The model consists of two sub-models: (a) droplet cooling and ice crust growth; (b) breakage of a partially frozen droplet caused by its collision with the solid surface.

2.1. Droplet Cooling and Solidification

Let us assume that a droplet maintains a spherical shape during its motion. This assumption is justified by the relatively small sizes of droplets generated on the surface of seawater. Seawater is usually contaminated with different impurities. Therefore, it is possible to assume that a droplet’s surface is rigid (immobile), and the circulation motion inside a droplet can be neglected [

10]. A small-sized droplet generated in the air is cooled due to convective heat transfer. Such a droplet usually rotates with an unknown and non-constant angular velocity. Due to this uncertainty, in engineering applications, the droplet–air heat transfer coefficient is calculated with empirical correlations (e.g., [

11]). Assuming that the heat flux through the droplet’s surface is uniform, we can conclude that the heat transfer inside the droplet can be described by the one-dimensional equation of heat conduction for a sphere. Prior to the solidification of a droplet, its surface should be cooled to the crystallization temperature. To describe the cooling of a liquid droplet, we use the heat conduction equation, which is formulated in the dimensionless form [

12]:

where

is the dimensionless temperature,

T is the temperature,

is the ambient air temperature,

is the water crystallization (freezing) temperature,

is the dimensionless time,

t is the time,

is the droplet radius,

is the water’s thermal diffusivity,

is the water’s thermal conductivity,

is the water’s density,

is the water’s specific heat capacity,

is the dimensionless radial coordinate, and

r is the radial coordinate.

