Energy Savings of Simultaneous Heating and Cooling System According to Indoor Set Temperature Changes in the Comfort Range

Abstract

:1. Introduction

2. Materials and Methods

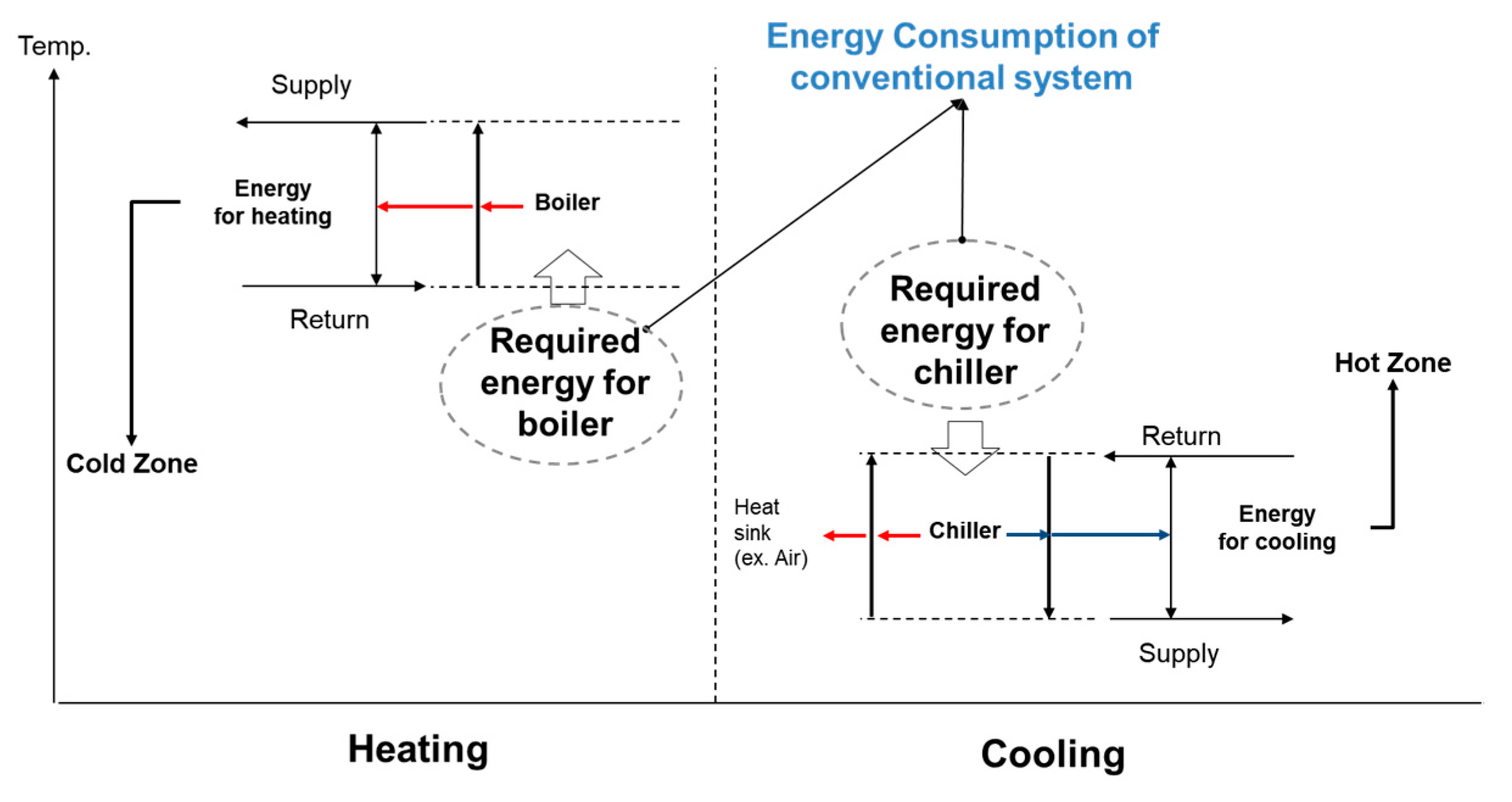

