Optimisation of the Two-Tier Distribution System in Omni-Channel Environment

Abstract

1. General Consideration

1.1. Omni-Channel Context of a Distribution System

1.2. State-of-the-Art Distribution System Using Several Commercial Channels

- Gross of the researchers formulates the distribution network design problem as the facility location and the flow of products, occasionally as the only facility location or the demand allocation.

- The key research objective discussed by the researchers is to build an optimal structure of a distribution network using a single-criterion approach or to obtain a compromise solution based on a multi-criteria evaluation. A few works compare the benefits of using the omni-channel distribution network in relation to conventional solutions; at the same time, there are no studies showing the benefits of using an omni-channel vs. a multi-channel distribution network.

- The structure of the distribution network considered in the literature is substantially different. It varies from a one-tier model composed of depots and customers to three-and four-tier models composed of suppliers, producers, depots at various operational levels, i.e., from central to local, and customers—either human beings or automatic devices. The location of each facility is usually defined a priori, and it is always with limited capacity. The results of the research presenting models with unlimited capacity of facilities have not been reported.

- Almost all distribution networks being the subject of the literature review consider the supply of single product type, except one case, where a variety of products are referred to.

- In most cases, there is presented in the literature a single, i.e., a unique, transport tariff at each distribution network tier; the exception is reported to one product with different tariffs depending on the type of products’ flow, i.e., one tariff for deliveries and the other tariff for returns. The results of the research with tariff differentiation at the same tier of the distribution network have not been reported.

- The distribution network design problem is modelled by many researchers using various programming techniques, both linear, i.e., MIP or MILP, and non-linear, e.g., NLP or NMIP. The mathematical model is formulated either with single-objective or multiple-criteria model; in each case, the basic and always present dimension is cost-oriented objective. The other dimensions are related to profitability, demand coverage, or environmental aspects. Moreover, the cost-oriented criterion can optionally be expressed in several dimensions, including the cost of transport, the cost of facilities (both fixed and variable costs), the cost of inventory or shortages, the cost of penalties, and price discounts.

- A demand in the analysed distribution networks is, in most cases, deterministic; only two results of the research are referred to stochastic demand.

- To solve the decision problem, single- and multi-criteria heuristic techniques are mostly used by the researchers. The experimental applications of the proposed models are verified on distribution networks of various sizes, considering the number of objects on different levels of this network; the medium-sized cases dominate.

1.3. Research Objective

- It includes the homogeneous product within each considered commercial channel; however, a diversified cargo unit, i.e., transport packaging, is applied;

- It defines the differentiated transport tariffs at each tier of the distribution network—each tariff can depend on the distance and/or the size of the cargo, i.e., transport packaging;

- It assumes an unlimited capacity of all facilities in the structure of the distribution network, and its volume is specified on the basis of optimisation computations;

- It allows the comparison of the benefits of using the omni-channel versus multi-channel distribution network.

- It is formulated as the facility location and the product flow problem;

- It assumes the multi-tier structure of the distribution network, i.e., a two-tier structure has been adopted, including the configuration of senders, depots, and receivers;

- It expresses the customers’ demand in a deterministic form;

- the mathematical model is formulated as a single criterion with the MILP technique; the objective function reflects the main components of the distribution network operating cost;

- It is applied a precise technique for LP problems solution due to the linear nature of the model and a consideration of a small size distribution network.

2. Methodology

2.1. Notations

2.2. Key Analytical Assumptions

- A one-operator of the distribution system with minimum two types of operated commercial p-channels is considered;

- A list of alternative locations of i-suppliers is defined a priori; their supply volume Sip is unknown;

- A list of alternative locations of k-depots is defined a priori; their capacity, Qkp, is not defined;

- A location of each j-receiver and its demand within commercial p-channel is known and defined a priori;

- A homogenous product is assumed for each commercial channel, represented by a type of cargo unit, e.g., a EUR-pallet, pack, cartoon, or returnable container;

- A distance between two points in a considered network, i.e., lik, lkj, and lij, is calculated using a typical shortest path procedure;

- Only the forward distribution is considered, i.e., returns (backflows) are omitted.

2.3. Decision Variables and Objective Function

- for the transportation cost dependent on distance l:

- for the transportation cost dependent on load size q:

2.4. Constraints

3. Experimental Application of the Optimization Model

3.1. Characteristic of the Decision Problem

- Option 1—a product is commissioned by i-supplier in (packs), and then palletised in (EUR) pallets; next, it is sent to the nearest selected depot as FTL service (vehicles’ capacity is 24 T, i.e., 33 EUR); after de-palletisation at k-depot site, the ordered quantity of products is delivered to j-recipients as a courier service (own or external) using the vehicles of capacity up to 3.5 T.

- Option 2—an ordered volume is commissioned by i-supplier in (packs) and sent directly to the j-recipient; the deliveries are performed by an external courier, exclusively.

- Option 1—The ordered goods are placed on EUR-pallets at i-supplier site and delivered to k-depot in the quantity expressed in (EUR); at k-depot, the product is accepted for a short-term storage and then the ordered quantity is commissioned in appropriate configurations and sent to the j-recipient; the capacity of vehicles in both situations is 24 T, i.e., 33 EUR).

- Option 2—On the i-supplier site, the ordered quantity is prepared and sent directly to the j-recipient; the deliveries are performed by an external forwarder exclusively.

