Potential Energy Savings from Circular Economy Scenarios Based on Construction and Agri-Food Waste in Italy

Abstract

:1. Introduction

1.1. The Environmental Impacts of C&D Sector

1.2. Circular Economy Opportunities for C&D Sector

1.3. Goal of the Present Study

2. Previous Literature on LCA of C&DW Management Systems

3. Material and Methods

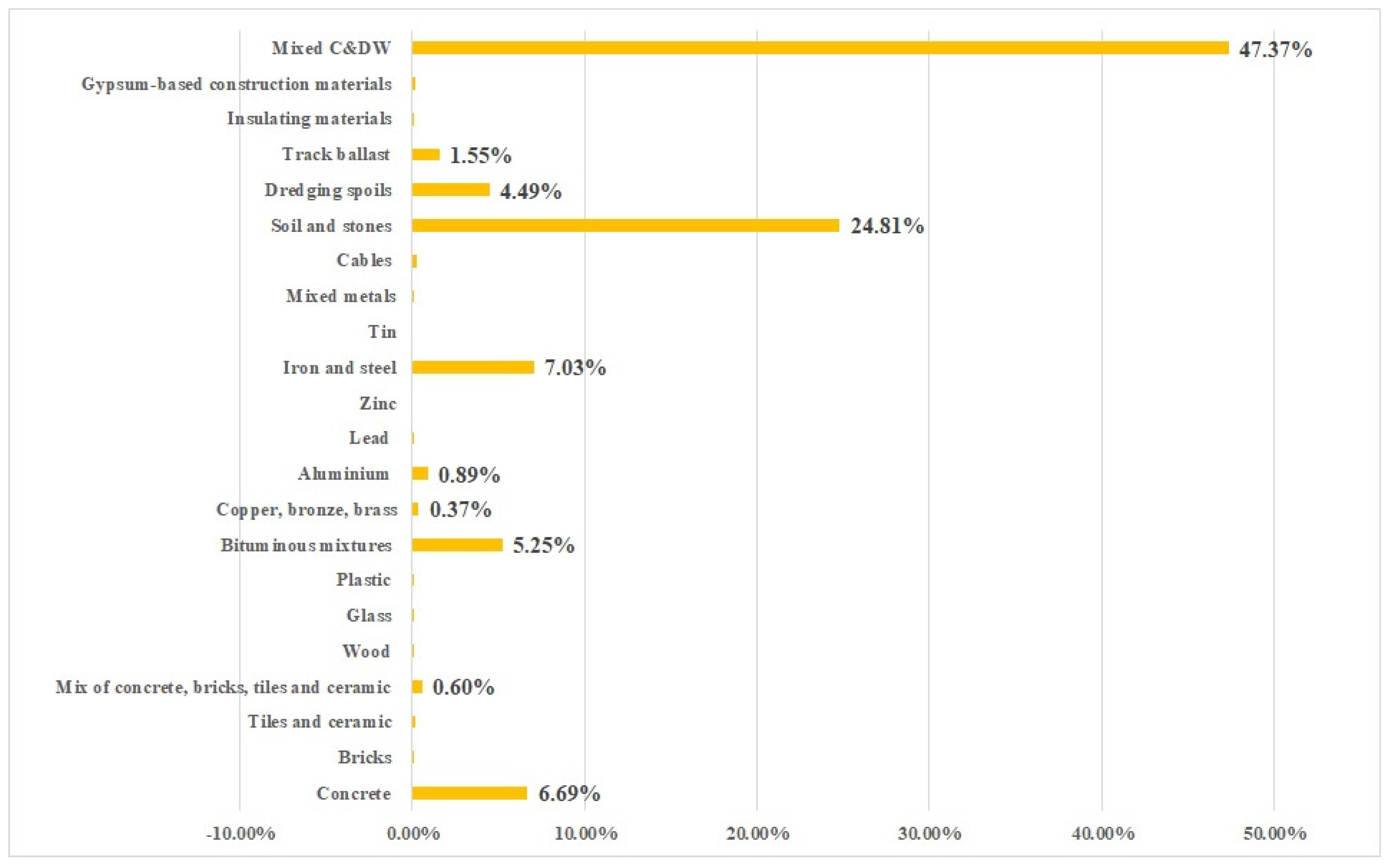

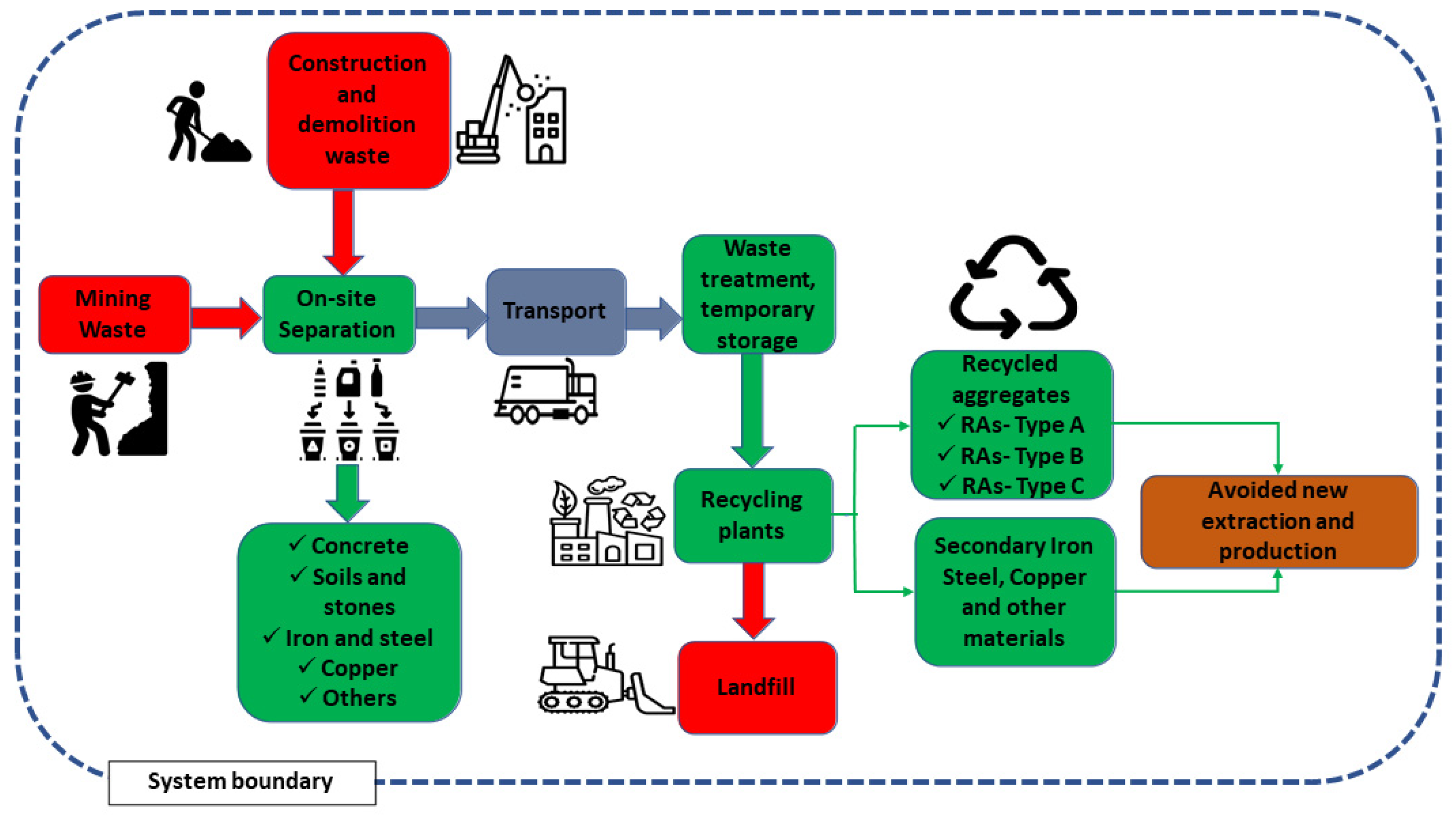

3.1. The Investigated C&DW Generating System

3.2. Life Cycle Assessment Method

- Improvement of the environmental performance of products throughout their life cycle;

