Aerodynamic Effect of the Gurney Flap on the Front Wing of a F1 Car and Flow Interactions with Car Components

Abstract

1. Introduction

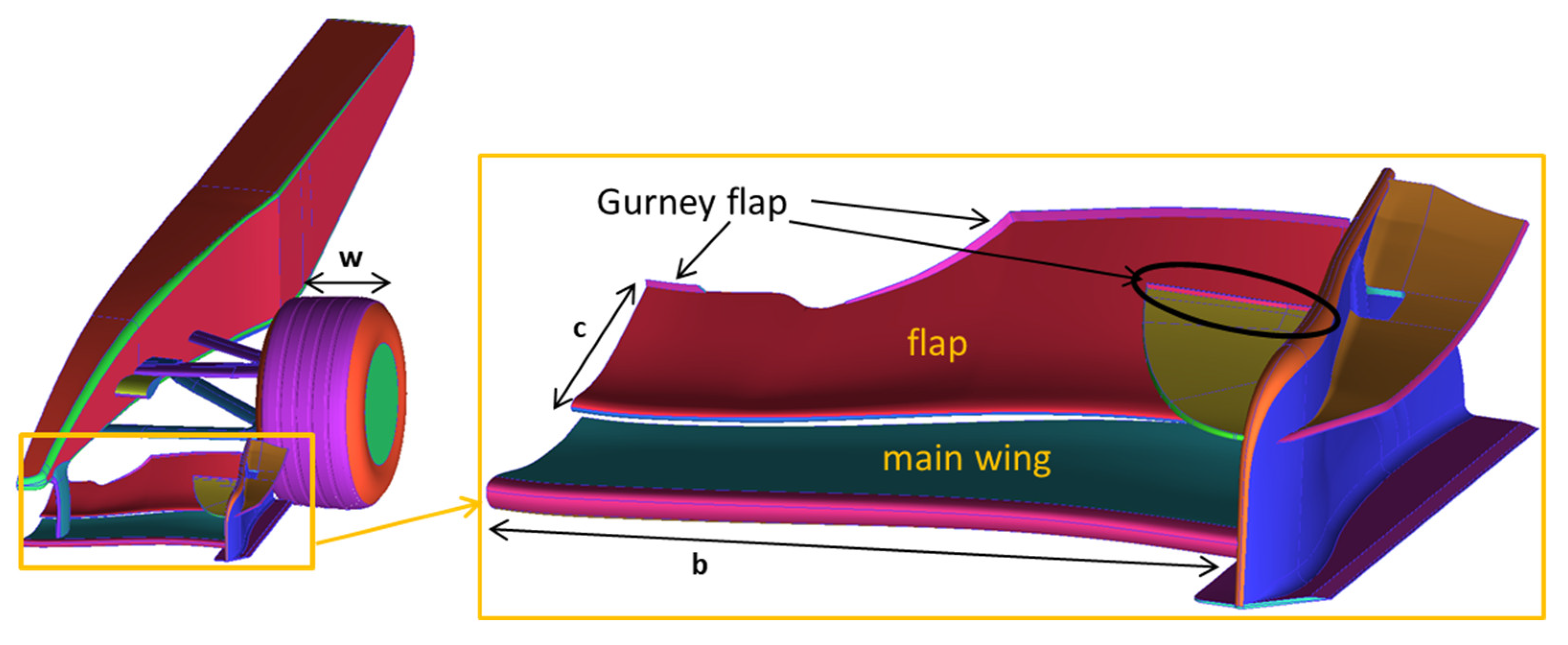

2. Geometry and CFD model

2.1. Application

- Central part with height of 1.35% of the aileron chord and thickness s = 1.75 mm;

- Lateral part of variable height between 1.8% and 0.36%, with thickness s = 1.9 mm;

- External part in contact with the endplate with h = 1.8% and s = 1.9 mm;

- Internal endplate with h = 1% of chord of the complete aileron.

