CFD-DEM Simulation of Spouted Bed Dynamics under High Temperature with an Adhesive Model

Abstract

1. Introduction

2. Mathematical Model

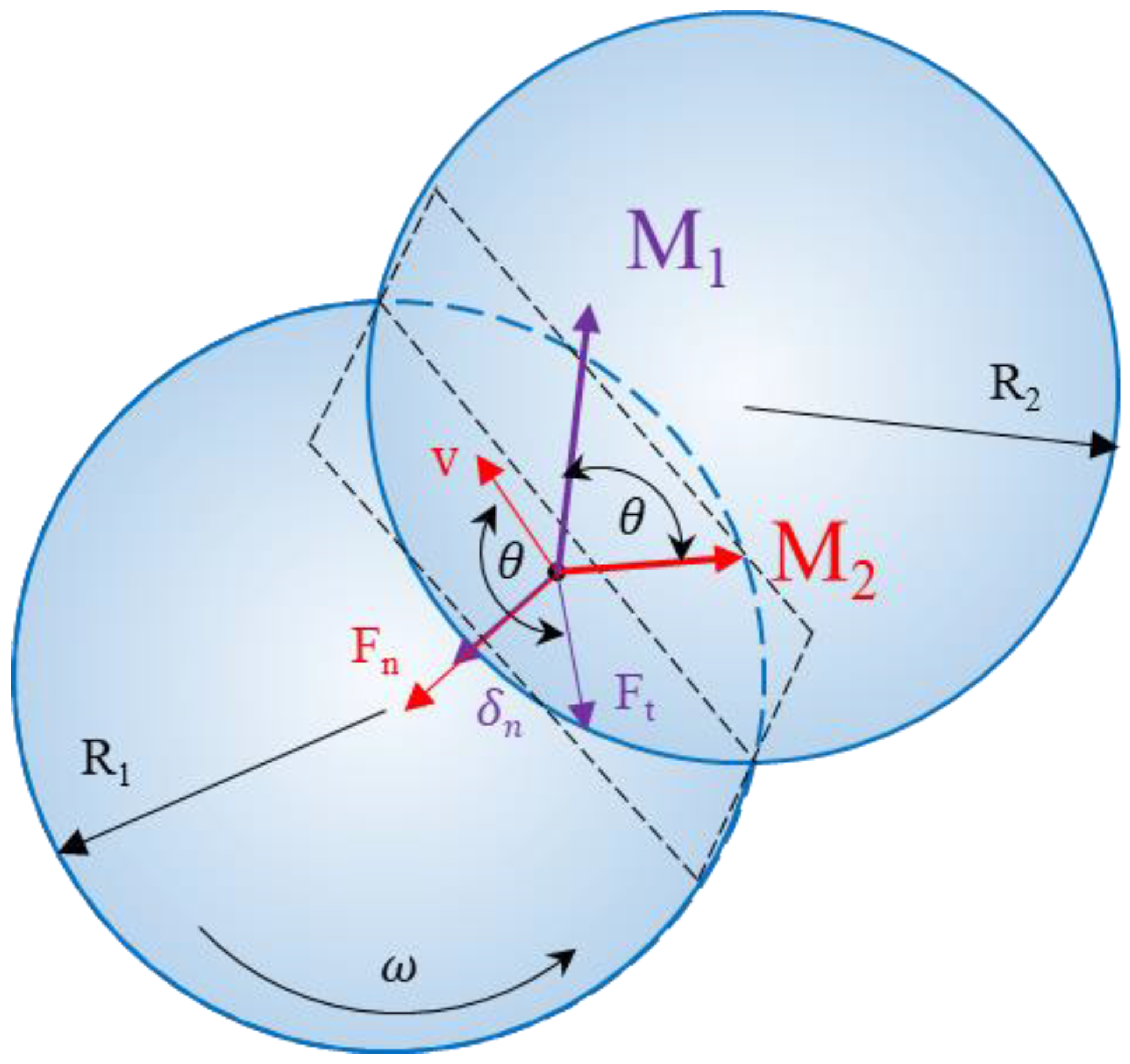

2.1. CFD-DEM Model

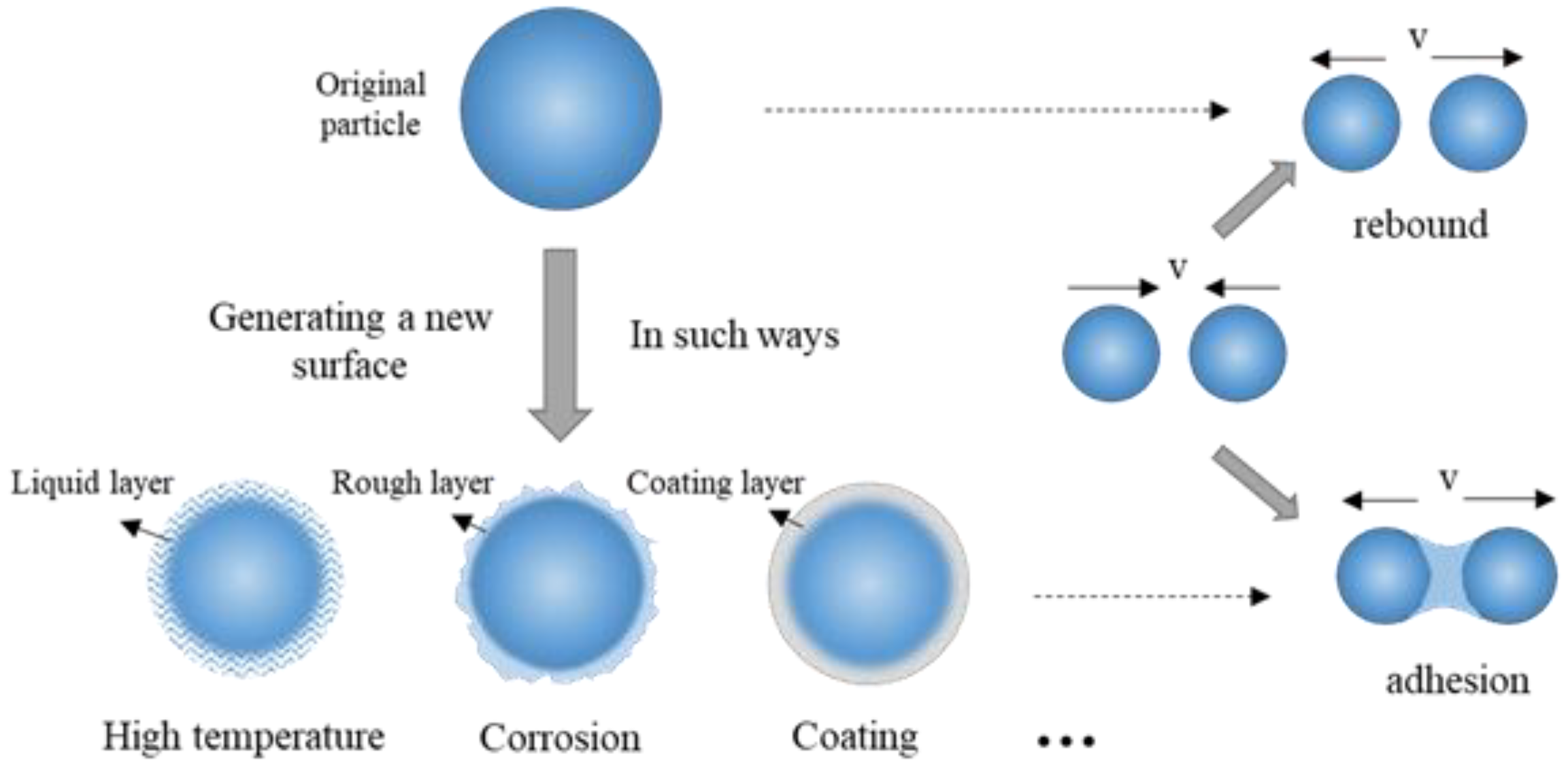

2.2. CFD-DEM with the Adhesion Model

2.3. Geometry and Parameters

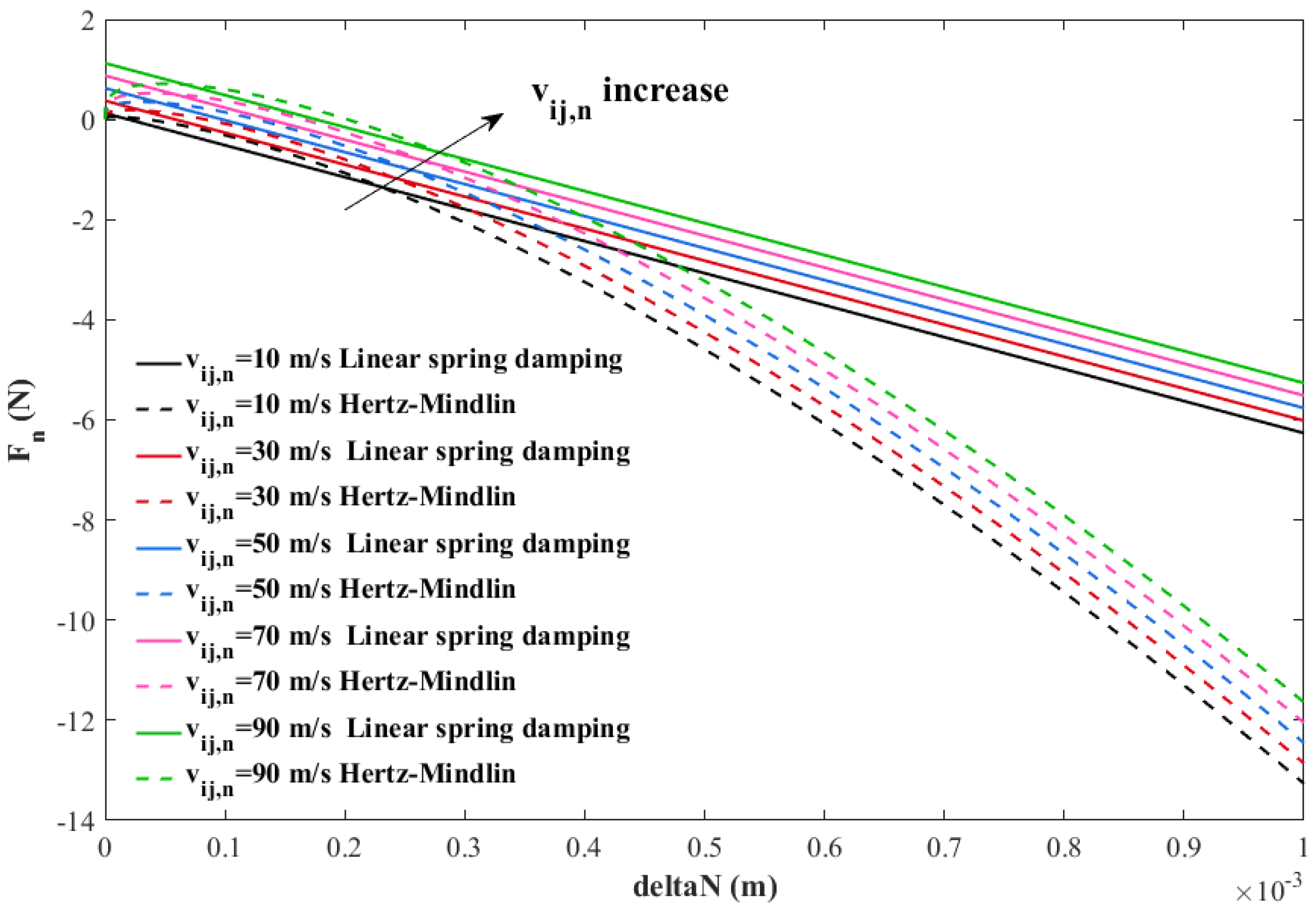

3. Comparison of Contact Force Models

4. Results and Discussion

