A Review of the Conceptualization and Operational Management of Seaport Microgrids on the Shore and Seaside

Abstract

1. Introduction

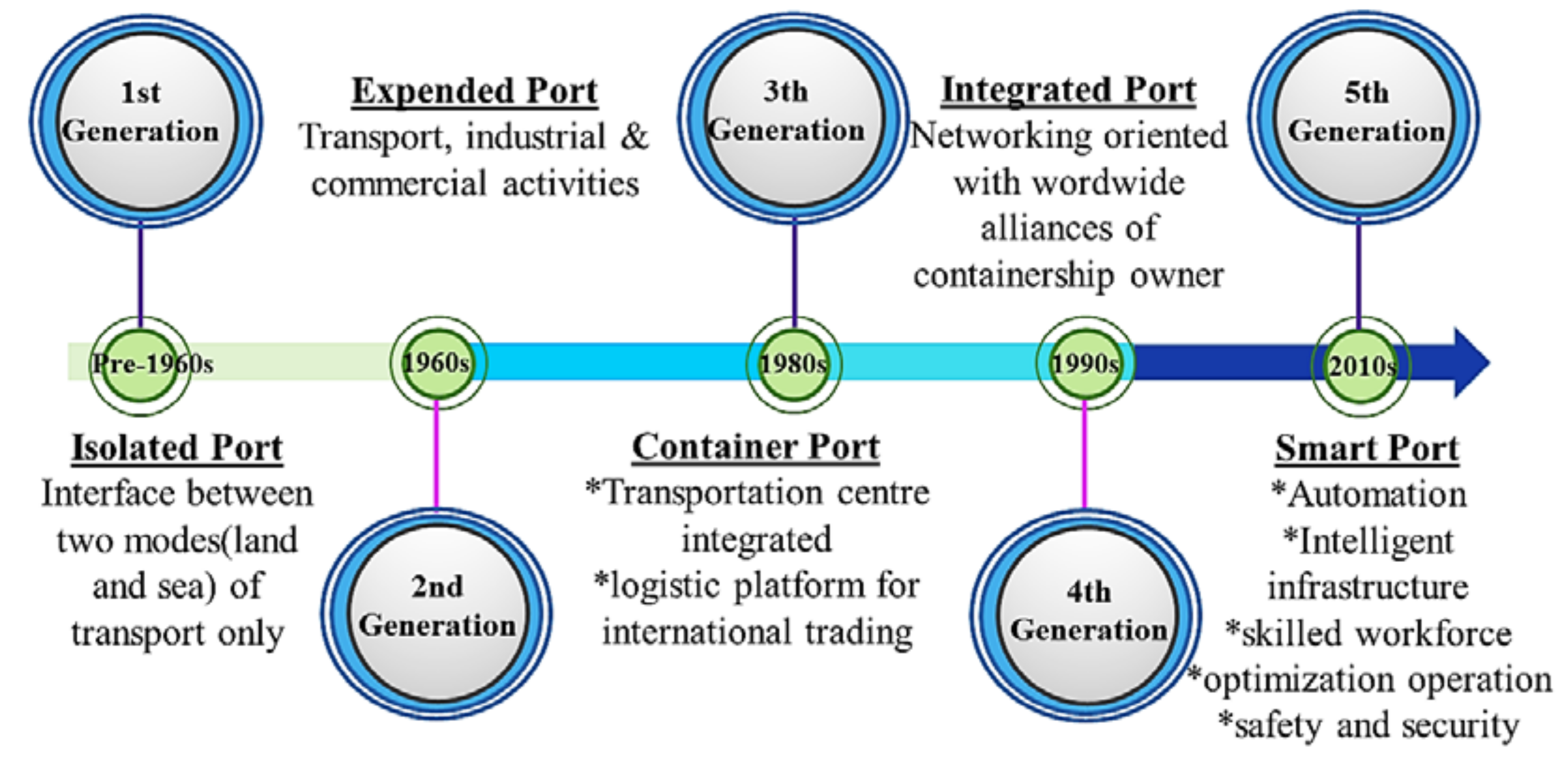

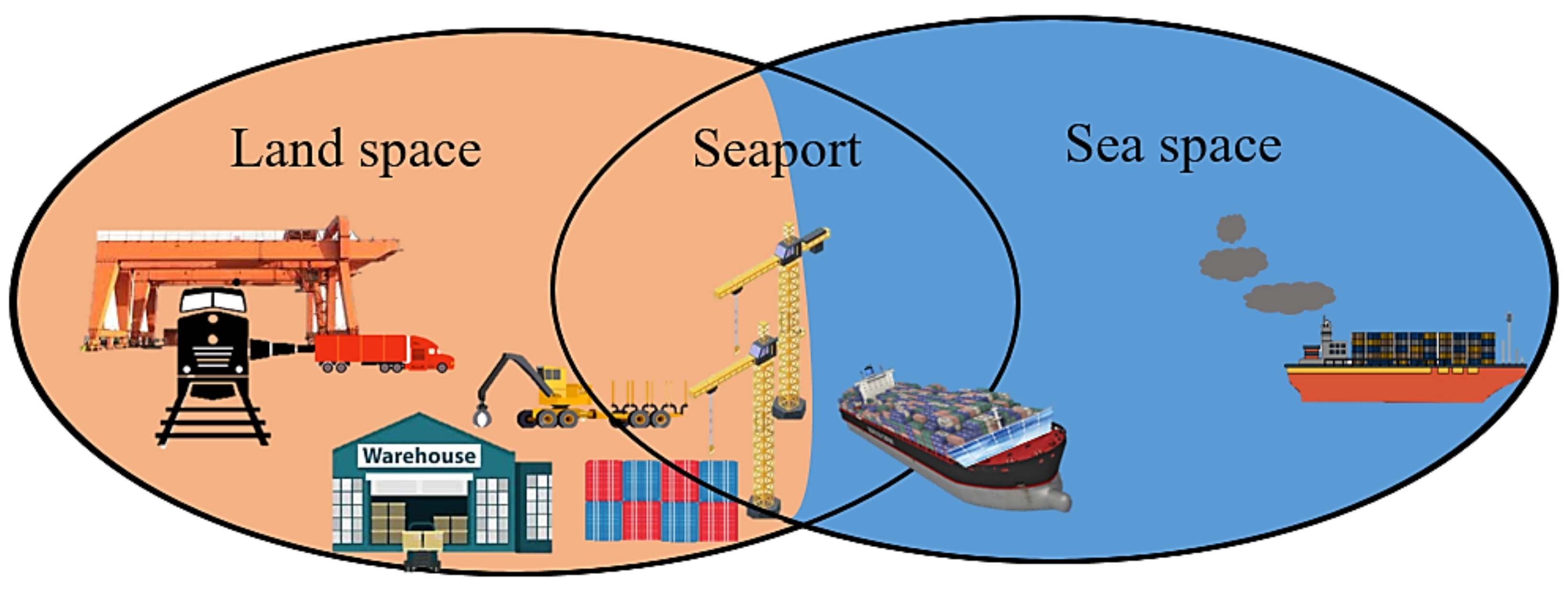

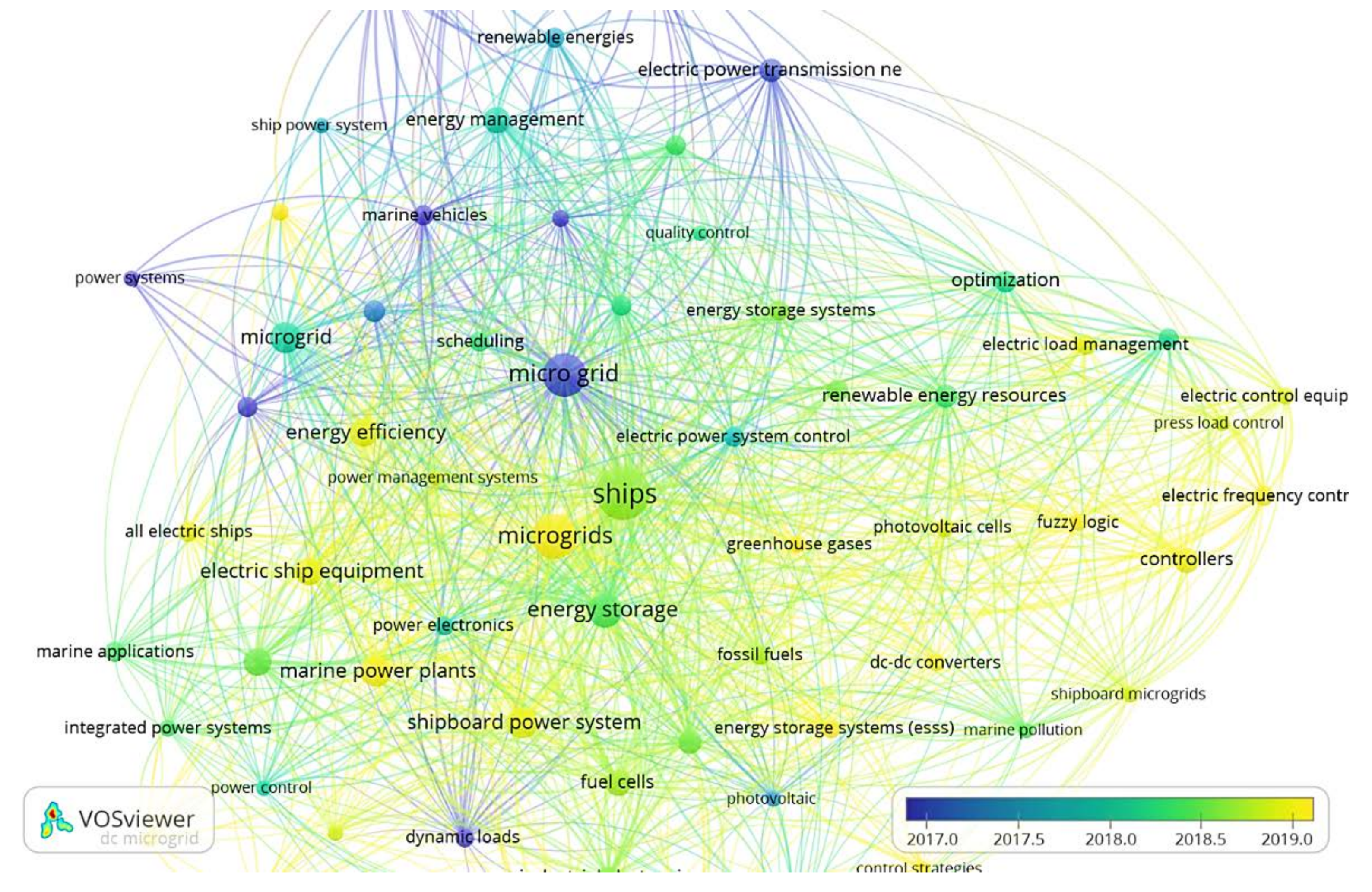

2. Seaport

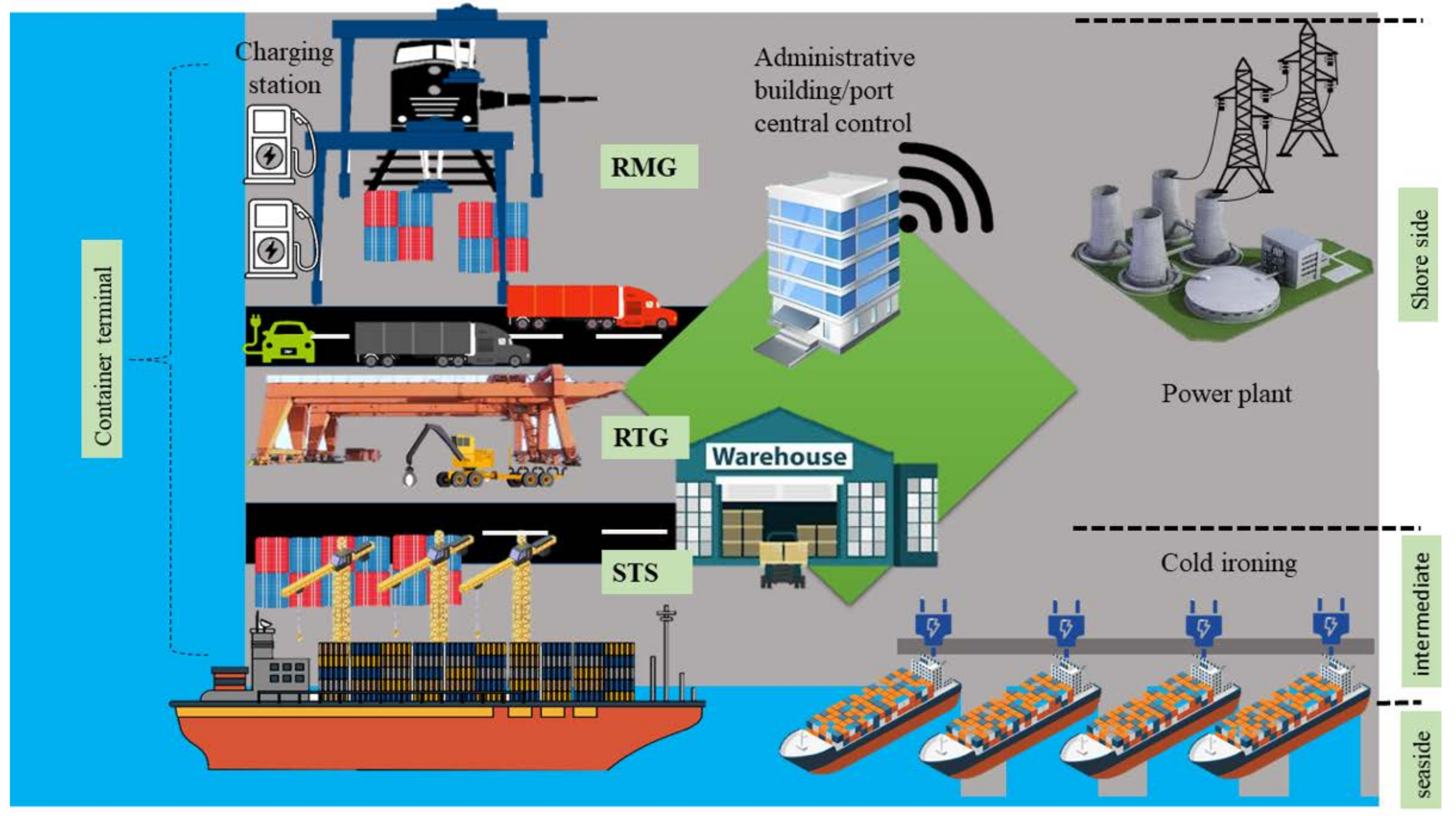

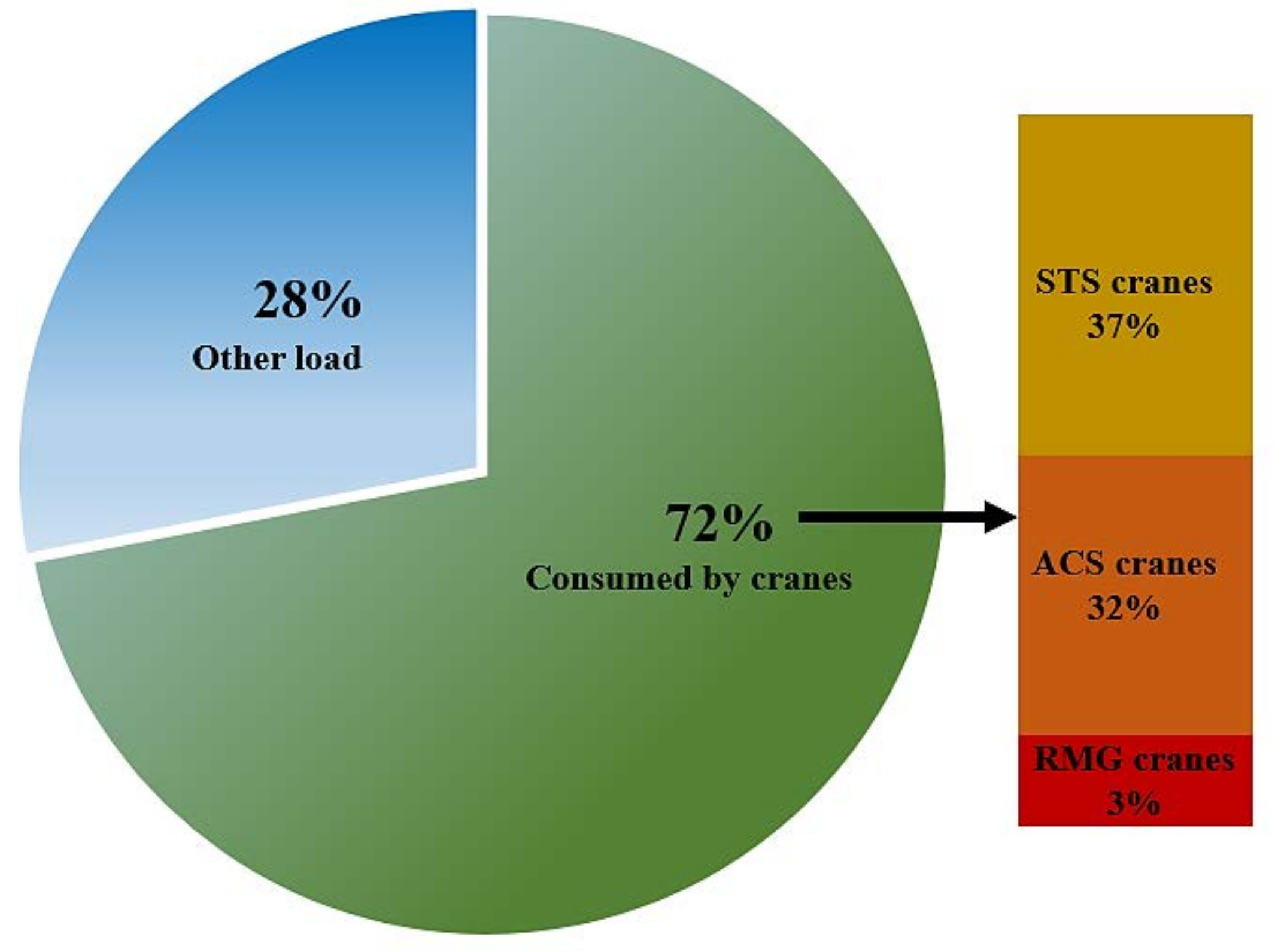

2.1. Port Activities and Power Consumers

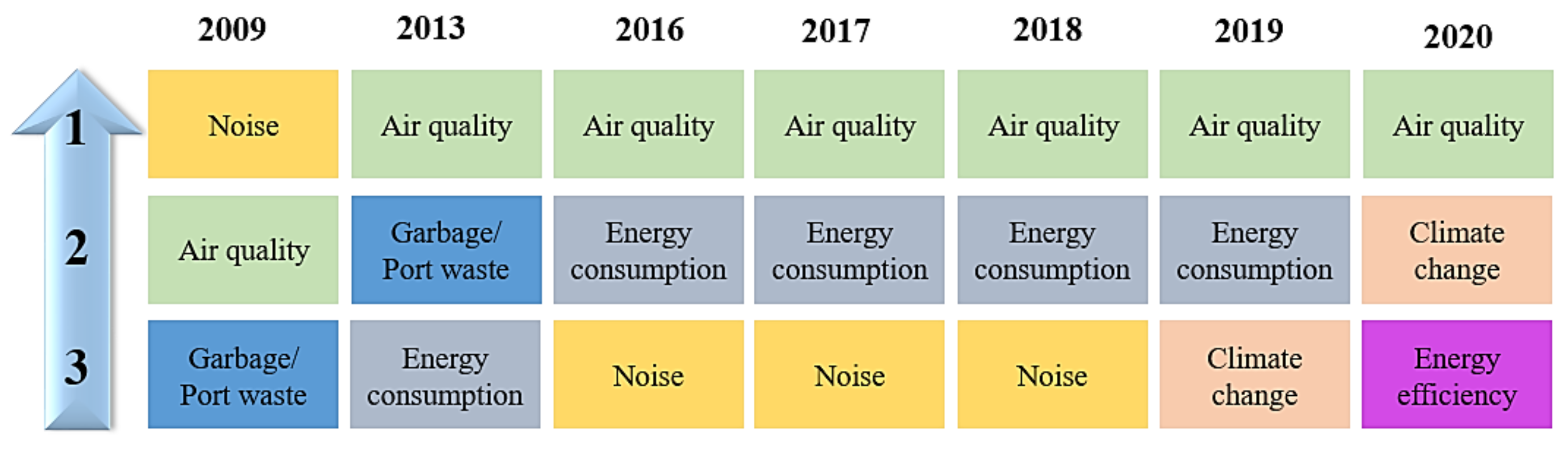

2.2. Port Critical Concerns and Green Maritime Policy

2.3. Seaport Energy Revolution

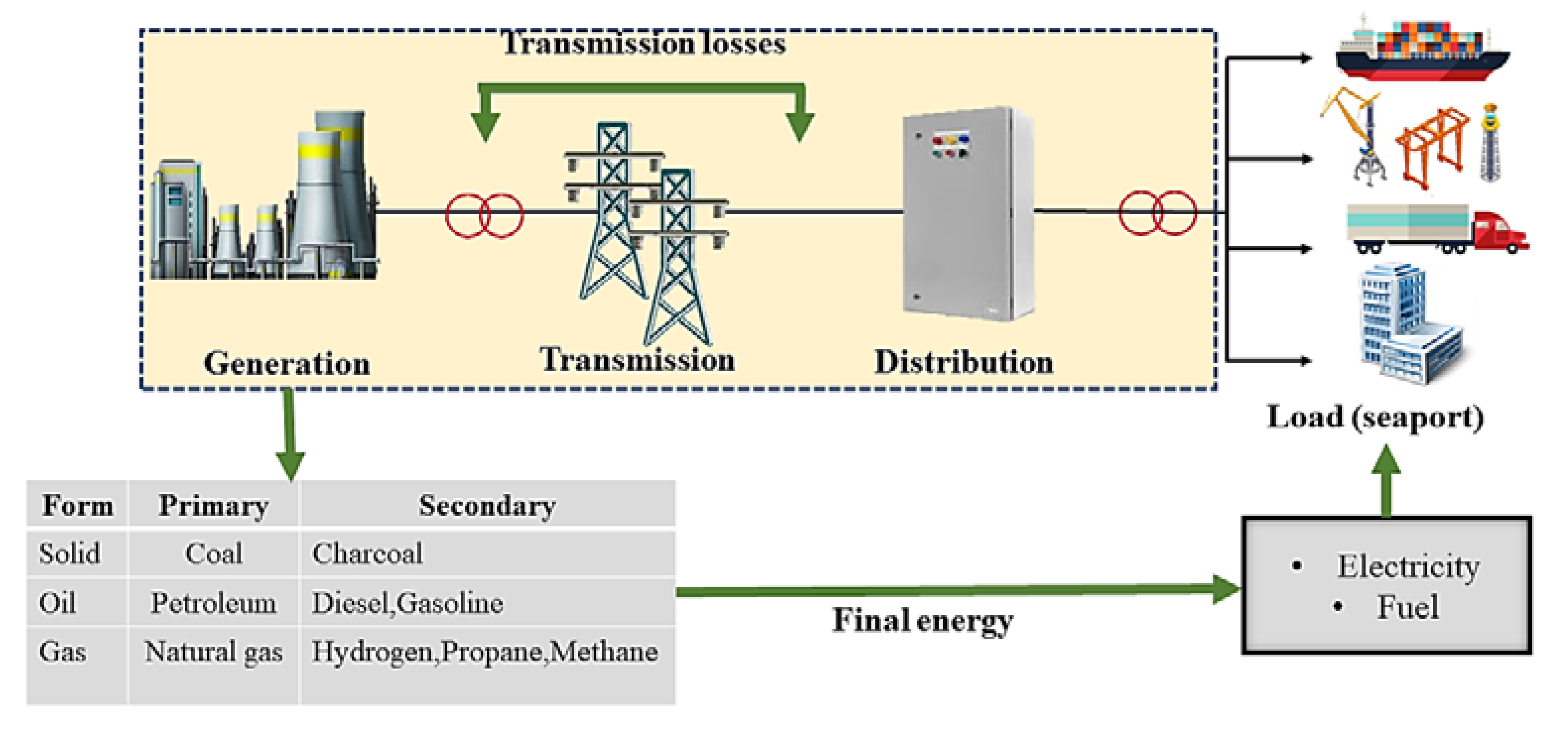

2.3.1. Conventional System

2.3.2. Ports and Ships Electrification

