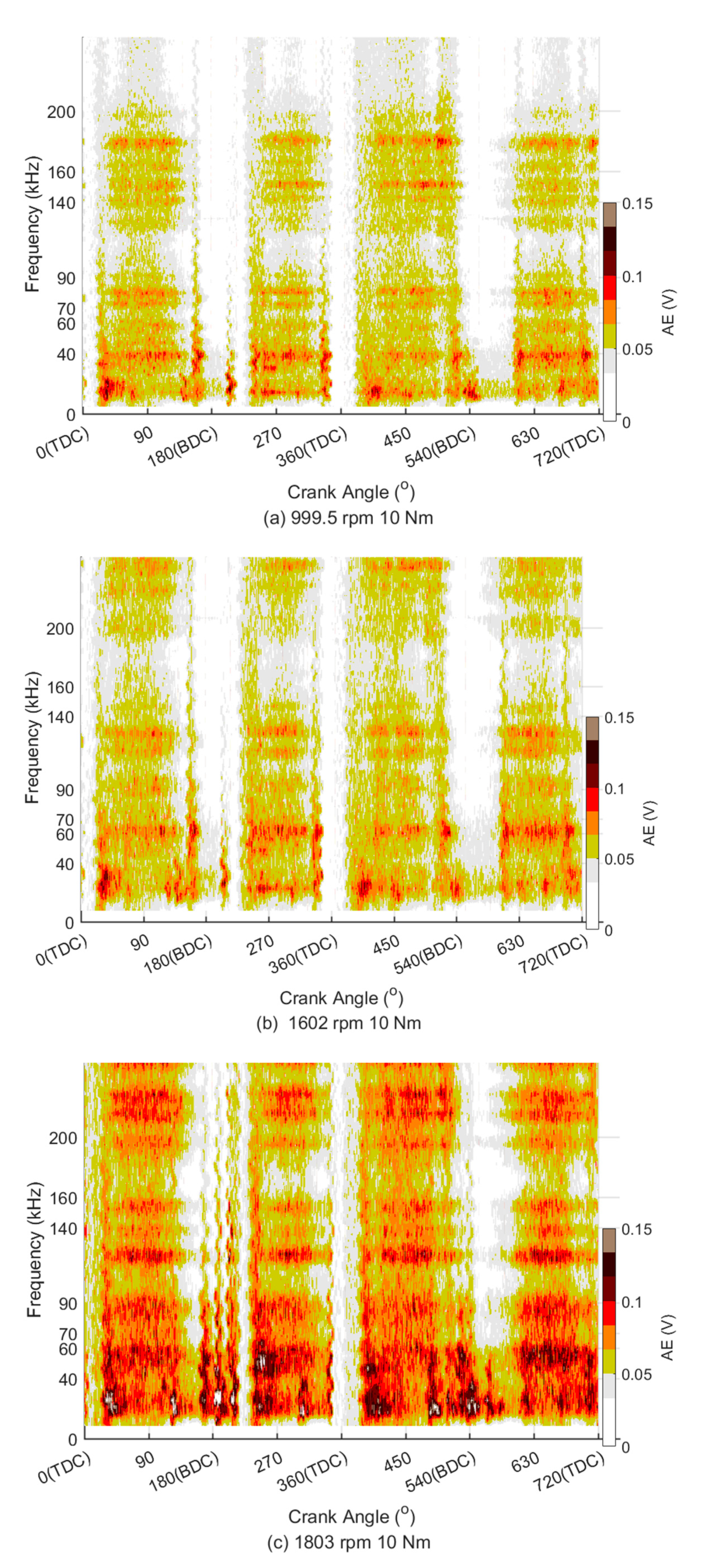

3.3.2. WPT Spectrum of AE Signals and Optimal Wavelet Basis

3.3.3. Optimal Threshold–WP Based on the Auto-Correlation Analysis of the Piston Velocity

- Apply the threshold given by Equation (2) to suppress the non-stationary AE bursts in the middle of the strokes; calculate the d value obtained Equation (4), and judge whether di − di−1 ≥ 0, otherwise reduce the iteration coefficient ci, and repeat step 1;

- Apply WPT to threshold–AE signals (K = 20 for the limited memory in the PC used) with analysis parameters: J = 8 and ‘db5’.

- Calculate the correlation coefficients between the envelope of WPT spectrums and modified piston speed , remove the frequency band with a low correlation which is less than 0.3;

- Calculate the residual WP coefficient RW as given in Equation (8) from 40–200 kHz to remove the noise of other sources.

- Perform inverses WPT to reconstruct the AE signals in the selected frequency bands; calculate the average envelope of 20 reconstructed signals of selected frequency bands, to enhance the similarity to the velocity profile sum the envelope signal matrix;

- Select the local sequence in the middle of each stroke, calculate the mean standard deviation for 20 working cycles as the FAS–AE indicator and AAC–AE indicator for four strokes.

