Investigation of Thermo-Flow Characteristics of Natural Draft Dry Cooling Systems Designed with Only One Tower in 2 × 660 MW Power Plants

Abstract

1. Introduction

2. Numerical Modeling

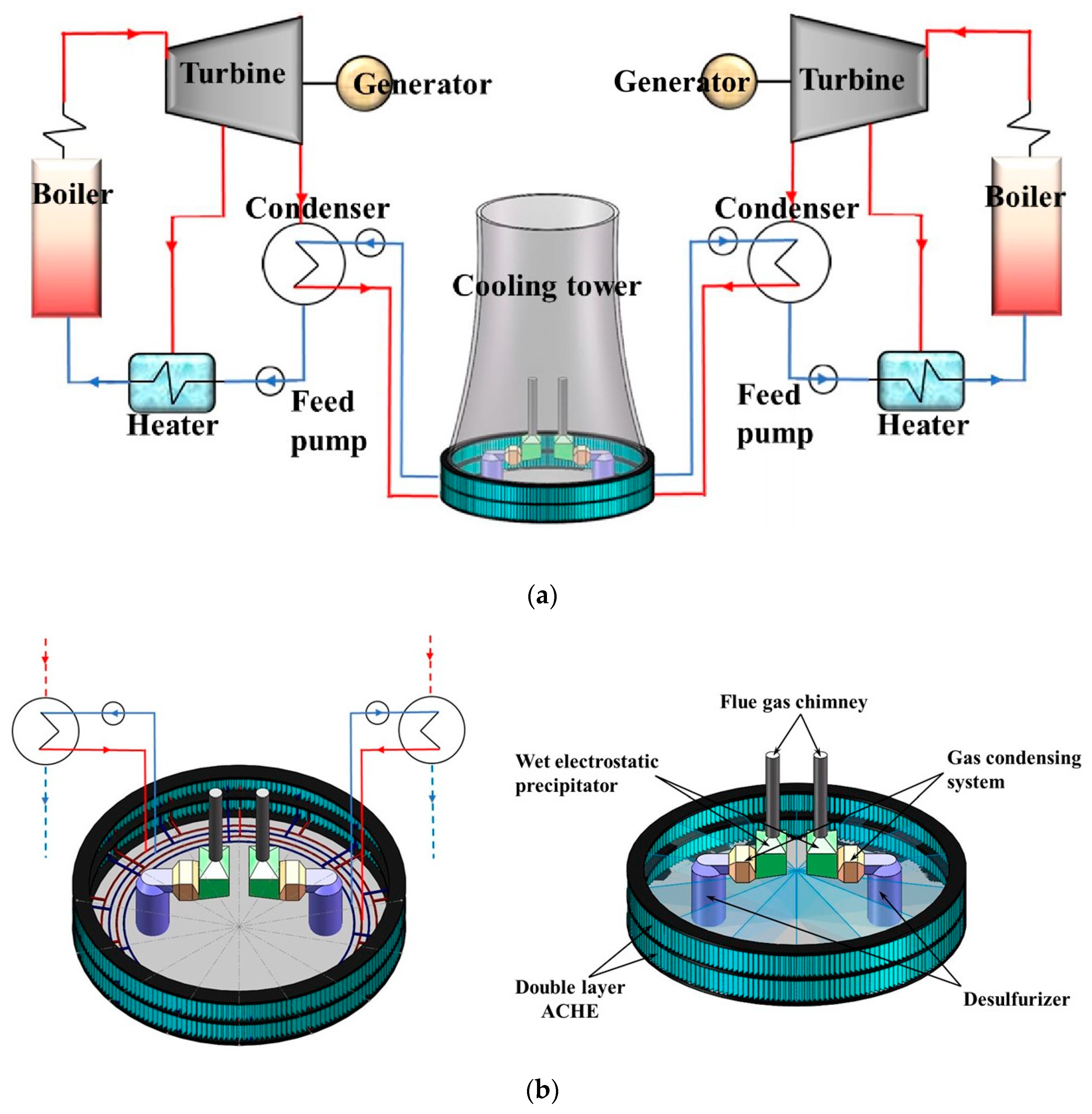

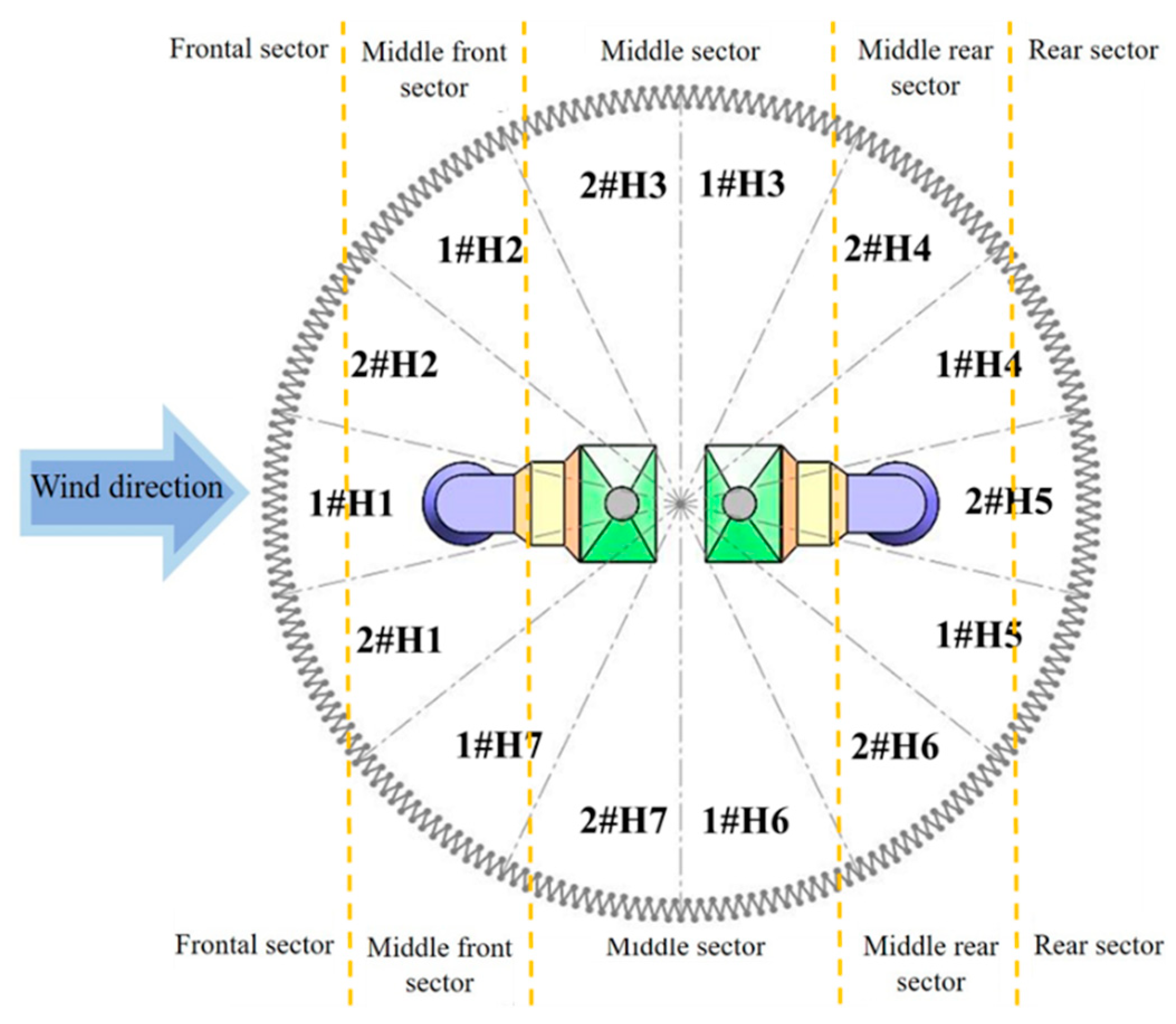

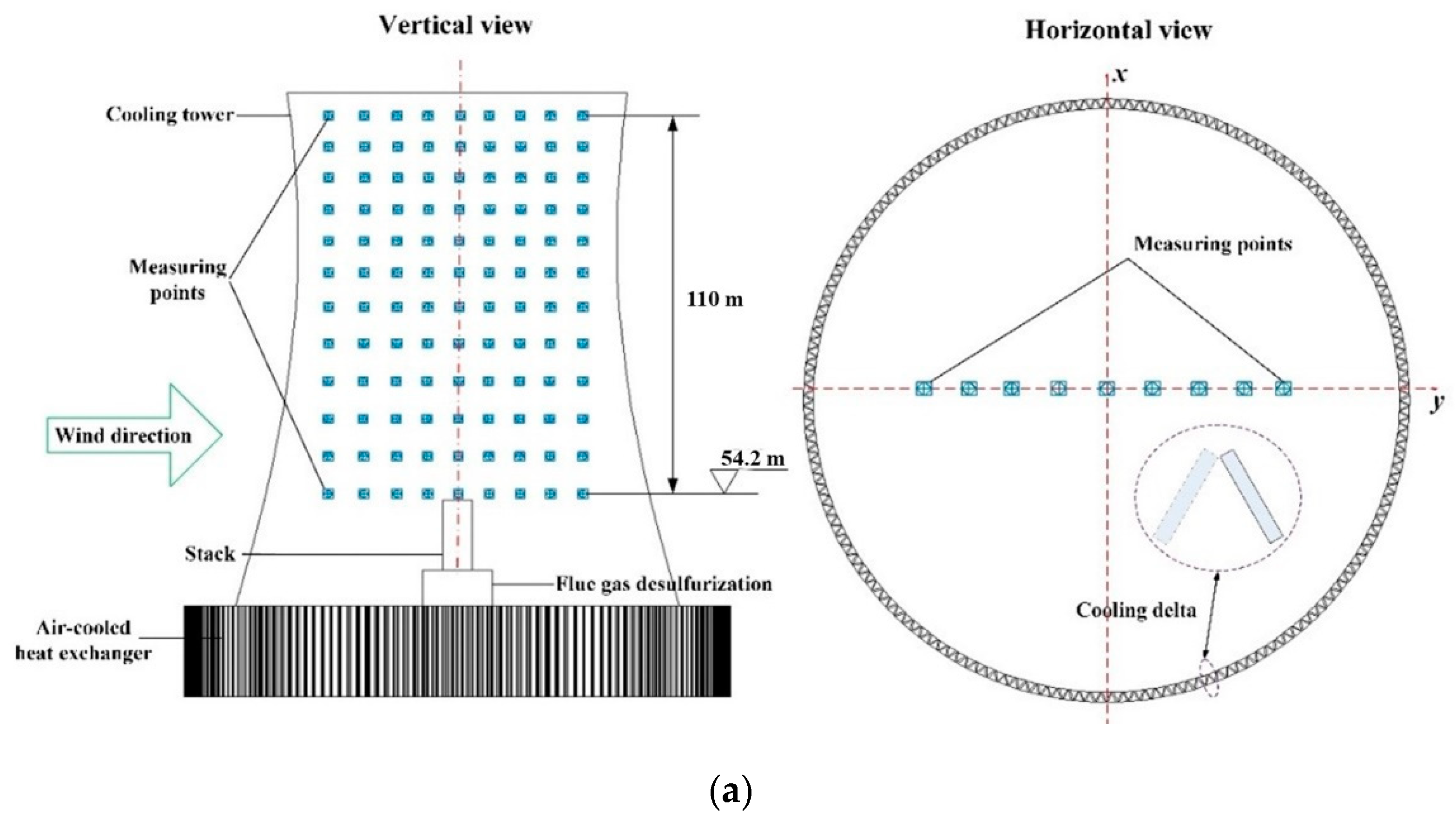

2.1. NDDCS with Only One Tower

2.2. Governing Equations

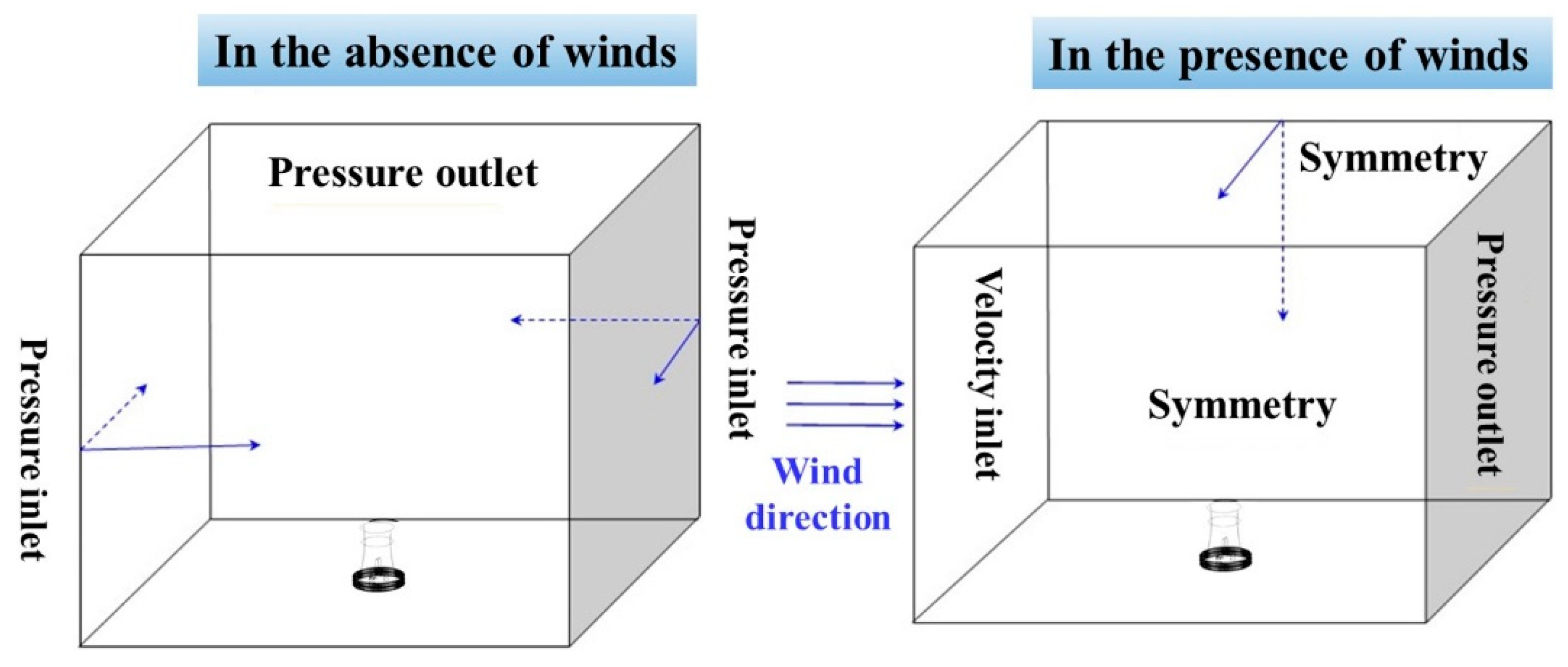

2.3. Boundaries, Meshing, and Solution

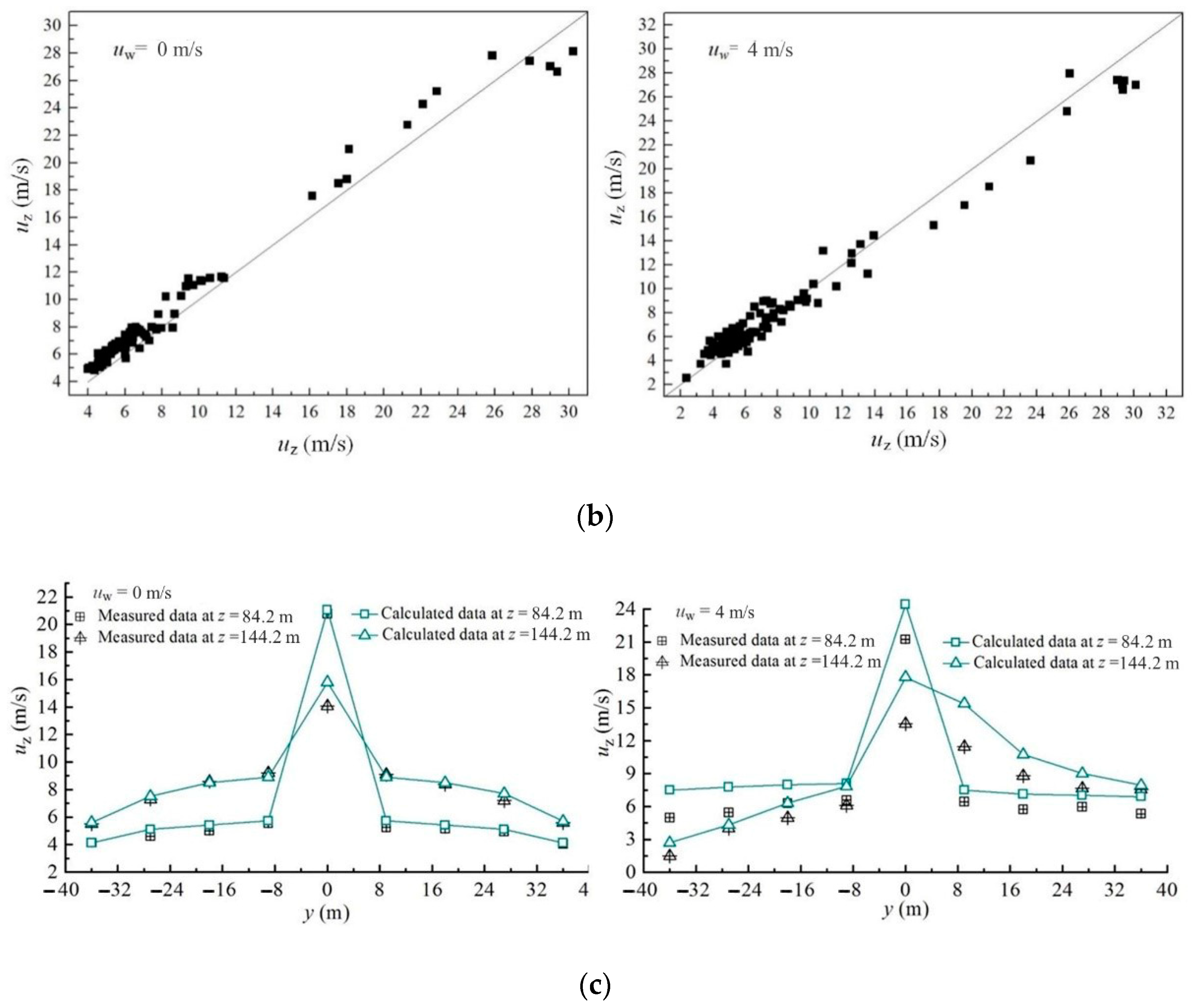

2.4. Model Validation

3. Results and Discussions

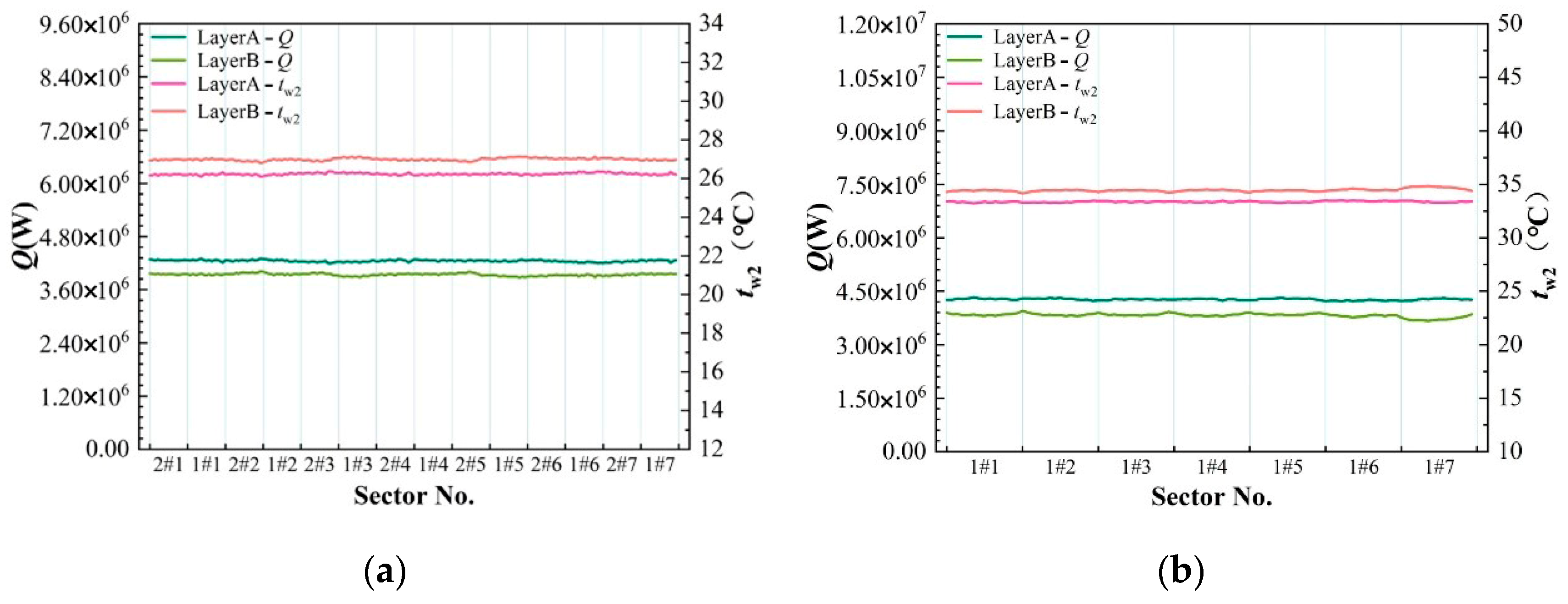