3. Seaport Microgrids

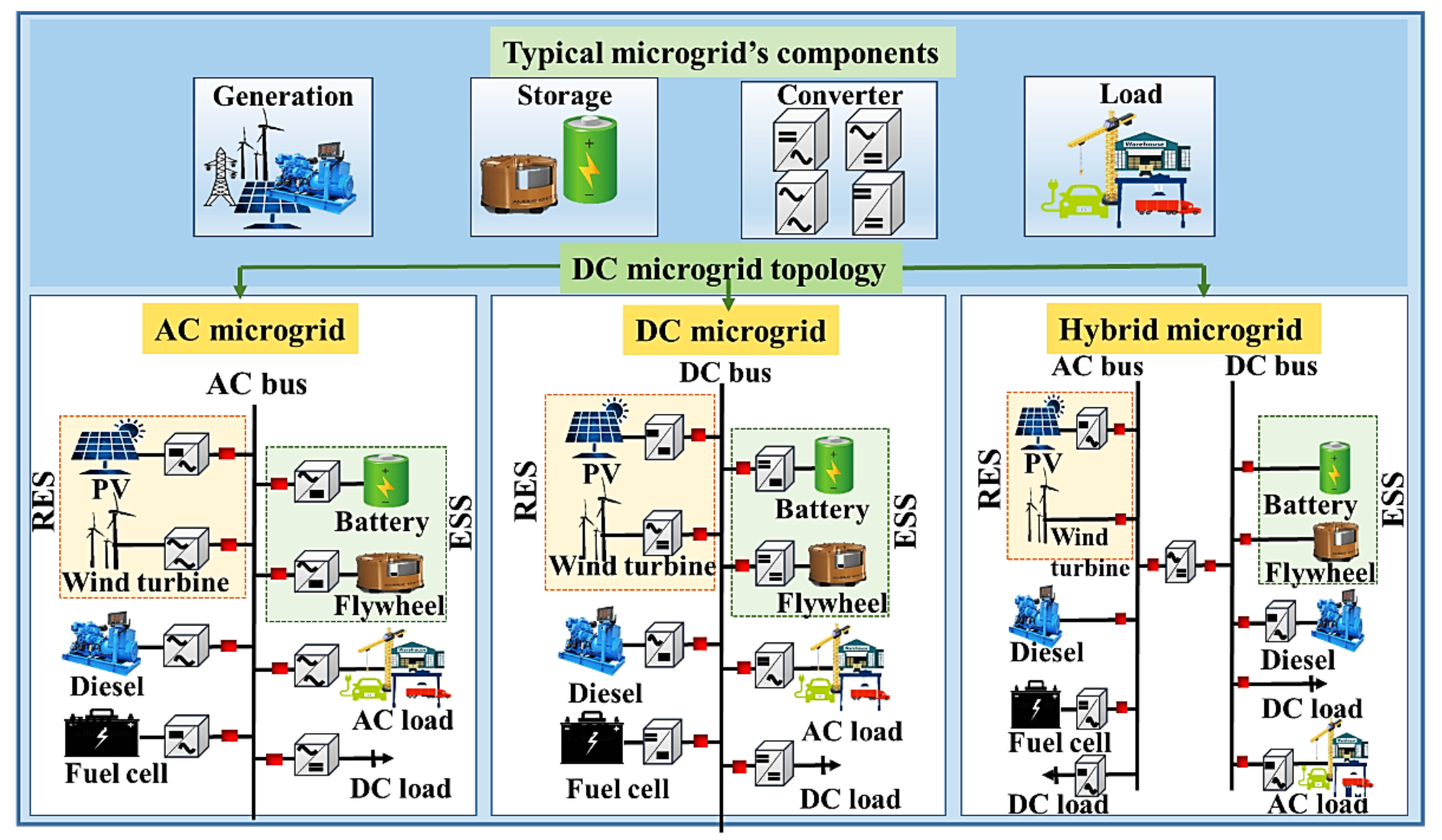

3.1. Seaport Microgrid Topology

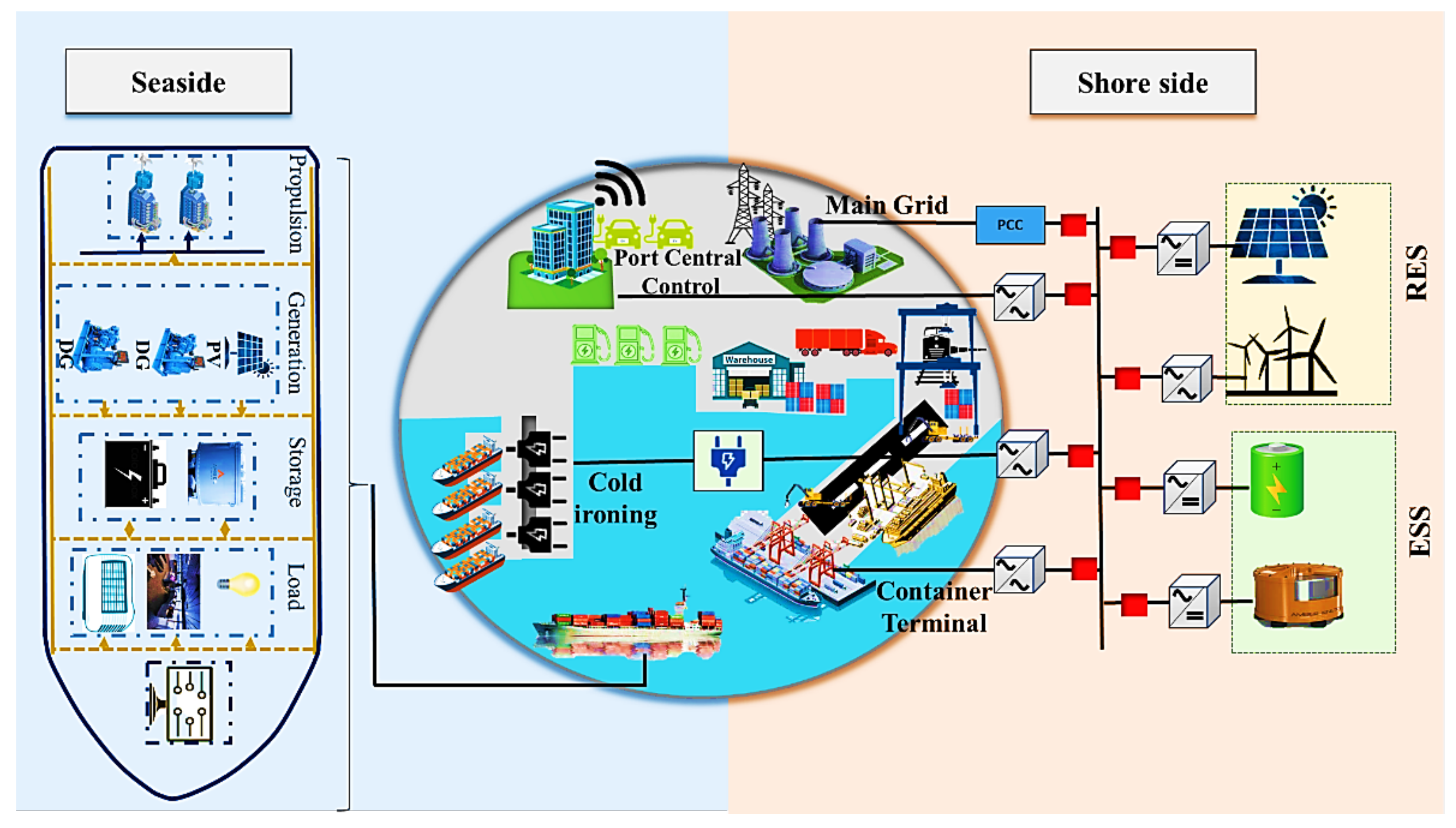

3.2. Conceptual Seaport Microgrids in Shore Side and Seaside

3.2.1. Shore Side

3.2.2. Seaside (Shipboard Microgrid)

3.2.3. Operation Management and Energy Planning of Seaport Microgrid

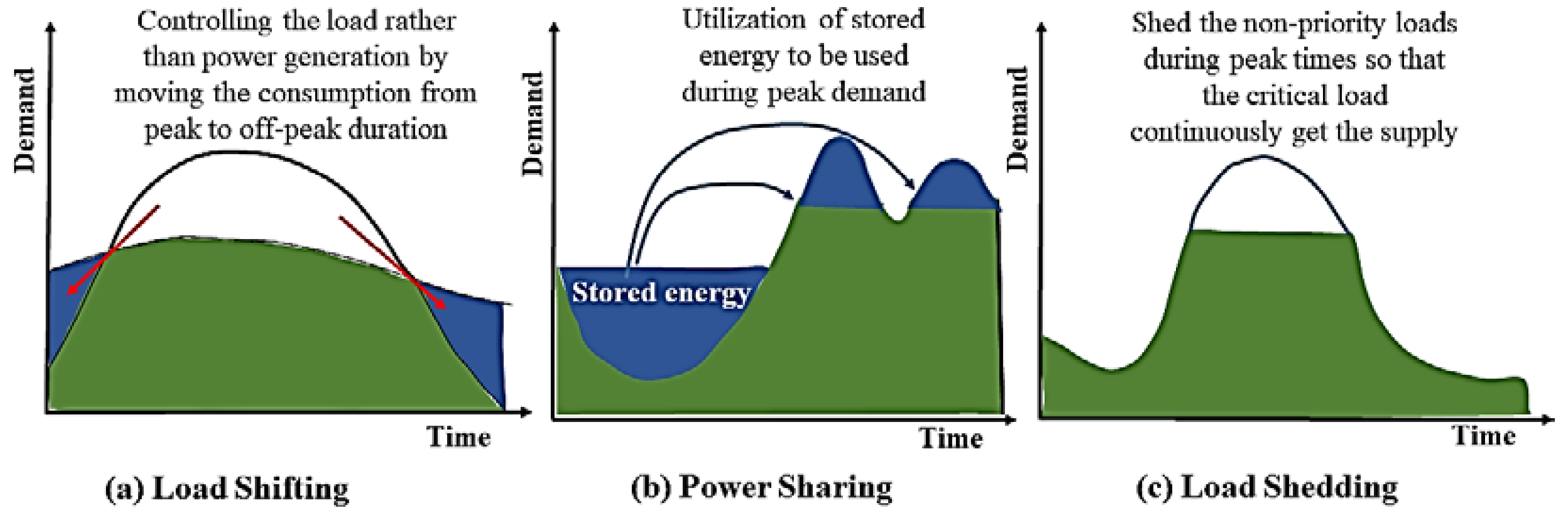

Shipboard/Seaport Microgrid Power Management and Load Scheduling

Load Factor Improvement

Peak Shaving

Load Forecasting

Storage Management

- (1)

- Mechanical-compressed air energy storage (CAES), pumped storage hydropower (PSH), and flywheel;

- (2)

