Thermal Monitoring and Simulation of Earthen Buildings. A Review

Abstract

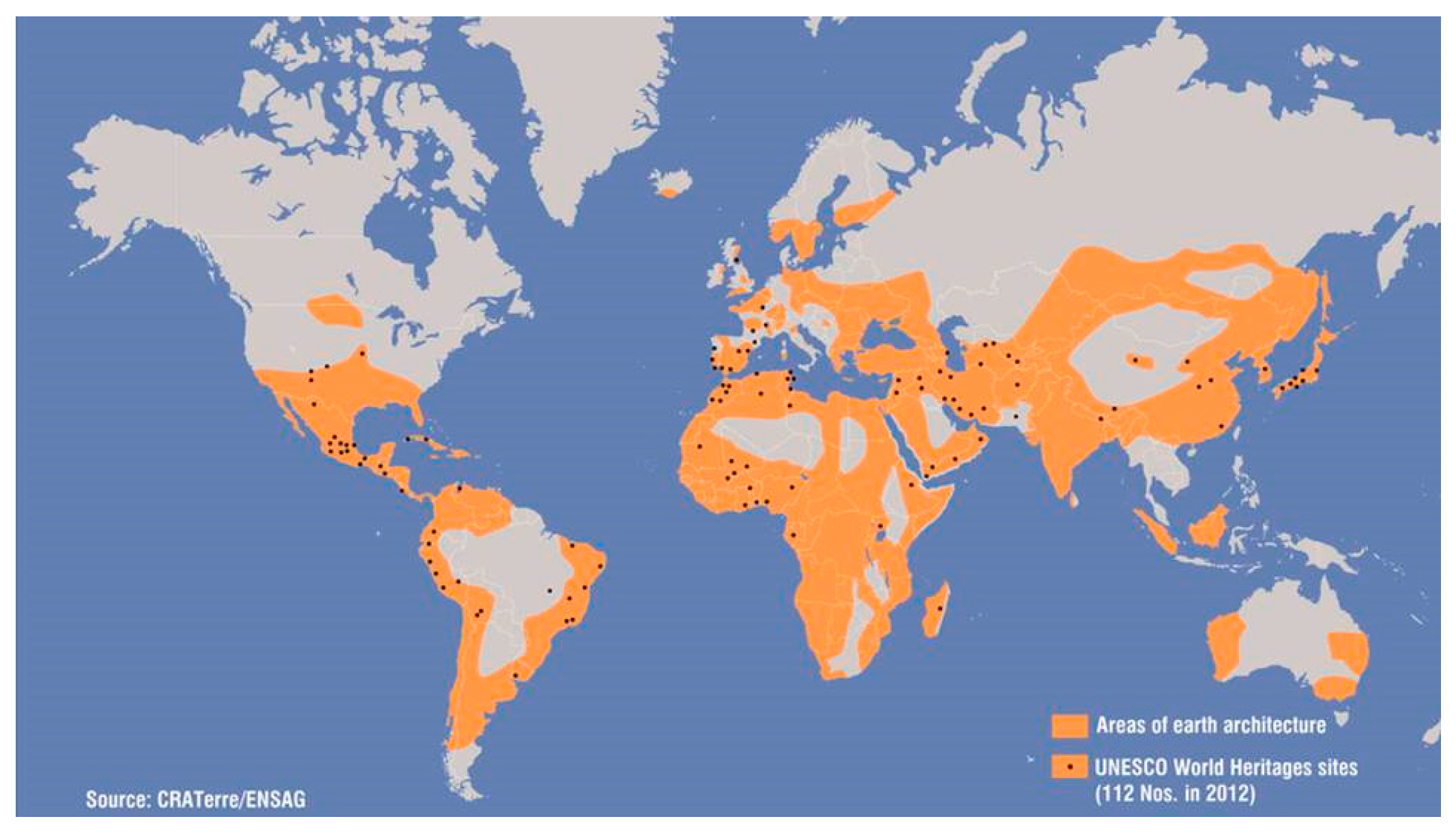

1. Introduction. Earth Architecture in the World

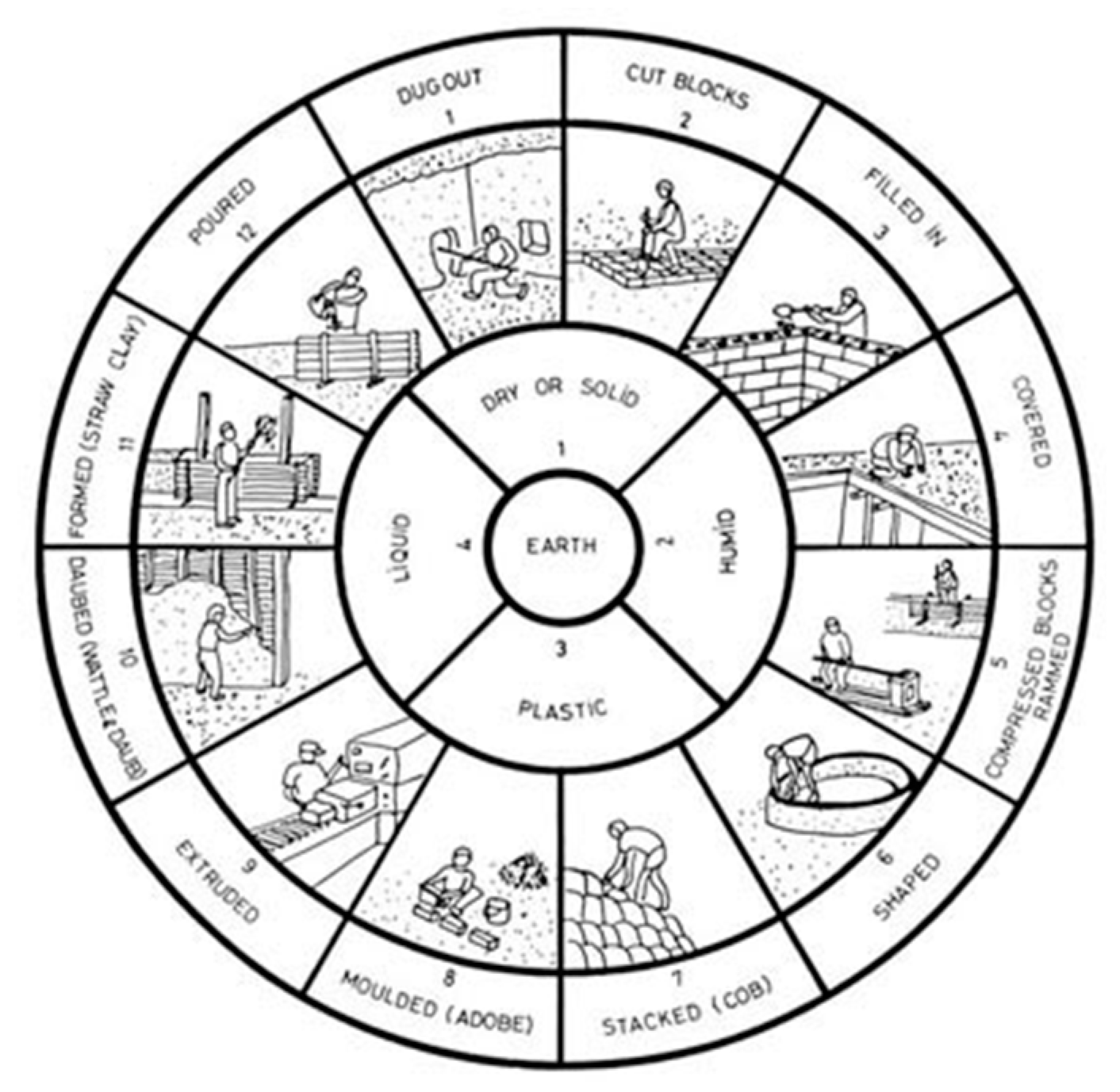

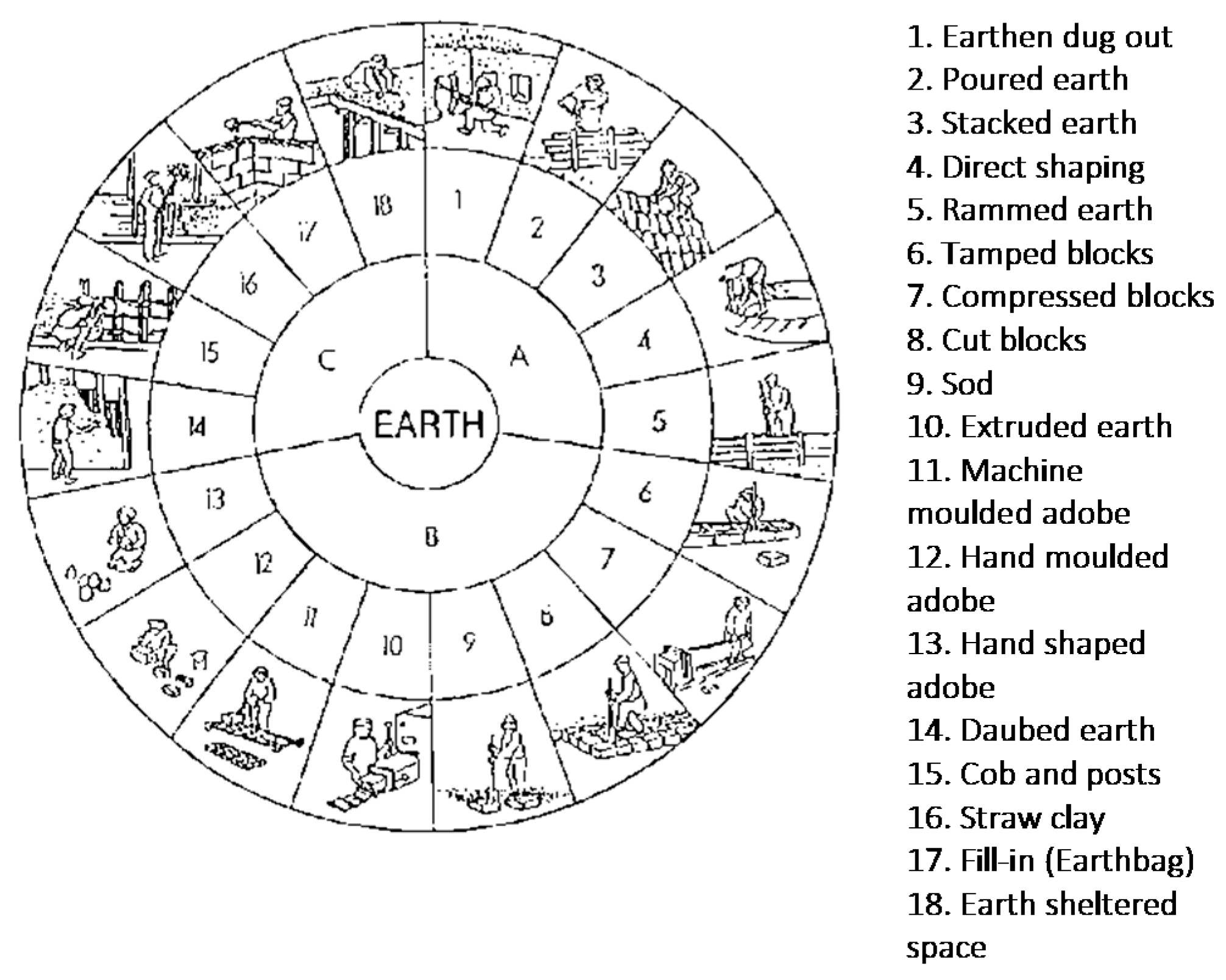

2. Classification for Earth Constructive Techniques

- (1)

- dry and solid corresponds to the earth in a completely solid state with no water added into the mixture;

- (2)

- humid stands for those techniques that contain a relatively low percentage of water, about 5% [11];

- (3)

- in the plastic category 15–30% of water is added [11] and

- (4)

- for the liquid category the earth is expected to be in a liquid state.

3. Methodology

- (5)

- MONITORING: Thermal monitoring of experimental buildings and in-use buildings.

- (6)

- SIMULATION: Thermal simulation of existing buildings and buildings designed exclusively for simulation.

4. Results

4.1. Thermal Monitoring

4.1.1. Earthen Dug Out

4.1.2. Earthbag

4.1.3. Rammed Earth

In-Use Buildings

Experimental Buildings

4.1.4. Compressed Earth Blocks

4.1.5. Adobe

In-Use Buildings

Experimental Buildings

4.1.6. Extruded Earth

4.1.7. Poured Earth

4.1.8. Earthship

4.2. Simulations

4.2.1. Earthen Dug Out

4.2.2. Earthbag

4.2.3. Rammed Earth

4.2.4. Compressed Earth Blocks

4.2.5. Cob

4.2.6. Adobe

4.2.7. Extruded Earth

4.2.8. Straw Clay

4.2.9. Earthship

5. Discussion

5.1. Earth Dug Out

5.2. Earthbag

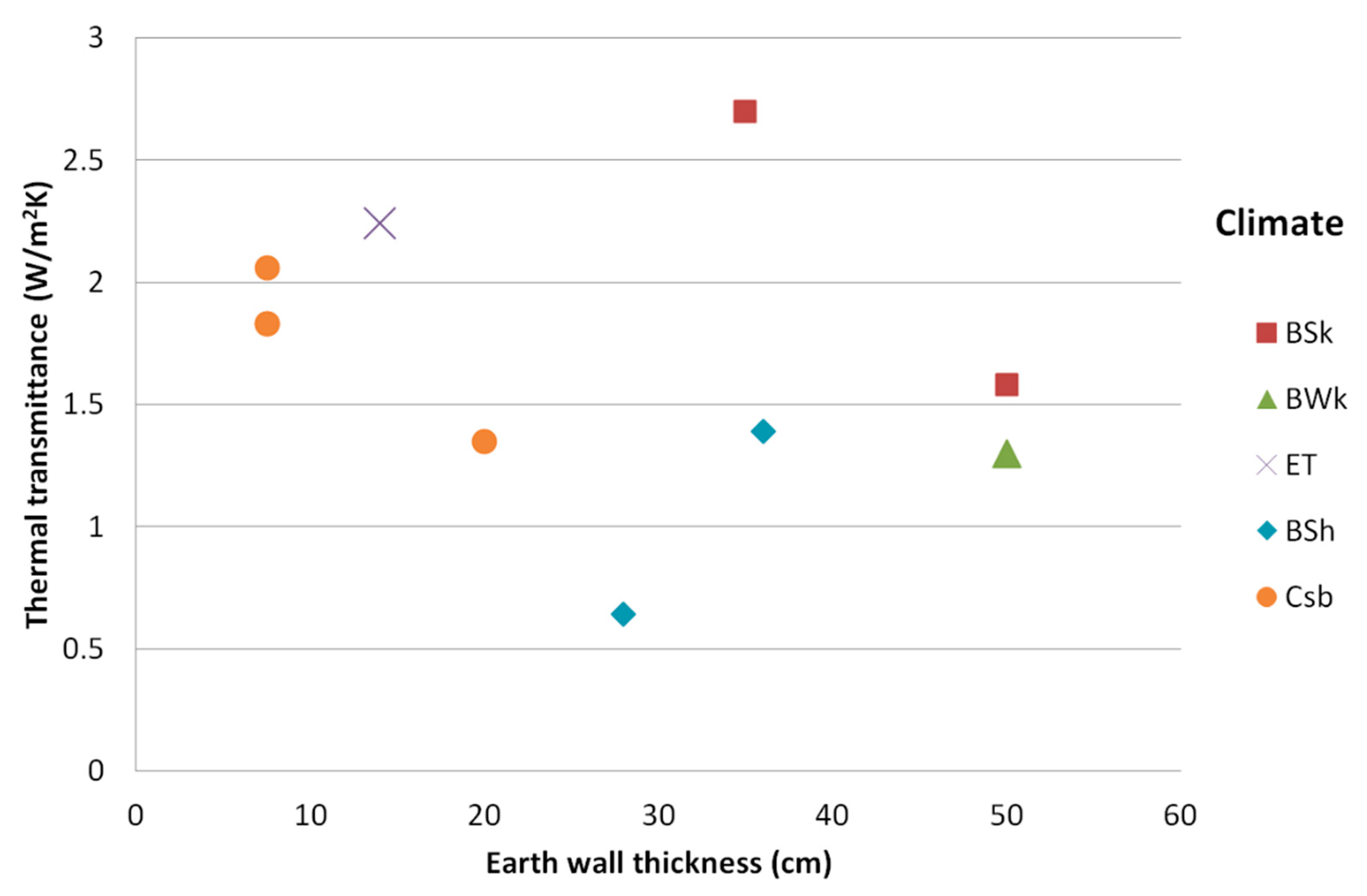

5.3. Rammed Earth

5.4. Compressed Earth Blocks

5.5. Cob

5.6. Adobe

5.7. Extruded Earth

5.8. Straw Clay

5.9. Earthship

6. Conclusions

- Although complete information regarding architectonic characteristics of earth building techniques is found in the literature, just partial information related to thermal performance of both monitored and simulated earth buildings exists. It is also conclude that for some earth techniques presented in Table 1, thermal performance information is not found. Thus, there is a gap of information regarding the thermal comfort in these techniques.

- Although a large number of studies monitoring or/and simulating earth construction buildings are published, little uniformity exists when collecting data for making comparisons.

- No thermal analyses have been found within the scope of this study for earth techniques such as cut blocks, direct shaping, stacked earth, daubed earth, or the newest technique, the earth 3D printing. It is necessary to study those technologies in order to provide knowledge to the scientific community regarding the thermal performance of these techniques.

- There is a general consensus in literature that a key aspect for using the earth as a construction material is the thermal inertia provided to the building. This thermal inertia is not enough for cold climates to achieve the thermal comfort but it is proved to be enough, combined with other passive design strategies, to meet the thermal comfort without any active system for hot climates.