- Support to decision-makers in industry, government or non-government organizations (e.g., strategic planning, priority setting, product or process design or redesign);

- Selection of relevant indicators of environmental performance, including measurement techniques;

- Marketing (e.g., implementation of an ecolabelling scheme of type I (ISO 14024) such as the Eco-label), or making an environmental claim (e.g., the environmental labelling of type II regulated by the ISO 14021) or adhering to an environmental product declaration (e.g., the environmental labelling of type III within the ISO 14025 standards).

3.2.1. Goal and Scope

- Collection and transportation of the generated C&DW to the recycling plants of the Metropolitan area;

- Recycling of the most relevant materials (mixed waste, iron and steel, Aluminium, soil and stones, concrete) into recycled aggregates of different types (A, B, C) and recycled metals;

- Delivery of the RA and secondary metals and their reintroduction in the production cycle (it was assumed to occur in the local market so as to reduce as much as possible the contribution of this stage);

- Avoided landfilling;

- Avoided extraction and production of virgin materials.

3.2.2. Life Cycle Inventory (LCI)

3.2.3. Life Cycle Impact Assessment

4. Results

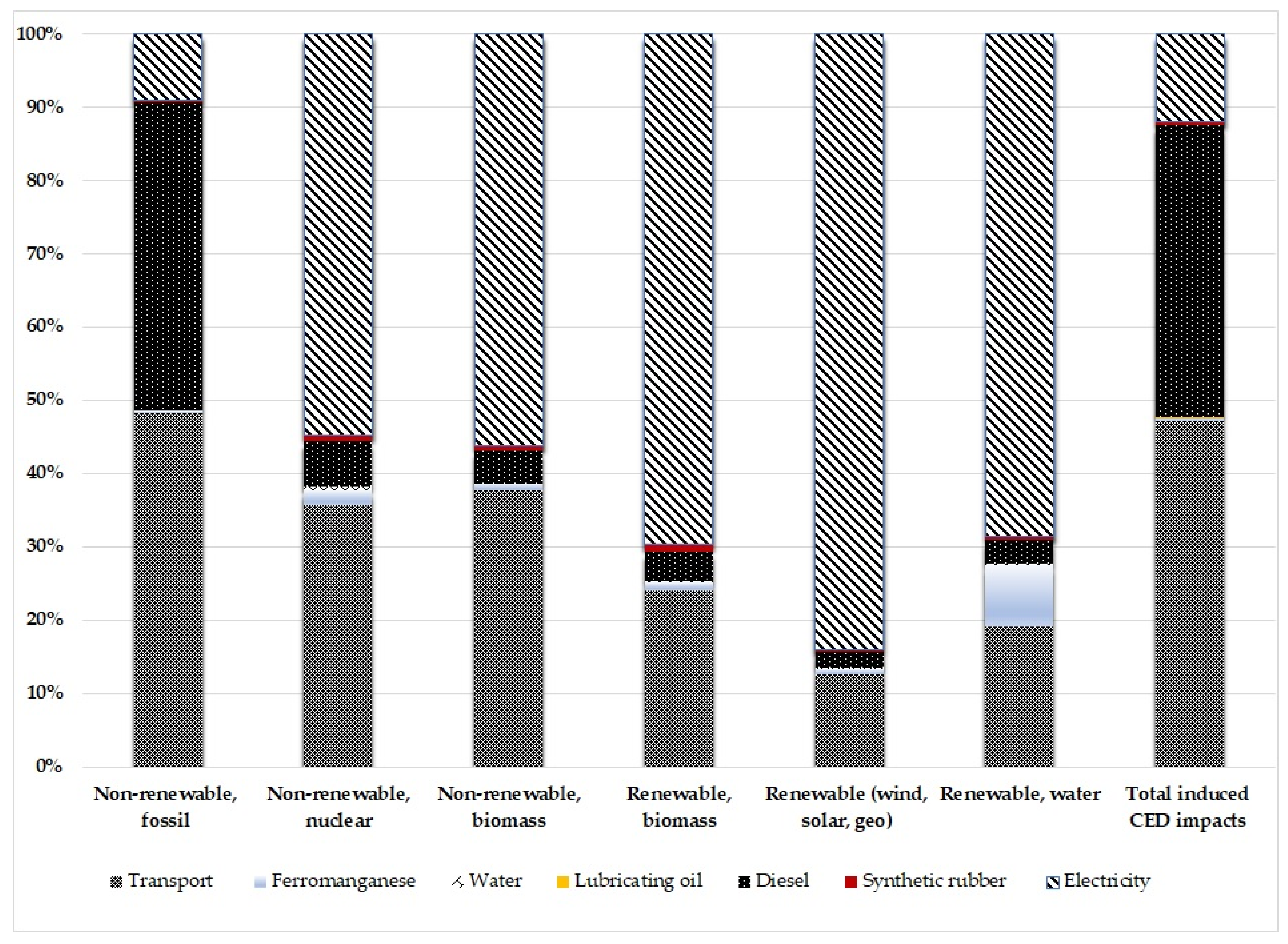

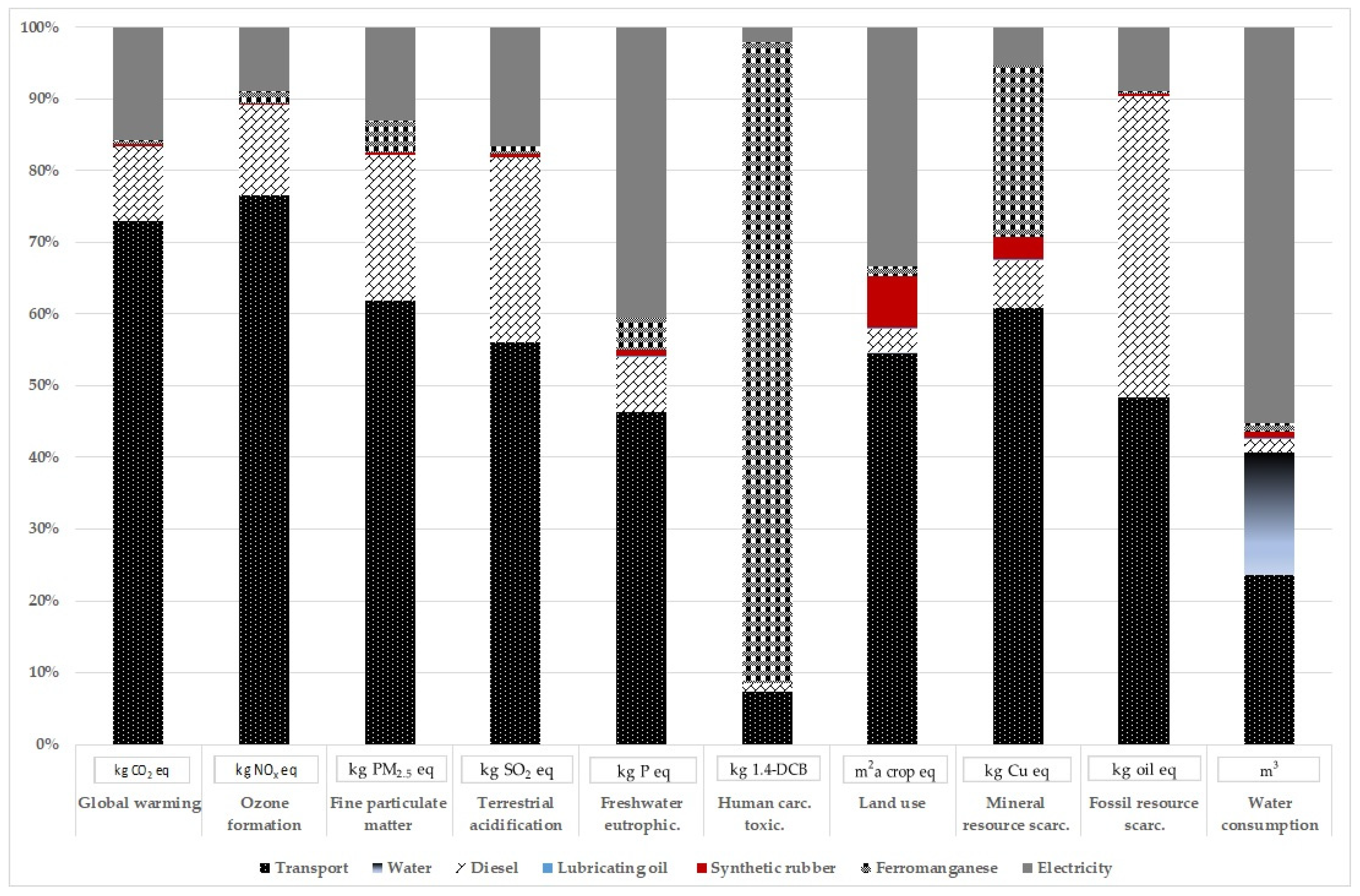

4.1. Energy and Environmental Impacts of the Recycling Scenario for C&DW

4.2. Comparison of Conventional, Recycled and Green Concrete Aggregates

4.3. Discussion

4.4. Policy Implications

5. Conclusions

- ○

- The construction sector as the biggest consumer of natural resources, by means of the adoption of CE recycling scenarios (as showed in this LCA study), has the potential of contributing to tackling the current environmental challenges also caused by the fossil energy use for mining and manufacturing of construction materials;

- ○

- The results show that prolonging the value of construction and demolition materials by means of their recycling has the potential of realizing environmental and energetic savings compared to the disposal in landfill in line with the waste hierarchy.

- ○

- Recycling of C&DW into RA should be encouraged at the political level to favour their use. The political support should occur in an integrated framework along with the other CE strategies (e.g., reduce, reuse) throughout the waste hierarchy.

- ○

- In a circular product design perspective, the recycling of C&DW into RA is an intended strategy and not an end-of-pipe solution, as it is still now, and then its adoption in the C&DW sector would be important for further progressing their recyclability including the quality of RA and increase the trust in their use.

- ○

- The circular designer may also decide to replace the use of technical conventional materials with bio-based construction materials and this study can be also useful for that purpose as it shows how the energy and environmental performances of concrete change according to the feed stock materials (natural aggregates, recycled aggregates, hemp by-products).

- ○

