Energy Consumption Structure and Its Improvement of Low-Lifting Capacity Scissor Lift

Abstract

1. Introduction

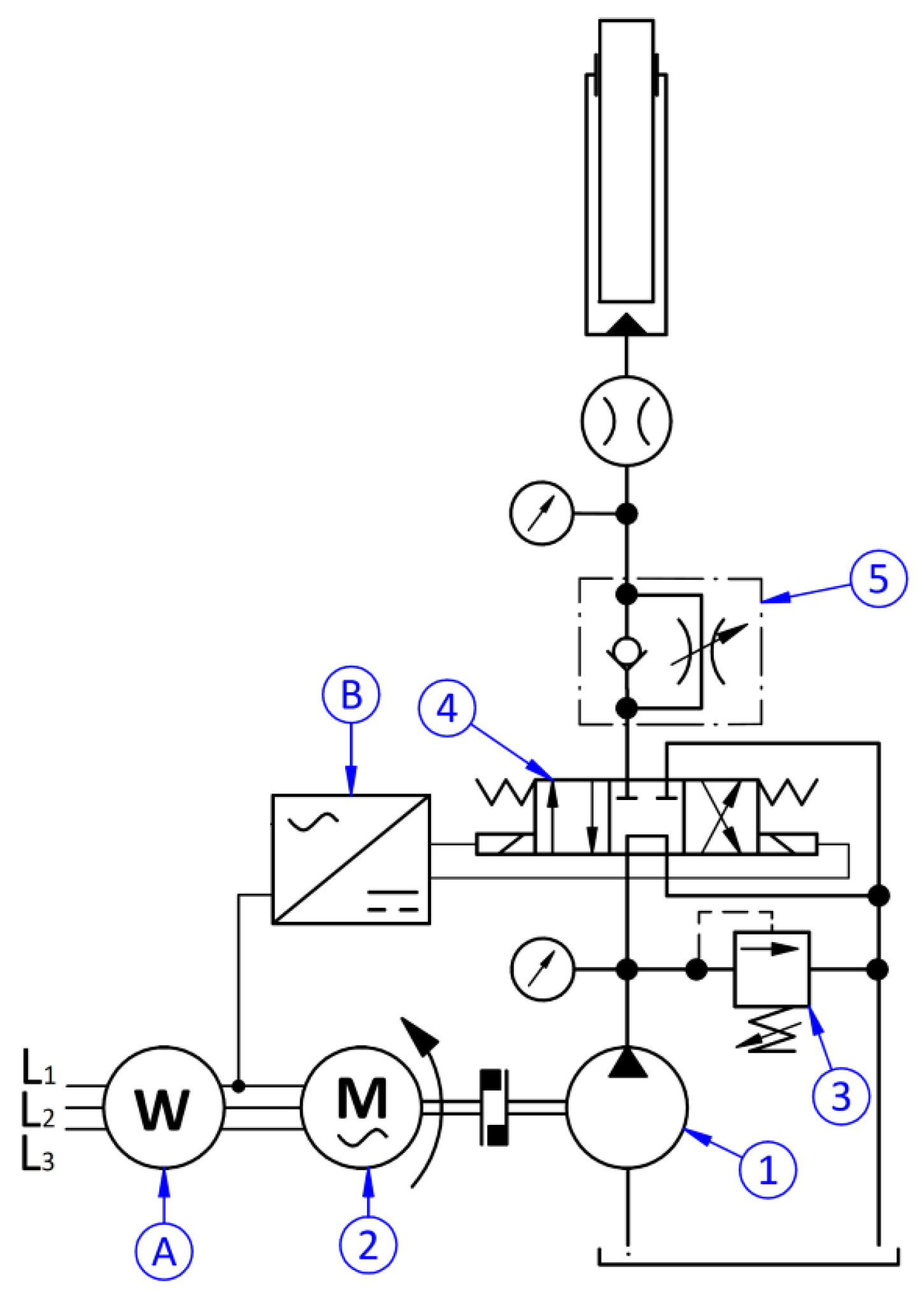

2. System Description

3. Description of Energy Consumption

4. Experimental Tests

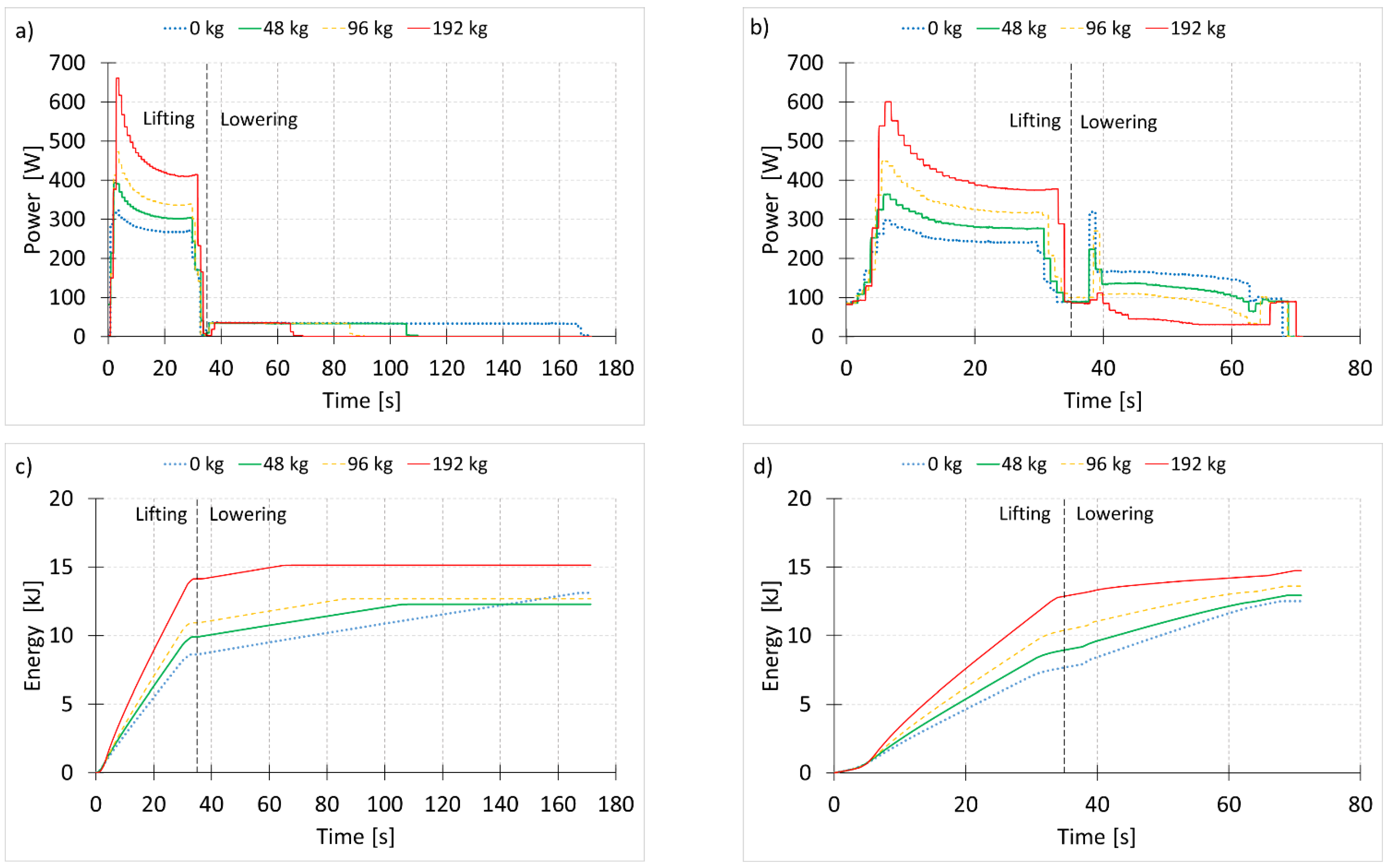

4.1. Total Power and Energy Consumption

- mass of the cargo on the platform mQ = (0, 48, 96, 192) kg;

- displacement of the scissor lift platform xp = 2 m;

- lifting depending on the system:

- ○

- speed of the motor according to its mechanical characteristics (conventional drive);

- ○

- speed of the motor nm = 1500 rpm (EHD);

- lowering depending on the system:

- ○

- via throttle valve (conventional drive);

- ○

- speed of the motor nm = 1500 rpm (EHD).