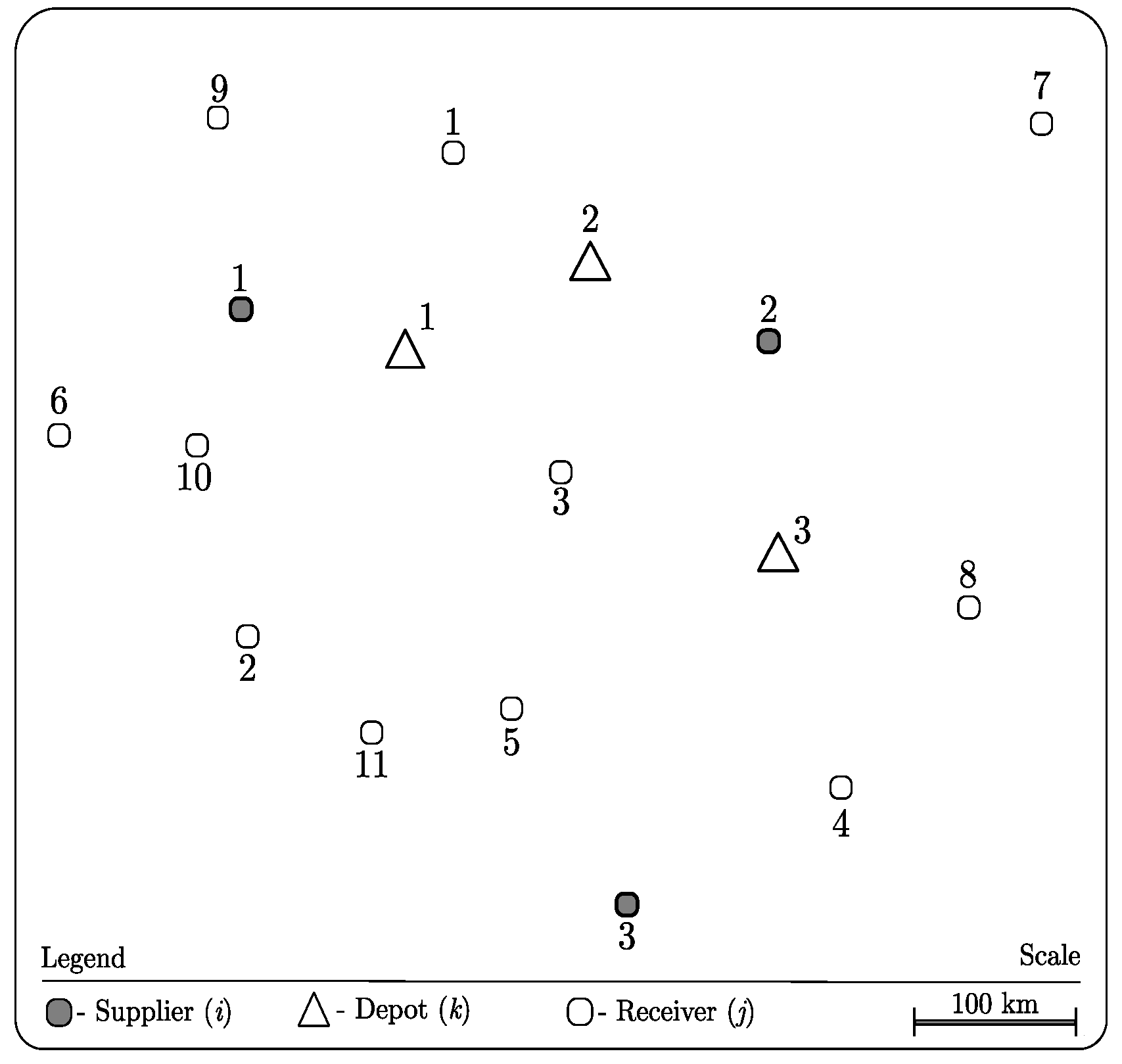

3.2. The Structure of Experimental Distribution System

- scenario 1 (S1): typical load size for p = 1 channel is limited to qikp = (0.1, 10.0) kg;

- scenario 2 (S2): typical load size for p = 2 channel is limited to qikp = (10.1, 25.0) kg.

