1. Introduction

Reducing energy consumption throughout the operation of an electric drive is an important goal in the design of automatic control structures for electric machines. The use of fuzzy PI regulators in the control of electric drives is a feasible solution that ensures the reduction in electricity consumption and the improvement of regulation performances. In recent years, numerous papers have appeared in the literature dealing with the use of fuzzy PI regulators in such applications.

From the specialized literature, we can mention some works such as an application on smart energy management based on a control scheme, which integrates a fuzzy logic controller within a voltage-oriented control strategy, implemented, and simulated in Simulink [

1]; a systematic categorization of multi-motor techniques with a review of fuzzy logic controllers and their functionalities in multi-motor control [

2]; and an application of a reversible three-phase PWM converter in a wide range of AC voltage and DC voltage drives by using a double fuzzy PI controller [

3]. The development of a power supply control system based on fuzzy logic for an electric vehicle, in order to minimize the total energy consumption and optimize the battery operation, is presented in [

4]. The paper shows improvements in some dynamics such as overshoot, settling time, and steady-state error parameters. It is shown that this fuzzy controller increases the overall energy efficiency of the vehicle. A type-2 fuzzy logic controller as the speed controller, acting as the driver model controller in autonomous electric vehicles, is presented in [

5] as an alternative to save energy and to preserve the performances. Several other recently published papers dealing with the problems of fuzzy control of electric drives may be mentioned, as follows. A type 1 Mamdani fuzzy logic controller for electric vehicle drive is discussed in [

6]. A real time adaptive speed control system of vector controlled induction motor drive based on online trained type 2 fuzzy neural network controller is presented in [

7]. The role of optimization algorithms based on fuzzy controller in achieving induction motoir performance enhancement is analyzed in [

8]. An experimental setup for implementation of fuzzy logic control for indirect vector-controlled induction motor drives is presented is presented in [

9].

The technology of control electric drives has been developed based on new control methods such as fuzzy logic, field-oriented regulation theory, and digital equipment based on advanced microprocessors. The problem of intelligent control of electric drives has been addressed in numerous papers over the years including the application of expert systems, fuzzy logic, and neural networks in electric drives [

10]; fuzzy control of switched reluctance motor drives [

11]; or fuzzy adaptive vector control of induction motor drives [

12]. The control structure of AC drives were developed based on the basic theory and principles from the literature as follows. The induction motors and the permanent magnet synchronous motors are the main actuators in industrial and commercial use, which offer energy savings and system optimization, and their control structures were developed using the principles presented in [

13,

14,

15,

16]. The modeling and simulation of electric drive control systems were made based on the principles presented in [

17]. The development of the fuzzy PI controllers was made based on the theoretical bases of the design of fuzzy PID controllers presented in [

18]. The author has researched the field of fuzzy control of electric drives and has published works in the literature, as follows. Fuzzy control systems for DC drives and permanent magnet synchronous are presented in [

19] and respectively in [

20]. The demonstration of the robustness of fuzzy control systems is presented in [

21]. Methods of designing PI fuzzy controllers based on a pseudo-equivalence with linear controllers are presented in [

22,

23,

24]. A method to assure the stability of fuzzy control systems based on fuzzy PI controllers is presented in [

25]. Additionally, some properties of fuzzy systems useful in control systems are presented in [

26,

27,

28].

