2.1. Outdoor Testbed Setup

As shown in

Figure 2, a testbed with fixed modules was established. Up to eight modules can be installed simultaneously in this testbed. The wind direction, irradiation, air temperature, and module temperature were measured, and the data sampling interval was set to 30 s.

The testbed was installed in Gyeongsan-si, South Korea (north latitude 36°), with the installation angle being 30°. An electronic load was used in this study and the maximum power point tracking (MPPT) was continuously traced with an MPPT program. The data-monitoring facility was installed directly adjacent to the test bed and air-conditioned because of the inverter heat. All the data were gathered in the monitoring facility and saved to one server.

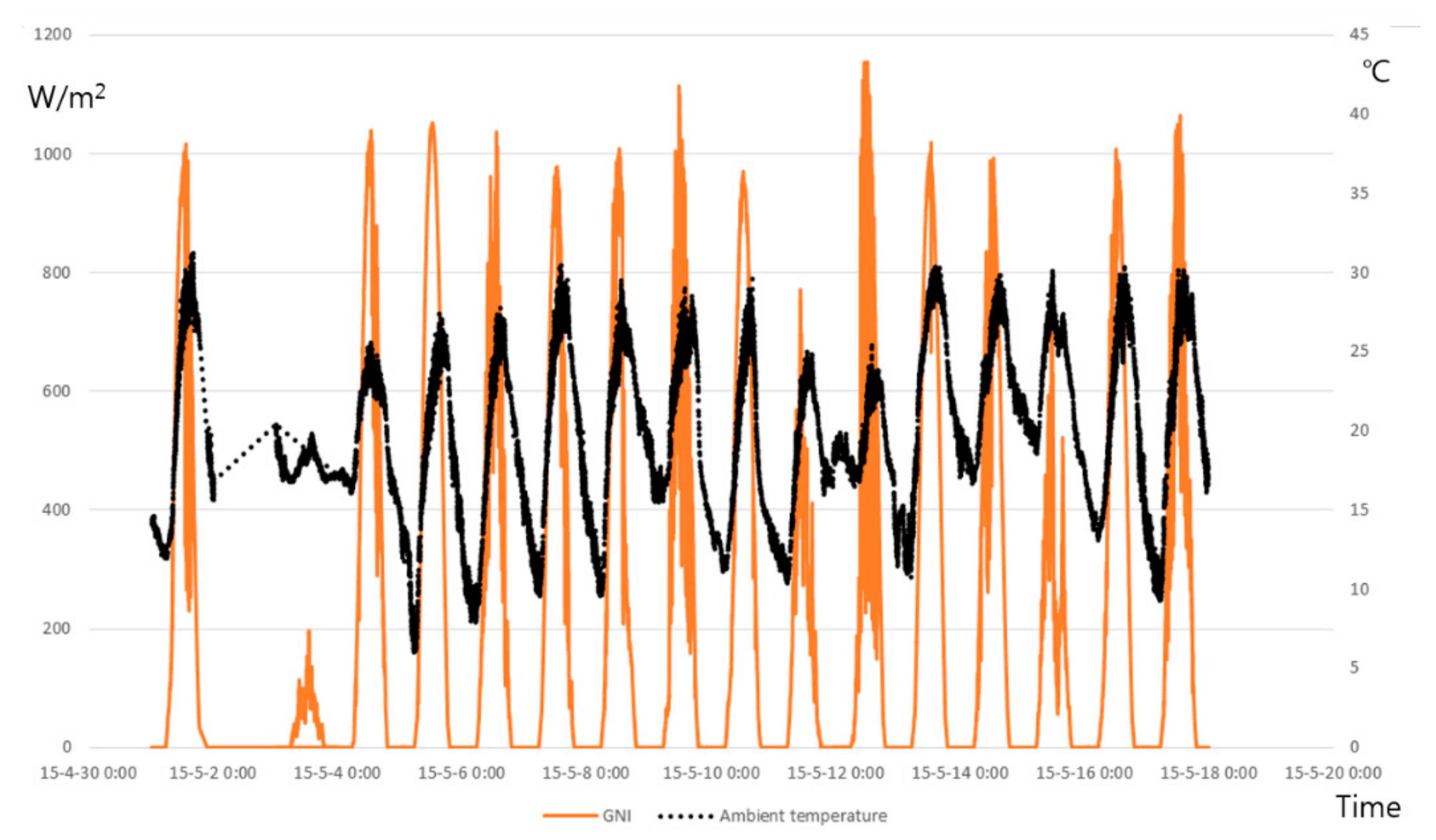

In

Figure 3, the

x-axis is shown in the order of year, month, day, and hour. The

y-axis is two, meaning W/

and °C. This is a graph obtained by extracting GNI and ambient temperature data for a day. In this experiment, 60 Cell 265 W multi-crystal modules were used. The multi-crystal module size is 1650 mm × 980 mm × 32 mm (including frame). This PV module type is commonly used in solar energy generation at present. The temperature sensor was attached to the center part of the cell, assuming that the temperature distribution on the total module area was actually not large. The actual temperature difference between the center and the corner part of the module was shown to be approximately 1–2 °C [

2]. The temperature sensor used a T type sensor and checked the temperature. The model name of the T type is TT-T-24-SLE-1000 and the insulation type has a range of −267 °C to 260 °C for the PFA type. Special Limits of Error is ±0.5 °C or 0.4% and it provides high temperature measurement accuracy. Hence, the testbed was used. In order to increase the accuracy, a weather station was also installed at the MegaWatt (MW) verification development center near Yeungnam University and was used to measure irradiation, ambient temperature, wind speed, wind direction, rainfall, humidity etc. Since both sites showed similar results, the temperature and wind speed data were simulated at the test site for PV modules.

2.2. Outdoor PV Module Temperature Measurement and Modeling

The equation relevant to the module temperature is based on the following equation: [

7].

where

Input: irradiation;

Output: thermal energy emitted from the PV module to the atmosphere;

Generation: energy generated by the PV module through irradiation;

Accumulation: input − output − remaining energy after generation.