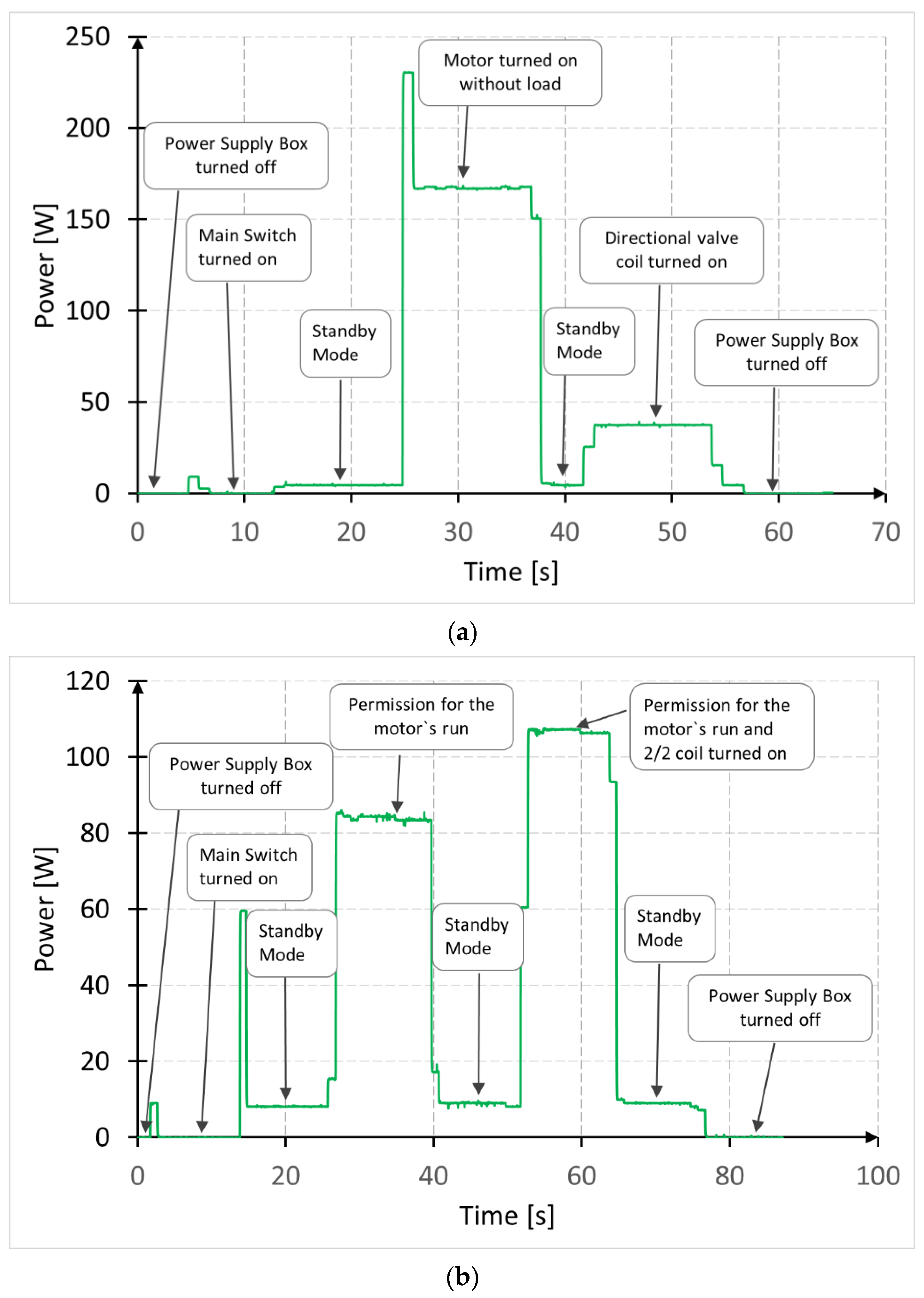

4.2. Power Demand of Individual Elements

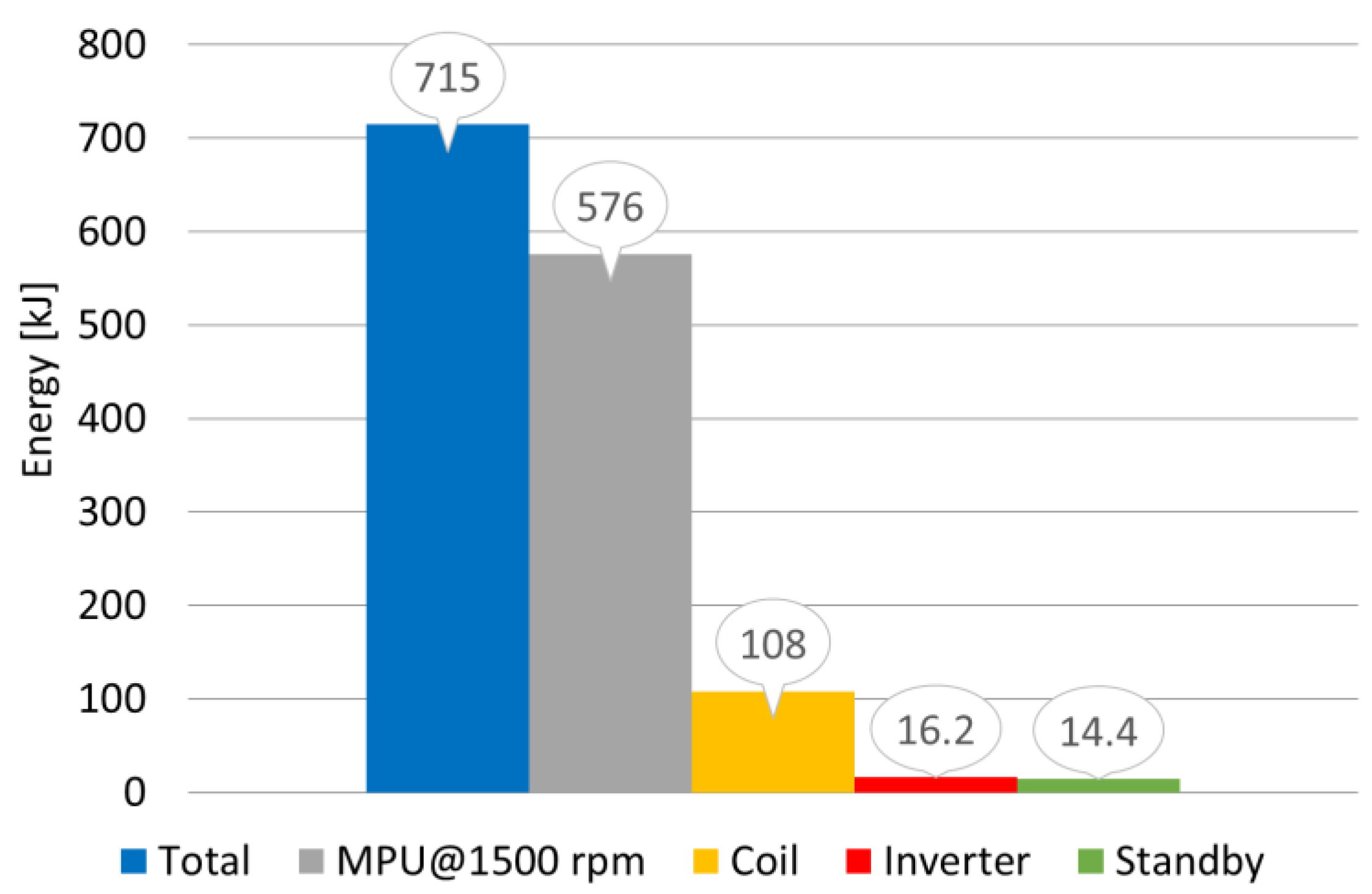

5. Results of Energy Consumption Investigation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huova, M.; Linjama, M.; Huhtala, K. Energy Efficiency of Digital Hydraulic Valve Control Systems; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Xia, L.; Quan, L.; Ge, L.; Hao, Y. Energy efficiency analysis of integrated drive and energy recuperation system for hydraulic excavator boom. Energy Convers. Manag. 2018, 156, 680–687. [Google Scholar] [CrossRef]

