Key Factors Influencing the Achievement of Climate Neutrality Targets in the Manufacturing Industry: LMDI Decomposition Analysis

Abstract

:1. Introduction

2. Literature Review

2.1. Methods for Analyzing Changes in CO2 Emissions in the Manufacturing Industry

2.2. Theoretical Foundation of Index Decomposition Analysis (IDA) Methods

2.3. LMDI Decomposition Analysis in the Manufacturing Industry

3. Methodology

- C—total aggregated energy-related CO2 emissions;

- Q—total produced volumes expressed as total value added;

- E—total energy consumption;

- Si—industrial production activity;

- Ii—energy intensity;

- Fij—fuel mix;

- Mij—emission factor.

- act—effect from changes in industrial activity;

- str—effect from changes in structure;

- eni—effect from changes in energy intensity;

- fuel—effect from changes in fuel mix;

- emi—effect from changes in emission intensity.

- —energy consumption in future year T;

- —energy consumption in initial year.

- —CO2 emission factor for heat produced in heat plants and combined heat and power plants in Latvia, tCO2/MWh;

- —amount of produced heat in heat and CHP plants in Latvia using fossil fuels;

- —emission factor of the utilized fuel according to the Appendix 1 of the Cabinet Regulation No. 42.

4. Results and Discussion

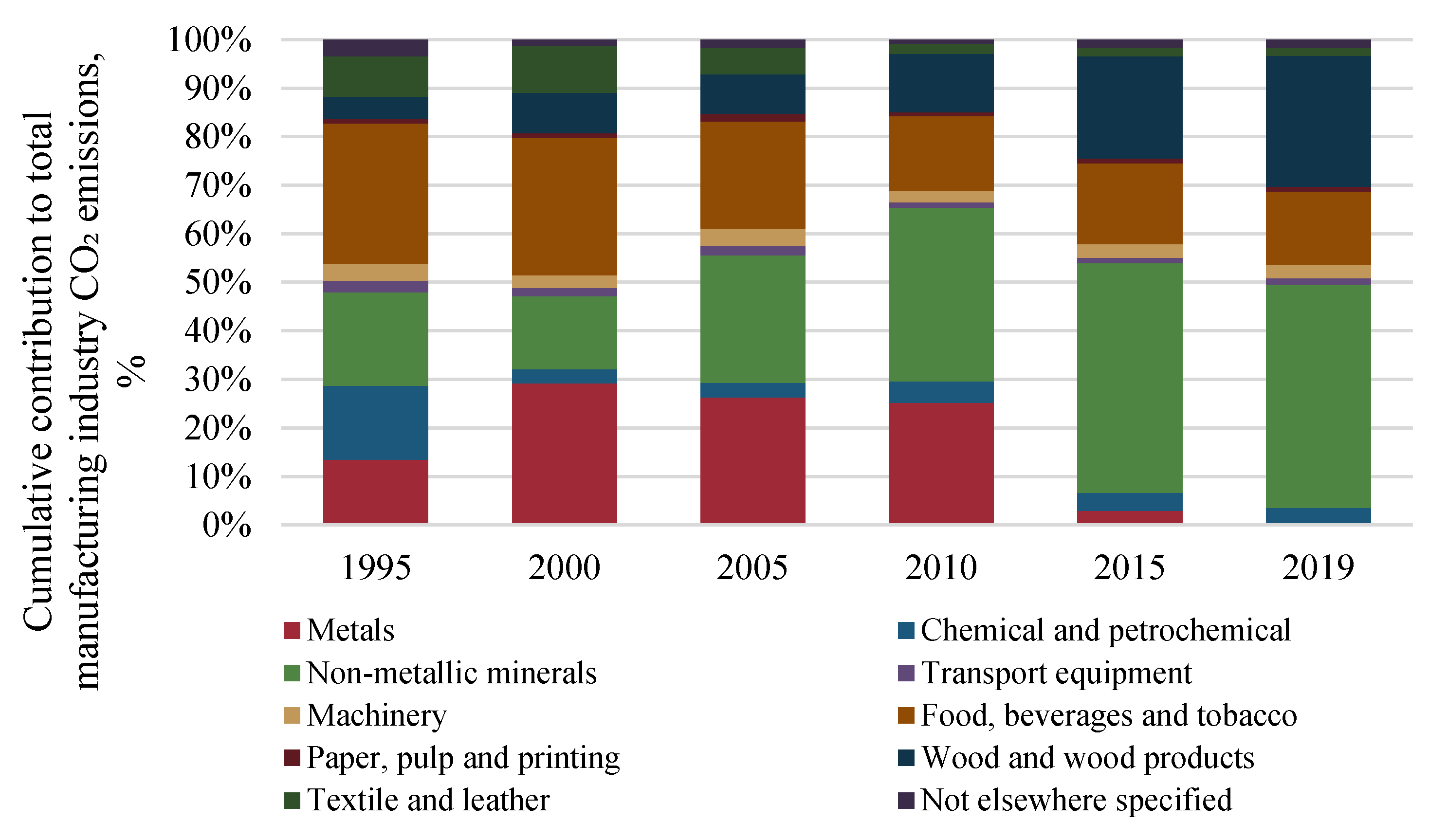

4.1. Manufacturing Industry Description

4.1.1. Total Energy Consumption and CO2 Emissions in Latvian Manufacturing Industry

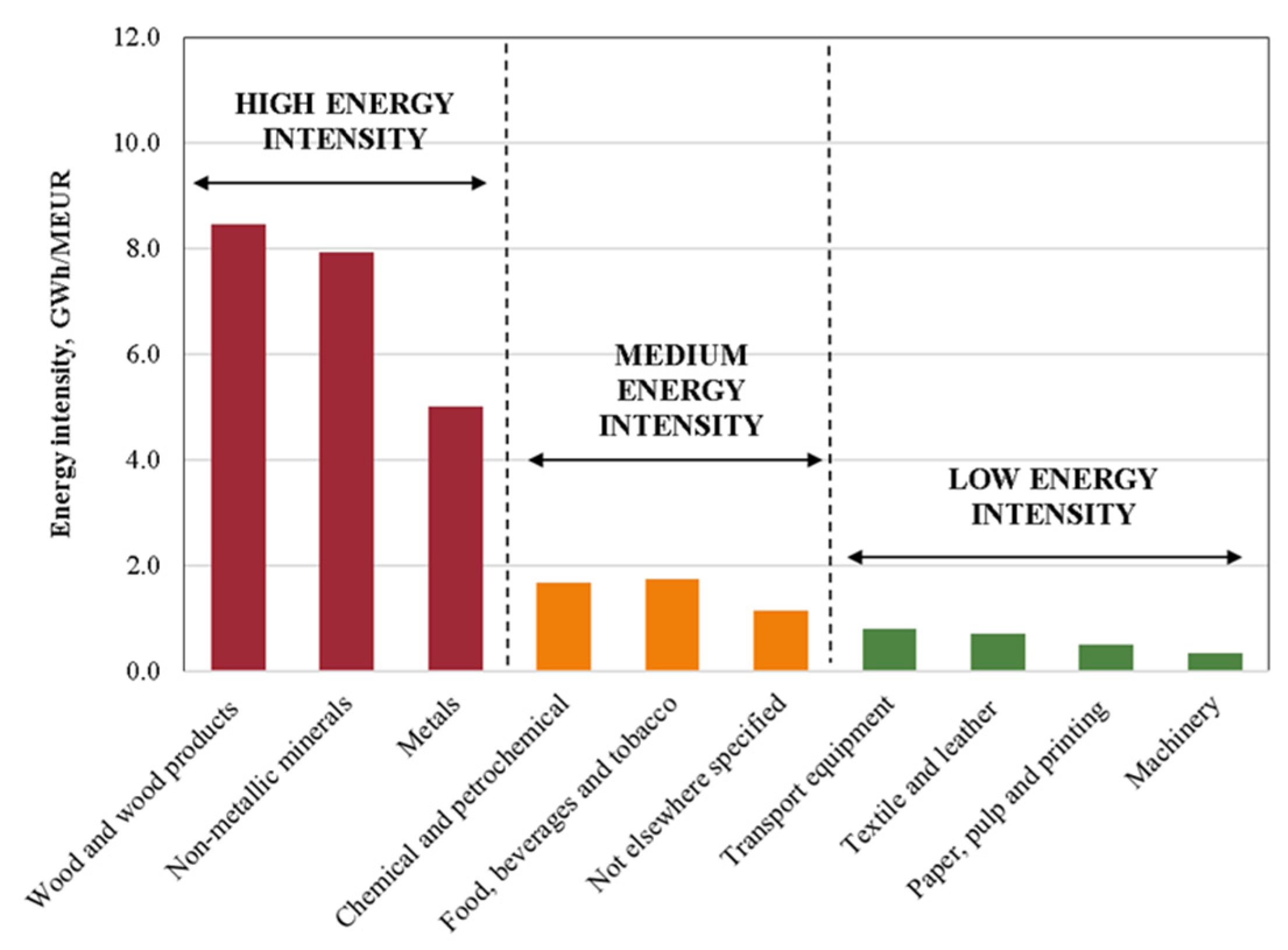

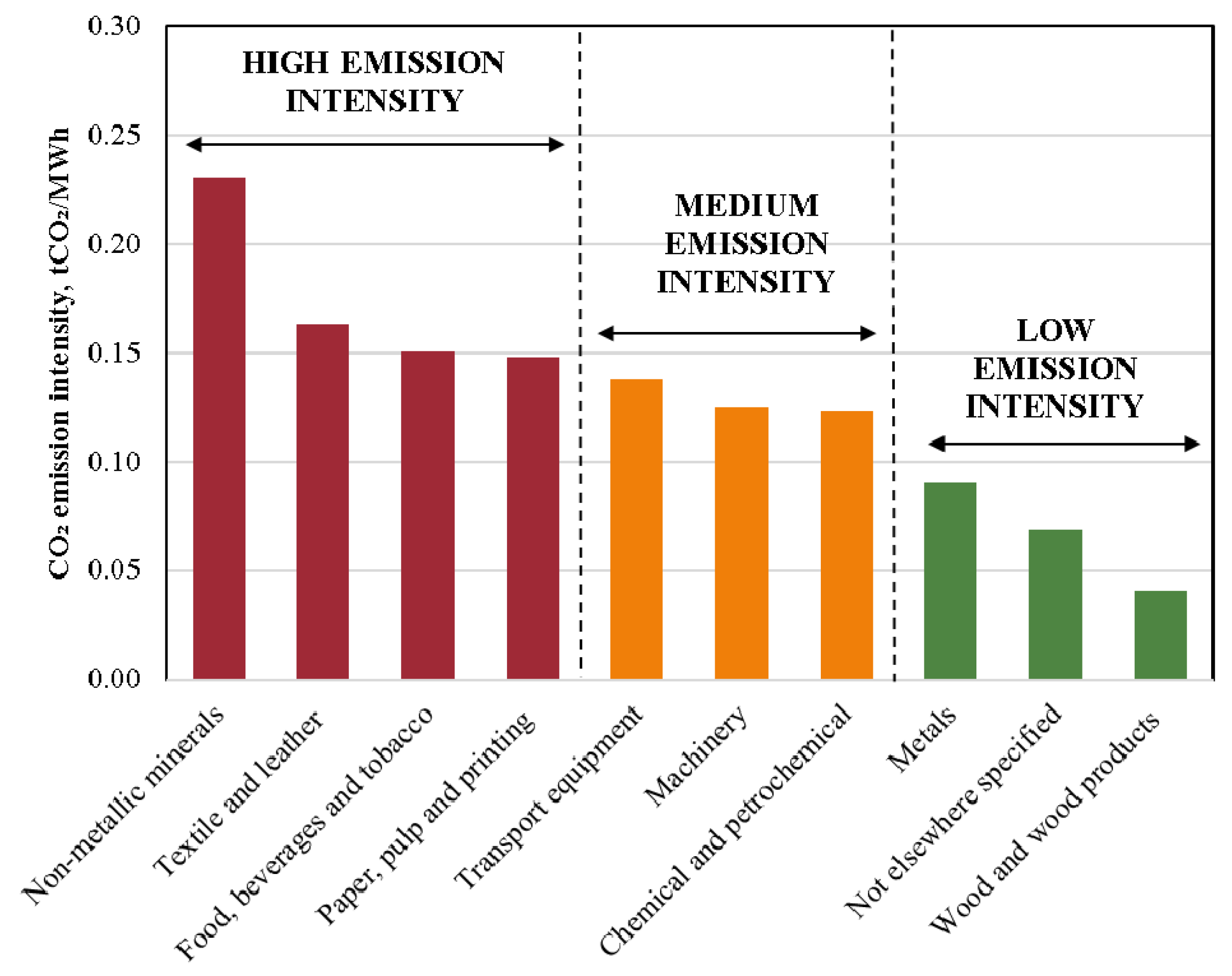

4.1.2. Energy and CO2 Emission Intensities

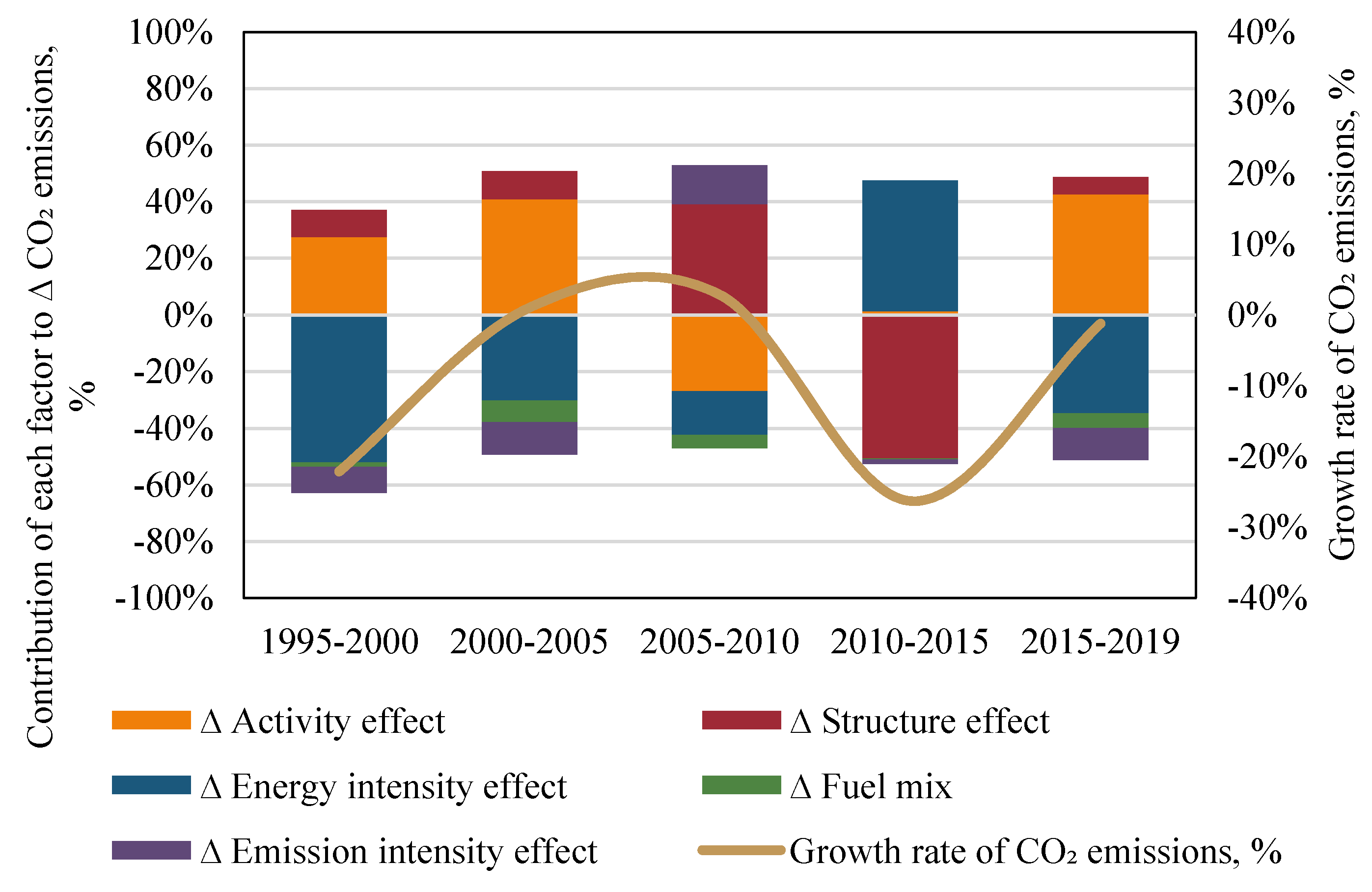

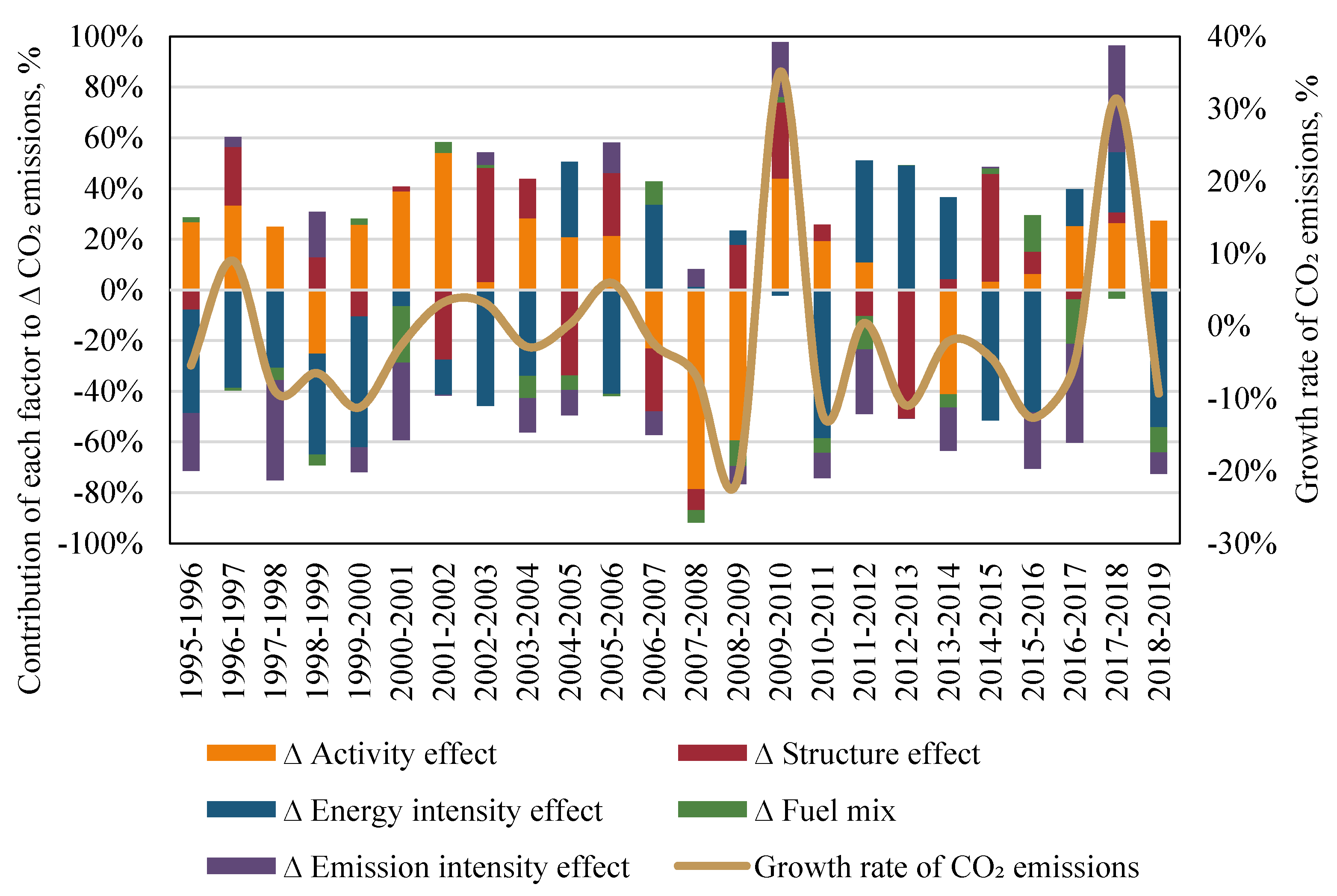