Input is irradiation; Output is the energy going out to the atmosphere; Generation is the energy that is transmitted after generating electricity; and Accumulation is the remaining energy after the PV module is generated, and it is the remaining energy related to temperature rise. Unlike the previous Equation (1), the decision equation is created. In Equation (4), Output and Generation are Output Energy, and Accumulation is the remaining energy after the module works, so Equation (5) is as follows [

7].

where

Input Energy: irradiation;

Output Energy: output, going out to the atmosphere + generation;

Remaining Energy: energy accumulation, after the module works.

It can be deduced from Equation (5) that the energy increasing the module temperature is the remaining energy, which is converted to heat and which subsequently increases the module temperature [

5]. Obviously, the heat cannot be measured precisely because the module is not composed of only one material. However, it is assumed that the module is composed of one new integrated material; therefore, the module temperature can be predicted by multiplying the converted value from the remaining energy. The only energy that could enter from the outdoor condition becomes the irradiation. Therefore, the input energy is the irradiation. The output energy is composed of electric energy generated by the module and thermal energy emitted by the difference between the module and the air temperature. The output energy is based on the convective heat transfer Equation (6) by convective energy heat exchange [

8].

where

: convective heat transfer (W);

: convective heat transfer coefficient (W/(K));

: area ();

: temperature difference (K).

The convective heat transfer coefficient and temperature difference are moved to the left side and the remaining right side becomes Equation (6) [

8].

Remaining energy is the Input − Output energy balance. It is assumed that the system (target volume) is PV module based on the energy balance equation of chemical engineering thermodynamics [

7,

8,

9].

where

mU: internal energy per unit mass [J/kg];

H: enthalpy [J];

u: velocity [m/s];

z: height from the reference level [m];

g: gravitational acceleration [m/];

: mass flow rate [kg/s];

: heat energy per hour [J/s];

: work rate [J/s].

If Equation (8) is expressed as remaining energy, which is equal to Input − Output and is expressed as Equation (9)

The Equation (7) left term is the amount of accumulation, which is a term based on how much the system changes over time.