3.3. Experimantal Results

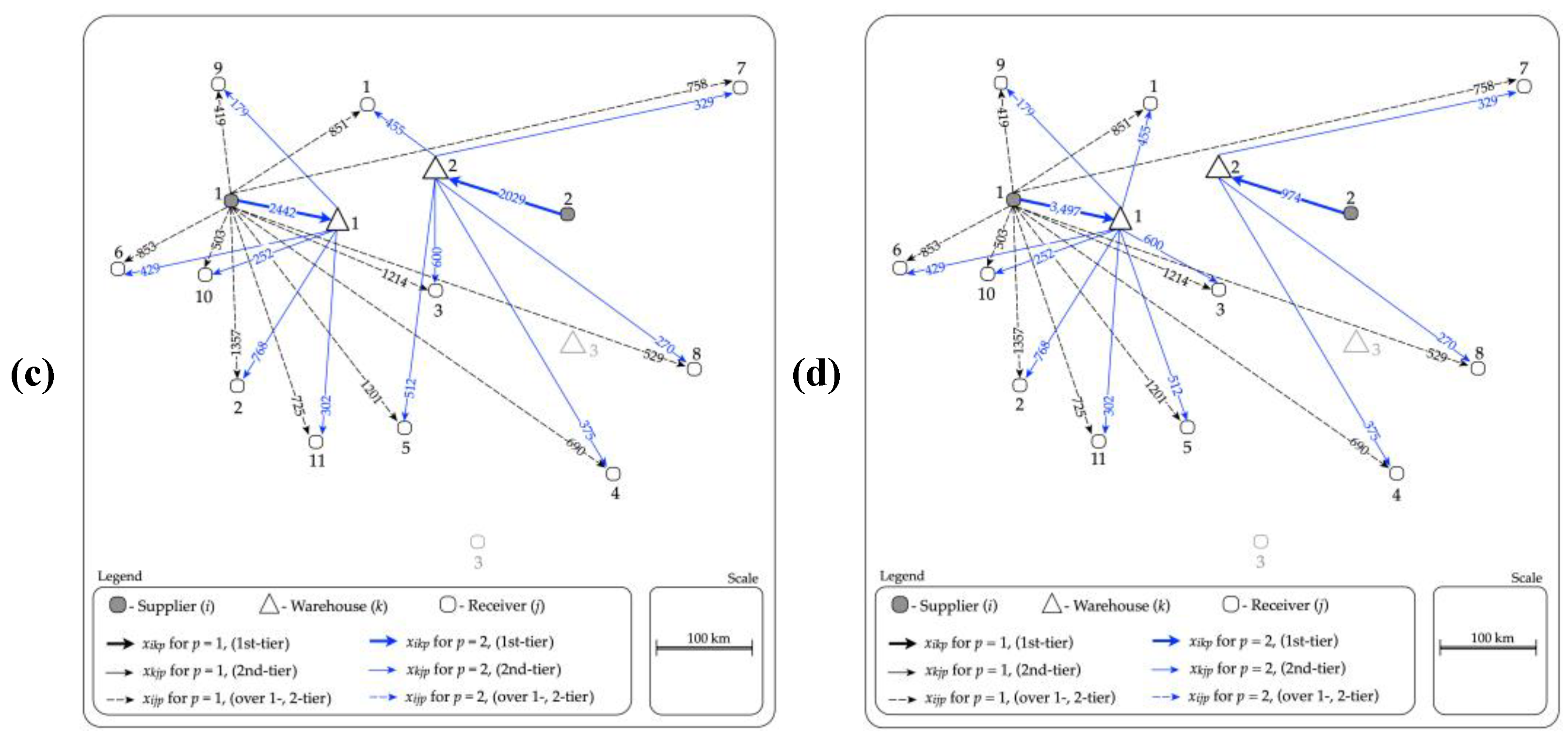

- The deliveries within p = 1 to recipient j = 8 (529 packs) are performed from supplier i = 1 (S1) or supplier i = 3 (S2);

- The deliveries within p = 2 to recipient j = 5 (512 packs) are performed from warehouse k = 1 (S1) or warehouse k = 2 (S2);

- The volume of deliveries from supplier i = 1 to depot k = 1 within p = 2 differs substantially, i.e., 2442 (packs) in S1 and 1903 (packs) in S2, and from supplier i = 2 to depot k = 2 is 2029 in S1 and 2541 in S2.

3.4. Sensitivity Analysis

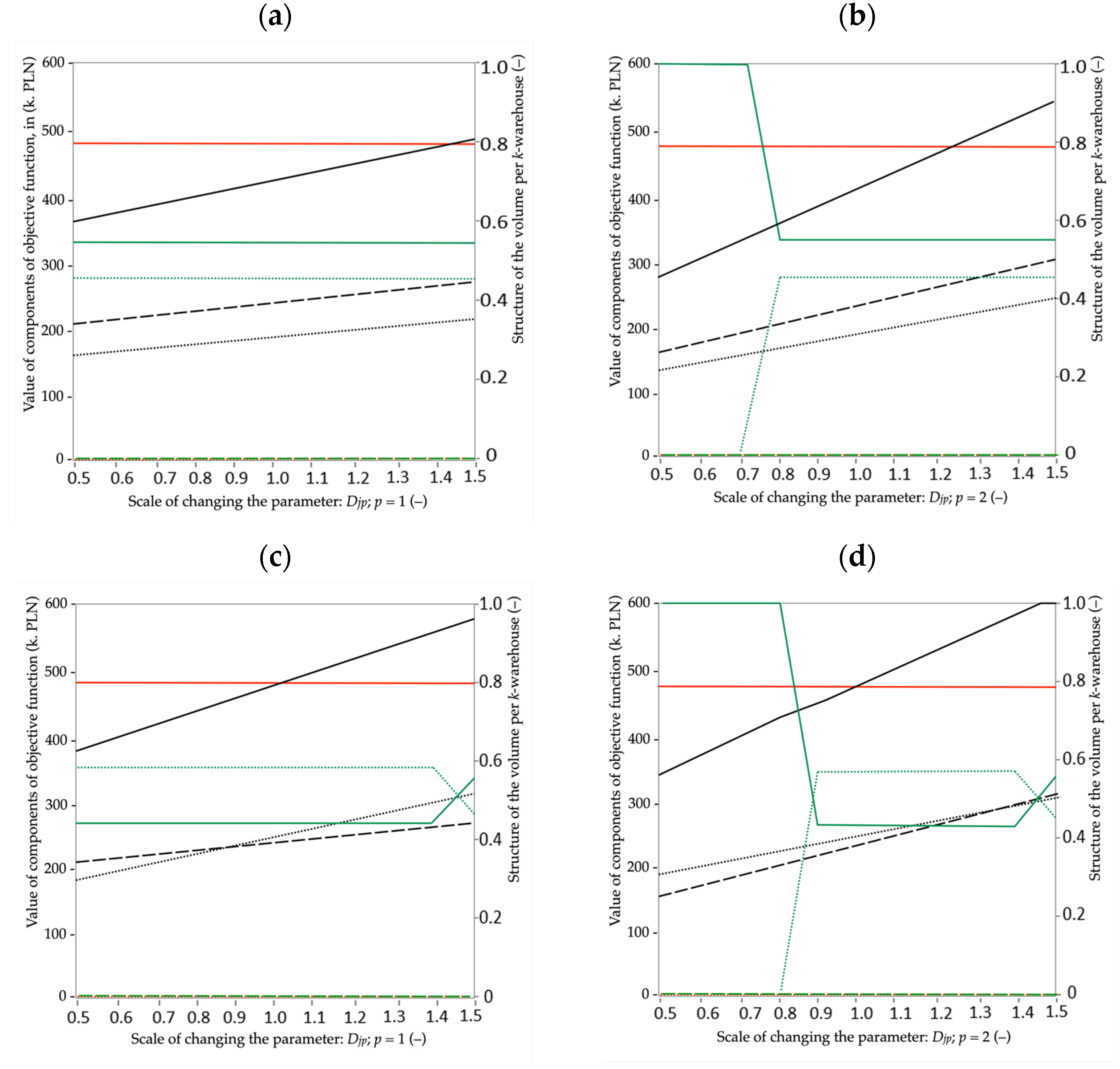

- The changed demand applied to one channel does not change the number of facilities in another channel;

- It does lead to significant changes in the load volume structure; for channel p = 2, the volume structure per facility is 100% across k = 1 for (0.5, 0.7) Djp and 55% across k = 1 and 45% across k = 2 for (0.7; 1.4) Djp, see Figure 5b,d;