2.2. Governing Equations

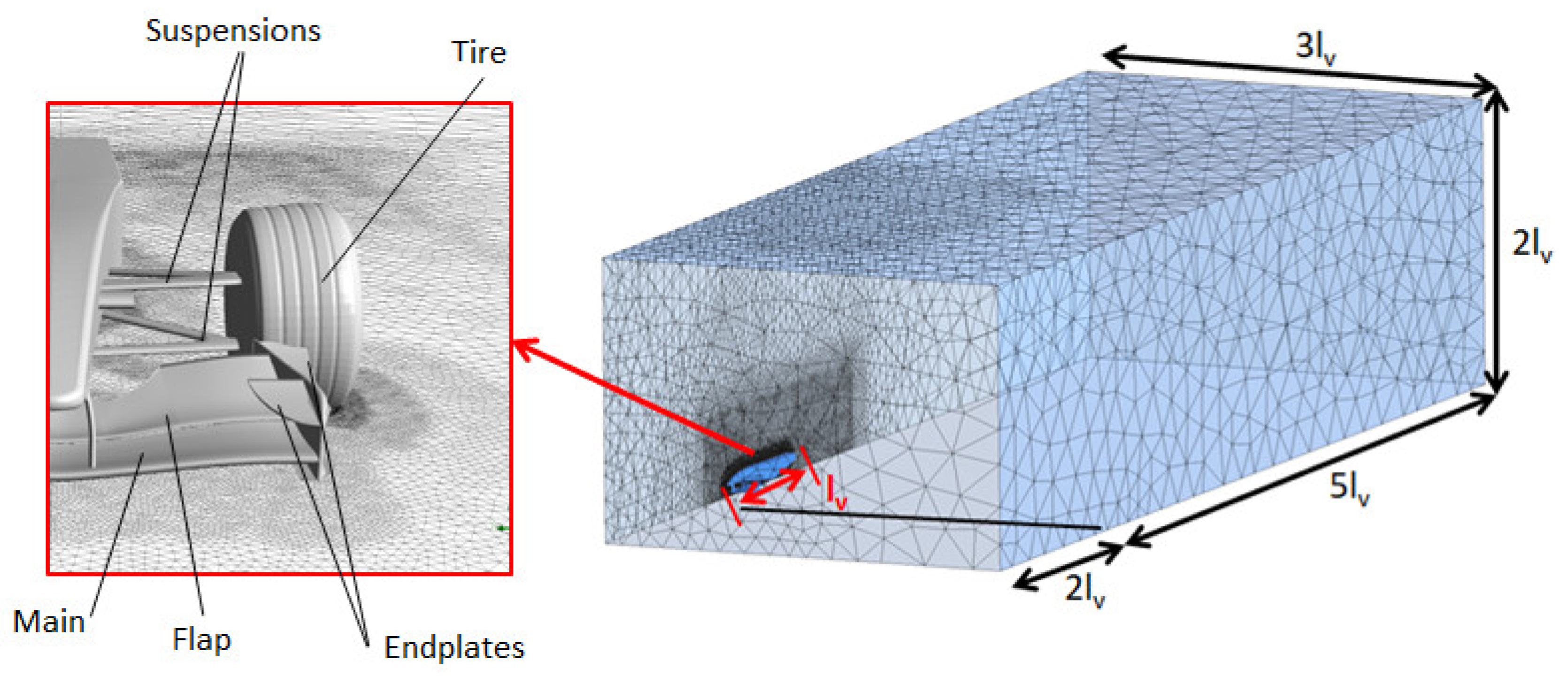

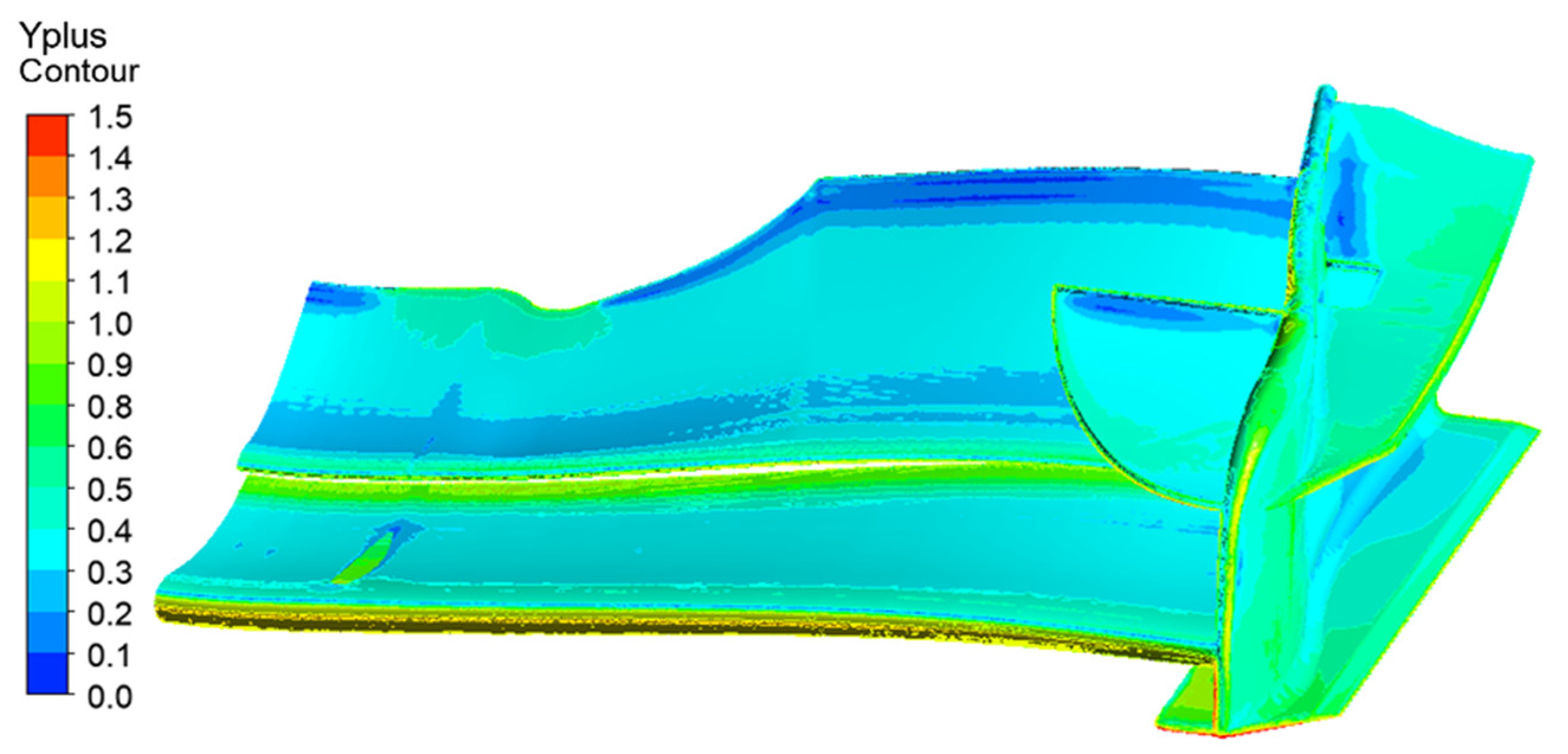

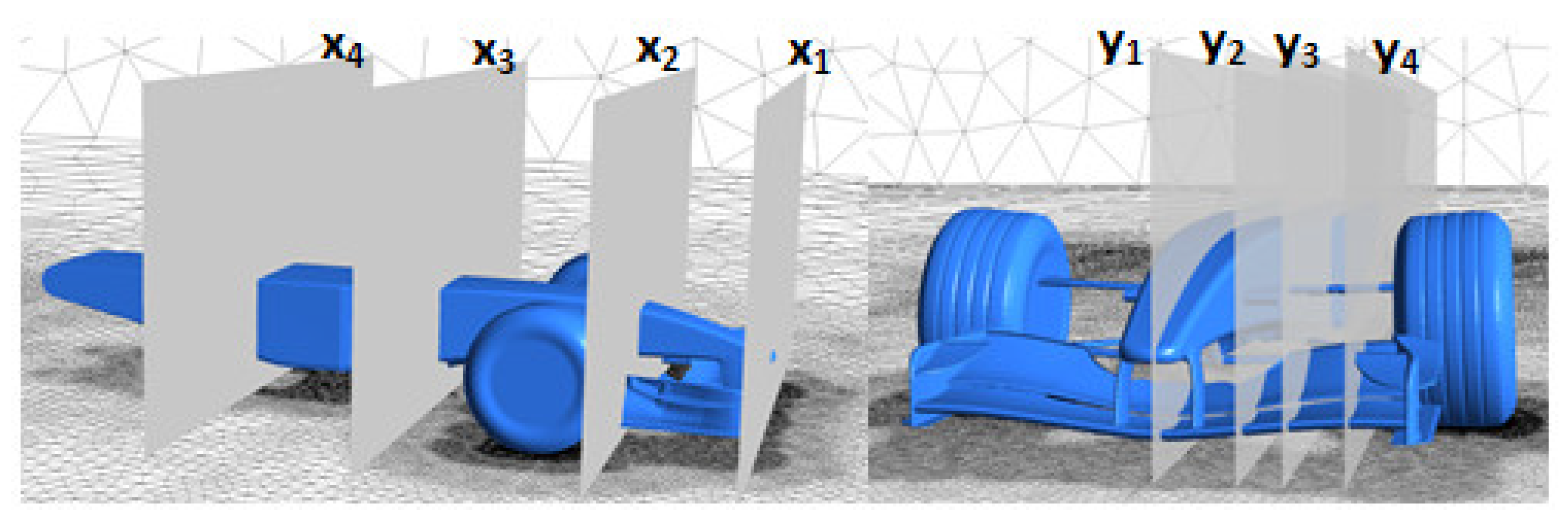

2.3. CFD Model

3. Results

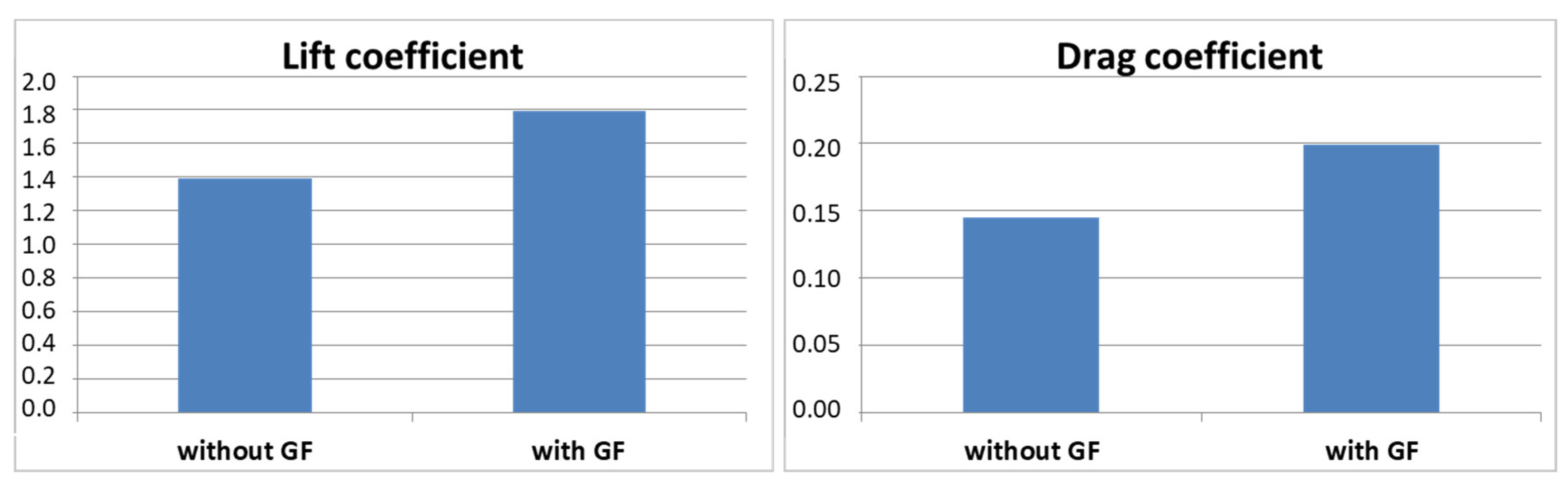

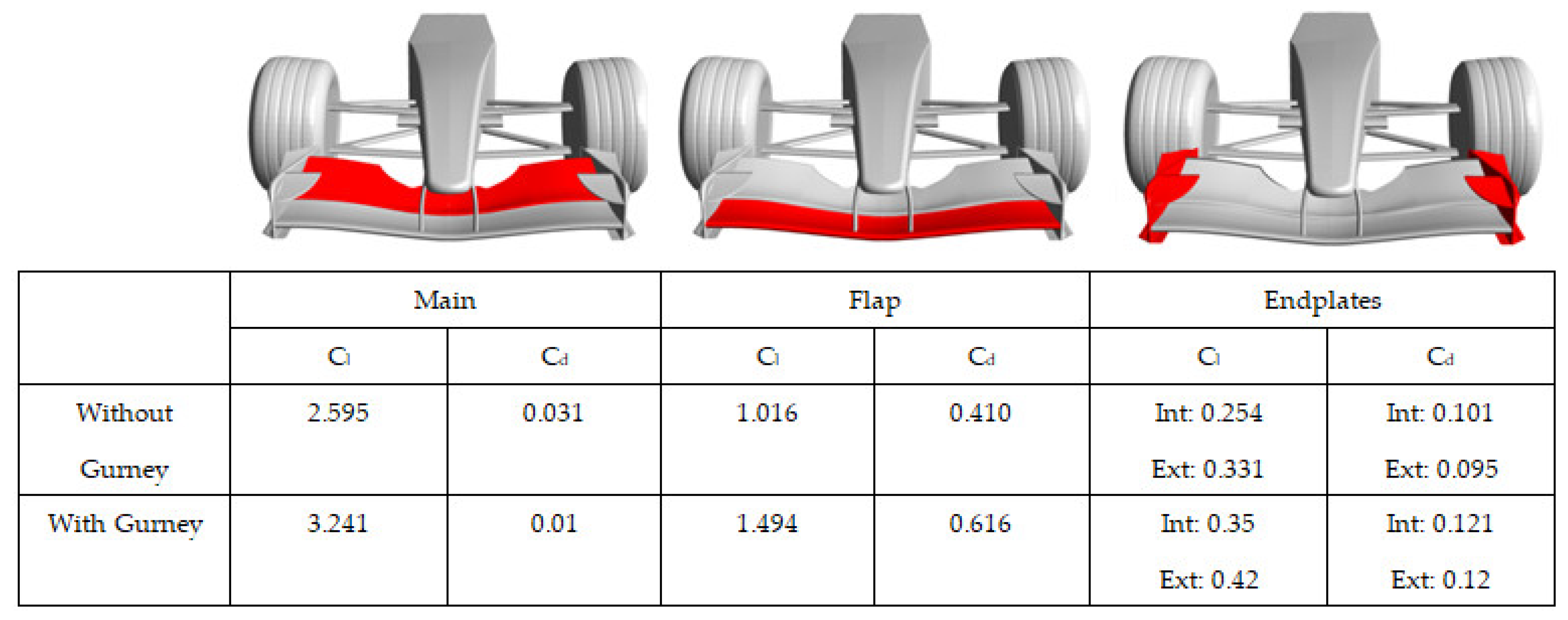

3.1. Global Performance of the Main Components

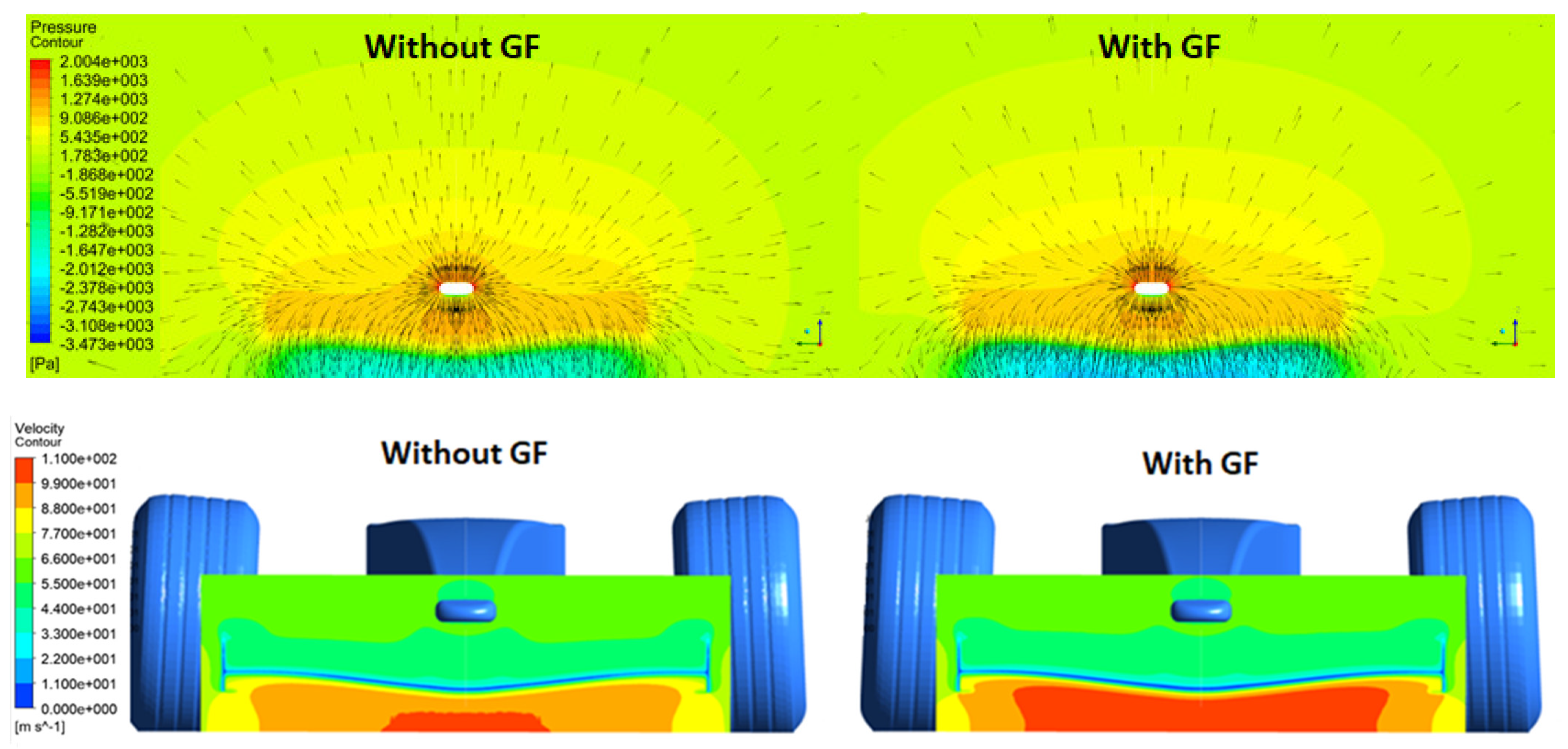

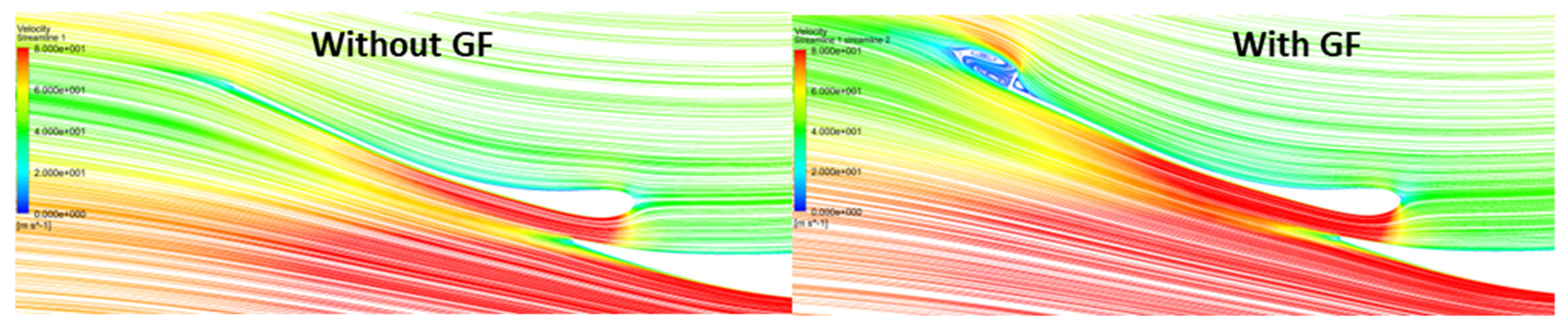

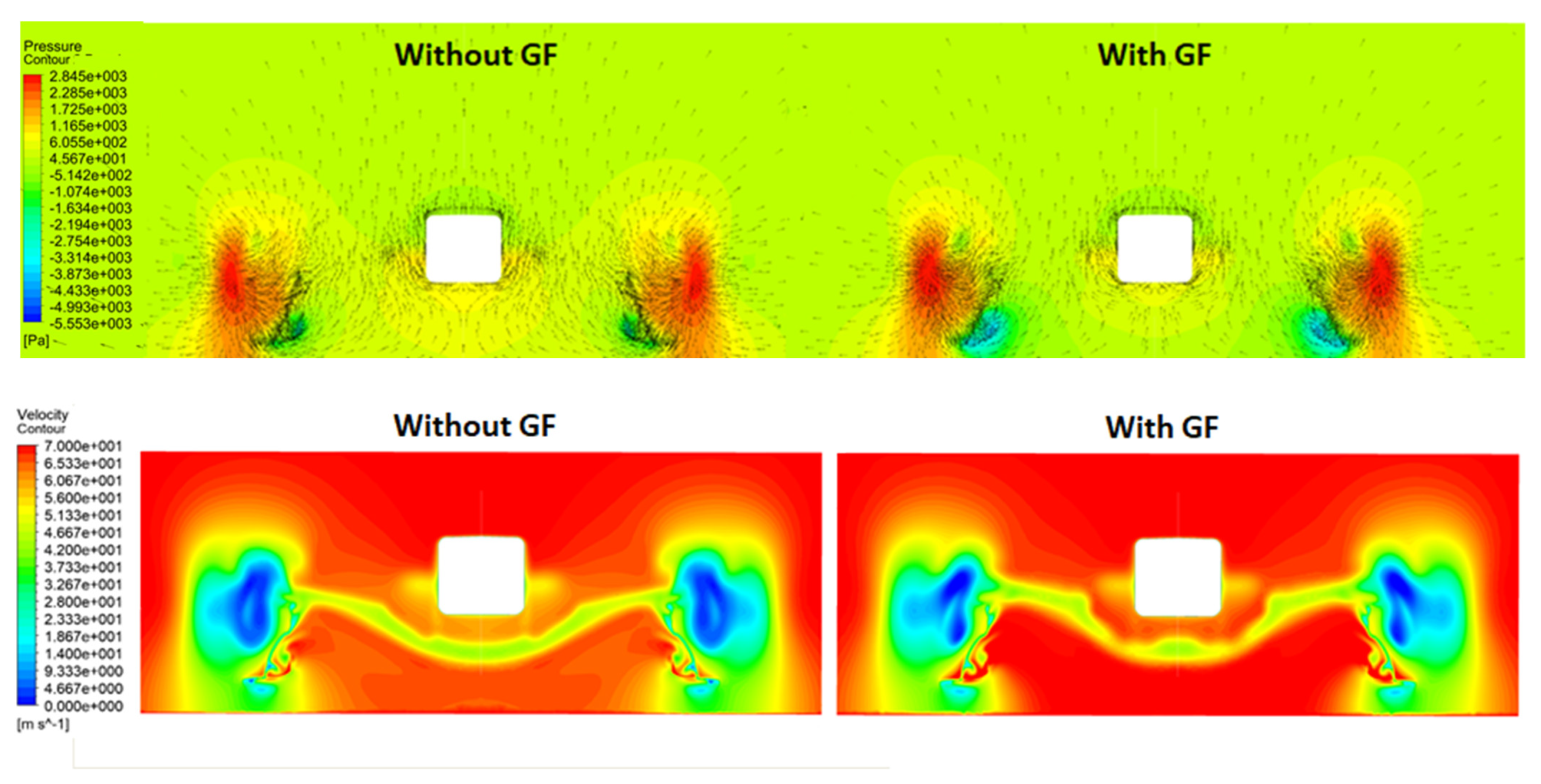

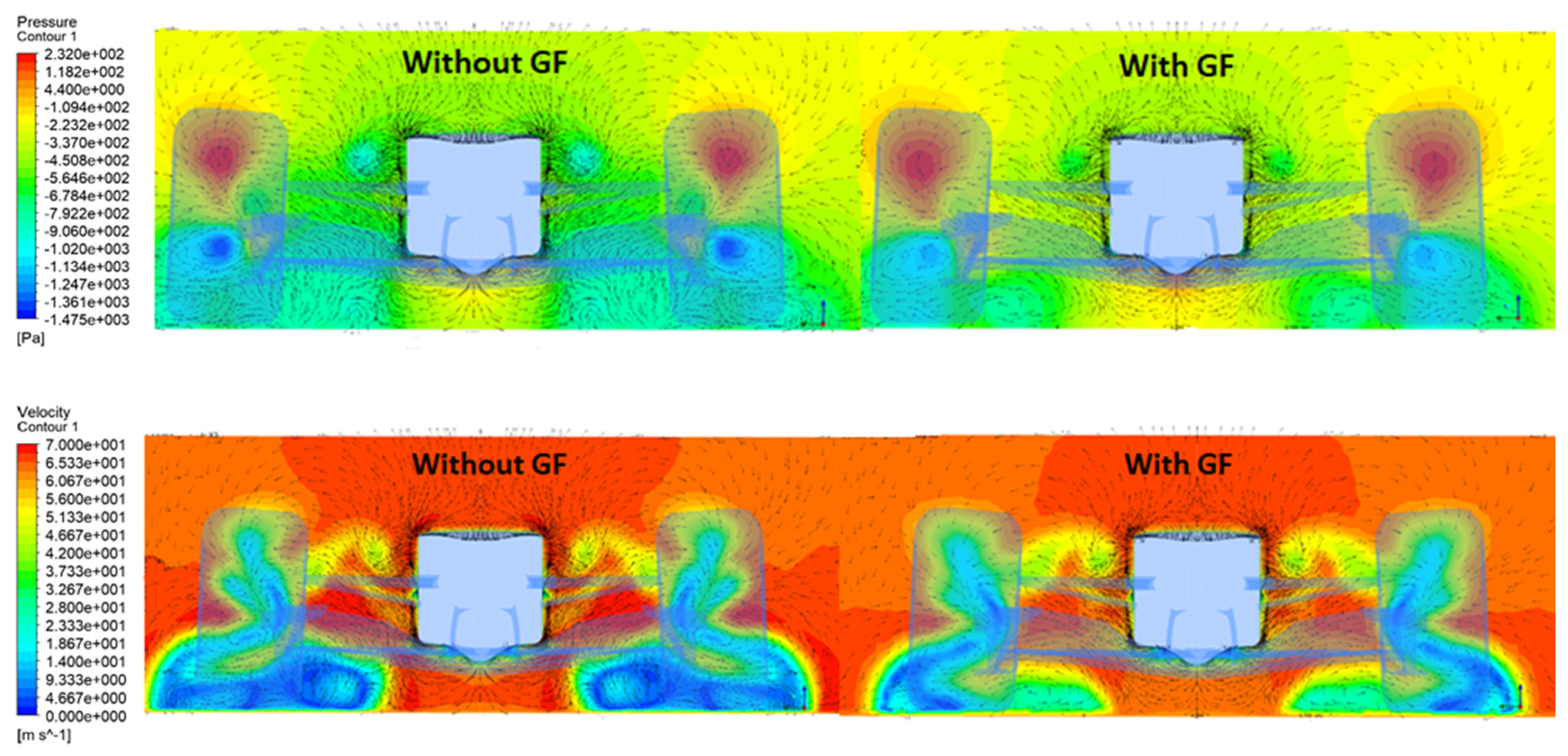

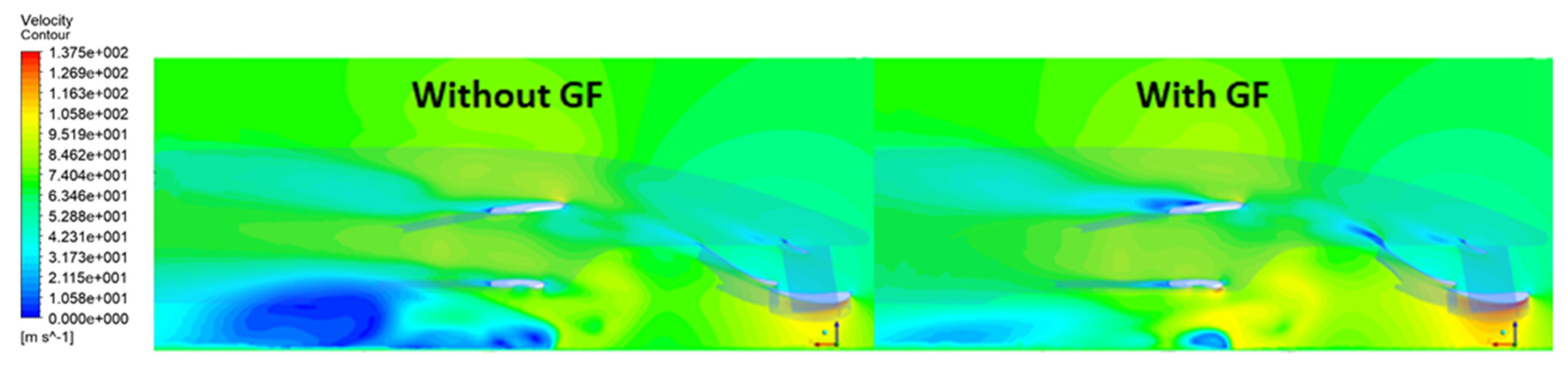

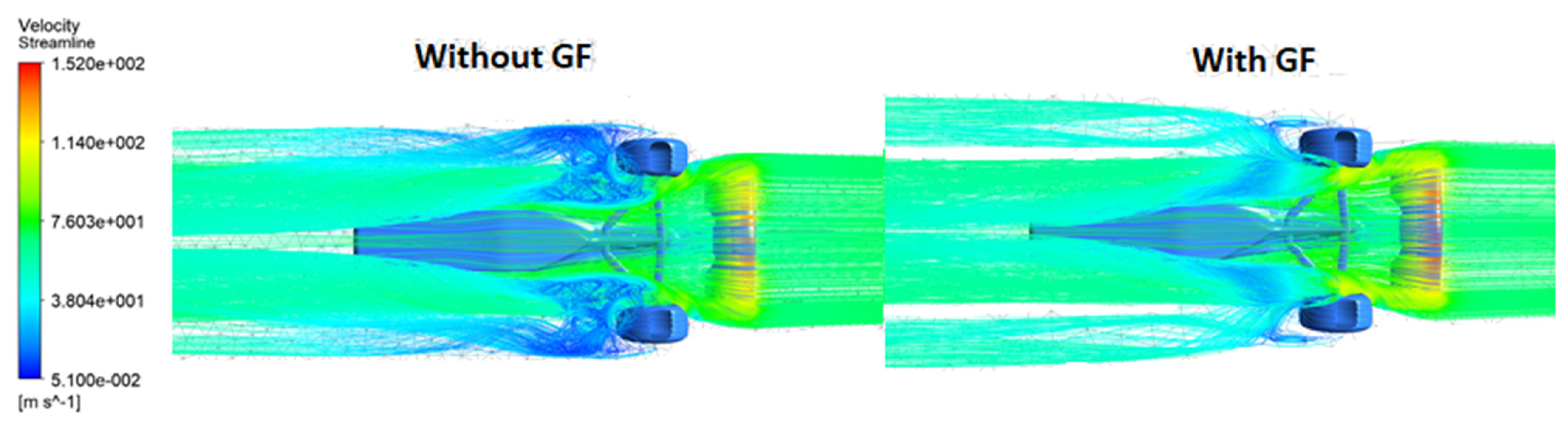

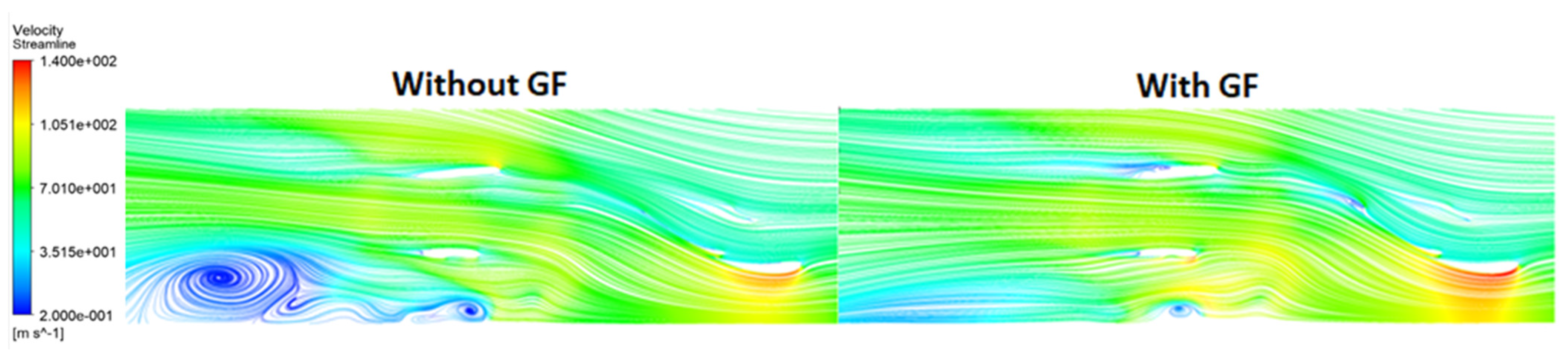

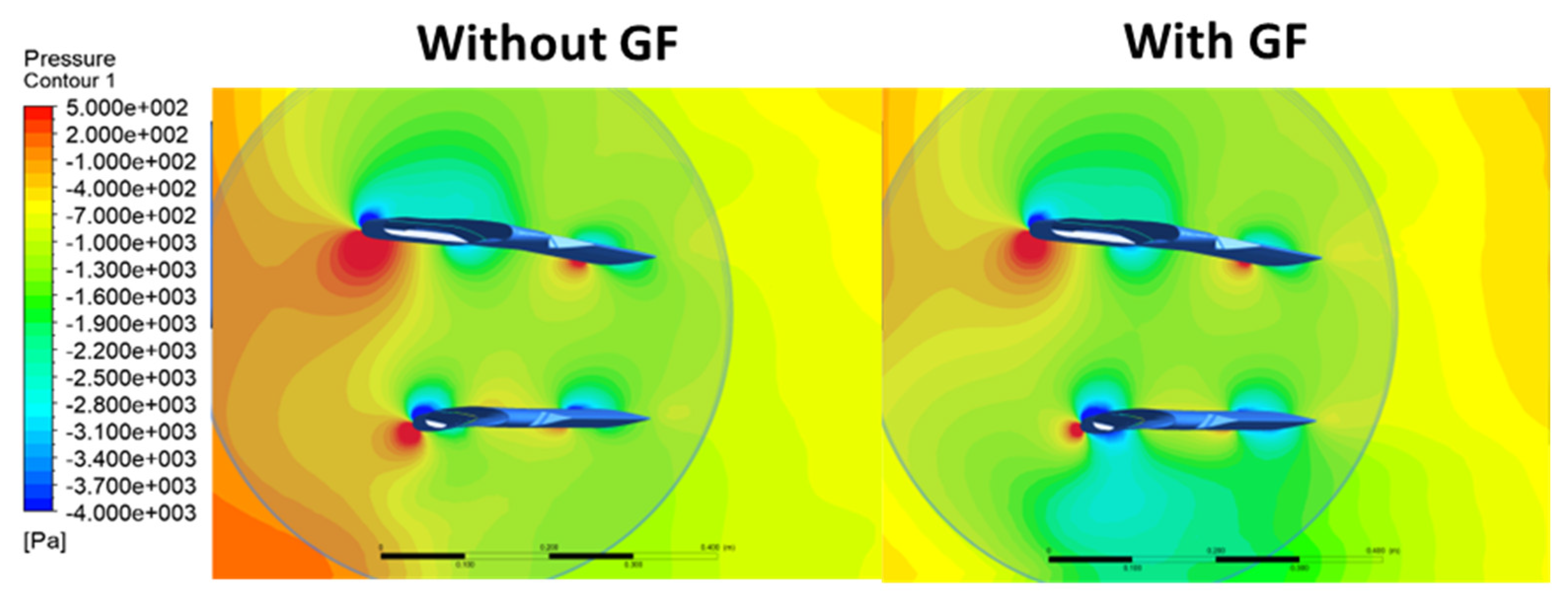