4.1. Spout Behavior Study Used CFD-DEM Model

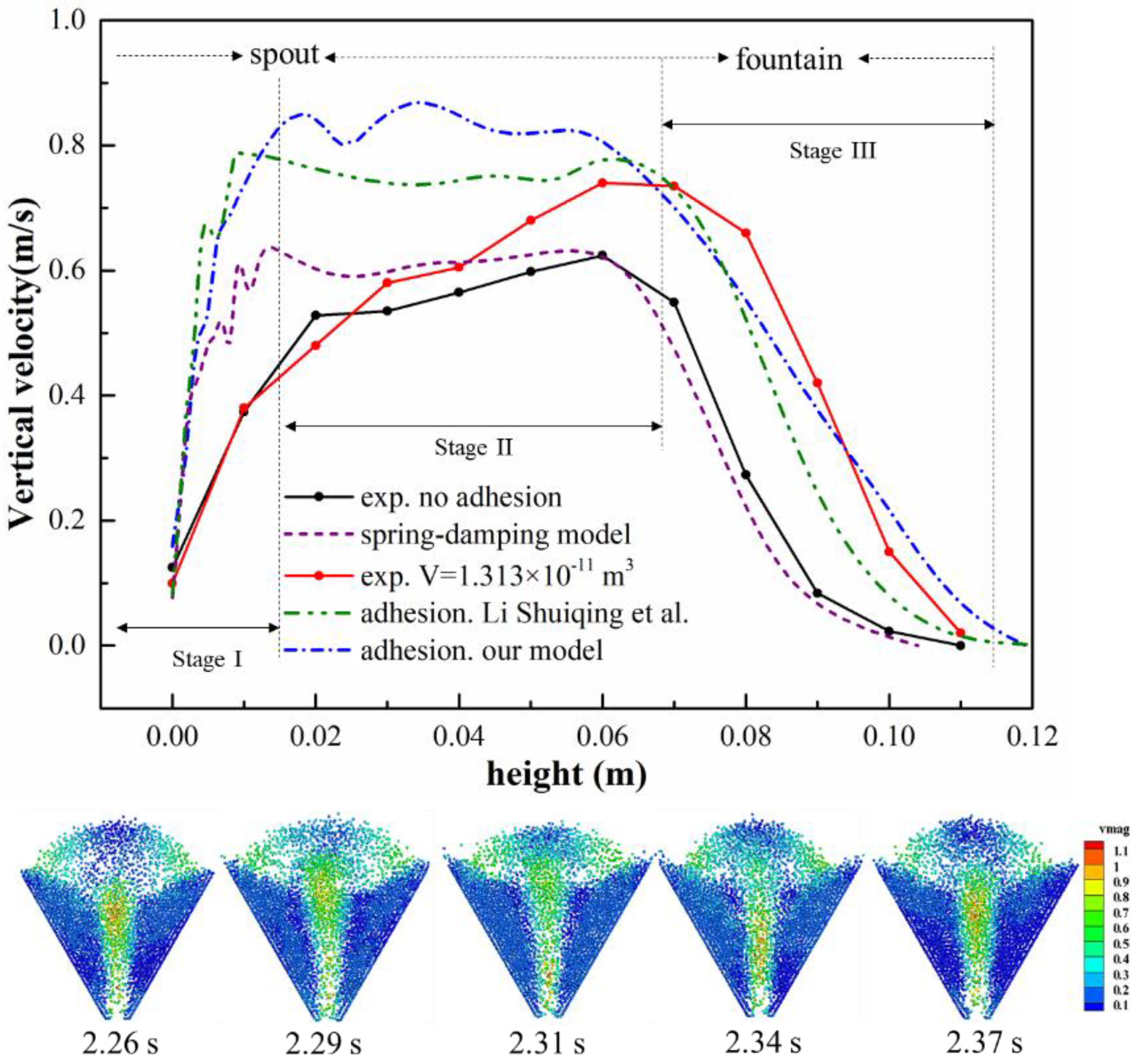

4.1.1. Validation by Literature and Experimental Results

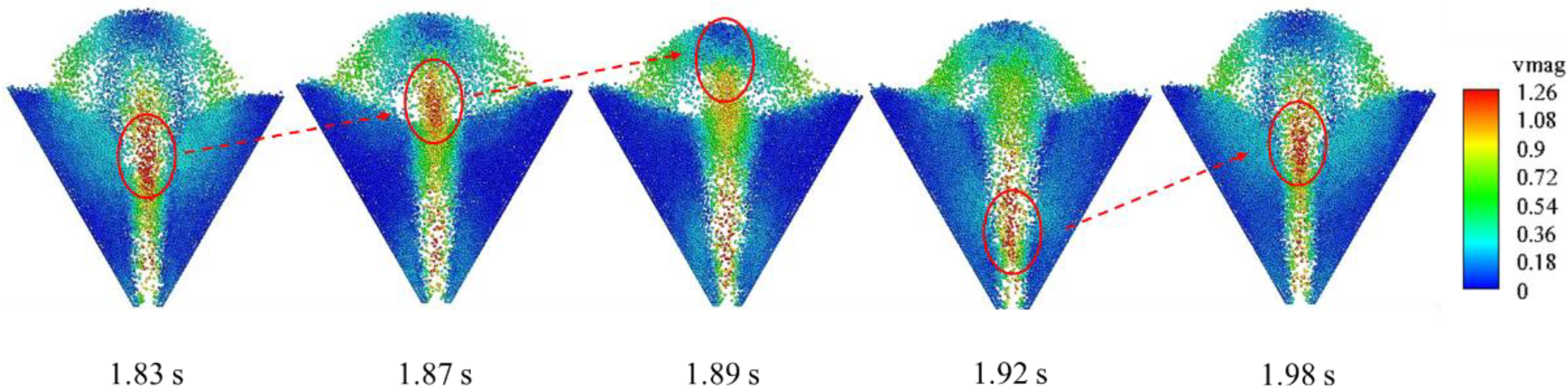

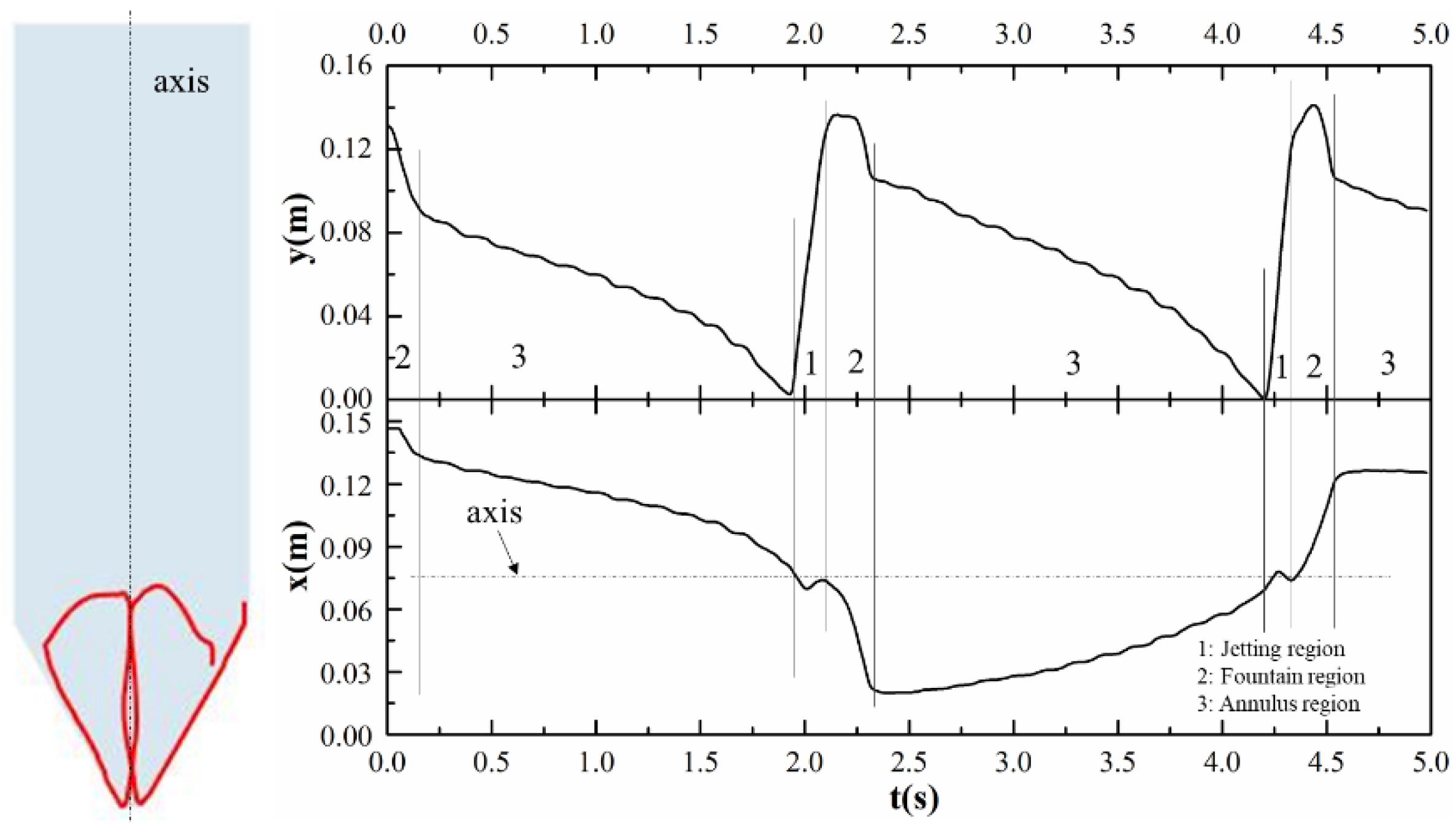

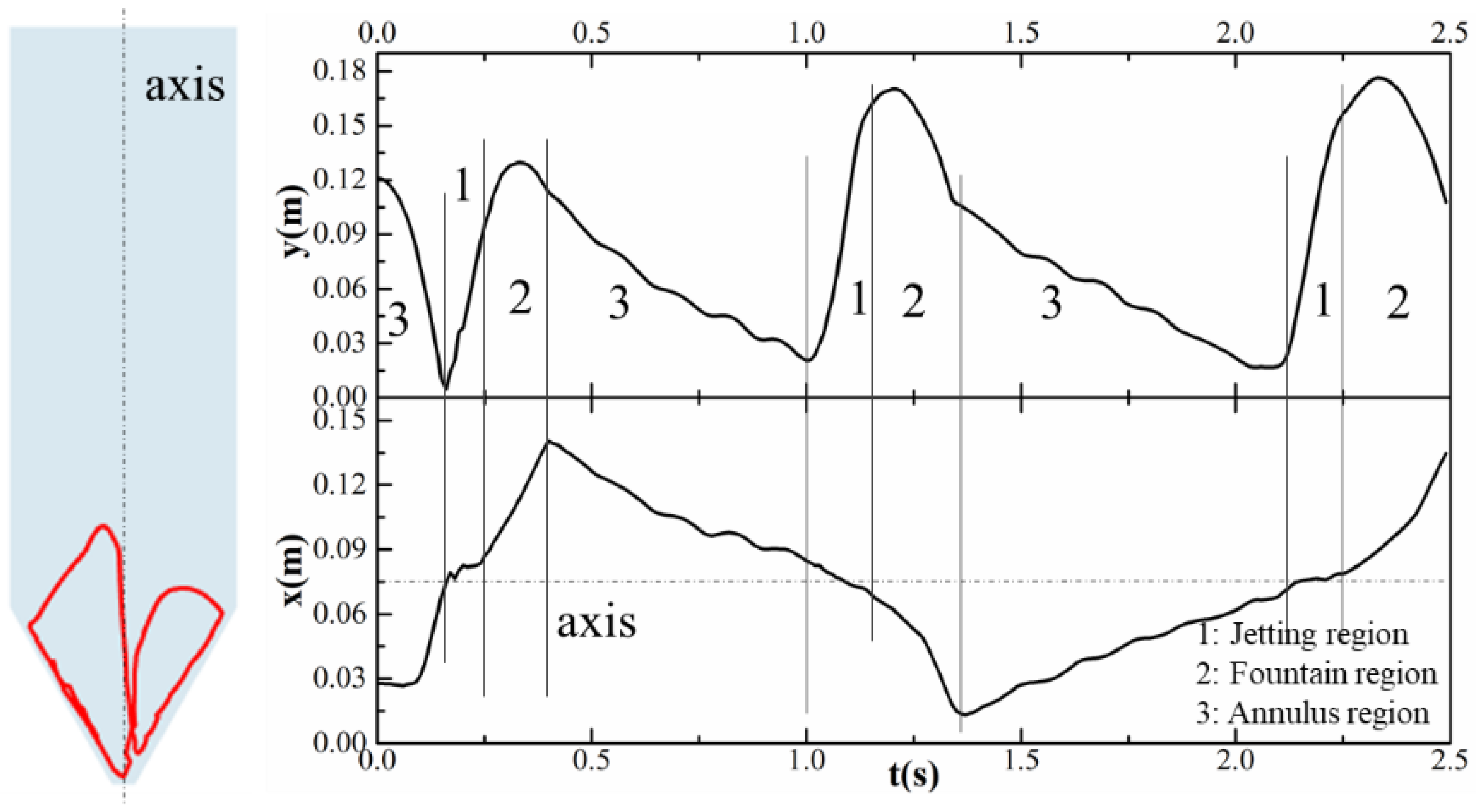

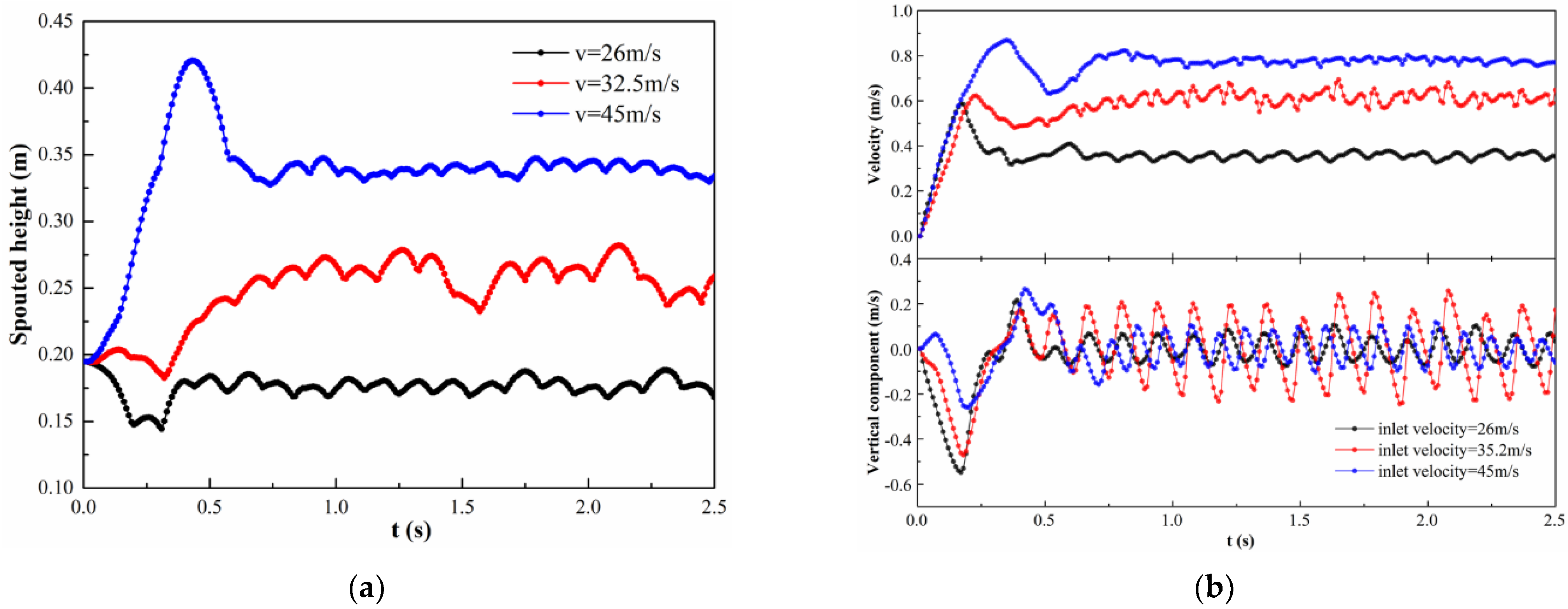

4.1.2. Periodicity

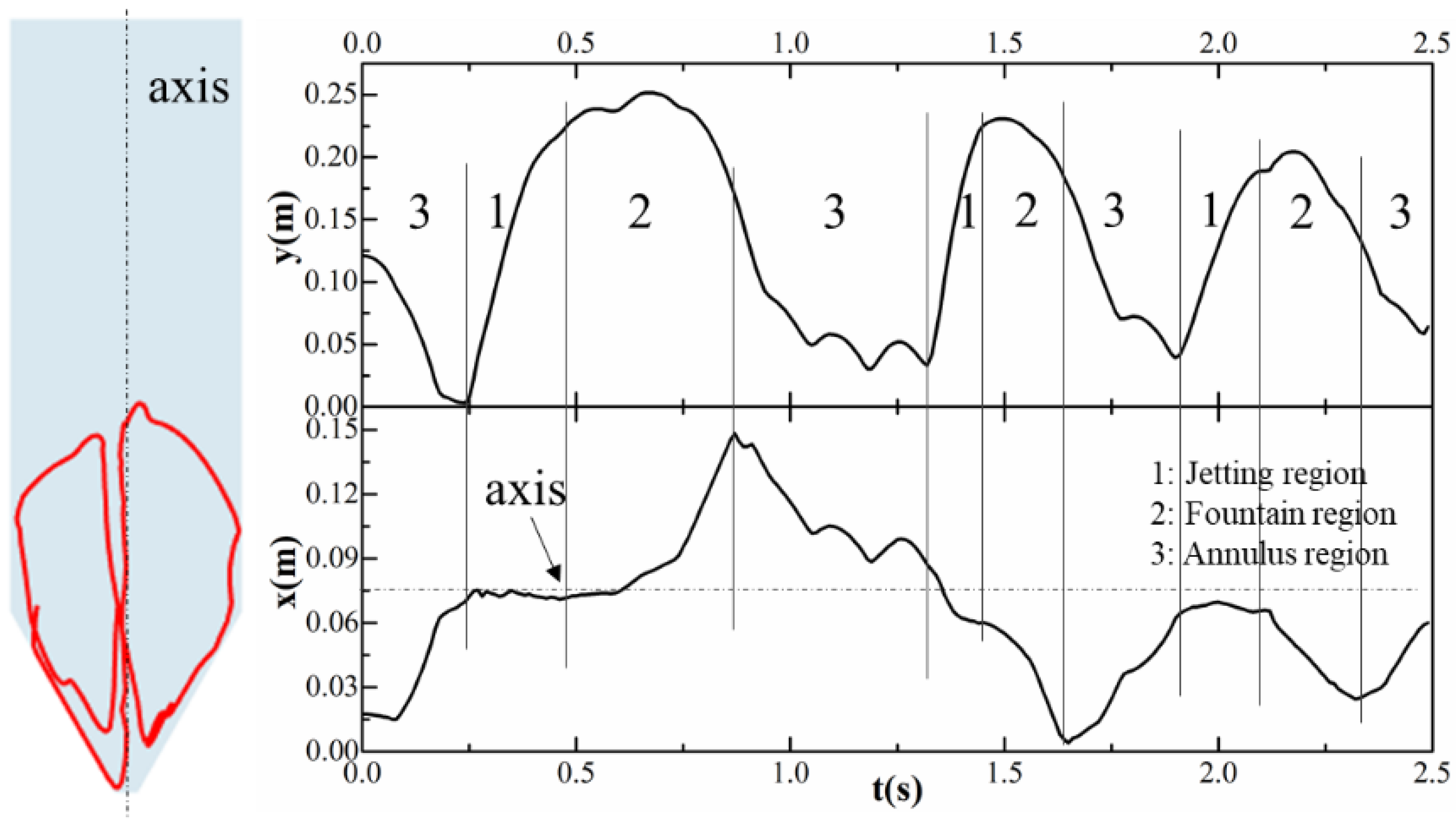

4.1.3. Particle Trajectory

