Performance of Hydraulically Fractured Wells in Xinjiang Oilfield: Experimental and Simulation Investigations on Laumontite-Rich Tight Glutenite Formation

Abstract

1. Introduction

2. Laboratory Investigation on Laumontite-Rich Tight Glutenite

2.1. Sample Preparation

2.2. Experimental Contents

- Mineral composition and physical properties analysis;

- Triaxial compression tests;

- Stress-coupled permeability tests;

- Fracture proppant conductivity tests.

2.3. Experimental Results

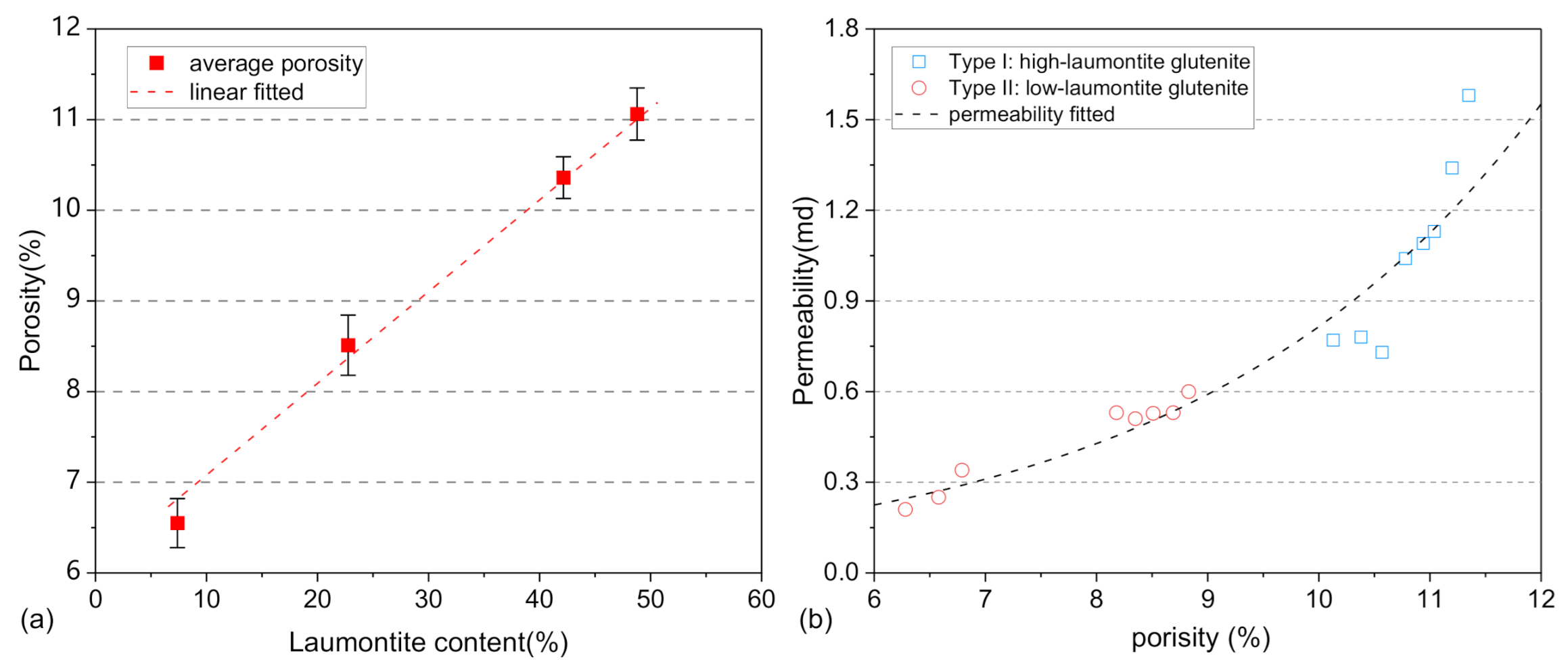

2.3.1. Mineral Composition and Physical Properties

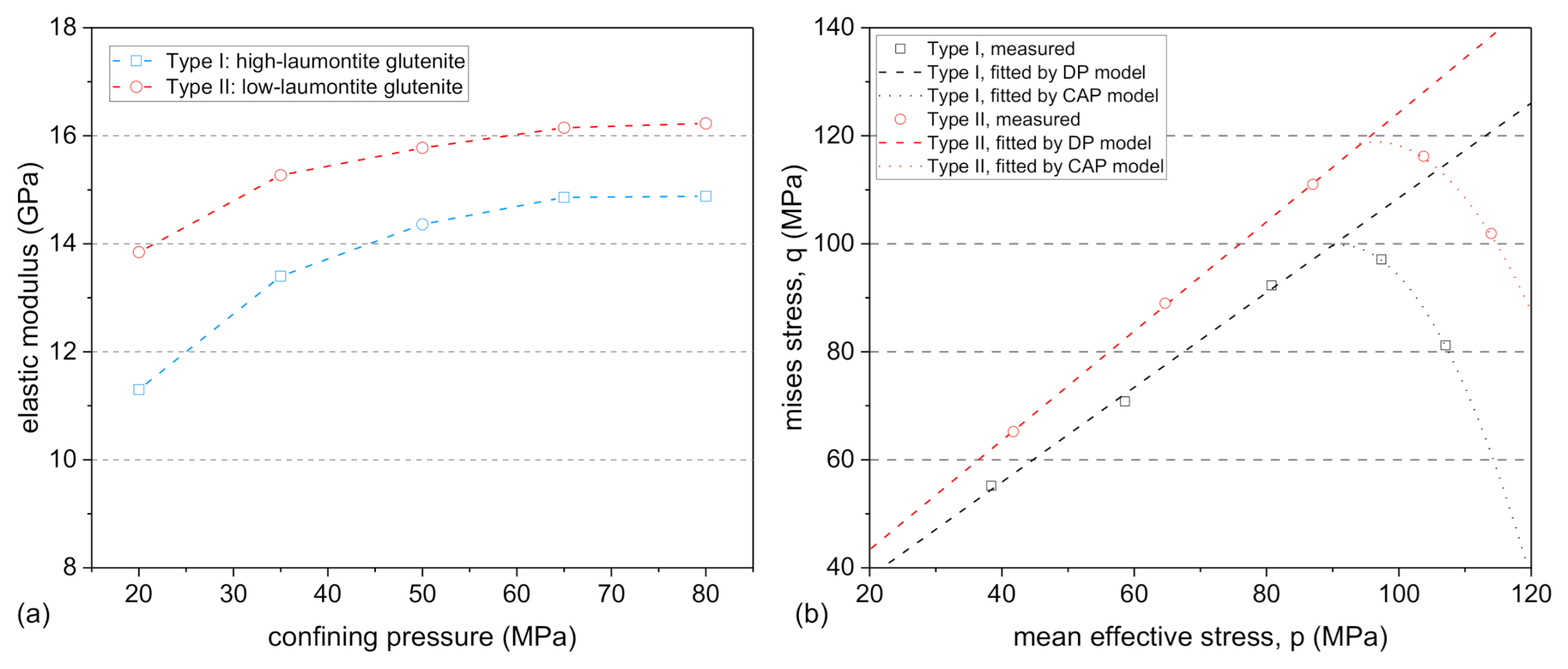

2.3.2. Rock Mechanical Properties

- (1)

