Transport Performance of a Steeply Situated Belt Conveyor

Abstract

:1. Introduction

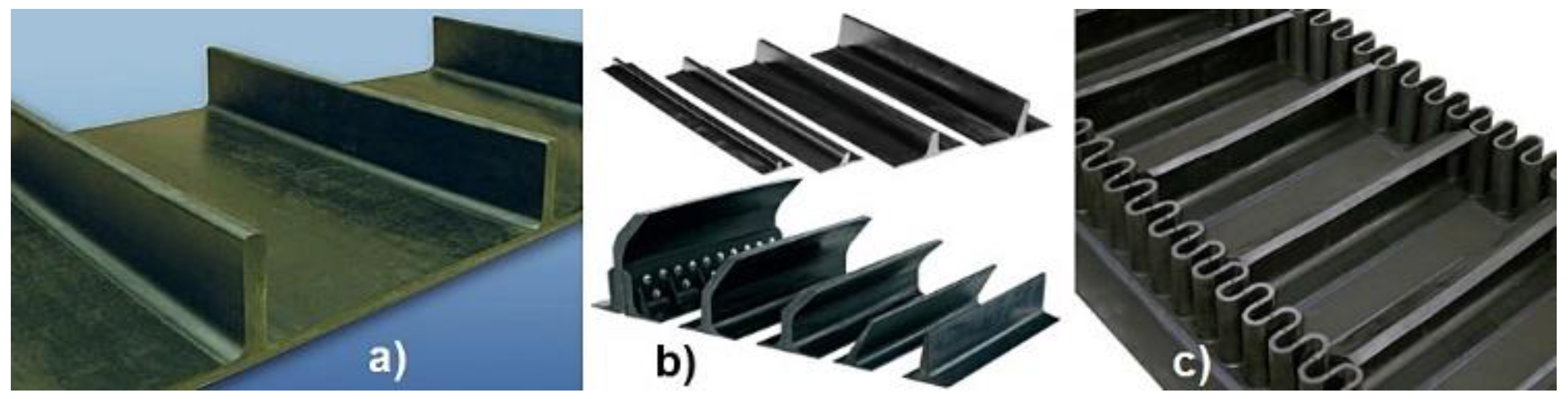

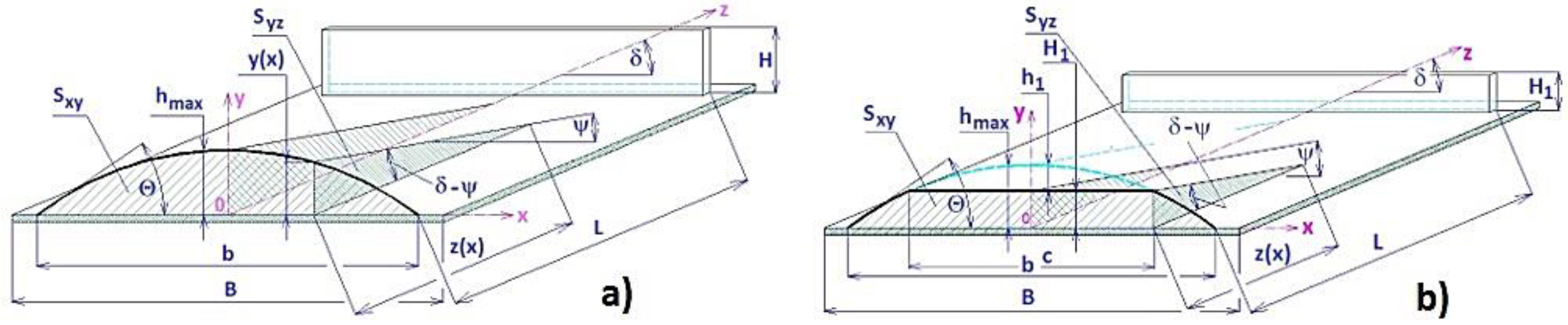

- (a)

- (b)

- (c)

- Increase the pressure of the transported material to the conveyor belt [36].