- An, K.; Kang, H.; An, Y.; Park, J.; Lee, J. Methodology of Excavator System Energy Flow-Down. Energies 2020, 13, 951. [Google Scholar] [CrossRef]

- Stump, P.M.; Keller, N.; Vacca, A. Energy Management of Low-Pressure Systems Utilizing Pump-Unloading Valve and Accumulator. Energies 2019, 12, 4423. [Google Scholar] [CrossRef]

- Ranjan, P.; Wrat, G.; Bhola, M.; Mishra, S.K.; Das, J. A novel approach for the energy recovery and position control of a hybrid hydraulic excavator. ISA Trans. 2020, 99, 387–402. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Lin, T.; Ren, H.; Fu, S. Novel potential energy regeneration systems for hybrid hydraulic excavators. Math. Comput. Simul. 2019, 163, 130–145. [Google Scholar] [CrossRef]

- Minav, T.; Immonen, P.; Laurila, L.; Vtorov, V.; Pyrhönen, J.; Niemelä, M. Electric energy recovery system for a hydraulic forklift–theoretical and experimental evaluation. IET Electr. Power Appl. 2011, 5, 377. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Q.; Hu, B. A review of developments in energy storage systems for hybrid excavators. Autom. Constr. 2017, 80, 1–10. [Google Scholar] [CrossRef]

- Latas, W.; Stojek, J. A new type of hydrokinetic accumulator and its simulation in hydraulic lift with energy recovery system. Energy 2018, 153, 836–848. [Google Scholar] [CrossRef]

- Donkov, V.; Andersen, T.; Ebbesen, M.; Pedersen, H. Applying Digital Hydraulic Technology on a Knuckle Boom Crane. In Proceedings of the Ninth Workshop on Digital Fluid Power, Aalborg, Denmark, 7–8 September 2017. [Google Scholar]

- Amico, D.A.; Carlsson, M.; Norlin, E.; Sethson, M. Investigation of a Digital Hydraulic Actuation System on an Excavator Arm. In Proceedings of the 13th Scandinavian International Conference on Fluid Power, Linköping, Sweden, 3–5 June 2013; Volume 92, pp. 505–511. [Google Scholar]

- Wang, T.; Wang, Q.; Lin, T. Improvement of boom control performance for hybrid hydraulic excavator with potential energy recovery. Autom. Constr. 2013, 30, 161–169. [Google Scholar] [CrossRef]

- Lin, T.; Wang, Q.; Hu, B.; Gong, W. Research on the energy regeneration systems for hybrid hydraulic excavators. Autom. Constr. 2010, 19, 1016–1026. [Google Scholar] [CrossRef]

- Bedotti, A.; Campanini, F.; Pastori, M.; Riccò, L.; Casoli, P. Energy saving solutions for a hydraulic excavator. Energy Procedia 2017, 126, 1099–1106. [Google Scholar] [CrossRef]

- Hao, Y.; Quan, L.; Cheng, H.; Xia, L.; Ge, L.; Zhao, B. Potential energy directly conversion and utilization methods used for heavy duty lifting machinery. Energy 2018, 155, 242–251. [Google Scholar] [CrossRef]

- Wang, T.; Wang, Q. Efficiency analysis and evaluation of energy-saving pressure-compensated circuit for hybrid hydraulic excavator. Autom. Constr. 2014, 47, 62–68. [Google Scholar] [CrossRef]

- Liu, B.; Quan, L.; Ge, L. Research on the performance of hydraulic excavator boom based pressure and flow accordance control with independent metering circuit. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2016, 231, 901–913. [Google Scholar] [CrossRef]

- Ge, L.; Quan, L.; Zhang, X.; Zhao, B.; Yang, J. Efficiency improvement and evaluation of electric hydraulic excavator with speed and displacement variable pump. Energy Convers. Manag. 2017, 150, 62–71. [Google Scholar] [CrossRef]

- Li, W.; Wu, B.; Cao, B. Control strategy of a novel energy recovery system for parallel hybrid hydraulic excavator. Adv. Mech. Eng. 2015, 7. [Google Scholar] [CrossRef]