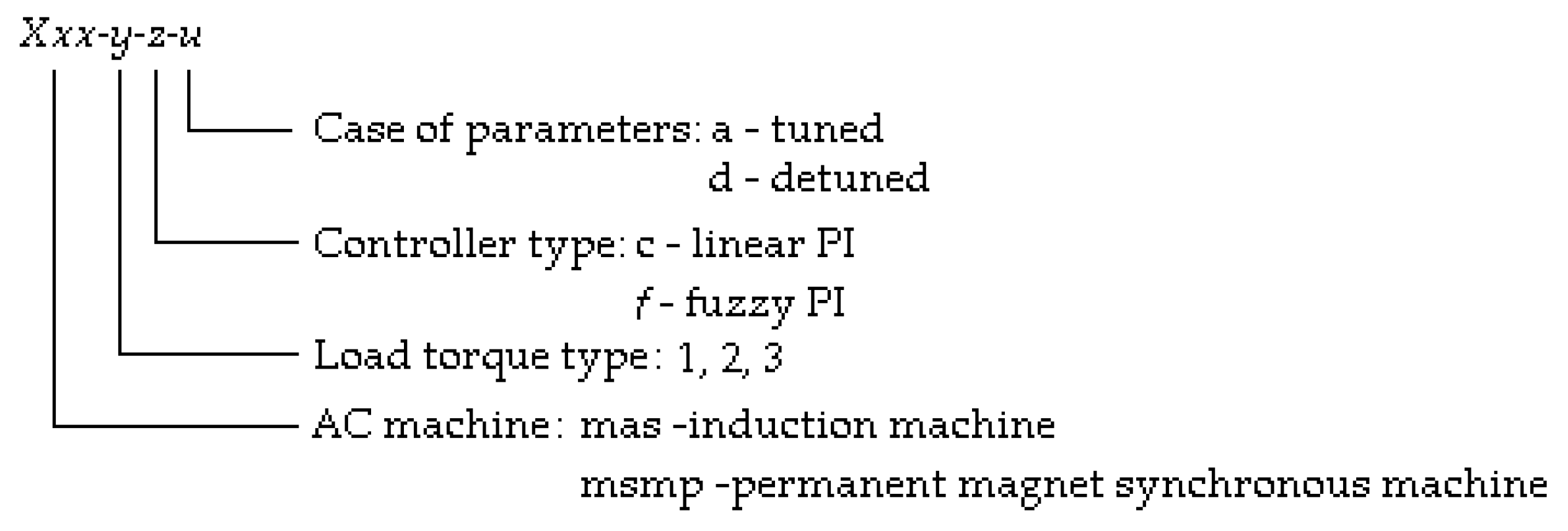

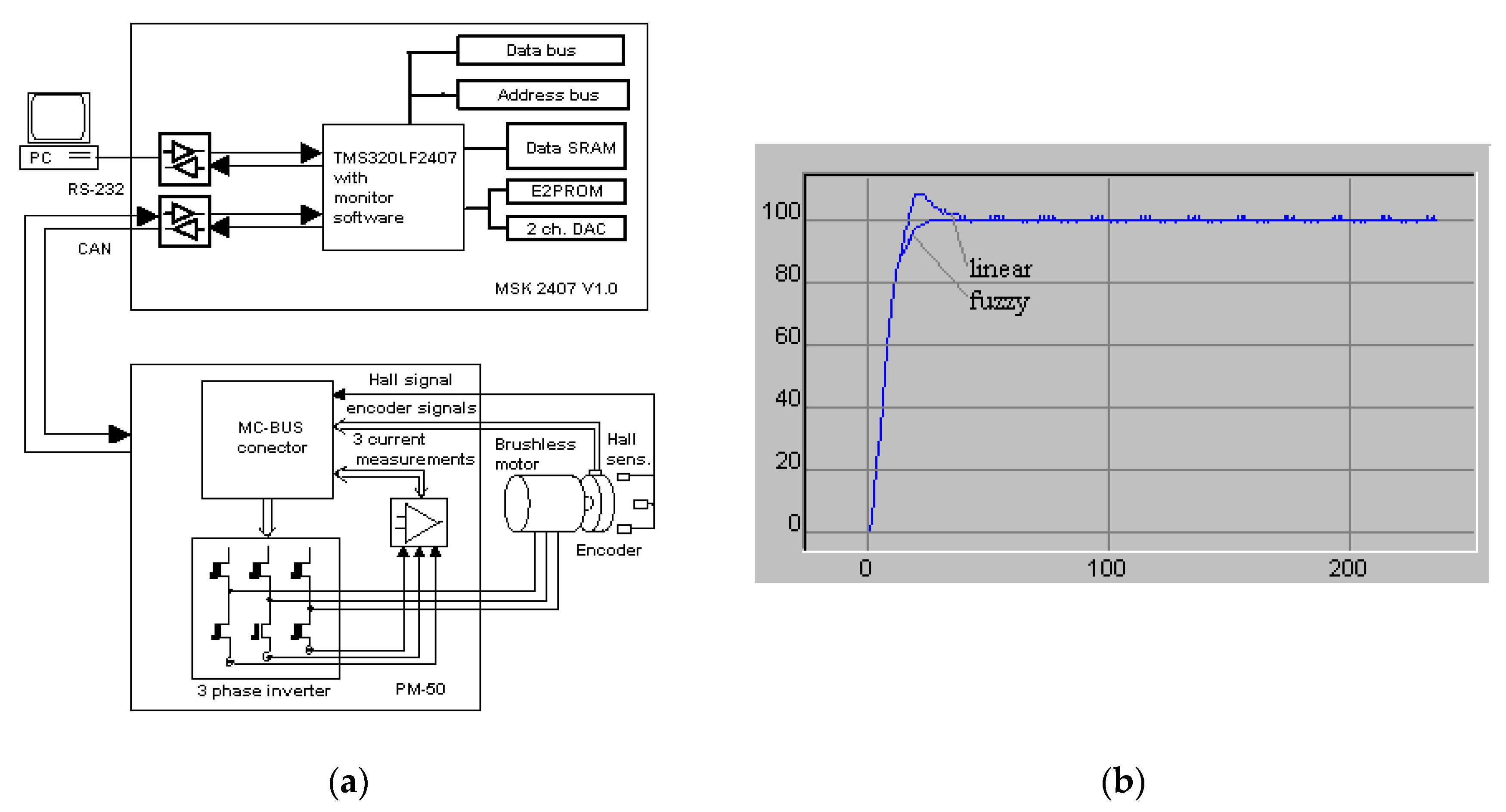

The paper presents a consideration of two digital fuzzy control structures of the two main AC machines used in practice: induction motors and permanent magnet synchronous motors. For each control system, the transient state characteristics obtained by simulation with Simulink are presented. Three types of load torques, common in practice, are considered. Transient state analyses are performed for nominal values of the machine parameters as well as in the case in which the machine parameters suffer a deviation of 100% from the nominal values. Based on the transient state characteristics, the values obtained for the performance indicators of the control systems can be highlighted such as overshoot, rise time, error, and others. A practical experiment conducted with a speed control system of a permanent magnet synchronous motor with a Hall sensor encoder, fed by a three phase inverter, based on a signal processor, demonstrated that by using fuzzy PI controllers, some performance indicators may be improved, obtaining a shorter rise time and a zero overshoot. An example of the calculation of the reduction in energy consumption is presented. The novelty of the paper is a synthetic analysis performed on the main alternating current machines by modeling and simulation, for nominal values and with deviations of the machine parameters, for three different types of load torques, resulting in 24 cases of analysis, with each case calculating the performance indicators of the regulation, demonstrating for each case that using fuzzy PI controllers obtains a reduction of the consumed energy, the improvement of the performance indicators, and the robustness of the control system.

2. Control Structures

2.1. Induction Motor

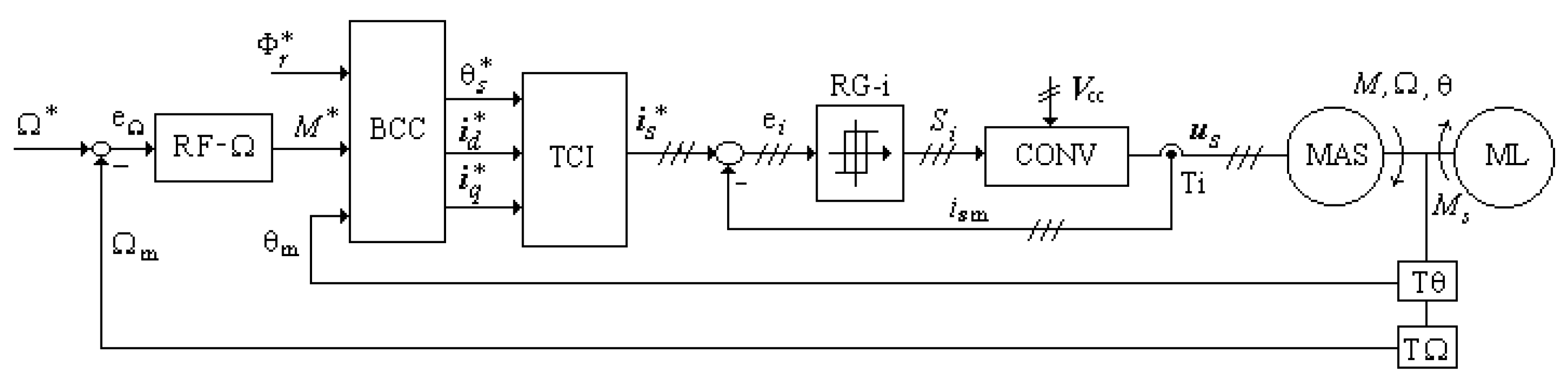

The block diagram of the fuzzy speed control structure for induction motors is presented in

Figure 1.

The meanings of the notations in the

Figure 1 are as follows: MAS—induction machine; ML—working machine; CONV—power electronic convertor; RG-i—stator phase current controllers; Ti—current sensor; Tθ—position sensor; TΩ—speed sensor; TCI—inverse Park coordinate transformation [

14]; BCC—block for calculating the reference currents in the vector control structure of the asynchronous machine with rotor flux orientation [

14,

29]; RF-Ω—speed fuzzy PI controller; Ω—rotor speed; Ω*—speed reference;

M*—torque reference; ф

r*—rotor flux reference; θ

s*—stator phasor position reference;

id*,

iq*—d, q stator current references;

is*—stator current reference; Ω

m—measured speed; θ

m—measured rotor position;

ism—measured stator currents;

eΩ—speed error;

ei—current error;

Si—control signals for power converter switches with pulse width modulation;

Vcc—DC converter supply voltage;

us—stator voltages;

Ms—load torque. The induction motor is vector controlled with rotor flux orientation, with rotor flux reference ϕ

*r and torque reference

M* and the measured rotor position θ

m. The reference stator currents are calculated with the block TCI. The current regulators RG-i give the pulse width modulation signals

Si for the electronic power convertor CONV, fed from a DC voltage source

VCC. The power converter CONV gives the stator voltages

us.