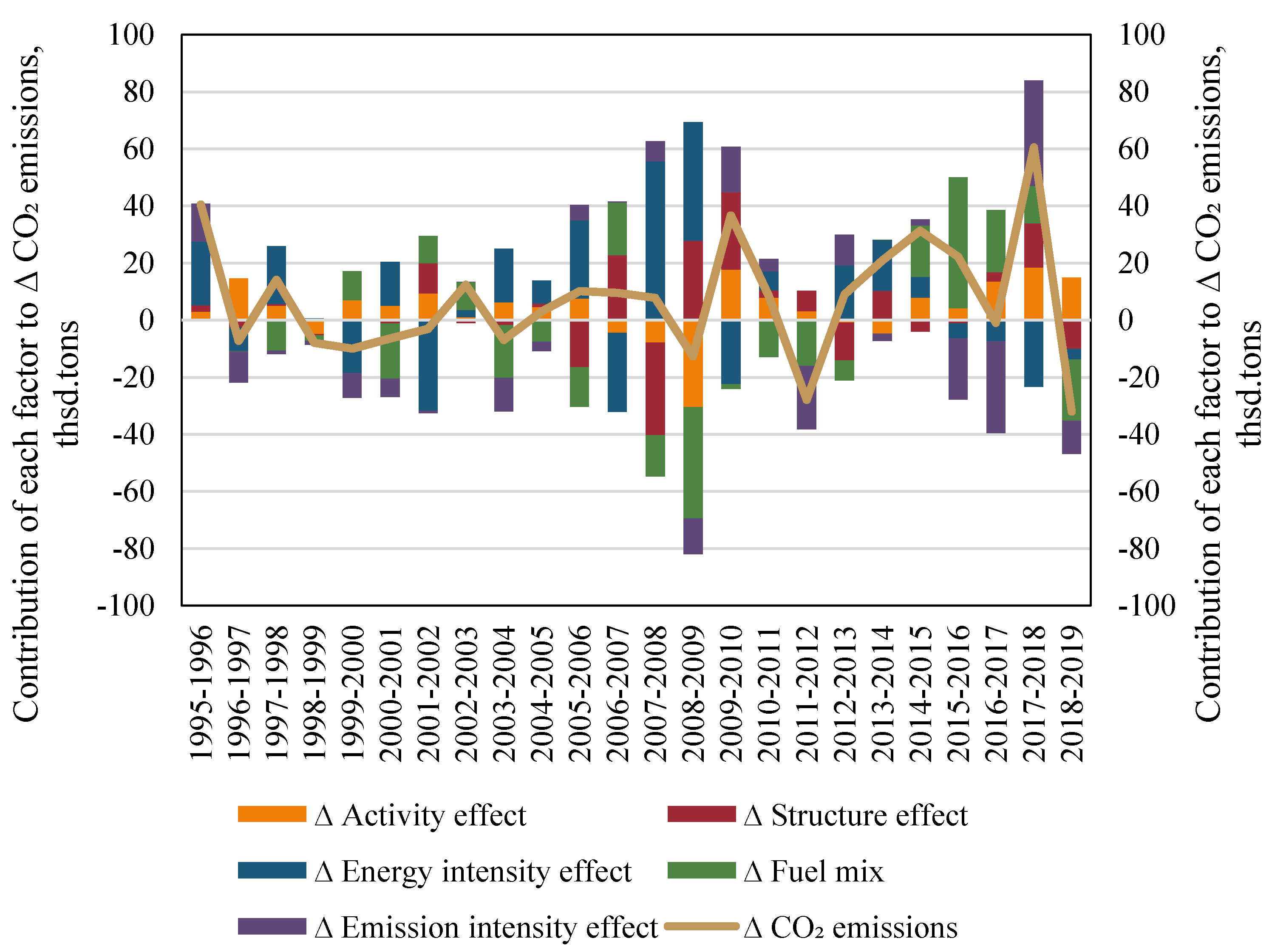

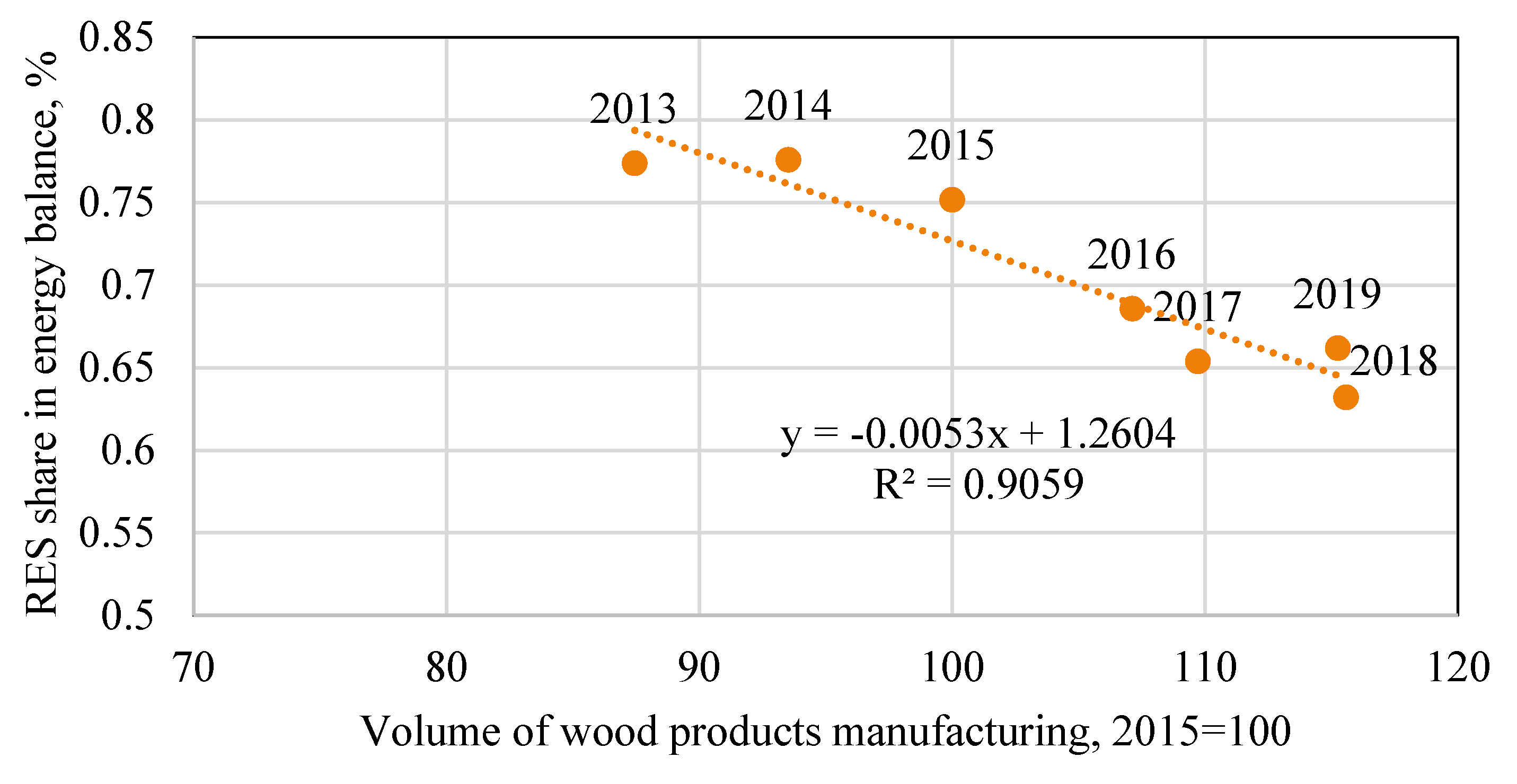

4.2. Decomposition Analysis Results

5. Conclusions and Policy Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| C | total aggregated energy-related CO2 emissions |

| Q | total produced volumes expressed as total value-added |

| E | total energy consumption |

| Si | industrial production activity |

| Ii | energy intensity |

| Fij | fuel mix |

| Mij | emission factor |

| i | representative value of a subsector |

| j | the type of energy carrier in the total energy balance |

| act | effect from changes in industrial activity |

| str | effect from changes in structure |

| eni | effect from changes in energy intensity |

| fuel | effect from changes in fuel mix |

| emi | effect from changes in emission intensity |

| ET | energy consumption in future year T |

| E0 | energy consumption in initial year |

References

- UNEP; UNEP DTU Partnership. UNEP Emissions Gap Report 2021. Available online: https://www.unep.org/resources/emissions-gap-report-2021 (accessed on 15 November 2021).