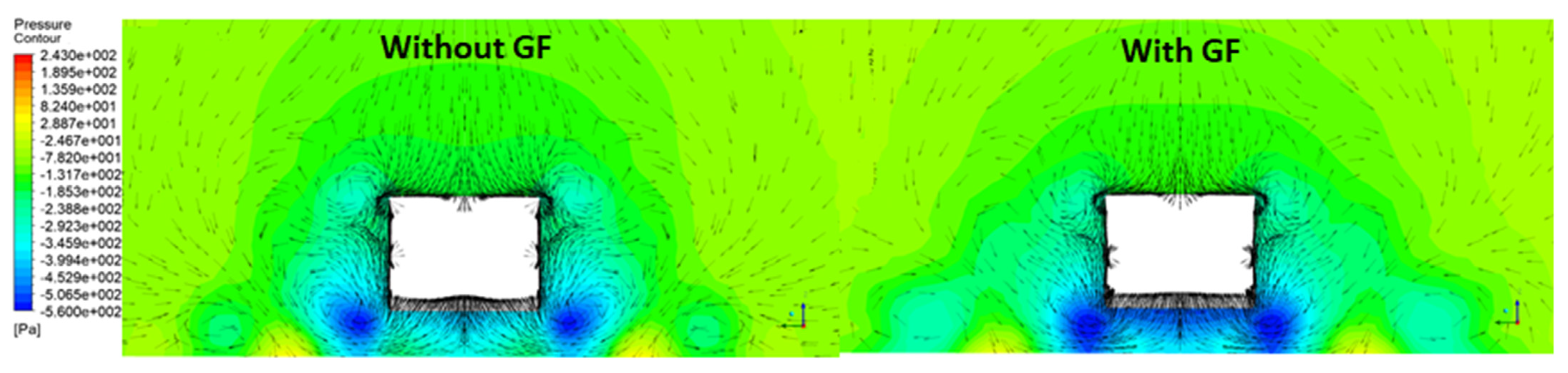

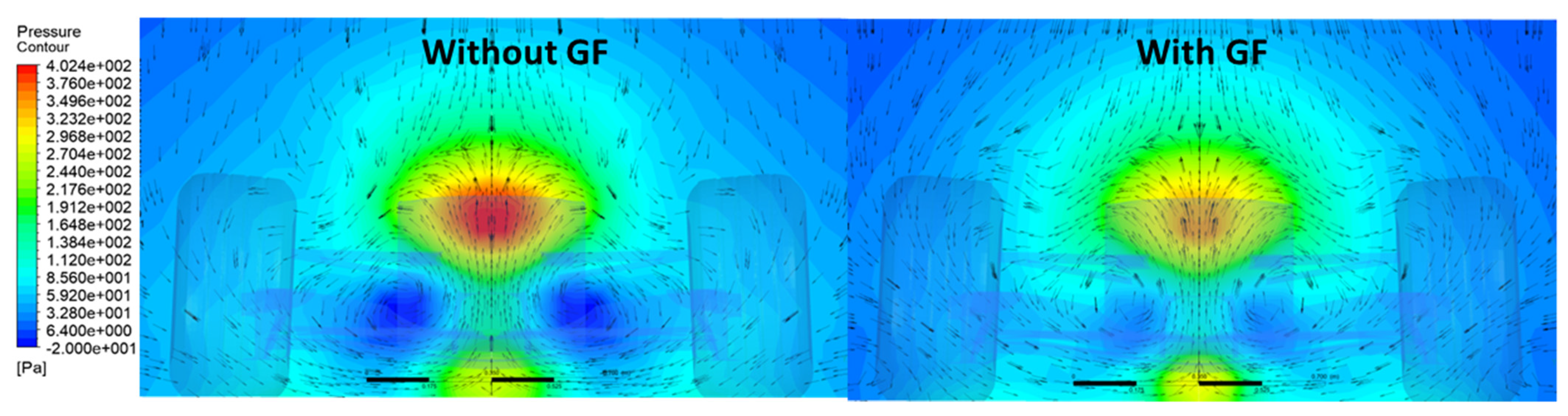

3.2. Fluid-Dynamic Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | Area |

| b | Wing span |

| c | Wing chord |

| Cd | Drag coefficient |

| Cl | Lift coefficient (downforce) |

| Cp | Pressure coefficient |

| d | Diameter |

| DR | Drag coefficient |

| E | Aerodynamic efficiency |

| h | Height of Gurney flap (percentage of the airfoil chord) |

| k | Turbulent kinetic energy |

| L | Lift (downforce) |

| lv | Vehicle length |

| p | Static pressure |

| s | Thickness |

| u | Velocity |

| u’ | Axial local velocity |

| Velocity at the domain inlet | |

| w | Width |