- Finally, the funding of research projects is essential for educating professionals that have the technical and knowledge skills on the CE model in order to be applied in the C&D sector and favour its technological renewal in line with the CE principles [92].

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| APOS | At Point of Substitution |

| C&DW | Construction and Demolition Waste |

| CE | Circular Economy |

| CED | Cumulative energy demand |

| EU | European Union |

| GHG | Greenhouse gas |

| IPCC | Intergovernmental Panel on Climate Change |

| ISO | International Organization for Standardization |

| LCA | Life Cycle Assessment |

| MJ | MegaJoules |

| NA | Natural aggregates |

| RA | Recyled aggregates |

| Non-renew. | Non-renewable |

| Renew. | Renewable |

| Renew. (w, solar, geo) | Renewable (wind, solar, geothermal) |

| Total Av. CED impacts | Total avoided CED impacts |

References

- European Commission, 2020. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A new Circular Economy Action Plan for a Cleaner and More Competitive Europe, 2020; COM/2020/98 Final. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN (accessed on 8 November 2021).

- European Cement Association (Cembureau). Construction and Demolition Waste. Available online: https://www.cembureau.eu/policy-focus/sustainable-construction/construction-demolition-waste/ (accessed on 22 November 2021).

- Ritchie, H. Our World in Data. Sector by Sector: Where Do Global Greenhouse Gas Emissions Come From? Available online: https://ourworldindata.org/ghg-emissions-by-sector (accessed on 22 November 2021).

- Liu, Y.; Li, H.; Huang, S.; An, H.; Santagata, R.; Ulgiati, S. Environmental and economic-related impact assessment of iron and steel production. A call for shared responsibility in global trade. J. Clean. Prod. 2020, 269, 122239. [Google Scholar] [CrossRef]

- World Economic Forum. Can the Circular Economy Transform the World’s Number One Consumer of Raw Materials? Available online: https://www.weforum.org/agenda/2016/05/can-the-circular-economy-transform-the-world-s-number-one-consumer-of-raw-materials (accessed on 8 November 2021).

- Meglin, R.; Kytzia, S.; Habert, G. Regional circular economy of building materials: Environmental and economic assessment combining Material Flow Analysis, Input-Output Analysis and Life Cycle Assessment. J. Ind. Ecol. 2021, 1–15. [Google Scholar] [CrossRef]

- Ginga, C.P.; Ongpeng, J.M.C.; Daly, M.K.M.; Klarissa, M. Circular economy on construction and demolition waste: A literature review on material recovery and production. Materials 2020, 13, 2970. [Google Scholar] [CrossRef] [PubMed]

- Jain, S.; Singhal, S.; Pandey, S. Environmental life cycle assessment of construction and demolition waste recycling: A case of urban India. Resour. Conserv. Recycl. 2020, 155, 104642. [Google Scholar] [CrossRef]

- Ma, M.; Tam, V.W.Y.; Le, K.N.; Li, W. Challenges in current construction and demolition waste recycling: A China study. Waste Manag. 2020, 118, 610–625. [Google Scholar] [CrossRef] [PubMed]

- UNEP (United Nations Environment Programme). March 2014. Sand, Rarer Than One Thinks. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/8665/GEAS_Mar2014_Sand_Mining.pdf?sequence=3&isAllowed=y (accessed on 27 October 2021).