- Elastic deformation and strength analysis

- (2)

- Post yield deformation analysis

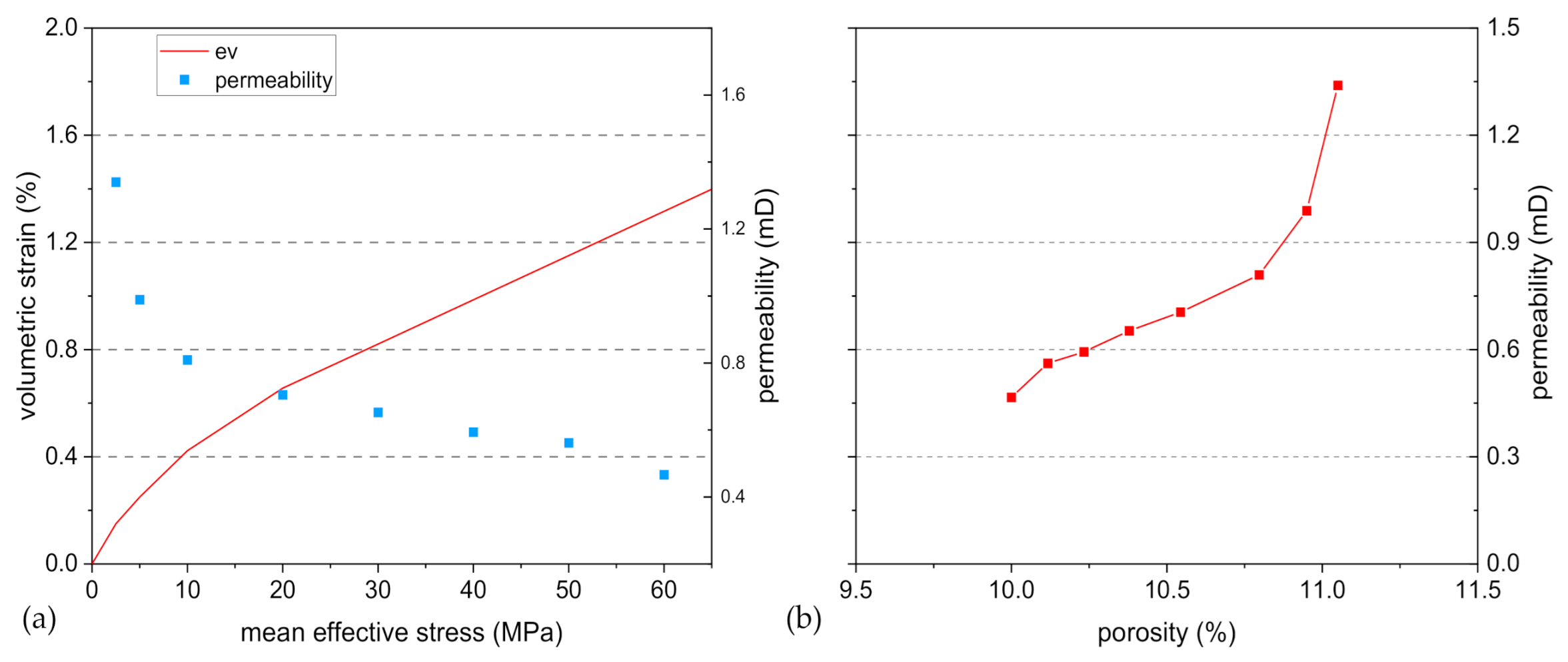

2.3.3. Stress-induced Permeability Reduction or Enhancement

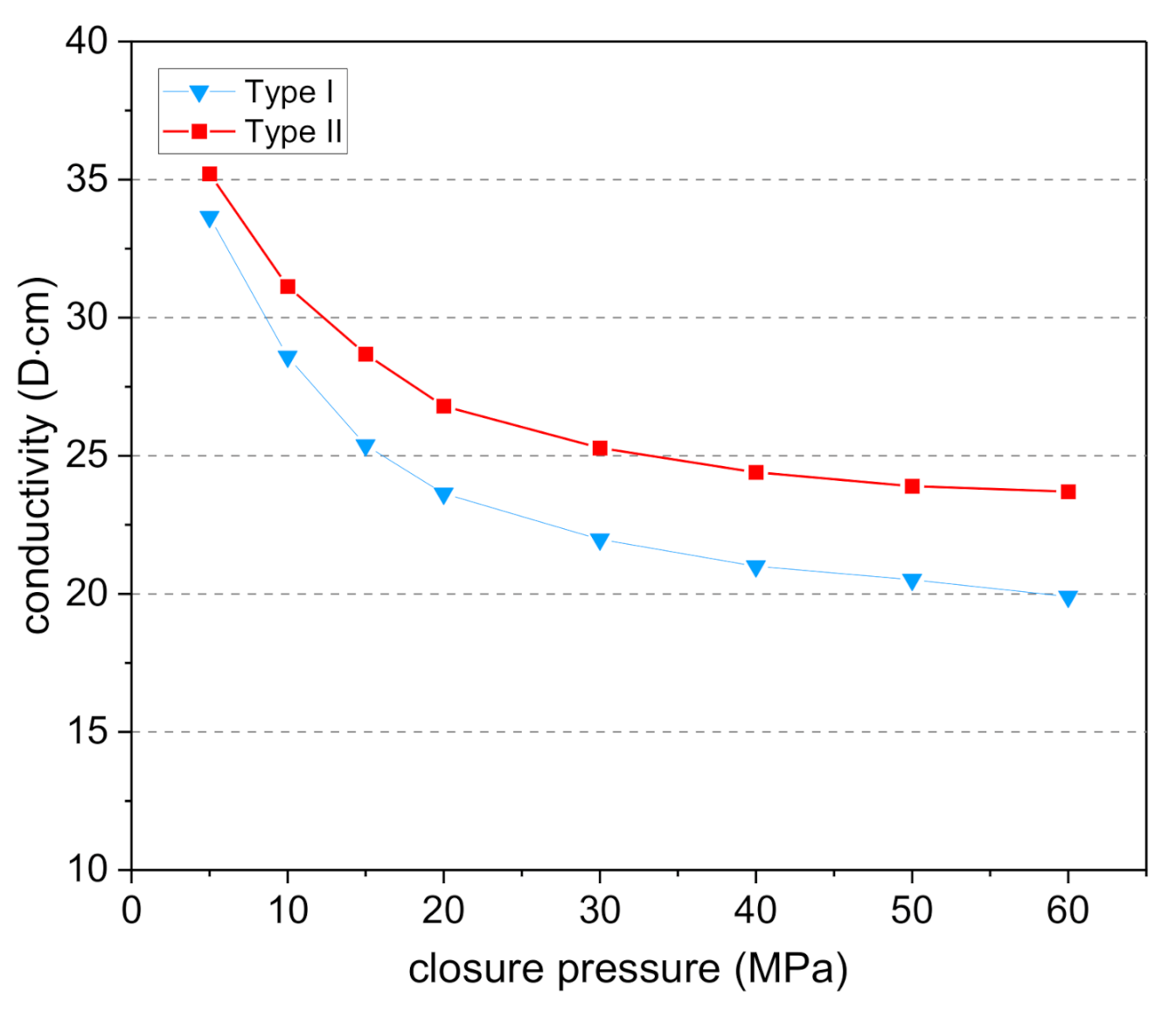

2.3.4. Fracture Proppant Conductivity Evolution

2.4. Hints for Well Production Evaluation

- Glutenite rocks with higher laumontite content have higher initial porosity and permeability. However, the permeability may vary significantly due to the pore deformation caused by the stress state. Therefore, initial porosity and permeability are not always the decisive factor of production.

- Formations with higher laumontite content have lower elastic modulus and yield strength, which means they are more likely to deform and yield. There are three types of rock deformation: elastic shear compression, shear dilation and plastic shear enhanced compaction. The mechanisms by which these three deformation forms change the pore structure are quite different, so their influence on permeability is different. As a consequence, permeability evolution under different stress state must be considered for evaluating production.

- Experiments on fracture proppant conductivity show that formations with higher laumontite content have a higher degree of proppant embedding, and the conductivity decreases faster with the increase in closure stress. Since hydraulic fractures are the main drainage channels for tight oil, fracture conductivity evolution should also be considered when evaluating production.

3. Fully Coupled Finite Element Model (FEM) for Production Simulation

3.1. Numerical Scheme

3.1.1. Mechanical Models

3.1.2. Fluid Flow Models

3.1.3. Permeability Evolution Model

- (1)

- Elastic deformation stage.

- (2)

- Shear dilation stage.

- (3)

- Shear enhanced compaction stage.

- (4)