The mathematical model of the induction machine [

14,

29,

30] is given by Equation (1) for a general flux orientation, where in the case or rotor orientation θ

f = θ

r.

The other notations in Equation (1) have the following meanings: usf, isf, Фsf—stator voltage, current, and flux, respectively, where the notation f means with general flux orientation; urf, irf, Фrf—rotor voltage, current, and flux, respectively; Rs—rotor resistance; Lm—magnetic flux inductance; ω—rotor frequency; ωf—stator frequency; J—motor inertia; kf—friction coefficient.

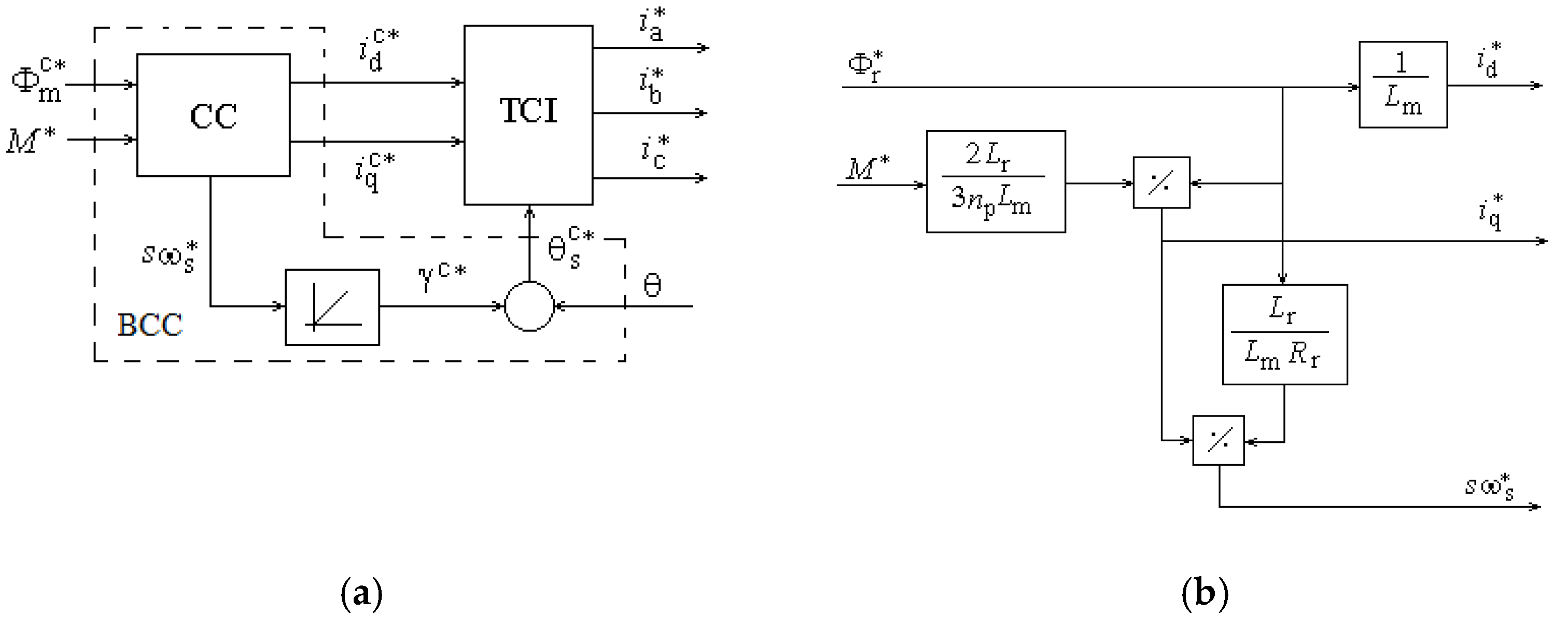

The block for calculating the reference currents in the vector control structure of the asynchronous machine with rotor flux orientation BCC has the block diagram from

Figure 2a [

14,

29,

31]. where the block CC has the structure from

Figure 2b and the general magnetic flux ϕ

mc* is the rotor flux Ф

r*;

np—is the pole pair number;

Lm,r—magnetic and rotor inductances;

s—slip frequency;

Rr—rotor resistance; ω

s*—stator frequency reference.

Two-position current regulators RG-i with hysteresis were used, considering an unfavorable regulation case.

Calculation values of the induction motor were: Rs = 12.4 ; Rr = 124 ; Lm = 0.8 H; Lsσ = 0.06 H; Lrσ = 0.06 H; p = 4; kf = 0.008 Nms; J = 0.01 kgm2; MMc = 7 Nm; MMt = 24 Nm; Ωb = 750 rot/min; PN(Mc) = 550 W; IsN = 1.77 A; IsM = 8 A; UsN = 220 V.

2.2. Permanent Magnet Synchronous Motor

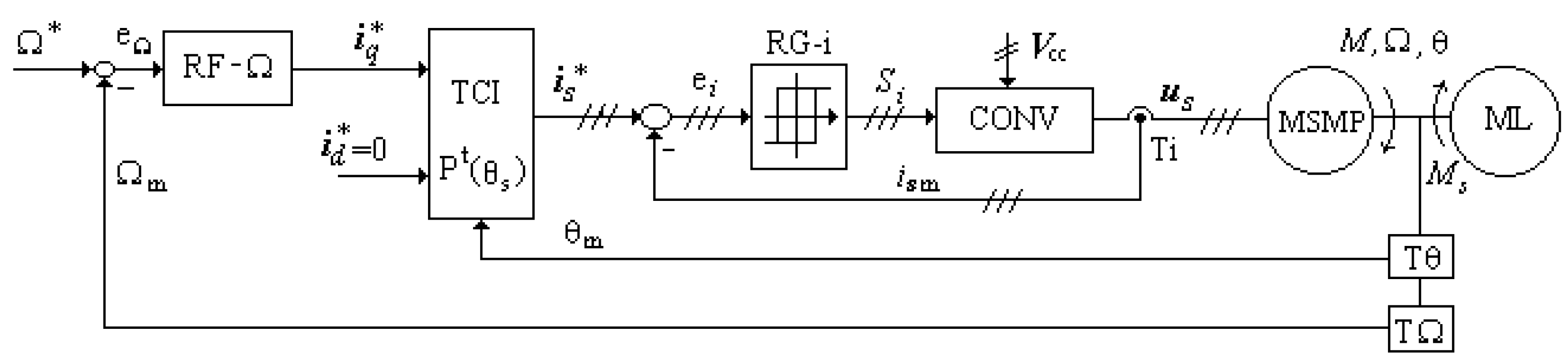

The block diagram of the fuzzy speed control structure for permanent magnet synchronous motor is presented in

Figure 3 [

20].