4.2. Spout Behavior Study Used CFD-DEM Model with Adhesion Model

4.2.1. Adhesion Model Validation

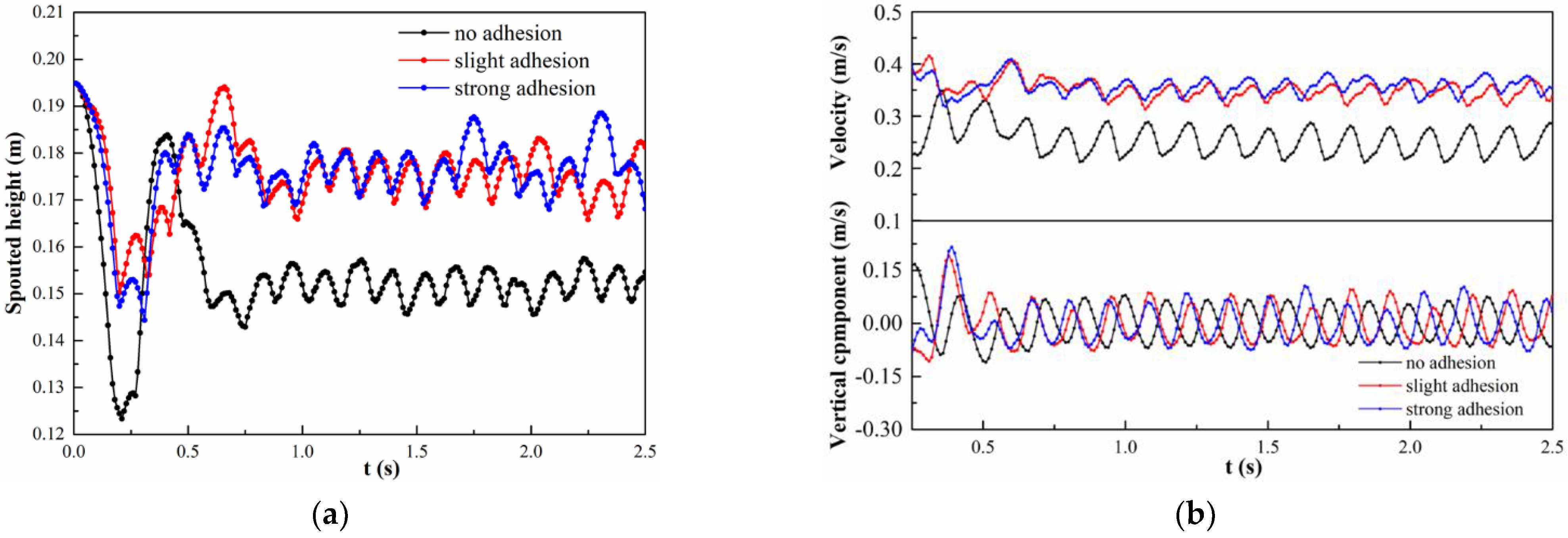

4.2.2. Effect of Adhesion Intensity

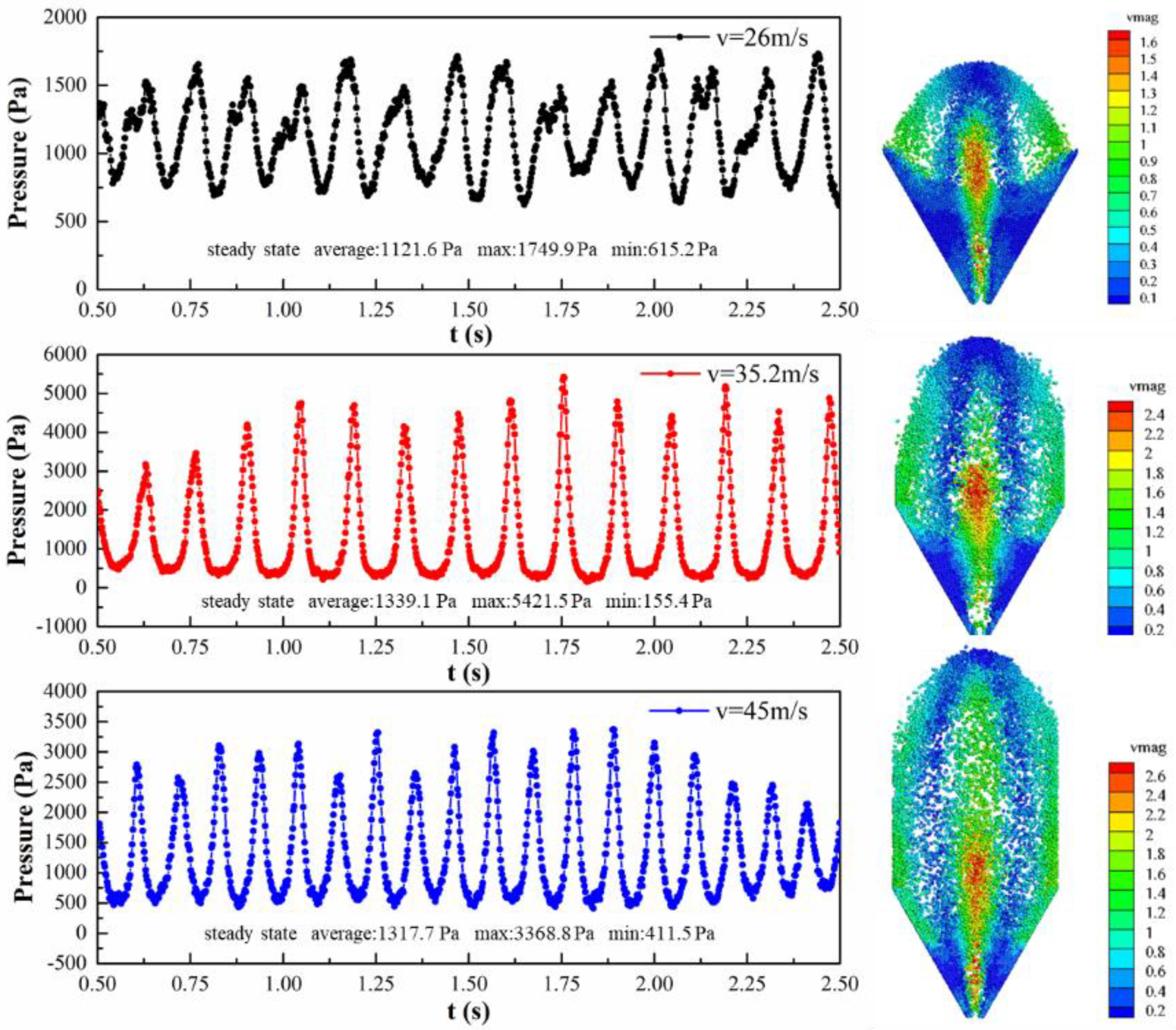

4.2.3. Effect of Inlet Velocity

5. Conclusions

- Comparing the linear spring model with Hertz-Mindlin model, it is found that in case of small overlap, the forces calculated by both models have little distinction. In case of large overlap, the forces calculated by Hertz-Mindlin are larger than those of the linear model, and the distinction cannot be ignored. Thus, it is suggested that a proper of linear model should be selected according to the maximum probability of overlap in the particle collision process. There is an angle between torques of the two models, which is the same angle between tangential force and linear velocity.

- An adhesion model with temperature is developed according to Luding’s idea and integrated with force relationships in JKR. It is validated by experiment results.

- It is concluded that fluidization cycle will be accelerated by adhesion, and intensity of fluidization will be enhanced. The presence or absence of adhesion is of great difference.

- In a certain adhesive state, the pressure drop cycle was more obvious and periodicity got longer with increasing inlet gas velocity. The fountain width and fountain height will increase as well. It also leads to strong intensity of particle motion.

- The effect of the particle surface adhesion on the spouted state will be further studied by the adhesion model developed based on the energy loss and balance in the future.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| a | contact area of radius: m2 |