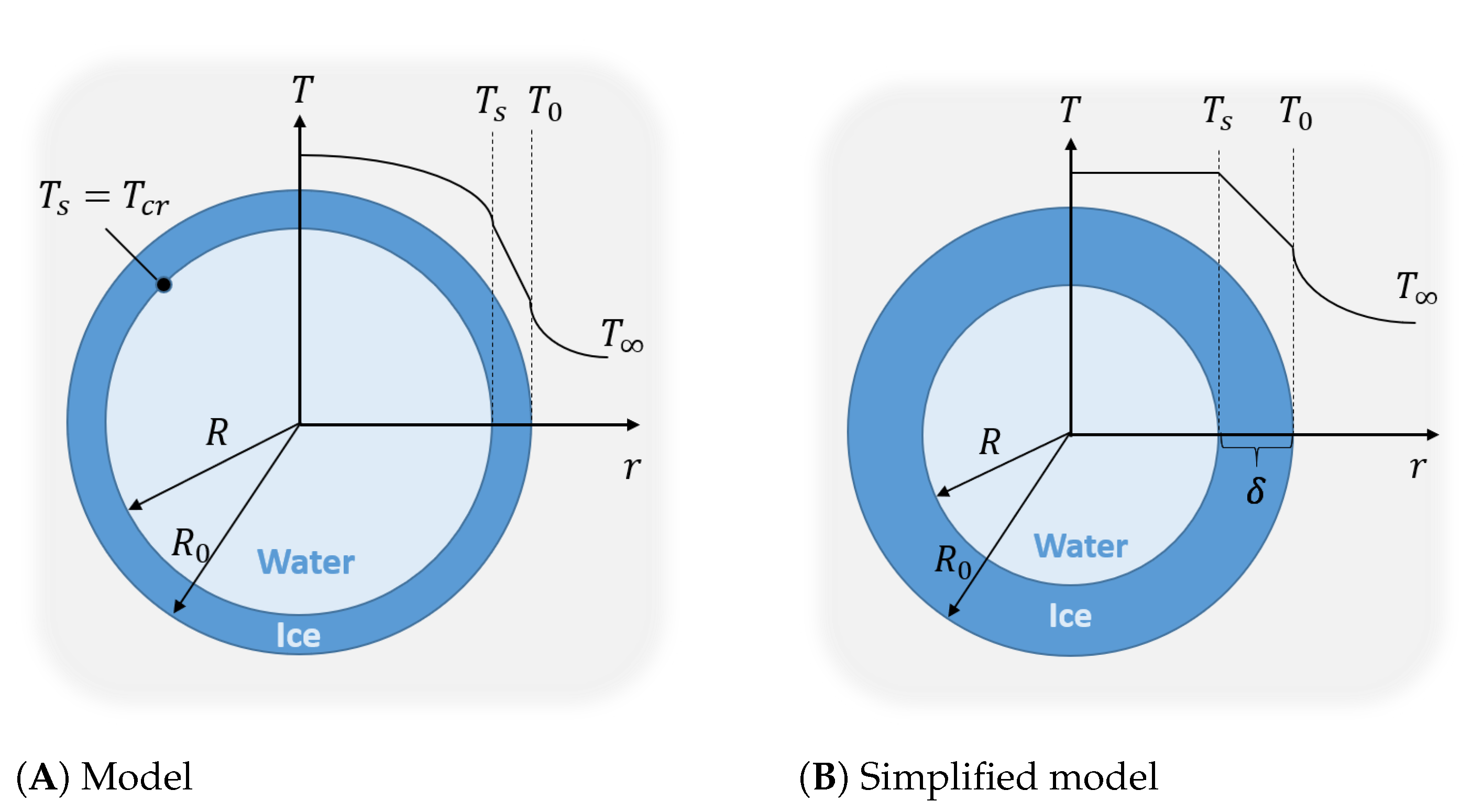

Equation (

1) is applicable until the moment when the temperature at the droplet’s surface,

, reaches the water’s freezing temperature. After that, the solid crust starts growing toward the droplet’s center. This solidification process represents a well-known Stefan problem. A diagram illustrating this process is shown in

Figure 1A. The heat conduction inside a shrinking liquid core that is coated with a solid crust of increasing thickness is described by the heat conduction equation, which is formulated in coordinates normalized by the radius of the liquid core. Equation (

1) can be converted into the heat conduction equation for the liquid core, accounting for a decreasing radius, through the following coordinate transformation [

13]:

where

is the dimensionless radial coordinate,

R is the liquid core’s radius, and

is the dimensionless radius of the liquid core.

This transformation leads to the following equation:

We would like to emphasize that Equation (

3) was successfully employed in [

14] for modeling the heat transfer inside an oil sand lump digested in a hot pipeline water flow.

The liquid core’s shrinkage rate, which is caused by ice crust formation, is derived from the heat balance at the liquid core/solid crust boundary formulated for a small time lapse

. During

, the heat rejected from the liquid core’s surface due to conduction through the solid crust is spent on both solidification of a thin spherical layer of the thickness

and on cooling of the liquid core by heat conduction through the liquid. The only assumption employed for the derivation of the shrinking rate equation is the steady-state heat conduction through the solid crust. This assumption is justified by both a rather small ice crust thickness, which is caused by the short time of droplet motion in cold air, and the relatively high thermal diffusivity of ice. After conducting routine math, the obtained heat balance equation is transformed into the dimensionless equation for the radius reduction rate of the unfrozen core as follows:

where

is the Stefan number,

is the latent heat of crystallization,

is the ice’s specific heat capacity,

is the ice’s density,

is the droplet’s Biot number,

is the ice’s thermal conductivity,

h is the droplet–ambient-air convective heat transfer coefficient,

is the droplet’s Nusselt number, and

is the air’s thermal conductivity.

In the present work, the Nusselt number was calculated with the well-known Ranz–Marshal correlation:

[

11], where

is the droplet’s Reynolds number,

U is the droplet–air relative velocity,

is the density of air,

is the air’s dynamic viscosity,

is the air’s Prandtl number, and

is the air’s specific heat capacity.