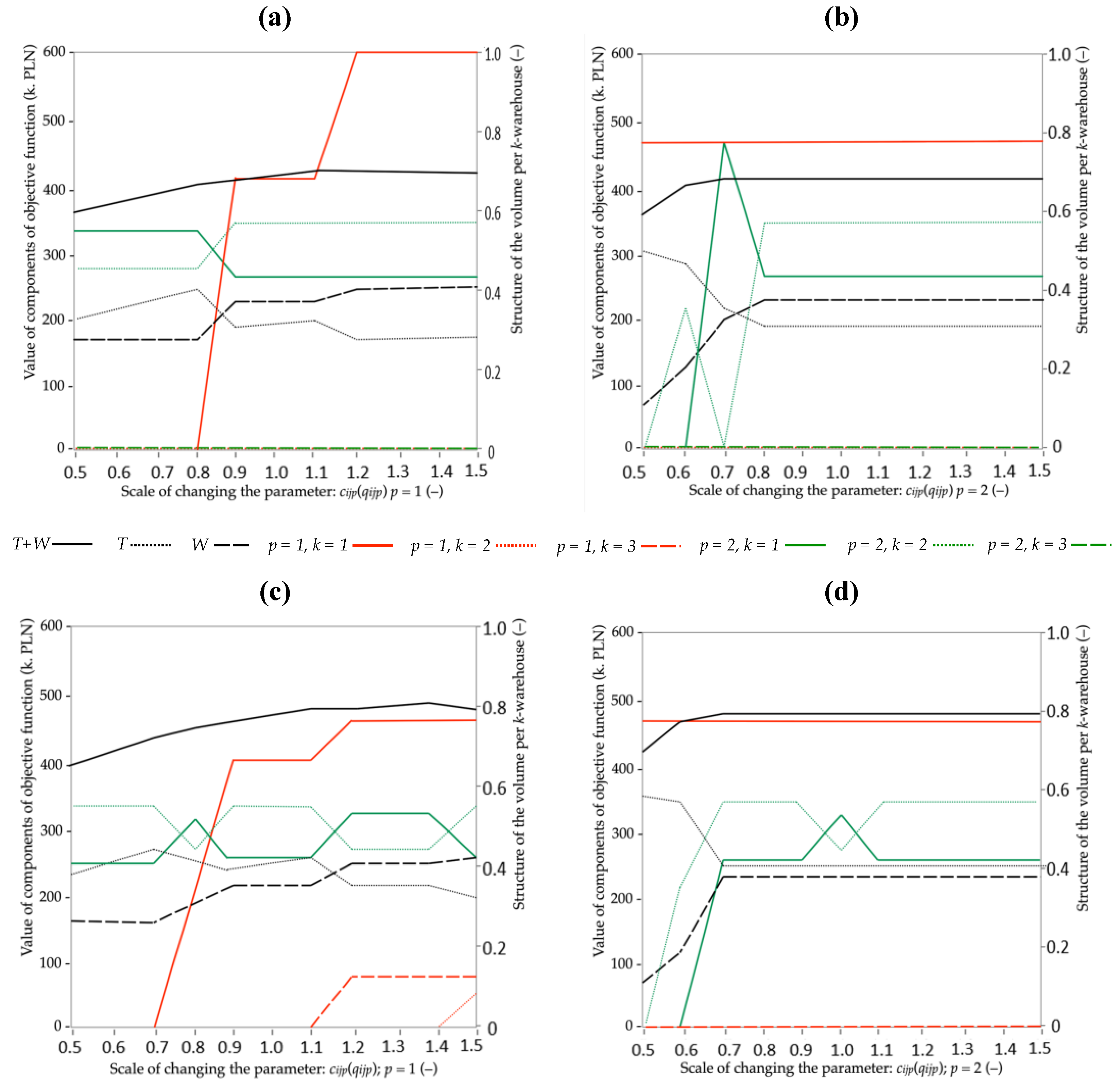

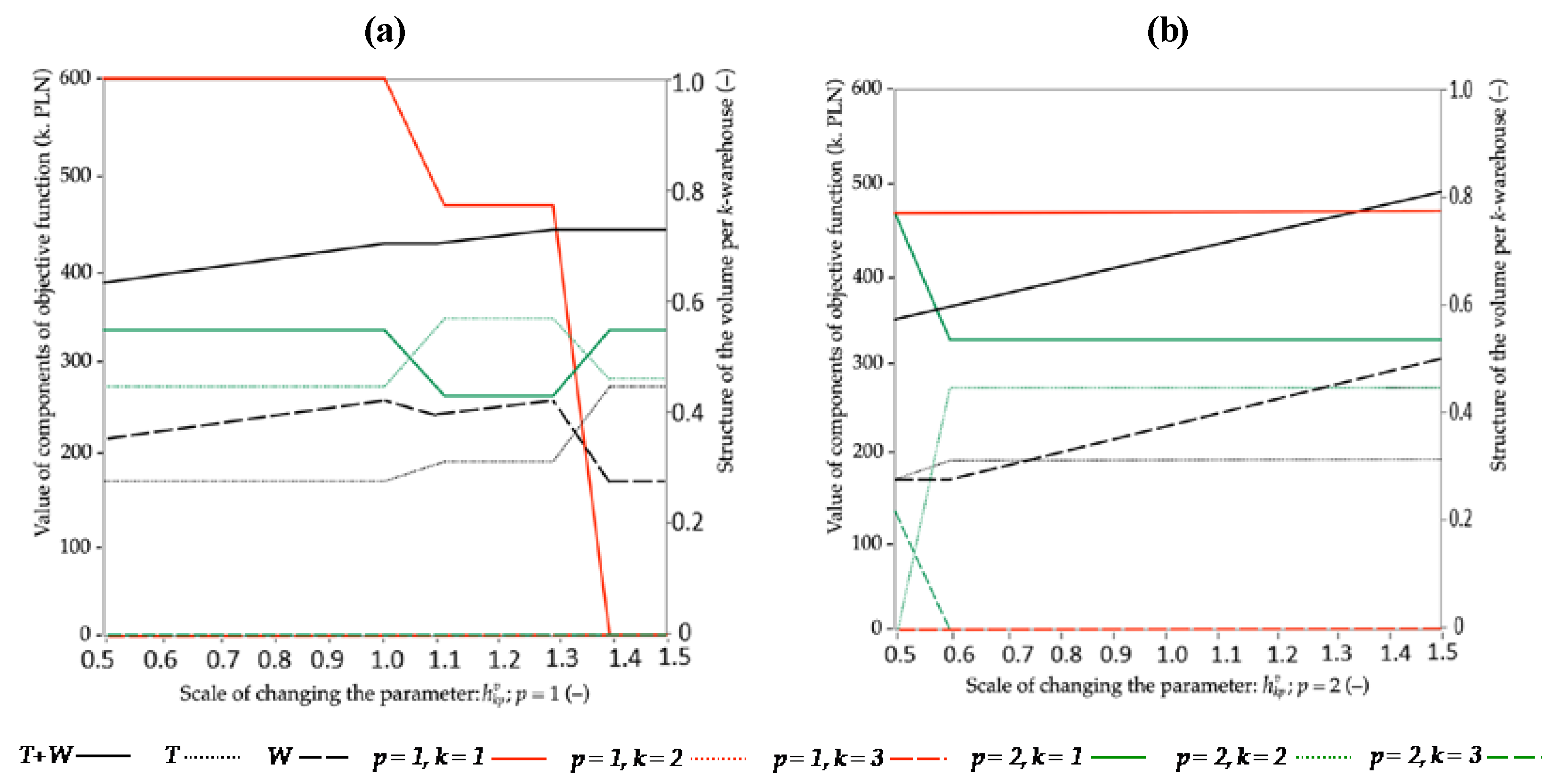

- A certain interval of cijp(qijp) changes stimulates the changes in the number of warehouse for individual sale channels; for interval (0.5, 0.8), cijp(qijp) all deliveries to j-recipients at p = 1 are carried out directly, i.e., the warehouse facilities are omitted, and for interval (0.8, 1.5) cijp(qijp), from one to three facilities are applied to, see Figure 6a,c;

- The change in transport cost per unit applied to one channel does not affect the change of the number of facilities in another channel;

- Specific intervals of c(q) lead to significant load volume structure changes (for p = 1 and qikp = (0.1, 10.0) kg load volume across k = 1 varies from 0 to 100%, see Figure 6a, and for qikp = (10.1; 25.0) kg load volume across k = 1 is 0–88%, 0–10% for k = 2, and 0–13% for k = 3, see Figure 6b; for p = 2 and interval (0.5, 0.8) cijp(qijp), the load volume across k = 1 and k = 2 varies from 0 to 80%, while for interval (0.8, 1.5), cijp(qijp) remains unchanged.

- In a very narrow range of changes, for a relatively very low value of changes, it influences the number of warehouse facilities for each channel of distribution network configuration, i.e., for p = 1 and qikp = (10.1, 25.0) (kg), two facilities exist (k = 1 ∧ k = 3), see Figure 7c; for p = 2 and the range (0.5, 0.6) , three facilities exist vs. two facilities for the remaining range of (k = 1 ∧ k = 2), see Figure 7b,d;

- Changes in the variable warehousing cost per unit applied to one channel does not affect the changes in the number of facilities in another channel;

- It leads to significant changes in the volume structure (for p = 1 and qikp = (0.1, 10.0) (kg), the volume across single facility k = 1 varies from 0 to 100% for a narrow range of changes, i.e., (1.0, 1.4), see Figure 7a; for p = 1, and qikp = (10.1, 25.0) (kg) for individual facilities it ranges from 0 to 30%, see Figure 7c for k = 1 ∧ k = 3, but for p = 2, a significant change in volume structure occurs (from 0 to 57%) for (0.5; 0.8) );

- Changes applied to one channel have a limited impact on the volume structure in another one, i.e., changes introduced within p = 1 are translated into a very narrow range of the volume structure changes for p = 2 (from 0 to 12% of total volume); some changes applied to p = 2 do not reflect in the changes of volume structure for p = 1; see Figure 7b,d.

4. Conclusions

4.1. Result of the Research

- A significant change in the demand level with reference to one of the commercial channels does not result in a change in the number of facilities essential within the distribution system responsible for servicing this channel; it leads, however, to significant change in the structure of the product flow via these facilities.