- Vieira, L.C.; Longo, M.; Mura, M. Are the European manufacturing and energy sectors on track for achieving net-zero emissions in 2050? An empirical analysis. Energy Policy 2021, 156, 112464. [Google Scholar] [CrossRef]

- Dolge, K.; Blumberga, D. Economic growth in contrast to GHG emission reduction measures in Green Deal context. Ecol. Indic. 2021, 130, 108153. [Google Scholar] [CrossRef]

- Wang, M.; Feng, C. Towards a decoupling between economic expansion and carbon dioxide emissions in resources sector: A case study of China’s 29 non-ferrous metal industries. Resour. Policy 2021, 74, 102249. [Google Scholar] [CrossRef]

- Talaei, A.; Gemechu, E.; Kumar, A. Key factors affecting greenhouse gas emissions in the Canadian industrial sector: A decomposition analysis. J. Clean. Prod. 2020, 246, 119026. [Google Scholar] [CrossRef]

- Sovacool, B.K.; Bazilian, M.; Griffiths, S.; Kim, J.; Foley, A.; Rooney, D. Decarbonizing the food and beverages industry: A critical and systematic review of developments, sociotechnical systems and policy options. Renew. Sustain. Energy Rev. 2021, 143, 110856. [Google Scholar] [CrossRef]

- Locmelis, K.; Blumberga, D.; Bariss, U. Energy efficiency in large industrial plants. Legislative aspects. Energy Procedia 2018, 147, 202–206. [Google Scholar] [CrossRef]

- Dolge, K.; Kubule, A.; Blumberga, D. Composite Index for Energy Efficiency Evaluation of Industrial Sector: Sub-Sectoral Comparison. Environ. Sustain. Indic. 2020, 8, 100062. [Google Scholar] [CrossRef]

- Fang, K.; Li, C.; Tang, Y.; He, J.; Song, J. China’s pathways to peak carbon emissions: New insights from various industrial sectors. Appl. Energy 2021, 306, 118039. [Google Scholar] [CrossRef]

- García-Quevedo, J.; Jové-Llopis, E. Environmental policies and energy efficiency investments. An industry-level analysis. Energy Policy 2021, 156, 112461. [Google Scholar] [CrossRef]

- Iqbal, N.; Abbasi, K.R.; Shinwari, R.; Guangcai, W.; Ahmad, M.; Tang, K. Does exports diversification and environmental innovation achieve carbon neutrality target of OECD economies? J. Environ. Manag. 2021, 291, 112648. [Google Scholar] [CrossRef]

- Zhang, G.; Cheng, P.; Sun, H.; Shi, Y.; Zhang, G.; Kadiane, A. Carbon reduction decisions under progressive carbon tax regulations: A new dual-channel supply chain network equilibrium model. Sustain. Prod. Consum. 2021, 27, 1077–1092. [Google Scholar] [CrossRef]

- Trotta, G. Assessing energy efficiency improvements and related energy security and climate benefits in Finland: An ex post multi-sectoral decomposition analysis. Energy Econ. 2020, 86, 104640. [Google Scholar] [CrossRef]

- Dolge, K.; Āzis, R.; Lund, P.D.; Blumberga, D. Importance of Energy Efficiency in Manufacturing Industries for Climate and Competitiveness. Environ. Clim. Technol. 2021, 25, 306–317. [Google Scholar] [CrossRef]

- Pan, X.; Guo, S.; Xu, H.; Tian, M.; Pan, X.; Chu, J. China’s carbon intensity factor decomposition and carbon emission decoupling analysis. Energy 2021, 239, 122175. [Google Scholar] [CrossRef]

- Xu, X.; Ang, B. Index decomposition analysis applied to CO2 emission studies. Ecol. Econ. 2013, 93, 313–329. [Google Scholar] [CrossRef]

- Ang, B.; Xu, X. Tracking industrial energy efficiency trends using index decomposition analysis. Energy Econ. 2013, 40, 1014–1021. [Google Scholar] [CrossRef]

- Cahill, C.J.; Gallachóir, B.P.Ó. Combining physical and economic output data to analyse energy and CO2 emissions trends in industry. Energy Policy 2012, 49, 422–429. [Google Scholar] [CrossRef]

- Ang, B.W. Decomposition analysis for policymaking in energy: Which is the preferred method? Energy Policy 2004, 32, 1131–1139. [Google Scholar] [CrossRef]

- Ang, B.; Liu, F.; Chew, E. Perfect decomposition techniques in energy and environmental analysis. Energy Policy 2003, 31, 1561–1566. [Google Scholar] [CrossRef]

- Xu, W.; Xie, Y.; Xia, D.; Ji, L.; Huang, G. A multi-sectoral decomposition and decoupling analysis of carbon emissions in Guangdong province, China. J. Environ. Manag. 2021, 298, 113485. [Google Scholar] [CrossRef]

- Singpai, B.; Wu, D.D. An integrative approach for evaluating the environmental economic efficiency. Energy 2021, 215, 118940. [Google Scholar] [CrossRef]

- Chontanawat, J.; Wiboonchutikula, P.; Buddhivanich, A. An LMDI decomposition analysis of carbon emissions in the Thai manufacturing sector. Energy Rep. 2020, 6, 705–710. [Google Scholar] [CrossRef]

- Shi, Y.; Han, B.; Zafar, M.W.; Wei, Z. Uncovering the driving forces of carbon dioxide emissions in Chinese manufacturing industry: An intersectoral analysis. Environ. Sci. Pollut. Res. 2019, 26, 31434–31448. [Google Scholar] [CrossRef] [PubMed]