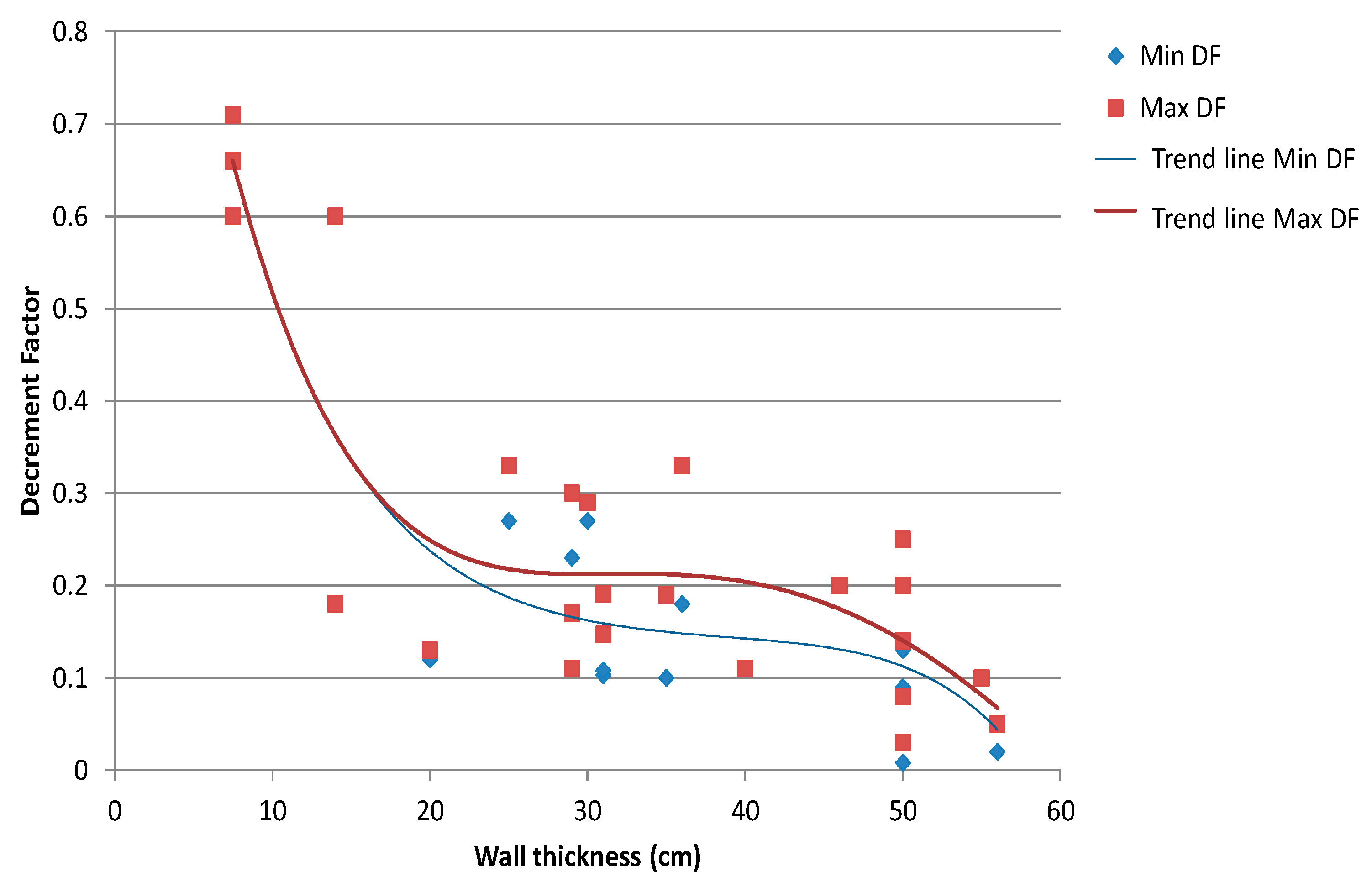

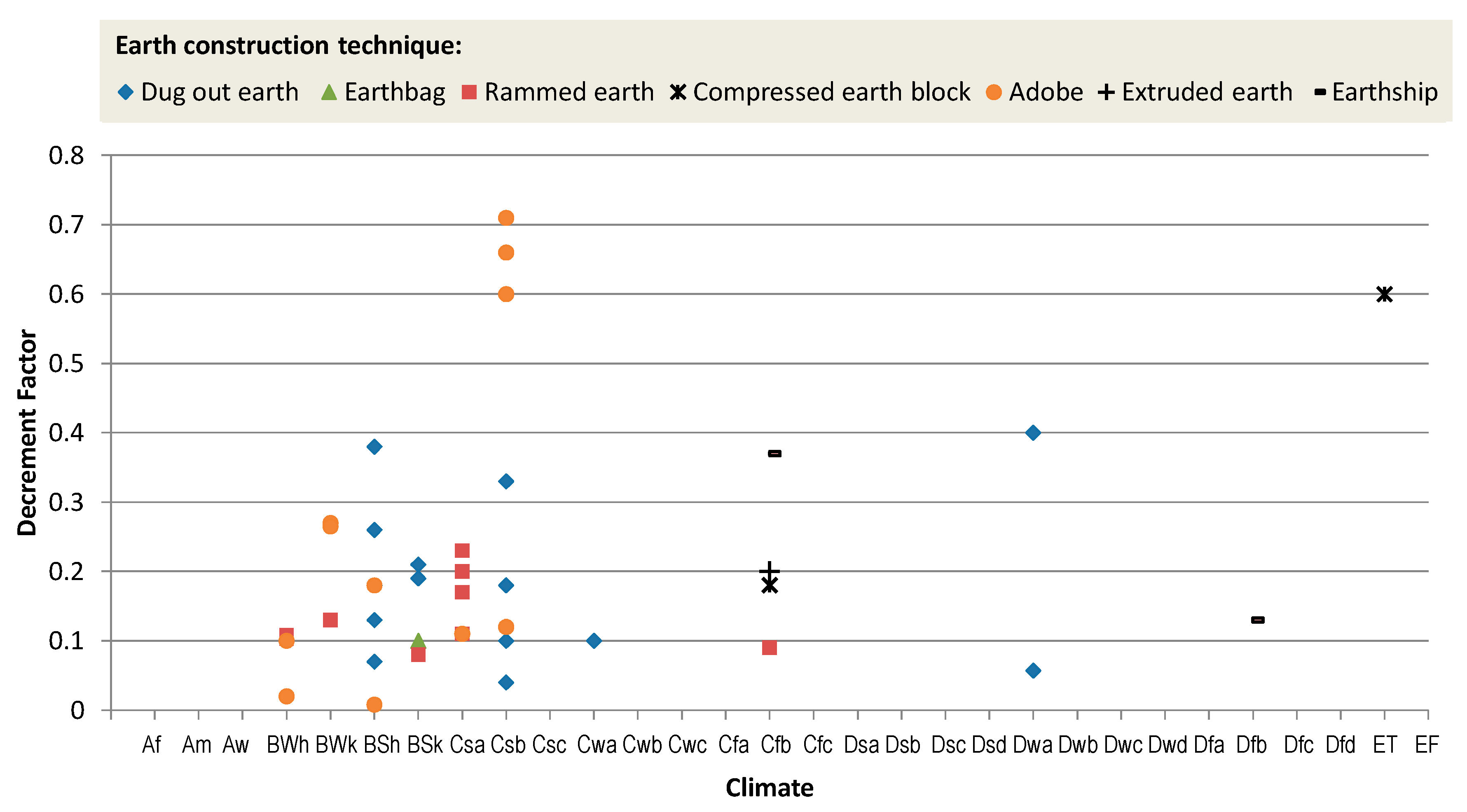

- Most of the locations of the earth buildings corresponded to arid and temperate climates according to Köppen and Geiger classification, which it is proved according to the literature to be suitable climates for earth constructions. This is due to its high thermal inertia that decreases the high thermal amplitude of the exterior temperatures, presenting decrements factors around 0.2 for the major part of the earth techniques.

- To assess the thermal comfort, ASHRAE 55 adaptive comfort model is the common standard used. For arid and temperate climates, earthbag, rammed earth and dugout constructions are the ones with higher levels of thermal comfort, obtaining values above 70% of the time within the limits of thermal comfort.

- When monitoring earth buildings indoor and outdoor temperatures are always measured. A large number of authors also recorded relative humidity, solar radiation and air velocity.

- Neither common equipment nor common monitoring methodology has been used, which complicates an objective comparison of the results. It is necessary to establish a common methodology for monitoring earth buildings.

- There is no consensus about the minimum period for conducting monitoring experiments.

- Rammed earth, adobe and dug out earth buildings are the techniques which there is more information on the literature regarding the thermal comfort assessment. However they are just partially studied, other parameters such as the water content or the building occupation are also involved in the thermal comfort.

- One of the main gaps concerning the monitoring of earth buildings, is the occupation. There is no information of the effect on the thermal comfort because of the occupation of the earth building. In the majority of the cases this occupation is not even mentioned.

- There is no homogeneity in the software used to simulate earth buildings, however EnergyPlus is the most used software.

- Base values of air infiltration of 0.4–0.8 ACH were considered.

- The numerical models that have been validated, present high coincidences with the monitoring results.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Coch, H. Bioclimatism in Vernacular Architecture. Renew. Sustain. Energy Rev. 1998, 2, 67–87. [Google Scholar] [CrossRef]

- Graham McHenry, P., Jr. Adobe and Rammed Earth Buildings. In Design and Construction; The University of Arizona Press: Tucson, AZ, USA, 1984. [Google Scholar]

- Costa, C.S.; Rocha, F.; Velosa, A.L. Sustainability in Earthen Heritage Conservation. Geol. Soc. Lond. Spec. Publ. 2016, 416, 91–100. [Google Scholar] [CrossRef]

- Hall, M.R.; Casey, S. Hygrothermal behaviour and occupant comfort in modern earth buildings. In Modern Earth Buildings; Woodhead Publishing, Elsevier: Cambridge, UK, 2012; pp. 17–40. ISBN 978-0-85709-026-3. [Google Scholar]

- Hoff, E.C. Appraisal of the Sustainability of Compressed Stabilized Earthen Masonry. University of Nebraska-Lincoln. December 2016. Available online: https://digitalcommons.unl.edu/archengdiss/43/ (accessed on 7 April 2021).

- Roux Gutiérrez, R.S. Los Bloques de Tierra Comprimida (BTC) En Zonas Húmedas; Plazay Valdés, S.A., Ed.; Universidad Autónoma de Tamaulipas: Tamaulipas, Mexico, 2010; ISBN 978-607-402-188-2. [Google Scholar]

- UNESCO. Earthen Architecture in Today’s World; UNESCO: Paris, France, 2013; ISBN 978-92-3-001236-6. Available online: http://whc.unesco.org/en/series/36/ (accessed on 7 April 2021).

- Auroville Earth Institute. Available online: http://www.earth-auroville.com/ (accessed on 27 April 2020).

- Birkhäuser, G.M. Building with Earth: Design and Technology of a Sustainable Architecture; Walter de Gruyter: Berlin, Germany, 2012; p. 198. [Google Scholar]

- Houben, H.; Guilland, H. Dossier Investing in People Country Reports: Mali, Western Samoa. In The Courier; 1996; Volume 159, Available online: http://www.nzdl.org/cgi-bin/library?e=d-00000-00---off-0hdl--00-0----0-10-0---0---0direct-10---4-------0-0l--11-en-50---20-about---00-0-1-00-0--4----0-0-11-10-0utfZz-8-00&cl=CL2.6.1&d=HASH01b7347bee24dda0b5908b86>=2 (accessed on 7 April 2021).