- A change in the value of such parameters as the load unit index (dependent on distance) or the variable storage index, in relation to one of the commercial channels, causes a change in such quantities as the number of facilities and the structure of the flow of goods through the individual facilities of the considered part of the distribution system.

- Changes in the values of individual parameters of the optimisation model in relation to the distribution system responsible for servicing one of the commercial channels do not affect the change in the number of facilities responsible for servicing the other commercial channels; however, they significantly affect the structure of the product flow through these facilities.

- The use of the omni-channel concept allows achieving noticeable benefits in contrast to multi-channel solutions; in the analysed case, 5–8% of operating costs savings is reached.

- The change in the structure of product flow through individual facilities in the distribution network depends mainly on the variation of such parameters as demand, transport rate, depending on the load size, and variable storage cost. The greatest sensitivity occurs, however, while changing the transport cost per unit c(q). In a relatively narrow range of the cost variation, it may lead to the disappearance of the product flow through the facility, or this flow can increase up to 100% of the total volume.

- The changes of all analysed parameters in relation to one of the commercial channels do not result in a change in the facilities serving other commercial channels.

- The number of facilities in the structure of the distribution network to a large extent depends on the variation of transport cost per unit c(q); the influence of the storage cost variations on the number of facilities is not significant, and this number does not depend on the demand variation, which, in fact, is crucial in the models with an unlimited capacity of facilities.

4.2. Limitation of the Research

- The degree of complexity of the considered omni-channel distribution network structure is low, i.e., the analysed network is two-tiered, including senders, depots, and recipients.

- The degree of computational complexity of a distribution network expressed by the number of objects at each tier is low; the computations are performed for a relatively small instance, and in the case of a higher complexity, it is necessary to apply approximate procedures to search for a near-optimal solution in an acceptable computation time CPU.

- The transport functions are simplified to the shortest path in a direct one-to-one relation; the proposed model does not consider a typical one-to-many routing problem; it is, however, an acceptable simplification while a typical strategic decision problem is considered, including the distribution network design problem.