- Manner, J.; Lindroos, O.; Arvidsson, H.; Nordfjell, T. Evaluation of a New Energy Recycling Hydraulic Lift Cylinder for Forwarders. Croat. J. For. Eng. 2016, 37, 219–231. [Google Scholar]

- Krakowski, T.; Ruta, H. Analysis and Assessment OF Energy Efficiency of Passenger Lifts. Adv. Sci. Technol. Res. J. 2018, 12, 257–265. [Google Scholar] [CrossRef]

- De Almeida, A. Options to Improve Lift Energy Efficiency; Tech. Rep.; Italian National Agency for New Technologies, Energy and Sustainable Economic Development: Roma, Italy, 2010. [Google Scholar] [CrossRef]

- Patrao, C.; Fong, J.; de Almeida, A.; Rivet, L. Energy Efficient Elevators and Escalators. In Proceedings of the Conference ECEEE 2009 Summer Study on energy efficiency: Act! Innovate! Deliver! Reducing Energy Demand Sustainably, La Colle sur Loup, France, 1–6 June 2009. [Google Scholar]

- Yang, H.; Sun, W.; Xu, B. New Investigation in Energy Regeneration of Hydraulic Elevators. IEEE/ASME Trans. Mechatron. 2007, 12, 519–526. [Google Scholar] [CrossRef]

- Koitto, T.; Kauranne, H.; Calonius, O.; Minav, T.; Pietola, M. Experimental Study on Fast and Energy-Efficient Direct Driven Hydraulic Actuator Unit. Energies 2019, 12, 1538. [Google Scholar] [CrossRef]

- Minav, T.A.; Laurila, L.I.; Pyrhönen, J.J. Analysis of electro-hydraulic lifting system’s energy efficiency with direct electric drive pump control. Autom. Constr. 2013, 30, 144–150. [Google Scholar] [CrossRef]

- Minav, T.; Hänninen, H.; Sinkkonen, A.; Laurila, L.; Pyrhönen, J. Electric or Hydraulic Energy Recovery Systems in a Reach Truck– A Comparison. Stroj. Vestn. J. Mech. Eng. 2014, 60, 232–240. [Google Scholar] [CrossRef]

- Mahmood, A.; Almaged, M.; Ismael, O.Y. Quantitative Design Analysis of an Electric Scissor Lift. Am. Sci. Res. J. Eng. Technol. Sci. 2009, 59, 128–141. [Google Scholar]

- Ciupan, C.; Ciupan, E.; Pop, E. Algorithm for designing a hydraulic scissor lifting platform. MATEC Web Conf. 2019, 299, 3012. [Google Scholar] [CrossRef]

- Chaturvedi, A.; Mishra, J.; Parmar, V. An Improved Scissor Lift working on Lead Screw Mechanism Aerial Scissor Lift and its Accessories. Int. J. Adv. Eng. Res. Dev. 2017, 4, 89–95. [Google Scholar]

- Burian, M.; Havlik, J.; Folta, Z.; Trochta, M.; Maršálek, P. Solution the Drive Lifting Scissor Platforms. In Proceedings of the 16th Asian Congress of Fluid Mechanics, Bangalaore, India, 3 April 2014; pp. 19–26. [Google Scholar]

- Dong, R.G.; Pan, C.S.; Hartsell, J.J.; Welcome, D.E.; Lutz, T.; Brumfield, A.; Harris, J.R.; Wu, J.Z.; Wimer, B.; Mucino, V.; et al. An Investigation on the Dynamic Stability of Scissor Lift. Open J. Saf. Sci. Technol. 2012, 2, 8–15. [Google Scholar] [CrossRef]

- Dengiz, C.G.; Şenel, M.C.; Yıldızlı, K.; Koc, E. Design and Analysis of Scissor Lifting System by Using Finite Elements Method. Univers. J. Mater. Sci. 2018, 6, 58–63. [Google Scholar] [CrossRef][Green Version]

- Rani, D.; Agarwal, N.; Tirth, V. Design and Fabrication of Hydraulic Scissor Lift. MIT Int. J. Mech. Eng. 2015, 5, 81–87. [Google Scholar]

- Thorat S., G.; Chiddarwar A., R.; Prusty, P.S. Design and Construction of Hydraulic Scissor Lift. Int. J. Curr. Eng. Technol. 2017, 7, 32–95. [Google Scholar]