| y+ | Non dimensional boundary layer distance from wall |

| µ | Dynamic viscosity |

| ρ | Density |

| ω | Specific rate of dissipation |

Acronyms

| ext | External |

| GF | Gurney Flap |

| inf | Inferior |

| int | Internal |

| sup | Superior |

References

- Roberts, L.S.; Correia, J.; Finnis, M.V.; Knowles, K. Aerodynamic characteristic of a wing-and-flap configuration in ground effect and yaw. Proc. IMechE Part D J. Automob. Eng. 2016, 230, 841–854. [Google Scholar] [CrossRef]

- Zerihan, J.; Zhang, X. Aerodynamics of Gurney Flaps on a Wing in Ground Effect. AIAA J. 2001, 39, 772–780. [Google Scholar] [CrossRef]

- Jeffrey, D.; Zhang, X.; Hurst, D.W. Aerodynamics of Gurney Flaps on a Single-Element High-Lift Wing. J. Aircr. 2000, 37, 295–301. [Google Scholar] [CrossRef]

- Liebek, R.H. Design of Subsonic Airfoils for High Lift. J. Aircr. 1978, 15, 547–561. [Google Scholar] [CrossRef]

- Myose, R.; Papadakis, M.; Heron, I. Gurney Flap Experiments on Airfoils, Wings and Reflection Plane Model. J. Aircr. 1998, 35, 206–211. [Google Scholar] [CrossRef]

- Coles, D.; Wadcock, A.J. Flying-Hot-Wire Study of Flow Past an NACA 4412 Airfoil at Maximum Lift. AIAA J. 1979, 17, 321–329. [Google Scholar] [CrossRef]

- Thompson, B.E.; Whitelae, J.H. Trailing-Edge Region of Airfoils. J. Aircr. 1989, 26, 225–234. [Google Scholar] [CrossRef]