+

is the term for energy access and

[(H +

)

] is the term for material access [

10].

That is, the right term has the meaning of Input energy − Output energy as a whole. Since PV module doesn’t have material entry, the term for material access is “0”.

Therefore,

+

is Input energy − Output energy. It becomes Equation (10). Because the only Input energy entering is insolation. So, Input energy is irradiance. Output energy is

− loss energy as above. In the loss energy, there is heat energy by convective energy heat exchange.

indicates that PV module generates electricity and the remaining energy is converted into heat, which increases temperature of the PV module. Based on this energy balance, the following Equation (11) was inferred [

10].

where

t: time step;

: temperature rise of module at t + 1 time (°C);

n: module temperature conversion coefficient, with respect to energy ((°C m2)/W);

: irradiation (W/m2);

: module power generation at t time (W/m2);

: thermal conductivity transferred from module to air (W/(m2 °C));

: module temperature (°C);

: air temperature (°C).

The left term of Equation (11) is the change of the system due to the right term, i.e., the work after the energy entry occurs and the right term can be seen as energy entry in and out from the surface. Equations (10) and (11) have different units, but they correspond to the cause and result of energy entry.

==

, and can be expressed in units of J (

). When

is integrated for t from 0 to 1 (0 is the equilibrium state without energy transfer, 1 is when energy transfer occurs), it becomes

, where

is the specific internal energy. Since

= m

(

), when the area is divided, it becomes

[

10].

where

: mass (kg);

: volume ();

: density (kg/);

: thickness ();

: area ().

After combining Equation (12) to Equation (13), mass is substituted by volume and denominator is divided by thickness [

9,

10].

is based on the convective heat transfer equation.

is based on the equation for the accumulation of the energy balance equation. While

looks similar to specific heat, it is viewed as a unit area rather than

per unit mass. PV module internal energy is the place where the remaining total energy exchanged through convective energy will go to power generation by efficiency prior to the increase in temperature. In other words, the temperature increases by providing sensible heat to PV module. Since

and

are complex, they can’t be viewed individually. So, their individual experimental values cannot be obtained. As a result, the following Equation (15) is derived.