- Brown, M.T.; Buranakarn, V. Emergy indices and ratios for sustainable material cycles and recycle options. Resour. Conserv. Recycl. 2003, 38, 1–22. [Google Scholar] [CrossRef]

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment, Italian ed.; Harvester Wheatsheaf: London, UK, 1991; Il Mulino: Bologna, Italy, 1991; pp. 1–362. [Google Scholar]

- Villagrán-Zaccardi, Y.A.; Marsh, A.T.M.; Sosa, M.E.; Zega, C.J.; De Belie, N.; Bernal, S.A. Complete re-utilization of waste concretes–Valorisation pathways and research needs. Resour. Conserv. Recycl. 2021, 177, 105955. [Google Scholar] [CrossRef]

- Gavriletea, M.D. Environmental Impacts of Sand Exploitation. Analysis of Sand Market. Sustainability 2017, 9, 1118. [Google Scholar] [CrossRef] [Green Version]

- Cochran, J.K.; Bokuniewicz, H.J.; Yager, P.L. Encyclopedia of Ocean Sciences, 3rd ed.; Academic Press: Cambridge, MA, USA, 2019; p. 4306. ISBN 978-0-12-813082-7. [Google Scholar]

- European Commission. Environmental Impacts along the Supply Chain. Available online: https://rmis.jrc.ec.europa.eu/?page=environmental-impacts-along-the-supply-chain-3dfccf (accessed on 22 January 2021).

- Ambrosini, C. Prevenire è Meglio Che Smaltire, Il Caso Dell’edilizia Italiana, Atlante dell’Economia Circolare. Available online: https://economiacircolare.com/prevenire-e-meglio-che-smaltire-il-caso-delledilizia-italiana/ (accessed on 28 October 2021).

- Quattrone, M.; Angulo, S.C.; John, V.M. Energy and CO2 from high performance recycled aggregate production. Resour. Conserv. Recycl. 2014, 90, 21–33. [Google Scholar] [CrossRef]

- Halkos, G.; Petrou, K.N. Analysing energy efficiency of EU Member States: The potential of energy recovery from waste in the circular economy. Energies 2019, 12, 3718. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.; Yazan, D.M.; Bhochhibhoya, S.; Volker, L. Towards Circular Economy through Industrial Symbiosis in the Dutch construction industry: A case of recycled concrete aggregates. J. Clean. Prod. 2021, 293, 126083. [Google Scholar] [CrossRef]

- Ambrosini, C. Ripensare L’edilizia Attraverso L’economia Circolare, Lo Studio Della Luiss, Atlante dell’Economia Circolare. Available online: https://economiacircolare.com/ripensare-ledilizia-attraverso-leconomia-circolare-lo-studio-della-luiss/ (accessed on 28 October 2021).

- Arrigoni, A.; Pelosato, R.; Melià, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Life cycle assessment of natural building materials: The role of carbonation, mixture components and transport in the environmental impacts of hempcrete blocks. J. Clean. Prod. 2017, 149, 1051–1061. [Google Scholar] [CrossRef]

- Farina, I.; Colangelo, F.; Petrillo, A.; Ferraro, A.; Moccia, I.; Cioffi, R. LCA of concrete with construction and demolition waste. In Advances in Construction and Demolition Waste Recycling: Management, Processing and Environmental Assessment; Pacheco-Torgal, F., Ding, Y., Colangelo, F., Tuladhar, R., Koutamanis, A., Eds.; Woodhead Publishing, Elsevier: Sawston, UK, 2020; pp. 520–594. [Google Scholar]

- Borghi, G.; Pantini, S.; Rigamonti, L. Life cycle assessment of non-hazardous Construction and Demolition Waste (CDW) management in Lombardy Region (Italy). J. Clean. Prod. 2018, 184, 815–825. [Google Scholar] [CrossRef]

- Bowea, M.D.; Powell, J.C. Developments in life cycle assessment applied to evaluate the environmental performance of construction and demolition wastes. Waste Manag. 2016, 50, 151–172. [Google Scholar]

- Penteado, C.S.G.; Rosado, L.P. Comparison of scenarios for the integrated management of construction and demolition waste by life cycle assessment: A case study in Brazil. Waste Manag. Res. 2016, 34, 1026–1035. [Google Scholar] [CrossRef] [PubMed]

- Vossberg, C.; Mason-Jones, K.; Cohen, B. An energetic life cycle assessment of C&D waste and container glass recycling in Cape Town, South Africa. Resour. Conserv. Recycl. 2014, 88, 39–49. [Google Scholar]

- Simion, I.M.; Fortuna, M.E.; Bonoli, A.; Gavrilescu, M. Comparing environmental impacts of natural inert and recycled construction and demolition waste processing using LCA. J. Environ. Eng. Landsc. Manag. 2013, 21, 273–287. [Google Scholar] [CrossRef]

- Yuan, H.P.; Shen, L.-Y.; Li, Q.-M. Emergy analysis of the recycling options for construction and demolition waste. Waste Manag. 2011, 31, 2503–2511. [Google Scholar] [CrossRef] [PubMed]

- Blengini, G.A.; Garbarino, E. Resources and waste management in Turin (Italy): The role of recycled aggregates in the sustainable supply mix. J. Clean. Prod. 2010, 18, 1021–1030. [Google Scholar] [CrossRef]

- Blengini, G.A. Life cycle of buildings, demolition and recycling potential: A case study in Turin, Italy. Build. Environ. 2009, 44, 319–330. [Google Scholar] [CrossRef]

- Garcia-Gonzalez, J.; Rodriguez-Robles, D.; De Belie, N.; Morán-del Pozo, J.M.; Guerra-Romero, M.I.; Juan-Valdés, A. Self-healing concrete with recycled aggregates. In Advances in Construction and Demolition Waste Recycling, Management, Processing and Environmental Assessment; Pacheco-Torgal, F., Ding, Y., Colangelo, F., Tuladhar, R., Koutamanis, A., Eds.; Woodhead Publishing, Elsevier: Sawston, UK, 2020; pp. 355–377. ISBN 978-0-12-819055-5. [Google Scholar]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- United Nations. Department of Economic and Social Affairs, Sustainable Development. The 17 Goals. Available online: https://sdgs.un.org/goals (accessed on 23 November 2021).

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Colangelo, F.; Forcina, A.; Farina, I.; Petrillo, A. Life cycle assessment (LCA) of different kinds of concrete containing waste for sustainable construction. Buildings 2018, 8, 70. [Google Scholar] [CrossRef] [Green Version]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Dahlbo, H.; Bachér, J.; Lähtinen, K.; Jouttijärvi, T.; Suoheimo, P.; Mattila, T.; Sironen, S.; Myllymaa, T.; Saramäki, K. Construction and demolition waste management e a holistic evaluation of environmental performance. J. Clean. Prod. 2015, 107, 333–341. [Google Scholar] [CrossRef]

- Iodice, S.; Garbarino, E.; Cerreta, M.; Tonini, D. Sustainability assessment of Construction and Demolition Waste management applied to an Italian case. Waste Manag. 2021, 128, 83–98. [Google Scholar] [CrossRef] [PubMed]

- Faleschini, F.; Zanini, M.A.; Pellegrino, C.; Pasinato, S. Sustainable managment and supply of natural and recycled aggregates in a medium-size integrated plant. Waste Manag. 2016, 49, 146–155. [Google Scholar] [CrossRef]

- Rosado, L.P.; Vitale, P.; Penteado, C.S.G. Life cycle assessment of natural and mixed recycled aggregate production in Brazil. J. Clean. Prod. 2017, 151, 634–642. [Google Scholar] [CrossRef]

- Pantini, S.; Rigamonti, L. Effectiveness and efficiency of construction and demolition waste in Lombardy: A life cycle based evaluation, 2019. In Proceedings of the 5th Conference on Final Sinks, Vienna, Austria, 8–11 December 2019; Available online: http://www.icfs2019.org/wp-content/uploads/2019/11/Se08-03_Rigamonti_Effectiveness-And-Efficiency-Of-Construction-And-Demolition-Waste-Recycling-In-Lombardy-A-Life-Cycle-Based-Evaluation.pdf (accessed on 5 November 2021).