- Electrical-supercapacitors and superconducting magnetic energy storage (SMES);

- (3)

- Electrochemical-lead-acid batteries, lithium-ion batteries, and flow batteries;

- (4)

- Hydrogen.

Price and Tax Incentives

4. Seaport Microgrid Challenges and Future Trends

4.1. Challenges in Developing Microgrid Systems at Seaports

4.1.1. Technical Challenge

4.1.2. Managerial

4.1.3. Security and Regulation

4.2. Potential Future Research Directions

4.2.1. Mobile Cold Ironing

4.2.2. Optimal Port Planning

4.2.3. Cluster Seaport Microgrids

4.2.4. Optimization

4.2.5. Economical Analysis

5. Conclusions

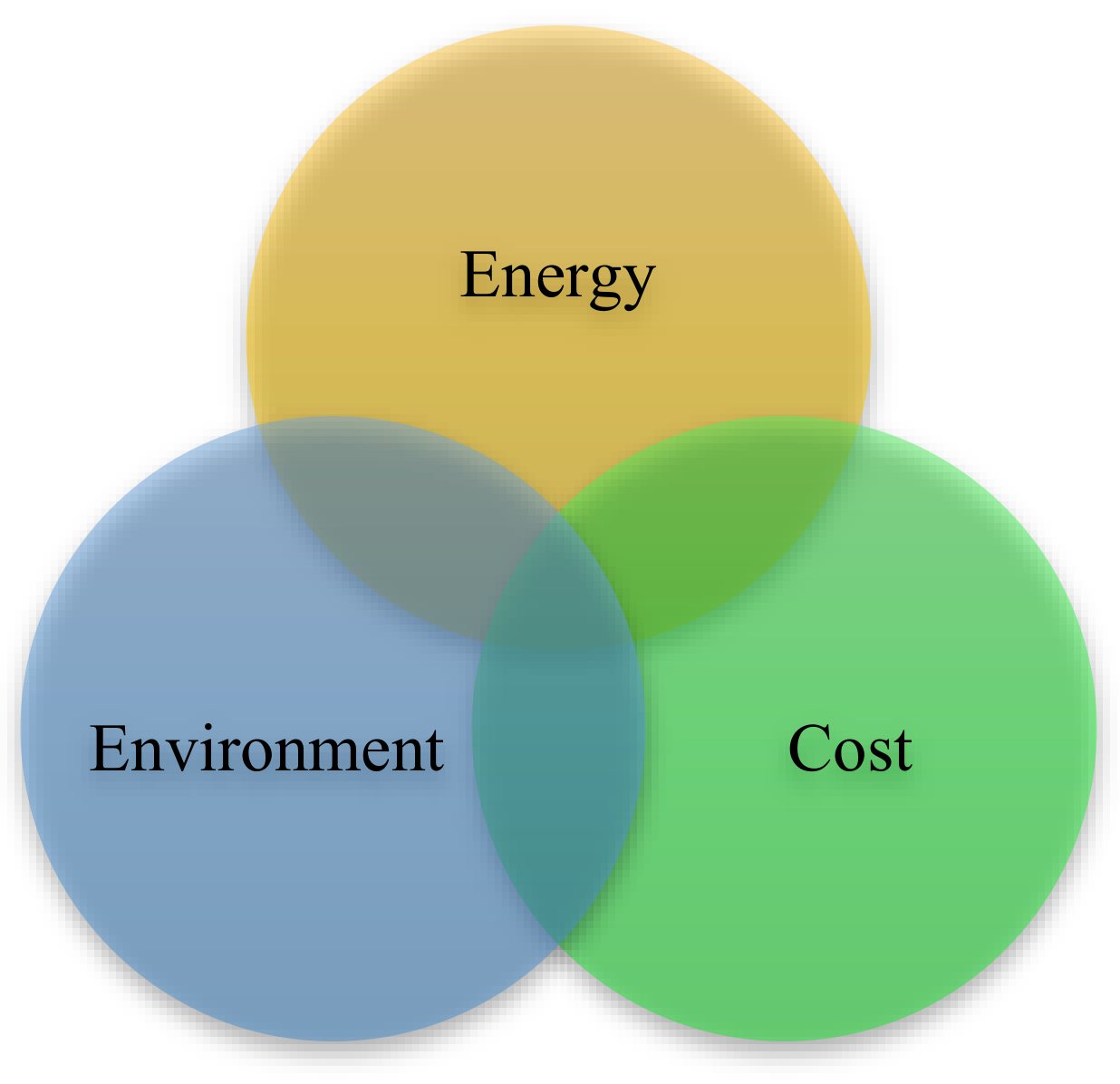

- Three major concerns at the ports include energy, environment, and cost. Future port planning should be geared toward addressing these issues.

- A microgrid is a promising power system for the marine sector that is capable of supporting the industry’s heavy loads. It enables the diversification of alternative energy resources, such as harnessing power from RES, rather than being limited to only fossil-based energy. A port will manage to achieve a substantial amount of cost-saving since electricity is generated locally by RES in the harbor area. It will reduce the investment costs in both utility grid expansion and long distribution cables.

