Research on Determination of Water Diffusion Coefficient in Single Particles of Wood Biomass Dried Using Convective Drying Method

Abstract

1. Introduction

1.1. General Characteristics of Wood Biomass

- Free water—contained in the capillaries, does not have an impact on the dimensions (size) of the material. Evaporation heat is used to evaporate this form of water.

- Bound or hygroscopic water—contained in pores between micelles and bound via hydrogen bonds. In order to evaporate this form of water, the heat of vaporization is used to break the hydrogen bonds.

- Constitutional or capillary water—contained in cell walls, forms organic compounds, and cannot be removed by physical means. Therefore, it is not taken into account when measuring the moisture content of the material and during drying [30].

1.2. Water Diffusion in the Process of Wood Drying

2. Objective of the Work

3. Methodology

3.1. Drying Kinetics Measurements

3.2. Determination of the Mass Diffusion Coefficient

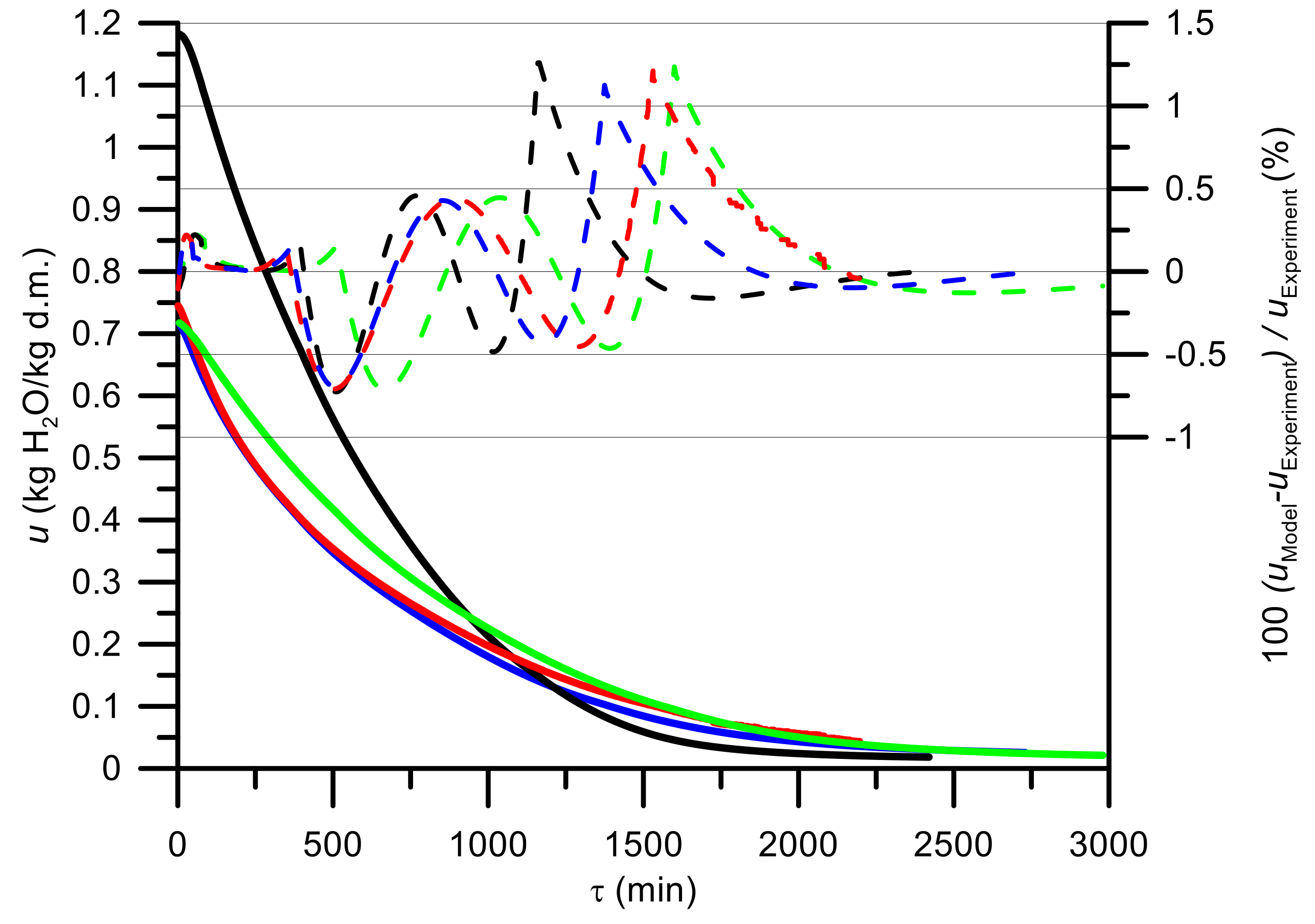

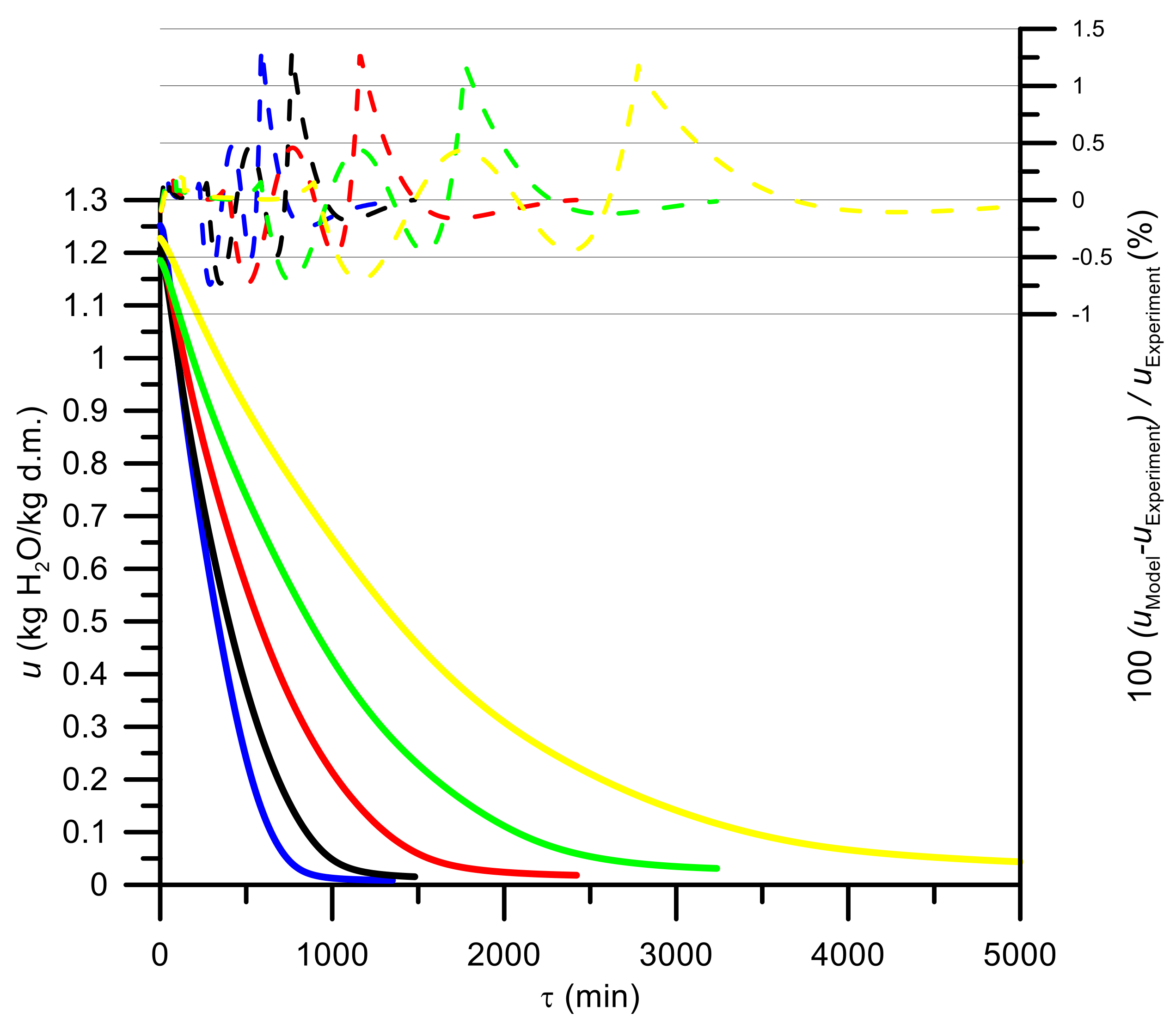

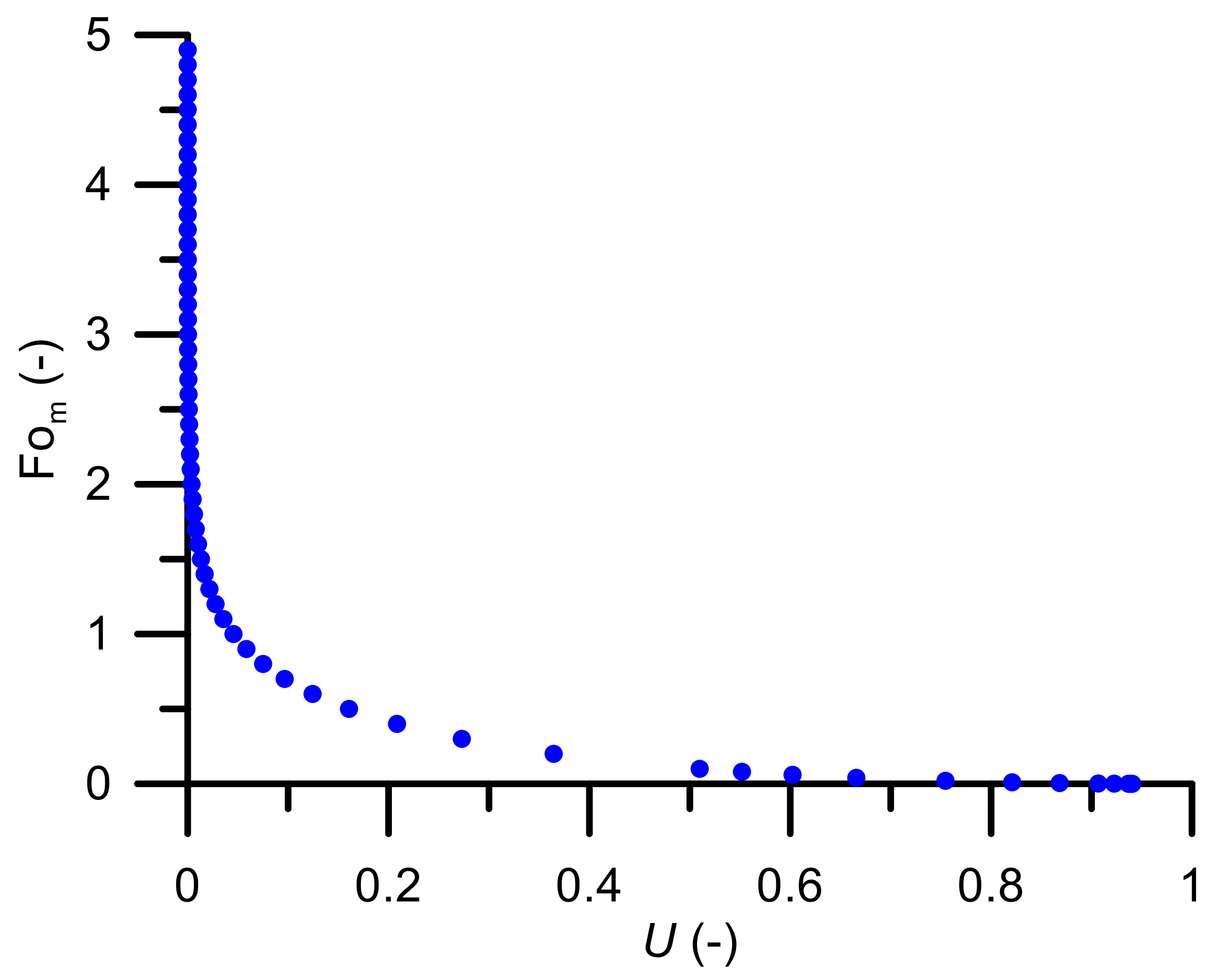

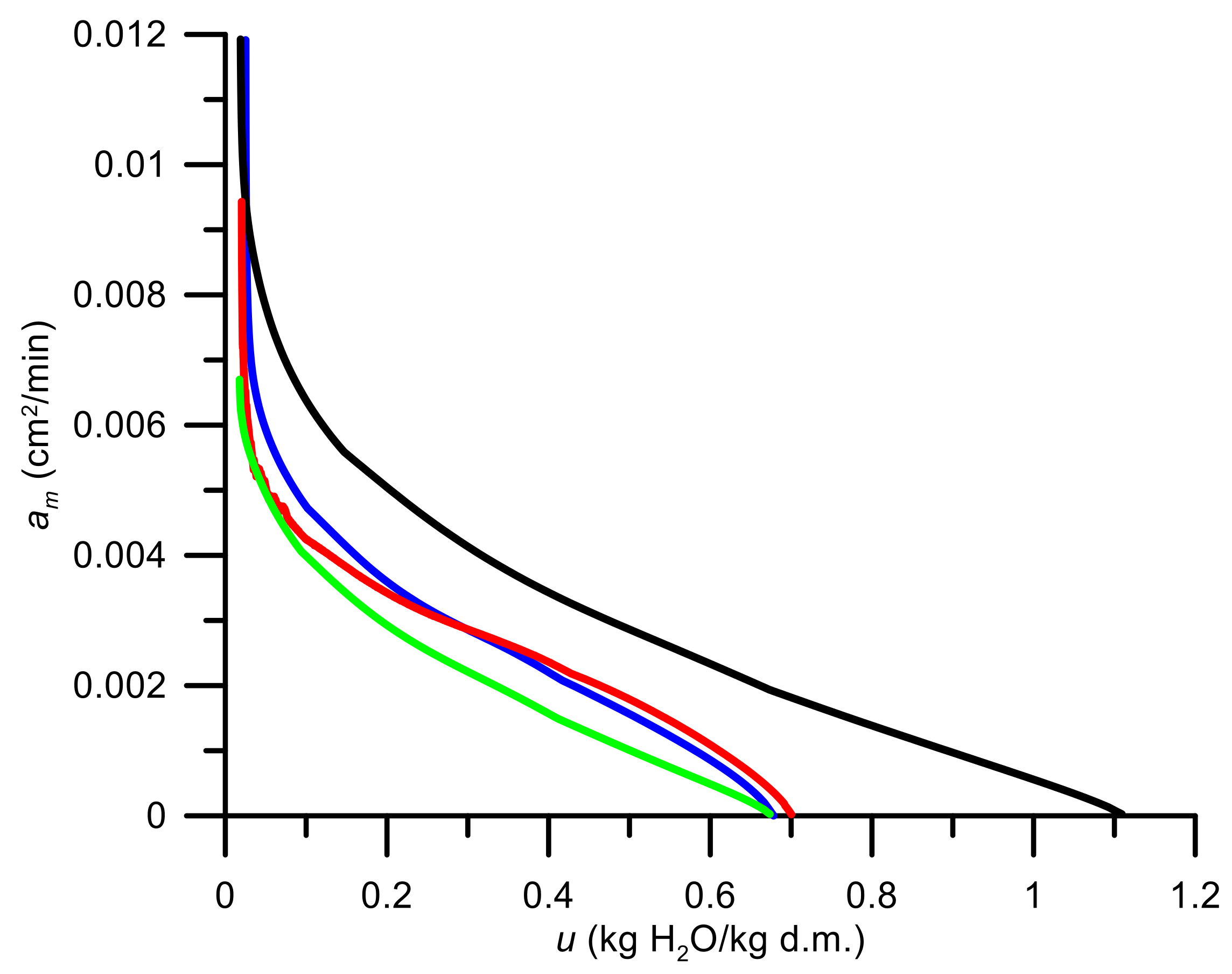

4. Results

5. Summary and Conclusions

- The value of the water diffusion coefficient for all types of examined wood biomass increases with the temperature of the drying agent.