The initial condition required for the solution of the equation of droplet cooling, Equation (

1), is the known water temperature uniformly distributed over the droplet volume. The first boundary condition in the droplet center is as follows:

Note that the first boundary condition is also the same for Equation (

3). The second boundary condition for Equation (

1) is obtained by equating the convection heat flux out of the droplet’s surface to the conduction flux toward this surface, and it is formulated as follows:

The second boundary condition for Equation (

3) expresses the equality of the temperature at the liquid core’s boundary to the water’s crystallization temperature, i.e.,

Thus, Equations (

1)–(

7) allow the calculation of both the cooling and freezing processes for a droplet moving in cold air.

Assuming that, at the initial moment in time, the temperature over the droplet’s liquid core is uniform and equal to the crystallization temperature (i.e.,

), Equation (

4) can be solved analytically. A diagram illustrating this simplified case is shown in

Figure 1B. The analytical equation relating the dimensionless time and the solid crust’s thickness has the following form [

15]:

where

is the ice’s thermal diffusivity and

is the ice crust’s thickness.

Although at the normal conditions, the ice’s density is about 9% lower than the water’s density, for the sake of simplicity, we assume . This simplification weakly affects the modeling results.

The model equations (Equations (

1), (

3), and (

4)) were solved numerically using an explicit finite difference technique. A Matlab code was developed for this purpose. The code demonstrated rapid convergence and independence of the solution on the chosen radial and time steps (

and

s, respectively). Note that for the one-dimensional heat conduction problem, the stability of an explicit numerical method is determined by the Fourier number formulated for a single integration cell [

16]. If this criterion is smaller than 0.5, the numerical method is stable. This condition has been satisfied for the computations conducted within the present work. To further support the correctness of the model validation presented here, we would like to emphasize again that the model of droplet solidification proposed in the present work has a single assumption that differentiates it from the accurate one-dimensional model that was solved and validated by different authors [

15,

17]. This assumption is the steady-state heat transfer through the ice crust, which is justified by both the small crust thickness and high thermal diffusivity of ice. We estimated the Fourier number for the crust, assuming that its characteristic size was equal to the crust’s thickness. It turned out that the Fourier numbers corresponding to the crust thickness range considered in the present work are almost always below the critical value, 0.1, indicating the nearly immediate formation of a uniform temperature profile across the crust if the liquid core is absent. This result means that heat conduction through the crust is practically the steady state process. Thus, the model for forecasting the thin ice crust growth suggested in this work has to provide results that are very close to those calculated using the standard (accurate) model [

15]. Therefore, the model validation given here is primarily aimed at validating not the model itself, but the numerical code developed.

The presented cooling/freezing model was validated by comparing the calculated results with those computed using the commercial STAR CCM+ CFD code. The model incorporated into this code assumes that solidification occurs not at a single temperature value, but within a defined temperature range [

18]. Note that this modeling approach was originally developed for metal alloys. According to this model, a mixture of solid and liquid is formed during the crystallization process. A solid-phase volume fraction corresponding to a certain temperature is assumed to be known. This model was meticulously validated [

19]. To apply it to the ice crust formation calculation, we assumed a very small range for the solidification temperature, 0.002 °C. The volume fraction of ice was linearly interpolated within this range.

The STAR CCM+ simulations were conducted in the three-dimensional formulation. The initial and boundary conditions for the CFD model were the same as those for the developed model. The uniform mesh was employed for all of the computations. The mesh size was assumed to be equal to the initial mesh size used in the Matlab code. The same time step was employed for both codes.

In

Figure 2, we show the dimensionless crust thickness vs. time, comparing the computed results using the STAR CCM+ CFD code with the results calculated using the in-house engineering code developed based on the model presented here. The computations were done for a droplet with a 2 mm diameter. The initial droplet temperature was assumed to be

= 3 °C and the ambient air temperature was assumed to be

°C. The air–droplet heat transfer coefficient was calculated, assuming that the droplet–air relative velocity was equal to the droplet’s terminal velocity. The properties of the water, ice, and air used for the calculations are given in

Table 1. These data were obtained at a constant temperature equal to 0 °C [

20].