2. Materials and Methods

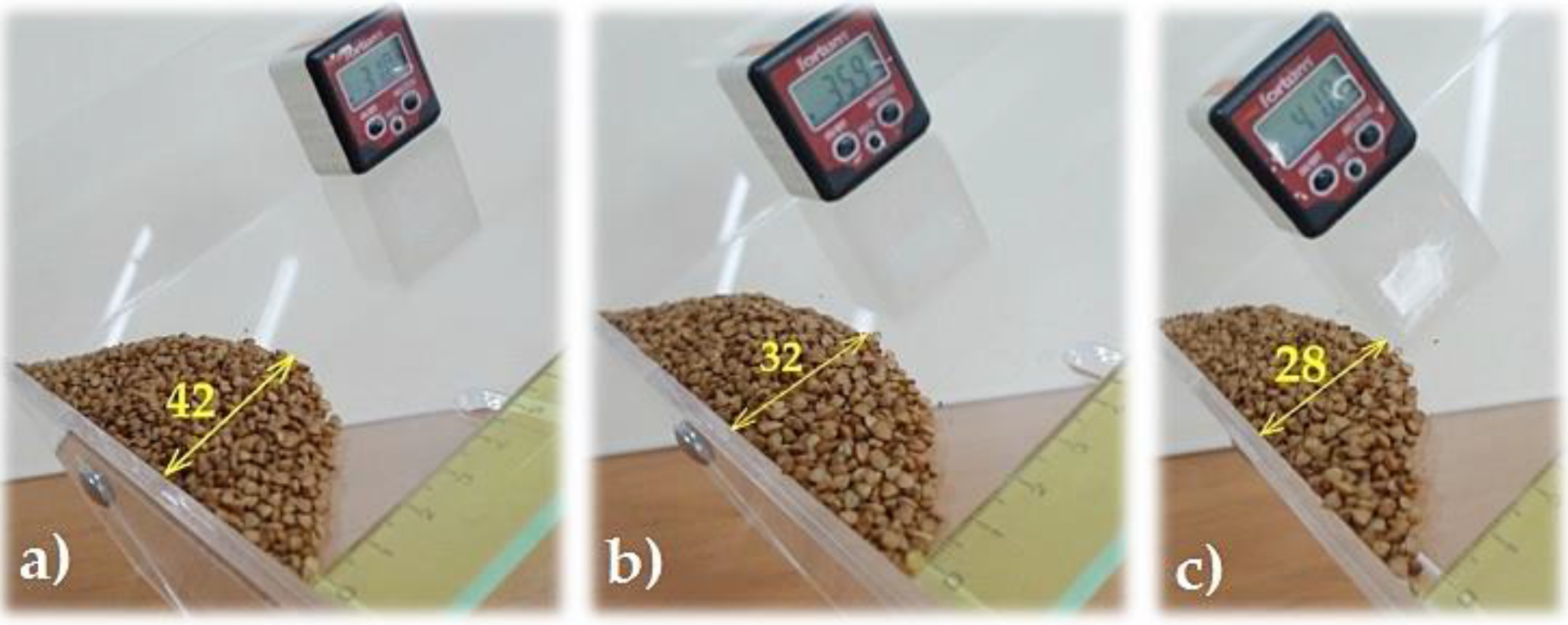

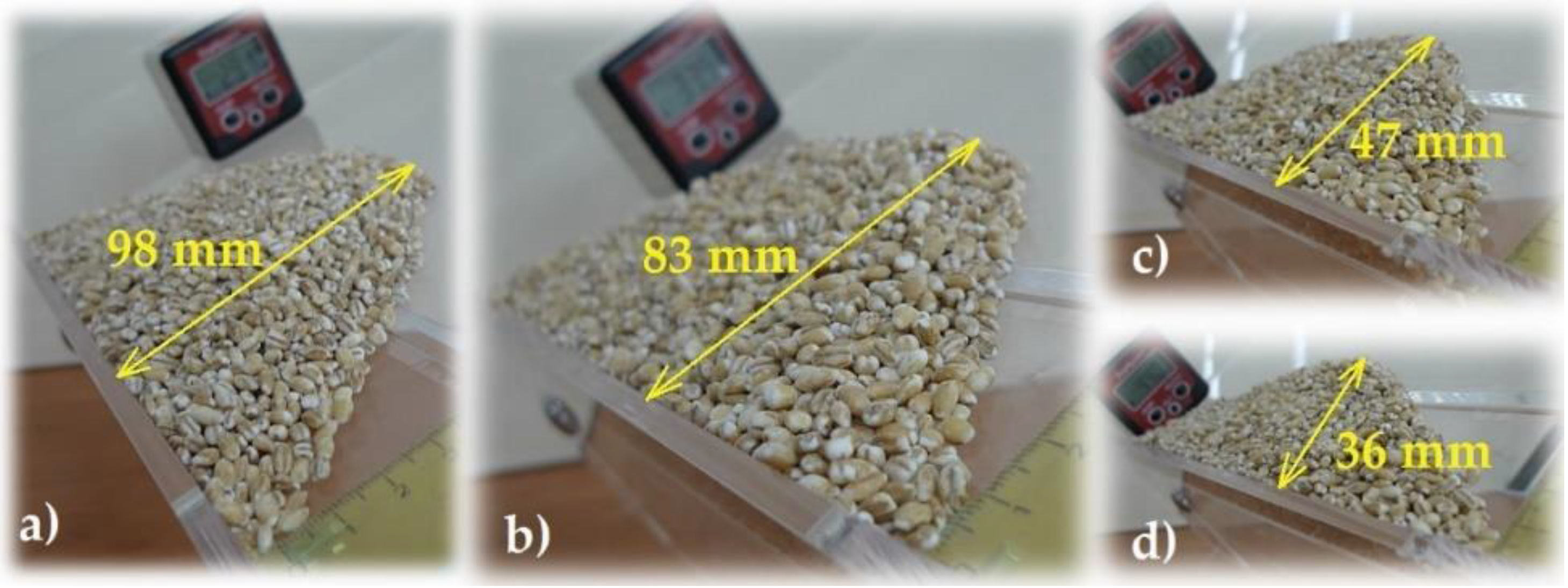

2.1. Experimental Testing Equipment and Measured Parameters

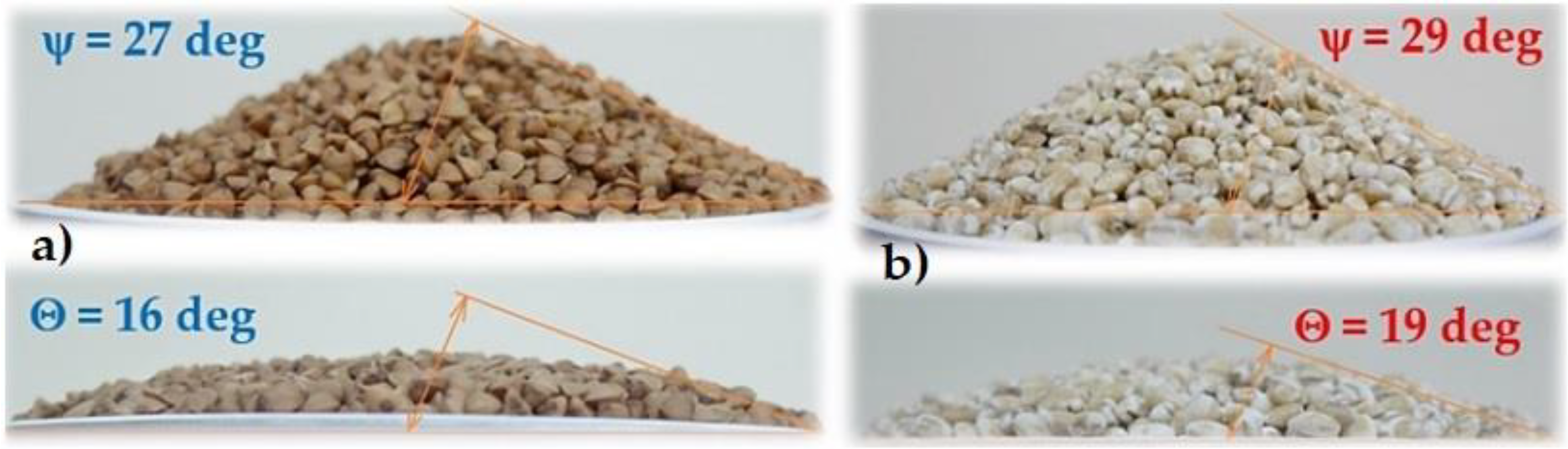

2.2. Properties of the Conveyed Material

3. Result

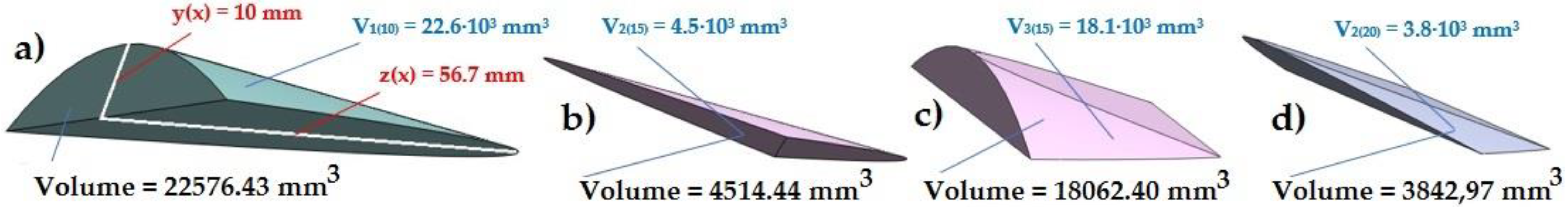

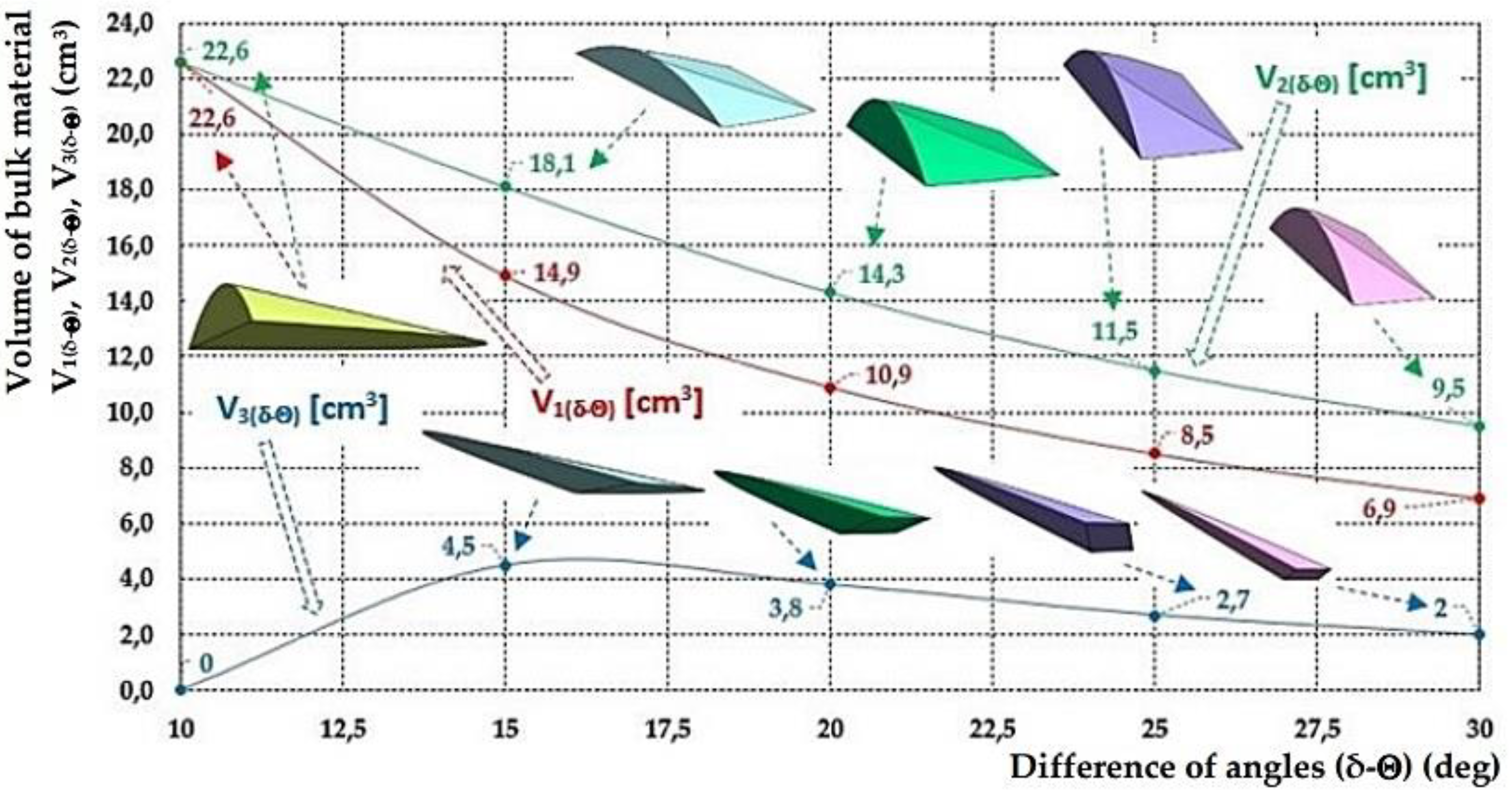

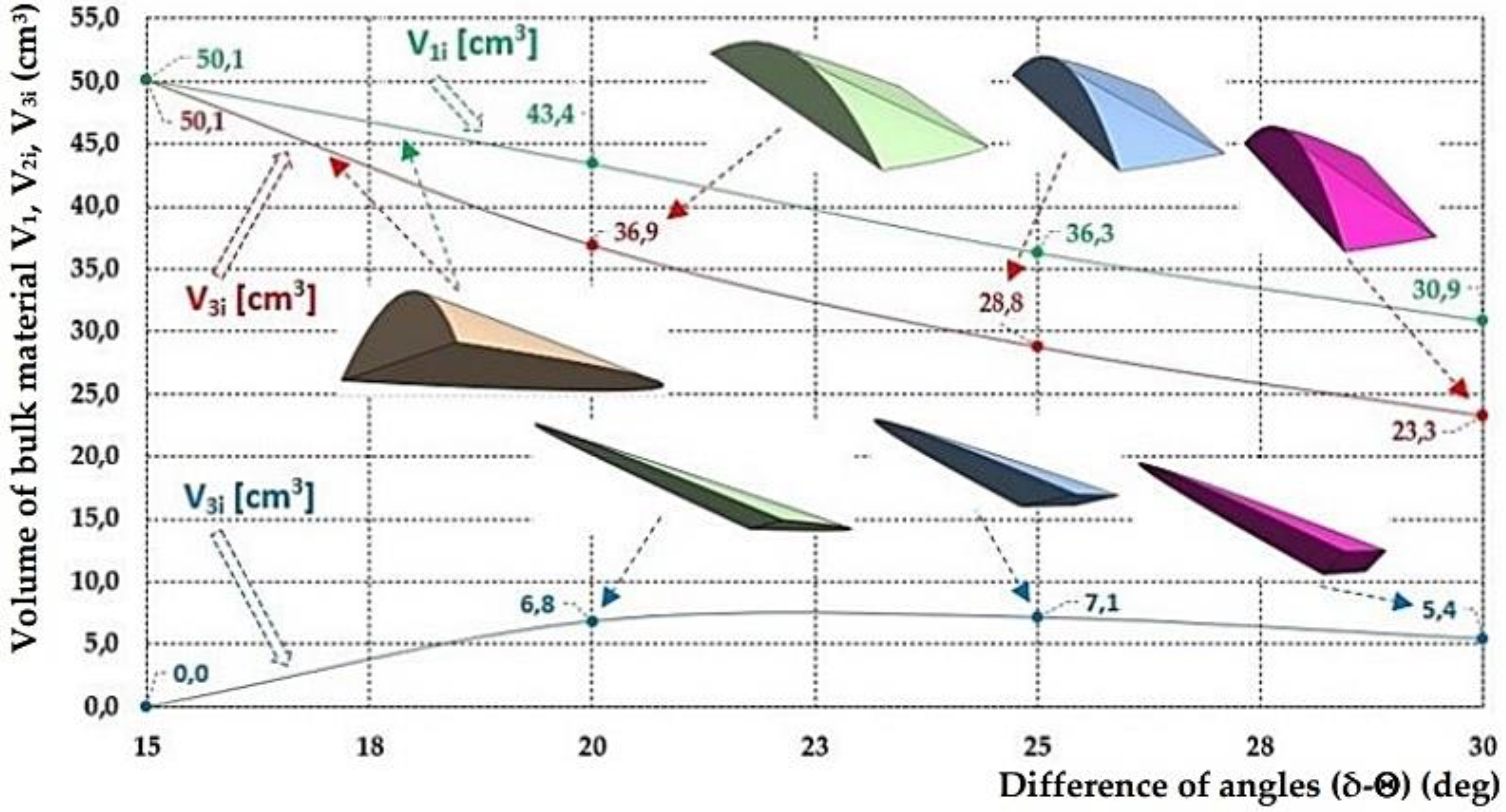

3.1. Transverse, Longitudinal Cross-Section and Batch Volume of Transported Material

| δ (deg) | 30 | 35 | 40 | 45 | 50 | 55 | 60 |

| δ–Θ (deg) | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

| B/b/y(x) (mm) | 400/310/13.7 | ||||||