The meanings of the notations in

Figure 3 are the same as in

Figure 1, and MSMP is the permanent magnet synchronous machine. The permanent magnet synchronous motor is vector controlled with rotor flux orientation [

15,

29,

30] with rotor q current

i*q as a torque reference, the rotor d current

i*d at zero as a flux reference ϕ

*r, and the measured rotor position θ

m.

The mathematical model of the permanent magnet synchronous machine [

15,

29,

30] is given by the Equation (2).

The notations in Equation (2) are similar to those in Equation (1).

Calculation values of the permanent magnet synchronous motor were: PN = 400 W; IN = 3 A; IM = 8 A; nm = 4000 rot/min; nb = 3000 rot/min; MMc = 1.3 Nm; MMt = 3.4 Nm; J = 0.001 kgm2; kf = 0.0001 Nms; Rs = 0.6 Ω; Ld = 4 mH; Lq = 5 mH; p = 4; Φe0 = 0.072 Wb; Vcc = 200 V.

2.3. Fuzzy PI Controller

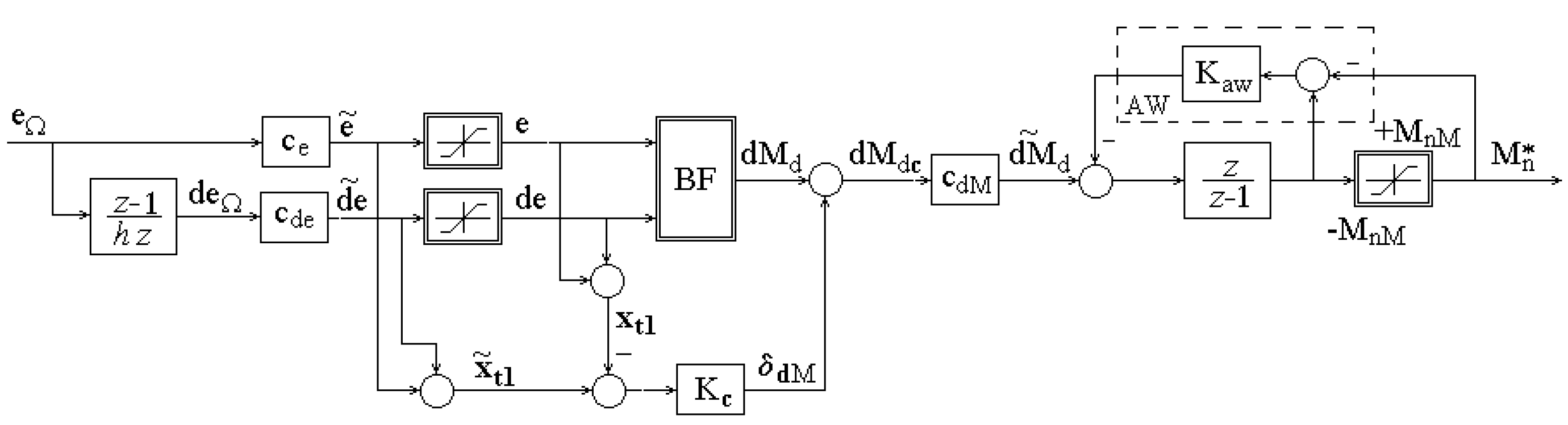

The block diagram of the fuzzy speed controller RF-Ω is presented in

Figure 4.

The meanings of the notations in

Figure 4 are:

e—scaled angular speed error;

de—scaled derivative of angular speed error;

dMd—reference of the derivative of torque

M; AW—anti-wind-up circuit;

M*—torque reference;

ce,

cde,

cdM—scaling coefficients;

xt1—compound variable; BF—fuzzy block.

The fuzzy block BF is designed based on the principle of Mamdani, with fuzzification, rule base with nine rules, maxim-minim inference, and defuzzification with center of gravity [

18,

19,

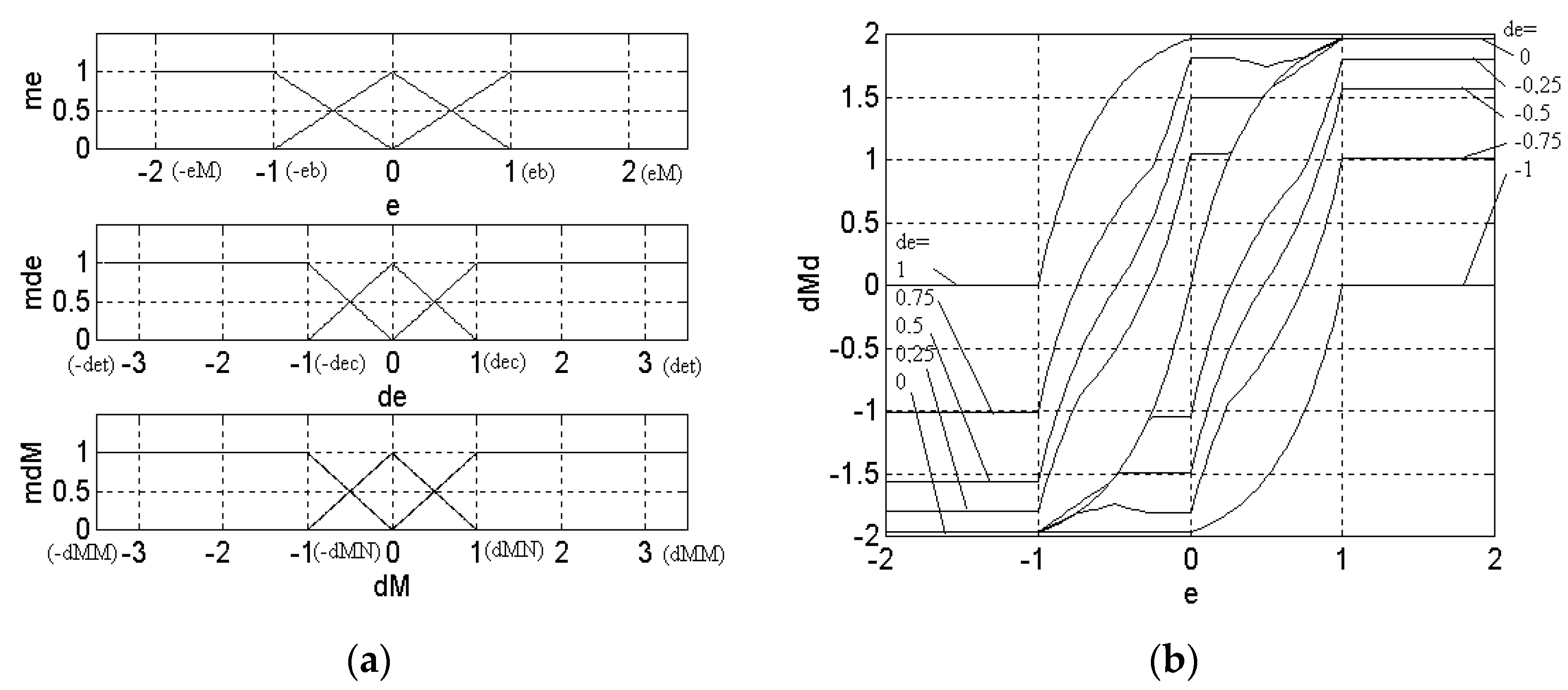

20]. For the input and output variables, three fuzzy values were chosen: negative, positive P, and zero Z—with the membership functions from

Figure 5a. This configuration of fuzzification, inference, and defuzzification gives the highest nonlinear character for the fuzzy block [

26,

27,

28], useful to improve control performances [

19,

21].