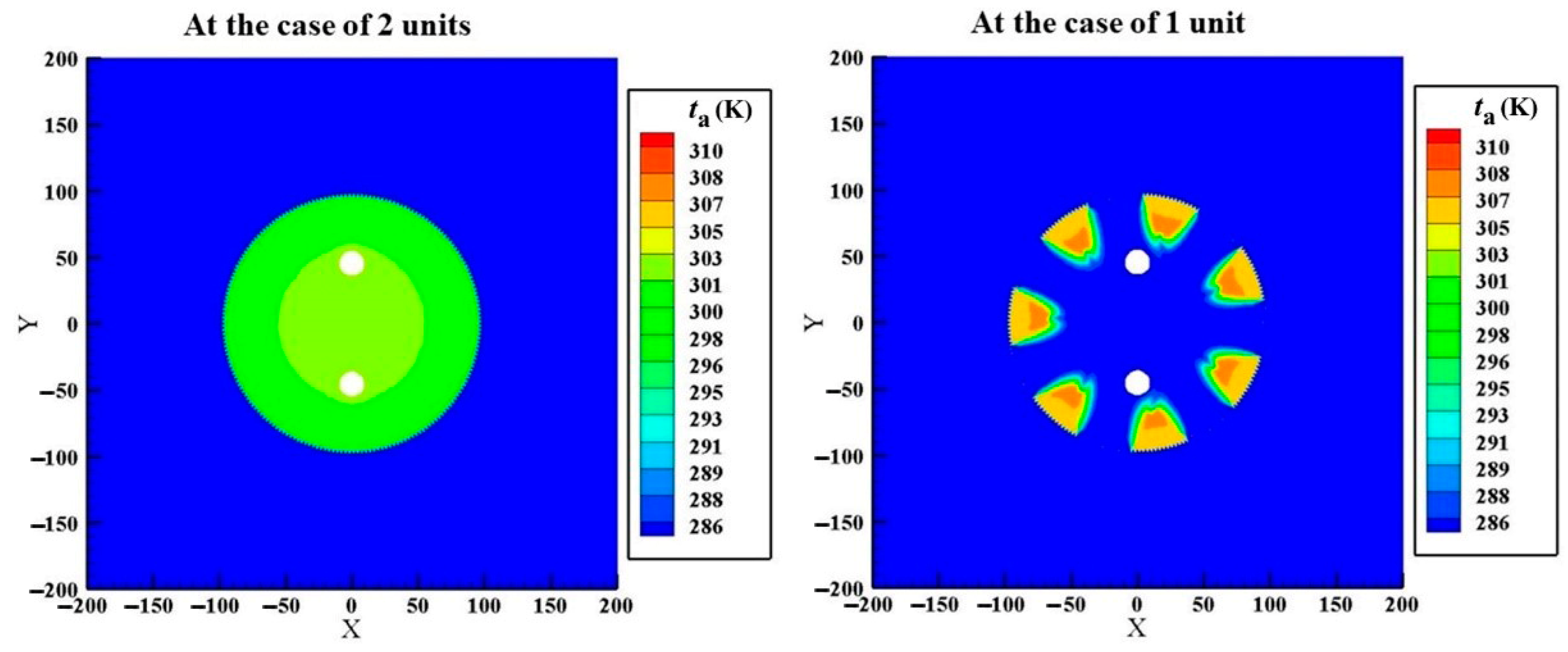

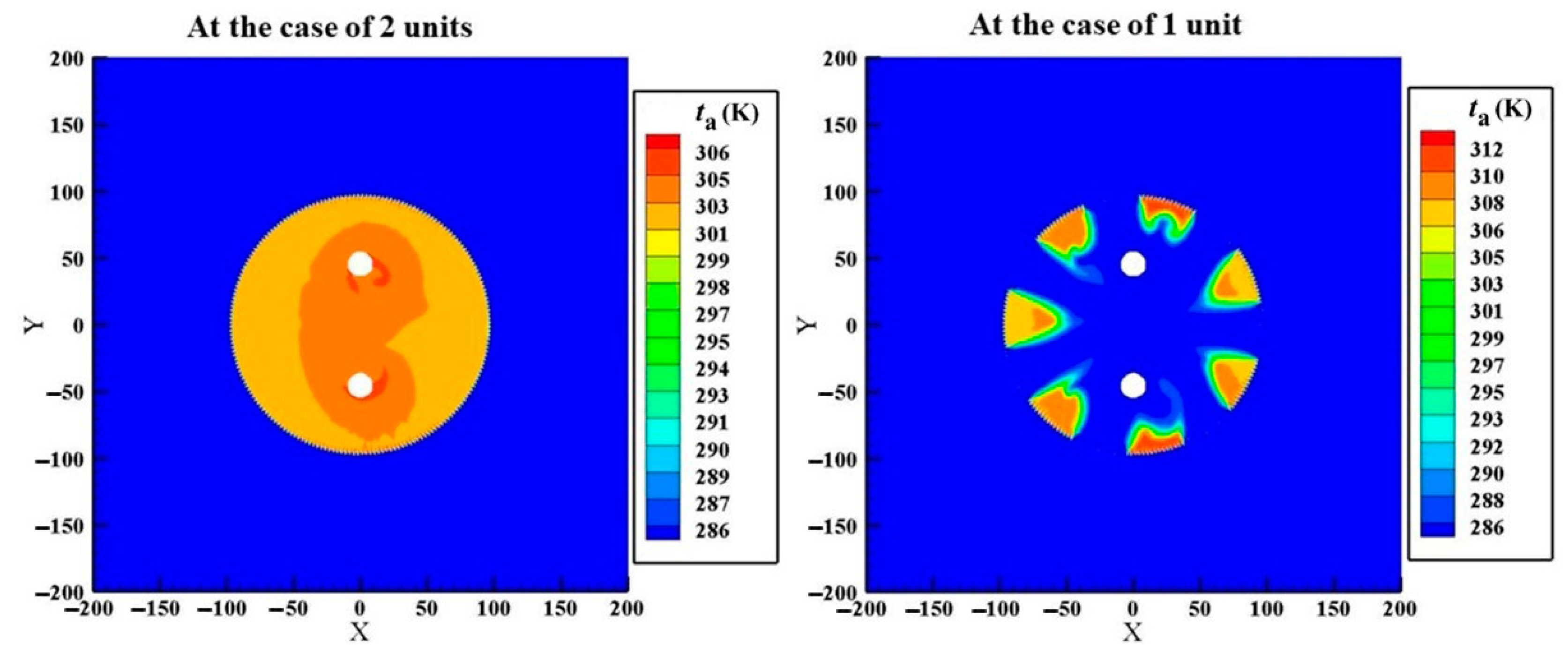

3.1. Thermo-Flow Performances of Cooling Deltas with One/Two Unit(s)

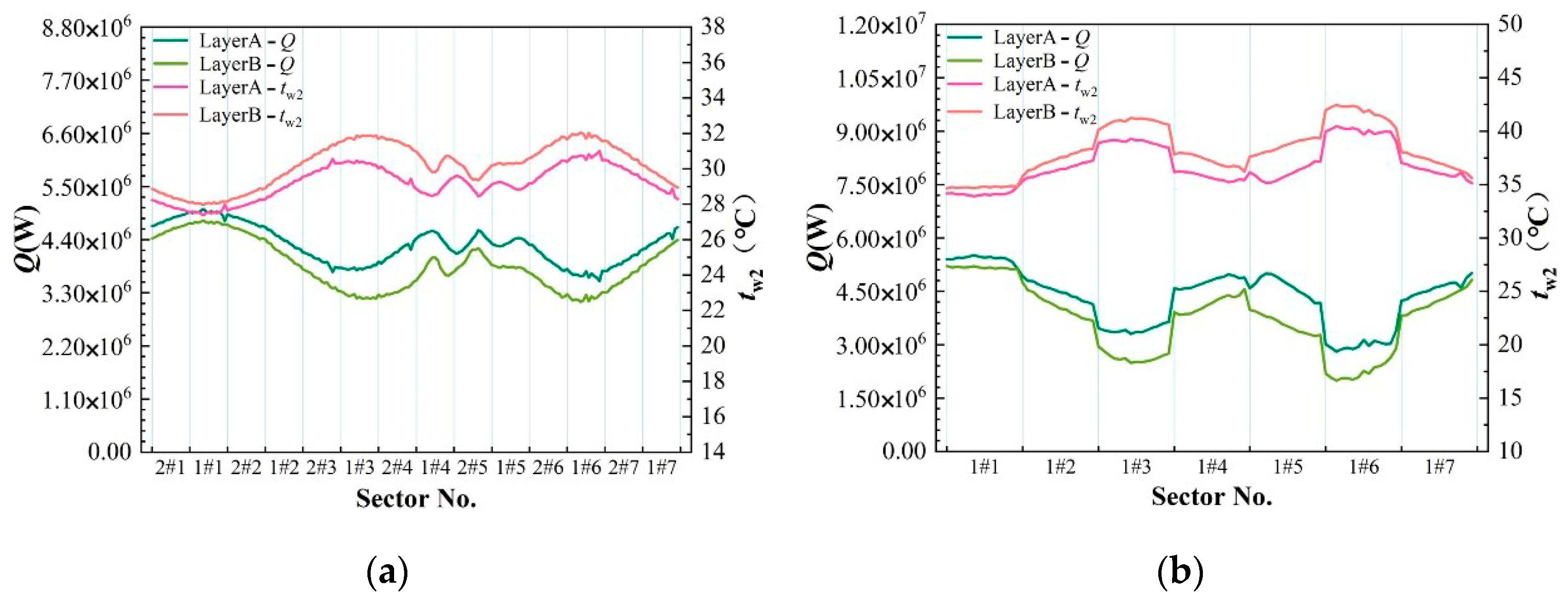

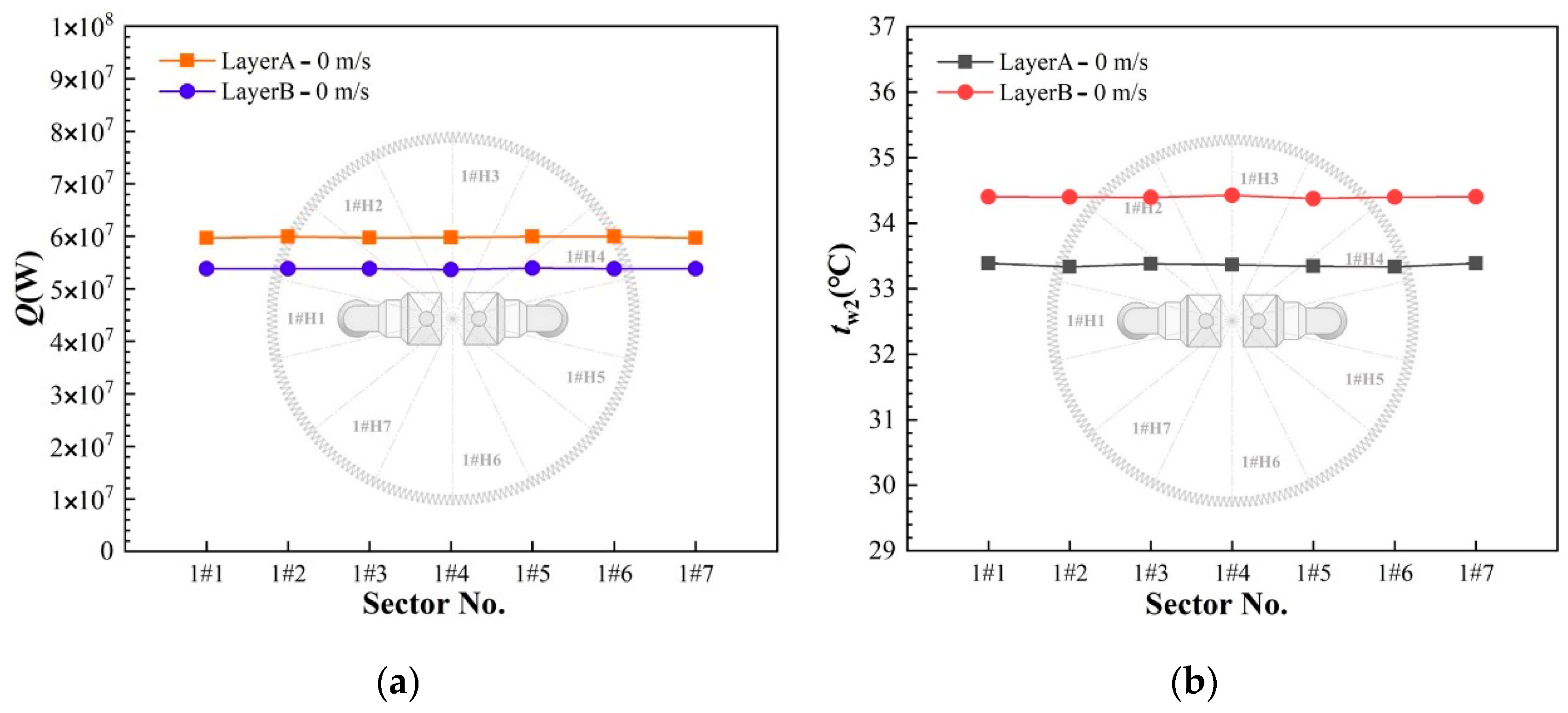

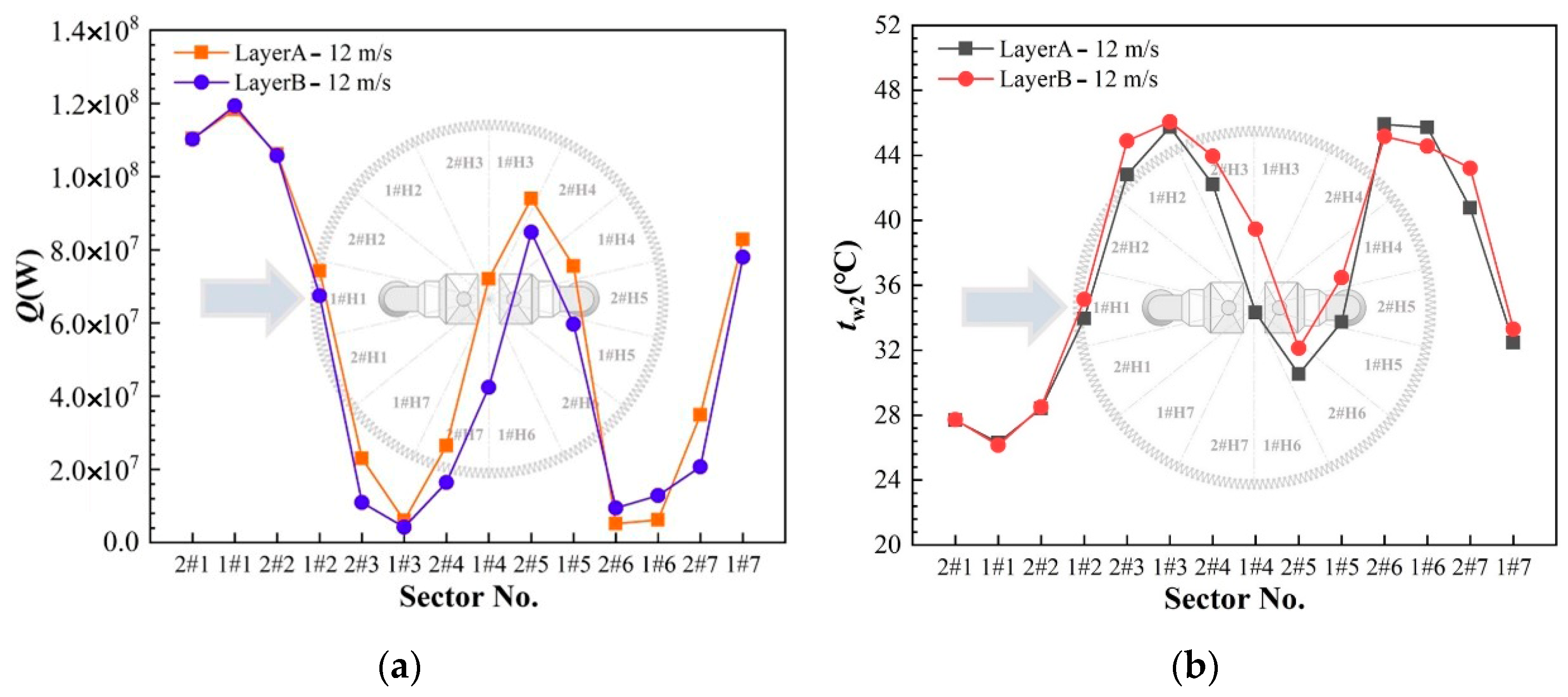

3.2. Thermo-Flow Performances of Air-Cooled Sectors with One/Two Unit(s)

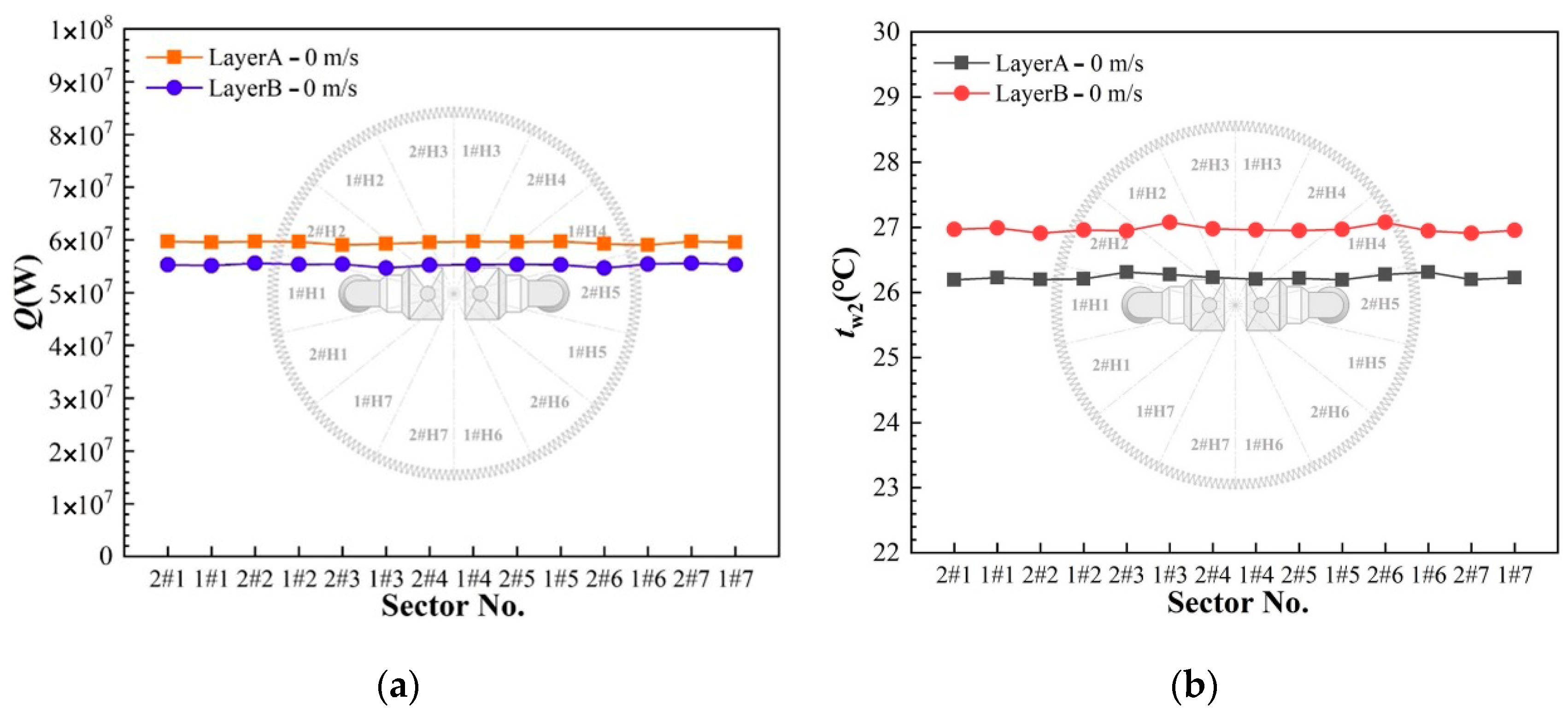

3.3. Overall Cooling Performances of NDDCS with One/Two Unit(s)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Nomenclature | |

| A | heat transfer surface area (m2) |

| cp | specific heat (J Kg−1 K−1) |