- Yuan, H. A SWOT analysis of successful construction waste management. J. Clean. Prod. 2013, 39, 1–8. [Google Scholar] [CrossRef]

- ISO 14040:2006 Environmental Management—Life Cycle Assessment—Principles and Framework. Available online: https://www.iso.org/standard/37456.html (accessed on 5 August 2021).

- Metropolitan City of Naples, Tavole di Progetto (In Italian). Available online: https://www.cittametropolitana.na.it/tavole-di-progetto (accessed on 23 November 2021).

- Baldo, G.L.; Marino, M.; Rossi, S. Analisi del Ciclo di Vita LCA. Materiali, Prodotti, Processi; Edizioni Ambiente: Milano, Italy, 2005; pp. 1–289. [Google Scholar]

- Ciacci, L.; Passarini, F. Life cycle assessment (LCA) of environmental and energy systems. Energies 2020, 13, 5892. [Google Scholar] [CrossRef]

- Al-Khori, K.; Al-Ghami, S.G.; Boulfraud, S.; Koç, M. Life cycle assessment for integration of solid oxide fuel cells into gas processing operations. Energies 2021, 14, 1–19. [Google Scholar]

- Nastro, R.A.; Leccisi, E.; Tuscanesi, M.; Liu, G.; Trifuoggi, M.; Ulgiati, S. Exploring avoided environmental impacts as well as energy and recource recovery from micribial desalination cell treatment of brine. Energies 2021, 14, 1–16. [Google Scholar]

- Buyle, M.; Braet, J.; Audenaert, A. Life cycle assessment in the construction sector: A review. Renew. Sustain. Energy Rev. 2013, 26, 379–388. [Google Scholar] [CrossRef]

- Buyle, M.; Braet, J.; Audenaert, A. Life Cycle Assessment of an Apartment Building: Comparison of an Attributional and Consequential Approach. Energy Procedia 2014, 62, 132–140. [Google Scholar] [CrossRef] [Green Version]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Asdrubali, F.; Roncone, M.; Grazieschi, G. Embodied energy and embodied GWP of windows: A critical review. Energies 2021, 14, 1–17. [Google Scholar]

- Vilches, A.; Garcia-Martinez, A.; Sanchez-Montanes, B. Life cycle assessment (LCA) of building refurbishment: A literature review. Energy Build. 2017, 135, 286–301. [Google Scholar] [CrossRef]

- Vitale, P.; Arena, N.; Di Gregorio, F.; Arena, U. Life cycle assessment of the end of-life phase of a residential building. Waste Manag. 2017, 60, 311–321. [Google Scholar] [CrossRef]

- Thormark, C. Environmental analysis of a building with reused building materials. Int. J. Low Energy Sust. Build. 2000, 1, 1–18. [Google Scholar]

- Da Rocha, C.G.; Sattler, M.A. A discussion on the reuse of building components in Brazil: An analysis of major social, economical and legal factors. Resour. Conserv. Recycl. 2009, 54, 104–112. [Google Scholar] [CrossRef]

- Diyamandoglu, V.; Fortuna, L.M. Deconstruction of wood-framed houses: Material recovery and environmental impact. Resour. Conserv. Recycl. 2015, 100, 21–30. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Availability and processing of recycled aggregates within the construction and demolition supply chain: A review. J. Clean. Prod. 2017, 143, 598–614. [Google Scholar] [CrossRef] [Green Version]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Ekvall, T.; Assefa, G.; Björklund, A.; Eriksson, O.; Finnveden, G. What life cycle assessment does and does not do in assessments of waste management. Waste Manag. 2007, 27, 989–996. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cristiano, S.; Santagata, R.; Gonella, F.; Dumontet, S.; Ulgiati, S. Report on the Construction and Demolition Waste Management and the Potential for Circular Options in the Metropolitan City of Naples. China-Italy Bilateral Project, Analysis on the Metabolic Process of Urban Agglomeration and the Cooperative Strategy of Circular Economy; Dipartimento di Scienze e Tecnologie, Università degli Studi Napoli “Parthenope”: Naples, Italy, 2019; Available online: http://www.urbancirculareconomy.it/wp-content/uploads/2019/09/Annex-7.pdf (accessed on 10 November 2021).

- Cristiano, S.; Ghisellini, P.; D’Ambrosio, G.; Xue, J.; Nesticò, A.; Gonella, F.; Ulgiati, S. Construction and demolition waste in the Metropolitan City of Naples, Italy: State of the art, circular design, and sustainable planning opportunities. J. Clean. Prod. 2021, 293, 125856. [Google Scholar] [CrossRef]

- Zampori, L.; Dotelli, G.; Vernelli, V. Life Cycle Assessment of Hemp Cultivation and Use of Hemp-Based Thermal Insulator Materials in Buildings. Environ. Sci. Technol. 2013, 47, 7413–7420. [Google Scholar] [CrossRef]

- Frischknecht, R.; Wyss, F.; Büsser Knöpfel, S.; Lützkendorf, T.; Balouktsi, M. Cumulative energy demand in LCA: The energy harvested approach. Int. J. Life Cycle Assess. 2015, 20, 957–969. [Google Scholar] [CrossRef]

- Puig, R.; Fullana-i-Palmer, P.; Baquero, G.; Riba, J.R.; Bala, A. A Cumulative Energy Demand indicator (CED), life cycle based, for industrial waste management decision making. Waste Manag. 2013, 33, 2789–2797. [Google Scholar] [CrossRef] [PubMed]

- Huijbregts, M.A.J.; Hellweg, S.; Frischknecht, R.; Hendriks, H.W.M.; Hungehbühler, K.; Hendriks, A.J. Cumulative energy demand as predictor for the environmental burden of commodity production. Environ. Sci. Technol. 2010, 44, 2189–2196. [Google Scholar] [CrossRef] [Green Version]

- National Institute for Public Health and the Environment. ReCiPe 2016 v1.1 A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level, Report I: Characterization; RIVM Report 2016-0104a; National Institute for Public Health and the Environment: Bilthoven, The Netherlands, 2016; Available online: https://pre-sustainability.com/legacy/download/Report_ReCiPe_2017.pdf (accessed on 6 December 2021).

- SimaPro. SimaPro, Version 9.1.1., Full Update Instruction. Available online: https://simapro.com/wp-content/uploads/2020/10/FullUpdateInstructionsToSimaPro911.pdf (accessed on 24 November 2021).

- Ecoinvent 3.8 Database. Available online: https://ecoinvent.org/the-ecoinvent-database/data-releases/ecoinvent-3-8/ (accessed on 24 November 2021).