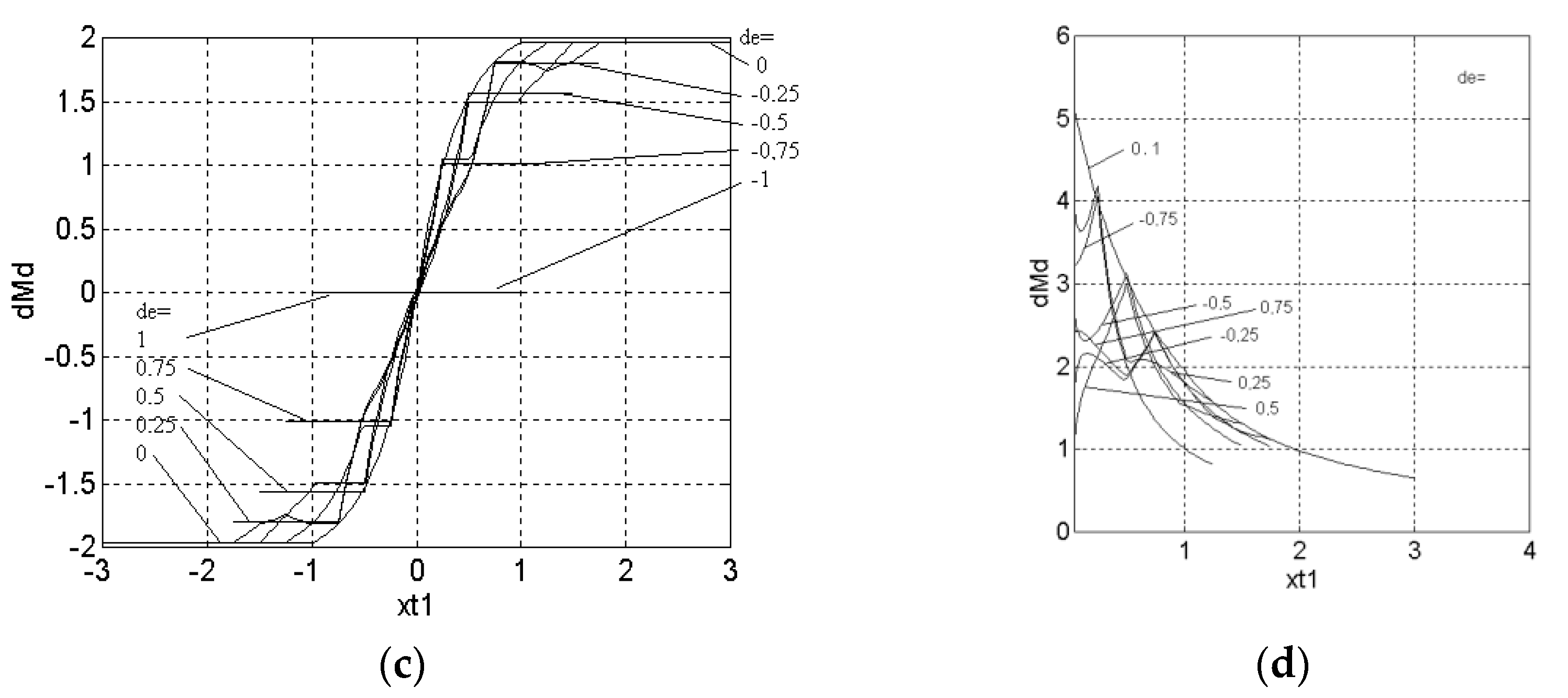

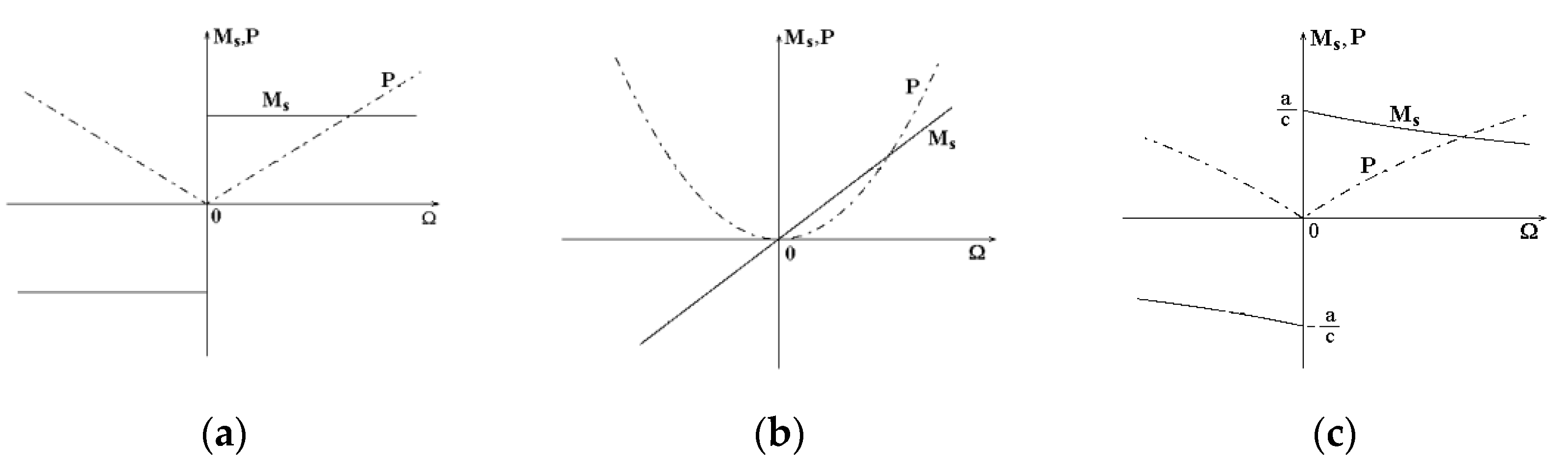

The fuzzy block BF may be analyzed based on the transfer characteristics presented in

Figure 5 [

19,

22].

The membership functions for the two inputs and one output are presented in

Figure 5a. The transfer characteristics

dMd = fe(

e;

de) are presented in

Figure 5b, were

e is the variable and

de is the parameter. The characteristics

dMd = f(

xt1;

de) are presented in

Figure 5c, were

xt1 is a compound variable, given by relation

xt1 =

e +

de. The gain characteristics

dMd = KBF(

xt1;

de) is given in

Figure 5d.