| D | diameter (m) |

| f | pressure loss coefficient |

| H | height (m) |

| k | turbulent kinetic energy (m2 s−2) |

| L | tube length (m) |

| m | mass flow rate (kg s−1) |

| N | number |

| p | pressure (Pa) |

| Q | heat rejection (W) |

| S | source term in generic equation |

| t | temperature (K) |

| u | velocity (m s−1) |

| V | volume (m3) |

| W | width (m) |

| Greek symbols | |

| ε | turbulence dissipation rate (m2 s−3) |

| εmacro | heat exchanger effectiveness |

| Γ | diffusion coefficient (m2 s−1) |

| φ | scalar variable |

| ρ | density (kg m−3) |

| Subscripts | |

| a | air |

| w | wind |

| wa | water |

| 1 | inlet |

| 2 | outlet |

| Acronyms | |

| ACHE | air-cooled heat exchanger |

| GCS | gas condensing system |

| NDDCS | natural draft dry cooling system |

| WESP | wet electrostatic precipitator |

| 1 # | one power-generating unit |

| 2 # | two power-generating unit |

References

- Kroger, D.G. Air-Cooled Heat Exchangers and Cooling Towers: Thermal-Flow Performance Evaluation and Design; Penn Well Corporation: Tulsa, OK, USA, 2004. [Google Scholar]