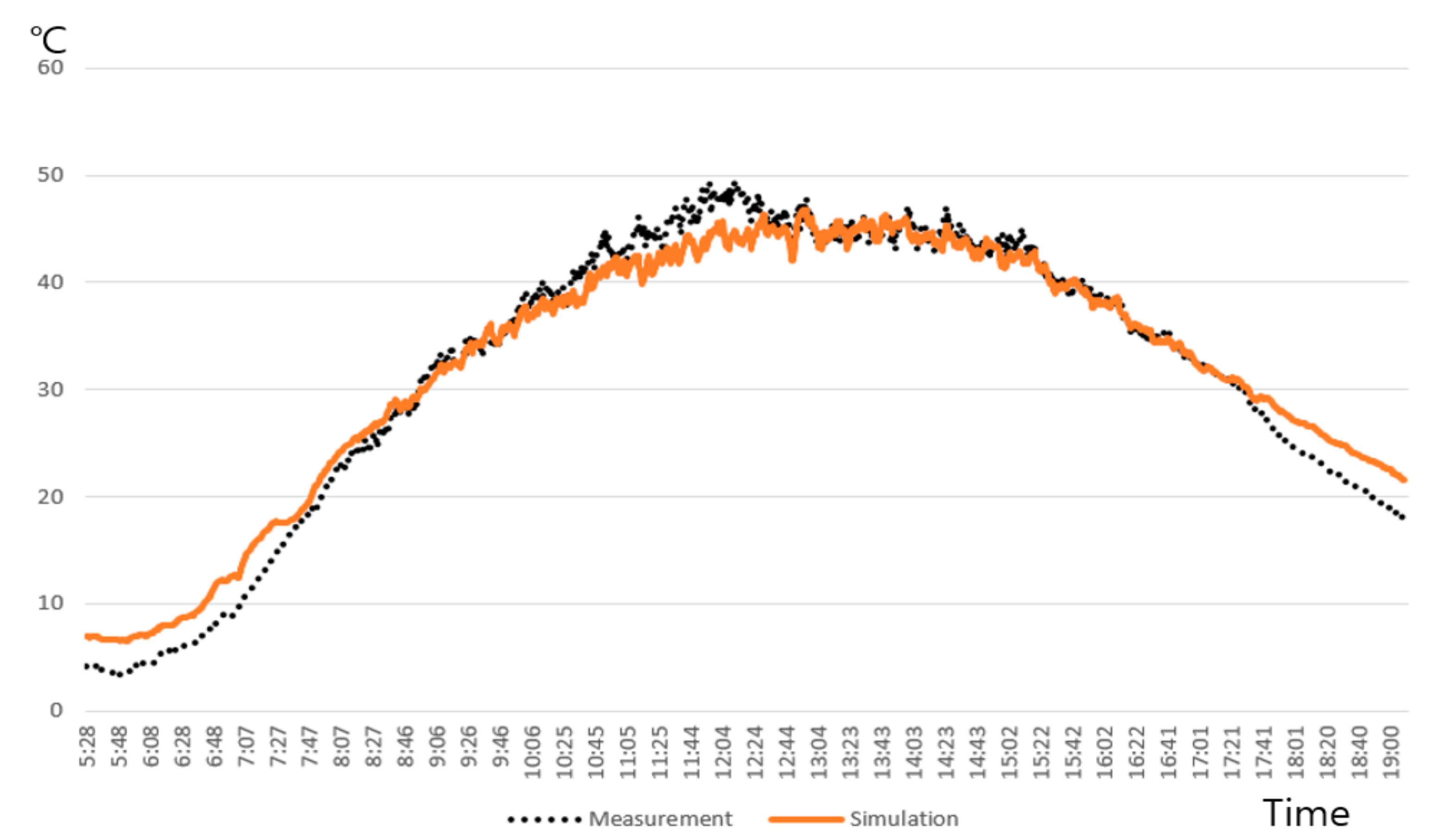

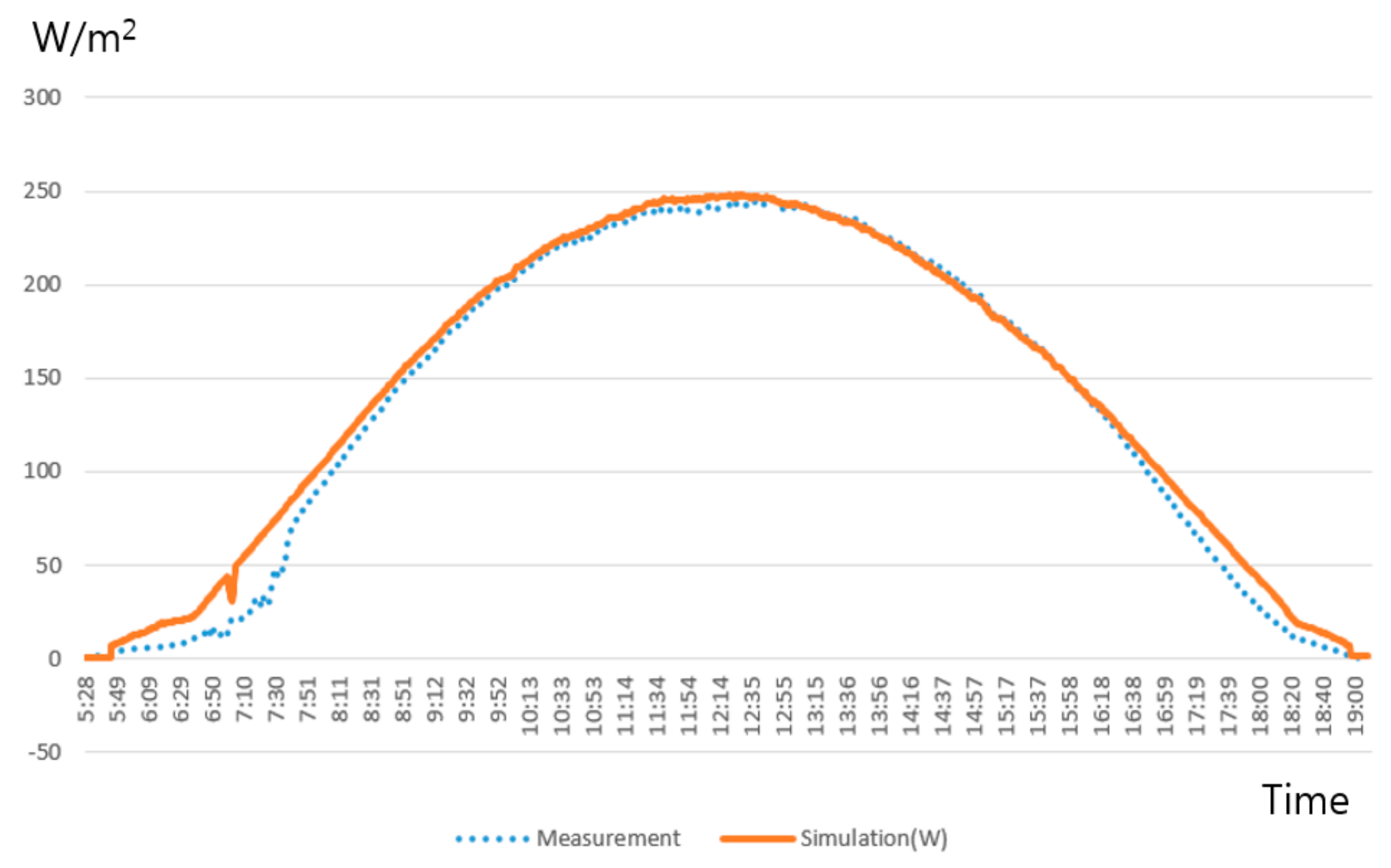

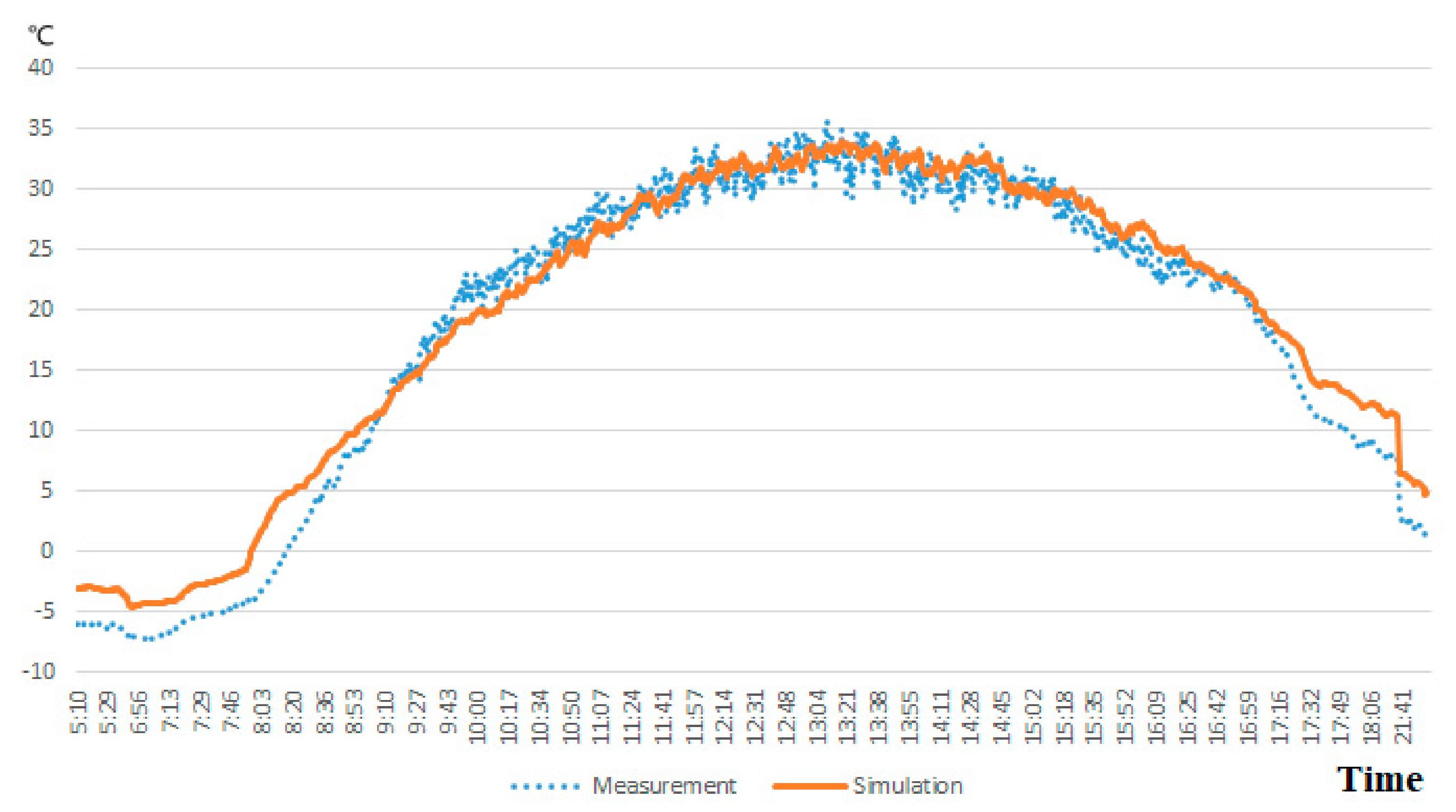

The interval of time t varies depending on the measurement time. In this study, the time interval was maintained at 30 s. The initial module temperature was assumed equivalent to the air temperature, as there was no generation without any irradiation. Starting from the following irradiation, the module power generation energy and the energy transferred to the air were calculated, with respect to actual irradiation, in order to predict the module temperature. The open-circuit voltage (Voc), voltage at maximum-power point (Vmp), short-circuit current (Isc), and current at the maximum-power point (Imp) equation presented by the Sandia National Laboratory was used to calculate the module generation with respect to irradiation [

3]. 265 W PV module Isc = 9.0922 A; Voc = 38.1612 V; Imp = 8.5144 A; Vmp = 30.2515 V; and comparison target 260 W PV module Isc = 8.96 A; Voc = 39.213 V; Imp = 8.5 A; Vmp = 31.361 V. The elements n and