- Fracture permeability evolution

3.2. Case Verification

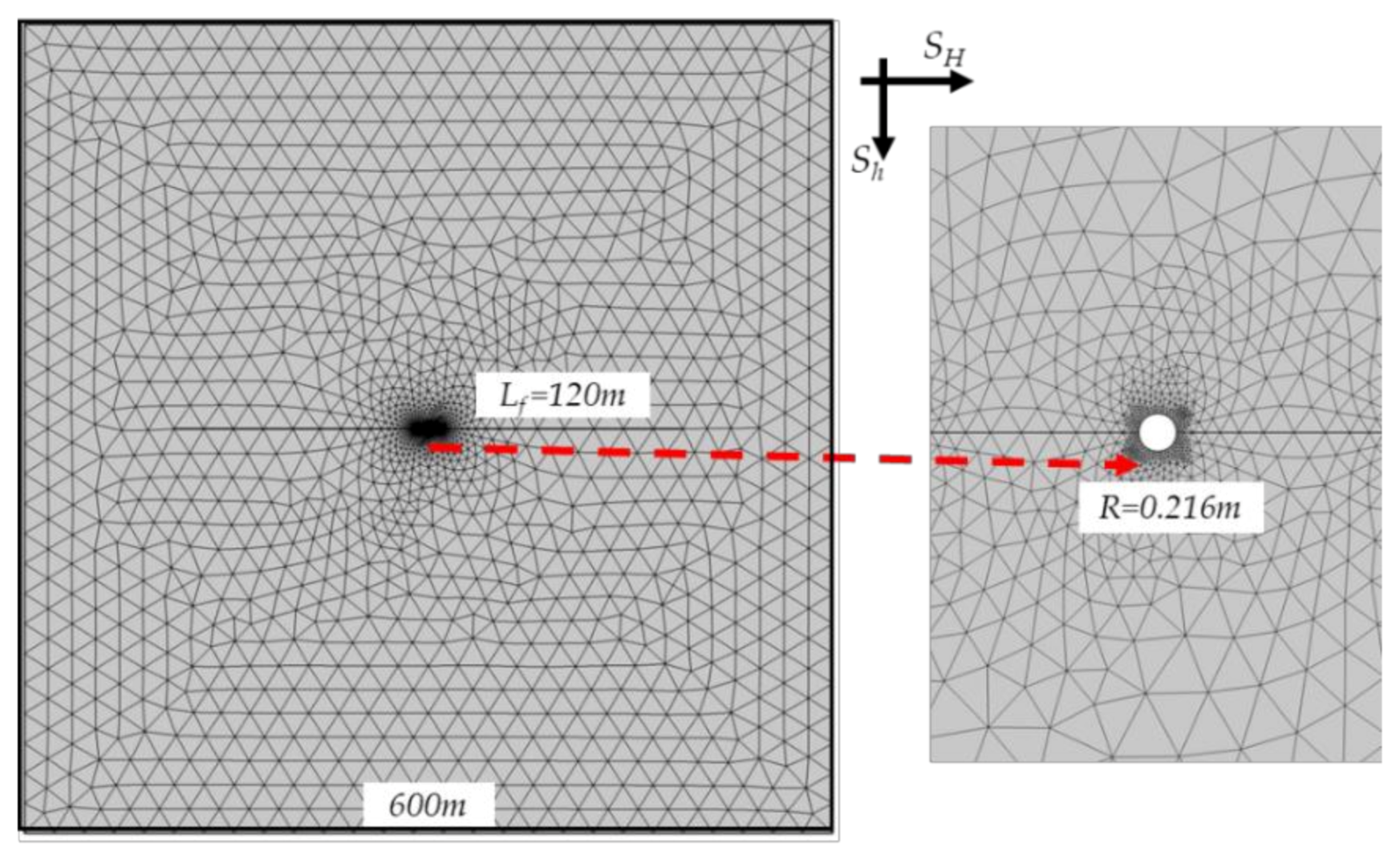

3.2.1. Model Description and Parameters

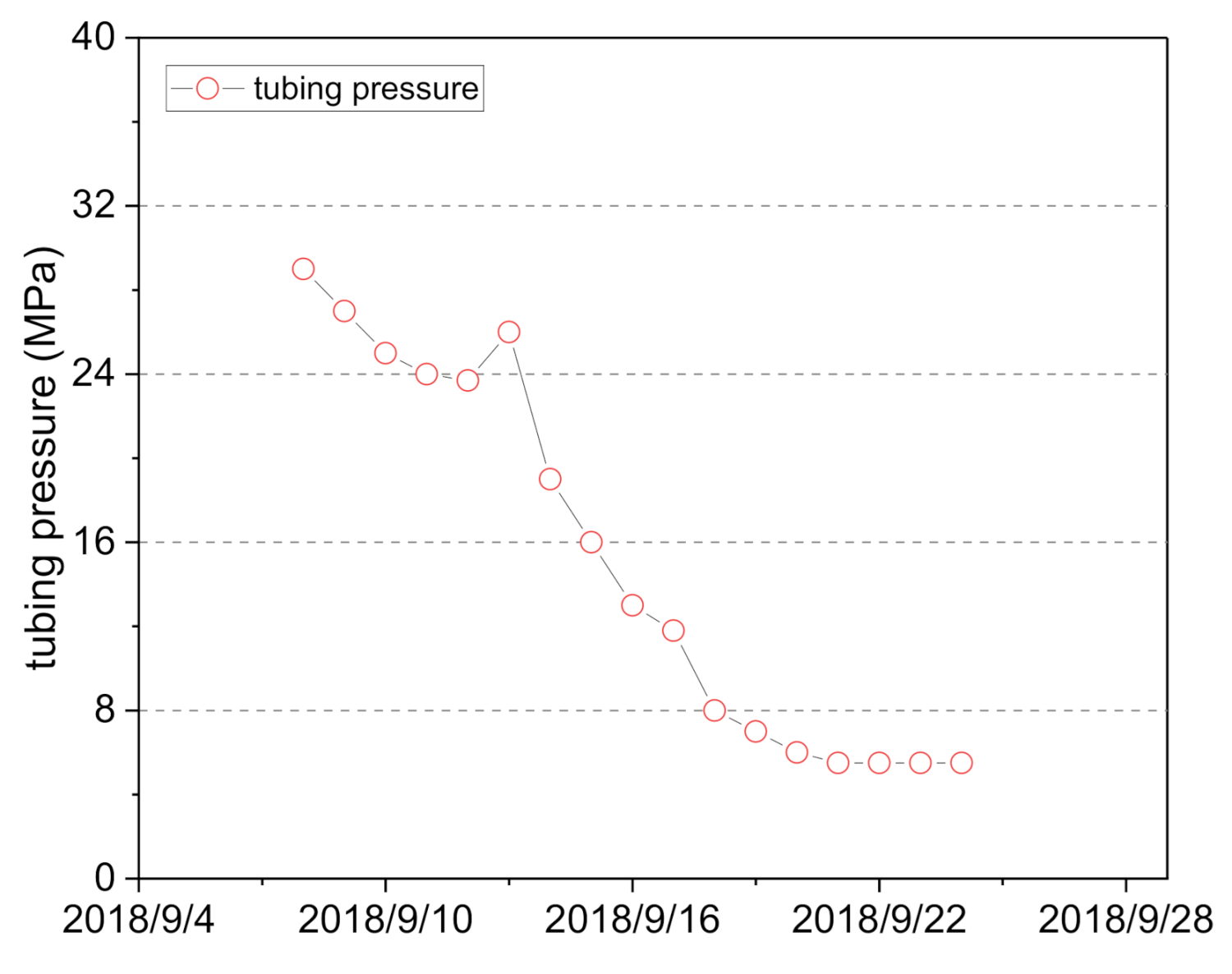

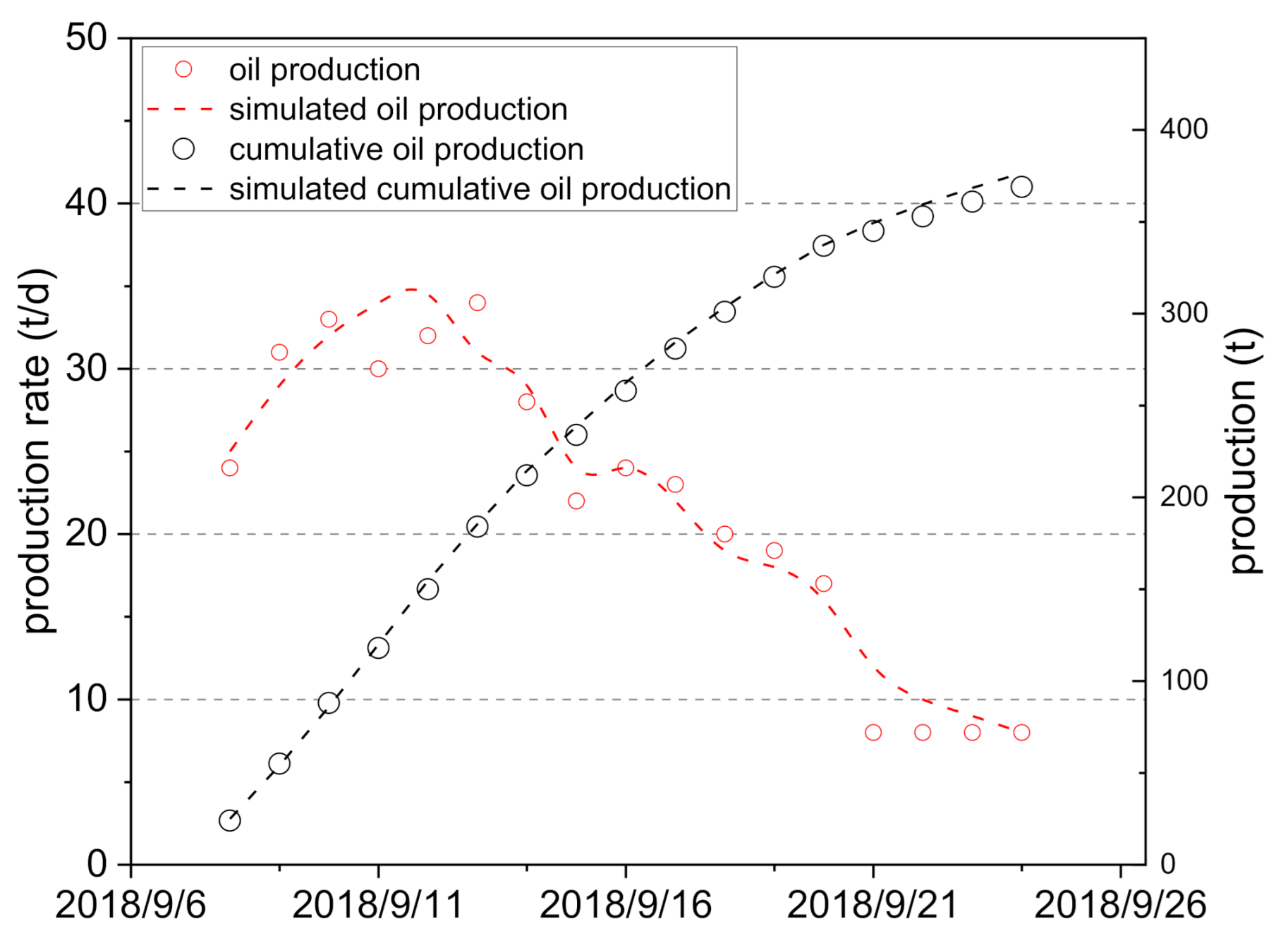

3.2.2. Comparison of Simulation and Field Data

3.3. Discussion

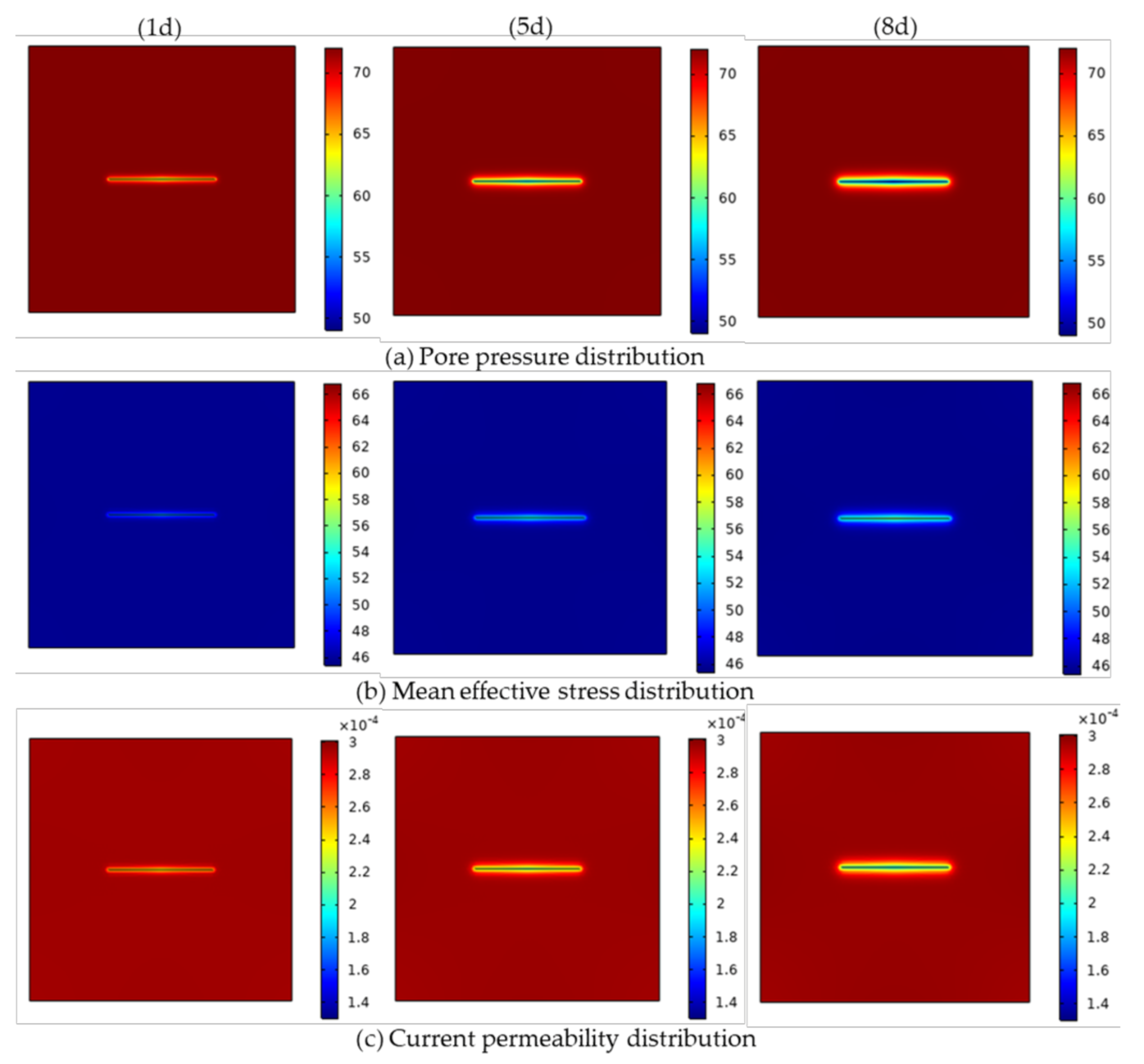

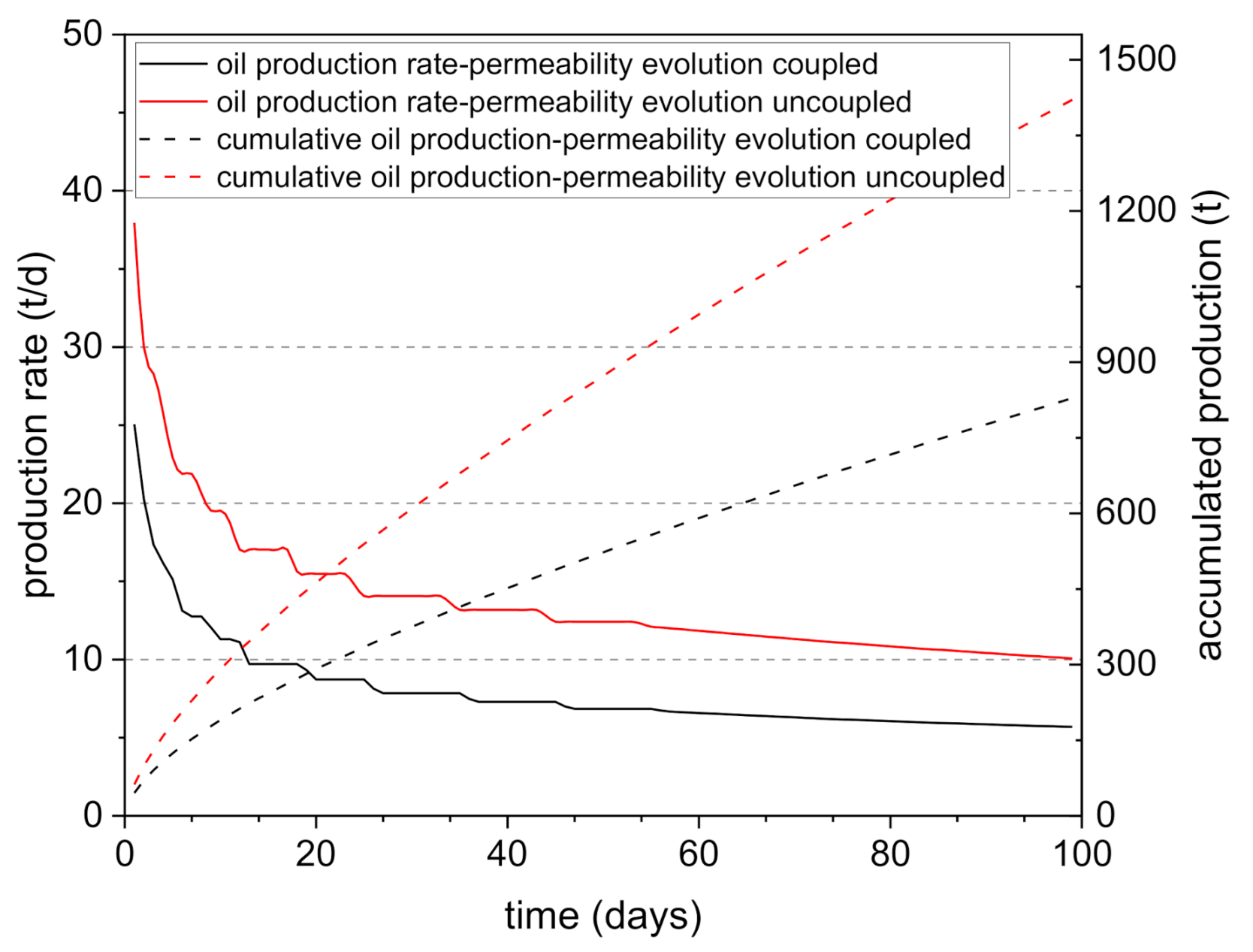

3.3.1. Effect of Stress-Induced Permeability Evolution on Production

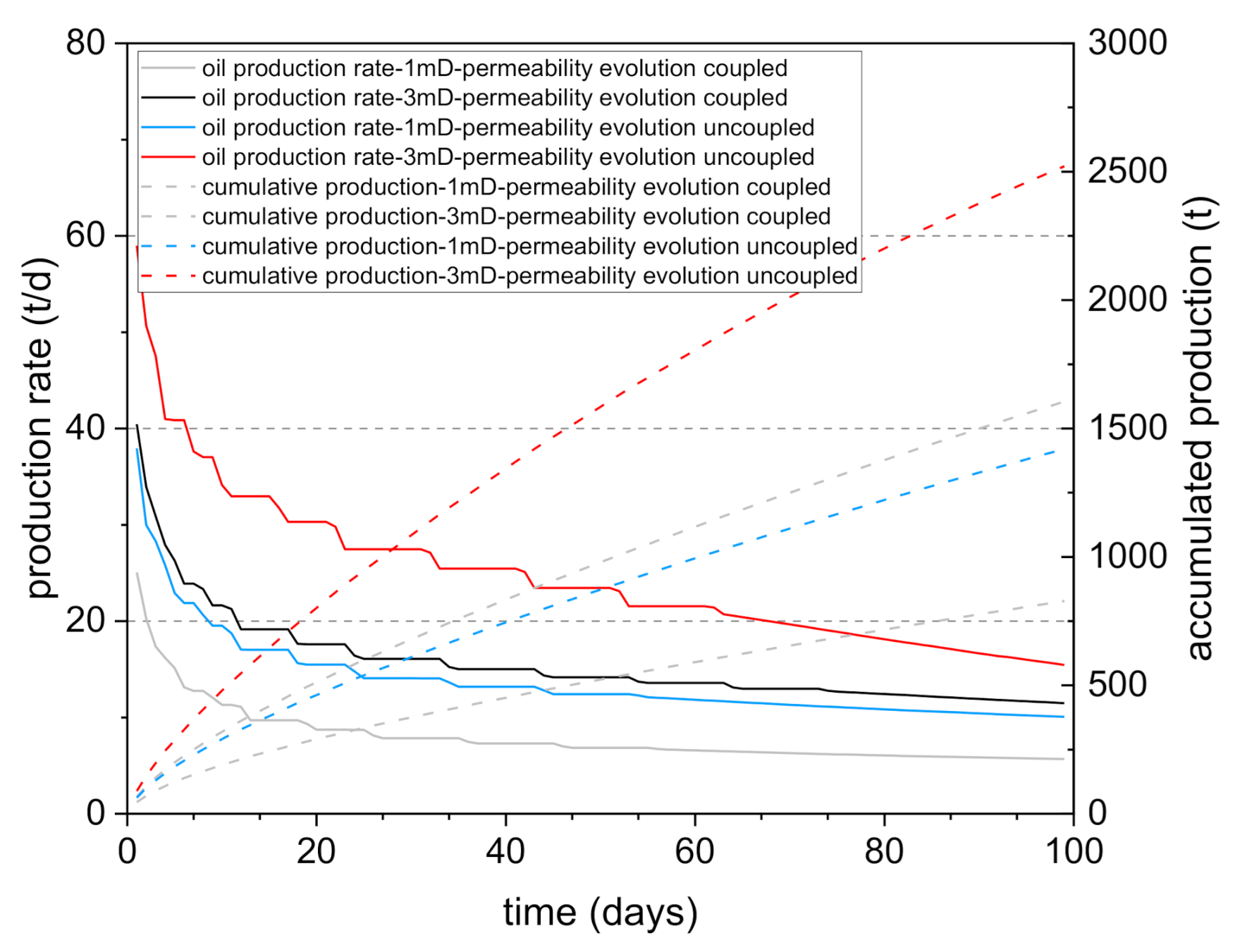

3.3.2. Effect of Initial Permeability on Production

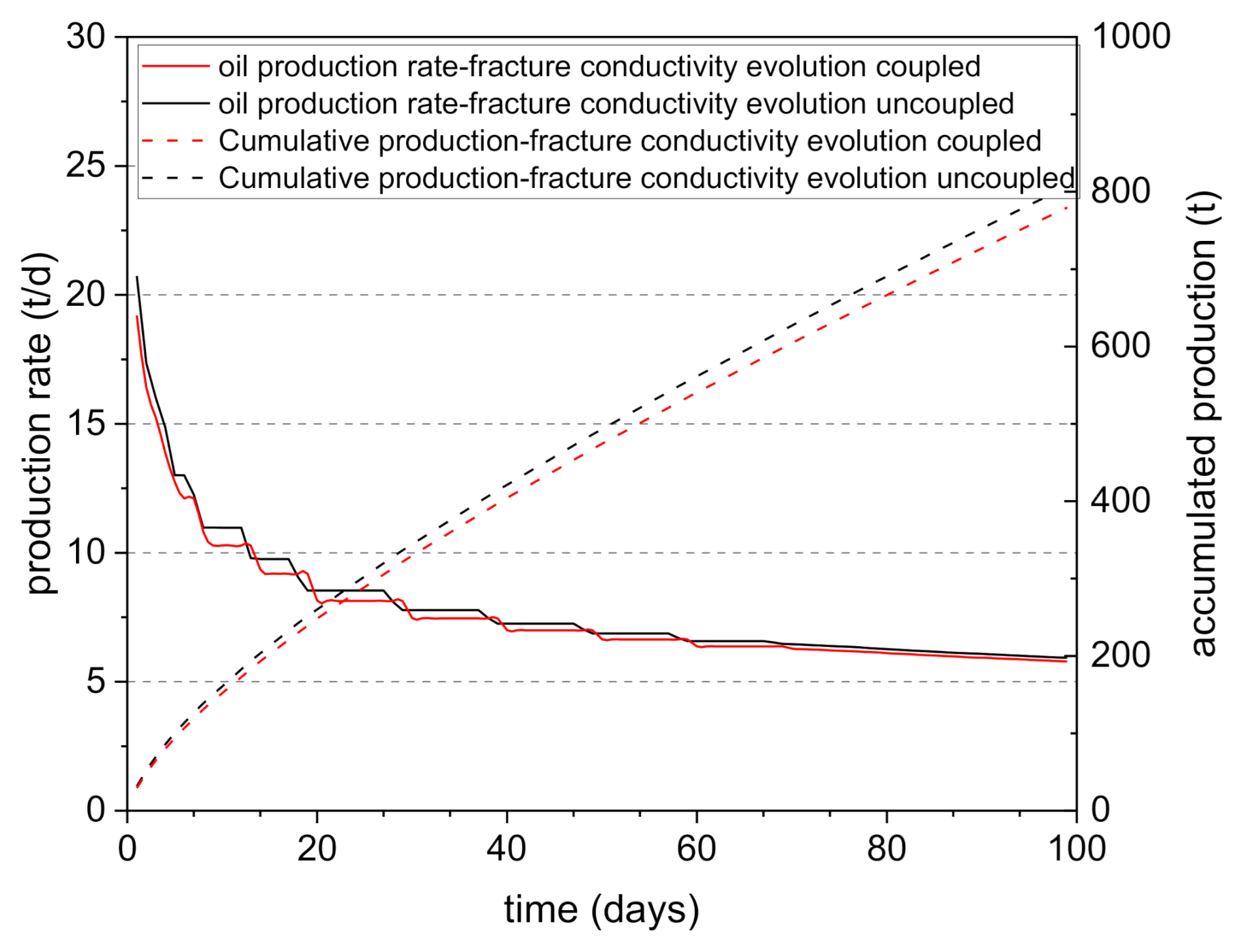

3.3.3. Effect of Fracture Conductivity Evolution on Production

4. Conclusions

- The laboratory data indicated that the tight glutenite formation with higher laumontite content has higher initial porosity and permeability but lower yield strength and more severe stress sensitivity in permeability. Through the rock mechanical tests and stress-coupled permeability tests, we found that there are three types of rock deformation that occur during the loading process: elastic compression, shear dilation and shear enhanced compaction. Both elastic compression and shear enhanced compaction will cause a reduction in rock porosity and permeability.