- Furthermore, ESS components in the microgrids help in improving port performance and serve as a useful tool for demand-side management. The good practice from the operation management in seaport microgrids enhances better operation at a lower price.

- With a seaport microgrid, it is possible to bring more electrification and automation into the ports than compared to the conventional grid, which cannot support factors such as large-scale cold ironing, full electrification of cranes, improved charging stations, and electrification of other modes of transportation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hein, K.; Xu, Y.; Gary, W.; Gupta, A.K. Robustly coordinated operational scheduling of a grid-connected seaport microgrid under uncertainties. IET Gener. Transm. Distrib. 2021, 15, 347–358. [Google Scholar] [CrossRef]

- Hlali, A.; Hammami, S. Seaport concept and services characteristics: Theoretical test. Open Transp. J. 2018, 11, 120–129. [Google Scholar] [CrossRef]

- Molavi, A.; Lim, G.J.; Race, B. A framework for building a smart port and smart port index. Int. J. Sustain. Transp. 2020, 14, 686–700. [Google Scholar] [CrossRef]

- Kaliszewski, A. Fifth and sixth generation ports (5Gp, 6Gp)—Evolution of economic and social roles of ports, translated from Polish: “Porty piątej oraz szóstej generacji (5GP, 6GP)—Ewolucja ekonomicznej i społecznej roli portów”. Studia I Materiały Instytutu Tra. 2017, 32. [Google Scholar] [CrossRef]

- Montwiłł, A. The role of seaports as logistics centers in the modelling of the sustainable system for distribution of goods in urban areas. Procedia-Soc. Behav. Sci. 2014, 151, 257–265. [Google Scholar] [CrossRef]

- De Langen, P.W. Governance in Seaport Clusters; Palgrave Macmillan: London, UK, 2015; pp. 138–154. [Google Scholar]

- Versteegt, G. Berthing Loads in Strcutural Design; Delft University of Technology: South Holland, The Netherlands, 2013. [Google Scholar]

- Bintiahamad, N.B. Integration of Microgrid Technologies in Future Seaports. 2019. Available online: https://www.forskningsdatabasen.dk/en/catalog/2471559831 (accessed on 20 July 2021).

- De Langen, P.W.; Sharypova, K. Intermodal connectivity as a port performance indicator. Res. Transp. Bus. Manag. 2013, 8, 97–102. [Google Scholar] [CrossRef]

- Sifakis, N.; Tsoutsos, T. Planning zero-emissions ports through the nearly zero energy port concept. J. Clean. Prod. 2021, 286, 125448. [Google Scholar] [CrossRef]

- Abu Bakar, N.N.; Hassan, M.Y.; Abdullah, H.; Rahman, H.A.; Abdullah, M.P.; Hussin, F.; Bandi, M. Energy efficiency index as an indicator for measuring building energy performance: A review. Renew. Sustain. Energy Rev. 2015, 44, 1–11. [Google Scholar] [CrossRef]

- Zhao, H.X.; Magoulès, F. A review on the prediction of building energy consumption. Renew. Sustain. Energy Rev. 2012, 16, 3586–3592. [Google Scholar] [CrossRef]

- Binti Ahamad, N.B.; Su, C.L.; Zhaoxia, X.; Vasquez, J.C.; Guerrero, J.M. Modeling and controls of flywheel energy storage systems for energy harvesting from harbor electrical cranes. In Proceeding of the 2018 IEEE Industry Applications Society Annual Meeting (IAS), Portland, OR, USA, 23–27 September 2018; pp. 1–8. [Google Scholar] [CrossRef]

- Comer, B.; Olmer, N.; Mao, X.; Roy, B.; Rutherford, D. Prevalence of Heavy Fuel Oil and Black Carbon in Arctic Shipping, 2015 to 2025; International Council on Clean Transportation (ICCT): Washington, DC, USA, 2017; p. 68. Available online: https://www.theicct.org/publications/prevalence-heavy-fuel-oil-and-black-carbon-arctic-shipping-2015-2025 (accessed on 25 June 2021).

- Yiğit, K.; Kökkülünk, G.; Parlak, A.; Karakaş, A. Energy cost assessment of shoreside power supply considering the smart grid concept: A case study for a bulk carrier ship. Marit. Policy Manag. 2016, 43, 469–482. [Google Scholar] [CrossRef]

- Thongam, J.S.; Tarbouchi, M.; Okou, A.F.; Bouchard, D.; Beguenane, R. All-electric ships—A review of the present state of the art. In Proceeding of the 2013 Eighth International Conference and Exhibition on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 27–30 March 2013; pp. 1–8. [Google Scholar] [CrossRef]

- Mutarraf, M.U.; Terriche, Y.; Nasir, M.; Guan, Y.; Su, C.L.; Vasquez, J.C.; Guerrero, J.M. A Decentralized control scheme for adaptive power-sharing in ships based seaport microgrid. In Proceeding of the IECON 2020 the 46th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 18–21 October 2020; pp. 3126–3131. [Google Scholar] [CrossRef]

- Ahamad, N.B.B.; Guerrero, J.M.; Su, C.L.; Vasquez, J.C.; Zhaoxia, X. Microgrids technologies in future seaports. In Proceeding of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Boile, M.; Theofanis, S.; Sdoukopoulos, E.; Plytas, N. Developing a port energy management plan: Issues, challenges, and prospects. Transp. Res. Rec. 2016, 2549, 19–28. [Google Scholar] [CrossRef]

- Kusuma, L.T.W.N.; Tseng, F.S. Analysis of the impact of the “sea toll” program for seaports: Resilience and competitiveness. Appl. Sci. 2019, 9, 3407. [Google Scholar] [CrossRef]

- Sadiq, M.; Ali, S.W.; Terriche, Y.; Mutarraf, M.U.; Hassan, M.A.; Hamid, K.; Ali, Z.; Sze, J.Y.; Su, C.-L.; Guerrero, J.M. Future greener seaports: A review of new infrastructure, challenges, and energy efficiency measures. IEEE Access 2021, 9, 75568–75587. [Google Scholar] [CrossRef]

- Port of Wilmington Cold Storage Becomes First in-Port Cold Storage Facility in North Carolina. Available online: https://www.provisioneronline.com/articles/104257-port-of-wilmington-cold-storage-becomes-first-in-port-cold-storage-facility-in-north-carolina (accessed on 23 July 2021).

- Mostafa, K.; Giuseppe, P.; Ben, C.; Luigi, M. Ultracapacitors for port crane applications: Sizing and techno-economic analysis. Energies 2020, 13, 2091. [Google Scholar]

- Kermani, M.; Parise, G.; Martirano, L.; Parise, L.; Chavdarian, B. Optimization of peak load shaving in STS group cranes based on pso algorithm. In Proceeding of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018. [Google Scholar] [CrossRef]

- Hariharan, R.; Usha Rani, P.; Muthu Kannan, P. Sustain the critical load in blackout using virtual instrumentation. In Intelligent and Efficient Electrical Systems; Springer: Singapore, 2018; pp. 77–88. [Google Scholar]

- Pei, R.; Xie, J.; Zhang, H.; Sun, K.; Wu, Z. Robust multi-layer energy management and control methodologies for reefer container park in port terminal. Energies 2021, 14, 4456. [Google Scholar] [CrossRef]

- Rosa Mari Darbra, M.P.; Wooldridge, C. ESPO Environmental Report 2020. 2020. Available online: https://www.espo.be/media/EnvironmentalReport-WEB-FINAL.pdf (accessed on 23 July 2021).

- Zhang, X. Analysis of the Incentives in Environmental Strategies Implementation in Chinese Ports. Master’s Thesis, Erasmus University Rotterdam, Rotterdam, The Netherlands, 2016; pp. 1–76. [Google Scholar]

- Endresen, Ø.; Sørgård, E.; Sundet, J.K.; Dalsøren, S.B.; Isaksen, I.S.A.; Berglen, T.F.; Gravir, G. Emission from international sea transportation and environmental impact. J. Geophys. Res. Atmos. 2003, 108, 14–21. [Google Scholar] [CrossRef]

- IMO. IMO 2020—Cutting Sulphur Oxide Emissions. Available online: https://www.imo.org/en/MediaCentre/HotTopics/Pages/Sulphur-2020.aspx (accessed on 8 August 2021).

- Acciaro, M.; Ghiara, H.; Inés, M.; Cusano, M.I. Energy management in seaports: A new role for port authorities. Energy Policy 2014, 71, 4–12. [Google Scholar] [CrossRef]

- Roh, S.; Thai, V.V.; Wong, Y.D. Towards sustainable asean port development: Challenges and opportunities for vietnamese ports. Asian J. Shipp. Logist. 2016, 32, 107–118. [Google Scholar] [CrossRef]

- Edoho, F.M. Oil transnational corporations: Corporate social responsibility and environmental sustainability. Corp. Soc. Responsib. Environ. Manag. 2008, 15, 210–222. [Google Scholar] [CrossRef]

- Matishov, G.G.; Selifonova, Z.P. New scientifically based methods for controlling ship ballast in ports. Dokl. Biol. Sci. 2008, 422, 342. [Google Scholar] [CrossRef]

- Behrends, B.; Liebezeit, P.G.; Gregory, D. Reducing SO2 and NOX Emissions from Ships by a Seawater Scrubber; BP Marine Report; Research Centre Terramare: Wilhelmshaven, Germany, 2003; pp. 11–64. [Google Scholar]

- Fouquet, R. Energy Research & social science historical energy transitions: Speed, prices and system transformation. Chem. Phys. Lett. 2016, 22, 7–12. [Google Scholar] [CrossRef]

- Heavy Fuel Oil. 2015. Available online: https://www.oiltanking.com/en/news-info/glossary/details/term/heavy-fuel-oil-hfo.html (accessed on 15 August 2021).