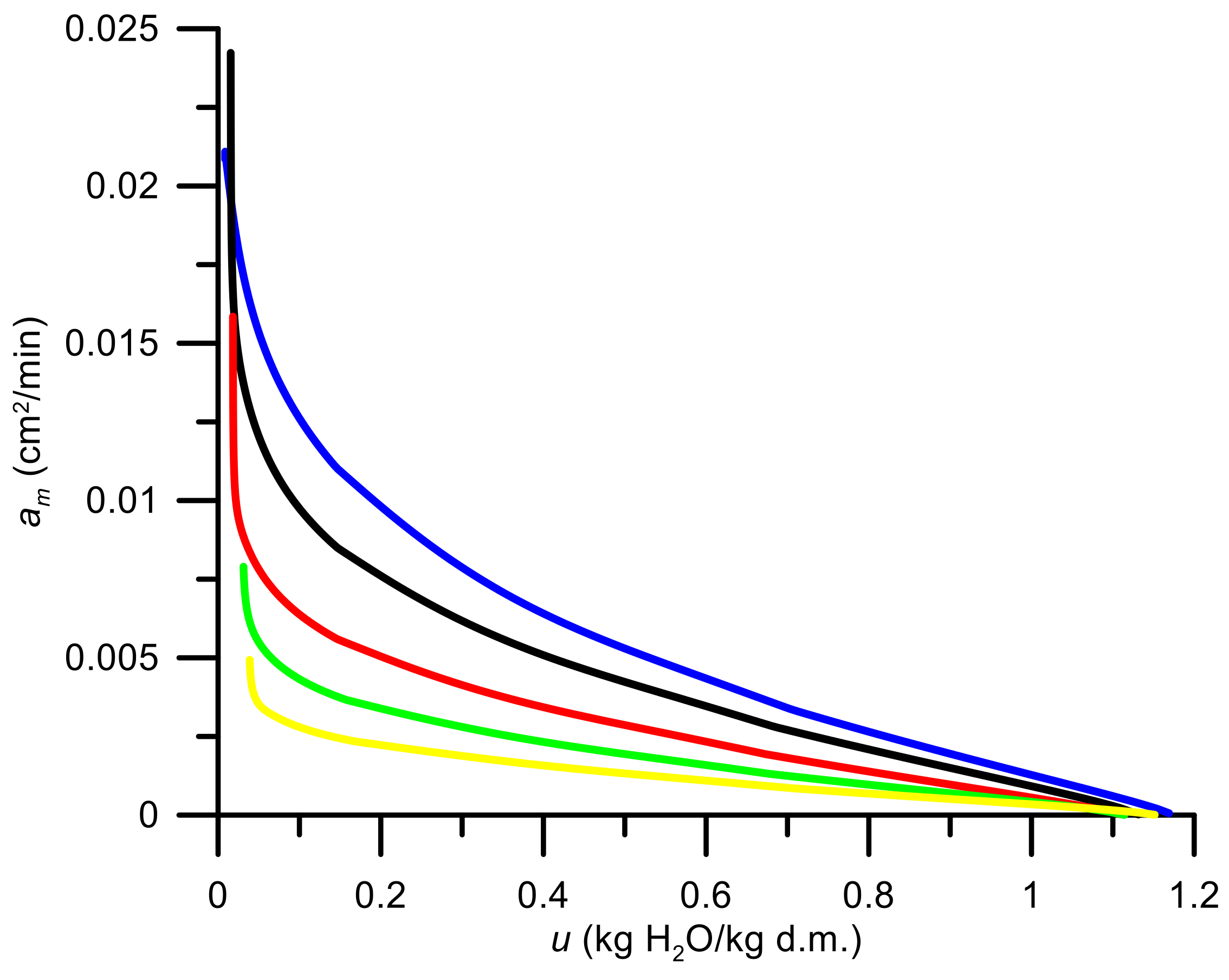

- In all examined cases, within the water content range from initial to approx. 0.03 kg/kg, values of the mass diffusion coefficient increase slightly; after reaching approx. 0.03 kg/kg, they rise sharply.

- Graphs showing changes of the diffusion coefficient versus water content for osier, acacia, and multiflora rose are similar, while the graph for poplar differs.

- At all drying temperatures, values of am calculated for osier, acacia, and rose were similar, while for the poplar, those values were considerably higher. This may be attributed to the highest initial water content as well as the smallest density of the material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Karbowniczak, A.; Hamerska, J.; Wróbel, M.; Jewiarz, M.; Nęcka, K. Evaluation of Selected Species of Woody Plants in Terms of Suitability for Energy Production. In Renewable Energy Sources: Engineering, Technology, Innovation; Mudryk, K., Werle, S., Eds.; Springer Proceedings in Energy; Springer: Cham, Switzerland, 2018; pp. 735–742. [Google Scholar] [CrossRef]

- Abuelnuor, A.A.A.; Wahid, M.A.; Hosseini, S.E.; Saat, A.; Saqr, K.M.; Sait, H.H.; Osman, M. Characteristics of biomass in flameless combustion: A review. Renew. Sustain. Energy Rev. 2014, 33, 363–370. [Google Scholar] [CrossRef]

- Corma, A.; De La Torre, O.; Renz, M.; Villandier, N. Production of high-quality diesel from biomass waste products. Angew. Chem. Int. Ed. 2011, 123, 2423–2426. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S.A. Review on torrefied biomass pellets as a sustainable alternative to coal in power generation. Renew. Sustain. Energy Rev. 2014, 40, 153–160. [Google Scholar] [CrossRef]

- Ruiz, J.A.; Juárez, M.C.; Morales, M.P.; Muñoz, P.; Mendívil, M.A. Biomass gasification for electricity generation: Review of current technology barriers. Renew. Sustain. Energy Rev. 2013, 18, 174–183. [Google Scholar] [CrossRef]