Figure 5 shows the characteristics of the fuzzy block for the induction machine. Those for the permanent magnet synchronous motor were almost similar.

The design of the fuzzy speed regulator was conducted by a pseudo-equivalence with the linear PI regulator [

19,

22,

23,

24], based on the following reasoning. If the fuzzy block BF is linearized around the permanent regime operating point with

e = 0,

de = 0, and

dMd = 0, a relation of the form (3) is obtained:

The value

K0 can be determined with sufficient approximation at the limit on the characteristic families of the fuzzy blocks

KBF = (

xt1;

de), see relation (4).

Taking into account the correction made on the fuzzy block with the torque increment coefficient

cdM, the characteristic of the corrected and linearized fuzzy block around the origin is given by the relations:

For the fuzzy speed controller RF-Ω with the linearized fuzzy block BF, the following input–output relationship can be written in the

z domain:

With these observations, the transfer function of the fuzzy linearized RF-Ω speed controller becomes:

A pseudo-equivalence of the fuzzy speed controller RF-Ω can be made with a continuous speed controller such as the one chosen for conventional speed control systems:

For this, the following quasi-continuous form is used:

It is observed that the above transfer function resembles the transfer function (9) of the linear speed PI controller, used in the conventional control structure. The identification of the coefficients of the transfer functions (9) and (10) shows some equalities, and from these equalities are deduced the relations of expression of the scaling coefficients based on the parameters of the already existing speed regulator:

where

h is the sampling period.

The coefficient

Kc is used to assure stability, according to the demonstration from [

25]. A nonlinear correction is made to move the characteristics

dMd = f(

xt1;

de), from

Figure 5c, from the non-intervention area from the x axis, were

dMd has zero values for

e and

de different from zero, in stability sector.

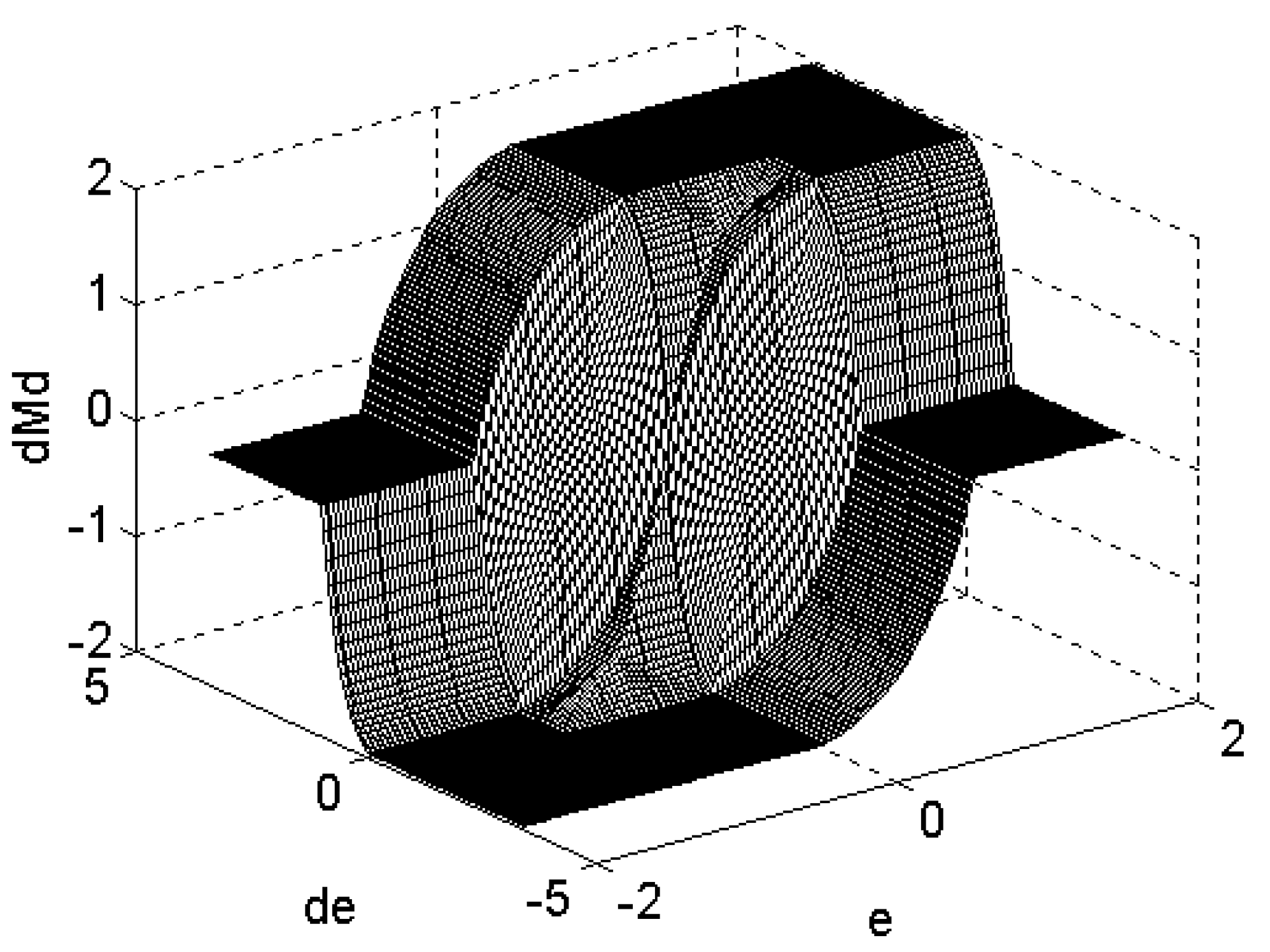

2.4. Look-Up Table Implementation of the Fuzzy Block

The solution for implementing the fuzzy blocks that gives the highest response speed, both in simulation and in practical applications, is the tabular implementation of the fuzzy block, in the form of a matrix, stored in the memory of the numerical control equipment. The models of the AC machine speed control structures are relatively complex, which makes the duration of a calculation step relatively long. The use of a pulse width modulation in the calculations resulted in a large number of iterations. The introduction of the fuzzy block in the simulation scheme in the form of the structure that requires the performance of fuzzification, inference, and defuzzification operations at each integration step, makes the calculation time increase even more. It is recalled that the inference method and the defuzzification method used are time consuming. The same fuzzy block computation problems arise when the practical implementation of fuzzy control on a physical control system of AC machines is required, at which an adequate real-time response speed must be ensured. The fuzzy block BF is represented by a nonlinear function of two variables

dMd =

fBF(

e,

de). This function is implemented tabularly, in the form of a matrix

DMd of elements

dMd(

ae,

ade), stored in the computer’s memory. Such a ‘fuzzy memory’ has a data output

dMd and two address inputs

ae and

ade. At the output, the memory shows the real value

dMd stored at the address (

ae,

ade.). Addresses have integer values. In order to create the matrix, the discourse universes of the input quantities of the fuzzy block

e and

de are discretized in

nc parts. By tabulating the function

dMd =

fBF(

e,

de) for all combinations of input values, we obtain (

nc + 1)

2 values for the output

dMdk =

fR(

eae,

deade), where

ae = 1, ...,

nc + 1 and

ade = 1, ...,

nc + 1. These values are stored in the matrix

DMd = [

did(

ae,

ade)]. This array memory must be addressed with values

ae and

ade. For the quantity

e, a translation is made from [-

eM,

eM] to [1,

nc + 1], and for the quantity

de, a translation is made from [-

deM,

deM] to [1,

nc + 1]. Memory addresses are integers, so to determine them, the integer part of

et and

det must be calculated:

The function of the fuzzy block BF is implemented with an approximation of it:

In the simulation, an implementation of fuzzy memory was chosen for an analog-to-digital converter of only eight bits, a situation that is the most unfavorable case.