- Papoutsoglou, T.G. A Cold Ironing Study o Modern Ports, Implementation and Benefits Thriving for Worldwide Ports. Bachelor’s Thesis, Marine Engineering National Technical University of Athens, Zografou, Greece, 2012. [Google Scholar]

- Innes, A.; Monios, J. Identifying the unique challenges of installing cold ironing at small and medium ports—The case of aberdeen. Transp. Res. Part D Transp. Environ. 2018, 62, 298–313. [Google Scholar] [CrossRef]

- Mutarraf, M.U.; Terriche, Y.; Nasir, M.; Guan, Y.; Su, C.-L.; Vasquez, J.C.; Guerrero, J.M. A communication-less multi-mode control approach for adaptive power-sharing in ships-based seaport microgrid. IEEE Trans. Transp. Electrif. 2021, 7, 3070–3082. [Google Scholar] [CrossRef]

- Mocci, S.; Porru, M.; Serpi, A.; Soma, G.G. The poseidon project: Microgrid in port areas to improve energy efficiency by the integration of res, flexible loads and smart mobility. In Proceeding of the 2019 1st International Conference on Energy Transition in the Mediterranean Area (SyNERGY MED), Cagliari, Italy, 28–30 May 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Salleh, N.A.S.; Muda, W.M.W.; Abdullah, S.S. Feasibility study of optimization and economic analysis for grid-connected renewable energy electric boat charging station in Kuala Terengganu. In Proceeding of the 2015 IEEE Conference on Energy Conversion (CENCON), Johor Bahru, Malaysia, 19–20 October 2015; pp. 510–515. [Google Scholar] [CrossRef]

- Roy, A.; Auger, F.; Olivier, J.; Schae, E.; Auvity, B. Design, Sizing, and Energy Management of Microgrids in Harbor Areas: A Review. Energies 2020, 13, 5314. [Google Scholar] [CrossRef]

- Soh, A. Jurong Port Starts World’s Largest Port-Based Solar Facility. 2016. Available online: https://www.businesstimes.com.sg/energy-commodities/jurong-port-starts-worlds-largest-port-based-solar-facility (accessed on 23 August 2021).

- Port of Aalborg Becomes the First co2 Neutral Port in Denmark. Available online: https://safety4sea.com/port-of-aalborg-becomes-the-first-co2-neutral-port-in-denmark/ (accessed on 23 August 2021).

- Shahidehpour, M.; Clair, J.F. A functional microgrid for enhancing reliability, sustainability, and energy efficiency. Electr. J. 2012, 25, 21–28. [Google Scholar] [CrossRef]

- Vicenzutti, A.; Bosich, D.; Giadrossi, G.; Sulligoi, G. The role of voltage controls in modern all electrical ships toward the all-electric ship. IEEE Electrif. Mag. 2015, 3, 49–65. [Google Scholar] [CrossRef]

- McCoy, T.J. Electric ships past, present, and future [technology leaders]. IEEE Electrif. Mag. 2015, 3, 4–11. [Google Scholar] [CrossRef]

- Murphy, J.F.H.M.; May, J.; Riksheim, R. International Cooperation on Marine Engineering Systems/Electric Propulsion—State-of-the-art and Trends in Electric Power Generation, Distribution, and Propulsion, and Their Associated Control Systems Report from Technical Committee B: Electric Pr. 2000; pp. 1–36. [Google Scholar]

- Fang, S.; Wang, Y.; Gou, B.; Xu, Y. Toward future green maritime transportation: An overview of seaport microgrids and all-electric ships. IEEE Trans. Veh. Technol. 2020, 69, 207–219. [Google Scholar] [CrossRef]

- Ding, X.; Yang, Z. Knowledge mapping of platform research: A visual analysis using VOSviewer and CiteSpace. Electron. Commer. Res. 2020, 1–23. [Google Scholar] [CrossRef]

- Bakar, N.N.A.; Hassan, M.Y.; Sulaima, M.F.; Mohd Nasir, M.N.; Khamis, A. Microgrid and load shedding scheme during islanded mode: A review. Renew. Sustain. Energy Rev. 2017, 71, 161–169. [Google Scholar] [CrossRef]

- Rajesh, K.S.; Dash, S.S.; Rajagopal, R.; Sridhar, R. A review on control of ac microgrid. Renew. Sustain. Energy Rev. 2017, 71, 814–819. [Google Scholar] [CrossRef]

- Mousavi, S.Y.M.; Jalilian, A.; Savaghebi, M.; Guerrero, J.M. Flexible compensation of voltage and current unbalance and harmonics in microgrids. Energies 2017, 10, 1568. [Google Scholar] [CrossRef]

- Farrok, O.; Sheikh, M.R.I.; Islam, M.R. An advanced controller to improve the power quality of microgrid connected converter. In Proceeding of the 2015 International Conference on Electrical & Electronic Engineering (ICEEE), Rajshahi, Bangladesh, 10 March 2016; pp. 185–188. [Google Scholar] [CrossRef]

- British Columbia Ministry of Agriculture. Market Opportunity Report: JAPAN; British Columbia Ministry of Agriculture: Abbotsford, BC, Canada, December 2014. [CrossRef]

- Huang, Z.; Zhu, T.; Gu, Y.; Irwin, D.; Mishra, A.; Shenoy, P. Minimizing electricity costs by sharing energy in sustainable microgrids. In Proceedings of The 12th ACM Conference on Embedded Network Sensor Systems, Memphis, TN, USA, 3–6 November 2014; pp. 120–129. [Google Scholar] [CrossRef]

- Haidar, A.M.A.; Fakhar, A.; Helwig, A. Sustainable energy planning for cost minimization of autonomous hybrid microgrid using combined multi-objective optimization algorithm. Sustain. Cities Soc. 2020, 62, 102391. [Google Scholar] [CrossRef]

- Lotfi, H.; Khodaei, A. AC versus DC microgrid planning. IEEE Trans. Smart Grid 2017, 8, 296–304. [Google Scholar] [CrossRef]

- Lu, X.; McElroy, M.B.; Nielsen, C.P.; Chen, X.; Huang, J. Optimal integration of offshore wind power for a steadier, environmentally friendlier, supply of electricity in China. Energy Policy 2013, 62, 131–138. [Google Scholar] [CrossRef]

- Wu, X.; Wang, Z.; Ding, T.; Li, Z. Hybrid AC/DC microgrid planning with optimal placement of DC feeders. Energies 2019, 12, 1751. [Google Scholar] [CrossRef]

- Justo, J.J.; Mwasilu, F.; Lee, J.; Jung, J.W. AC-microgrids versus DC-microgrids with distributed energy resources: A review. Renew. Sustain. Energy Rev. 2013, 24, 387–405. [Google Scholar] [CrossRef]

- Gao, L.; Liu, Y.; Ren, H.; Guerrero, J.M. A DC microgrid coordinated control strategy based on integrator current-sharing. Energies 2017, 10, 1116. [Google Scholar] [CrossRef]

- Lago, J.; Heldwein, M.L. Operation and control-oriented modeling of a power converter for current balancing and stability improvement of DC active distribution networks. IEEE Trans. Power Electron. 2011, 26, 877–885. [Google Scholar] [CrossRef]

- Kakigano, H.; Miura, Y.; Ise, T.; Uchida, R. DC micro-grid for super high quality distribution—System configuration and control of distributed generations and energy storage devices. In Proceeding of the 2006 37th IEEE Power Electronics Specialists Conference, Jeju, Korea, 18–22 June 2006. [Google Scholar] [CrossRef]

- Jin, Z.; Savaghebi, M.; Vasquez, J.C.; Meng, L.; Guerrero, J.M. Maritime DC microgrids—A combination of microgrid technologies and maritime onboard power system for future ships. In Proceeding of the 2016 IEEE 8th International Power Electronics and Motion Control Conference (IPEMC-ECCE Asia), Hefei, China, 22–26 May 2016; pp. 179–184. [Google Scholar] [CrossRef]

- Prenc, R.; Cuculić, A.; Baumgartner, I. Advantages of using a DC power system on board ship. J. Marit. Transp. Sci. 2016, 52, 83–97. [Google Scholar] [CrossRef]

- Fregosi, D.; Ravula, S.; Brhlik, D.; Saussele, J.; Frank, S.; Bonnema, E.; Scheib, J.; Wilson, E. A comparative study of DC and AC microgrids in commercial buildings across different climates and operating profiles. In Proceeding of the 2015 IEEE First International Conference on DC Microgrids (ICDCM), Atlanta, GA, USA, 7–10 June 2015; pp. 159–164. [Google Scholar] [CrossRef]

- Liu, X.; Wang, P.; Loh, P.C. A hybrid AC/DC microgrid and its coordination control. IEEE Trans. Smart Gird 2011, 2, 278–286. [Google Scholar]

- Guerrero, J.M.; Jin, Z.; Liu, W.; Othman, M.B.; Savaghebi, M.; Anvari-Moghaddam, A.; Meng, L.; Vasquez, J.C. Shipboard microgrids: Maritime islanded power systems technologies. In Proceeding of the PCIM Asia 2016; International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Shanghai, China, 28–30 June 2016; pp. 28–30. [Google Scholar]

- Al-Falahi, M.D.A.; Tarasiuk, T.; Jayasinghe, S.G.; Jin, Z.; Enshaei, H.; Guerrero, J.M. Ac ship microgrids: Control and power management optimization. Energies 2018, 11, 1458. [Google Scholar] [CrossRef]

- Liu, W.; Tarasiuk, T.; Gorniak, M.; Savaghebi, M.; Vasquez, J.C.; Su, C.L.; Guerrero, J.M. Power quality assessment in shipboard microgrids under unbalanced and harmonic AC bus voltage. IEEE Trans. Ind. Appl. 2019, 55, 765–775. [Google Scholar] [CrossRef]

- Feste, M.D.; Chiandone, M.; Bosich, D.; Sulligoi, G. Evolution of the Trieste Port: A real-time system for a coordinated cold ironing. In Proceeding of the 2019 IEEE International Conference on Environment and Electrical Engineering and 2019 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Genova, Italy, 11–14 June 2019. [Google Scholar] [CrossRef]

- Jin, B.Z.; Sulligoi, G.; Cuzner, R.; Meng, L.; Vasquez, J.C.; Guerrero, J.M. Next-generation shipboard DC power system. IEEE Electrif. Mag. 2016, 4, 45–57. [Google Scholar] [CrossRef]

- D’Agostino, F.; Kaza, D.; Martelli, M.; Schiapparelli, G.P.; Silvestro, F.; Soldano, C. Development of a multiphysics real-time simulator for model-based design of a DC shipboard microgrid. Energies 2020, 13, 3580. [Google Scholar] [CrossRef]