- Sahu, S.G.; Chakraborty, N.; Sarkar, P. Coal–biomass co-combustion: An overview. Renew. Sustain. Energy Rev. 2014, 39, 575–586. [Google Scholar] [CrossRef]

- Scurlock, J.M.; Hall, D.O. The contribution of biomass to global energy use. Biomass 1990, 21, 75–81. [Google Scholar] [CrossRef]

- González Martínez, M.; Hélias, E.; Ratel, G.; Thiéry, S.; Melkior, T. Torrefaction of Woody and Agricultural Biomass: Influence of the Presence of Water Vapor in the Gaseous Atmosphere. Processes 2021, 9, 30. [Google Scholar] [CrossRef]

- Arias, B.; Pevida, C.; Fermoso, J.; Plaza, M.G.; Rubiera, F.; Pis, J. Influence of torrefaction on the grindability and reactivity of woody biomass. Fuel Process. Technol. 2008, 89, 169–175. [Google Scholar] [CrossRef]

- Porteiro, J.; Mı´guez, J.L.; Granada, E.; Moran, J.C. Mathematical modelling of the combustion of a single wood particle. Fuel Proc. Technol. 2006, 87, 169–175. [Google Scholar] [CrossRef]

- Wróbel, M.; Mudryk, K.; Jewiarz, M.; Głowacki, S.; Tulej, W. Characterization of Selected Plant Species in Terms of Energetic Use. In Renewable Energy Sources: Engineering, Technology, Innovation; Mudryk, K., Werle, S., Eds.; Springer Proceedings in Energy; Springer: Cham, Switzerland, 2018; pp. 671–681. [Google Scholar] [CrossRef]

- Tarasov, D.; Leitch, M.; Fatehi, P. Lignin–carbohydrate complexes: Properties, applications, analyses, and methods of extraction: A review. Biotech. Bio. 2018, 11, 269. [Google Scholar] [CrossRef]

- Targoński, Z. Wesołowska-Trojanowska, M.; Hemicellulases–properties, application and production. Eng. Sci. Technol. 2015, 2, 79–94. [Google Scholar]

- Stamm, A.J. Wood and Cellulose Science; The Ronald Press: New York, NY, USA, 1977. [Google Scholar]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G.; Morgan, T.J. An overview of the organic and inorganic phase composition of biomass. Fuel 2012, 94, 1–33. [Google Scholar] [CrossRef]

- Lapczynska-Kordon, B.; Lis, S.; Tomasik, M. Control of the microwave drying process of selected fruits and vegetables. Przegląd Elektrotechniczny 2019, 95, 74–77. [Google Scholar] [CrossRef]

- Tursunov, O.; Dobrowolski, J.; Zubek, K.; Czerski, G.; Grzywacz, P.; Dubert, F.; Lapczynska-Kordon, B.; Klima, K.; Handke, B. Kinetic Study of the Pyrolysis and Gasification of Rosa Multiflora and Miscanthus Giganteus Biomasses Via Thermogravimetric Analysis. Ther. Sci. 2018, 22, 3057–3071. [Google Scholar] [CrossRef]

- Hoffmann, C.T.; Praß, J.; Uhlemann, T.H.J.; Franke, J. Improving the energy efficiency of industrial drying processes: A computational fluid dynamics approach. Proc. Manuf. 2019, 33, 422–429. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhang, J.; Wang, D.; Xu, Y.; Bhandari, B. Molecular dynamics simulation on moisture diffusion process for drying of porous media in nanopores. Int. J. Heat Mass Transfer 2018, 121, 555–564. [Google Scholar] [CrossRef]

- Kuznetsov, G.V.; Syrodoy, S.V.; Nigay, N.A.; Maksimov, V.I.; Gutareva, N.Y. Features of the processes of heat and mass transfer when drying a large thickness layer of wood biomass. Renew. Energy 2021, 169, 498–511. [Google Scholar] [CrossRef]

- Pari, L.; Brambilla, M.; Bisaglia, C.; Del Giudice, A.; Croce, S.; Salerno, M.; Gallucci, F. Poplar wood chip storage: Effect of particle size and breathable covering on drying dynamics and biofuel quality. Biomass Bioenerg. 2015, 81, 282–287. [Google Scholar] [CrossRef]

- Głowacki, S.; Gendek, A. Application of forced drying methods in preparation of forest chips for energy purposes. Ann. Warsaw Univ. Life Sci. Agric. 2011, 58, 29–34. [Google Scholar]