- Knoeri, C.; Sany_e-Mengual, E.; Althaus, H.-J. Comparative LCA of recycled and conventional concrete for structural applications. Int. J. Life Cycle Assess. 2013, 18, 909–918. [Google Scholar] [CrossRef] [Green Version]

- Gargiulo, A.; Carvalho, M.L.; Girardi, P. Life cycle assessment of Italian Electricity Scenarios to 2030. Energies 2020, 13, 3852. [Google Scholar] [CrossRef]

- Cellura, M.; Cosenza, M.A.; Guarino, F.; Longo, S.; Mistretta, M. Life cycle assessment of electricty generation scenarios in Italy. In Life Cycle Assessment of Energy Systems and Sustainable Energies Technologies; Springer: Cham, Switzerland, 2018; pp. 3–15. [Google Scholar]

- Roussat, N.; Méhu, J.; Dujet, C. Indicators to assess the recovery of natural resources contained in demolition waste. Waste Manag. Res. 2009, 27, 159–166. [Google Scholar] [CrossRef]

- Dewulf, J.; Van der Vorst, G.; Versele, N.; Janssens, A.; Van Langenhove, H. Quantification of the impact of the end-of-life scenario on the overall resource consumption for a dwelling house. Resour. Conserv. Recycl. 2009, 53, 231–236. [Google Scholar] [CrossRef]

- Carpenter, A.; Jambeck, J.R.; Gardner, K.; Weitz, K. Life cycle assessment of end-of-life management options for construction and demolition debris. J. Ind. Ecol. 2012, 17, 396–406. [Google Scholar] [CrossRef]

- Kucukvar, M.; Egilmez, G.; Tatari, O. Evaluating environmental impacts of alternative construction waste management approaches using supply chainlinked life-cycle analysis. Waste Manag. Res. 2014, 32, 500–508. [Google Scholar] [CrossRef]

- Ortiz, O.; Pasqualino, J.C.; Castells, F. Environmental performance of construction waste: Comparing three scenarios from a case study in Catalonia, Spain. Waste Manag. 2010, 30, 646–654. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Tam, V.W.Y. A closed-loop life cycle assessment of recycled aggregate concrete utilization in China. Waste Manag. 2016, 56, 367–375. [Google Scholar] [CrossRef]

- Ferronato, N.; Lizarazu, G.E.G.; Portillo, M.A.G.; Moresco, F.; Conti, F.; Torretta, V. Environmental assessment of construction and demolition waste recycling in Bolivia: Focus on transportation distances and selective collection rates. Waste Manag. Res. 2021, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Giorgi, S.; Lavagna, M.; Campioli, A. Circular economy and regeneration of building stock in the Italian context: Policies, partnership and tools. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012065. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ulgiati, S. Economic assessment of circular patterns and business models for reuse and recycling of construction and demolition waste. In Advances in Construction and Demolition Waste Recycling: Management, Processing and Environmental Assessment; Pacheco-Torgal, F., Ding, Y., Colangelo, F., Tuladhar, R., Koutamanis, A., Eds.; Woodhead Publishing, Elsevier: Sawston, UK, 2020; pp. 31–50. ISBN 978-0-12-819055-5. [Google Scholar]

- Wijayasundara, M.; Mendis, P.; Crawford, R.H. Integrated assessment of the use of recycled concrete aggregate replacing natural aggregate in structural concrete. J. Clean. Prod. 2018, 174, 591–604. [Google Scholar] [CrossRef]

- Capucci, M.G.; Ruffini, V.; Barbieri, V.; Siligardi, C.; Ferrari, A.M. Life cycle assessment of a wall made with agro-concrete blocks with wheat husk. In Proceedings of the EM4SS’21–Engineered Materials for Sustainable Structures, Modena, Italy, 26–28 April 2021; p. 101. [Google Scholar]

- Annibaldi, V.; Cucchiella, F.; D’Adamo, I.; Gastaldi, M.; Rotilio, M. Recycled materials for circular economy in construction sector. A review. In Proceedings of the EM4SS’21–Engineered Materials for Sustainable Structures, Modena, Italy, 26–28 April 2021; p. 95. [Google Scholar]

- Ghisellini, P.; Passaro, R.; Ulgiati, S. The role of product certification in the transition towards the circular economy for construction sector. In Proceedings of the EM4SS’21–Engineered Materials for Sustainable Structures, Modena, Italy, 26–28 April 2021; p. 103. [Google Scholar]

- Legambiente, 2016. Rapporto dell’Osservatorio Recycle Legambiente, Cento Materiali per una Nuova Edilizia. Available online: https://www.legambiente.it/sites/default/files/docs/cento_materiali_rapporto_osservatorio_recycle.pdf (accessed on 5 November 2021).

- Equilibrium, Natural Beton (Italian Company and Product). Available online: https://www.equilibrium-bioedilizia.it/it/prodotto/natural-beton (accessed on 24 November 2021).

- Decree 56/2017 establishing “Minimal Criteria for the Design Services and Works for the Construction, Restoring, and Refurbishing of Public Buildings. (In Italian). Available online: https://www.mite.gov.it/sites/default/files/archivio/allegati/GPP/dlgs_19_04_2017_56.pdf (accessed on 24 November 2021).

- The Italian Decree October 2017 “Minimum Environmental Criteria for the Assignment of Design Services and Works for the New Construction, Renovation and Maintenance of Buildings and for the Management of Public Administration Sites”. (In Italian). Available online: https://www.mite.gov.it/sites/default/files/archivio/allegati/GPP/allegato_tec_CAMedilizia.pdf (accessed on 24 November 2021). (In Italian)

- ReMade in Italy. Frantoio Fondovalle (Italian Company). Available online: https://www.remadeinitaly.it/portfolio-tag/frantoio-fondovalle/ (accessed on 24 November 2021).

- Stahel, W.R. Circular Economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| 1 | Processes | Amount | Unit | CED (MJ) |

|---|---|---|---|---|

| Collection and recycling of C&D waste (functional unit) | 1 | tonne | ||

| Avoided landfilling | ||||

| Inert waste (Europe without Switzerland) | landfill (Ecoinvent 3.8) | 1 | tonne | ||

| Materials/fuels (Input) | ||||

| Diesel, low sulphur | 0.68 | kg | 38.58 | |

| Ferromanganese, high-coal, 74.5% Mn (GLO)| market for | APOS, S | 0.02 | kg | 0.44 | |

| Transport, freight, lorry >32 metric ton, EURO5 (RER)| market for transport, freight, lorry >32 metric ton, EURO5 | APOS, S | 30 | tkm | 45.52 | |

| Water | 3.7 | kg | 0.03 | |

| Lubricating oil (RER) | market for lubricating oil | APOS, S | 0.001 | kg | 0.07 | |

| Synthetic rubber (GLO) | market for | APOS, S | 0.0043 | kg | 0.38 | |

| Electricity, medium voltage (IT)| market for | APOS, S | 1.13 | kWh | 11.58 | |

| Total CED | 96.59 | |||

| Outputs | ||||

| Recycled aggregates Type A | 66.9 | kg | ||

| Recycled aggregates Type B | 336.28 | kg | ||

| Recycled aggregates Type C | 504.52 | kg | ||

| Recycled Iron and Steel | 70.3 | kg | ||

| Recycled aluminium | 22.10 | kg | ||

| 2 | Potentially avoided landfilling and mining and production of virgin construction material | 1 | tonne | |

| Avoided landfilling of inert material | 1 | tonne | ||

| Avoided steel production | 70.3 | kg | ||

| Avoided aluminium production | 22.1 | kg | ||

| Avoided production of other virgin construction materials | 504.42 | kg | ||

| Avoided extraction of gravel | 336.28 | kg | ||

| Concrete production | 66.9 | kg |

| Input and Output | Amount | Units |

|---|---|---|

| Concrete from natural aggregates * | 1 | m3 |

| Materials/fuels (input) * | ||

| Cement, Portland (Europe without Switzerland) | market for | APOS, S | 300 | kg |