- Maldonado, C.A. Evaluación del Comportamiento Térmico de los Domos de Superadobe en Climas Fríos. Master’s Thesis, Universitat Politècnica de Catalunya, Catalonia, Spain, 2014. [Google Scholar]

- Rubel, F.; Kottek, M. Observed and Projected Climate Shifts 1901-2100 Depicted by World Maps of the Köppen-Geiger Climate Classification. Meteorol. Z. 2010, 19, 135–141. [Google Scholar] [CrossRef]

- Rincón, L.; Carrobé, A.; Medrano, M.; Solé, C.; Castell, A.; Martorell, I. Analysis of the Thermal Behavior of an Earthbag Building in Mediterranean Continental Climate: Monitoring and Simulation. Energies 2019, 13, 162. [Google Scholar] [CrossRef]

- Porras-Amores, C.; Mazarrón, F.R.; Cañas, I.; Villoría Sáez, P. Natural Ventilation Analysis in an Underground Construction: CFD Simulation and Experimental Validation. Tunn. Undergr. Space Technol. 2019, 90, 162–173. [Google Scholar] [CrossRef]

- Sadoughi, A.; Kibert, C.; Sadeghi, F.M.; Jafari, S. Thermal Performance Analysis of a Traditional Passive Cooling System in Dezful, Iran. Tunn. Undergr. Space Technol. 2019, 83, 291–302. [Google Scholar] [CrossRef]

- Mazarrón, F.R.; Cid-Falceto, J.; Cañas, I. Ground Thermal Inertia for Energy Efficient Building Design: A Case Study on Food Industry. Energies 2012, 5, 227–242. [Google Scholar] [CrossRef]

- Mazarrón, F.R.; Cid-Falceto, J.; Cañas, I. An Assessment of Using Ground Thermal Inertia as Passive Thermal Technique in the Wine Industry around the World. Appl. Therm. Eng. 2012, 33–34, 54–61. [Google Scholar] [CrossRef]

- Mazarron, F.R.; Canas, I. Exponential Sinusoidal Model for Predicting Temperature inside Underground Wine Cellars from a Spanish Region. Energy Build. 2008, 40, 1931–1940. [Google Scholar] [CrossRef]

- Mazarrón, F.R.; Cañas, I. Seasonal Analysis of the Thermal Behaviour of Traditional Underground Wine Cellars in Spain. Renew. Energy 2009, 34, 2484–2492. [Google Scholar] [CrossRef]

- Cañas Guerrero, I.; Martin Ocaña, S. Study of the Thermal Behaviour of Traditional Wine Cellars: The Case of the Area of “Tierras Sorianas Del Cid” (Spain). Renew. Energy 2005, 30, 43–55. [Google Scholar] [CrossRef]

- Zhu, J.; Tong, L. Experimental Study on the Thermal Performance of Underground Cave Dwellings with Coupled Yaokang. Renew. Energy 2017, 108, 156–168. [Google Scholar] [CrossRef]

- Zhu, J.; Tong, L.; Li, R.; Yang, J.; Li, H. Annual Thermal Performance Analysis of Underground Cave Dwellings Based on Climate Responsive Design. Renew. Energy 2020, 145, 1633–1646. [Google Scholar] [CrossRef]

- Zhao, X.; Nie, P.; Zhu, J.; Tong, L.; Liu, Y. Evaluation of Thermal Environments for Cliff-Side Cave Dwellings in Cold Region of China. Renew. Energy 2020, 158, 154–166. [Google Scholar] [CrossRef]

- Wang, F.; Liu, Y. Thermal Environment of the Courtyard Style Cave Dwelling in Winter. Energy Build. 2002, 34, 985–1001. [Google Scholar] [CrossRef]

- American Society of Heating, Refrigeration and Air-Conditioning Engineers, Inc. ANSI/ASHRAE Standard 55-2013. Thermal Environmental Conditions for Human Occupancy; ASHRAE Headquarters: Atlanta, GA, USA, 2013. [Google Scholar]

- Soudani, L.; Woloszyn, M.; Fabbri, A.; Morel, J.-C.; Grillet, A.-C. Energy Evaluation of Rammed Earth Walls Using Long Term In-Situ Measurements. Sol. Energy 2017, 141, 70–80. [Google Scholar] [CrossRef]

- Allinson, D.; Hall, M. Hygrothermal Analysis of a Stabilised Rammed Earth Test Building in the UK. Energy Build. 2010, 42, 845–852. [Google Scholar] [CrossRef]

- Taylor, P.; Fuller, R.J.; Luther, M.B. Energy Use and Thermal Comfort in a Rammed Earth Office Building. Energy Build. 2008, 40, 793–800. [Google Scholar] [CrossRef]

- Soebarto, V. Analysis Of Indoor Performance Of Houses Using Rammed Earth Walls. In Proceedings of the Eleventh International IBPSA Conference, Glasgow, UK, 27–30 July 2009. [Google Scholar]

- Palme, M.; Guerra, J.; Alfaro, S. Thermal Performance of Traditional and New Concept Houses in the Ancient Village of San Pedro De Atacama and Surroundings. Sustainability 2014, 6, 3321–3337. [Google Scholar] [CrossRef]

- Palme, M.; Guerra, J.; Alfaro, S. Earth of the Andes. Comparing Techniques and Materials Used in Houses in San Pedro de Atacama. In Proceedings of the 28th International PLEA Conference, Lima, Peru, 6–9 November 2012. [Google Scholar]

- Balaguer, L.; Vegas López-Manzanares, F.; Mileto, C.; García-Soriano, L. Assessment of the Thermal Behaviour of Rammed Earth Walls in the Summer Period. Sustainability 2019, 11, 1924. [Google Scholar] [CrossRef]

- Serrano, S.; Rincón, L.; González, B.; Navarro, A.; Bosch, M.; Cabeza, L.F. Rammed Earth Walls in Mediterranean Climate: Material Characterization and Thermal Behaviour. Int. J. Low-Carbon Technol. 2017, 12, 281–288. [Google Scholar] [CrossRef]

- Serrano, S.; de Gracia, A.; Cabeza, L.F. Adaptation of Rammed Earth to Modern Construction Systems: Comparative Study of Thermal Behavior under Summer Conditions. Appl. Energy 2016, 175, 180–188. [Google Scholar] [CrossRef]

- Beckett, C.T.S.; Cardell-Oliver, R.; Ciancio, D.; Huebner, C. Measured and Simulated Thermal Behaviour in Rammed Earth Houses in a Hot-Arid Climate. Part A: Structural Behaviour. J. Build. Eng. 2018, 15, 243–251. [Google Scholar] [CrossRef]

- Miño-Rodríguez, I.; Naranjo-Mendoza, C.; Korolija, I. Thermal Assessment of Low-Cost Rural Housing—A Case Study in the Ecuadorian Andes. Buildings 2016, 6, 36. [Google Scholar] [CrossRef]

- Ouédraogo, E. Determination of Parameters Influencing Thermal Comfort in a Building. Sci. J. Energy Eng. 2018, 6, 42. [Google Scholar] [CrossRef]

- Brambilla, A.; Jusselme, T. Preventing Overheating in Offices through Thermal Inertial Properties of Compressed Earth Bricks: A Study on a Real Scale Prototype. Energy Build. 2017, 156, 281–292. [Google Scholar] [CrossRef]

- SIA 180 Isolamento Termico, Protezione Contro l’umidità e Clima Interno Degli edifici. I-180 520180. 2014. Available online: http://shop.sia.ch/normenwerk/architekt/sia%20180/i/1999/D/Product (accessed on 7 April 2021).

- Zhang, L.; Sang, G.; Han, W. Effect of Hygrothermal Behaviour of Earth Brick on Indoor Environment in a Desert Climate. Sustain. Cities Soc. 2020, 55, 102070. [Google Scholar] [CrossRef]

- Heathcote, K. El Comportamiento Térmico de Los Edificios de Tierra. Inf. De La Construccióninf 2011, 63, 117–126. [Google Scholar] [CrossRef]

- Desogus, G.; Di Benedetto, S.; Grassi, W.; Testi, D. Environmental Monitoring of a Sardinian Earthen Dwelling during the Summer Season. J. Phys. Conf. Ser. 2014, 547, 012009. [Google Scholar] [CrossRef]

- Desogus, G.; Di Benedetto, S.; Ricciu, R. The Use of Adaptive Thermal Comfort Models to Evaluate the Summer Performance of a Mediterranean Earth Building. Energy Build. 2015, 104, 350–359. [Google Scholar] [CrossRef]

- ISO 13786: 2007. Thermal Performance of Building Components-Dynamic Thermal Characteristics- Calculation Methods; International Organization for Standardization: Geneva, Switzerland, 2007; Available online: https://www.iso.org/standard/65711.html (accessed on 7 April 2021).

- Ekici, C. A review of thermal comfort and method of using fanger’s pmv equation. In Proceedings of the 5th International Symposium on Measurement, Analysis and Modeling of Human Functions, Vancouver, BC, Canada, 27–29 June 2013. [Google Scholar]

- Zhang, J.; Xu, W.; Li, A.; Zheng, K.; Zhang, J. Study on Improving Thermal Environment and Energy Conservation of Quadrangle Adobe Dwelling. Energy Build. 2016, 129, 92–101. [Google Scholar] [CrossRef]

- Martín, S.; Mazarrón, F.R.; Cañas, I. Study of Thermal Environment inside Rural Houses of Navapalos (Spain): The Advantages of Reuse Buildings of High Thermal Inertia. Constr. Build. Mater. 2010, 24, 666–676. [Google Scholar] [CrossRef]

- Chel, A.; Tiwari, G.N. Thermal Performance and Embodied Energy Analysis of a Passive House—Case Study of Vault Roof Mud-House in India. Appl. Energy 2009, 86, 1956–1969. [Google Scholar] [CrossRef]

- Algifri, A.H.; Bin Gadhi, S.M.; Nijaguna, B.T. Thermal Behaviour of Adobe and Concrete Houses in Yemen. Renew. Energy 1992, 2, 597–602. [Google Scholar] [CrossRef]

- Meneses, T.; Vicente, R.; Costa, A.; Figueiredo, A.; Varum, H.; Soares, N. Comportamento térmico de construções em alvenaria de adobe: Ensaios experimentais sobre três células de teste à escala 1:4. In Proceedings of the VII Congreso Internacional de Arquitectura de Tierra, Valladolid, Spain, 26–27 September 2010. [Google Scholar]

- DECRETO-LEY 80/2006: “RCCTE— Regulamento das Características de Comportamento Térmico dos Edifícios”. 2006. Available online: https://dre.pt/home/-/dre/672456/details/maximized (accessed on 7 April 2021).

