An Experimental Study of Gas Flow Regime and Pressure Drop in a Random Packed Bed with Sinter Particles

Abstract

1. Introduction

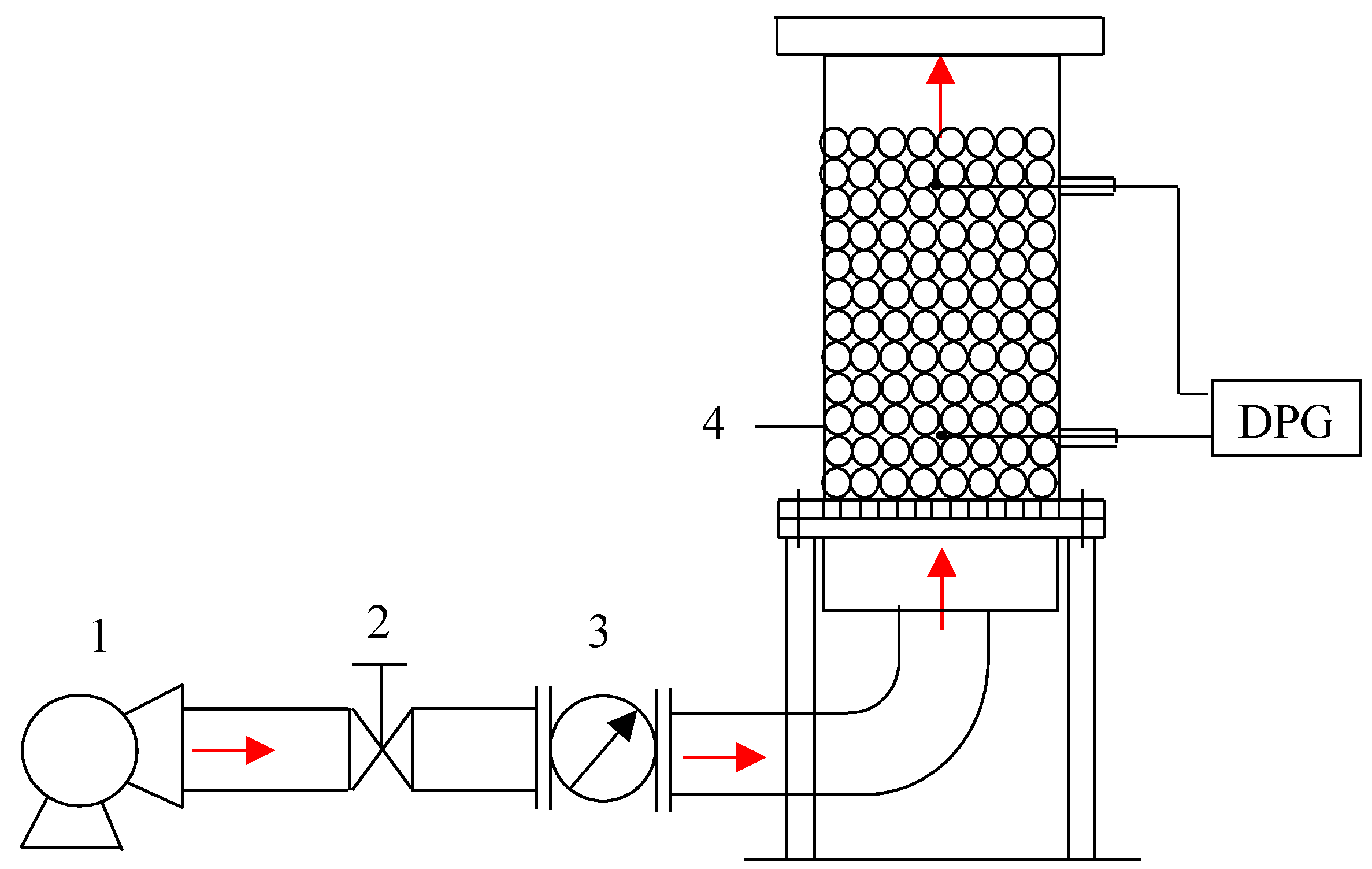

2. Experimental Description

3. Results and Discussion

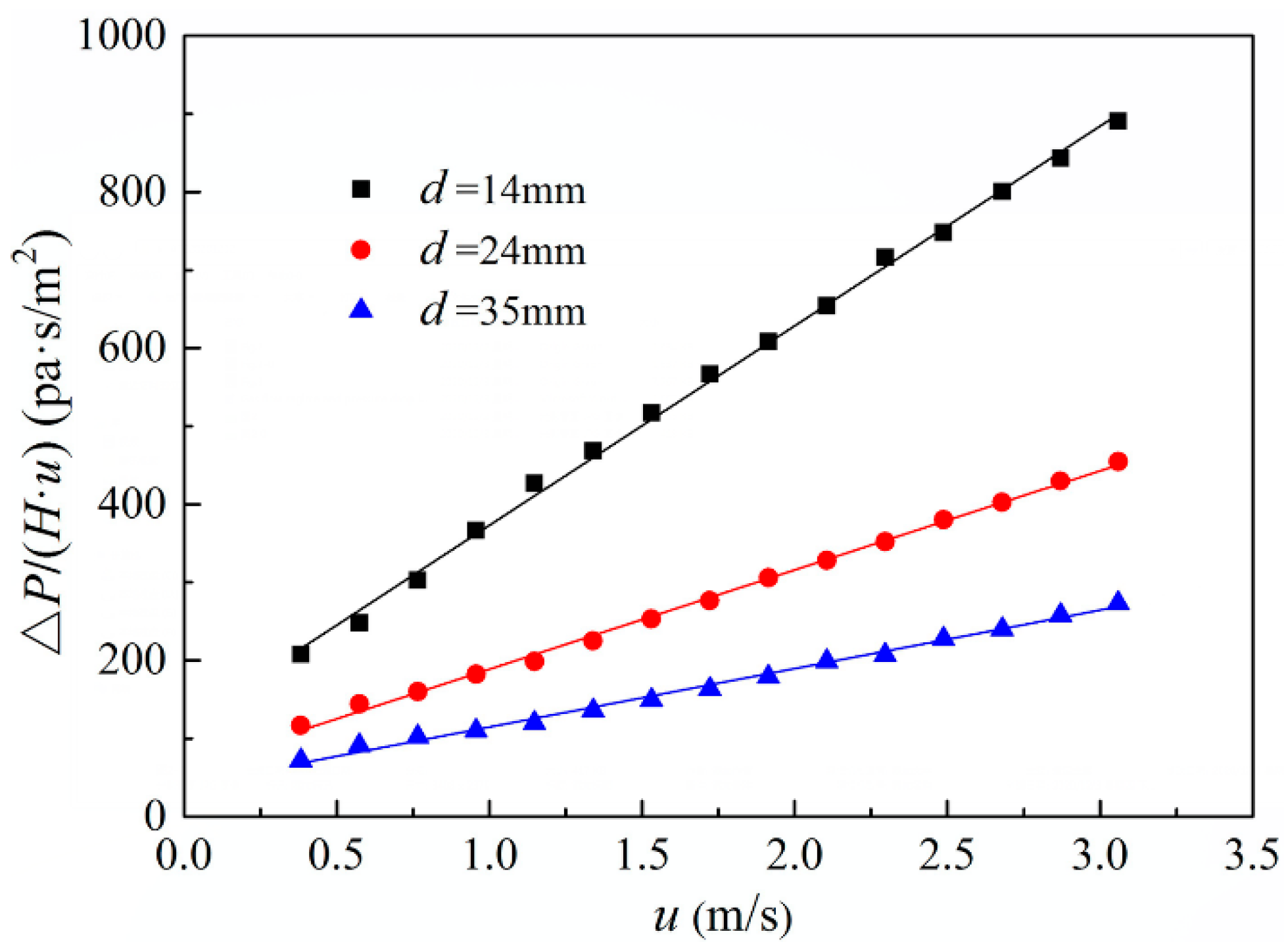