- Du, G.; Sun, C.; Ouyang, X.; Zhang, C. A decomposition analysis of energy-related CO2 emissions in Chinese six high-energy intensive industries. J. Clean. Prod. 2018, 184, 1102–1112. [Google Scholar] [CrossRef]

- Liu, J.; Yang, Q.; Zhang, Y.; Sun, W.; Xu, Y. Analysis of CO2 Emissions in China’s Manufacturing Industry Based on Extended Logarithmic Mean Division Index Decomposition. Sustainability 2019, 11, 226. [Google Scholar] [CrossRef] [Green Version]

- Ang, B. The LMDI approach to decomposition analysis: A practical guide. Energy Policy 2005, 33, 867–871. [Google Scholar] [CrossRef]

- Ouyang, X.; Lin, B. An analysis of the driving forces of energy-related carbon dioxide emissions in China’s industrial sector. Renew. Sustain. Energy Rev. 2015, 45, 838–849. [Google Scholar] [CrossRef] [Green Version]

- Jeong, K.; Kim, S. LMDI decomposition analysis of greenhouse gas emissions in the Korean manufacturing sector. Energy Policy 2013, 62, 1245–1253. [Google Scholar] [CrossRef]

- Akbostancı, E.; Tunç, G.I.; Türüt-Aşık, S. CO2 emissions of Turkish manufacturing industry: A decomposition analysis. Appl. Energy 2011, 88, 2273–2278. [Google Scholar] [CrossRef]

- González, D.; Martinez, M. Changes in CO2 emission intensities in the Mexican industry. Energy Policy 2012, 51, 149–163. [Google Scholar] [CrossRef]

- Eurostat. Energy Balance Guide—Methodology Guide for the Construction of Energy Balances & Operational Guide for the Energy Balance Builder Tool; Eurostat: Luxembourg, 2019; Available online: https://ec.europa.eu/eurostat/documents/38154/4956218/ENERGY-BALANCE-GUIDE-DRAFT-31JANUARY2019.pdf (accessed on 15 October 2021).

- Central Statistics Bureau of Latvia. Entrepreneurship Indicators of Enterprises (SBG010) 2020. Available online: http://data1.csb.gov.lv/pxweb/en/uzn/uzn__uzndarb/SBG010.px/ (accessed on 10 February 2020).

- Eurostat. GDP and Main Components (Output, Expenditure and Income) Nama_10_Gdp. Available online: https://appsso.eurostat.ec.europa.eu/nui/show.do?dataset=nama_10_gdp&lang=en (accessed on 15 October 2021).

- Eurostat. Complete Energy Balances [nrg_bal_c]. Available online: https://appsso.eurostat.ec.europa.eu/nui/show.do?dataset=nrg_bal_c&lang=en (accessed on 15 October 2021).

- Gómez, D.R.; Watterson, J.D.; Americano, B.B.; Ha, H.; Marland, G.; Matsika, E.; Namayanga, N.; Osman-Elsha, B.; Kalenga-Saka, J.D.; Trenton, K. Stationary Combustion. In 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2006; Volume 2, Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/pdf/2_Volume2/V2_2_Ch2_Stationary_Combustion.pdf (accessed on 8 October 2021).

- European Environment Agency. Greenhouse Gas Emission Intensity of Electricity Generation 2020. Available online: https://www.eea.europa.eu/data-and-maps/daviz/co2-emission-intensity-6#tab-googlechartid_googlechartid_googlechartid_googlechartid_chart_11111 (accessed on 2 September 2021).

- Cabinet of Ministers. Regulation No. 42. Methodology for Calculating Greenhouse Gas Emissions. Available online: https://likumi.lv/ta/en/en/id/296651 (accessed on 3 June 2021).

- Central Statistics Bureau of Latvia. Fuel Consumption, Heat and Electricity Produced in Combined Heat and Power Plants by CHP, Energy Resources, Indicator and Time period [ENB140]. Available online: https://data.stat.gov.lv/pxweb/en/OSP_PUB/START__NOZ__EN__ENB/ENB140/ (accessed on 3 June 2021).

- Central Statistics Bureau of Latvia. Fuel Consumption and Heat Produced in Heat Plants, TJ by Heat Plants, Energy Resources, Indicator and Time Period [ENB110]. Available online: https://data.stat.gov.lv/pxweb/en/OSP_PUB/START__NOZ__EN__ENB/ENB110/ (accessed on 3 June 2021).

- ODYSSEE-MURE. Latvia Energy Profile. Energy Efficiency Trends and Policies 2021. Available online: https://www.odyssee-mure.eu/publications/efficiency-trends-policies-profiles/latvia.html (accessed on 20 November 2021).

- Central Statistical Bureau of Latvia. ATN010 Exports and Imports by Commodity Section and by Economic Activity (NACE Rev.2) of the Importer (Thsd Euro) by Flow of Goods, Economic Activity (NACE Rev.2), Commodity Group (CN) and Time period. Available online: https://data.stat.gov.lv/pxweb/en/OSP_PUB/START__TIR__AT__ATN/ATN010/table/tableViewLayout1/ (accessed on 20 November 2021).