4. Diagnosis of AL Fuel Tribological Impact

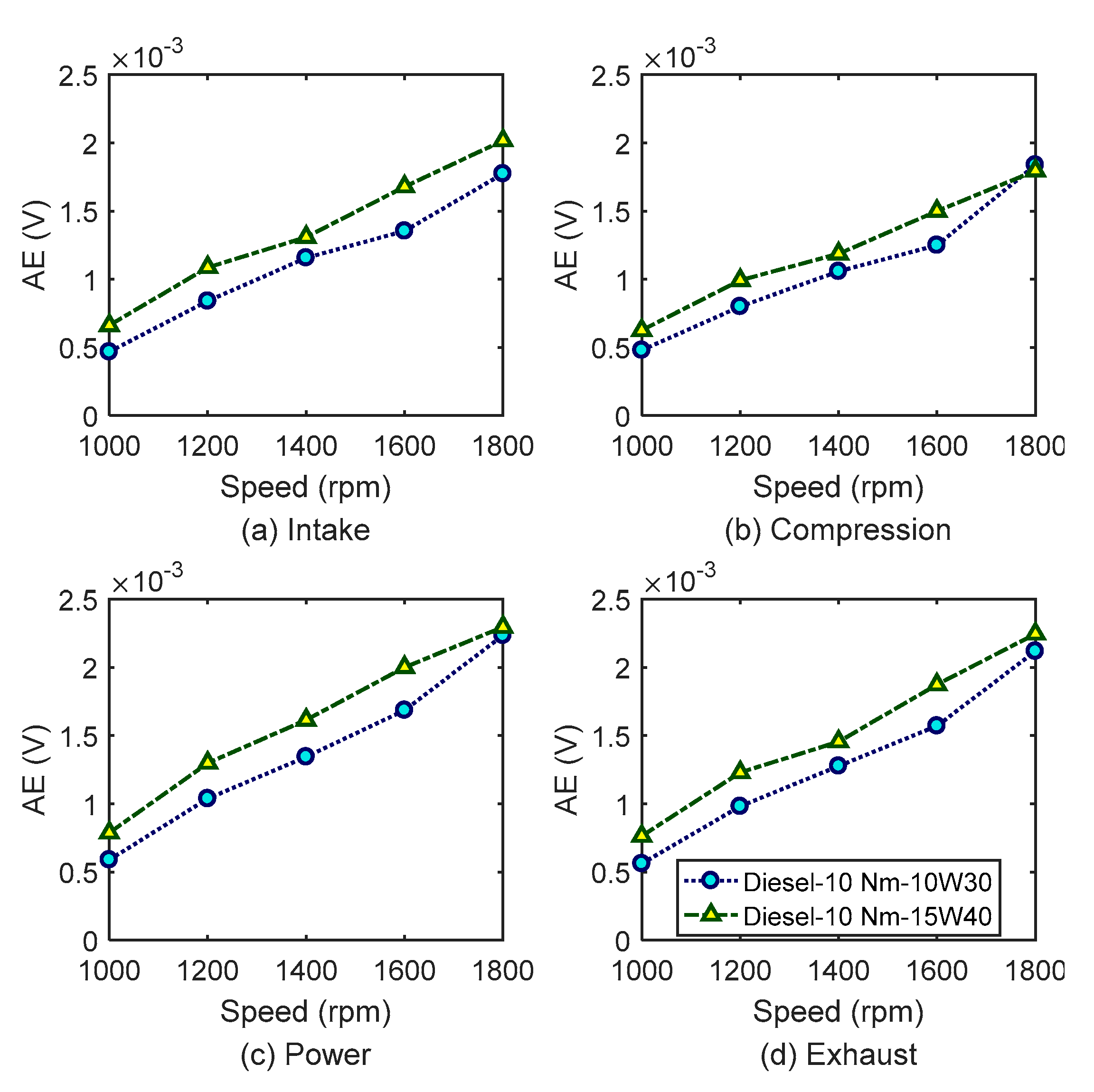

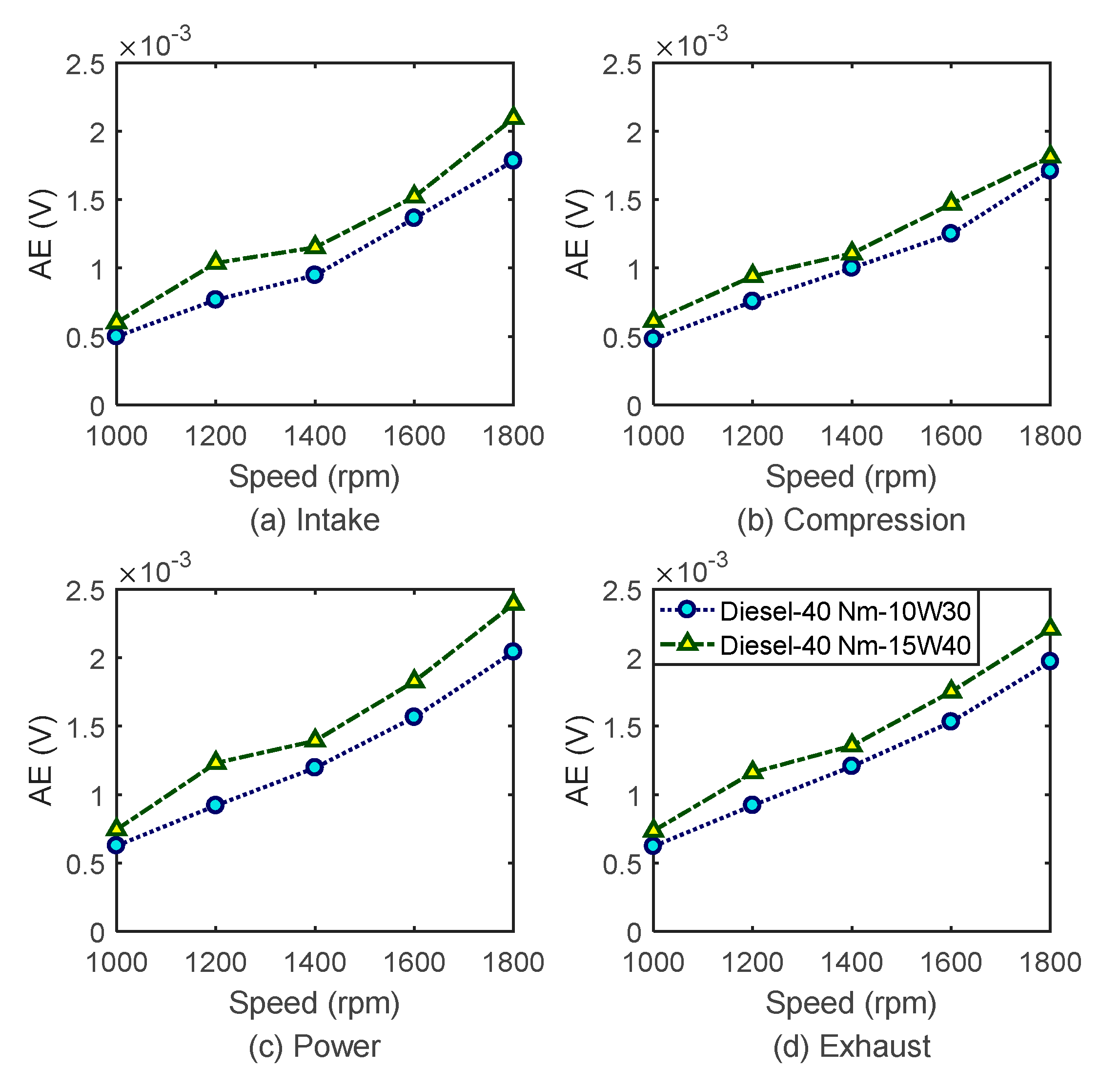

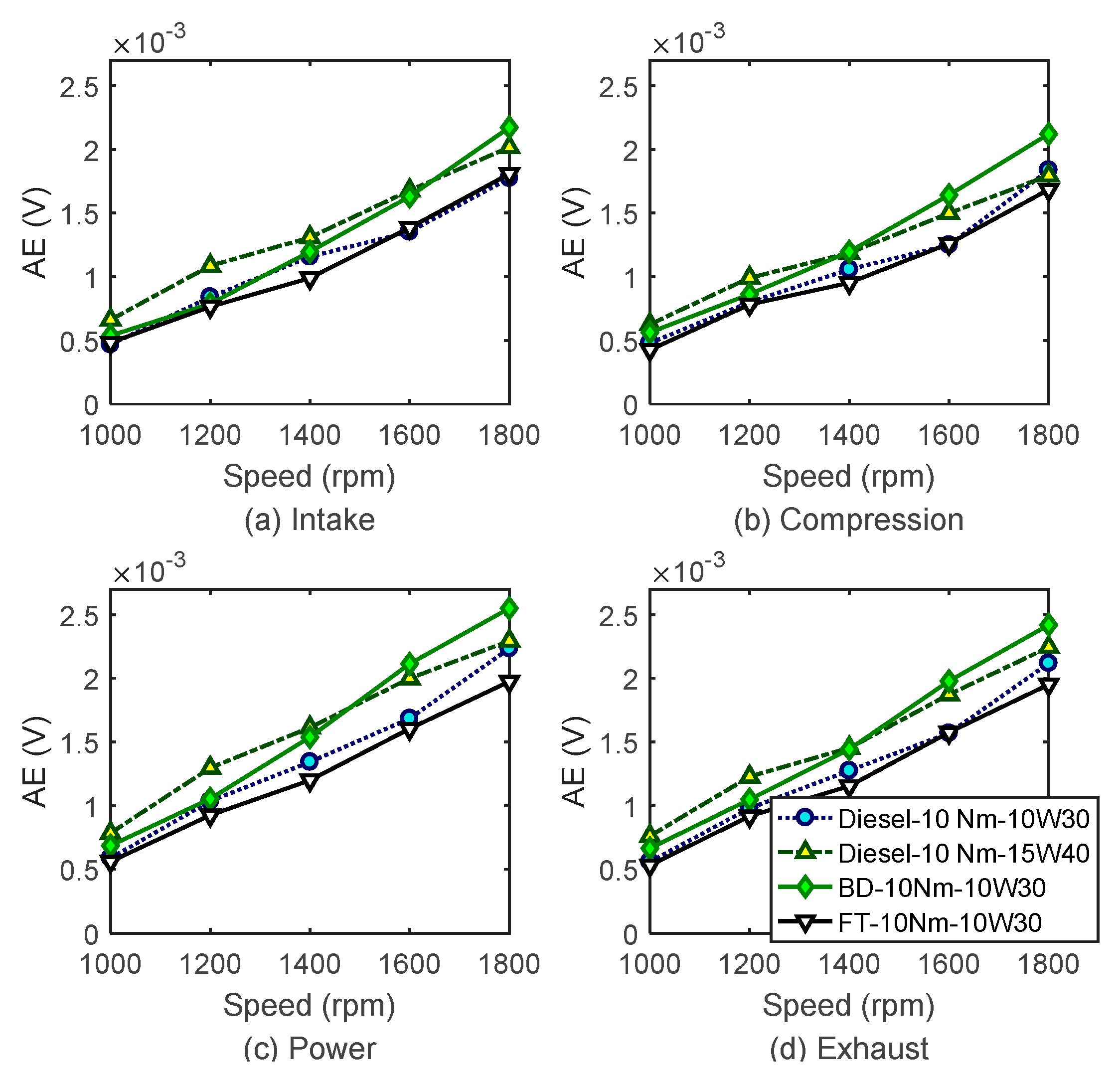

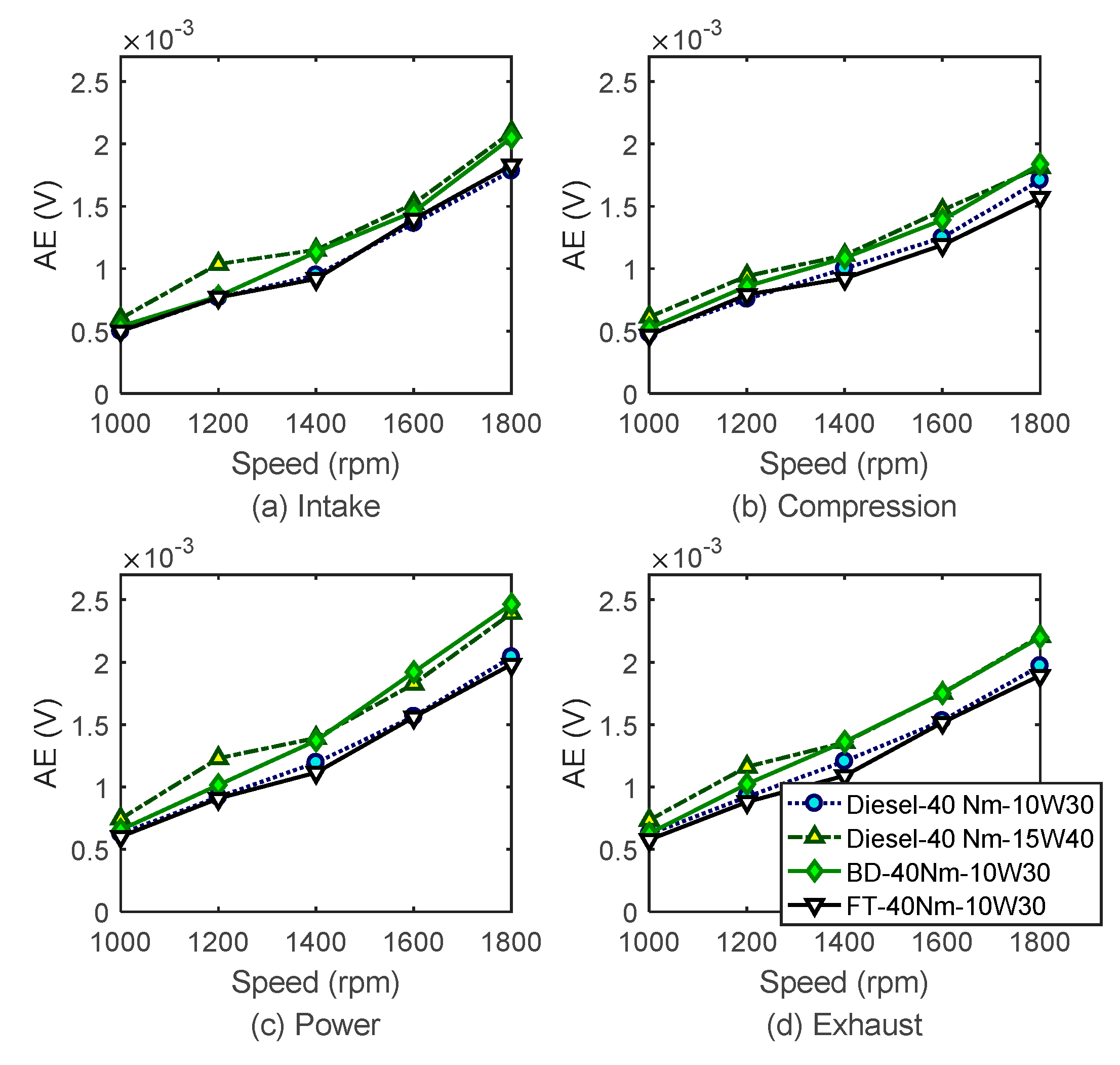

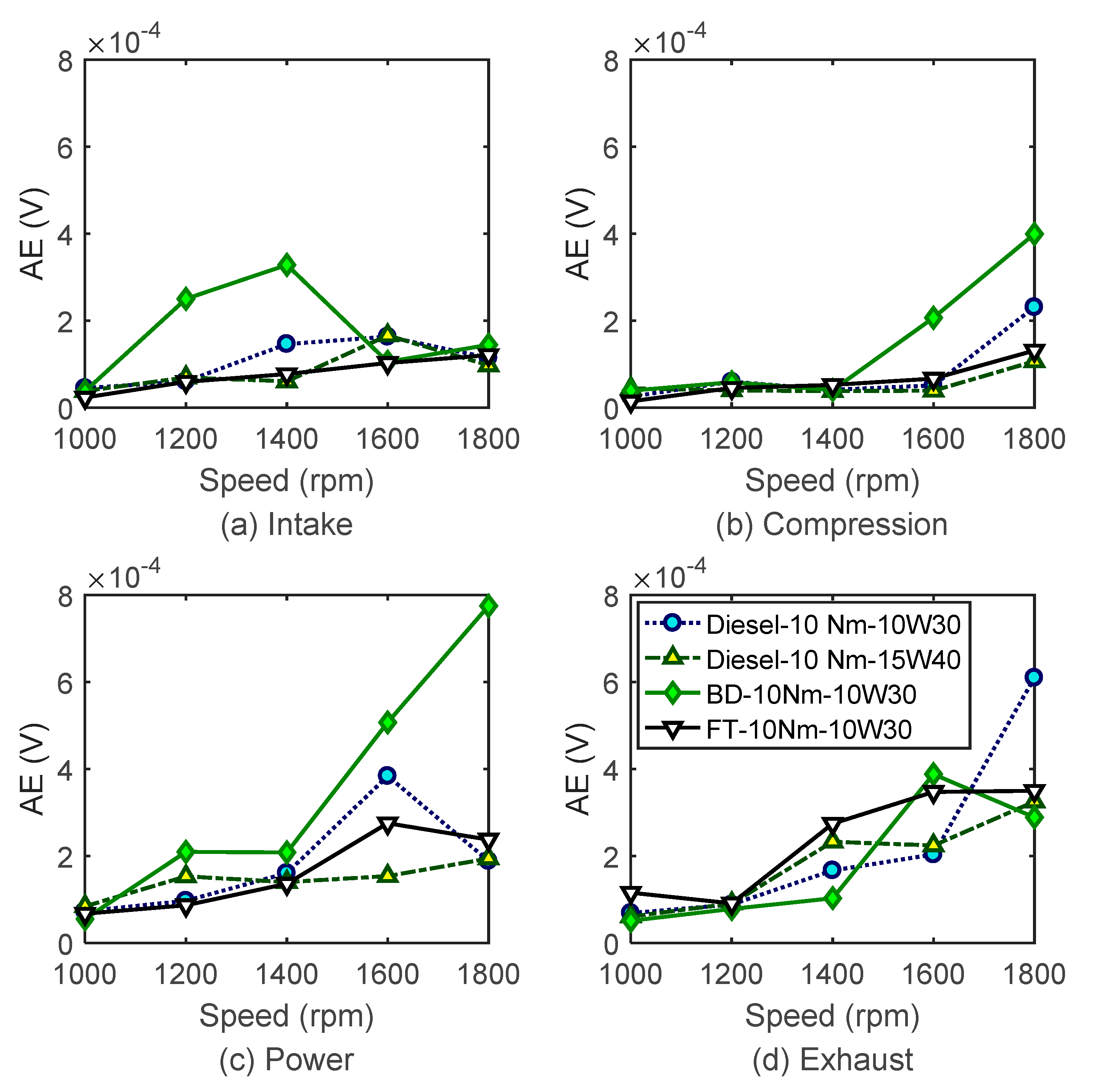

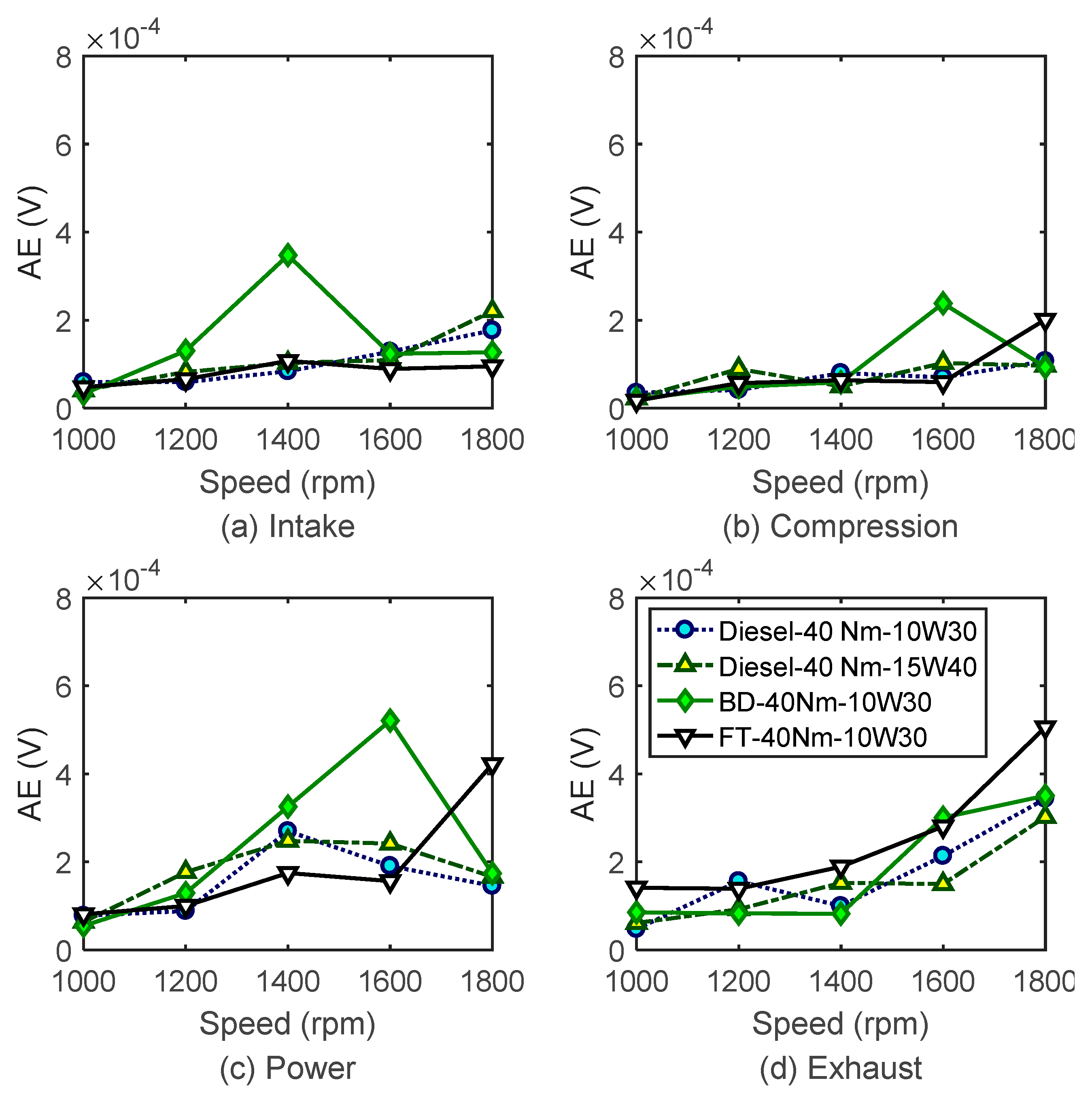

4.1. Diagnosis of Alternatives and the Baselines with FAS Effects

4.2. Diagnosis with AAC Effects

5. Conclusions

- The FAS–AE indicators are increased with speed and viscosity increasing. The AAC–AE is less significant using diesel than using biodiesel.

- The developed FAS–AE indicators from AE signals for biodiesel show tiny higher than the baseline diesel with the same lubricant 10W30 and similar to the baseline using oil 15W40. The developed FAS–AE of F–T diesel is close to the baseline diesel using 10W30.

- The FAS–AE exhibits the impacts on the lubricity of the oil film fueling the alternatives. Too high FAS–AE indicates high power consumption to overcome viscous friction using AL fuel, and too low FAS–AE shows the decreasing the lubricity of oil film using AL fuels.

- Biodiesel produces more AAC impacts with higher AAC–AE responses than F–T diesel, which occurs at high speeds due to high temperatures and more particles after combustion than diesel.