- Gerrard, J.H. The mechanics of the formation region of vortices behind bluff bodies. J. Fluid Mech. 1966, 25, 401–413. [Google Scholar] [CrossRef]

- Roshko, A. On the Drag and Shedding Frequency of Two-Dimensional Bluff Bodies; NACA TN 3169; National Advisory Committee Aeronautics: Moffett Field, CA, USA, 1954.

- Bearman, P.W.; Trueman, D.M. An Investigation of the Flow around Rectangular Cylinders. Aeronaut. J. 1972, 23, 229–237. [Google Scholar] [CrossRef]

- Bearman, P.W. Investigation of the flow behind a two-dimensional model with a blunt trailing edge and fitted with splitter plates. J. Fluids Mech. 1965, 21, 241–255. [Google Scholar] [CrossRef]

- Good, M.C.; Joubert, P.N. The form drag of two-dimensional bluff-plates immersed in turbulent boundary layers. J. Fluid Mech. 1968, 31, 547–582. [Google Scholar] [CrossRef]

- Kennedy, J.L.; Marsden, D.J. The development of High Lift, Single-component Airfoil Sections. Aeronaut. J. 1979, 30, 343–359. [Google Scholar] [CrossRef]

- Zhang, X.; Zerihan, J. Off-Surface Aerodynamic Measurements of a Wing in Ground Effect. J. Aircr. 2003, 40, 716–725. [Google Scholar] [CrossRef]

- Zhang, X.; Zerihan, J. Aerodynamics of a Double-Element Wing in Ground Effect. AIAA J. 2003, 41, 1007–1016. [Google Scholar] [CrossRef]