One can see that the results of computations by the different models are relatively close to each other. The slightly faster growth of the ice crust forecasted by the Matlab code was probably caused by the assumption of the steady-state heat transfer through this crust. The difference between the computational results increases with an increase in the crust thickness: The thicker the crust is, the longer the time needed to obtain the steady-state temperature distribution across the crust assumed in the Matlab code. The larger the deviation from the steady-state assumption, the larger the error caused by this simplification. Note that the Matlab code’s numerical inaccuracy is excluded from the present analysis due to the proven independence of the generated data on both the spatial and time steps. It is possible to affirm that the results presented in

Figure 2 support our conclusion that the developed ice crust formation model is sufficiently accurate for practical calculations. We would like to stress that further model validation with experimental data is unfeasible for two reasons: (1) It has been proven that the developed model provides results close to those produced by the accurate model for a small crust thickness; (2) there are no known experimental data on droplet freezing that were obtained while monitoring the thickness of a thin ice crust.

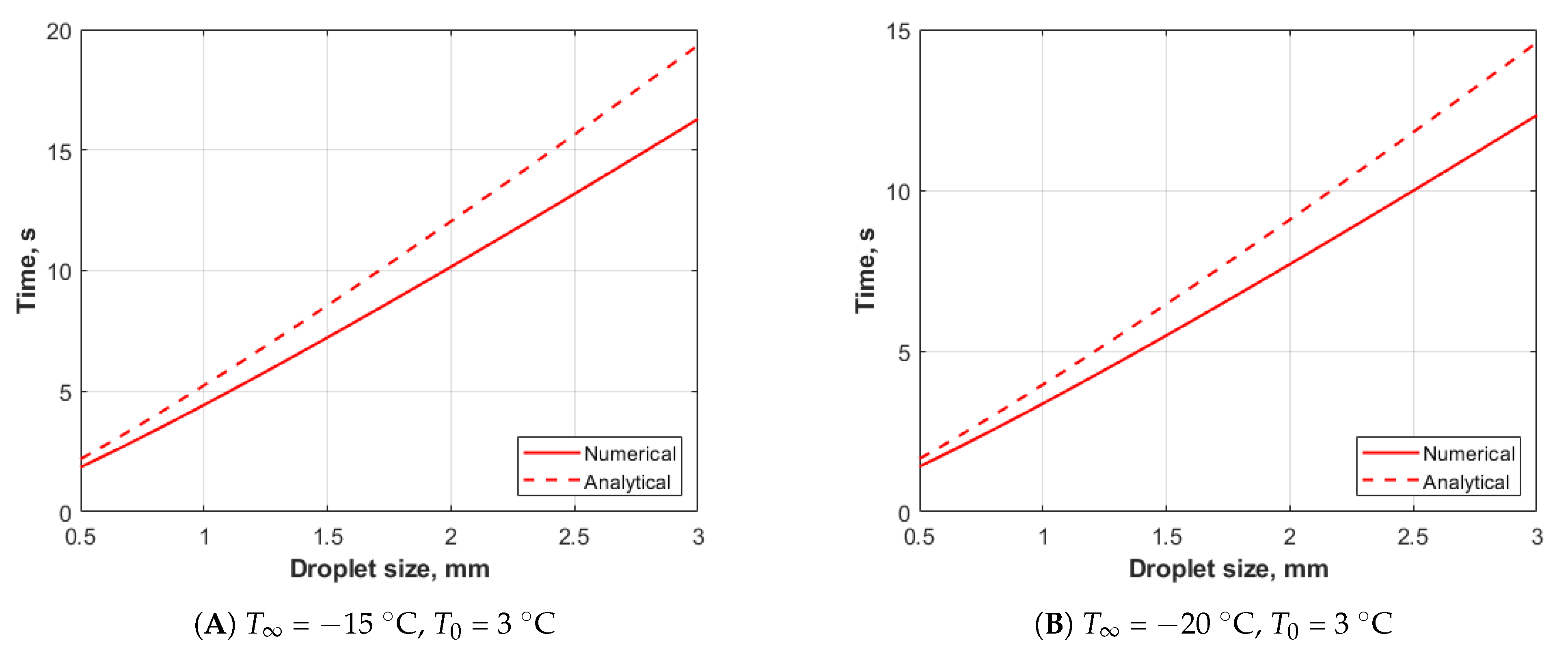

In

Figure 3, we compare the numerical solution obtained by the developed Matlab code with the analytical solution. The initial droplet temperature was assumed to be

= 3 °C. For

Figure 3A, the ambient air temperature was set equal to

= −15 °C, and for

Figure 3B, it was set to

= −20 °C. All of the calculations for

Figure 3 were conducted with the assumption that the obtained crust thickness,

, was equal to

of the droplet’s radius. Note that the curve showing the analytical solution was obtained as a sum of the crystallization time, which was calculated by Equation (