- He, X.; Lau, A.K.; Sokhansanj, S.; Jim Lim, C.; Xiaotao, T.B.; Melin, S.; Keddy, T. Moisture sorption isotherms and drying characteristics of Aspen. Biomass Bioennerg. 2013, 57, 161–167. [Google Scholar] [CrossRef]

- Lapczynska-Kordon, B.; Krzysztofik, B.; Sobol, Z. Quality of dried cauliflower according to the methods and drying parameters. BIO Web Conf. 2018, 10, 02017. [Google Scholar] [CrossRef]

- Gonzalez Martinez, M.; Dupont, C.; Thiery, S.; Meyer, X.; Gourdon, C. Characteristic Time Analysis of Biomass Torrefaction Phenomena-Application to Thermogravimetric Analysis Device. Chem. Eng. Trans. 2016, 50, 61–66. [Google Scholar]

- Dupont, C.; Boissonnet, G.; Seiler, J.M.; Gauthier-Maradei, P.; Schweich, D. Study about the kinetic process of biomass steam gasification. Fuel 2007, 86, 32–40. [Google Scholar] [CrossRef]

- Cai, L.; Avramidis, S. A study on the separation of diffusion and surface emission coefficients in wood. Drying Technol. 1997, 15, 1457–1473. [Google Scholar] [CrossRef]

- Göken, J.; Fayed, S.; Schäfer, H.; Enzenauer, J. A Study on the Correlation between Wood Moisture and the Damping Behaviour of the Tonewood Spruce. Acta Physica Polonica A 2018, 133, 1241–1260. [Google Scholar] [CrossRef]

- Scaar, C. Wood-Water Relations; Springer: Berlin/Heidelberg, Germany, 1988. [Google Scholar] [CrossRef]

- González, J.F.; Ledesma, B.; Alkassir, A.; González, J. Study of the influence of the composition of several biomass pellets on the drying process. Biomass Bioenerg. 2011, 35, 4399–4406. [Google Scholar] [CrossRef]

- Styks, J.; Wróbel, M.; Frączek, J.; Knapczyk, A. Effect of Compaction Pressure and Moisture Content on Quality Parameters of Perennial Biomass Pellets. Energies 2020, 13, 1859. [Google Scholar] [CrossRef]

- Abdoli, M.A.; Golzary, A.; Hosseini, A.; Sadeghi, P. Wood Pellet as a Renewable Source of Energy from Production to Consumption; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Hu, Q.; Shao, J.; Yang, H.; Yao, D.; Wang, X.; Chen, H. Effects of binders on the properties of bio-char pellets. Appl. Energy 2015, 157, 508–516. [Google Scholar] [CrossRef]

- Tumuluru, J. Effect of moisture content and hammer mill screen size on the briquetting characteristics of woody and herbaceous biomass. KONA Powder Part. J. 2019, 36, 241–251. [Google Scholar] [CrossRef]

- Górnicki, K.; Winiczenko, R.; Kaleta, A. Estimation of the Biot Number Using Genetic Algorithms: Application for the Drying Process. Energies 2019, 12, 2822. [Google Scholar] [CrossRef]

- Bruin, S.; Luyben, K.C.A.M. Drying of Food Materials: A Review of Recent Developments. Adv. Drying 1980, 1, 155–215. [Google Scholar]

- Dudek, G.; Borys, P. A Simple Methodology to Estimate the Diffusion Coefficient in Pervaporation-Based Purification Experiments. Polymers 2019, 11, 343. [Google Scholar] [CrossRef]

- Dincer, I.; Dost, S. An analytical model for moisture diffusion in solid objects during drying. Drying Technol. 1997, 13, 425–435. [Google Scholar] [CrossRef]

- Jaros, M.; Król, K.; Woźniak, K.; Głowacki, S. Wyznaczanie współczynnika dyfuzji wody w biomasie drzewnej zależnego od zawartości wody i temperatury. Inżynieria Rolnicza 2011, 8, 153–160. [Google Scholar]

- Weres, J.; Olek, W.; Kujawa, S. Comparison of optimization algorithms for inverse FEA of heat and mass transport in biomaterial. J. Theor. Appl. Mech. 2009, 47, 701–716. [Google Scholar]

- Stępniak, Ł. Wyznaczenie Temperatury Mokrego Termometru dla Wierzby Energetycznej Podczas Suszenia w Konwekcji Swobodnej; SGGW: Warsaw, Poland, 2008. [Google Scholar]