4.3. Further Research

- Diversified parcel structure, i.e., diversified weight ranges;

- Feet composition, i.e., variable structure of the means of transport used;

- Variable vehicle utilisation, i.e., introducing a variable degree of vehicle capacity utilisation;

- Do-or-buy, i.e., different structure of transport and warehouse service performed by own resources or the outsourced logistics contractors;

- Frequency of deliveries, i.e., the implementation of fixed vs. variable delivery schedule.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Research | Distribution System (DS) | Commercial Channels | Demand 2 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Reference | Decision Problem | Context | Type | Structure of DS | Channels | No. of Products | Tariff | |||

| Actors 1 | Location | Capacity | ||||||||

| Alptekinoğlu, Tang [18] | Demand assignment | Logistics network design under stochastic demand | 2-tier | S, D, C | Defined | Capacitated | Multi- | Single | Single | Stoch. |

| Zhang et al. [20] | Facility location and product flow | Compromise network design | 4-tier | S, P, CD, RD, C | Defined | Capacitated | Multi- | Single | Single | Determ. |

| Yadav et al. [4] | Facility location and product flow | Comparison between omni-channel and conventional supply chain | 4-tier | S, P, CD, RD, C | Defined | Capacitated | Omni- | Single | Single | Determ. |

| Si et al. [25] | Facility location and product flow | Logistics network design under uncertain demand | 4-tier | CD, RD, LD, D, C | Defined | Capacitated | Omni- | Multiple | Single | Stoch. |

| Guerrero-Lorente et al. [26] | Facility location and product flow | logistics Network design for deliveries and returns | 4-tier | CD, RD, LD, D, A | Pre-defined | Capacitated | Omni- | Single (parcel) | Different (per deliveries and returns) | Determ. |

| Huang, Shi [27] | Facility location | Relocation of the front distribution center | 1-tier | D, C | Pre-defined | Capacitated | Omni- | Single | Single | Determ. |

| This paper | Facility location and product flow | Comparison between omni-channel and multi-channel | 2-tier | S, RD, C | Pre-defined | Incapacitated | Omni- | Multiple | Different per product | Determ. |

| Research | Mathematical Model | Solution and Application | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Program. Technique 1 | No. of Criteria | Objective Function | Solution Procedure | Area of Application | ||||||

| Cost Factors 2 | Other Criteria | |||||||||

| Transp. | Facil. 3 | Invent. | Backord. | Other | ||||||

| Alptekinoğlu, Tang [18] | NLP | 1 | Yes | No | Yes | Yes | No | N/a | Problem decomposition into single depot sub-network, solved by any convex NLP procedure | 2 networks (small) |

| Zhang et al. [20] | MILP | 3 | Yes | Yes (f) | No | No | No | Demand coverage; Environmental aspect | MOABC (modified multi-objective artificial bee colony) | 3 networks (small, medium, large) |

| Yadav et al. [4] | MIP | 2 | Yes | Yes (f, v) | No | No | No | Carbon content caused by facilities and transport | CPLEX | 4 networks (different size) |

| Si et al. [25] | MIP | 1 | Yes | Yes (f, v) | No | No | Carbon treatment | N/a | CPLEX and improved PCO (particle swarm optimization) | 1 network (medium) |

| Guerrero-Lorente et al. [26] | NMIP | 1 | Yes | Yes (f, v) | No | No | Penalty and discounts | N/a | MIP-based heuristic | 1 network (medium) |

| Huang, Shi [27] | MIP | 2 | No | Yes (f) | No | No | Distribution costs | N/a | CPLEX, MOSA (multi-objective simulated annealing) | 1 network (medium); region of Beijing |

| This paper | MILP | 1 | Yes | Yes (f, v) | No | No | No | N/a | Exact procedure, simplex | 1 network (small) |

References

- Biggs, C.; Suhren, J. Omnichannel Alchemy: Turning Online Grocery Sales to Gold, The Boston Consulting Group Report, 1–20. 2013. Available online: https://www.bcg.com/publications/2013/retail-growth-omnichannel-alchemy-online-grocery-sales (accessed on 21 November 2018).

- Hübner, A.; Holzapfel, A.; Kuhn, H. Distribution systems in omni-channel retailing. Bus. Res. 2016, 9, 255–296. [Google Scholar] [CrossRef]

- Beck, N.; Rygl, D. Categorization of multiple channel retailing in multi-, cross-, and omni- channel retailing for retailers and retailing. J. Retail. Consum. Serv. 2015, 27, 170–178. [Google Scholar] [CrossRef]

- Yadav, V.S.; Tripathi, S.; Singh, A.R. Exploring omnichannel and network design in omni environment. Cogent Eng. 2017, 4, 1382026. [Google Scholar] [CrossRef]

- Chopra, S. How omni-channel can be the future of retailing. Decision 2016, 43, 135–144. [Google Scholar] [CrossRef]

- Brynjolfsson, E.; HU, Y.J.; Rahman, M.S. Competing in the Age of Omnichannel Retailing. MIT Sloan Manag. Rev. 2013, 54, 23–29. [Google Scholar]

- Abdulkader, M.M.S.; Gajpal, Y.; ElMekkawy, T.Y. Vehicle routing problem in omni-channel retailing distribution systems. Int. J. Prod. Econ. 2018, 196, 43–55. [Google Scholar] [CrossRef]

- Geoffrion, A.M.; Graves, G.W. Multicommodity distribution system design by Benders decomposition. Manag. Sci. 1974, 20, 822–844. [Google Scholar] [CrossRef]

- Geoffrion, A.M.; Graves, G.W.; Lee, S.J. A management support system for distribution planning. INFOR 1982, 20, 287–314. [Google Scholar] [CrossRef][Green Version]

- Gelders, L.F.; Pintelon, L.M.; van Wassenhove, L.N. A location-allocation problem in a large Belgian brewery. Eur. J. Oper. Res. 1987, 28, 196–206. [Google Scholar] [CrossRef]

- Klose, A.; Drexl, A. Facility location models for distribution system design. Eur. J. Oper. Res. 2005, 162, 4–29. [Google Scholar] [CrossRef]

- Laport, G.; Nickel, S.; Saldanha da Gama, F. Location Science; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar] [CrossRef]

- Melo, M.T.; Nickel, S.; Saldanha-da-Gama, F. Facility location and supply chain management—A review. Eur. J. Oper. Res. 2009, 196, 401–412. [Google Scholar] [CrossRef]

- Farahani, R.Z.; Rezapour, S.; Drezner, T.; Fallah, S. Competitive supply chain network design: An overview of classifications, models, solution techniques and applications. Omega 2014, 45, 92–118. [Google Scholar] [CrossRef]

- Mangiaracina, R.; Song, G.; Perego, A. Distribution network design: A literature review and a research agenda. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 506–531. [Google Scholar] [CrossRef]