- Tang, D.; Dowell, E.H. Aerodynamic loading for an airfoil with an oscillating gurney flap. J. Aircr. 2007, 44, 1245–1257. [Google Scholar] [CrossRef]

- Camocardi, M.; Marañon, J.; Delnero, J.; Colman, J. Experimental study of a naca 4412 airfoil with movable gurney flap. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011. [Google Scholar]

- Lee, T. Piv study of near-field tip vortex behind perforated gurney flaps. Exp. Fluids 2010, 50, 351–361. [Google Scholar] [CrossRef]

- Cole, J.A.; Vieira, B.A.O.; Coder, J.G.; Premi, A.; Maughmer, M.D. Experimental Investigation into the Effect of Gurney Flaps on Various Airfoils. J. Aircr. 2013, 50, 1287–1294. [Google Scholar] [CrossRef]

- Min, B.Y.; Sankar, L.N.; Rajmohan, N.; Prasad, J.V.R. Computational Investigation of Gurney Flap Effects on Rotors in Forward Flight. J. Aircr. 2009, 46, 1957–1964. [Google Scholar] [CrossRef]

- Pastrikakis, V.A.; Steijl, R.; Barakos, G.N. Effect of active Gurney flaps on overall helicopter flight envelope. Aeronaut. J. 2016, 120, 1230–1261. [Google Scholar] [CrossRef]

- Mohammadi, M.; Doosttalab, A.; Doosttalab, M. The effect of various gurney flaps shapes on the performace of wind turbine airfoils. In Proceedings of the ASME Early Career Technical Conference, Atlanta, GA, USA, 2–3 November 2012. [Google Scholar]

- Woodgate, M.A.; Pastrikakis, V.A.; Barakos, G.N. Rotor Computations with Active Gurney Flaps. Adv. Fluid-Struct. Interact. 2016, 133, 133–166. [Google Scholar]

- Fernandez-Gamiz, U.; Gomez-Mármol, M.; Chacón-Rebollo, T. Computational Modeling of Gurney Flaps and Microtabs by POD Method. Energies 2018, 11, 2091. [Google Scholar] [CrossRef]

- Aramendia, I.; Fernandez-Gamiz, U.; Zulueta, E.; Saenz-Aguirre, A.; Teso-Fz-Betoño, D. Parametric Study of a Gurney Flap Implementation in a DU91W(2)250 Airfoil. Energies 2019, 12, 294. [Google Scholar] [CrossRef]

- Cravero, C. Aerodynamic performance prediction of a profile in ground effect with and without a Gurney flap. ASME J. Fluids Eng. 2017, 139. [Google Scholar] [CrossRef]

- Cravero, C.; Marogna, N.; Marsano, D. A Numerical Study of correlation between recirculation length and shedding frequency in vortex shedding phenomena. WSEAS Trans. Fluid Mech. 2021, 16, 48–62. [Google Scholar] [CrossRef]

- Cravero, C.; Marsano, D. Numerical prediction of tonal noise in centrifugal blowers. In Proceedings of the Turbo Expo 2018: Turbomachinery Technical Conference & Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Niccolini Marmont Du Haut Champ, C.A.; Silvestri, P. Experimental and numerical vibro-acoustic investigation on a trimmed car door to analyze slamming event. Appl. Acoust. 2020, 166, 107380. [Google Scholar] [CrossRef]

- Guerrero, J.E.; Pacioselli, C.; Pralits, J.O.; Negrello, F.; Silvestri, P.; Lucifredi, A.; Bottaro, A. Preliminary design of a small-sized flapping UAV: I. Aerodynamic performance and static longitudinal stability. Meccanica 2016, 51, 1343–1367. [Google Scholar] [CrossRef]

- Huminic, A.; Chiru, A. On CFD Investigations of Vehicle Aerodynamics with Rotating Wheels’ Simulation; Technical Paper 2006-01-08-04; SAE World Congress: Detroit, MI, USA, 2006. [Google Scholar]

- Wang, Y.N.; Tseng, C.Y.; Huang, Y.L.; Leong, J.C. Investigation of 2004 Ferrari Formula One Race Car Wing Effects. In Proceedings of the International Symposium on Computer, Communication, Control and Automation, Tainan, Taiwan, 5–7 May 2010; pp. 85–88. [Google Scholar]

- Kieffer, W.; Moujares, S.; Armbya, N. CFD study of section characteristics of Formula Mazda race car wings. Math. Comput. Model. 2006, 43, 1275–1287. [Google Scholar] [CrossRef]

- Huminic, A.; Huminic, G. CFD Investigations of an Open-Wheel Race Car. In Proceedings of the 4th European Automotive Simulation Conference, Munich, Germany, 6–7 July 2009. [Google Scholar]

- Soso, M.D.; Wilson, P.A. Aerodynamic of a wing in ground effect in generic racing car wake flows. Proc. IMechE Part D J. Automob. Eng. 2006, 220, 1–13. [Google Scholar] [CrossRef]

- Newbon, J.; Dominy, R.; Sims-Williams, D. CFD Investigation of the Effect of the Salient Flow Features in the Wake of a Generic Open-Wheel Race Car. SAE Int. J. Passeng. Cars-Mech. Syst. 2015, 8, 217–232. [Google Scholar] [CrossRef][Green Version]

- ANSYS Inc. Ansys CFX Theory Guide; v.17; ANSYS Inc.: Canonsburg, PA, USA, 2016. [Google Scholar]

- Zerihan, J.; Zhang, X. Aerodynamics of a Single Element Wing in Ground Effect. J. Aircr. 2000, 37, 1058. [Google Scholar] [CrossRef]

- Zerihan, J. An Investigation into the Aerodynamics of Wings in Ground Effect. Ph.D. Thesis, University of Southampton, Southampton, UK, 2001; 236p. [Google Scholar]

| Suspensions | Tire | Vehicle Body | |||

|---|---|---|---|---|---|

| Downforce | Drag | Downforce | Drag | Downforce | Drag |

| Upper: +22.7 | Upper: +2.6 | +37.9 | −25.8 | +62.9 | +48.7 |

| Lower: +62.8 | Lower: +57.4 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Basso, M.; Cravero, C.; Marsano, D. Aerodynamic Effect of the Gurney Flap on the Front Wing of a F1 Car and Flow Interactions with Car Components. Energies 2021, 14, 2059. https://doi.org/10.3390/en14082059

Basso M, Cravero C, Marsano D. Aerodynamic Effect of the Gurney Flap on the Front Wing of a F1 Car and Flow Interactions with Car Components. Energies. 2021; 14(8):2059. https://doi.org/10.3390/en14082059

Chicago/Turabian StyleBasso, Mattia, Carlo Cravero, and Davide Marsano. 2021. "Aerodynamic Effect of the Gurney Flap on the Front Wing of a F1 Car and Flow Interactions with Car Components" Energies 14, no. 8: 2059. https://doi.org/10.3390/en14082059

APA StyleBasso, M., Cravero, C., & Marsano, D. (2021). Aerodynamic Effect of the Gurney Flap on the Front Wing of a F1 Car and Flow Interactions with Car Components. Energies, 14(8), 2059. https://doi.org/10.3390/en14082059