- DIN EN ISO 6946:2008-04: Building Components and Building Elements-Thermal Resistance and Thermal Transmittance-Calculation Method. 2008. Available online: https://shop.snv.ch/Standard/Protection-of-and-in-buildings/DIN-EN-ISO-6946/2008-04.html (accessed on 7 April 2021).

- Michael, A.; Philokyprou, M.; Thravalou, S. The Role of Adobes in the Thermal Performance of Vernacular Dwellings. In Proceedings of the XII Congrès Mondial sur les Architectures de Terre, Grenoble, France, 11–14 July 2016. [Google Scholar]

- El Fgaier, F.; Lafhaj, Z.; Brachelet, F.; Antczak, E.; Chapiseau, C. Thermal Performance of Unfired Clay Bricks Used in Construction in the North of France: Case Study. Case Stud. Constr. Mater. 2015, 3, 102–111. [Google Scholar] [CrossRef]

- Aranda-Jiménez, Y.G.; Espuna-Mujica, J.A.; Suarez-Domínguez, E.J. Structural and Thermal Monitoring of Sustainable Housing with Poured Earth Walls. Int. J. Sci. Res. Eng. Technol. (IJSRET) 2016, 5. [Google Scholar]

- Freney, M.H.P.; Soebarto, V.; Williamson, T. Thermal Comfort of Global Model Earthship in Various European Climates. In Proceedings of the 13th Conference of International Building Performance Simulation Association, Chambéry, France, 26–28 August 2013. [Google Scholar]

- Ip, K.; Miller, A. Thermal Behaviour of an Earth-Sheltered Autonomous Building—The Brighton Earthship. Renew. Energy 2009, 34, 2037–2043. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. GBT50785-2012, Indoor Thermal and Humidity Environment Evaluation Standard for Civil Buildings; China Building Industry Press: Beijing, China, 2012. (In Chinese)

- Asadi, S.; Fakhari, M.; Sendi, M. A Study on the Thermal Behavior of Traditional Residential Buildings: Rasoulian House Case Study. J. Build. Eng. 2016, 7, 334–342. [Google Scholar] [CrossRef]

- Rincón, L.; Carrobé, A.; Martorell, I.; Medrano, M. Improving Thermal Comfort of Earthen Dwellings in Sub-Saharan Africa with Passive Design. J. Build. Eng. 2019, 24, 100732. [Google Scholar] [CrossRef]

- Desideri, U.; Proietti, S.; Sdringola, P.; Vuillermoz, E. Feasibility Study and Design of a Low-Energy Residential Unit in Sagarmatha Park for Environmental Impact Reduction of High Altitude Buildings. In Proceedings of the 25th International Conference on Efficiency, Cost, Optimization and Simulation of Energy Conversion Systems and Processes, ECOS 2012, Perugia, Italy, 26–29 June 2012. [Google Scholar]

- Geiger, O. Insulated Earthbag Houses. Ezine Article. 2009. Available online: http://www.earthbagbuilding.com/articles/insulated.htm (accessed on 7 April 2021).

- Fivos Sargentis, G. Earth Building, Models, Technical Aspects, Tests and Environmental Evaluation. In Proceedings of the 11th International Conference on Environemental Science and Technology, Chania, Greece, 3–5 September 2009. [Google Scholar]

- Hyde, R. Bioclimatic Housing: Innovative Design for Warm Climates; Earthscan: London, UK, 2008; ISBN 978-1-84407-284-2. Available online: www.earthscan.co.uk (accessed on 7 April 2021).

- Zhao, Z.; Lu, Q.; Jiang, X. An Energy Efficient Building System Using Natural Resources--Superadobe System Research. Procedia Eng. 2015, 121, 1179–1185. [Google Scholar] [CrossRef]

- Stevanović, S. Optimal Rammed Earth Wall Thickness for a Single-Family House in Serbia, Rammed Earth Conservation. In Proceedings of the First International Conference on Rammed Earth Conservation, Valencia, Spain, 21–23 June 2012; pp. 223–228. [Google Scholar]

- Dong, X.; Soebarto, V.; Griffith, M. Achieving Thermal Comfort in Naturally Ventilated Rammed Earth Houses. Build. Environ. 2014, 82, 588–598. [Google Scholar] [CrossRef]

- Dong, X.; Soebarto, V.; Griffith, M. Design Optimization of Insulated Cavity Rammed Earth Walls for Houses in Australia. Energy Build. 2015, 86, 852–863. [Google Scholar] [CrossRef][Green Version]

- Dong, X.; Soebarto, V.; Griffith, M. Strategies for Reducing Heating and Cooling Loads of Uninsulated Rammed Earth Wall Houses. Energy Build. 2014, 77, 323–331. [Google Scholar] [CrossRef]

- Degelman, L.O.; Soebarto, V.I. Software Description for Ener-Win: A Visual Interface Model For Hourly Energy Simulation. Build. Proc. Build. Simul. 1995, 95, 692–696. [Google Scholar]

- Nicol, J.F.; Humphreys, M.A. Adaptive Thermal Comfort and Sustainable Thermal Standards for Buildings. Energy Build. 2002, 34, 563–572. [Google Scholar] [CrossRef]

- Janjai, S.; Sripradit, A.; Wattan, R.; Buntoung, S.; Pattarapanitchai, S.; Masiri, I. A Simple Semi-Empirical Model for the Estimation of Photosynthetically Active Radiation from Satellite Data in the Tropics. Int. J. Photoenergy 2013. [Google Scholar] [CrossRef]

- Janjai, S.; Deeyai, P. Comparison of Methods for Generating Typical Meteorological Year Using Meteorological Data from a Tropical Environment. Appl. Energy 2009, 86, 528–537. [Google Scholar] [CrossRef]

- Coulibaly, O.; Ouédraogo, E.; Ouedraogo, A.; Koulidiati, J. Détermination d’années Météorologiques Types Utilisées Pour La Simulation Thermique et Énergétique Des Bâtiments de Dix Villes Du Burkina Faso. Afr. Sci. 2015, 11, 158–169. [Google Scholar]

- Hema, C.M.; Van Moeseke, G.; Evrad, A.; Courard, L.; Messan, A. Vernacular Housing Practices in Burkina Faso: Representative Models of Construction in Ouagadougou and Walls Hygrothermal Efficiency. Energy Procedia 2017, 122, 535–540. [Google Scholar] [CrossRef]

- Wati, E.; Meukam, P.; Damfeu, J.C. Modeling Thermal Performance of Exterior Walls Retrofitted from Insulation and Modified Laterite Based Bricks Materials. Heat Mass Transf. 2017, 53, 3487–3499. [Google Scholar] [CrossRef]

- Wati, E.; Bidoung, J.C.; Damfeu, J.C.; Meukam, P. Energy Performance of Earthen Building Walls in the Equatorial and Tropical Climates: A Case Study of Cameroon. Energy Effic. 2020, 13, 735–750. [Google Scholar] [CrossRef]

- Ozel, M. Determination of Optimum Insulation Thickness Based on Cooling Transmission Load for Building Walls in a Hot Climate. Energy Convers. Manag. 2013, 66, 106–114. [Google Scholar] [CrossRef]

- Collet, F.; Serres, L.; Miriel, J.; Bart, M. Study of Thermal Behaviour of Clay Wall Facing South. Build. Environ. 2006, 41, 307–315. [Google Scholar] [CrossRef]

- Zeghari, K.; Louahlia, H.; Leguern, M.; Boutouil, M.; Gualous, H.; Marion, M.; Schaetzel, P.; Goodhew, S.; Streif, F. Comparison of the Thermal Performance between Conventional and Cob Building. E3S Web Conf. 2019, 111, 03003. [Google Scholar] [CrossRef]

- Azhary, K.E.; Raefat, S.; Laaroussi, N.; Garoum, M. Energy Performance and Thermal Proprieties of Three Types of Unfired Clay Bricks. Energy Procedia 2018, 147, 495–502. [Google Scholar] [CrossRef]

- Toguyeni, D.Y.K.; Coulibaly, O.; Ouedraogo, A.; Koulidiati, J.; Dutil, Y.; Rousse, D. Study of the Influence of Roof Insulation Involving Local Materials on Cooling Loads of Houses Built of Clay and Straw. Energy Build. 2012, 50, 74–80. [Google Scholar] [CrossRef]

- Bou-Saada, T.E.; Haberl, J.S. An Improved Procedure for Developing Calibrated Hourly Simulation Models. Proc. Build. Simul. 1995. [Google Scholar]

| Technique | Soil Characteristics | Construction Technique | Water Content | Tools for Construction | Time of Construction | Houben & Guilland [10] | Auroville Earth Institute [8] |

|---|---|---|---|---|---|---|---|

Earthen dug out | (-) | Digging out earth (Horiz. or Vert.) | (-) | (-) | (-) | 1 | 1 |

Earthbag | Any soil | PVC continuous bags, building in layers | 5–20% | Rammer, wire | Immediately without interruptions | 17 | 3 |

Cut blocks | Lateritic soils rich in iron and aluminium | Excavate and cut the bricks directly from the ground | 0% | Metal tools and large knife for cutting | After extraction, drying to gain more resistance | 8 | 2 |