Figure 6 shows the multi-input-single-output (MISO) transfer surface of the fuzzy block for the asynchronous machine. It was obtained by tabulating the function

fBF(

e,

de) with a resolution of 1/2

8 of the universes of discourse of the inputs.

The required memory decreases significantly. The number of samples for each speech universe becomes 28 + 1 = 257. The number of memory locations required is 66.049. The required memory capacity is almost 265 KB. Such fuzzy memory can be stored in RAM during calculations. The simulations showed that even in this unfavorable case, good values of the quality indicators of the regulation can be obtained.

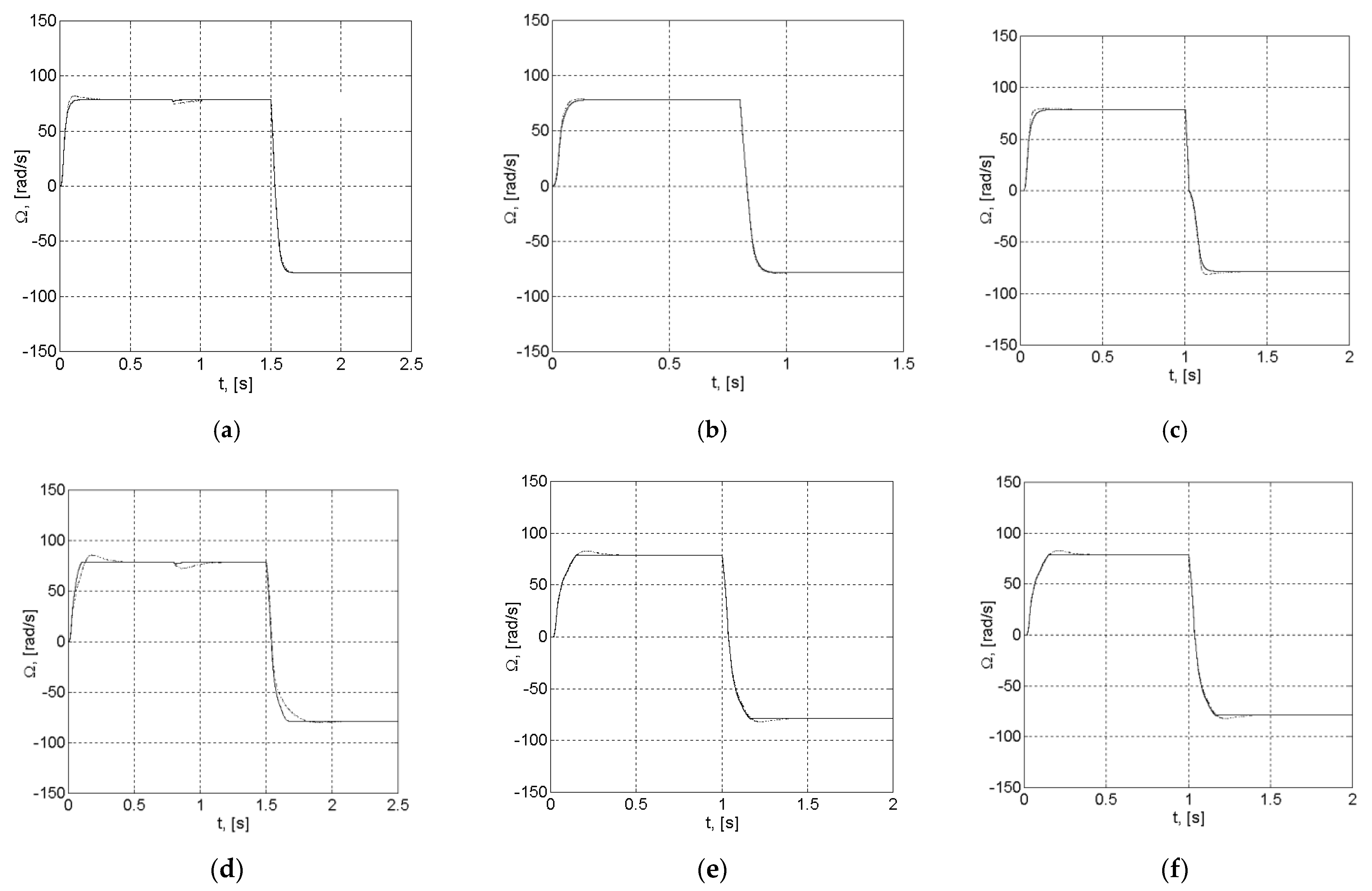

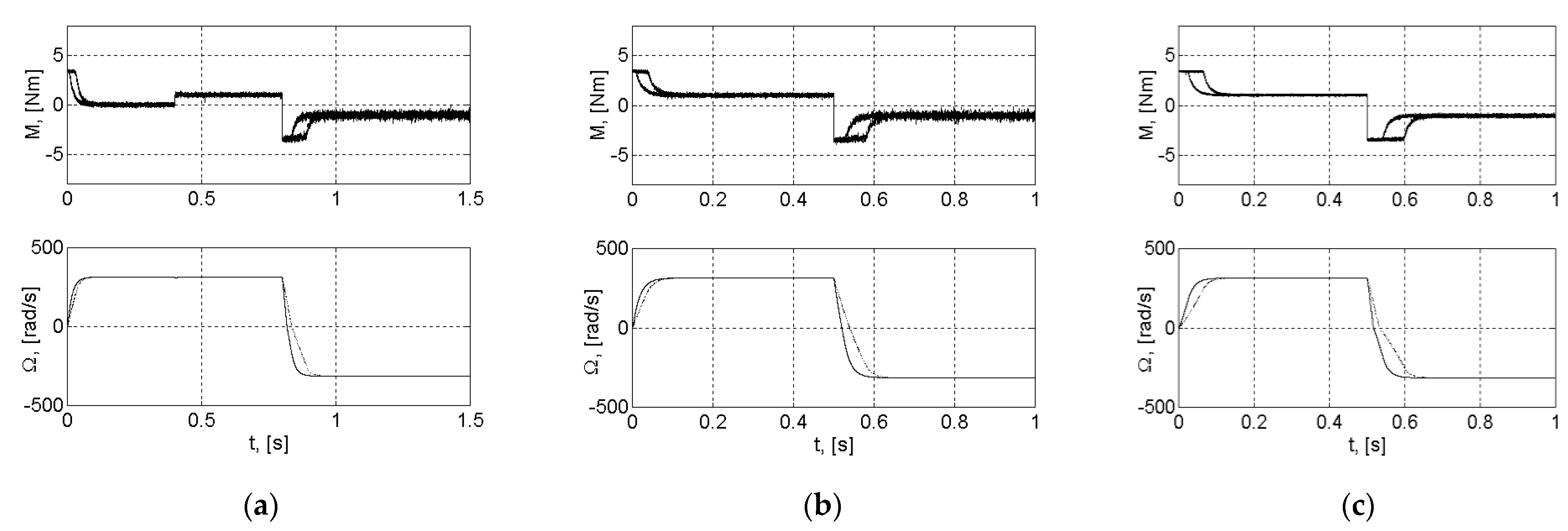

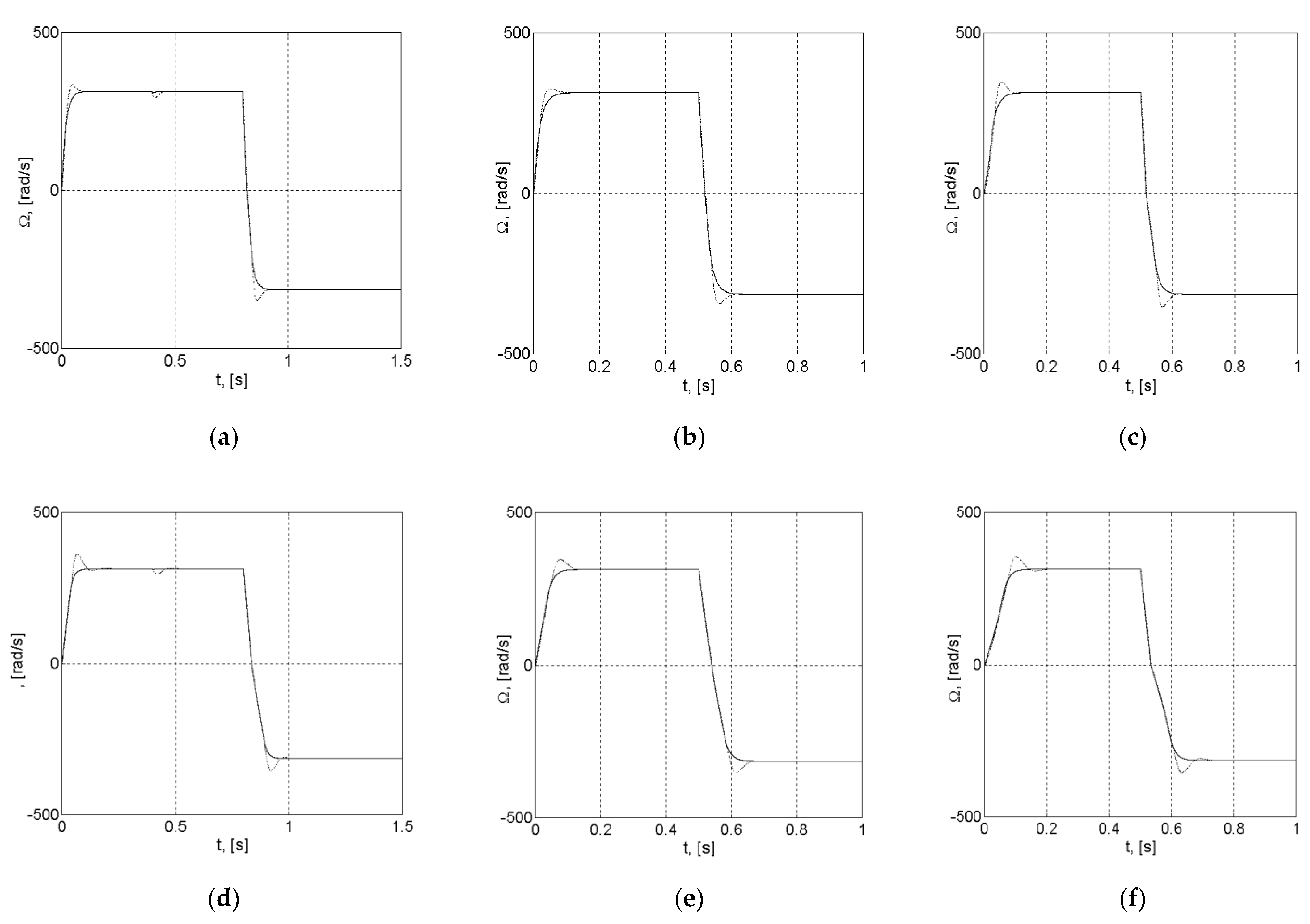

4. Discussion

From the characteristics of the transient regime and from the values from the tables presented above, the following can be observed. Fuzzy logic-based control provides zero overshoot σ1, unlike conventional control, which provides a greater overshoot, both in the case of tuned parameters and in the case of detuned parameters, for all three load torques. The rise time trΩ was smaller in all cases with fuzzy control. The effect of disturbing load torque was eliminated faster in the case of fuzzy control: tcM and σ1M were smaller. The reversal time trr was shorter for fuzzy control. The error integral criterium had smaller values for fuzzy control. The values of all quality indicators were better in the case of fuzzy control, in all cases analyzed. It should be noted that better values were obtained in the most unfavorable cases using bipositional current regulators and the implementation of fuzzy memory with the lowest resolution. The values of the torque developed by the machine in transient mode were lower in the case of fuzzy control than in the case of conventional control. The duration of the