| Gravel, crushed (RoW) | market for gravel, crushed | APOS, S | 1890 | kg |

| Water, deionized (Europe without Switzerland) | market for water, deionized | APOS, S | 105 | kg |

| Adhesive mortar (GLO) | market for | APOS, S | 3.3 | kg |

| Transport, freight, lorry 7.5–16 metric ton, EURO5 (RER)| market for transport, freight, lorry 7.5-16 metric ton, EURO5 | APOS, S | 50 | tkm |

| Concrete from recycled aggregates * | 1 | m3 |

| Materials/fuels (input) * | ||

| Cement, Portland (Europe without Switzerland) | market for | APOS, S | 320 | kg |

| Water, deionized (Europe without Switzerland) | market for water, deionized | APOS, S | 130 | kg |

| Concrete mixing factory (CH) | construction | APOS, S | 4.57 × 10−7 | p |

| Lubricating oil (GLO) | market for | APOS, S | 1.19 × 10−2 | kg |

| Steel, low-alloyed, hot rolled (GLO) | market for | APOS, S | 2.38 × 10−2 | kg |

| Synthetic rubber (GLO) | market for | APOS, S | 7.13 × 10−3 | kg |

| Electricity/heat | ||

| Electricity, medium voltage (IT)| market for | APOS, S | 4.36 | kWh |

| Heat, district or industrial, natural gas (RER)| market group for | APOS, S | 1.04 | MJ |

| Recycled aggregates | 1890 | kg |

| Green concrete from Agri-industry (Hemp by-products) aggregates | 1 | m3 |

| Materials/fuels (Input) (**) and (*) | ||

| Water, deionized (Europe without Switzerland) | market for water, deionized | APOS, S | 130 | kg |

| Concrete mixing factory (CH)| construction | APOS, S | 4.57 × 10−7 | p |

| Lubricating oil (GLO)| market for | APOS, S | 1.19 × 10−2 | kg |

| Steel, low-alloyed, hot rolled (GLO) | market for | APOS, S | 2.38 × 10−2 | kg |

| Synthetic rubber (GLO) | market for | APOS, S | 7.13 × 10−3 | kg |

| Sun hemp plant, harvested (GLO) | market for sun hemp plant, harvested | APOS, S | 1570 | kg |

| Cement, pozzolana and fly ash 36–55% (Europe without Switzerland) | market for cement, pozzolana and fly ash 36–55% | APOS, S (*) | 320 | kg |

| CED Impact Categories | Unit | Transport | Ferromang. | Water | Lubricat. Oil | Diesel | Synthetic Rubber | Electricity | Total CED |

|---|---|---|---|---|---|---|---|---|---|

| Non-renew. Fossil | MJ | 44.13 | 0.25 | 0.02 | 0.06 | 38.34 | 0.34 | 8.17 | 91.31 |

| Non-renew. Nuclear | MJ | 0.82 | 0.05 | 0.01 | 0.00 | 0.14 | 0.02 | 1.26 | 2.29 |

| Non-renew. Biomass | MJ | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Renew. Biomass | MJ | 0.17 | 0.01 | 0.00 | 0.00 | 0.03 | 0.01 | 0.50 | 0.72 |

| Renew. (w. Solar, geo.) | MJ | 0.08 | 0.01 | 0.00 | 0.00 | 0.01 | 0.00 | 0.56 | 0.66 |

| Renew. Water | MJ | 0.31 | 0.13 | 0.00 | 0.00 | 0.05 | 0.01 | 1.10 | 1.61 |

| Total induced CED impacts | MJ | 45.52 | 0.44 | 0.03 | 0.07 | 38.58 | 0.38 | 11.58 | 96.59 |

| CED IMPACT Categories | Unit | Avoided Inert Landfill | Avoided Concrete | Avoided Gravel Crushing | Avoided Steel | Avoided Other Virgin Materials | Avoided Aluminium | Total Avoided CED Impacts | Total Induced CED Impacts | Net Energy Savings |

|---|---|---|---|---|---|---|---|---|---|---|

| Non-renew. Fossil | MJ | −37.19 | −85.88 | −54.46 | −1095.94 | −102.23 | −214.01 | −1589.71 | 91.31 | −1498.40 |

| Non-renew. Nuclear | MJ | −0.32 | −4.06 | −2.59 | −38.26 | −16.10 | −6.57 | −67.89 | 2.29 | −65.60 |

| Non-renew. Biomass | MJ | 0.00 | −0.02 | 0.00 | −0.05 | −0.01 | 0.00 | −0.09 | 0.00 | −0.09 |

| Renew. Biomass | MJ | −0.33 | −3.73 | −0.55 | −14.90 | −1.76 | −1.86 | −23.12 | 0.72 | −22.40 |

| Renew. (w, Solar, geo) | MJ | −0.04 | −0.43 | −0.29 | −4.56 | −1.48 | −0.78 | −7.59 | 0.66 | −6.92 |

| Renew. Water | MJ | −0.17 | −2.06 | −1.13 | −27.42 | −3.58 | −2.81 | −37.17 | 1.61 | −35.56 |

| Total Av. CED impacts | MJ | −38.05 | −96.18 | −59.03 | −1181.13 | −125.15 | −226.03 | −1725.58 | 96.59 | −1628.98 |

| Impact Categories | Unit | Transport | Water | Diesel | Lubric. Oil | Synthetic Rubber | Ferromang. | Electricity | Total ind. env. imp. |

|---|---|---|---|---|---|---|---|---|---|

| Global Warming | kg CO2 eq. | 2.73 | 0.00 | 0.39 | 0.00 | 0.01 | 0.02 | 0.59 | 3.74 |

| Ozone Formation | kg NOx eq. | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 |

| Fine Partic. Matter | kg PM2.5 eq. | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 |

| Terrestrial Acidific. | kg SO2 eq. | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 |

| Freshwater Eutroph. | kg P eq. | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Human carc. Toxicity | kg 1,4-DCB | 0.05 | 0.00 | 0.01 | 0.00 | 0.00 | 0.61 | 0.01 | 0.68 |

| Land Use | m2a crop eq. | 0.36 | 0.00 | 0.02 | 0.00 | 0.05 | 0.01 | 0.22 | 0.65 |

| Miner. Resour. Scarc. | kg Cu eq. | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 |

| Fossil Resour. Scarc. | kg oil eq. | 0.96 | 0.00 | 0.84 | 0.00 | 0.01 | 0.01 | 0.18 | 1.99 |

| Water Consumption | m3 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 | 0.02 |