- Yang, L.J.; Wu, X.P.; Du, X.Z.; Yang, Y.P. Dimensional characteristics of wind effects on the performance of indirect dry cooling system with vertically arranged heat exchanger bundles. Int. J. Heat Mass Transf. 2013, 67, 853–866. [Google Scholar] [CrossRef]

- Wang, W.J.; Chen, L.; Kong, Y.Q.; Yang, L.J.; Niu, Y.G.; Du, X.Z. Cooling performance evaluation for double-layer configuration of air-cooled heat exchanger. Int. J. Heat Mass Transf. 2020, 151, 119396. [Google Scholar] [CrossRef]

- Dai, Y.; Lu, Y.; Klimenko, A.Y.; Wang, Y.; Hooman, K. Numerical investigation of swirl effects on a short natural draft dry cooling tower under windless and crosswind conditions. Appl. Therm. Eng. 2021, 21, 116628. [Google Scholar] [CrossRef]

- Khamooshi, M.; Anderson, T.N.; Nates, R.J. A numerical study on interactions between three short natural draft dry cooling towers In an in-line arrangement. Int. J. Therm. Sci. 2021, 159, 106505. [Google Scholar] [CrossRef]

- Ge, W.; Zhao, Y.; Song, S.; Li, W.; Gao, S.; Chen, T. Thermal characteristics of dry cooling tower reconstructed from obsolete natural draft wet cooling tower and the relevant thermal system coupling optimization—ScienceDirect. Appl. Therm. Eng. 2020, 174, 115202. [Google Scholar] [CrossRef]