- Jin, Z.; Meng, L.; Vasquez, J.C.; Guerrero, J.M.; Jin, Z.; Meng, L.; Vasquez, J.C.; Guerrero, J.M. Specialized Hierarchical Control Strategy for DC Distribution based Shipboard Microgrids A combination of emerging DC shipboard power systems and microgrid technologies. In Proceeding of the IECON 2017-43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017; pp. 10–12. [Google Scholar]

- Kwon, K.; Park, D. Load frequency-based power management for shipboard DC hybrid power systems. In Proceeding of the 2020 IEEE 29th International Symposium on Industrial Electronics (ISIE), Delft, The Netherlands, 17–19 June 2020; pp. 142–147. [Google Scholar]

- German-Galkin, S.; Tarnapowicz, D. Energy optimization of the ‘shore to ship’ system—A universal power system for ships at berth in a port. Sensors 2020, 20, 3815. [Google Scholar] [CrossRef]

- Reed, G.F.; Grainger, B.M.; Sparacino, A.R.; Mao, Z.H. Ship to grid: Medium-voltage dc concepts in theory and practice. IEEE Power Energy Mag. 2012, 10, 70–79. [Google Scholar] [CrossRef]

- Guide for Direct Current (DC). Power Distribution Systems for Marine and Offshore Applications Direct Current (DC) Power Distribution Systems for Marine and Offshore Applications; American Bureau of Shipping: Houston, TX, USA, 2018. [Google Scholar]

- Zhaoxia, X.; Tianli, Z.; Huaimin, L.; Guerrero, J.M.; Su, C.; Member, S.; Vásquez, J.C.; Member, S. Coordinated Control of a Hybrid-Electric-Ferry Shipboard Microgrid. IEEE Trans. Transp. Electrif. 2019, 5, 828–839. [Google Scholar] [CrossRef]

- Mutarraf, M.U.; Terriche, Y.; Niazi, K.A.K.; Khan, F.; Vasquez, J.C.; Guerrero, J.M. Control of hybrid diesel/PV/battery/ultra-capacitor systems for future shipboard microgrids. Energies 2019, 12, 3460. [Google Scholar] [CrossRef]

- Ahamad, N.B.; Othman, M.; Vasquez, J.C.; Guerrero, J.M.; Su, C.L. Optimal sizing and performance evaluation of a renewable energy based microgrid in future seaports. In Proceeding of the 2018 IEEE International Conference on Industrial Technology (ICIT), Lyon, France, 20–22 February 2018; pp. 1043–1048. [Google Scholar] [CrossRef]

- Gennitsaris, S.G.; Kanellos, F.D. Emission-aware and cost-effective distributed demand response system for extensively electrified large ports. IEEE Trans. Power Syst. 2019, 34, 4341–4351. [Google Scholar] [CrossRef]

- Hamburg Port Authority. Hamburg Port Authority Hamburg Is Staying on Course—The Port Development Plan to 2025; Hamburg Port Authority: Hamburg, Germany, 2012; pp. 1–98. [Google Scholar]

- Iris, Ç.; Lam, J.S.L. A review of energy efficiency in ports: Operational strategies, technologies and energy management systems. Renew. Sustain. Energy Rev. 2019, 112, 170–182. [Google Scholar] [CrossRef]

- Elwany, M.H.; Ali, I.; Abouelseoud, Y. A heuristics-based solution to the continuous berth allocation and crane assignment problem. Alex. Eng. J. 2013, 52, 671–677. [Google Scholar] [CrossRef]

- Liu, A.; Liu, H.; Tsai, S.B.; Lu, H.; Zhang, X.; Wang, J. Using a hybrid model on joint scheduling of berths and quay cranes-from a sustainable perspective. Sustainability 2018, 10, 1959. [Google Scholar] [CrossRef]

- Wang, Y.; Ding, W.; Dai, L.; Hu, H.; Jing, D. How would government subsidize the port on shore side electricity usage improvement? J. Clean. Prod. 2021, 278, 123893. [Google Scholar] [CrossRef]

- Xie, P.; Guerrero, J.M.; Tan, S.; Bazmohammadi, N.; Vasquez, J.C.; Mehrzadi, M.; Al-Turki, Y. Optimization-based power and energy management system in shipboard microgrid: A review. IEEE Syst. J. 2021, 1–13. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, H.; Khajepour, A.; He, H.; Ji, J. Model predictive control power management strategies for HEVs: A review. J. Power Sources 2017, 341, 91–106. [Google Scholar] [CrossRef]

- Sun, Z.; Li, L. Potential capability estimation for real time electricity demand response of sustainable manufacturing systems using markov decision process. J. Clean. Prod. 2014, 65, 184–193. [Google Scholar] [CrossRef]

- Subramani, G.; Ramachandaramurthy, V.K.; Padmanaban, S.; Mihet-Popa, L.; Blaabjerg, F.; Guerrero, J.M. Grid-tied photovoltaic and battery storage systems with Malaysian electricity tariff—A review on maximum demand shaving. Energies 2017, 10, 1884. [Google Scholar] [CrossRef]

- Hirsch, A.; Parag, Y.; Guerrero, J. Microgrids: A review of technologies, key drivers, and outstanding issues. Renew. Sustain. Energy Rev. 2018, 90, 402–411. [Google Scholar] [CrossRef]

- Divshali, P.H.; Choi, B.J. Electrical market management considering power system constraints in smart distribution grids. Energies 2016, 9, 405. [Google Scholar] [CrossRef]

- Huang, Y.; Lan, H.; Hong, Y.Y.; Wen, S.; Fang, S. Joint voyage scheduling and economic dispatch for all-electric ships with virtual energy storage systems. Energy 2020, 190, 116268. [Google Scholar] [CrossRef]

- Othman, M.; Anvari-Moghaddam, A.; Ahamad, N.; Chun-Lien, S.; Guerrero, J.M. Scheduling of Power Generation in Hybrid Shipboard Microgrids with Energy Storage Systems. In Proceeding of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018. [Google Scholar] [CrossRef][Green Version]

- Rao, K.S.; Chauhan, P.J.; Panda, S.K.; Wilson, G.; Liu, X.; Gupta, A.K. Optimal scheduling of diesel generators in offshore support vessels to minimize fuel consumption. In Proceeding of the IECON 2015-41st Annual Conference of the IEEE Industrial Electronics Society, Yokohama, Japan, 9–12 November 2015; pp. 4726–4731. [Google Scholar] [CrossRef]

- Pande, S.; Ghodekar, P.J.G. Computation of technical power loss of feeders and transformers in distribution system using load factor and load loss factor. Int. J. Multidiscip. Sci. Eng. 2012, 3, 22–25. [Google Scholar]

- Chua, K.H.; Lim, Y.S.; Morris, S. Energy storage system for peak shaving. Int. J. Energy Sect. Manag. 2016, 10, 3–18. [Google Scholar] [CrossRef]

- Uddin, M.; Romlie, M.F.; Abdullah, M.F. Performance assessment and economic analysis of a gas-fueled islanded microgrid—A malaysian case study. Infrastructures 2019, 4, 61. [Google Scholar] [CrossRef]

- Robert, F.C.; Sisodia, G.S.; Gopalan, S. The critical role of anchor customers in rural microgrids: Impact of load factor on energy. In Proceeding of the 2017 International Conference on Computation of Power, Energy Information and Commuincation (ICCPEIC), Melmaruvathur, India, 22–23 March 2017; pp. 398–403. [Google Scholar] [CrossRef]

- Davydova, A.; Chakirov, R.; Vagapov, Y.; Komenda, T.; Lupin, S. Coordinated in-home charging of plug-in electric vehicles from a household smart microgrid. In Proceeding of the 2013 Africon, Pointe aux Piments, Mauritius, 9–12 September 2013. [Google Scholar]

- Ma, X.; Qu, H.; Pei, W.; Xiao, H. Optimal interactive operation of microgrid under demand response based on rolling optimization algorithm. Energy Procedia 2018, 145, 97–102. [Google Scholar] [CrossRef]

- Chowdhury, A.H.; Alam, S.; Hossain, A. Home energy management for community microgrids using optimal power sharing algorithm. Energies 2021, 14, 1060. [Google Scholar]

- Geerlings, H.; Heij, R.; Van Duin, R. Opportunities for Peak Shaving the Energy Demand of Ship-to-Shore Quay cranes at Container Terminals. J. Shipp. Trade 2018, 3, 1–20. [Google Scholar] [CrossRef]

- Heij, R. Opportunities for Peak Shaving Electricity Consumption at Container Terminals. Applying New Rules of Operation to Achieve a More Balanced Electricity Consumption. Master’s thesis, Delft University of Technology, Delft, The Netherlands, 2015. [Google Scholar]

- Bunnonn, P.; Chalermyanont, K.; Limsakul, C. A computing model of artificial intelligent approaches to mid-term load forecasting: A state of the art survey for the researcher. Int. J. Eng. Technol. 2010, 2, 94–100. [Google Scholar] [CrossRef]

- Hong, W.; Li, M.; Fan, G. Short-Term Load Forecasting by Artificial Intelligent Technologies; MDPI: Basel, Switzerland, 2019; ISBN 9783038975823. [Google Scholar]

- Soliman Abdel-hady Soliman, A.M.A.-K. 8-Dynamic Electric Load Forecasting; Electric Load Forecast: Seattle, WA, USA, 2010; pp. 291–352. ISBN 978012381543. [Google Scholar] [CrossRef]

- Gross, G.; Galiana, F.D. Short-Term Load Forecasting. Proc. IEEE 1987, 75, 1558–1573. [Google Scholar] [CrossRef]

- Samuel, I.A.; Emmanuel, A.; Odigwe, I.A.; Felly-Njoku, F.C. A comparative study of regression analysis and artificial neural network methods for medium-term load forecasting. Indian J. Sci. Technol. 2017, 10, 1–7. [Google Scholar] [CrossRef]

- Alasali, F.; Haben, S.; Becerra, V.; Holderbaum, W. Optimal energy management and MPC strategies for electrified RTG cranes with energy storage systems. Energies 2017, 10, 1598. [Google Scholar] [CrossRef]