| z(x) (mm) | 37.6 | 29.3 | 23.7 | 19.5 | 16.3 | 13.7 | 11.5 |

| Syz (mm2) | 256.5 | 200.2 | 161.7 | 133.4 | 111.3 | 93.4 | 78.4 |

| V1 (mm3) | 42.4 | 33.1 | 26.7 | 22.1 | 18.4 | 15.4 | 13.0 |

| B/b/y(x) (mm) | 500/400/17.6 | ||||||

| z(x) (mm) | 48.5 | 37.8 | 30.5 | 25.2 | 21.0 | 17.6 | 14.8 |

| Syz (mm2) | 427.1 | 333.4 | 269.3 | 222.0 | 185.3 | 155.5 | 130.4 |

| V1 (mm3) | 91.1 | 71.1 | 57.4 | 47.4 | 39.5 | 33.2 | 27.8 |

| B/b/y(x) (mm) | 650/535/23.6 | ||||||

| z(x) (mm) | 64.8 | 50.6 | 40.9 | 33.7 | 28.1 | 23.6 | 19.8 |

| Syz (mm2) | 764.1 | 596.4 | 481.7 | 397.2 | 331.4 | 278.1 | 233.4 |

| V1 (cm3) | 218.0 | 170.2 | 137.4 | 113.3 | 94.6 | 79.4 | 66.6 |

| H1 (mm)/bp (mm) | 10/149.3 | ||||

| δ–Θ (deg) | 10 | 15 | 20 | 25 | 30 |

| z(x)(δ–Θ) (mm) | 56.7 | 37.3 | 27.5 | 21.5 | 17.3 |

| V1(δ–Θ) (cm3) | 22.6 1,2 | 14.9 | 10.9 | 8.5 | 6.9 |

| - | V3(δ–Θ) (cm3) | 18.1 1,2 | 12.8 | 9.8 | 7.8 |

| - | V2(δ–Θ) (cm3) | 4.5 1,2 | 2.1 | 1.1 | 0.7 |

| - | - | - | 14.3 2 | 10.7 | 9.1 |

| - | - | - | 3.8 1,2 | 2.1 | 5.8 |

| - | - | - | - | 11.5 2 | 9.0 |

| - | - | - | - | 2.7 2 | 1.7 |

| - | - | - | - | - | 9.5 2 |

| - | - | - | - | - | 2.0 2 |

| H1 (mm)/bp (mm) | 15/224.0 | ||||