- Yang, G.; Ding, L.; Guo, T.; Li, X.; Tian, W.; Xu, Z.; Wang, Z.; Sun, F.; Min, J.; Xu, J.; et al. Study of flue gas emission and improvement measure in a natural draft dry-cooling tower with flue gas injection under unfavorable working conditions. Atmos. Pollut. Res. 2020, 11, 963–972. [Google Scholar] [CrossRef]

- Song, G.; Zhi, X.; Fan, F.; Wang, W.; Wang, P. Cooling performance of cylinder-frustum natural draft dry cooling tower. Appl. Therm. Eng. 2020, 180, 115797. [Google Scholar] [CrossRef]

- Soltani, M.; Dehghani-Sanij, A.; Sayadnia, A.; Kashkooli, F.M.; Gharali, K.; Mahbaz, S.; Dusseault, M.B. Investigation of Airflow Patterns in a New Design of Wind Tower with a Wetted Surface. Energies 2018, 11, 1100. [Google Scholar] [CrossRef]

- Kashkooli, F.M.; Soltani, M.; Zargar, B.; Ijaz, M.K.; Taatizadeh, E.; Sattar, S.A. Analysis of an indoor air decontamination device inside an aerobiology chamber: A numerical-experimental study. Air Qual. Atmos. Health 2020, 13, 281–288. [Google Scholar] [CrossRef]

- Mehryan, S.A.M.; Kashkooli, F.M.; Soltani, M. Comprehensive study of the impacts of surrounding structures on the aero-dynamic performance and flow characteristics of an outdoor unit of split-type air conditioner. Build Simul. 2018, 11, 325–337. [Google Scholar] [CrossRef]

- Ma, H.; Si, F.Q.; Li, L.; Yan, W.S.; Zhu, K.P. Effects of ambient temperature and crosswind on thermo-flow performance of the tower under energy balance of the indirect dry cooling system. Appl. Therm. Eng. 2015, 78, 90–100. [Google Scholar] [CrossRef]

- Ma, H.; Si, F.Q.; Kong, Y.; Zhu, K.P.; Yan, W.S. A new theoretical method for predicating the part-load performance of natural draft dry cooling towers. Appl. Therm. Eng. 2015, 78, 1106–1115. [Google Scholar] [CrossRef]

- Zhao, Y.B.; Long, G.Q.; Sun, F.Z.; Li, Y.; Zhang, C.J. Numerical study on the cooling performance of dry cooling tower with vertical two-pass column radiators under crosswind. Appl. Therm. Eng. 2015, 75, 1106–1117. [Google Scholar] [CrossRef]

- Zhao, Y.B.; Sun, F.Z.; Li, Y.; Long, G.Q.; Yang, Z. Numerical study on the cooling performance of natural draft dry cooling tower with vertical delta radiators under constant heat load. Appl. Energy 2015, 149, 225–237. [Google Scholar] [CrossRef]

- Li, X.X.; Gurgenci, H.; Guan, Z.Q.; Sun, Y.B. Experimental study of cold inflow effect on a small natural draft dry cooling tower. Appl. Therm. Eng. 2018, 128, 762–771. [Google Scholar] [CrossRef]

- Li, X.X.; Gurgenci, H.; Guan, Z.Q.; Wang, X.R.; Xia, L. A review of the crosswind effect on the natural draft cooling towers. Appl. Therm. Eng. 2019, 150, 250–270. [Google Scholar] [CrossRef]

- Dong, P.X.; Li, X.X.; Sun, Y.B.; Hooman, K.; Guan, Z.Q.; Dai, Y.C.; Gurgenci, H. Numerical investigation of the influence of local effects on the transient start-up process of natural draft dry cooling towers in dispatchable power plants. Int. J. Heat Mass Transf. 2019, 133, 166–178. [Google Scholar] [CrossRef]

- Dong, P.X.; Li, X.X.; Hooman, K.; Sun, Y.B.; Li, J.S.; Guan, Z.Q.; Gurgenci, H. The crosswind effects on the start-up process of natural draft dry cooling towers in dispatchable power plants. Int. J. Heat Mass Transf. 2019, 135, 950–961. [Google Scholar] [CrossRef]

- Dai, Y.C.; Kaiser, A.S.; Lu, Y.S.; Klimenko, A.Y.; Dong, P.X.; Hooman, K. Addressing the adverse cold air inflow effects for a short natural draft dry cooling tower through swirl generation. Int. J. Heat Mass Transf. 2019, 145, 118738. [Google Scholar] [CrossRef]

- Zhao, Y.B.; Long, G.Q.; Sun, F.Z.; Li, Y.; Zhang, C.J.; Liu, J.B. Effect mechanism of air deflectors on the cooling performance of dry cooling tower with vertical delta radiators under crosswind. Energy Convers. Manag. 2015, 93, 321–331. [Google Scholar] [CrossRef]

- Chen, L.; Yang, L.J.; Du, X.Z.; Yang, Y.P. Performance improvement of natural draft dry cooling system by interior and exterior windbreaker configurations. Int. J. Heat Mass Transf. 2016, 96, 42–63. [Google Scholar] [CrossRef]

- Gu, H.F.; Wang, H.J.; Gu, Y.Q.; Yao, J.N. A numerical study on the mechanism and optimization of wind-break structures for indirect air-cooling towers. Energy Convers. Manag. 2016, 108, 43–49. [Google Scholar] [CrossRef]

- Wang, W.L.; Zhang, H.; Li, Z.; Lv, J.F.; Ni, W.D.; Li, Y.S. Adoption of enclosure and windbreaks to prevent the degradation of the cooling performance for a natural draft dry cooling tower under crosswind conditions. Energy 2016, 116, 1360–1369. [Google Scholar] [CrossRef]

- Wang, W.L.; Zhang, H.; Liu, P.; Li, Z.; Lv, J.F.; Ni, W.D. The cooling performance of a natural draft dry cooling tower under crosswind and an enclosure approach to cooling efficiency enhancement. Appl. Energy 2017, 186, 336–346. [Google Scholar] [CrossRef]

- Ma, H.; Si, F.Q.; Kong, Y.; Zhu, K.P.; Yan, W.S. Wind-break walls with optimized setting angles for natural draft dry cooling tower with vertical radiators. Appl. Therm. Eng. 2017, 112, 326–329. [Google Scholar] [CrossRef]

- Ma, H.; Si, F.Q.; Zhu, K.P.; Wang, J.S. The adoption of windbreak wall partially rotating to improve thermo-flow performance of natural draft dry cooling tower under crosswind. Int. J. Therm. Sci. 2018, 134, 66–88. [Google Scholar] [CrossRef]

- Wu, T.; Ge, Z.H.; Yang, L.J.; Du, X.Z. Flow deflectors to release the negative defect of natural wind on large scale dry cooling tower. Int. J. Heat Mass Transf. 2019, 128, 248–269. [Google Scholar] [CrossRef]

- Goodarzi, M.; Amooie, H. Heat transfer enhancement in a natural draft dry cooling tower under crosswind operation with heterogeneous water distribution. Int. J. Nuclear Power 2016, 61, 252–259. [Google Scholar]

- Wang, X.B.; Yang, L.J.; Du, X.Z.; Yang, Y.P. Performance improvement of natural draft dry cooling system by water flow distribution under crosswinds. Int. J. Heat Mass Transf. 2017, 108, 1924–1940. [Google Scholar] [CrossRef]

- Li, X.X.; Xia, L.; Gurgenci, H.; Guan, Z.Q. Performance enhancement for the natural draft dry cooling tower under crosswind condition by optimizing the water distribution. Int. J. Heat Mass Transf. 2017, 107, 271–280. [Google Scholar] [CrossRef]