- Alasali, F.; Haben, S.; Becerra, V.; Holderbaum, W. Day-ahead industrial load forecasting for electric RTG cranes. J. Mod. Power Syst. Clean Energy 2018, 6, 223–234. [Google Scholar] [CrossRef]

- Colarossi, D.; Principi, P. Feasibility Study of a Cold Ironing System and District Heating in Port Area; Department of Industrial Engineering and Mathematic Sciences: Ancona, Italy, 2020; pp. 666–675. [Google Scholar] [CrossRef]

- D’Agostino, F.; Schiapparelli, G.P.; Dallas, S.; Spathis, D.; Georgiou, V.; Prousalidis, J. On estimating the port power demands for cold ironing applications. In Proceeding of the 2021 IEEE Electric Ship Technologies Symposium (ESTS), Arlington, VA, USA, 3–6 August 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Peng, Y.; Li, X.; Wang, W.; Liu, K.; Bing, X.; Song, X. A method for determining the required power capacity of an on-shore power system considering uncertainties of arriving ships. Sustainability 2018, 10, 4524. [Google Scholar] [CrossRef]

- José, E.; Gutierrez-Romero, J.; Esteve-Pérez, B.Z. Implementing onshore power supply from renewable energy sources for requirements of ships at berth. Appl. Energy 2019, 255, 113883. [Google Scholar] [CrossRef]

- Hein, K.; Yan, X.; Wilson, G. Multi-objective optimal scheduling of a hybrid ferry with shore-to-ship power supply considering energy storage degradation. Electronics 2020, 9, 849. [Google Scholar] [CrossRef]

- Mehrzadi, M.; Terriche, Y.; Su, C.L.; Xie, P.; Bazmohammadi, N.; Costa, M.N.; Liao, C.H.; Vasquez, J.C.; Guerrero, J.M. A deep learning method for short-term dynamic positioning load forecasting in maritime microgrids. Appl. Sci. 2020, 10, 4889. [Google Scholar] [CrossRef]

- Hein, K.; Xu, Y.; Wilson, G.; Gupta, A.K. Coordinated optimal voyage planning and energy management of all-electric ship with hybrid energy storage system. IEEE Trans. Power Syst. 2021, 36, 2355–2365. [Google Scholar] [CrossRef]

- Lai, C.S.; Locatelli, G.; Pimm, A.; Wu, X.; Lai, L.L. A review on long-term electrical power system modeling with energy storage. J. Clean. Prod. 2021, 280, 124298. [Google Scholar] [CrossRef]

- Amirante, R.; Cassone, E.; Elia Distaso, P.T. Overview on recent developments in energy storage: Mechanical, electrochemical and hydrogen technologies. Energy Convers. Manag. 2017, 132, 372–387. [Google Scholar] [CrossRef]

- Mutarraf, M.U.; Terriche, Y.; Niazi, K.A.K.; Vasquez, J.C.; Guerrero, J.M. Energy storage systems for shipboard microgrids—A review. Energies 2018, 11, 3492. [Google Scholar] [CrossRef]

- Kim, K.; An, J.; Park, K.; Roh, G.; Chun, K. Analysis of a supercapacitor/battery hybrid power system for a bulk carrier. Appl. Sci. 2019, 9, 1547. [Google Scholar] [CrossRef]

- Nayak, A.; Lee, S.; Sutherland, J.W. Storage trade-offs and optimal load scheduling for cooperative consumers in a microgrid with different load types. IISE Trans. 2019, 51, 397–405. [Google Scholar] [CrossRef]

- Palensky, P.; Dietrich, D. Demand side management: Demand response, intelligent energy systems, and smart loads. IEEE Trans. Ind. Inform. 2011, 7, 381–388. [Google Scholar] [CrossRef]

- Vahedipour-Dahraie, M.; Najafi, H.R.; Anvari-Moghaddam, A.; Guerrero, J.M. Study of the effect of time-based rate demand response programs on stochastic day-ahead energy and reserve scheduling in islanded residential microgrids. Appl. Sci. 2017, 7, 378. [Google Scholar] [CrossRef]

- Commission, E. Reducing Emissions from the Shipping Sector—European Commission; European Commission: Brussels, Belgium, 2016; p. 1. [Google Scholar]

- Sanz, J.F.; Matute, G.; Fernández, G.; Alonso, M.A.; Sanz, M. Analysis of european policies and incentives for microgrids. Renew. Energy Power Qual. J. 2014, 1, 874–879. [Google Scholar] [CrossRef]

- Hansen, J.F.; Wendt, F. History and state of the art in commercial electric ship propulsion, integrated power systems, and future trends. Proc. IEEE 2015, 103, 2229–2242. [Google Scholar] [CrossRef]

- Sahoo, S.; Yang, Y.; Blaabjerg, F. Resilient synchronization strategy for ac microgrids under cyber attacks. IEEE Trans. Power Electron. 2021, 36, 73–77. [Google Scholar] [CrossRef]

- Rana, M.; Li, L.; Su, S.W. Cyber attack protection and control of microgrids. IEEE/CAA J. Autom. Sin. 2018, 5, 602–609. [Google Scholar] [CrossRef]

- Colarossi, D.; Principi, P. Technical analysis and economic evaluation of a complex shore-to-ship power supply system. Appl. Therm. Eng. 2020, 181, 115988. [Google Scholar] [CrossRef]

| Port Type | Characteristics |

|---|---|

| Local port | Serves for local needs Limited space and capacity Small size No logistic activity handling Do not support cruise ships Boats, vessels, yachts, and small-sized ships < 500 passengers |

| National port | Serves country needs Medium-sized (larger than local port) Cover all ships type with small logistic and cruise activities Medium-sized ships < 2500 passengers, cargo (packages), and logistics (only trucks) |

| International port | Serves international needs Largest sized Provide huge logistic infrastructure Cruise ships > 2500 passengers, cargo, containerships, and RTG cranes |

| Seaport’s Services | Load | Factor Influence Energy Consumption | Load Classifications | Form of Energy |

|---|---|---|---|---|

| Vessel | Passenger ships (cruise, ferry), container ships, electric ships, tugs, gliders, bunkers, boats, tankers, hovercraft, sailboats, submarines, yachts | Size of the ship, activity conduct on the ship, time of operation, weather, wave, speed |

|

|

| Goods handling | Cargo, container, quay, logistic, freight forwarder, customs warehouse, storage, security, loading-unloading | Number of cranes, amount of cargo, hours of operation | ||

| Administration | Management and administrative building, planning, service solution, IT, monitoring | Type of electrical equipment, weather, building material, hours of operation, occupant behavior | ||

| Transportation | Electric vehicles, cranes, trucks, yard tractors, trains | Number of transportation, hours of consumption | ||

| Electric Facility | Cold ironing, charging station for electric vehicles | Time of berthing, number of ships per berthing, size, and ship’s load | ||

| Maintenance | Repair and maintenance | Type of the maintenance |

| Date | Sulfur Limit in Fuel (% m/m) | |

|---|---|---|

| SOx ECA | Global | |

| 2000 | 1.5 | 4.5 |

| 2010 | 1.0 | |

| 2012 | 3.5 | |

| 2015 | 0.1 | |

| 2020 | 0.5 | |

| Country | Legislation |

|---|---|

| EU | Classification Societies—Regulation (EC) No 391/2009; Ship-Source Pollution—Directive 2000/59/EC; Marine Equipment—Directive 96/98/EC and Directive 2014/90/EU |

| Australia | Environmental Protection Act 1986 (WA) |

| New Zealand | Resource Management (Marine Pollution) Regulations |

| USA | Diesel Emission Reduction Act (DERA) |

| Singapore | Environmental Protection and Management Act (Cap.94A) |

| No | Variant | Sulfur Content |

|---|---|---|

| 1 | High Sulfur Fuel Oil (HSFO) | 3.5% |

| 2 | Low Sulfur Fuel Oil (LSFO) | 1.0% |

| 3 | Ultra-Low Sulfur Fuel Oil (ULSO) | 0.1% |

| Topology | Seaport Application | References |

|---|---|---|

| AC | Shipboard microgrid | [70,71,72] |

| Cold ironing | [73] | |

| DC | Ship-based seaport microgrid | [16,40] |

| Shipboard microgrid | [70,74,75,76,77] | |

| Cold ironing | [78] | |

| Electric ship | [79] | |

| Offshore application | [80] | |

| Hybrid AC/DC | Electric ferry shipboard | [81] |

| Shipboard microgrid | [82] | |

| Cranes | [22] | |

| Cold ironing | [83] |

| Load Forecasting Approach | Technique | Parameter Requirement | Load Forecasting Time Horizon |

|---|---|---|---|

| Traditional parametric techniques |

|

|

|

| Artificial intelligence-based techniques |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bakar, N.N.A.; Guerrero, J.M.; Vasquez, J.C.; Bazmohammadi, N.; Yu, Y.; Abusorrah, A.; Al-Turki, Y.A. A Review of the Conceptualization and Operational Management of Seaport Microgrids on the Shore and Seaside. Energies 2021, 14, 7941. https://doi.org/10.3390/en14237941

Bakar NNA, Guerrero JM, Vasquez JC, Bazmohammadi N, Yu Y, Abusorrah A, Al-Turki YA. A Review of the Conceptualization and Operational Management of Seaport Microgrids on the Shore and Seaside. Energies. 2021; 14(23):7941. https://doi.org/10.3390/en14237941

Chicago/Turabian StyleBakar, Nur Najihah Abu, Josep M. Guerrero, Juan C. Vasquez, Najmeh Bazmohammadi, Yun Yu, Abdullah Abusorrah, and Yusuf A. Al-Turki. 2021. "A Review of the Conceptualization and Operational Management of Seaport Microgrids on the Shore and Seaside" Energies 14, no. 23: 7941. https://doi.org/10.3390/en14237941

APA StyleBakar, N. N. A., Guerrero, J. M., Vasquez, J. C., Bazmohammadi, N., Yu, Y., Abusorrah, A., & Al-Turki, Y. A. (2021). A Review of the Conceptualization and Operational Management of Seaport Microgrids on the Shore and Seaside. Energies, 14(23), 7941. https://doi.org/10.3390/en14237941