8), and the cooling time,

, which was estimated assuming a uniform droplet temperature [

21]. The dimensionless cooling time is calculated as follows:

Our calculations showed that the cooling time stage is relatively short for the droplet size range considered. The crust formation times calculated by the analytical equation are close to those computed by the Matlab code; however, the deviations of the analytical solution from the numerical one increase with an increase in the droplet size. This observation is explained as follows. The analytical solution does not account for heat conduction through the liquid core during the solidification process. The larger the droplet size, the higher the corresponding heat conduction flux because larger droplets are characterized by higher temperature gradients; therefore, the error associated with neglecting the conduction flux in the liquid core increases with an increase in the droplet size. Nevertheless, the analytical equations (Equations (

8) and (

9)) are accurate enough to be used for practical estimations of the crust thickness vs. time if the droplet size is relatively small.

2.2. Particle–Wall Collision

We would like to emphasize that rapid growth of the ice crust is accompanied with the formation of different defects (e.g., micro-cracks) and, consequently, is characterized by a relatively low strength. There are numerous research works on solid particle–wall collisions. It is worth mentioning a couple of recent experimental works [

22,

23] where ice particle–wall interactions were studied.

Our estimations showed that a collision of a droplet coated by an ice crust with a wall is usually associated with plastic deformation of the ice. Elastic deformation corresponds to a very low collision velocity and, therefore, does not represent a practical interest.