| C1 | specific heat capacity of particles, J/(kg·K) |

| C2 | specific heat capacity of gas, J/(kg·K) |

| CD | drag coefficient of a particle |

| D | the gap between the spherical surfaces, m |

| D0 | diameter of nozzle, m |

| Dc | width of spouted bed, m |

| dc | rupture distance, m |

| dp | particle diameter, m |

| E* | equivalent Young’s modulus, Pa |

| en | normal coefficient of restitution between particles |

| en_w | normal coefficient of restitution between a particle and a wall |

| et | tangential coefficient of restitution between particles |

| et_w | tangential coefficient of restitution between a particle and a wall |

| Fadhesion | the adhesion force at overlap of zero, N |

| Ff | interaction force that the particle suffers from the surrounding gas, N |

| the maximum magnitude of the cohesive force, N | |

| Fn | normal contact force, N |

| damping term of normal force, N | |

| spring term of normal force, N | |

| Fp | source term, N |

| Ft | tangential contact force, N |

| damping term of tangential force, N | |

| G | shear modulus, Pa |

| G* | equivalent shear modulus, Pa |

| h | latent heat of melting, J/kg |

| H | height of spouted bed, m |

| H0 | particle loading, m |

| I | the identity tensor |

| Ii | moment of inertia, kg·m2 |

| kn | normal spring constant between particles, N/m |

| kn_w | normal spring constant between a particle and a wall, N/m |

| kload | loading stiffness, N/m |

| kunload | unloading stiffness, N/m |

| kt | tangential spring constant between particles, N/m |

| kt_w | tangential spring constant between a particle and a wall, N/m |

| ktemp | the ratio of particle temperature rising to gas temperature drop |

| L | thickness of spouted bed, m |

| Li | the distance from the point of contact to the center of the sphere, m |

| m* | equivalent mass, kg |

| M1 | the torque calculated by linear spring damping model, N·m |

| M2 | the torque calculated by Hertz-Mindlin model, N·m |

| mi | mass of ith particle, kg |

| Mij | torque that the jth particle exerts on the ith particle, N·m |

| Mlayer | mass of liquid layer for total particles, kg |

| N | number of total particles |

| p | pressure, Pa |

| qm | mass flow rate of gas, kg/s |

| Qd | energy loss due to heat dissipation, J |

| R | radius of particles, m |

| R* | equivalent radius, m |

| Re | particle Reynolds number |

| tCFD | CFD time step, s |

| tDEM | DEM time step, s |

| u | gas velocity, m/s |

| V | volume of liquid layer, m3 |

| Vcell | volume of the CFD cell, m3 |

| vf | velocity of inlet gas, m/s |

| vij,n | normal relevant velocity of i th and j th particles, m/s |

| vij,t | tangential relevant velocity of i th and j th particles, m/s |

| Fc | contact force, N |

| ncj | number of contact particles |

| Vp | volume of a single particle, m3 |

| vp | particle velocity, m/s |

| ΔTg | temperature change of gas, K |

| ΔTp | temperature change of particles, K |

| Greek letters | |

| drag force coefficient, kg/(s·m3) | |

| inverted cone angle | |

| surface tension, N/m | |

| the particle overlap corresponding to , m | |

| maximum overlap during collision, m | |

| normal overlap of two particles, m | |

| the permanent plastic deformation, m | |

| tangential overlap of two particles, m | |

| local voidage | |

| coefficient of particle normal dissipation, N·s/m | |

| coefficient of particle tangential dissipation, N·s/m | |

| the angle between tangential force and linear velocity | |

| contact angle between liquid and grain surface | |

| bulk viscosity of gas flow, Pa·s | |

| Poisson’s ratio | |

| cinematic viscosity of gas flow, Pa·s | |

| the coefficient of rolling friction | |

| coefficient of sliding friction between particles | |

| coefficient of sliding friction between a particle and a wall | |

| drag scaling factor | |

| particle density, kg/m3 | |

| gas density, kg/m3 | |

| stress tensor of gas | |

| plasticity index | |

| angular velocity vector, 1/s |

References

- Liu, M.L.; Chen, M.; Li, T.J. CFD-DEM-CVD multi-physical field coupling model for simulating particle coating process in spout bed. Particuology 2019, 42, 67–78. [Google Scholar] [CrossRef]

- Hattori, H.; Morimoto, T.; Yamaguchi, M.; Onezawa, T.; Arai, C. Drying of porous solid particles in various-shaped spouted bed with a draft-tube. J. Chem. Eng. Jpn. 2001, 34, 1549–1552. [Google Scholar] [CrossRef]

- Jose, M.J.S.; Alvarez, S.; Lopez, R. Modelling of drying of biomass wastes in a conical spouted bed dryer. Comput. Aided Chem. Eng. 2017, 40A, 517–522. [Google Scholar] [CrossRef]

- Makibar, J.; Fernandez-Akarregi, A.R.; Alava, I.; Cueva, F.; Lopez, G.; Olazar, M. Investigations on heat tranfer and hydrodynamics under pyrolysis conditions of a pilot-plant draft tube conical spouted bed reactor. Chem. Eng. Process. Process Intensif. 2011, 50, 790–798. [Google Scholar] [CrossRef]

- Artetxe, M.; Lopez, G.; Amutio, M.; Barbarias, I.; Arregi, A.; Aguado, R.; Bilbao, J.; Olazar, M. Styrene recovery from polystyrene by flash pyrolysis in a conical spouted bed reactor. Waste Manag. 2015, 45, 126–133. [Google Scholar] [CrossRef]

- Salam, P.A.; Bhattacharya, S.C. A comparative study of charcoal gasification in two types of spouted bed reactors. Energy 2006, 31, 228–243. [Google Scholar] [CrossRef]

- Zivkovic, V.; Kashani, M.N.; Biggs, M.J. Experimental and theoretical study of a micro-fluidized bed. AIP Conf. Proc. 2013, 1542, 93–96. [Google Scholar] [CrossRef]

- Farivar, F.; Zhang, H.; Tian, Z.F.; Gupte, A. CFD-DEM-DDM model for spray coating process in a Wurster coater. J. Pharm. Sci. 2020, 109, 3678–3689. [Google Scholar] [CrossRef]

- Grohn, P.; Lawall, M.; Oesau, T.; Heinrich, S.; Antonyuk, S. CFD-DEM simulation of a coating process in a fluidized bed rotor granulator. Processes 2020, 8, 1090. [Google Scholar] [CrossRef]

- Chen, T.; Ku, X.K.; Lin, J.Z.; Strom, H. CFD-DEM simulation of biomass pyrolysis in fluidized-bed reactor with a multistep kinetic scheme. Energies 2020, 13, 5358. [Google Scholar] [CrossRef]

- Bao, X.J.; Du, W.; Xu, J. An overview on the recent advances in computational fluid dynamics simulation of spouted beds. Can. J. Chem. Eng. 2013, 91, 1822–1836. [Google Scholar] [CrossRef]

- Moliner, C.; Marchelli, F.; Spanachi, N.; Martinez-Felipe, A.; Bosio, B.; Arato, E. CFD simulation of a spouted bed: Comparison between the discrete element method (DEM) and the two fluid model (TFM). Chem. Eng. J. 2019, 377, 120466. [Google Scholar] [CrossRef]

- Liu, M.L.; Wen, Y.Y.; Liu, R.Z.; Liu, B.; Shao, Y.L. Investigation of fluidization behavior of high density particle in spouted bed using CFD-DEM coupling method. Powder Technol. 2015, 280, 72–82. [Google Scholar] [CrossRef]

- Yue, Y.H.; Zhang, C.X.; Shen, Y.S. CFD-DEM model study of gas-solid flow in a spout fluidized bed with an umbrella-like baffle. Chem. Eng. Sci. 2021, 230, 116234. [Google Scholar] [CrossRef]

- Mema, I.; Padding, J.T. Fluidization of elongated particles-effect of multi-particle correlations for drag, lift, and torque in CFD-DEM. AIChE J. 2021, 67, e17157. [Google Scholar] [CrossRef]

- Qiang, S. Formation and Evolution of Particle Agglomerates in Gas-Solid Fluidized Beds; Zhejiang University: Zhejiang, China, 2018; p. 33. [Google Scholar]

- Horabik, J.; Molenda, M. Parameters and contact models for DEM simulations of agricultural granular materials: A review. Biosyst. Eng. 2016, 147, 206–225. [Google Scholar] [CrossRef]

- Yeom, S.B.; Ha, E.-S.; Kim, M.S.; Jeong, S.H.; Hwang, S.J.; Choi, D.H. Application of the discrete element method for manufacturing process simulation in the pharmaceutical industry. Pharmaceutics 2019, 11, 414. [Google Scholar] [CrossRef]

- Li, S.Q.; Marshall, J.S.; Liu, G.Q.; Yao, Q. Adhesive particulate flow: The discrete-element method and its application in energy and environmental engineering. Prog. Energy Combust. Sci. 2011, 37, 633–668. [Google Scholar] [CrossRef]

- Tsuji, Y.; Tanaka, T.; Ishida, T. Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol. 1992, 71, 239–250. [Google Scholar] [CrossRef]

- Luding, S. Cohesive, frictional powders: Contact models for tension. Granul. Matter 2008, 10, 235–246. [Google Scholar] [CrossRef]

- Yang, W.M.; Wang, M.X.; Zhou, Z.Q.; Li, L.P.; Yang, G.; Ding, R.S. Research on the relationship between macroscopic and mesoscopic mechanical parameters of limestone based on Hertz Mindlin with bonding model. Geomech. Geophys. Geo-Energy Geo-Resour. 2020, 6, 68. [Google Scholar] [CrossRef]

- Wang, N.; Yang, S.Q.; Zhao, T.T.; Cao, B.; Wang, C.W. Amending research on the expression of the contact force of the spindle barrel finishing based on EDEM simulation. Chin. J. Mech. Eng. 2020, 33, 83. [Google Scholar] [CrossRef]

- Zhang, T.; Zhao, M.Q.; Liu, F.; Tian, H.Q.; Wulan, T.Y.; Yue, Y.; Li, D.P. A discrete element method model of corn stalk and its mechanical characteristic parameters. Bioresources 2020, 15, 9337–9350. [Google Scholar] [CrossRef]