- Experiments on fracture proppant conductivity showed that formations with higher laumontite content have a higher degree of proppant embedding, and the conductivity decreases faster with the increase in closure stress.

- A fully coupled finite element model (FEM) considering stress-induced permeability evolution was introduced to simulate the production process. Permeability evolution models of three different deformation stages were presented, respectively. Simulation results showed that our model is in good agreements with the well testing data.

- The simulated oil production characteristics for permeability evolution coupled and uncoupled models were compared. Results showed the strong stress-induced permeability reduction is the major factor that laumontite causing the low and quickly declining oil rates. The initial permeability has a positive effect on productivity and the productivity variance will reduce when stress-induced permeability reduction is considered. Stress-induced fracture permeability reduction has a slight influence on productivity, which can be neglected when evaluating reservoirs in the studied area.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EIA. Natural Gas Gross Withdrawals and Production. Natural Gas. 2017. Available online: https://www.eia.gov/todayinenergy/detail.php?id=34212 (accessed on 10 March 2021).

- Zhang, R.; Hou, B.; Tan, P.; Muhadasi, Y.; Fu, W.; Dong, X.; Chen, M. Hydraulic fracture propagation behavior and diversion characteristic in shale formation by temporary plugging fracturing. J. Pet. Sci. Eng. 2020, 190, 107063. [Google Scholar] [CrossRef]

- Chen, Y.; Jin, Y.; Chen, M.; Yi, Z.; Zheng, X. Quantitative evaluation of rock brittleness based on the energy dissipation principle, an application to type II mode crack. J. Nat. Gas Sci. Eng. 2017, 45, 527–536. [Google Scholar] [CrossRef]

- Du, H.; Carpenter, K.; Hui, D.; Radonjic, M. Microstructure and micromechanics of shale rocks: Case study of marcellus shale. Facta Univ. Ser. Mech. Eng. 2017, 15, 331–340. [Google Scholar] [CrossRef][Green Version]