| δ–Θ (deg) | 10 | 15 | 20 | 25 | 30 |

| z(x)(δ–Θ) (mm) | 85.1 | 56.0 | 41.2 | 32.2 | 26.0 |

| V1(δ–Θ) (cm3) | 76.2 | 50.1 3 | 36.9 | 28.8 | 23.3 |

| - | V2(δ–Θ) (cm3) | 61.0 | 43.4 3 | 33.1 | 26.4 |

| - | V3(δ–Θ) (cm3) | 15.2 | 6.8 3 | 3.8 | 2.4 |

| - | - | - | 48.0 | 36.3 3 | 28.9 |

| - | - | - | 13.0 | 7.1 3 | 4.2 |

| - | - | - | - | 38.8 | 30.9 3 |

| - | - | - | - | 9.2 | 5.4 3 |

| - | - | - | - | - | 32.5 |

| -- | - | - | - | - | 6.3 |

| H1 (mm)/bp (mm) | 20/298.6 | ||||

| δ–Θ (deg) | 10 | 15 | 20 | 25 | 30 |

| z(x)(δ–Θ) (mm) | 113.4 | 74.6 | 55.0 | 42.9 | 34.6 |

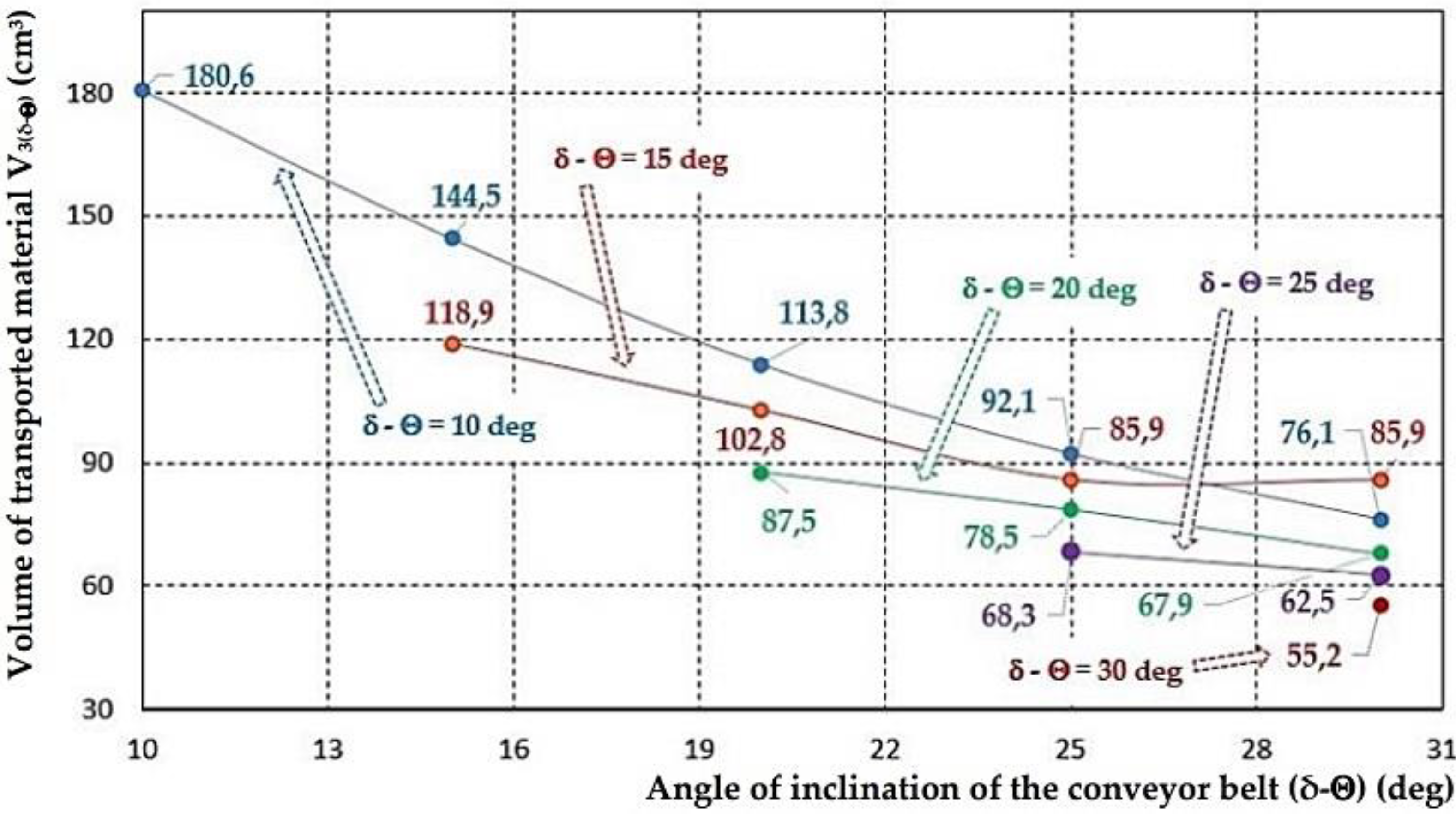