3.1. Analysis of Gas Flow Regime

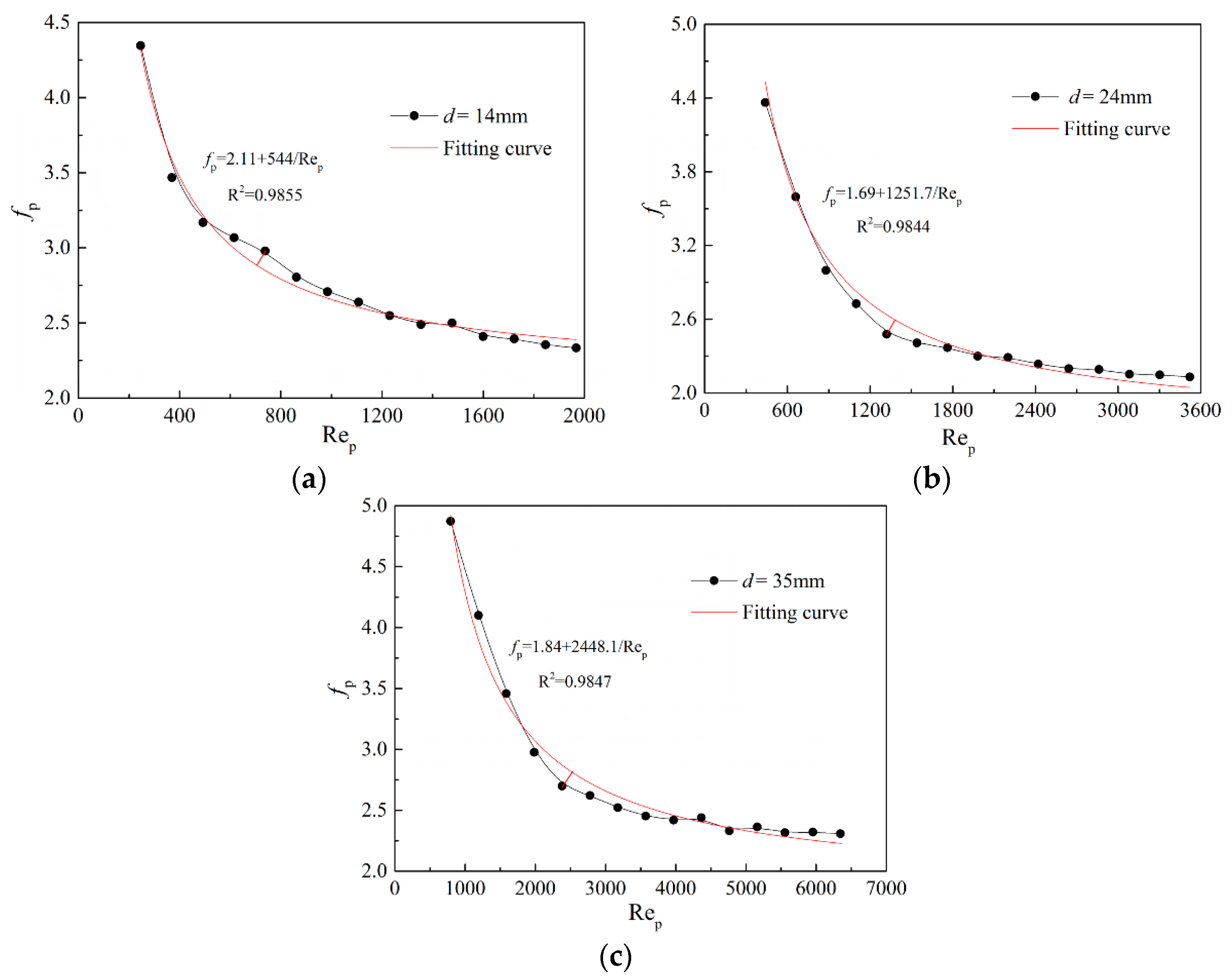

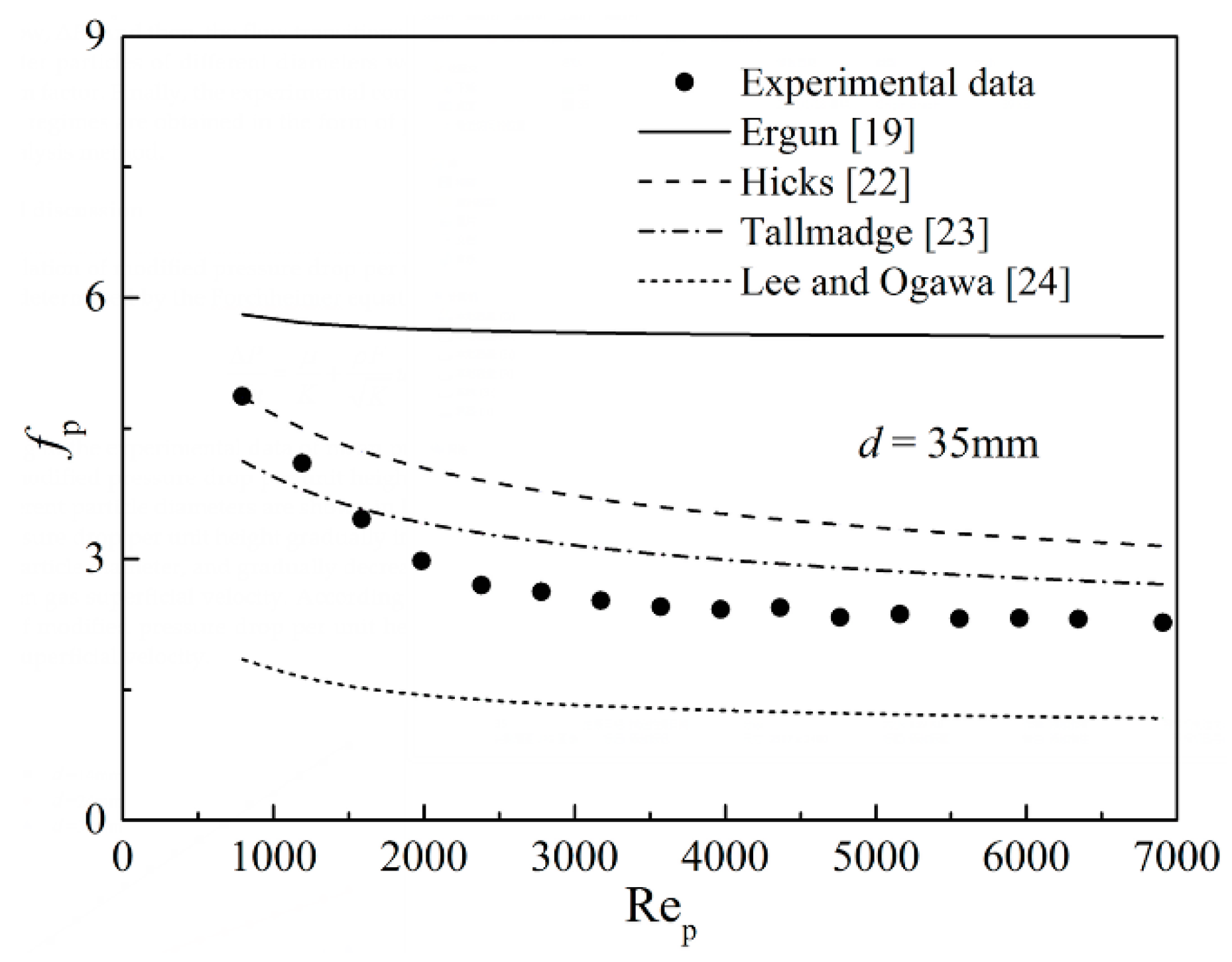

3.2. Determination of the Particle Friction Factor

4. Conclusions

- (1)

- For a certain particle diameter, the modified pressure drop per unit height, ΔP/Hu, increased linearly with the increase in gas superficial velocity, and the decrease in the particle friction factor, fp, demonstrated a power exponential relationship with the increasing particle Reynolds number, Rep.

- (2)

- Because of the differences in the modified coefficients α and β for various flow regimes, when the gas superficial velocity was larger than 1.15 m/s under atmospheric conditions, the gas flow regime in the sinter bed layer at that moment was the turbulent flow.

- (3)