- Chen, B.; Xu, B.; Li, B.; Kong, M.; Wang, W.; Chen, H. Understanding the performance of hydraulically fractured wells in the laumontite-rich tight glutenite formation. J. Pet. Sci. Eng. 2020, 185, 106600. [Google Scholar] [CrossRef]

- Noh, J.; Boles, J. Origin of Zeolite Cements in the Miocene Sandstones, North Tejon Oil Fields, California. J. Sediment. Res. 1993, 63, 248–260. [Google Scholar]

- Hall, A. The occurrence of laumontite in volcanic and volcaniclastic rocks from southern Sumatra. J. Asian Earth Sci. 1997, 15, 55–59. [Google Scholar] [CrossRef]

- Frost, B.; Surdam, R.; Crossey, L. Secondary porosity in laumontite-bearing sandstones. AAPG Bull. Am. Assoc. Pet. Geol. 1982, 66, 569–570. [Google Scholar]

- Duan, W.; Luo, C.; Lou, Z.; Liu, J.; Jin, A.; Zhu, R. Diagenetic differences caused by the charging of natural gases with various compositions—A case study on the lower Zhuhai Formation clastic reservoirs in the WC-A sag, the Pearl River Mouth Basin. Mar. Pet. Geol. 2017, 81, 149–168. [Google Scholar] [CrossRef]

- Yuan, G.; Cao, Y.; Zhang, Y.; Gluyas, J. Diagenesis and reservoir quality of sandstones with ancient “deep” incursion of meteoric freshwater—An example in the Nanpu Sag, Bohai Bay Basin, East China. Mar. Pet. Geol. 2017, 82, 444–464. [Google Scholar] [CrossRef]

- White, C.; Ruiz-Salvador, A.R.; Lewis, D. Pressure-Induced Hydration Effects in the Zeolite Laumontite. Angew. Chem. Int. Ed. 2004, 43, 469–472. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Ding, X.; Yang, P.; Liu, Y.; Jiang, Q.; Zhang, S. Reservoir formation mechanism analysis and deep high-quality reservoir prediction in Yingcheng Formation in Longfengshan area of Songliao Basin, China. Petroleum 2016, 2, 334–343. [Google Scholar] [CrossRef]

- David, C.; Wong, T.-F.; Zhu, W.; Zhang, J. Laboratory measurement of compaction-induced permeability change in porous rocks: Implications for the generation and maintenance of pore pressure excess in the crust. Pure Appl. Geophys. 1994, 143, 425–456. [Google Scholar] [CrossRef]