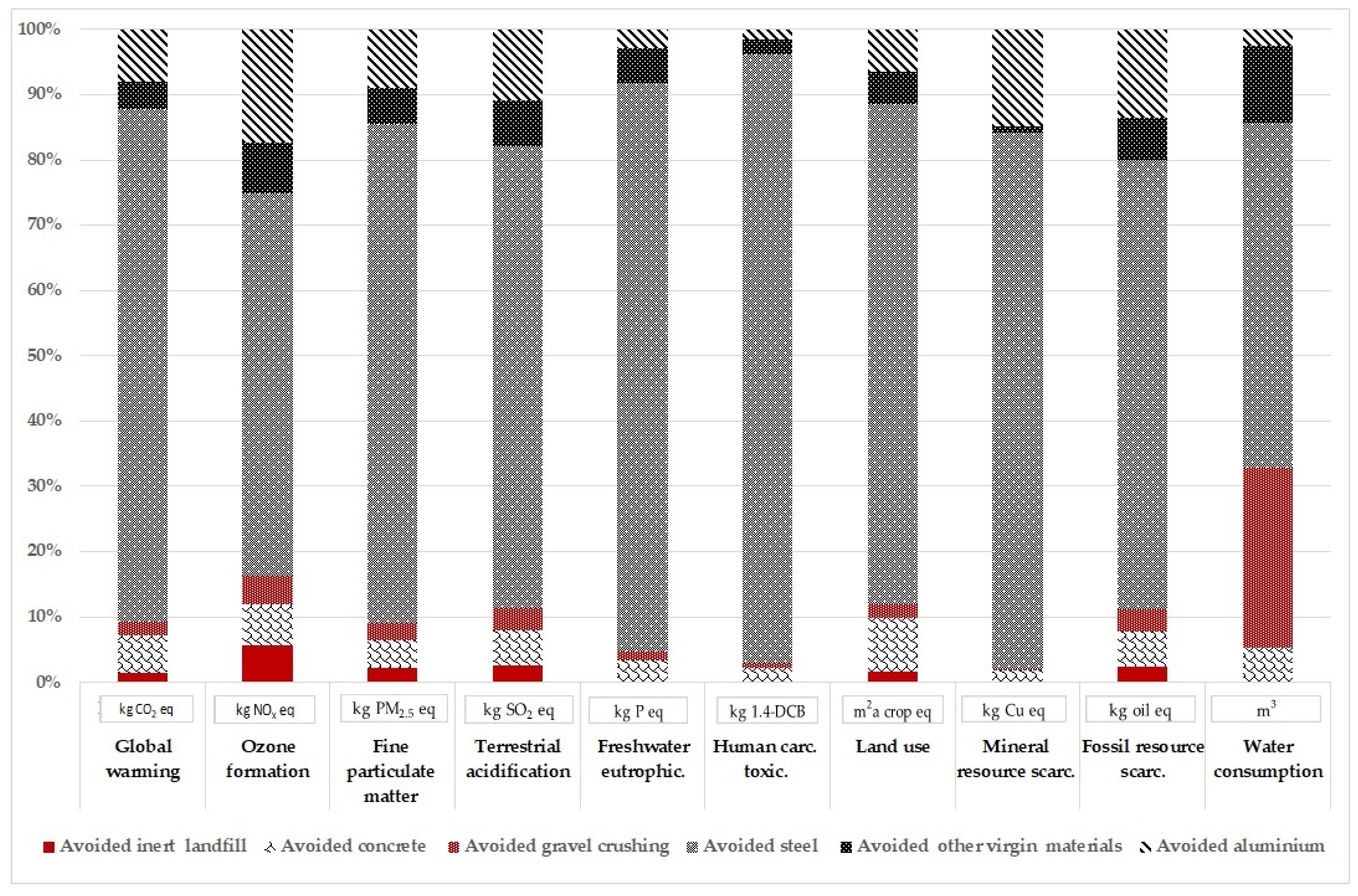

| Impact Categories | Unit | Avoided Inert Landfill | Avoided Concrete | Avoided Gravel Crushing | Avoided Steel | Avoided Other v. Materials | Avoided Aluminium | Total Av. env. Impacts | Net Environ. Impacts |

|---|---|---|---|---|---|---|---|---|---|

| Global Warming | kg CO2 eq. | −2.56 | −10.60 | −3.91 | −145.29 | −7.75 | −14.75 | −184.87 | −181.13 |

| Ozone Formation | kg NOx eq. | −0.03 | −0.03 | −0.02 | −0.31 | −0.04 | −0.09 | −0.53 | −0.52 |

| Fine Partic. Matter | kg PM2.5 eq. | −0.01 | −0.01 | −0.01 | −0.23 | −0.02 | −0.03 | −0.30 | −0.30 |

| Terrestrial Acidific. | kg SO2 eq. | −0.01 | −0.03 | −0.02 | −0.37 | −0.04 | −0.06 | −0.52 | −0.51 |

| Freshwater Eutroph. | kg P eq. | 0.00 | 0.00 | 0.00 | −0.05 | 0.00 | 0.00 | −0.06 | −0.06 |

| Human carc. Toxicity | kg 1,4-DCB | −0.05 | −0.47 | −0.18 | −21.01 | −0.54 | −0.35 | −22.59 | −21.90 |

| Land Use | m2a crop eq. | −0.49 | −2.55 | −0.62 | −23.47 | −1.54 | −2.00 | −30.67 | −30.01 |

| Miner. Resour. Scarc. | kg Cu eq. | 0.00 | −0.11 | −0.02 | −5.51 | −0.07 | −0.99 | −6.71 | −6.70 |

| Fossil Resour. Scarc. | kg oil eq. | −0.81 | −1.87 | −1.19 | −23.77 | −2.23 | −4.68 | −34.55 | −32.56 |

| Water Consumption | m3 | 0.00 | −0.09 | −0.48 | −0.92 | −0.20 | −0.04 | −1.74 | −1.72 |

| Impact Categories | Unit | Natural agg. Concrete | Recycled agg. Concrete | Green Concrete *** | Green Concrete ** | Green Concrete * |

|---|---|---|---|---|---|---|

| Non-renewable, Fossil | MJ | 1635.53 | 1138.80 | 766.92 | 757.02 | 747.12 |

| Non-renewable, Nuclear | MJ | 217.51 | 165.94 | 110.06 | 109.62 | 109.18 |

| Non-renewable, Biomass | MJ | 0.50 | 0.52 | 0.37 | 0.35 | 0.33 |

| Renewable, Biomass | MJ | 42.08 | 40.75 | 385.46 | 266.35 | 147.25 |

| Renewable, (Wind, Solar, geo) | MJ | 21.43 | 18.01 | 12.38 | 12.33 | 12.27 |

| Renewable, Water | MJ | 46.62 | 37.00 | 26.31 | 26.12 | 25.93 |

| Total CED impacts | MJ | 1963.67 | 1401.02 | 1301.50 | 1171.78 | 1042.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghisellini, P.; Ncube, A.; D’Ambrosio, G.; Passaro, R.; Ulgiati, S. Potential Energy Savings from Circular Economy Scenarios Based on Construction and Agri-Food Waste in Italy. Energies 2021, 14, 8561. https://doi.org/10.3390/en14248561

Ghisellini P, Ncube A, D’Ambrosio G, Passaro R, Ulgiati S. Potential Energy Savings from Circular Economy Scenarios Based on Construction and Agri-Food Waste in Italy. Energies. 2021; 14(24):8561. https://doi.org/10.3390/en14248561

Chicago/Turabian StyleGhisellini, Patrizia, Amos Ncube, Gianni D’Ambrosio, Renato Passaro, and Sergio Ulgiati. 2021. "Potential Energy Savings from Circular Economy Scenarios Based on Construction and Agri-Food Waste in Italy" Energies 14, no. 24: 8561. https://doi.org/10.3390/en14248561

APA StyleGhisellini, P., Ncube, A., D’Ambrosio, G., Passaro, R., & Ulgiati, S. (2021). Potential Energy Savings from Circular Economy Scenarios Based on Construction and Agri-Food Waste in Italy. Energies, 14(24), 8561. https://doi.org/10.3390/en14248561