- The AL fuel diagnosis of AAC–AE indicator shows a slight abnormality accompanied by FAS. That demonstrates the potential of AE to conduct a comprehensive analysis of the tribological effects of alternative fuels.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Abbreviations

| AAC | Asperity–Asperity Collision |

| AE | Acoustic Emission |

| BDC | Bottom Dead Centre |

| BL | Boundary Lubrication |

| DWT | Discrete Wavelet Transform |

| db | Daubechies |

| EVO | Exhaust Valve Opening |

| EVC | Exhaust Valve Closing |

| FAS | Fluid–Asperity Shearing |

| HL | Hydrodynamic Lubrication |

| IC | Internal Combustion |

| IVO | Inlet Valve Opening |

| IVC | Inlet Valve Closing |

| ML | Mixed Lubrication |

| STFT | Short-Time Fourier Transform |

| TDC | Top Dead Centre |

| WPT | Wavelet Packet Transform |

| WP | Wavelet Packets |

References

- Qu, J.; Truhan, J.J.; Blau, P.J.; Meyer, H.M. Scuffing transition diagrams for heavy duty diesel fuel injector materials in ultra low-sulfur fuel-lubricated environment. Wear 2005, 259, 1031–1040. [Google Scholar] [CrossRef]

- Tesfa, B.; Gu, F.; Mishra, R.; Ball, A. Emission Characteristics of a CI Engine Running with a Range of Biodiesel Feedstocks. Energies 2014, 7, 334–350. [Google Scholar] [CrossRef]

- Ramadhas, A.; Muraleedharan, C.; Jayaraj, S. Performance and emission evaluation of a diesel engine fueled with methyl esters of rubber seed oil. Renew. Energy 2005, 30, 1789–1800. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Masjuki, H.; Kalam, M.; Mofijur, M.; Hazrat, M.; Liaquat, A. Effect of Additive on Performance of C.I. Engine Fuelled with Bio Diesel. Energy Procedia 2012, 14, 1624–1629. [Google Scholar] [CrossRef] [Green Version]

- Agarwal, A.K.; Das, L.M. Biodiesel Development and Characterization for Use as a Fuel in Compression Ignition Engines. J. Eng. Gas Turbines Power 2001, 123, 440–447. [Google Scholar] [CrossRef]

- Carraretto, C. Biodiesel as alternative fuel: Experimental analysis and energetic evaluations. Energy 2004, 29, 2195–2211. [Google Scholar] [CrossRef]

- Cheng, A.S.; Dibble, R.W. Emissions Performance of Oxygenate-in-Diesel Blends and Fischer-Tropsch Diesel in a Compression Ignition Engine; SAE Technical Paper: Warrendale, PA, USA, 1999. [Google Scholar] [CrossRef]

- Schaberg, P.W.; Myburgh, I.S.; Botha, J.J.; Khalek, I.A. Comparative Emissions Performance of Sasol Fischer-Tropsch Diesel Fuel in Current and Older Technology Heavy-Duty Engines; SAE Technical Paper: Warrendale, PA, USA, 2000. [Google Scholar] [CrossRef]

- Alleman, T.L.; Mccormick, R.L. Fischer-Tropsch Diesel Fuels—Properties and Exhaust Emissions: A Literature Review; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Vicente, G.; Coteron, A.; Martinez, M.; Aracil, J. Application of the factorial design of experiments and response surface methodology to optimize biodiesel production. Ind. Crop. Prod. 1998, 8, 29–35. [Google Scholar] [CrossRef]

- Rahman, M.; Rasul, M.; Hassan, N.M.S. Study on the Tribological Characteristics of Australian Native First Generation and Second Generation Biodiesel Fuel. Energies 2017, 10, 55. [Google Scholar] [CrossRef]

- Haseeb, A.; Sia, S.; Fazal, M.; Masjuki, H. Effect of temperature on tribological properties of palm biodiesel. Energy 2010, 35, 1460–1464. [Google Scholar] [CrossRef]

- Gill, S.; Tsolakis, A.; Dearn, K.; Rodríguez-Fernández, J. Combustion characteristics and emissions of Fischer–Tropsch diesel fuels in IC engines. Prog. Energy Combust. Sci. 2011, 37, 503–523. [Google Scholar] [CrossRef]

- Fazal, M.; Haseeb, A.; Masjuki, H. Investigation of friction and wear characteristics of palm biodiesel. Energy Convers. Manag. 2013, 67, 251–256. [Google Scholar] [CrossRef]

- Sharma, B.K.; Rashid, U.; Anwar, F.; Erhan, S.Z. Lubricant properties of Moringa oil using thermal and tribological techniques. J. Therm. Anal. Calorim. 2009, 96, 999–1008. [Google Scholar] [CrossRef]

- Habibullah, M.; Masjuki, H.; Kalam, M.; Zulkifli, N.; Masum, B.; Arslan, A.; Gulzar, M. Friction and wear characteristics of Calophyllum inophyllum biodiesel. Ind. Crop. Prod. 2015, 76, 188–197. [Google Scholar] [CrossRef]

- Agarwal, A.K. Experimental investigations of the effect of biodiesel utilization on lubricating oil tribology in diesel engines. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2005, 219, 703–713. [Google Scholar] [CrossRef]

- Peterson, C.L.; Thompson, J.L.; Zhang, X.; Hammond, B.L.; Beck, S. Development of Eapeseed Biodiesel for Use in High Speed Disesl Engines; Report to USDOE University of Idaho; University of Idaho: Moscow, ID, USA, 1996. [Google Scholar]

- Serrano, L.; Carreira, V.; Câmara, R.; Gameiro da Silva, M. On-road performance comparison of two identical cars consuming petrodiesel and biodiesel. Fuel Process. Technol. 2012, 103, 125–133. [Google Scholar] [CrossRef]