- Hu, J.P.; Xu, G.H.; Shi, Y.J.; Wu, L.B. A numerical simulation investigation of the influence of rotor wake on sediment particles by computational fluid dynamics coupling discrete element method. Aerosp. Sci. Technol. 2020, 105, 106046. [Google Scholar] [CrossRef]

- Jin, Q.; Zhang, J.N.; Ge, Y.; Gao, B. Ship Ice Resistance in polar brash/broken ice area based on discrete element method. Ship Eng. 2020, 42, 35–41. [Google Scholar]

- Lyu, J.; Park, J. Analysis of particle packing process by contact model in discrete element method. J. Korean Soc. Manuf. Process Eng. 2019, 18, 59–65. [Google Scholar] [CrossRef]

- Zhao, S.; Evans, T.M.; Zhou, X. Effects of curvature-related DEM contact model on the macro- and micro-mechanical behaviours of granular soils. Geotechnique 2018, 68, 1085–1098. [Google Scholar] [CrossRef]

- Difelice, R. The voidage function for fluid particle interaction systems. Int. J. Multiph. Flow 1994, 20, 153–159. [Google Scholar] [CrossRef]

- Liu, D.Y.; van Wachem, B.G.M.; Mudde, R.F.; Chen, X.P.; van Ommen, J.R. An adhesive CFD-DEM model for simulating nanoparticle agglomerate fluidization. AIChE J. 2016, 62, 2259–2270. [Google Scholar] [CrossRef]

- Guo, Y.; Curtis, J.S. Discrete Element Method Simulations for Complex Granular Flows. Annu. Rev. Fluid Mech. 2015, 47, 21–46. [Google Scholar] [CrossRef]

- Lian, G.P.; Thornton, C.; Adams, M.J. A theoretical study of the liquid bridge forces between two rigid spherical bodies. J. Colloid Interface Sci. 1993, 161, 138–147. [Google Scholar] [CrossRef]

- Zhu, R.R.; Li, S.Q.; Yao, Q. Effects of cohesion on the flow patterns of granular materials in spouted beds. Phys. Rev. E 2013, 87, 022206. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.Q.; Li, S.Q.; Zhao, X.L.; Yao, Q. Experimental studies of particle flow dynamics in a two-dimensional spouted bed. Chem. Eng. Sci. 2008, 63, 1131–1141. [Google Scholar] [CrossRef]

- Zhang, H.; Li, S.Q. DEM simulation of wet granular-fluid flows in spouted beds: Numerical studies and experimental verifications. Powder Technol. 2017, 318, 337–349. [Google Scholar] [CrossRef]

| Geometry | Gas Properties | ||

|---|---|---|---|

| Diameter of nozzle () | 9 mm | Gas density () | |

| Inverted cone angle | 60° | Gas viscosity () | 1.81 × 10−5 Pa·s |

| Width of spouted bed | 150 mm | Particle Properties | |

| Height of spouted bed (H) | 500 mm | Particle diameter | 2 mm |

| Thickness of spouted bed (L) | 15 mm | Granule density (ρ) | |

| Simulation | Loading () | 100 mm | |

| Particle to Particle | Particle to Wall | ||

| Normal spring constant (kn) | 800 (N/m) | Normal spring constant (kn) | 800 (N/m) |

| Tangential spring constant (kt) | 228.57 (N/m) | Tangential spring constant (kt) | 228.57 (N/m) |

| Normal coefficient of restitution (en) | 0.9 | Normal coefficient of restitution (en) | 0.9 |

| Tangential coefficient of restitution (et) | 0.9 | Tangential coefficient of restitution (et) | 0.9 |

| Coefficient of sliding friction (μS) | 0.2 | Coefficient of sliding friction (μS) | 0.2 |

| Others | |||

| Number of particles (N) | 15,000 | CFD time step (tCFD) | 4 × 10−5 s |

| Velocity of inlet gas (vf) | 26, 35.2, 45 m/s | DEM time step (tDEM) | 4 × 10−6 s |

| Case | Liquid Content V (m3) | Rupture Distance dc (m) | k1 | Temperature T (°C) | Inlet Gas Velocity v (m/s) | |

|---|---|---|---|---|---|---|

| Adhesion intensity | No adhesion | Spring-dashpot model (room temperature) | 26 | |||

| Slight adhesion | 2.798 × 10−19 | 7.111 × 10−7 | 1 | 600 | 26 | |

| Strong adhesion | 6.427 × 10−11 | 4.355 × 10−9 | 10−5 | 1600 | 26 | |

| Gas velocity | Low | 6.427 × 10−11 | 4.355 × 10−9 | 10−5 | 1600 | 26 |

| Medium | 6.427 × 10−11 | 4.355 × 10−9 | 10−5 | 1600 | 35.2 | |

| High | 6.427 × 10−11 | 4.355 × 10−9 | 10−5 | 1600 | 45 | |

| Item | Linear Spring-Damping Model | Hertz-Mindlin Model |

|---|---|---|

| Normal force | ||

| Relevant equations | E = 2(1 + ν)G | |

| Input parameters | Normal spring constant (kn) Normal coefficient of restitution (en) | Particle radius R1, R2 Particle Poisson ratio ν1, ν2 Shear modulus G1, G2 |

| Final expression | ||

| Example | kn = 6388.8 N/m en = 0.9·ηn = 0.0125 Fn = −6388.8δn + 0.0125vij,n | R1 = R2 = 0.001 m ν1 = ν2 = 0.3 G1 = G2 = 107 Pa |

| Item | Linear Spring-Damping Model | Hertz-Mindlin Model |

|---|---|---|

| Tangential force | ||

| Relevant equations | ||

| Input parameters | Tangential spring constant (kt) Tangential coefficient of restitution (et) | Particle radius R1, R2 Particle Poisson ratio ν1, ν2 Shear modulus G1, G2 |

| Final expression | ||

| Example | kt = 5261.3 N/m·μs = 0.3 et = 0.9·ηt = 0.0113 Ft = −5261.3 δt + 0.0113 νij,t | R1 = R2 = 0.001 m ν1 = ν2 = 0.3 G1 = G2 = 107 Pa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Jiang, L.; Qiu, M.; Chen, M.; Liu, R.; Liu, M. CFD-DEM Simulation of Spouted Bed Dynamics under High Temperature with an Adhesive Model. Energies 2021, 14, 2276. https://doi.org/10.3390/en14082276

Chen Z, Jiang L, Qiu M, Chen M, Liu R, Liu M. CFD-DEM Simulation of Spouted Bed Dynamics under High Temperature with an Adhesive Model. Energies. 2021; 14(8):2276. https://doi.org/10.3390/en14082276

Chicago/Turabian StyleChen, Zhao, Lin Jiang, Mofan Qiu, Meng Chen, Rongzheng Liu, and Malin Liu. 2021. "CFD-DEM Simulation of Spouted Bed Dynamics under High Temperature with an Adhesive Model" Energies 14, no. 8: 2276. https://doi.org/10.3390/en14082276

APA StyleChen, Z., Jiang, L., Qiu, M., Chen, M., Liu, R., & Liu, M. (2021). CFD-DEM Simulation of Spouted Bed Dynamics under High Temperature with an Adhesive Model. Energies, 14(8), 2276. https://doi.org/10.3390/en14082276