- Stępniewska, K. Badanie Kinetyki Suszenia Robinii Akacjowej; SGGW: Warsaw, Poland, 2008. [Google Scholar]

- Wajs, K. Badanie Kinetyki Suszenia Topoli Osiki; SGGW: Warsaw, Poland, 2008. [Google Scholar]

- Witek, I. Badanie Kinetyki Suszenia Róży Energetycznej w Konwekcji Swobodnej; SGGW: Warsaw, Poland, 2009. [Google Scholar]

- Jaros, M.; Cenkowski, S.; Jayas, D.S.; Pabis, S. A method of determination of the diffusion coefficient based on kernel moisture content and its temperature. Drying Technol. 1992, 10, 213–222. [Google Scholar] [CrossRef]

- Lykov, A.V. Teoriya sushki (Drying Theory), 2nd ed.; Energiya: Moscow, Russia, 1968. [Google Scholar]

- Pabis, S. Teoria Konwekcyjnego Suszenia Produktów Rolniczych; PWRiL: Warszawa, Poland, 1982. [Google Scholar]

- Górnicki, K.; Kaleta, A. Some properties related to mathematical modelling of mass transfer exemplified of convection drying of bilogical materials. In Heat and Mass Transfer—Modeling and Simulation; Hossain, M.M., Ed.; InTech: Rijeka, Croatia, 2011; pp. 143–166. [Google Scholar]

- Olek, W.; Weres, J. Effects of the method of identification of the diffusion coefficient on accuracy of modeling bound water transfer in wood. In Drying of Porous Materials; Kowalski, S.J., Ed.; Springer: Dordrecht, The Netherlands, 2006. [Google Scholar] [CrossRef]

- Olek, W.; Perré, P.; Weres, J. Inverse analysis of the transient bound water diffusion in wood. Holzforschung 2005, 59, 38–45. [Google Scholar] [CrossRef]

- Li, T.Q.; Henriksson, U.; Klason, T.; Ödberg, L. Water diffusion in wood pulp cellulose fibers studied by means of the pulsed gradient spin-echo method. J. Colloid Interf. Sci. 1992, 154, 305–315. [Google Scholar] [CrossRef]

- Anisimov, A.V.; Sorokina, N.Y.; Dautova, N.R. Water diffusion in biological porous systems: A NMR approach. Magnet. Res. Imag. 1998, 16, 565–568. [Google Scholar] [CrossRef]

| w (m) | t (m) | h (m) | K1 | K2 | K3 | R |

|---|---|---|---|---|---|---|

| 0.0135 ± 0.002 | 0.0135 | 0.025 | 0.6606 | 0.6606 | 0.3567 | 0.891 |

| Interval | Approximating Function Fo = f − 1(U) | Coefficient r |

|---|---|---|

| (0; 0.12437> | y = −0.405ln(U) − 0.2508 | r = 1 |

| (0.12437; 0.67> | y = 7.8128U4 − 15.912U3 + 12.941U2 − 5.471U + 1.1077 | r = 1 |

| (0.67; 0.9225> | y = − 0.4395U3 + 1.4667U2 − 1.6428U + 0.6133 | r = 1 |

| (0.9225; 1> | y = 0.2058U2 − 0.4392U + 0.231 | r = 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tulej, W.; Głowacki, S.; Bryś, A.; Sojak, M.; Wichowski, P.; Górnicki, K. Research on Determination of Water Diffusion Coefficient in Single Particles of Wood Biomass Dried Using Convective Drying Method. Energies 2021, 14, 927. https://doi.org/10.3390/en14040927

Tulej W, Głowacki S, Bryś A, Sojak M, Wichowski P, Górnicki K. Research on Determination of Water Diffusion Coefficient in Single Particles of Wood Biomass Dried Using Convective Drying Method. Energies. 2021; 14(4):927. https://doi.org/10.3390/en14040927

Chicago/Turabian StyleTulej, Weronika, Szymon Głowacki, Andrzej Bryś, Mariusz Sojak, Piotr Wichowski, and Krzysztof Górnicki. 2021. "Research on Determination of Water Diffusion Coefficient in Single Particles of Wood Biomass Dried Using Convective Drying Method" Energies 14, no. 4: 927. https://doi.org/10.3390/en14040927

APA StyleTulej, W., Głowacki, S., Bryś, A., Sojak, M., Wichowski, P., & Górnicki, K. (2021). Research on Determination of Water Diffusion Coefficient in Single Particles of Wood Biomass Dried Using Convective Drying Method. Energies, 14(4), 927. https://doi.org/10.3390/en14040927