- Fraer, R.; Dinh, H.; Proc, K.; McCormick, R.L.; Chandler, K.; Buchholz, B. Operating Experience and Teardown Analysis for Engines Operated on Biodiesel Blends (B20); SAE Technical Paper: Warrendale, PA, USA, 2005. [Google Scholar] [CrossRef] [Green Version]

- Sundus, F.; Fazal, M.; Masjuki, H. Tribology with biodiesel: A study on enhancing biodiesel stability and its fuel properties. Renew. Sustain. Energy Rev. 2017, 70, 399–412. [Google Scholar] [CrossRef]

- Hu, E.; Xu, Y.; Hu, X.; Pan, L.; Jiang, S. Corrosion behaviors of metals in biodiesel from rapeseed oil and methanol. Renew. Energy 2012, 37, 371–378. [Google Scholar] [CrossRef]

- Hassan, M.B.H. Comparative corrosive characteristics of petroleum diesel and palm biodiesel for automotive materials. Fuel Process. Technol. 2010, 91, 1308–1315. [Google Scholar]

- Haseeb, A.; Masjuki, H.; Ann, L.; Fazal, M. Corrosion characteristics of copper and leaded bronze in palm biodiesel. Fuel Process. Technol. 2010, 91, 329–334. [Google Scholar] [CrossRef]

- Mthis, K.; Chmelk, F. Exploring Plastic Deformation of Metallic Materials by the Acoustic Emission Technique. In Acoustic Emission; Sikorski, W., Ed.; InTech: Rijeka, Croatia, 2012; ISBN 978-953-51-0056-0. [Google Scholar]

- Sánchez, R.-V.; Lucero, P.; Vásquez, R.E.; Cerrada, M.; Cabrera, D. A comparative feature analysis for gear pitting level classification by using acoustic emission, vibration and current signals. IFAC-PapersOnLine 2018, 51, 346–352. [Google Scholar] [CrossRef]

- Hutt, S.; Clarke, A.; Evans, H. Generation of Acoustic Emission from the running-in and subsequent micropitting of a mixed-elastohydrodynamic contact. Tribol. Int. 2018, 119, 270–280. [Google Scholar] [CrossRef]

- Poddar, S.; Tandon, N. Study of Oil Starvation in Journal Bearing Using Acoustic Emission and Vibration Measurement Techniques. J. Tribol. 2020, 142. [Google Scholar] [CrossRef]

- Mokhtari, N.; Pelham, J.G.; Nowoisky, S.; Bote-Garcia, J.-L.; Gühmann, C. Friction and Wear Monitoring Methods for Journal Bearings of Geared Turbofans Based on Acoustic Emission Signals and Machine Learning. Lubricants 2020, 8, 29. [Google Scholar] [CrossRef] [Green Version]

- Hase, A. Early Detection and Identification of Fatigue Damage in Thrust Ball Bearings by an Acoustic Emission Technique. Lubricants 2020, 8, 37. [Google Scholar] [CrossRef] [Green Version]

- Jiang, J.; Gu, F.; Gennish, R.; Moore, D.; Harris, G.; Ball, A. Monitoring of diesel engine combustions based on the acoustic source characterisation of the exhaust system. Mech. Syst. Signal Process. 2008, 22, 1465–1480. [Google Scholar] [CrossRef]

- Elamin, F.; Fan, Y.; Ball, A.; Gu, F. Diesel Engine Valve Clearance Detection Using Acoustic Emission. Adv. Mech. Eng. 2010, 2, 495741. [Google Scholar] [CrossRef]

- Albarbar, A.; Gu, F.; Ball, A. Diesel engine fuel injection monitoring using acoustic measurements and independent component analysis. Measurement 2010, 43, 1376–1386. [Google Scholar] [CrossRef] [Green Version]

- Khurshudov, A.G.; Talke, F.E. A Study of Subambient Pressure Tri-Pad Sliders Using Acoustic Emission. J. Tribol. 1998, 120, 54–59. [Google Scholar] [CrossRef]

- Lee, D.-Y.; Lee, J.; Hwang, J.; Choa, S.-H. Effect of relative humidity and disk acceleration on tribocharge build-up at a slider–disk interface. Tribol. Int. 2007, 40, 1253–1257. [Google Scholar] [CrossRef]

- Deshpande, P.; Pandiyan, V.; Meylan, B.; Wasmer, K. Acoustic emission and machine learning based classification of wear generated using a pin-on-disc tribometer equipped with a digital holographic microscope. Wear 2021, 203622. [Google Scholar] [CrossRef]

- Douglas, R.; Steel, J.; Reuben, R. A study of the tribological behaviour of piston ring/cylinder liner interaction in diesel engines using acoustic emission. Tribol. Int. 2006, 39, 1634–1642. [Google Scholar] [CrossRef]

- Shuster, M.; Combs, D.; Karrip, K.; Burke, D. Piston Ring Cylinder Liner Scuffing Phenomenon Studies Using Acoustic Emission Technique; SAE Technical Paper 2000-01–1782; SAE International: Warrendale, PA, USA, 2000. [Google Scholar]

- Wei, N.; Ball, A.; Gu, F. A Study of Alternative Fuels Potential Effects on the Combustion Engines using acoustic emission. In Proceedings of the Computing and Engineering Annual Researchers’ Conference 2013: CEARC’13, San Juan, Puerto, 18–22 May 2013; Lucas, G., Ed.; University of Huddersfield: Huddersfield, UK, 2013; p. 239. [Google Scholar]

- Wei, N.; Gu, F.; Wang, T.; Li, G.; Xu, Y.; Yang, L.; Ball, A.D. Characterisation of acoustic emissions for the frictional effect in engines using wavelets based multi-resolution analysis. In Proceedings of the 2015 21st International Conference on Automation and Computing (ICAC), Glasgow, UK, 11–12 September 2015; pp. 1–6. [Google Scholar]