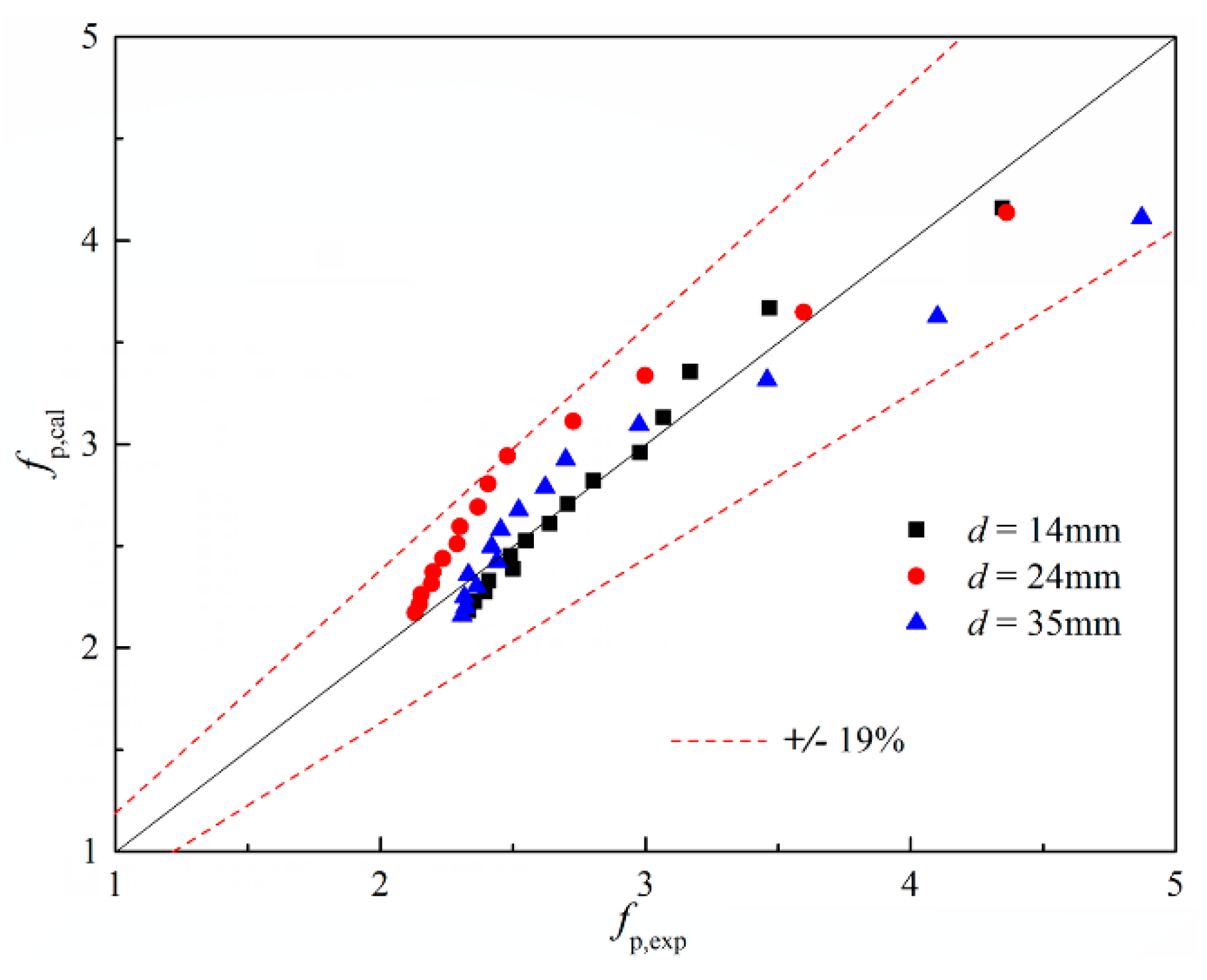

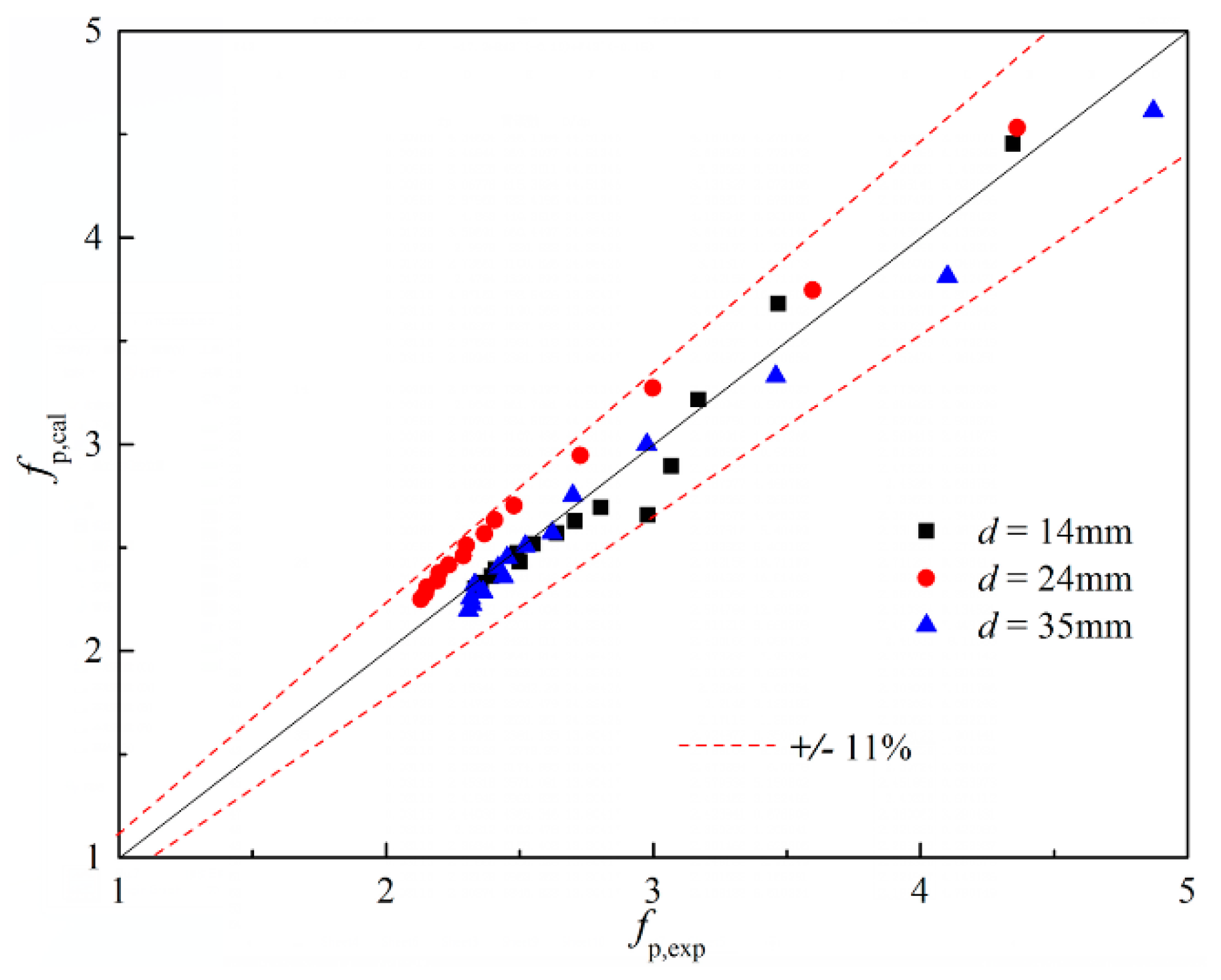

- On the basis of the dimensional analysis method, the specific equations of particle friction factor for the whole flow, the Forchheimer flow, and the turbulent flow in a sinter bed layer were determined. Compared with the experimental correlation of whole flow, the pressure drop correlations, obtained by the piecewise fitting method, provided a better prediction of the experimental data, and the average deviations of the obtained equations for the Forchheimer flow and the turbulent flow were 5.31% and 4.07%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| d | average particle diameter (m) |

| D | inner diameter of sinter bed layer (m) |

| dp | particle equivalent diameter (m) |

| F | Forchheimer coefficient (−) |

| fp | particle friction factor (−) |

| H | height of sinter bed layer (m) |

| K | permeability (m2) |

| P0 | atmospheric pressure (MPa) |

| Rep | particle Reynolds number (−) |

| T0 | ambient temperature (K) |

| u | gas superficial velocity (m/s) |

| Greek symbols | |

| ΔP | gas flow pressure drop through bed layer (Pa) |