- Swaminathan, J.M.; Tayur, S.R. Models for supply chain in e-business. Manag. Sci. 2003, 49, 1387–1406. [Google Scholar] [CrossRef]

- Ishfaq, R.; Defee, C.C.; Gibson, B.J.; Raja, U. Realignment of the physical distribution process in omni-channel fulfilment. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 543–561. [Google Scholar] [CrossRef]

- Alptekinoğlu, A.; Tang, C.S. A model for analysing multi-channel distribution systems. Eur. J. Oper. Res. 2005, 163, 802–824. [Google Scholar] [CrossRef]

- Xie, W.; Jiang, Z.; Zhao, Y.; Hong, J. Capacity planning and allocation with multi-channel distribution. Int. J. Prod. Econ. 2014, 147, 108–116. [Google Scholar] [CrossRef]

- Zhang, S.; Lee, C.K.M.; Wu, K.; Choy, K.L. Multiobjective optimization for sustainable supply chain network design considering multiple distribution channels. Expert Syst. Appl. 2016, 65, 87–99. [Google Scholar] [CrossRef]

- Lim, S.F.W.T.; Srai, J.S. Examining the anatomy of last-mile distribution in e-commerce omnichannel retailing: A supply network configuration approach. Int. J. Oper. Prod. Manag. 2018, 38, 1735–1764. [Google Scholar] [CrossRef]

- Raza, S.A.; Govindaluri, S.M. Omni-channel retailing in supply chains: A systematic literature review. Benchmarking Int. J. 2021, 28. [Google Scholar] [CrossRef]

- Ya-Jun, C.; Chris, K.Y.L. Omni-channel management in the new retailing era: A systematic review and future research agenda. Int. J. Prod. Econ. 2020, 229, 107729. [Google Scholar] [CrossRef]

- Shpak, N.; Kyrylych, T.; Greblikaitė, J. Diversification models of sales activity for steady development of an enterprise. Sustainability 2016, 8, 393. [Google Scholar] [CrossRef]

- Si, Z.; Heying, Z.; Xia, L.; Yan, W. Omni-Channel Product Distribution Network Design by Using the Improved Particle Swarm Optimization Algorithm. Discret. Dyn. Nat. Soc. 2019, 1520213. [Google Scholar] [CrossRef]

- Guerrero-Lorente, J.; Gabor, A.G.; Ponce-Cueto, E. Omnichannel logistics network design with integrated customer preference for deliveries and returns. Comput. Ind. Eng. 2020, 144, 106433. [Google Scholar] [CrossRef]

- Huang, J.; Shi, X. Solving the location problem of front distribution center for omni-channel retailing. Complex Intell. Syst. 2021, 7. [Google Scholar] [CrossRef]

| Symbol | Definition | |

|---|---|---|

| Type | Notation | |

| indices | i | – supplier in a distribution system responsible for sending correct quantity of products with respect to available volume, i = 1, 2, …, I |

| j | – recipient in a distribution system, an entity whose demand for product is met, j = 1, 2, …, J | |

| k | – depot, a facility in a structure of a distribution system being located between supplier and recipient, responsible for receiving appropriate quantity of products from the supplier and their resupply to the customer, k = 1, 2, …, K | |

| p | – commercial channel, i.e., the composition of supply chain, p = 1, 2, …, P | |

| decision variables | xikp, xkjp, xijp | – volume of transported products within a commercial p-channel, from i-supplier to k-depot (i,k), from k-depot to j-recipient (k,j), and from i-supplier to j-recipient (i,j), expressed in (unit) |

| ykp | – location of k-depot in a distribution system within a commercial p-channel (-) | |

| parameters | c(l) | – unit transportation cost depended on distance l |

| c(q) | – unit transportation cost dependent on load size q, i.e., independent on distance l | |

| cikp, ckjp, cijp | – transportation cost of a product per unit within p-channel, from i-supplier to k-depot (i,k,p), from k-depot to j-recipient (k,j,p), and from i-supplier to j-recipient (i,j,p); expressed in (MU/unit) 1 | |

| cikp(lik), ckjp(lkj), cijp(lij) | – unit transportation cost rate, dependent on distance (l), within p-channel at (i,k) relation, (k,j) and (i,j) relations, respectively, expressed in (MU/unit⋅km) | |

| cikp(qikp), ckjp(qkjp), cijp(qijp) | – unit transportation cost rate, dependent on load size (q), within p-channel at (i,k) relation, (k,j) and (i,j) relations, respectively, expressed in (MU/unit) | |

| Djp | – demand of j-recipient within p-channel; in (units/month) | |

| – fixed storage cost (cost of facility) at k-location within p-channel; in (MU/month) | ||

| – variable storage cost (handling and commissioning costs) at k-location within p-channel; expressed in (MU/unit) | ||

| l | – distance defined on a considered relation, expressed in (km) | |

| lik, lkj, lij | – distance from i-supplier to k-depot (i,k), from k-depot to j-recipient (k,j), and from i-supplier to j-recipient (i,j); expressed in (km) | |

| rikp, rkjp, rijp | – load conversion rate of unit load size transported within p-channel into the unified load size at (i,k) relation, (k,j) relation, and (i,j), respectively (-) | |

| Sip | – supply volume of i-supplier within p-channel (unit/month) | |

| Qkp | – processing capacity of k-depot within p-channel (unit/month) | |

| – unit load size (current, min and max) in (i,k) relation within p-channel (unit) | ||

| – unit load size (current, min and max) in (k,j) relation within p-channel (unit) | ||

| – unit load size (current, min and max) in (i,j) relation within p-channel (unit) | ||

| – unified load size offered in a distribution system, transported in relations (i,k), (k,j), and (i,j), respectively, of a commercial p-channel (unit) | ||

| objective function and components | F | – minimized cost of transportation and storage, expressed in (MU) |

| T | – total transportation cost, expressed in (MU) | |

| TSD | – transportation cost of load movement between the supplier and depots (MU) | |

| TDR | – transportation cost of load movement between the depots and recipients (MU) | |

| TSR | – transportation cost of load movement between the suppliers and recipients (MU) | |