- Ulusay, R. The ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 2007–2014; Springer International Publishing: Cham, Switzerland, 2015; p. 293. [Google Scholar]

- Brace, W.F.; Walsh, J.B.; Frangos, W.T. Permeability of granite under high pressure. J. Geophs. Res. 1968, 73, 2225–2236. [Google Scholar] [CrossRef]

- Rider, M.H. The Geological Interpretation of Well Logs; Cambridge University Press: Cambridge, UK, 2018. [Google Scholar]

- Wong, T.; Baud, P. The brittle-ductile transition in porous rock: A review. J. Struct. Geol. 2012, 44, 25–53. [Google Scholar] [CrossRef]

- Wang, R. Fundamentals of rock mechanics. Eng. Geol. 1981, 17, 302. [Google Scholar] [CrossRef]

- Meng, F.; Baud, P.; Ge, H.; Wong, T. The Effect of Stress on Limestone Permeability and Effective Stress Behavior of Damaged Samples. J. Geophys. Res. Solid Earth 2019, 124, 376–399. [Google Scholar] [CrossRef]

- Wang, J.; Ge, H.; Wang, X.; Shen, Y.; Liu, T.; Zhang, Y.; Meng, F. Effect of Clay and Organic Matter Content on the Shear Slip Properties of Shale. J. Geophys. Res. Solid Earth 2019, 124, 9505–9525. [Google Scholar] [CrossRef]

- Wong, T.; David, C.; Zhu, W. The transition from brittle faulting to cataclastic flow in porous sandstones; mechanical deformation. J. Geophys. Res. Solid Earth 1997, 102, 3009–3025. [Google Scholar] [CrossRef]

- Baud, P.; Reuschlé, T.; Ji, Y.; Cheung, C.S.N.; Wong, T.F. Mechanical compaction and strain localization in Bleurswiller sandstone. J. Geophys. Res. Solid Earth 2015, 120, 6501–6522. [Google Scholar] [CrossRef]

- Baud, P.; Klein, E.; Wong, T.F. Compaction localization in porous sandstones: Spatial evolution of damage and acoustic emission activity. J. Struct. Geol. 2004, 26, 603–624. [Google Scholar] [CrossRef]

- Wu, R.; Deng, J.; Liu, W.; Mao, S.; Sun, J.; Yan, M.; Li, M.; Li, Y. Numerical investigation of fluid injection into poorly consolidated geomaterial considering shear dilation and compaction. J. Pet. Sci. Eng. 2018, 168, 119–132. [Google Scholar] [CrossRef]

- Ottosen, N.S.; Ristinmaa, M. The Mechanics of Constitutive Modeling; Elsevier Science Ltd.: Amsterdam, The Netherlands, 2005; pp. 145–202. [Google Scholar]

- Li, L.; Li, X.; Wang, Y.; Qin, C.; Li, B.; Luo, Y.; Feng, J. Investigating the Interaction Effects between Reservoir Deformation and Hydrate Dissociation in Hydrate-Bearing Sediment by Depressurization Method. Energies 2021, 14, 548. [Google Scholar]

- McKee, C.R.; Bumb, A.C.; Koenig, R.A. Stress-Dependent Permeability and Porosity of Coal and Other Geologic Formations. SPE Form. Eval. 1988, 3, 81–91. [Google Scholar] [CrossRef]

- Paterson, M.S. The equivalent channel model for permeability and resistivity in fluid-saturated rock—A re-appraisal. Mech. Mater. 1983, 2, 345–352. [Google Scholar] [CrossRef]

| Well | Depth (m) | Type | Average Mineralogy Composition (%) | Porosity (%) | ||||

|---|---|---|---|---|---|---|---|---|

| Clay | Quartz | Feldspar | Calcite | Laumontite | ||||

| Well-1 | 4200–4207 | I | 3.07 | 32.15 | 13.69 | 2.3 | 48.79 | 11.00 |

| Well-2 | 4160–4172 | I | 4.53 | 29.31 | 17.63 | 6.38 | 42.15 | 10.36 |

| Well-3 | 3958–3965 | II | 4.69 | 44.2 | 21.9 | 6.45 | 22.76 | 8.51 |

| Well-4 | 4012–4025 | II | 3.99 | 49.71 | 28.41 | 10.51 | 7.38 | 6.55 |

| Parameters | Value | Unit | Definition |

|---|---|---|---|

| H | 15 | m | Reservoir thickness |

| ϕ | 0.11 | - | Porosity |

| k0 | 1.12 | mD | Initial permeability |

| kcb | 0.1 | mD | Permeability of shear bands |

| kf0 | 30,000 | mD | Initial fracture conductivity |

| E | 14 | GPa | Elastic modulus |

| υ | 0.2 | - | Poisson’s ratio |

| αb | 0.8 | - | Biot’s coefficient |

| Pp | 72 | MPa | Pore pressure |

| σv | 118.5 | MPa | Vertical stress |

| σH | 107.3 | MPa | Minimum horizontal stress |

| σh | 83.0 | MPa | maximum horizontal stress |

| Lf | 120 | m | Fracture length |

| ρ | 0.84 | g/m3 | Oil density |

| μo | 7 | mPa·s | Oil viscosity |

| d | 20.79 | MPa | Cohesive |

| β | 41.26 | ° | DP angle of friction |

| a | 118.3 | MPa | Coefficient of cap model |

| b | 100.2 | MPa | Coefficient of cap model |

| c | 91.5 | MPa | Coefficient of cap model |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Jin, Y.; Lu, Y.; Zhang, Y.; Chen, B. Performance of Hydraulically Fractured Wells in Xinjiang Oilfield: Experimental and Simulation Investigations on Laumontite-Rich Tight Glutenite Formation. Energies 2021, 14, 1667. https://doi.org/10.3390/en14061667

Yang S, Jin Y, Lu Y, Zhang Y, Chen B. Performance of Hydraulically Fractured Wells in Xinjiang Oilfield: Experimental and Simulation Investigations on Laumontite-Rich Tight Glutenite Formation. Energies. 2021; 14(6):1667. https://doi.org/10.3390/en14061667

Chicago/Turabian StyleYang, Shuai, Yan Jin, Yunhu Lu, Yanru Zhang, and Beibei Chen. 2021. "Performance of Hydraulically Fractured Wells in Xinjiang Oilfield: Experimental and Simulation Investigations on Laumontite-Rich Tight Glutenite Formation" Energies 14, no. 6: 1667. https://doi.org/10.3390/en14061667

APA StyleYang, S., Jin, Y., Lu, Y., Zhang, Y., & Chen, B. (2021). Performance of Hydraulically Fractured Wells in Xinjiang Oilfield: Experimental and Simulation Investigations on Laumontite-Rich Tight Glutenite Formation. Energies, 14(6), 1667. https://doi.org/10.3390/en14061667