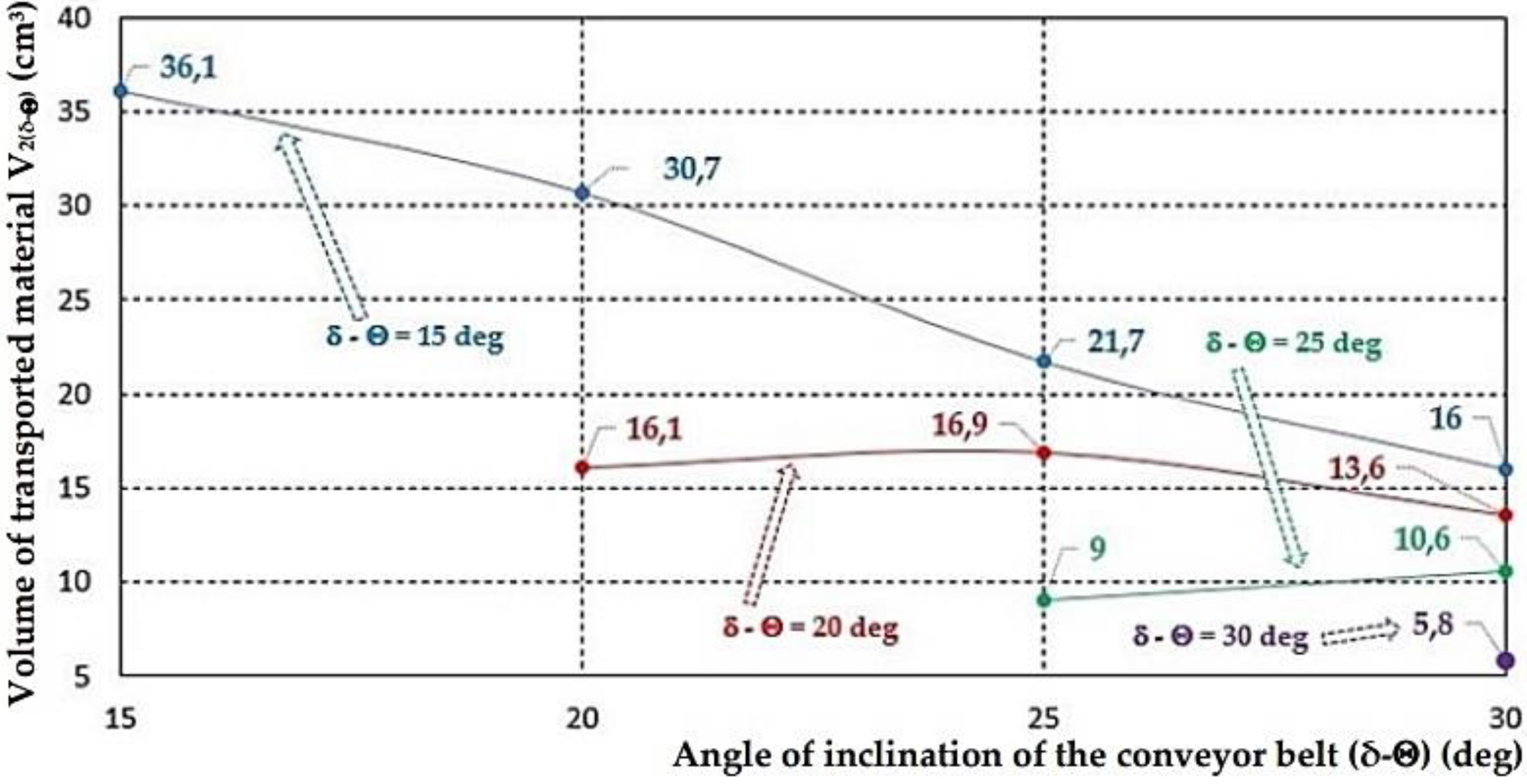

| V1(δ–Θ) (cm3) | 180.6 | 118.9 | 87.5 4 | 68.3 | 55.2 |

| - | V3(δ–Θ) (cm3) | 144.5 | 102.8 | 78.5 4 | 62.5 |

| - | V2(δ–Θ) (cm3) | 36.1 | 16.1 | 9.0 4 | 5.8 |

| - | - | - | 113.8 | 85.9 | 67.9 4 |

| - | - | - | 30.7 | 16.9 | 10.6 4 |

| - | - | - | - | 92.1 | 72.3 |

| - | - | - | - | 21.7 | 13.6 |

| - | - | - | - | - | 76.1 |

| - | - | - | - | - | 16.0 |

3.2. Experimentally Determined Distribution of Material and Its Volumes

| Material | Buckwheat | Barley Greats | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| H1/bp (mm) | 10/149.3 | |||||||||