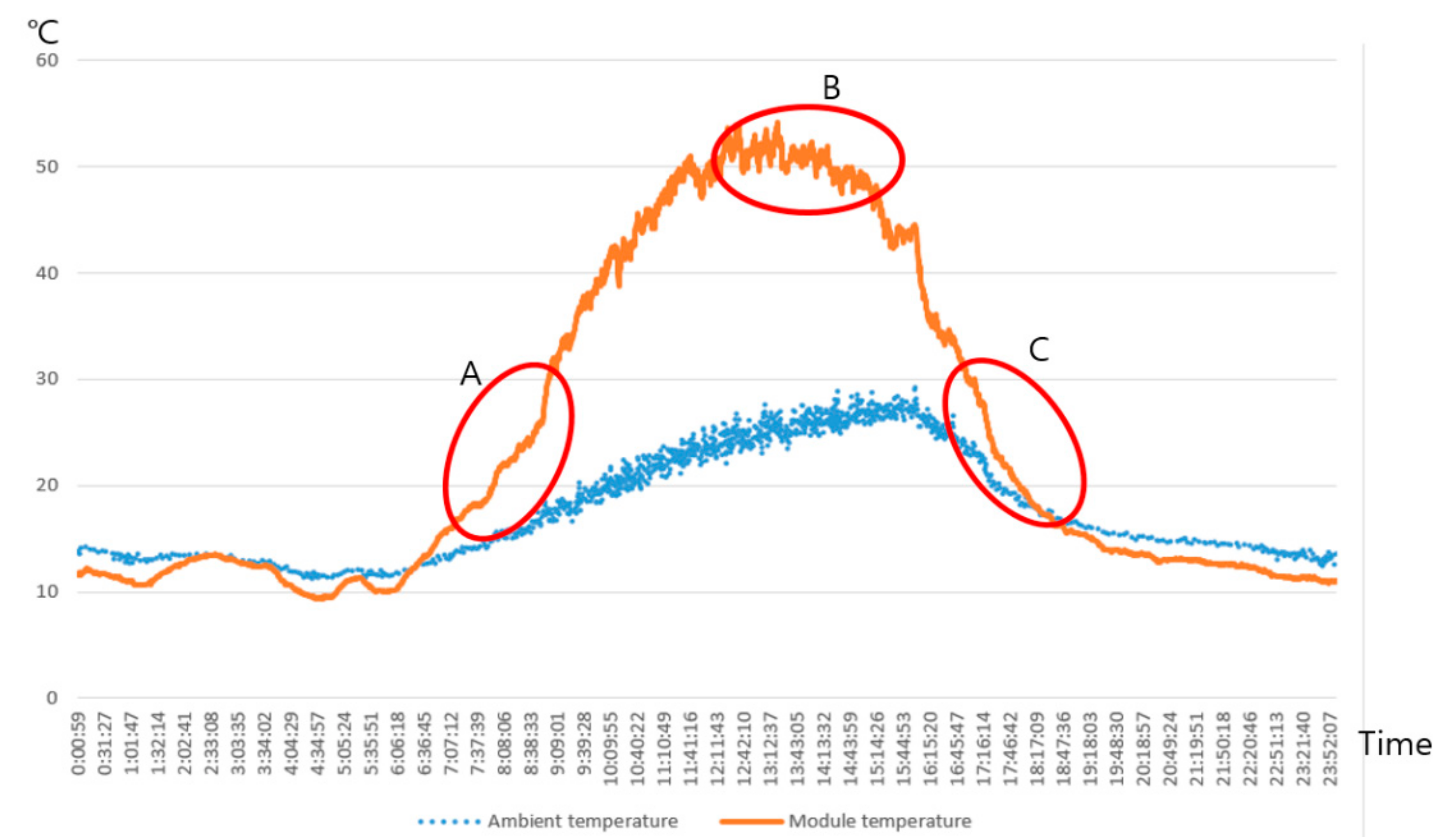

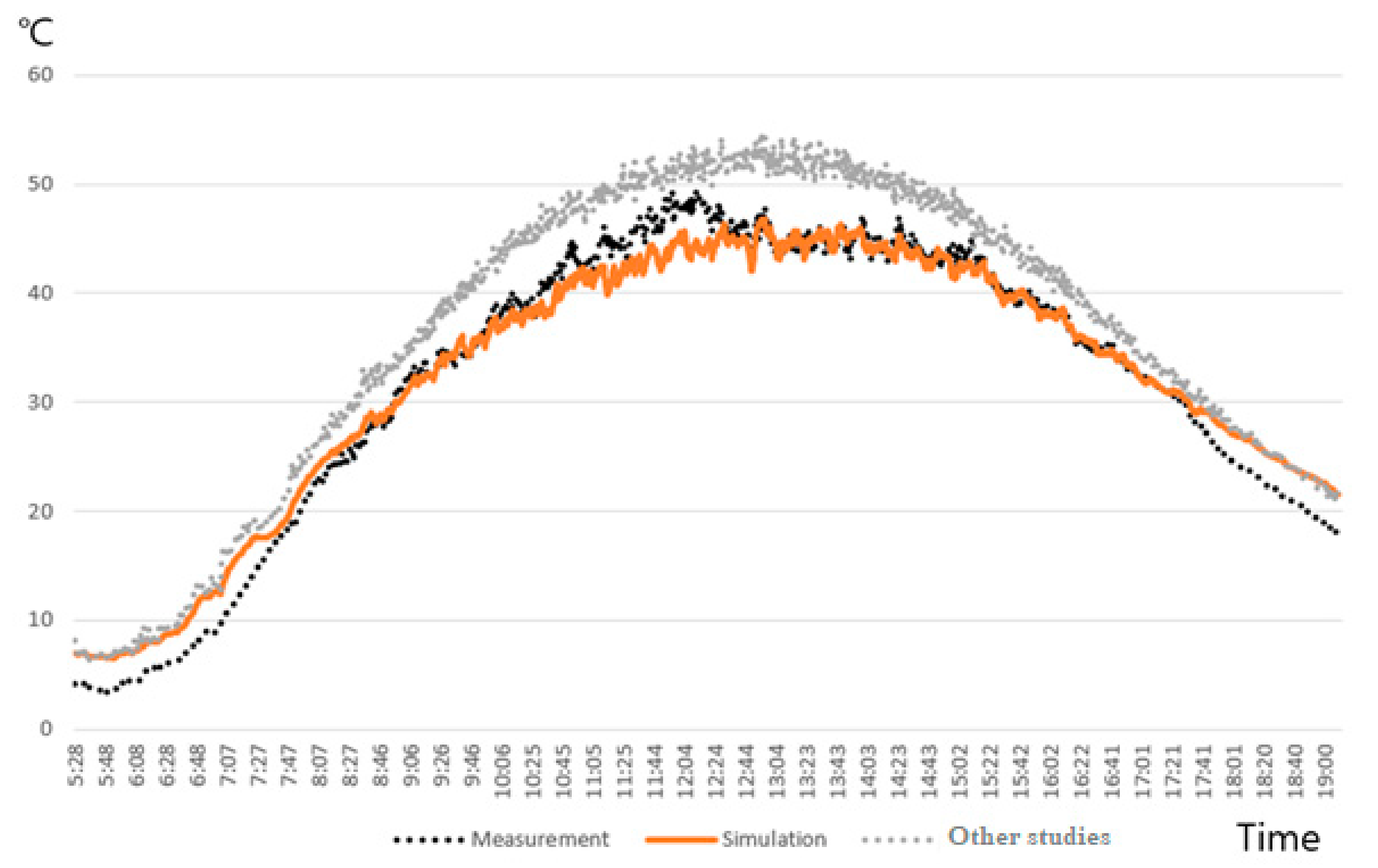

in Equation (15) can be characterized from the collected data. As shown in

Figure 4, when the module starts to generate electricity, the PV module temperature rises to generate electricity. Assuming 1000 W/

of solar radiation is generated, electricity is converted to 15%–20%. The remaining energy is energy related to heat, which is consumed outside the module rather than PV module inside like convective energy. However, PV module temperature rises due to the presence of remaining thermal energy generated and accumulated. There is a large difference between ambient temperature and PV module temperature. PV module temperature is inevitably higher than the ambient temperature. The higher the PV temperature, the lower the generation due to the characteristics of the PV module temperature change. In addition, the reason that voltage is affected by temperature and current is affected by insolation is also due to characteristics of the PV module temperature change.

The conversion coefficient n and is calculated as follows.

First, a region, such as part B in

Figure 4, where the module temperature does not rise or fall, is identified with clear irradiation and low wind speed (2 m/s or below). Temperature that does not change (rise or fall) means that

= 0. Therefore, the following equation becomes valid:

After identifying

here, the n value can be determined by using the data in part A of

Figure 4.

can be expanded as below to include the wind effect [

3,

4,

5].

where

The initial

becomes

, as it is the conversion coefficient identified when the wind speed was low. After identifying

and n,

can be identified, based on the data of the date with wind speed that is higher than a certain value. In addition, it is necessary to verify the value of n,

by looking at the entire point through the graph in

Figure 4. In the case of 200~900 W/

or more based on insolation, the average values

n and

are obtained by dividing a total of 8 sections and after substituting into Equation (15) and simulating. However, due to KS C IEC/TS 61724-2:2016, the minimum POA insolation intensity during the four seasons is more than 450 W/m

2. Then, 6 equations with different

n,

are expressed. Among the regressing analysis methods, if the RMS (Root Mean Square) error is used and a combination of coefficients when the RMS error of the module temperature values is minimized is used, the result of conversion coefficient can be more accurately expressed [

11,

12].