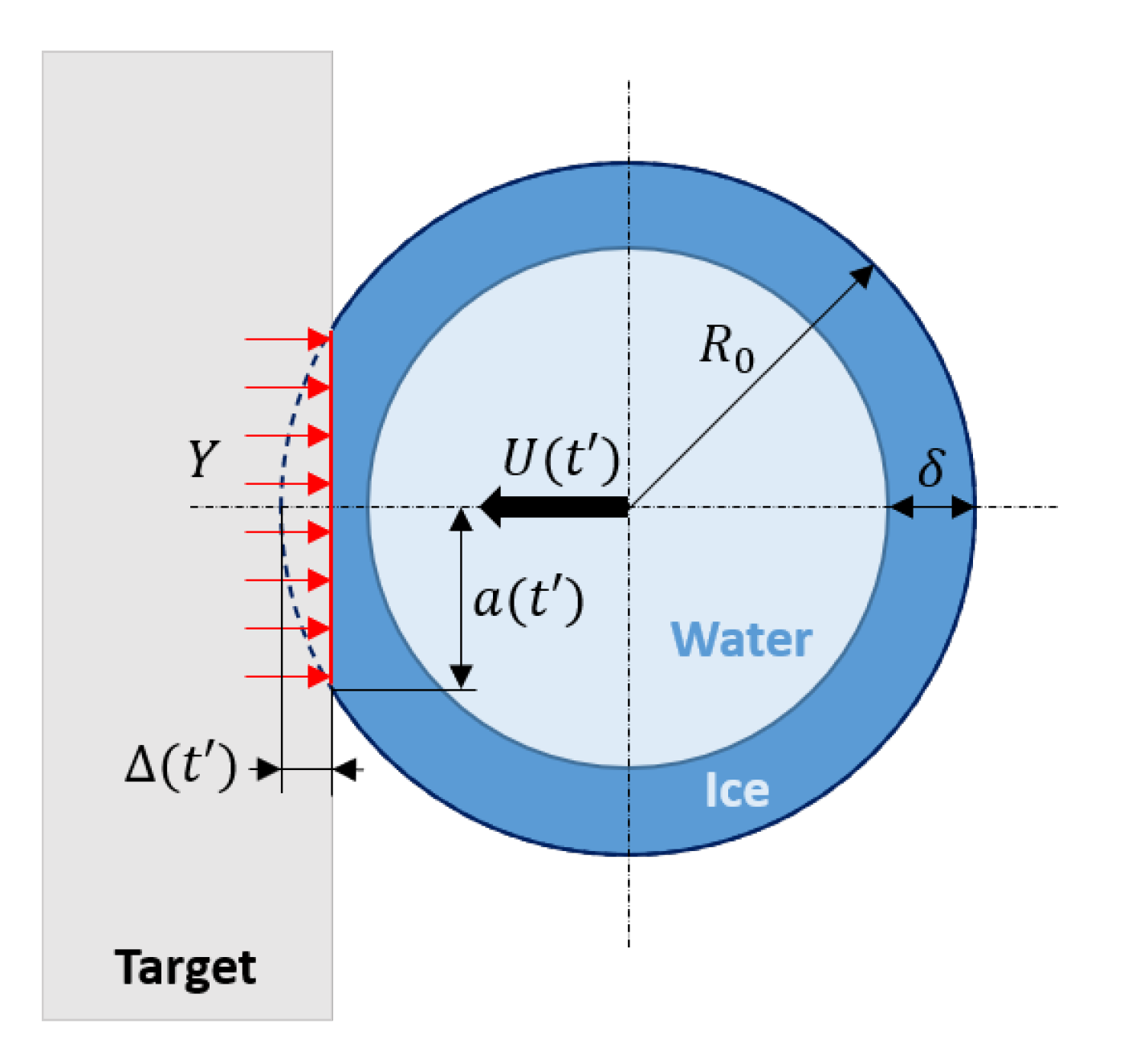

The process of a collision of a partially frozen droplet with a solid surface can be modeled using the approach suggested in [

9]. The corresponding diagram is shown in

Figure 4. We limit our analysis to normal collisions, i.e., we assume that the droplet’s velocity is normal to the wall. However, this approach can also be employed for oblique collisions if a velocity component that is normal to the wall is used.

The particle’s displacement during the plastic deformation of the solid crust is described by the following equation [

9]:

where

is the dimensionless droplet displacement during an interaction with the wall surface,

is the droplet displacement,

Y is the ice’s yield strength (assumed to be

MPa [

24]),

is the radius of the particle–wall contact area, and

is the volume of the uncrushed particle part. Note that the time count,

, for this equation starts from the moment at which the particle touches the wall.

The initial condition for Equation (

10) is the known particle velocity at the moment of touching the wall,

, which is written as:

Equation (

10) has the analytical solution [

9], where the maximum dimensionless center displacement,

, is expressed as:

where

is the collision duration.

In the present work, the equation describing plastic deformation of the ice crust was utilized to evaluate the probability of a particle sticking to the wall in the following way. It was assumed that if the deformation is smaller than the crust thickness, the droplet bounces from the wall. In contrast, if the deformation exceeds the crust thickness, the droplet sticks to the wall due to adhesion caused by the immediate formation of an ice bridge induced by water released from the droplet’s core.