| δ–Θ (deg) | 10 | 15 | 20 | 25 | 30 | 10 | 15 | 20 | 25 | 30 |

| z(x)(δ–Θ) (mm) | 60 | 44 | 32 5 | 28 5 | 21 | 59 | 42 | 31 | 24 | 19 |

| 63 | 42 5 | 34 | 26 | 22 | 60 | 45 | 33 | 22 | 21 | |

| 61 | 41 | 33 | 29 | 21 | 59 | 43 | 32 | 21 | 21 | |

| Σ z(x)(δ–Θ) | 184 | 127 | 99 | 83 | 64 | 178 | 130 | 96 | 67 | 61 |

| Σ z(x)(δ–Θ)/n | 61.3 | 42.3 | 33.0 | 27.6 | 21.3 | 59.3 | 43.3 | 32.0 | 22.3 | 20.3 |

| V3(δ–Θ) (cm3) | 23 | 18 | 14 | 11 | 10 | 23 | 19 | 15 | 12 | 10 |

| V2(δ–Θ) (cm3) | - | 5 | 4 | 3 | 2 | - | 4 | 4 | 3 | 2 |

| Material | Buckwheat | Barley Greats | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| H1/bp (mm | 15/224 | |||||||||

| δ–Θ (deg) | 10 | 15 | 20 | 25 | 30 | 10 | 15 | 20 | 25 | 30 |

| z(x)(δ–Θ) (mm) | 100 | 89 | 49 | 39 | 31 | 94 | 86 | 52 | 39 | 28 |

| 96 | 85 | 53 | 40 | 30 | 98 6 | 84 | 47 6 | 40 | 26 | |

| 98 | 86 | 51 | 36 | 28 | 97 | 83 6 | 49 | 36 6 | 29 | |

| Σ z(x)(δ–Θ) | 294 | 260 | 153 | 115 | 89 | 289 | 253 | 148 | 115 | 83 |

| Σ z(x)(δ–Θ)/n | 98.0 | 86.6 | 51.0 | 38.3 | 29.7 | 96.3 | 84.3 | 49.3 | 38.3 | 27.6 |

| V3(δ–Θ) [cm3] | 77 | 60 | 49 | 39 | 33 | 77 | 61 | 48 | 39 | 32 |

| V2(δ–Θ) [cm3] | - | 17 | 11 | 10 | 6 | - | 16 | 13 | 9 | 7 |

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yardley, E.D.; Stace, L.R. Belt Conveying of Minerals; Woodhead Publishing: Sawston, UK, 2008; ISBN 9781845692308. [Google Scholar]

- Marasova, D.; Taraba, V.; Grujic, M.; Fedorko, G.; Bindzar, P.; Husakova, N. Pásová doprava; PONT s.r.o.: Košice, Slovakia, 2006; ISBN 80-8073-628-6. [Google Scholar]

- Zur, T.; Hardygora, M. Przenośniki taśmowe w górnictwie; Śląsk sp. z o.o.: Katowice, Poland, 1996; ISBN 83-7164-004-8. [Google Scholar]

- Antoniak, J. Urządzenia i systemy transportu podziemnego w kopalniach, wyd. II; Wydawnictwo Śląsk: Katowice, Poland, 1990. [Google Scholar]

- Antoniak, J. Obliczenia przenośników taśmowych; Wydawnictwo Politechniki Śląskiej, skrypty uczelniane: Gliwice, Poland, 1992; Volume 1683. [Google Scholar]

- Antoniak, J. Przenośniki taśmowe. Wprowadzenia do teorii i obliczenia; Wydawnictwo Politechniki Śląskiej: Gliwice, Poland, 2004; ISBN 83-7335-266-X. [Google Scholar]

- Hardygora, M.; Wachowicz, J.; Czaplicka-Kolarz, K.; Markusik, S. Taśmy przenośnikowe; Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 1999; ISBN 83-204-2402-X. [Google Scholar]

- Kozłowski, T.; Wodecki, J.; Zimroz, R.; Błazej, R.; Hardygora, M. A Diagnostics of Conveyor Belt Splices. Appl. Sci. 2020, 10, 6259. [Google Scholar] [CrossRef]

- ČSN ISO 5048. Continuous Mechanical Handling Equipment—Belt Conveyors with Carrying Idlers—Calculation of Operating Power and Tensile Forces; ÚNI: Praha, Czech Republic, 1994; p. 15. [Google Scholar]

- ČSN 26 3102. Belt Conveyors—Calculation Bases; ÚNM: Praha, Czech Republic, 1988; p. 48. [Google Scholar]

- ČSN ISO 2406. Continuous Mechanical Handling Equipment—Mobile and Portable Conveyors—Constructional Specifications; ÚNI: Praha, Czech Republic, 1993; p. 4. [Google Scholar]

- Grujic, M.; Dragana, E. Advantages of high angle belt conveyors (hac) in mining. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2014; Volume 683. [Google Scholar]

- Perten, J. Krutonaklonnyje konvejeri. (In English: High Angle Conveyors); Mashinostrejenie: Leningrad, Russia, 1997; ISBN 621-867-212-7. [Google Scholar]

- Hrabovsky, L. Pásové dopravníky převyšující mezní úhel slonu dopravy; VSB-Technical University Ostrava: Ostrava, Czech Republic, 2005; Volume 127, ISBN 80-248-0779-3. [Google Scholar]

- Ross, E. Using Cleats to Extend Belt Conveyor Capabilities. Plant Eng. 1983, 37, 58–63. [Google Scholar]

- Ross, E. How to Attach and Apply Belt Conveyor Cleats. Plant Eng. 1983, 37, 132–139. [Google Scholar]

- Molnar, V.; Fedorko, G.; Honus, S.; Andrejiova, M.; Grincova, A.; Michalik, P.; Palencar, J. Research in placement of measuring sensors on hexagonal idler housing with regard to requirements of pipe conveyor failure analysis. Eng. Fail. Anal. 2020, 116, 104703. [Google Scholar] [CrossRef]