| ΔP | gas flow pressure drop through bed layer (Pa) |

| μ | gas dynamic viscosity (Pa·s) |

| ε | bed voidage (−) |

| ρ | gas density (kg/m) |

| Φ | particle sphericity (−) |

| Subscripts | |

| c | critical point |

| cal | calculated value |

| exp | experimental value |

| p | particle |

References

- Barton, N.G. Simulations of air-blown thermal storage in a rock bed. Appl. Therm. Eng. 2013, 55, 43–50. [Google Scholar] [CrossRef]

- Bansal, P.; Jain, S.; Moon, C. Performance comparison of an adiabatic and an internally cooled structured packed-bed dehumidifier. Appl. Therm. Eng. 2011, 31, 14–19. [Google Scholar] [CrossRef]

- Bindra, H.; Bueno, P.; Morris, J.F.; Shinnar, R. Thermal analysis and exergy evaluation of packed bed thermal storage systems. Appl. Therm. Eng. 2013, 52, 255–263. [Google Scholar] [CrossRef]

- Dong, H.; Zhao, Y.; Cai, J.J.; Zhou, J.W.; Ma, G.Y. On the air leakage problem in sintering cooling system. Iron Steel 2012, 47, 95–99. [Google Scholar]

- Cai, J.J.; Dong, H. Method and Device of Sinter Waste Heat Recovery and Utilization with Vertical Tank. Chinese Patent 200910187381.8, 5 January 2011. [Google Scholar]