Rammed earth | mix of soil with all granulometries (sand, clay, gravel) | Fill formwork with layers of earth from 10 to 15 cm compacted | 5–20% | Rammer, formwork | The placement of formwork and manual tamping is long | 5 | 5 |

Compressed earth blocks (CEB) | Balanced mix of sand, silt and clay. It cannot contain stone or gravel | The slightly humid screened earth is compressed into presses | 5–20% | Manual press | Immediately after its manufacture | 6,7 | 5 |

Direct shaping | Plastic soil | Shaping the earth in place | (-) | Minimal and very simple, hands | (-) | 4 | 6 |

Stacked earth | Land without stone or gravel, it can be clay or sandy, it must contain straw | Modelling the mixture in a plastic state building the wall in layers | 15–30% | Non specific | Between layers drying time must be expected | 3 | 7 |

Cob | Mixture of clay, sand, straw and water | Shaping and compressing together lumps to form the wall | (-) | Hands, feet or simple tools | (-) | 15 | - |

Adobe | Mud mixture with straw, no graver or stones | Poured mixture in a formwork, let it sun dry | 15–30% | Metal formwork | 2 weeks to dry the blocks, stacking upon them | 11,12,13 | 8 |

Extruded earth | Sandy and stabilised | Extruded stabilized earth at a plastic state | (-) | Machine for the extruded bricks | Fast production of large homogeneous bricks | 10 | 9 |

Straw clay | Chopped straw and clay as stabilizer | Straw clay bales in a timer frame | (-) | Wooden formwork | 30-ton wall in less than 5 days | 16 | 11 |

Daubed earth | Thin, clayey, binder soil, mixed with straw to avoid fissures | Woven structure filled with mud mixture | 15–35% | Any specific | Long mixing preparation | 14 | 10 |

Poured earth | Ordinary soil (some specifications) | Poured earth in a formwork | (-) | Formwork | Pouring after doing the mixture. Wait until it dries | 2 | 12 |

Earth 3D * | Raw earth with clay | Earth extruded | 45% | Earth 3D printer | 9 min for the mixture 24 h for 3 m wall | (-) | (-) |

Earthship ** | Ordinary soil | (-) | (-) | Any specific | (-) | (-) | (-) |

| Reference Number | Monitoring Period | Location | Climate | Use | Building Description | Decrement Factor | Thermal Lag | Thermal Amplitude | Thermal Comfort |

|---|---|---|---|---|---|---|---|---|---|

| [14] | cold period (Text < Tint) and warm period (Text > Tint) | San Esteban de Gormaz (Spain) | Cfb | In-use building (warehouse) | Deep: 10 m; Volume: 250 m3 | - | - | - | - |

| [15] | #1, #2, #4: 1 June to 21 December #3, #5: 15 August to 21 December | Dezful (Iran) | BSh | In-use buildings (dwelling) | Depth from the courtyard level: #1: 9 m; #2: 8.8 m; #3: 7.25 m; #4: 6.5 m; #5: 8 m | #1: 0.38; #2: 0.13; #3: 0.18; #4: 0.26; #5: 0.07 | - | #1: 8.8 °C; #2: 4.5 °C; #3: 6.9 °C; #4: 9.1 °C; #5: 2.6 °C | - |

| [16] | 2006–2009 | Ribera del Duero (Spain) | Csb | In-use building (wine cellar) | #1 (basement) 50 × 17 × 6 m3; #2 (earth-sheltered construction) 50 × 17 m2; #3 underground construction) tunnel of 100 m long and 4 m high | #1: 0.33; #2: 0.18; #3: 0.10 | #1: 28 days; #2: 58 days; #3: 51 days | - | #1: 58%; #2: 80% #3: 100% |

| [17] | #1: 2006–2009; #2: January 2008 to December 2009 | Ribera del Duero (Spain) | Csb | In-use building (wine cellar) | #1: cave of 10 m2, 2.4 m high, depth of 2.3 m + ventilation chimney; #2 cave of 84 m2, 2.5 m high, depth of 9 m + ventilation chimney. | - | - | - | - |

| [18,19] | 2006–2007 | Morcuera (Soria, Spain) | Csb | In-use building (wine cellar) | #1: cave of 6 m2 and 1.9 m high, 3.1 m deep + 9 m canyon; #2 same as #1 with 6.5 m canyon; #3 linear layout cave of 12 m2, 7 m canyon. | - | - | Daily, weekly, montly average:#1: 0.2, 0.7, 2.3 °C; #2: 0.7, 1.6, 3.4 °C; #3: 0.2, 0.7, 2.1 °C | - |

| [20] | 1 July to 7 July | Morcuera (Soria, Spain) | Csb | In-use building (wine cellar) | #1: 16.2 m long hillside with no ventilation; #2: 14.7 m long 3.4 m deep with 8 m canyon. | #1: 0.04; #2: 0 | - | #1: 0.8 °C #2: 0 °C | - |

| [21] | - | Miaoshang (China) | BSk | In-use building (dwelling) | 9 cave rooms with the depth of 7.5 m and plane size of 12 m2 + Yaokang (Adobe stove) | Summer: 0.19; Winter: 0.46 | - | - | - |

| [22] | - | Miaoshang (China) | BSk | In-use building (dwelling) | Four cave rooms located in north, south, east and west around a courtyard. | 0.21 | - | - | - |

| [23] | Winter: 6 January to 28 February 2018; summer: 26 August to 26 September 2018 | Gongyi (China) | Cwa | In-use building (dwelling) | 7.6 × 3 m2 facing south | Summer: 0.25; Winter: 0.1 | - | - | - |

| [24] | 15 January to 18 January 2000 | Jiang Yao Zu (China) | Dwa | In-use building (dwelling) | Courtyard surrounded by cave rooms (3–3.8 m high) #1 Occupied cave room; #2 Unoccupied cave room | #1: 0.057; #2: 0.4 | - | #1: 7–8 °C; #2: 0.65 °C | - |

| Reference Number | Location | Climate | Use | Building Description | Simulation Software | Ventilation | Thermal Transmittance | Decrement Factor | Thermal Lag | Monitoring vs. Simulation | Thermal Comfort | Comfort Standard |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [14] | San Esteban de Gormaz (Spain) | Cfb | in-use building | Deep: +10 m; Volume: 250 m3 | STAR-CCM+ | - | - | - | - | - | average temperature of 10.5 °C | - |

| [17] | Ribera del Duero (Soria, Spain) | Csb | in-use building (wine cellar) | Cellar #1 is 5 × 2 × 2.4 m3 and cellar #2 is 20 × 4.2 × 2.5 m3. Both with a ventilation chimney | EnergyPlus | - | - | #1: 0.19–0.35 (average 0.28); #2: 0.05–0.11 (average 0.08). | #1: 39–63 days (average 49); #2: 63–92 (average 78) | - | - | - |

| [22] | Miaoshang (China) | BSk | in-use building | 9 cave rooms with the depth of 7.5 m and plane size of 12 m2 + Yaokang (Adobe stove) | Sketchup + EnergyPlus | - | - | 0.42 (annual behaviour) | - | Average deviation in: Summer: 0.54%; Winter: 3.08%; Spring: 3.1% | 42.8% in comfort Zone II | Chinese Standard, GBT50785−2012 |

| [23] | Gongyi (China) | Cwa | in-use building | 7.6 × 3 m2 facing south | EnergyPlus | - | Cave roof: 0.067 W/(m2·K); South façade: 1.72 W/(m2·K) and Interior wall: 0.2 W/(m2·K) | - | Cave roof: 360.15 h; South façade: 10.06 h; Interior wall: 109.04 h | NMBE: 0.6% (summer) and 2.6% (winter); RMSE: 4.1% (summer) and 6.1% (winter). | 52.3% in comfort Zone II | Chinese Standard, GBT50785–2012 |

| [24] | Jiang Yao Zu (China) | Dwa | in-use building | courtyard surrounded by cave rooms (3–3.8 m high) | 0.43 ACH | Earth wall: 1.56 W/(m2·K) | - | 0.5 h for the courtyard | 1.7% deviation in the courtyard; 16% for the south cave room and 8.5% for the west cave room. | - | - | |

| [59] | Yazd (Iran) | Bwk | in-use building | - | ECOTEC + EnergyPLus | - | - | Summer: 0.03–0.08 | - | RMSE: 0.19–0.97 | - | - |

| Reference Number | Monitoring Period | Location | Climate | Use | Thickness | Thermal Transmittance | Decrement Factor | Thermal Lag | Thermal Comfort |

|---|---|---|---|---|---|---|---|---|---|

| [13] | July 2017–June 2018 | Lleida, (Spain) | BSk | Experimental building | 70 cm (buttress)–28 cm (roof) | 2.7 W/(m2·K) | Theory: 0.12; winter 0.12; equinox 0.19; summer 0.10 | Theory: 8.1 h; Experimental: Free floating (8–9 h) | Good performance in hot climates |

| Reference Number | Location | Climate | Use | Simulation Software | Building Description | Thickness | Ventilation | Conductivity/Thermal Transmittance | Decrement Factor | Thermal Lag | Thermal Comfort | Comfort Standard |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [13] | Lleida (Spain) | BSk | Experimental building | EnergyPlus | Dome Ø3 m, height 3.3 m | 70 cm (buttress)–28 cm (roof) | 0.5 ACH (base); 10 ach (night ventilation) | 2.7 W/(m2· K) | Free floating winter, equinox, summer (0.17; 0.16; 0,14) | Free floating winter, equinox, summer (8, 7, 6 h) | good performance in hot climates | ASHRAE Standard 55 Adaptive Comfort |

| [60] | Ouagadougou (Burkina Faso) | Bsh | In-use building | EnergyPlus | Dome Ø4.5 m, height 4.7 m | 64 cm (buttress)–32 cm (roof) | 0.5 ach (base); 4 ach (night ventilation) | 1.1 W/(m·K) | 0.15 (equinox) | - | 94–99% better than adobe | ASHRAE Standard 55 Adaptive Comfort |