- Gao, Z.; Geng, Y.; Wu, R.; Chen, W.; Wu, F.; Tian, X. Analysis of energy-related CO2 emissions in China’s pharmaceutical industry and its driving forces. J. Clean. Prod. 2019, 223, 94–108. [Google Scholar] [CrossRef]

- Broniszewski, M.; Werle, S. CO2 reduction methods and evaluation of proposed energy efficiency improvements in Poland’s large industrial plant. Energy 2020, 202, 117704. [Google Scholar] [CrossRef]

| Indicator | Notation | Time Period | Variable | Explanation | Data Source |

|---|---|---|---|---|---|

| Activity effect | Act | 1995–2019 | ) * | Measures changes in the growth of the total production output | [33,34] |

| Structural effect | Str | 1995–2019 | ) * | Measures the level of restructuring in industry by shifting to less energy-intensive sectors | [33,34] |

| Energy intensity effect | Int | 1995–2019 | The amount of energy consumed per unit of production output (GWhi/EURi) * | Measures the level of energy efficiency improvement | [34,35] |

| Fuel mix effect | Fuel | 1995–2019 | ) | Measures the decarbonization effect of the industry | [35] |

| Emission intensity effect | Emi | 1995–2019 | Emission intensity of consumed energy resources (tCO2/GWh) * | Measures the emissions intensity of the fuel mix | [36] |

| Fuel Type | Emission Factor, tCO2/MWh |

|---|---|

| Anthracite | 0.354 |

| Other bituminous coal | 0.341 |

| Coke oven coke | 0.385 |

| Natural gas | 0.202 |

| Gas oil and diesel oil | 0.267 |

| Fuel oil | 0.279 |

| Other oil products n.e.c. | 0.264 |

| Renewables and biofuels | 0 |

| Peat | 0.382 |

| Liquefied petroleum gases | 0.227 |

| Motor gasoline | 0.249 |

| Other kerosene | 0.259 |

| Lignite | 0.364 |

| Petroleum coke | 0.351 |

| Non-renewable waste | 0.330 |

| Kerosene-type jet fuel | 0.257 |

| 1995–2000 | 2000–2005 | 2005–2010 | 2010–2015 | 2015–2019 | |

|---|---|---|---|---|---|

| ∆ Activity effect | 353.1 | 336.8 | −154.7 | 86.9 | 186.9 |

| ∆ Structure effect | 123.9 | 81.4 | 225.3 | −3242.6 | 26.5 |

| ∆ Energy intensity effect | −668.5 | −248.8 | −88.5 | 2956.1 | −151.5 |

| ∆ Fuel mix | −19.5 | −62.2 | −27.0 | −21.4 | −23.3 |

| ∆ Emission intensity effect | −119.1 | −95.0 | 78.8 | −96.9 | −49.4 |

| ∆ CO2 emissions | −330.2 | 12.3 | 33.8 | −317.8 | −10.7 |

| Time Period | Main Events during the Representative Period Driving Change in CO2 Emissions |

|---|---|

| 1995–2000 | Period after the restoration of independence during which the entire Latvian economy, including the manufacturing industry, was significantly restructured. Significant reforms in the form of ownership and changes in the foreign trade regime affected the overall development of manufacturing industry. Imported raw materials and energy resources were now subject to world market prices, which meant that some factories that had previously been successful due to low energy costs were no longer competitive in export markets. This forced manufacturing companies to redesign production processes and invest in energy efficiency measures. |

| 2000–2005 | The period before the financial crisis was mainly characterized by high economic growth and the increase in industrial production and energy consumption. Investments in the modernization of factories and in energy efficiency could not compensate for the effect of increasing activity, which drove up CO2 emissions. |

| 2005–2010 | Period of the global financial crisis, during which a sharp decline in total production volumes was observed from 2006 to 2009. As a result, a significant reduction in energy consumption and emissions produced was achieved. However, in 2010, a sharp increase in industrial activity led to an increase in total CO2 emissions during this period. A shift towards more energy intensive sectors was observed during this period. The entire industrial sector experienced a significant structural change. |

| 2010–2015 | Bankruptcy and market exit of the largest metal producer led to significant structural changes in the entire industry. The sudden decline in metal production was largely offset by the rapid expansion of the wood processing sector, which drove up energy consumption overall in the industry. |

| 2015–2019 | Higher economic growth and rising demand in the largest export markets led to an increase in production output and caused energy consumption to rise. Although there is a positive trend in the overall decarbonization of the fuel mix and reduction of the emission factor, the overall growth rate of CO2 emissions shows an upward trend and reduction of CO2 is stagnating. |

| 2010–2011 | 2011–2012 | 2012–2013 | 2013–2014 | 2014–2015 | 2015–2016 | 2016–2017 | 2017–2018 | 2018–2019 | |

|---|---|---|---|---|---|---|---|---|---|

| ∆ Activity effect | 58 | 24 | −7 | −30 | 42 | 17 | 49 | 66 | 55 |

| ∆ Structure effect | 19 | −23 | −3787 | 3 | 545 | 24 | −7 | 11 | −1 |

| ∆ Energy intensity effect | −176 | 90 | 3677 | 24 | −659 | −133 | 29 | 59 | −107 |

| ∆ Fuel mix | −17 | −30 | 2 | −4 | 28 | 40 | −34 | −9 | −20 |

| ∆ Emission intensity effect | −30 | −57 | −2 | −13 | 5 | −61 | −76 | 105 | −17 |

| ∆ CO2 emissions | −146 | 5 | −117 | −20 | −40 | −113 | −40 | 232 | −90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dolge, K.; Blumberga, D. Key Factors Influencing the Achievement of Climate Neutrality Targets in the Manufacturing Industry: LMDI Decomposition Analysis. Energies 2021, 14, 8006. https://doi.org/10.3390/en14238006

Dolge K, Blumberga D. Key Factors Influencing the Achievement of Climate Neutrality Targets in the Manufacturing Industry: LMDI Decomposition Analysis. Energies. 2021; 14(23):8006. https://doi.org/10.3390/en14238006

Chicago/Turabian StyleDolge, Kristiāna, and Dagnija Blumberga. 2021. "Key Factors Influencing the Achievement of Climate Neutrality Targets in the Manufacturing Industry: LMDI Decomposition Analysis" Energies 14, no. 23: 8006. https://doi.org/10.3390/en14238006

APA StyleDolge, K., & Blumberga, D. (2021). Key Factors Influencing the Achievement of Climate Neutrality Targets in the Manufacturing Industry: LMDI Decomposition Analysis. Energies, 14(23), 8006. https://doi.org/10.3390/en14238006