- Dong, H.; Li, L.; Liu, W.J.; Wang, B.; Suo, Y.S.; Cai, J.J. Process of waste heat recovery and utilization for sinter in vertical tank. China Metall. 2012, 22, 6–11. [Google Scholar]

- Jolls, K.R.; Hanratty, T.J. Transition to turbulence for flow through a dumped bed of spheres. Chem. Eng. Sci. 1966, 21, 1185–1190. [Google Scholar] [CrossRef]

- Bu, S.S.; Yang, J.; Dong, Q.T.; Wang, Q.W. Experimental study of flow transitions in structured packed beds of spheres with electrochemical technique. Exp. Therm. Fluid. Sci. 2015, 60, 106–114. [Google Scholar] [CrossRef]

- Bu, S.S.; Yang, J.; Dong, Q.T.; Wang, Q.W. Experimental study of transition flow in packed beds of spheres with different particle sizes based on electrochemical microelectrodes measurement. Appl. Therm. Eng. 2014, 73, 1525–1532. [Google Scholar] [CrossRef]

- Yang, J.; Bu, S.S.; Dong, Q.T.; Wu, J.Q.; Wang, Q.W. Experimental study of flow transitions in random packed beds with low tube to particle diameter ratios. Exp. Therm. Fluid Sci. 2015, 66, 117–126. [Google Scholar] [CrossRef]

- Johns, M.L.; Sederman, A.J.; Bramley, A.S.; Gladden, L.F.; Alexander, P. Local transitions in flow phenomena through packed beds identified by MRI. AIChE J. 2000, 46, 2151–2161. [Google Scholar] [CrossRef]

- Horton, N.A.; Pokrajac, D. Onset of turbulence in a regular porous medium: An experimental study. Phys. Fluids 2009, 21, 104–113. [Google Scholar] [CrossRef]

- Saayman, J.; Nicol, W.; Ommen, J.R.V.; Mudde, R.F. Fast X-ray tomography for the quantification of the bubbling-, turbulentand fast fluidization-flow regimes and void structures. Chem. Eng. J. 2013, 234, 437–447. [Google Scholar] [CrossRef]

- Ma, J.; Ommen, J.R.V.; Liu, D.; Mudde, R.F.; Chen, X.; Pan, S.; Liang, C. Fluidization dynamics of cohesive Geldart B particles. Part II: Pressure fluctuation analysis. Chem. Eng. J. 2019, 368, 627–638. [Google Scholar] [CrossRef]

- Fand, R.M.; Kim, B.Y.Y.; Lam, A.C.C.; Phan, R.T. Resistance to the flow of fluids through simple and complex porous media whose matrices are composed of randomly packed spheres. J. Fluids Eng. 1987, 109, 268–273. [Google Scholar] [CrossRef]

- Kececioglu, I.; Jiang, Y. Flow through porous media of packed spheres saturated with water. J. Fluids Eng. 1994, 116, 164–170. [Google Scholar] [CrossRef]

- Liu, S.; Masliyah, J.H. Single fluid flow in porous media. Chem. Eng. Commun. 1996, 148, 653–732. [Google Scholar] [CrossRef]

- Çarpinlioglu, M.Ö.; Özahi, E.; Gündogdu, M.Y. Determination of laminar and turbulent flow ranges through vertical packed beds in terms of particle friction factors. Adv. Powder Technol. 2009, 20, 515–520. [Google Scholar] [CrossRef]

- Ergun, S. Fluid flow through packed columns. Chem. Eng. Prog. 1952, 48, 89–94. [Google Scholar]

- Rose, H.E. On the resistance coefficient–Reynolds number relationship for fluid flow through beds of granular materials. Proc. Inst. Mech. Eng. 1945, 153, 154–168. [Google Scholar] [CrossRef]

- Rose, H.E.; Rizk, A.M.A. Further researches in fluid flow through beds of granular material. Proc. Inst. Mech. Eng. 1949, 160, 493–511. [Google Scholar] [CrossRef]

- Hicks, R.E. Pressure drop in packed beds of spheres. Ind. Eng. Chem. Fundam. 1970, 9, 500–502. [Google Scholar] [CrossRef]

- Tallmadge, J.A. Packed bed pressure drop—An extension to higher Reynolds numbers. AIChE J. 1970, 16, 1092–1093. [Google Scholar] [CrossRef]