- Suresh, P.; Sivathanu, A. Fabrication of Hydraulic Scissor Lift. Int. J. Innov. Work. Eng. Technol. 2017, 3. [Google Scholar] [CrossRef]

- Stawiński, Ł.; Kosucki, A.; Morawiec, A.; Sikora, M. A new approach for control the velocity of the hydrostatic system for scissor lift with fixed displacement pump. Arch. Civ. Mech. Eng. 2019, 19, 1104–1115. [Google Scholar] [CrossRef]

- Stawiński, Ł.; Kosucki, A.; Morawiec, A. Hydrostatic Actuator Drive Control with Pump Leakage Compensation. In NSHP 2020: Advances in Hydraulic and Pneumatic Drives and Control 2020; Stryczek, J., Warzyńska, U., Eds.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

| Component | Parameters |

|---|---|

| Nominal capacity | 192 kg |

| Pump XV-0R/0.98 | 0.92 cc/rev |

| Motor Simotics GP 1AV1082B | 0.55 kW/1385 rpm |

| Pressure relief valve VMP V0700 | 30 MPa/45 lpm |

| Directional control valve (4/3) HP-4WE6-G/D24-SR-Z5L | 36 MPa/80 lpm |

| Solenoid operated check valve (2/2) EP-08W-05-M-04 | 35 MPa/30 lpm |

| Throttle valve VRFU 9001 | 35 MPa/35 lpm |

| Power network analyzer LUMEL P43 | 5A/400V |

| Frequency inverter SX2400-0R7G-2 | 0.75 kW/0–10 V |

| Pressure sensors P3297B084001 | 25 MPa/4–20 mA |

| Flowmeter GFM-5 | 0.05–2 lpm/5.250 pulses/l |

| Symbol | Description | Unit |

|---|---|---|

| E | Energy | J |

| P | Power | W |

| Pc | Power of the hydraulic cylinder | W |

| Fc | Force on the hydraulic cylinder | N |

| pc | Inlet pressure of the hydraulic cylinder | Pa |

| ηc | Efficiency of the hydraulic cylinder | m/s |

| Pp | Power of the pump | W |

| pp | Inlet pressure of the pump | Pa |

| Qp | Outlet flow from the pump | m3/s |

| Qc | Cylinder inlet flow | m3/s |

| ηp | Efficiency of the pump | - |

| qp | Displacement of the pump | m3/rad |

| Pm | Power of the motor | W |

| Tm | Torque on the motor shaft | Nm |

| ωm | Angular motor velocity | rad/s |

| ηm | Efficiency of the motor | - |

| Eeff | Effective energy | J |

| Peff | Effective power | W |

| EHL | Energy of hydraulic losses | J |

| PHL | Power of hydraulic losses | W |

| EL | Energy of losses | J |

| EMPU | Energy of motor-pump unit | J |

| ECoil | Energy of valve coil | J |

| EStandby | Energy of standby mode | J |

| EInverter | Energy of frequency inverter | J |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stawinski, L.; Zaczynski, J.; Morawiec, A.; Skowronska, J.; Kosucki, A. Energy Consumption Structure and Its Improvement of Low-Lifting Capacity Scissor Lift. Energies 2021, 14, 1366. https://doi.org/10.3390/en14051366

Stawinski L, Zaczynski J, Morawiec A, Skowronska J, Kosucki A. Energy Consumption Structure and Its Improvement of Low-Lifting Capacity Scissor Lift. Energies. 2021; 14(5):1366. https://doi.org/10.3390/en14051366

Chicago/Turabian StyleStawinski, Lukasz, Jakub Zaczynski, Adrian Morawiec, Justyna Skowronska, and Andrzej Kosucki. 2021. "Energy Consumption Structure and Its Improvement of Low-Lifting Capacity Scissor Lift" Energies 14, no. 5: 1366. https://doi.org/10.3390/en14051366

APA StyleStawinski, L., Zaczynski, J., Morawiec, A., Skowronska, J., & Kosucki, A. (2021). Energy Consumption Structure and Its Improvement of Low-Lifting Capacity Scissor Lift. Energies, 14(5), 1366. https://doi.org/10.3390/en14051366