- Silvey, D.H.; Rugman, G. Belting. In Encyclopedia of Polymer Science and Technology; Wiley: New York, NY, USA, 2002. [Google Scholar]

- McTurk, J.R.; Birdsey, N. Specialised belt conveyors. South Afr. Mech. Eng. 1993, 43, 142–146. [Google Scholar]

- Homišin, J.; Grega, R.; Kaššay, P.; Fedorko, G.; Molnár, V. Removal of systematic failure of belt conveyor drive by reducing vibrations. Eng. Fail. Anal. 2019, 99, 192–202. [Google Scholar] [CrossRef]

- Hardygóra, M.; Bajda, M.; Błażej, R. Laboratory testing of conveyor textile belt joints used in underground mines. Min. Sci. 2015, 22, 161–169. [Google Scholar]

- Alviari, L.P.; Anggamawarti, M.F.; Sanjiwani, Y.; Risonarta, V.Y. Classification of Impact Damage on A Rubber-Textile Conveyor Belt: A Review. Int. J. Mech. Eng. Technol. Appl. 2020, 1, 21–27. [Google Scholar] [CrossRef]

- Krol, R.; Kawalec, W.; Gladysiewicz, L. An effective belt conveyor for underground ore transportation systems. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2017; Volume 95, p. 042047. [Google Scholar]

- Dos Santos, J.A. The Cost and Value of High Angle Conveying—A Comparison of Economics for different Conveying Paths. Bulk Solids Handl. 2013, 33, 18. [Google Scholar]

- Stehlikova, B.; Molnar, V.; Fedorko, G.; Michalik, P.; Paulikova, A. Research about influence of the tension forces, asymmetrical tensioning and filling rate of pipe conveyor belt filled with the material on the contact forces of idler rolls in hexagonal idler housing. Measurement 2020, 156, 107598. [Google Scholar] [CrossRef]

- Fedorko, G.; Molnar, V.; Vasil, M.; Salai, R. Proposal of digital twin for testing and measuring of transport belts for pipe conveyors within the concept Industry 4.0. Measurement 2021, 174, 108978. [Google Scholar] [CrossRef]

- Wozniak, D.; Hardygora, M. Method for laboratory testing rubber penetration of steel cords in conveyor belts. Min. Sci. 2020, 27, 105–117. [Google Scholar]

- Marasova, D.; Ambrisko, L.; Caban, L. Determination of the Quality of Rubber Composites Based on their Testing. Qual. Access Success 2019, 20, 18–21. [Google Scholar]

- Gierz, Ł.; Warguła, Ł.; Kukla, M.; Koszela, K.; Zwiachel, T.S. Computer aided modeling of wood chips transport by means of a belt conveyor with use of discrete element method. Appl. Sci. 2020, 10, 9091. [Google Scholar] [CrossRef]

- Bajda, M.; Hardygóra, M. Analysis of the Influence of the Type of Belt on the Energy Consumption of Transport Processes in a Belt Conveyor. Energies 2021, 14, 6180. [Google Scholar] [CrossRef]

- Hrabovsky, L. Loose Material Filling in the Loading Trough Profile of the Belt Conveyor. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; p. 012016. [Google Scholar]

- Fullard, B. Improve Operations Through the Use of Conveyor Belt Cleats. Ind. Eng. 1992, 24, 32–40. [Google Scholar]

- Bruce, R.C. Development of cleated belt bagasse conveyors. In Proceedings of the 2008 Conference of the Australian Society of Sugar Cane Technologists, Townsville, Qld, Australia, 29 April–2 May 2008; pp. 517–525. [Google Scholar]

- Wang, M.; Liu, Q.; Ou, Y.; Zou, X. Experimental Study of the Seed-Filling Uniformity of Sugarcane Single-Bud Billet Planter. Sugar Tech 2021, 23, 827–837. [Google Scholar] [CrossRef]

- Guo, S.; Huang, W.; Li, X. Normal Force and Sag Resistance of Pipe Conveyor. Chin. J. Mech. Eng. 2020, 33, 1–12. [Google Scholar] [CrossRef]

- Tarpay, I. Steep incline and vertical conveyors-advantages, challenges and applications. In 13th International Conference on Bulk Materials Storage, Handling and Transportation; Engineers Australia: Barton, ACT, Australia, 2019; Volume 330. [Google Scholar]

- Paelke, J.W.; Emerton, R.C.; Williams, J.A. Wyoming coal mine truck load-out facility carries 65,000 tons per month on FLEXOWELL steep angle conveyors. Bulk Solids Handling 1986, 6, 321–324. [Google Scholar]

- Klimecky, O.; Veverkova, H.; Bailotti, K.; Muller, J. Manipulace s Materiálem: Doprava v Lomech; VSB of Ostrava: Ostrava, Czech Republic, 1988; p. 320. [Google Scholar]

- Havelka, Z.; Tuma, J. Teorie Pásových Dopravníků; SNTL Praha: Praha, Czech Republic, 1971; p. 211. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hrabovský, L.; Fries, J. Transport Performance of a Steeply Situated Belt Conveyor. Energies 2021, 14, 7984. https://doi.org/10.3390/en14237984

Hrabovský L, Fries J. Transport Performance of a Steeply Situated Belt Conveyor. Energies. 2021; 14(23):7984. https://doi.org/10.3390/en14237984

Chicago/Turabian StyleHrabovský, Leopold, and Jiří Fries. 2021. "Transport Performance of a Steeply Situated Belt Conveyor" Energies 14, no. 23: 7984. https://doi.org/10.3390/en14237984

APA StyleHrabovský, L., & Fries, J. (2021). Transport Performance of a Steeply Situated Belt Conveyor. Energies, 14(23), 7984. https://doi.org/10.3390/en14237984