| W | – total storage cost, expressed in (MU) | |

| WD,f | – fixed cost of a depot, i.e., real estate cost (MU) | |

| WD,v | – variable cost of storing and handling process at depot, i.e., processing cost (MU) | |

| Parameters | Distribution Channel/Scenario | |||

|---|---|---|---|---|

| Notation | Unit 2 | p = 1 | p = 2 | |

| S1 | S2 | |||

| cikp(lik) | PLN/vkm | 3.0 | 3.0 | 3.0 |

| kg | 727.0 | 727.0 | 727.0 | |

| kg | (0.1, 10.0) | (10.1, 25.0) | (500.0, 727.0) | |

| rikp | - | 73 | 29 | 1 |

| ckjp(lkj) | PLN/vkm | 2.25 | 2.25 | 3.0 |

| kg | (0.1, 10.0) | (10.1, 25.0) | 727.0 | |

| kg | (0.1, 10.0) | (10.1, 25.0) | (500.0, 727.0) | |

| rkjp | - | 1 | 1 | 1 |

| cijp(lij) | PLN/vkm | 2.25 | 2.25 | 3.0 |

| kg | (0.1, 10.0) | (10.1, 25.0) | 727.0 | |

| qijp | kg | (0.1, 10.0) | (10.1, 25.0) | (500.0, 727.0) |

| rijp | - | 1 | 1 | 1 |

| cikp(qikp) | PLN/pack | 16.18 | 24.31 | 105 |

| ckjp(qkjp) | PLN/pack | 16.18 | 24.31 | 105 |

| cijp(qijp) | PLN/pack | 16.18 | 24.31 | 105 |

| lik | km | sp 1 | sp 1 | |

| lkj | km | sp 1 | sp 1 | |

| lij | km | sp 1 | sp 1 | |

| , k = 1 | PLN/mth | 2520.0 | 8700.0 | |

| , k = 2 | PLN/mth | 2150.0 | 7500.0 | |

| , k = 3 | PLN/mth | 2410.0 | 9200.0 | |

| , k = 1 | PLN/EUR | – | 35.0 | |

| , k = 2 | PLN/EUR | – | 32.0 | |

| , k = 3 | PLN/EUR | – | 45.0 | |

| , k = 1 | PLN/pack | 9.0 | – | |

| , k = 2 | PLN/pack | 12.0 | – | |

| , k = 3 | PLN/pack | 18.0 | – | |

| Component of Objective Function | Unit | Omni-Channels | Multi-Channels | ||||||

|---|---|---|---|---|---|---|---|---|---|

| S1 | S2 | S1 | S2 | ||||||

| p = 1 | p = 2 | p = 1 | p = 2 | p = 1 | p = 2 | p = 1 | p = 2 | ||

| qikp > 0 | qikp > 500 | qikp > 10 | qikp > 500 | qikp > 0 | qikp > 500 | qikp > 10 | qikp > 500 | ||

| qikp ≤ 10 | qikp ≤ 727 | qikp ≤ 25 | qikp ≤ 727 | qikp ≤ 10 | qikp ≤ 727 | qikp ≤ 25 | qikp ≤ 727 | ||

| TSD | k.PLN/mth | 0.899 | 42,528 | 2248 | 42,900 | 0 | 41,760 | 0 | 42,528 |

| TDR | k.PLN/mth | 27,907 | 78,988 | 69,767 | 80,152 | 0 | 79,509 | 0 | 78,988 |

| TSR | k.PLN/mth | 31,988 | 0 | 48,061 | 0 | 147,238 | 0 | 221,221 | 0 |

| T | k.PLN/mth | 60,794 | 121,516 | 120,076 | 123,052 | 147,238 | 121,269 | 221,221 | 121,516 |

| WD,v | k.PLN/mth | 64,107 | 150,398 | 64,107 | 148,862 | 0 | 153,563 | 0 | 150,398 |

| WD,f | k.PLN/mth | 2520 | 16,200 | 2520 | 16,200 | 0 | 16,200 | 0 | 16,200 |

| W | k.PLN/mth | 66,627 | 166,598 | 66,627 | 165,062 | 0 | 169,763 | 0 | 166,598 |

| T + W | k.PLN/mth | 127,421 | 288,114 | 186,703 | 288,114 | 147,238 | 291,032 | 221,221 | 288,114 |

| 415,535 | 474,817 | 438,270 | 509,335 | ||||||

| Savings | % | 5.2 | 6.8 | 0 | 0 | ||||

| Indices | Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| p | k | cijp(qijp) | cikp(lik) | ckjp(lkj) | Djp | ||||

| - | - | PLN/pack | PLN/EUR | PLN/vkm | PLN/vkm | PLN/mth | PLN/pack | pack/mth | EUR/mth |

| 1 | 1 | 1260–3780 | 4.5–13.5 | (209, 678)–(628, 2035) | - | ||||

| 1 | 2 | (16.18, 24.31) | - | (1.5–4.5) | (0.75–2.25) | 1075–3225 | 6.0–18.0 | ||

| 1 | 3 | 1205–3615 | 8.5–25.5 | ||||||

| 2 | 1 | 4350–13,050 | 17.5–52.5 | - | (89, 384)–(268, 1152) | ||||

| 2 | 2 | - | (52.5–157.5) | (1.5–4.5) | (1.5–4.5) | 3750–11,250 | 16.0–48.0 | ||

| 2 | 3 | 4600–13,800 | 22.5–67.5 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sawicki, P.; Sawicka, H. Optimisation of the Two-Tier Distribution System in Omni-Channel Environment. Energies 2021, 14, 7700. https://doi.org/10.3390/en14227700

Sawicki P, Sawicka H. Optimisation of the Two-Tier Distribution System in Omni-Channel Environment. Energies. 2021; 14(22):7700. https://doi.org/10.3390/en14227700

Chicago/Turabian StyleSawicki, Piotr, and Hanna Sawicka. 2021. "Optimisation of the Two-Tier Distribution System in Omni-Channel Environment" Energies 14, no. 22: 7700. https://doi.org/10.3390/en14227700

APA StyleSawicki, P., & Sawicka, H. (2021). Optimisation of the Two-Tier Distribution System in Omni-Channel Environment. Energies, 14(22), 7700. https://doi.org/10.3390/en14227700