- Lee, J.S.; Ogawa, K. Pressure drop through packed beds. J. Chem. Eng. Jpn. 1974, 27, 691–693. [Google Scholar] [CrossRef]

- Montillet, A.; Akkari, E.; Comiti, J. About a correlating equation for predicting pressure drops through packed beds of spheres in a large range of Reynolds numbers. Chem. Eng. Process. 2007, 46, 329–333. [Google Scholar] [CrossRef]

- Özahi, E.; Gündogdu, M.Y.; Çarpınlıoglu, M.Ö. A modification on Ergun’s correlation for use in cylindrical packed beds with non-spherical particles. Adv. Powder Technol. 2008, 19, 369–381. [Google Scholar] [CrossRef]

- Antohe, B.V.; Lage, J.L.; Price, D.C.; Weber, R.M. Experimental determination of permeability and inertial coefficients of mechanically compressed aluminum porous matrices. J. Fluids Eng. 1997, 11, 404–412. [Google Scholar] [CrossRef]

- Mancin, S.; Zilio, C.; Cavallini, A.; Rossetto, L. Pressure drop during air flow in aluminum foam. Int. J. Heat Mass Trans. 2010, 53, 3121–3130. [Google Scholar] [CrossRef]

- Feng, J.S.; Dong, H.; Liu, J.Y.; Liang, K.; Gao, J.Y. Experimental study of gas flow characteristics in vertical tank for sinter waste heat recovery. Appl. Therm. Eng. 2015, 91, 73–79. [Google Scholar] [CrossRef]

- Feng, J.S.; Dong, H.; Dong, H.D. Modification of Ergun’s correlation in vertical tank for sinter waste heat recovery. Powder Technol. 2015, 280, 89–93. [Google Scholar] [CrossRef]

| d (mm) | Φ | dp (mm) | u (m/s) |

|---|---|---|---|

| 14 | 0.69 | 9.66 | 0.3827, 0.5741, 0.7655, 0.9569, 1.15, 1.34, 1.531, 1.722, 1.9138, 2.105, 2.2965, 2.4879, 2.6793, 2.8707, 3.06 |

| 24 | 0.72 | 17.28 | 0.3827, 0.5741, 0.7655, 0.9569, 1.15, 1.34, 1.531, 1.722, 1.9138, 2.105, 2.2965, 2.4879, 2.6793, 2.8707, 3.06 |

| 35 | 0.89 | 31.15 | 0.3827, 0.5741, 0.7655, 0.9569, 1.15, 1.34, 1.531, 1.722, 1.9138, 2.105, 2.2965, 2.4879, 2.6793, 2.8707, 3.06 |

| Coefficients | Forchheimer Flow | Turbulent Flow | ||||

|---|---|---|---|---|---|---|

| d = 14 mm | d = 24 mm | d = 35 mm | d = 14 mm | d = 24 mm | d = 35 mm | |

| α | 456.8 | 1305.2 | 2798.1 | 745.6 | 753.1 | 1658 |

| β | 2.35 | 1.5 | 1.55 | 1.96 | 1.92 | 2.03 |

| Flow Regions | Fitting Parameters | ||

|---|---|---|---|

| k | a1 | a2 | |

| Whole flow | 71.6 | −0.31 | −0.3 |

| Forchheimer flow | 395.2 | −0.47 | −0.5 |

| Turbulent flow | 17.2 | −0.19 | −0.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Z.; Wang, H.; Feng, J.; Dong, H. An Experimental Study of Gas Flow Regime and Pressure Drop in a Random Packed Bed with Sinter Particles. Energies 2021, 14, 872. https://doi.org/10.3390/en14040872

Cheng Z, Wang H, Feng J, Dong H. An Experimental Study of Gas Flow Regime and Pressure Drop in a Random Packed Bed with Sinter Particles. Energies. 2021; 14(4):872. https://doi.org/10.3390/en14040872

Chicago/Turabian StyleCheng, Zude, Haitao Wang, Junsheng Feng, and Hui Dong. 2021. "An Experimental Study of Gas Flow Regime and Pressure Drop in a Random Packed Bed with Sinter Particles" Energies 14, no. 4: 872. https://doi.org/10.3390/en14040872

APA StyleCheng, Z., Wang, H., Feng, J., & Dong, H. (2021). An Experimental Study of Gas Flow Regime and Pressure Drop in a Random Packed Bed with Sinter Particles. Energies, 14(4), 872. https://doi.org/10.3390/en14040872