- Goodarzi, M.; Ramezanpour, R.R. Alternative geometry for cylindrical natural draft cooling tower with higher cooling efficiency under crosswind condition. Energy Convers. Manag. 2014, 77, 243–249. [Google Scholar] [CrossRef]

- Liao, H.T.; Yang, L.J.; Du, X.Z.; Yang, Y.P. Influences of height to diameter ratios of dry-cooling tower upon thermo-flow characteristics of indirect dry cooling system. Int. J. Therm. Sci. 2015, 94, 178–192. [Google Scholar] [CrossRef]

- Kong, Y.Q.; Wang, W.J.; Yang, L.J.; Du, X.Z.; Yang, Y.P. A novel natural draft dry cooling system with bilaterally arranged air-cooled heat exchanger. Int. J. Therm. Sci. 2017, 112, 313–334. [Google Scholar] [CrossRef]

- Goodarzi, M. Proposing a new technique to enhance thermal performance and reduce structural design wind loads for natural drought cooling tower. Energy 2013, 62, 164–172. [Google Scholar] [CrossRef]

- Goodarzi, M. A proposed stack configuration for dry cooling tower to improve cooling efficiency under crosswind. J. Wind Eng. Ind. Aerodyn. 2010, 98, 858–863. [Google Scholar] [CrossRef]

- Lu, Y.S.; Klimenko, A.; Russell, H.; Dai, Y.C.; Warner, J.; Hooman, K. A conceptual study on air jet-induced swirling plume for performance improvement of natural draft cooling towers. Appl. Energy. 2018, 217, 496–508. [Google Scholar] [CrossRef]

- Chen, L.; Wang, W.; Kong, Y.; Yang, L.; Du, X. Hot air extraction to improve aerodynamic and heat transfer performances of natural draft dry cooling system. Int. J. Heat Mass Transf. 2020, 163, 120476. [Google Scholar] [CrossRef]

- Xia, L.; Gurgenci, H.; Liu, D.Y.; Guan, Z.Q.; Zhou, L.; Wang, P. CFD analysis of pre-cooling water spray system in natural draft dry cooling towers. Appl. Therm. Eng. 2016, 105, 1051–1060. [Google Scholar] [CrossRef]

- Chen, L.; Huang, X.W.; Yang, L.J.; Du, X.Z.; Yang, Y.P. Evaluation of natural draft dry cooling system incorporating water spray air precooling. Appl. Therm. Eng. 2019, 151, 294–307. [Google Scholar] [CrossRef]

- Huang, X.W.; Chen, L.; Yang, L.J.; Du, X.Z.; Yang, Y.P. Evaporation aided improvement for cooling performance of large scale natural draft dry cooling system. Appl. Therm. Eng. 2019, 163, 114350. [Google Scholar] [CrossRef]

- Sun, Y.B.; Guan, Z.Q.; Gurgenci, H.; Li, X.X.; Hooman, K. A study on multi-nozzle arrangement for spray cooling system in natural draft dry cooling tower. Appl. Therm. Eng. 2017, 124, 795–814. [Google Scholar] [CrossRef]

- Sun, Y.B.; Guan, Z.Q.; Gurgenci, H.; Li, X.X.; Hooman, K.; Li, X.X. Investigations on the influence of nozzle arrangement on the pre-cooling effect for the natural draft dry cooling tower. Appl. Therm. Eng. 2018, 130, 979–996. [Google Scholar] [CrossRef]

- Ge, W.J.; Fan, J.; Liu, C.X.; Li, W.D.; Chen, G.G.; Zhao, Y.B. Critical impact factors on the cooling performance design of natural draft dry cooling tower and relevant optimization strategies. Appl. Therm. Eng. 2019, 154, 614–627. [Google Scholar] [CrossRef]

- Wang, W.J.; Huang, X.W.; Yang, L.J.; Du, X.Z.; Yang, Y.P. Anti-freezing operation strategies of natural draft dry cooling system. Int. J. Heat Mass Transf. 2018, 118, 165–170. [Google Scholar] [CrossRef]

- Kong, Y.Q.; Yang, L.J.; Du, X.Z.; Yang, Y.P. Effects of continuous and alternant rectangular slots on thermo-flow performances of plain finned tube bundles in in-line and staggered configurations. Int. J. Heat Mass Transf. 2016, 93, 97–107. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value |

|---|---|---|

| Air-cooled heat exchanger and cooling tower | ||

| Height of tower (m) | Ht | 225 |

| Height of tower throat (m) | Htt | 168.75 |

| Height of each ACHE layer (m) | HA/B | 14.65 |

| Interval of ACHE layer (m) | Hi | 1.2 |

| Diameter of tower outlet (m) | Do | 128 |

| Diameter of tower throat (m) | Dtt | 121 |

| Diameter of tower bottom (m) | Db | 195 |

| Number of cooling deltas | Ncd | 392 |

| Number of air-cooled sectors | Ns | 14 |

| Four subsystems inside cooling tower | ||

| Diameter of desulfurizer (m) | Dd | 18.6 |

| Height of desulfurizer (m) | Hd | 38.05 |

| Length of GCS (m) | LG | 20.9 |

| Width of GCS (m) | WG | 14 |

| Hight of GCS (m) | HG | 3.5 |

| Length of WESP (m) | LW | 17.5 |

| Width of WESP (m) | WW | 27.85 |

| Height of WESP (m) | HW | 16.7 |

| Diameter of flue gas chimney (m) | Dc | 8 |

| Height of flue gas chimney (m) | Hc | 12.25 |

| Equations | φ | Γφ | Sφ |

|---|---|---|---|

| Continuity | 1 | 0 | 0 |

| x-momentum | ui | μe | |

| y-momentum | uj | μe | |

| z-momentum | uk | μe | |

| Energy | cpt | μe/σT | 0 |

| Turbulence kinetic energy | k | μ + μT/σk | |

| Turbulence dissipation rate | ε | μ + μT/σε |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Chen, L.; Jiang, K.; Zhou, X.; Zhang, Z.; Zhou, H.; Wang, W.; Yang, L.; Niu, Y. Investigation of Thermo-Flow Characteristics of Natural Draft Dry Cooling Systems Designed with Only One Tower in 2 × 660 MW Power Plants. Energies 2021, 14, 1308. https://doi.org/10.3390/en14051308

Liu M, Chen L, Jiang K, Zhou X, Zhang Z, Zhou H, Wang W, Yang L, Niu Y. Investigation of Thermo-Flow Characteristics of Natural Draft Dry Cooling Systems Designed with Only One Tower in 2 × 660 MW Power Plants. Energies. 2021; 14(5):1308. https://doi.org/10.3390/en14051308

Chicago/Turabian StyleLiu, Mohan, Lei Chen, Kaijun Jiang, Xiaohui Zhou, Zongyang Zhang, Hanyu Zhou, Weijia Wang, Lijun Yang, and Yuguang Niu. 2021. "Investigation of Thermo-Flow Characteristics of Natural Draft Dry Cooling Systems Designed with Only One Tower in 2 × 660 MW Power Plants" Energies 14, no. 5: 1308. https://doi.org/10.3390/en14051308

APA StyleLiu, M., Chen, L., Jiang, K., Zhou, X., Zhang, Z., Zhou, H., Wang, W., Yang, L., & Niu, Y. (2021). Investigation of Thermo-Flow Characteristics of Natural Draft Dry Cooling Systems Designed with Only One Tower in 2 × 660 MW Power Plants. Energies, 14(5), 1308. https://doi.org/10.3390/en14051308