- Lu, X.; Khonsari, M.M.; Gelinck, E.R.M. The Stribeck Curve: Experimental Results and Theoretical Prediction. J. Tribol. 2006, 128, 789–794. [Google Scholar] [CrossRef]

- Boness, R.; McBride, S. Adhesive and abrasive wear studies using acoustic emission techniques. Wear 1991, 149, 41–53. [Google Scholar] [CrossRef]

- Fan, Y.; Gu, F.; Ball, A. Modelling acoustic emissions generated by sliding friction. Wear 2010, 268, 811–815. [Google Scholar] [CrossRef]

- Elamin, F.; Gu, F.; Ball, A. Online Monitoring of Engine Oil Quality Based on AE Signal Analysis. In Future Technologies in Computing and Engineering, Proceedings of Computing and Engineering Annual Researchers’ Conference 2010: CEARC’10, Athens, Greece, 7–10 July 2010; Lucas, G., Xu, Z., Eds.; University of Huddersfield: Huddersfield, UK, 2010; pp. 116–123. ISBN 978-1-86218-093-2. [Google Scholar]

- Wei, N.; Gu, J.X.; Gu, F.; Chen, Z.; Li, G.; Wang, T.; Ball, A.D. An Investigation into the Acoustic Emissions of Internal Combustion Engines with Modelling and Wavelet Package Analysis for Monitoring Lubrication Conditions. Energies 2019, 12, 640. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; Zhang, H.; Shi, Z.; Chu, F.; Gu, F.; Ball, A.D. Modelling Acoustic Emissions induced by dynamic fluid-asperity shearing in hydrodynamic lubrication regime. Tribol. Int. 2021, 153, 106590. [Google Scholar] [CrossRef]

- Fan, X.; Zuo, M.J. Gearbox fault detection using Hilbert and wavelet packet transform. Mech. Syst. Signal Process. 2006, 20, 966–982. [Google Scholar] [CrossRef]

- Dalvand, F.; Kalantar, A.; Safizadeh, M.S. A Novel Bearing Condition Monitoring Method in Induction Motors Based on Instantaneous Frequency of Motor Voltage. IEEE Trans. Ind. Electron. 2015, 63, 364–376. [Google Scholar] [CrossRef]

- Wang, X.; Liu, C.; Bi, F.; Bi, X.; Shao, K. Fault diagnosis of diesel engine based on adaptive wavelet packets and EEMD-fractal dimension. Mech. Syst. Signal Process. 2013, 41, 581–597. [Google Scholar] [CrossRef]

- Bianchi, D.; Mayrhofer, E.; Gröschl, M.; Betz, G.; Vernes, A. Wavelet packet transform for detection of single events in acoustic emission signals. Mech. Syst. Signal Process. 2015, 64–65, 441–451. [Google Scholar] [CrossRef]

- Gómez, M.J.; Castejón, C.; García-Prada, J.C. Review of Recent Advances in the Application of the Wavelet Transform to Diagnose Cracked Rotors. Algorithms 2016, 9, 19. [Google Scholar] [CrossRef]

- Wickerhauser, M.V. Lectures on Wavelet Packet Algorithms. In Lecture Notes; INRIA: Washington, DC, USA, 1992. [Google Scholar]

- Xu, Y.; Zhen, D.; Gu, J.X.; Rabeyee, K.; Chu, F.; Gu, F.; Ball, A.D. Autocorrelated Envelopes for early fault detection of rolling bearings. Mech. Syst. Signal Process. 2021, 146, 106990. [Google Scholar] [CrossRef]

| Technical Parameters | Technical Data |

|---|---|

| Manufacturer | Anhui Quanchai Engine Co., Ltd., China |

| Engine model | QCH1125 |

| Number of cylinder | One |

| Combustion system | Direct injection, vertical type |

| Bore/stroke | 125/120 mm |

| Displacement | 1.473 L |

| Compression ratio | 18:1 |

| Rated power | 20.6 kW @ 2200 rpm |

| Maximum torque | 67 Nm @ 1920 rpm |

| Fuel | Lube-Oil | Engine Speed (rpm) | Load (Nm) | Lower Heating Value (MJ/kg) | Cetane Number | Viscosity (mm2/s) at 20 °C | Density (g/cm3) at 20 °C |

|---|---|---|---|---|---|---|---|

| Bio–Diesel | CD10W30 | 1000 1200 1400 1600 1800 | 10 40 | 39 | 59 | 5.2 | 0.88 |

| F–T diesel | CD10W30 | 44.2 | 74.8 | 2.14 | 0.76 | ||

| Standard Diesel | CD10W30 | 42.6 | 45 | 4.65 | 0.83 | ||

| Standard Diesel | CD15W40 | 42.6 | 45 | 4.65 | 0.83 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, N.; Chen, Z.; Xu, Y.; Gu, F.; Ball, A. The Investigation into the Tribological Impact of Alternative Fuels on Engines Based on Acoustic Emission. Energies 2021, 14, 2315. https://doi.org/10.3390/en14082315

Wei N, Chen Z, Xu Y, Gu F, Ball A. The Investigation into the Tribological Impact of Alternative Fuels on Engines Based on Acoustic Emission. Energies. 2021; 14(8):2315. https://doi.org/10.3390/en14082315

Chicago/Turabian StyleWei, Nasha, Zhi Chen, Yuandong Xu, Fengshou Gu, and Andrew Ball. 2021. "The Investigation into the Tribological Impact of Alternative Fuels on Engines Based on Acoustic Emission" Energies 14, no. 8: 2315. https://doi.org/10.3390/en14082315

APA StyleWei, N., Chen, Z., Xu, Y., Gu, F., & Ball, A. (2021). The Investigation into the Tribological Impact of Alternative Fuels on Engines Based on Acoustic Emission. Energies, 14(8), 2315. https://doi.org/10.3390/en14082315