| [61] | Sagarmatha National Park (Nepal) | Cwa | In-use building | - | Modified earthbag + insulation | 33 cm | - | 0.22 W/(m2·K) | - | - | - | - |

| [63] | - | - | - | ECOTEC | one space earthbag construction | - | - | - | - | - | - | - |

| [65] | - | - | - | PHOENICS | - | - | - | - | - | - | - | - |

| Reference Number | Monitoring Period | Location | Climate | Use | Building Description | Thickness | Conductivity/Thermal Transmittance | Decrement Factor | Thermal Lag | Thermal Amplitude |

|---|---|---|---|---|---|---|---|---|---|---|

| [26] | March 2013 to June 2015 | Saint-Antoine l’Abbaye (France) | Cfb | In-use building | two floors, 150 m2, 3 m high | 50 cm | 0.6 W/(m·K) completely dried | 0.09–0.2 | 6–9 h | - |

| [27] | 4 July 2008 to 1 April 2009 | Leicestershire (UK) | Cfb | In-use building | - | 17.5 cm + 5 cm extruded polystyrene insulation + 17.5 cm | 0.643 W/(m·K) | - | - | - |

| [28] | 13 February 2001–13 March 2000) | Albury-Wodonga (Australia) | Cfa | In-use building | two floors with offices, 10 m2 | 30 cm | - | - | - | - |

| [29] | - | Willunga, Adelaide (Australia) | Csb | In-use building | 104 m2, occupied by 2 people mainly on weekends and night time | 22 cm external, 11 cm internal | - | - | - | - |

| Willunga, Adelaide (Australia) | Csb | In-use building | 96 m2 occupied by 1 person | 33 cm external, 22 cm internal | - | - | - | |||

| - | Willunga, Adelaide (Australia) | Csb | In-use building | 175 m2, occupied by 5 person | 11 cm + 2.5 cm air gap + R2 insulation externally clad | - | - | - | - | |

| [30,31] | - | San Pedro de Atacama (Chile) | BWk | In-use building | - | 50 cm wall, 15 cm earth roof | Theoretical: wall (1.3 W/(m2 K)); roof (2.3 W/(m2·K)) | summer: 0.14; winter: 0.13 | - | - |

| [32] | - | La Serranía, Valencia (Spain) | Bsk | In-use building | 345.5 m2 in three floors | 50 cm | 1.58 W/(m2·K) | 0.08 | Increasing temp: 5–8; decreasing Temp: 1–2 h | 1.5 °C |

| [33] | Summer and winter 2013 | Barcelona (Spain) | Csa | Experimental building | 2.48 × 2.15 × 2.50 m3 inner dimensions | 50 cm | - | summer: 0.2; winter: 0.25 | - | Inner surface summer: 2 °C; winter 0.5 °C. External surface summer: 5 °C; winter: 1 °C |

| Puigverd de Lleida (Spain) | Csa/Cfa | Experimental building | 2.40 × 2.40 × 2.40 m3 of inner dimensions | 29 cm | - | summer: 0.23; winter: 0.3 | - | Inner surface summer: 3.5 °C; winter 5 °C. External surface summer: 15°C; winter: 17 °C | ||

| [34] | Summer 2015 | Puigverd de Lleida (Spain) | Csa/Cfa | Experimental building | 2.40 × 2.40 × 2.40 m3 | 29 cm | - | Free floating in winter: 0.17 | - | Winter: 1–2 °C |

| Puigverd de Lleida (Spain) | Csa/Cfa | Experimental building | 3 cubicles of 2.40 × 2.40 × 2.40 m3 | 29 cm + 6 cm wood fibers panel + 1 cm clay and straw coating | - | Free floating in winter: 0.11 | - | winter <1 °C | ||

| [35] | - | Kalgoorlie-Boulder (Australia) | Bwh | Experimental building | Complete house. 50.3 m × 20.1 m2 | 31 cm thick | - | 0.103–0.191 | 0.364–1.5 h | - |

| - | Kalgoorlie-Boulder (Australia) | Bwh | Experimental building | Complete house. 50.3 × 20.1 m2 | 31 cm thick; kitchen and bathroom 30 cm + insulation | - | 0.108–0.147 | 0.48–0.949 h | - |

| Reference Number | Simulation Software | Location | Climate | Use | Building Description | Thickness | Monitoring vs. Simulation | Ventilation | Conductivity/Thermal Transmittance | Decrement Factor | Thermal Lag | Thermal Comfort | Comfort Standard |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [27] | WUFI Plus v1.2 | Leicestershire (UK) | Cfb | experimental building | One space room 8 m2 | 17.5 cm + 5 cm extruded polystyrene insulation + 17.5 cm | 1 °C discrepancy | 1.5 ACH | - | - | - | - | - |

| [28] | TRNSYS | Albury-Wodonga (Australia) | Cfa | In-use building | two floors with offices, 10 m2 | 30 cm | - | - | - | - | - | 75% | ASHRAE Standard 55 Adaptive |

| [29] | - | Willunga, Adelaide (Australia) | Csb | In-use building | 104 m2, occupied by 2 people mainly on weekends and night time | 22 cm | correlation coefficient (R2) in summer: 0.987 | 0.8 ACH | Theory: 4.26 W/(m2·K) | Theory: 0.714 | Theory: 2.81 h | - | - |

| - | Willunga, Adelaide (Australia) | Csb | In-use building | 96 m2 occupied by 1 person | 33 cm | correlation coefficient (R2) in winter: 0.828; summer: 0.987 | 0.8 ACH | Theory: 3.089 W/(m2·K) | Theory: 0.374 | Theory: 6.16 h | - | - | |

| - | Willunga, Adelaide (Australia) | Csb | In-use building | 175 m2, occupied by 5 person | 11 cm + 2.5 cm air gap | correlation coefficient (R2) in summer: 0.984 | 0.8 ACH | Theory: 2.411 W/(m2·K) | Theory: 0.189 | Theory: 9.3 h | - | - | |

| [30,31] | ECOTEC | San Pedro de Atacama (Chile) | BWk | In-use building | - | 50 cm wall, 15 cm earth roof | - | 0.4 ACH | - | 80% | 14 h | Reduction 70% discomfort | ASHRAE standards |

| [35] | - | Kalgoorlie-Boulder (Australia) | Bwh | Experimental building | Complete house. 50.3 m × 20.1 m | 31 cm thick | - | - | - | 0.119–0.425 | 0.357–5.75 h | - | - |

| - | Kalgoorlie-Boulder (Australia) | Bwh | Experimental building | Complete house. 50.3 m × 20.1 m | 31 cm thick; kitchen and bathroom 30 cm + insulation | - | - | - | 0.145–0.427 | 0.69–3.4 h | - | - | |

| [66] | EnergyPlus | Belgrade (Serbia) | Cfa | in-use building | 83 m2 | 30–40−50 cm | - | 0.7 ACH | 2.07, 1.76 and 1.54 W/(m2·K) | - | - | - | 2010/31/EU |

| [67] | AccuRate | Longreach (Australia) | Bsh | experimental building | One space room 8 × 12 m | - | - | - | 1.25 W/(m·K) (AccuRate library) | Winter: 0.32; Summer: 0.37 | Winter: 7.5; Summer: 9 | 37% overheating | ASHRAE Standard 55 Adaptive |

| AccuRate | Adelaide (Australia) | Csb | experimental building | One space room 8 × 12 m | - | - | - | 1.25 W/(m·K) (AccuRate library) | Winter: 0.38; Summer: 0.45 | Winter: 8; Summer: 10.5 | 50% out of the limits | ASHRAE Standard 55 Adaptive | |

| AccuRate | Ballarat (Australia) | Cfb | experimental building | One space room 8 × 12 m | - | - | - | 1.25 W/(m·K) (AccuRate library) | Winter: 0.41; Summer: 0.31 | Winter: 7; Summer: 8.5 | 70% Undercooling | ASHRAE Standard 55 Adaptive |

| Reference Number | Monitoring Period | Location | Climate | Use | Thickness | Conductivity/Thermal Transmittance | Decrement Factor | Thermal Lag | Thermal Amplitude | Comfort Standard |

|---|---|---|---|---|---|---|---|---|---|---|

| [36] | - | Zumbahua (Equator) | ET | In-use building | 14 cm thick + plaster coating (unspecified thickness) | 2.24 W/(m2 K) | 0.6 | 2.5 h for increase. 1 h for decrease | - | - |

| [37] | - | Burkina Faso | BSh | Experimental building | 14 cm or 28 cm | Earth with paper (0.588 W/(m2·K)), Only earth (0.644 W/(m2·K)), earth with cement and paper (0.671 W/(m2·K)), earth with cement (0.742 W/(m2·K)). | 33.54–44% | 6–7 h | - | - |

| [38] | summer 2016 | Fribourg (Switzerland) | Cfb | Experimental building | 14 + 18 cm insulation | 0.79 W/m·K | 0.18 | 2 h | 3.1 °C | SIA 180:2014 |

| [40] | 1 August to 4 August 2016 | Turpan (China) | Bwk | In-use building | 40 cm + 1.5 cm cement-lime mortar | - | - | - | Ground floor: 2.5 °C; Semi-underground floor: 0.5 °C; first floor: 2 °C | - |

| Reference Number | Simulation Software | Location | Climate | Use | Thickness | Monitoring vs. Simulation | Ventilation | Decrement Factor | Thermal Lag | Thermal Comfort |

|---|---|---|---|---|---|---|---|---|---|---|

| [36] | EnergyPlus | Zumbahua (Equator) | ET | In-use building | 14 cm thick + plaster coating (unspecified thickness) | R2: 0.89; RMSE: 1.1 °C | - | - | - | 75% under comfort |

| [37] | - | Burkina Faso | BSh | Experimental building | 14 cm or 28 cm | MBD < 5.6%; RMSD < 10% | - | - | ||