transitional regime was shorter. These aspects were valid in all cases analyzed, for different values of the parameters and for different load torques. The fact that at fuzzy control, the torque developed by the machine was lower, the speed overshoot was zero, and the duration of the transient state was shorter, leading to the conclusion that the consumed energy was smaller, which leads to energy saving.

5. Conclusions

The paper presents an analysis performed by the modeling and simulation of the behavior of the speed control structures with a fuzzy PI controller of the asynchronous machine vector controlled with indirect orientation after the rotor flux and the speed control structure with a fuzzy PI controller of the permanent magnet synchronous machine vector controlled with orientation after the rotor flux. The analyses were performed for nominal values of the machine parameters and for deviated values of the parameters by 100%. Additionally, three different types of load torques commonly encountered in practice were considered. The paper shows the design of the fuzzy regulators used. The fuzzy blocks were implemented in the tabular manner, as matrix stored in memory, the solution that gives the highest response speed.

The values obtained for fuzzy regulation were compared with the values obtained for conventional regulation with linear PI speed regulators. Linear PI regulators are the most common and widely used in commercial electric drives.

This paper demonstrates that the use of fuzzy PI regulators for regulating the speed of AC electric motors leads to a reduction in energy consumed in transient states and an improvement in the quality indicators of regulation. The paper also demonstrates that control systems based on fuzzy logic are more robust to errors in identifying the parameters of electric machines. They are also more robust to the effect of disturbing load torque.