| [40] | EnergyPlus | Turpan (China) | Bwk | In-use building | 30 cm | - | 0.5 ACH (base); night ventilation 2.5 ACH | - | - | - |

| [75] | - | Ouagadougou (Burkina Faso) | Bsh | Experimental building | - | - | - | - | - | - |

| [76] | EnergyPlus | Garoua (Cameroon) | Am | Experimental building | 30 cm | - | - | CSEB 0,6; Sawdust 0.3; Pozzolan 0.2 | sawdust +4.21%; Pozzolan + 16.14% | - |

| [77] | - | Garoua, Youndé and Douala (Cameroon) | Am, Aw | In-use building | 14 cm | - | 0.35 ACH | - | - | - |

| Reference Number | Simulation Software | Location | Climate | Use | Building Description | Thickness | Ventilation | Conductivity | Decrement Factor |

|---|---|---|---|---|---|---|---|---|---|

| [79] | TRNSYS | Rennes (France) | Cfb | in-use building | 32 dwellings of 65.7 m2 | 30 to 80 cm | 60 m3/h | - | - |

| [80] | - | France and UK | Cfb | in-use building | two floors | 35 cm insulation Cob + 30 cm construction cob | - | insulation Cob (0.1 W/m·K); construction cob (0.494 W/m·K) | - |

| Reference Number | Monitoring Period | Location | Climate | Use | Building Description | Thickness | Conductivity/Thermal Transmittance | Decrement Factor | Thermal Lag | Thermal Amplitude | Thermal Comfort | Comfort Standard |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [30,31] | Summer 2012 | San Pedro de Atacama (Chile) | BWk | In-use building | Bedroom and small lavatory | 30 cm + rammed earth roof 15 cm | - | Summer 0.29; Winter 0.27 | Summer: 3–4 h; Winter: close to zero | Summer: 1.5 °C; Winter: 6 °C | - | - |

| [41] | March 2007 (summer) and May 2007 (winter) | Australia | - | Experimental building | 4 m2 | 25 cm stabilized with bitumen | Theoretical: 0.82 W/m·K | Winter: 0.33; Summer: 0,27 | Theoretical: 8 h; Summer 5–6 h; Winter: 3–4 h | Winter: 4 °C; Summer: 1.75 °C | - | - |

| [42] | Summer 2010 | Serramanna (Italy) | Csa | In-use building | Living room (24.5 m2) and bedroom (14.7 m2) | 40 cm | Experimental in the lab: 0.127 W/(m2·K) | Experimental in the lab: 0.098; monitored: 0.11 | Experimental in the lab: 14.5 h | - | - | - |

| [43] | Summer 2011 | Serramanna (Italy) | Csa | In-use building | Living room (24.5 m2) and bedroom (14.7 m2) | - | - | - | - | - | Living room 99% bedroom 87% | Fanger’s method |

| [46] | 8 December 2012 to 30 December 2012 | Gansu (China) | BSk or BWk | In-use building | - | - | - | 0.265 | 1 h | - | −2 (Cool) | PMV |

| [47] | Summer: 20 June to 1 July; Winter: 1 January to 8 March | Navapalos (Spain) | Csb | In-use building | - | Adobe (40 × 20 × 15 cm) + 1 cm plaster | 1.35 W/(m2·K) | Winter: 0.12; Summer: 0.13 | - | - | cross point: 7 °C (Winter) and 21°C (summer) | cumulative distribution function (CDF) |

| [48] | - | New Delhi (India) | Bsh | In-use building | 6 rooms (3 inverted U-shaped rooms and 3 dome shaped rooms) | 36 cm | 1.39 W/(m2·K) | Winter: 0.28–0.33; Summer: 0.18–0.28 | - | - | - | - |

| [49] | - | Sieyoung (China) | BWh | In-use building | - | 55 cm adobe + 0.5 cm of mud plaster | - | Winter: 0.1 | Summer: 14–15 h, Winter 12–14 h | <5 °C | - | - |

| - | Lahij (Yemen) | BWh | In-use building | - | 56 cm adobe + 0.5 cm of mud plaster | - | Summer: 0.02; Winter: 0.05 | Summer: 12–16 h, Winter 17 h | <5 °C | - | - | |

| [50] | May | Universdade de Aveiro (Portugal) | Csb | Experimental building | One space area of 1 × 1.35 × 0.75 m, with adobe bricks of 11.25 × 7.5 × 3.75 cm | Adobes produced in the lab | 2.06 W/(m2·°C) (RCCTE) and 2.22 W/m2· K (DIN EN ISO 6946) | 0.71 | 3 h 16 min | - | - | - |

| May | Universdade de Aveiro (Portugal) | Csb | Experimental building | One space area of 1 × 1.35 × 0.75 m, with adobe bricks of 11.25 × 7.5 × 3.75 cm | adobes taken from a demolished construction in Aveiro | 1.83 W/(m2· K) (RCCTE) and 1.95 W/(m2·°C) (DIN EN ISO 6946) | 0.66 | 2 h 17 m | - | - | - | |

| May | Universdade de Aveiro (Portugal) | Csb | Experimental building | One space area of 1 × 1.35 × 0.75 m, with adobe bricks of 11.25 × 7.5 × 3.75 cm | Adobes produced in the lab adding 2% cork. | 1.47 W/(m2· K) (RCCTE) and 1.65 W/m2·°C (DIN EN ISO 6946) | 0.6 | 2 h 05 min | - | - | - | |

| [53] | - | Cyprus | BSh | Experimental building | - | 50 cm | - | Summer: 0.03; winter: 0.008 | 5 | - | - | - |

| Reference Number | Simulation Software | Location | Climate | Use | Building Description | Thickness | Monitoring vs. Simulation | Ventilation | Thermal Transmittance | Decrement Factor | Thermal Lag | Thermal Comfort | Comfort Standard | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [30,31] | ECOTEC | San Pedro de Atacama (Chile) | BWk | In-use building | Bedroom and small lavatory | 30 cm, 15 cm (roof) | - | 0.4 ACH | - | 55% | 8 h | 5500 h discomfort | ASHRAE 55 Adaptive comfort model | |

| [46] | FLUENT | Gansu (China) | Bs | In-use building | - | - | - | - | - | - | - | - | - | |

| [48] | - | New Delhi, Bangalore, Jodhpur, Mumbai and Srinagar (India) | Bsh | In-use building | - | - | R2 097–0.98; RMSE 0.2–3% | - | - | - | - | - | - | |

| [60] | EnergyPlus | Ouagadougou (Burkina Faso) | Bsh | In-use building | one space area, 15.9 m2 | 15 cm | - | 0.5 ACH; night ventilation (4 ACH) | 0.95 W/(m2·K) | - | - | +3000 h discomfort; + 200 discomfort degree days | ASHRAE 55 Adaptive comfort model, Discomfort degree days (DDD) |

| Reference Number | Monitoring Period | Location | Climate | Use | Thickness | Conductivity | Decrement Factor | Thermal Lag |

|---|---|---|---|---|---|---|---|---|

| [54] | 26 July 2012 to 12 July 2013 | Lille (France) | Cfb | Experimental building | 46–60 cm | 0.9 W/m·K | 0.2 | 10 h |

| Reference Number | Simulation Software | Location | Climate | Use | Building Description | Ventilation | Decrement Factor | Thermal Lag |

|---|---|---|---|---|---|---|---|---|

| [81] | Design Building | Marrakech | Bsh | - | 288 m2 | 36 m3/h | winter: 0.33; summer 0.2 | - |

| Reference Number | Simulation Software | Location | Climate | Use | Building Description | Thickness | Ventilation | Thermal Transmittance | Decrement Factor |

|---|---|---|---|---|---|---|---|---|---|

| [82] | TRNSYS 16.1 | Ouagadougou (Burkina Faso) | Bsh | In-use building | 50.02 m2 | 20 cm clay and 20 cm clay-straw 3% | - | clay: 2.12 W/(m2·K); clay-straw 3%: 0.53 W/m2·K | - |

| Reference Number | Monitoring Period | Location | Climate | Use | Thickness | Thermal Transmittance | Decrement Factor | Thermal Lag | Thermal Comfort | Comfort Standard |

|---|---|---|---|---|---|---|---|---|---|---|

| [56] | 2012 | Taos (New Mexico, USA) | Dfb | In-use building | 160 cm | 0.613 W/(m2·K) | Summer: 0.13; Winter: 0.33 | - | - | - |

| [57] | 2004–2005 | Brighton (United Kingdom) | Cfb | In-use building | 100 cm (tyres + earth) | - | Summer: 0.37; Winter: 0.625 | - | 80% | ASHRAE 55 Adaptive comfort |

| Reference Number | Simulation Software | Location | Climate | Use | Monitoring VS Simulation | Ventilation | Thermal Transmittance | Decrement Factor |

|---|---|---|---|---|---|---|---|---|

| [56] | EnergyPlus + Design Builder | Taos (USA), Paris (France) Albacete, Seville and Valladolid (Spain), and London (UK) | Dfb, Cfb BSk Csa Csb Cfa | In-use building | RMSE: 6.3% | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carrobé, A.; Rincón, L.; Martorell, I. Thermal Monitoring and Simulation of Earthen Buildings. A Review. Energies 2021, 14, 2080. https://doi.org/10.3390/en14082080

Carrobé A, Rincón L, Martorell I. Thermal Monitoring and Simulation of Earthen Buildings. A Review. Energies. 2021; 14(8):2080. https://doi.org/10.3390/en14082080

Chicago/Turabian StyleCarrobé, Ariadna, Lídia Rincón, and Ingrid Martorell. 2021. "Thermal Monitoring and Simulation of Earthen Buildings. A Review" Energies 14, no. 8: 2080. https://doi.org/10.3390/en14082080

APA StyleCarrobé, A., Rincón, L., & Martorell, I. (2021). Thermal Monitoring and Simulation of Earthen Buildings. A Review. Energies, 14(8), 2080. https://doi.org/10.3390/en14082080