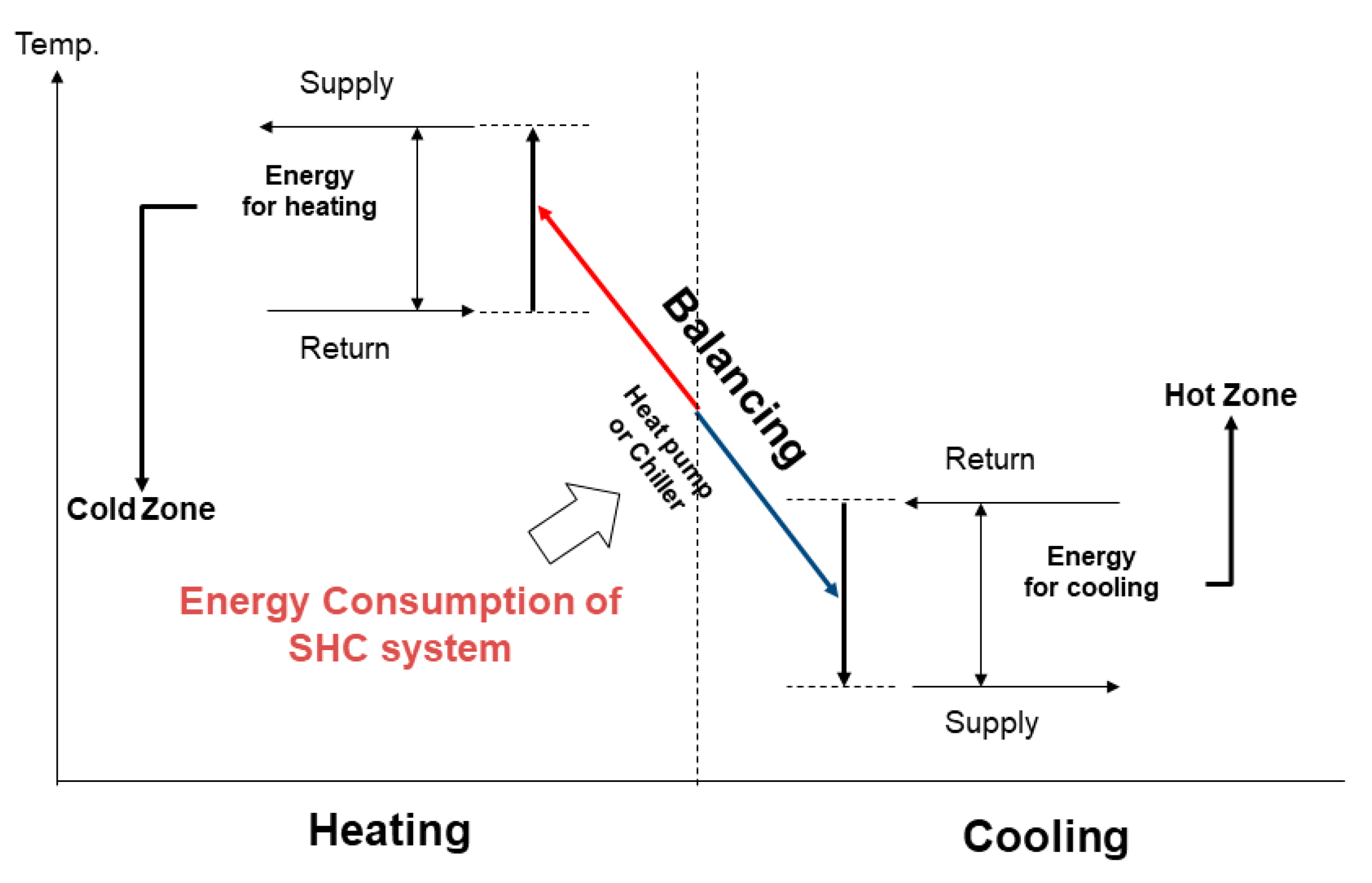

2.1. Simultaneous Heating and Cooling System (SHCs)

2.2. Energy Consumption Analysis of SHCs

2.2.1. Energy Consumption of SHCs without Load Balancing (General)

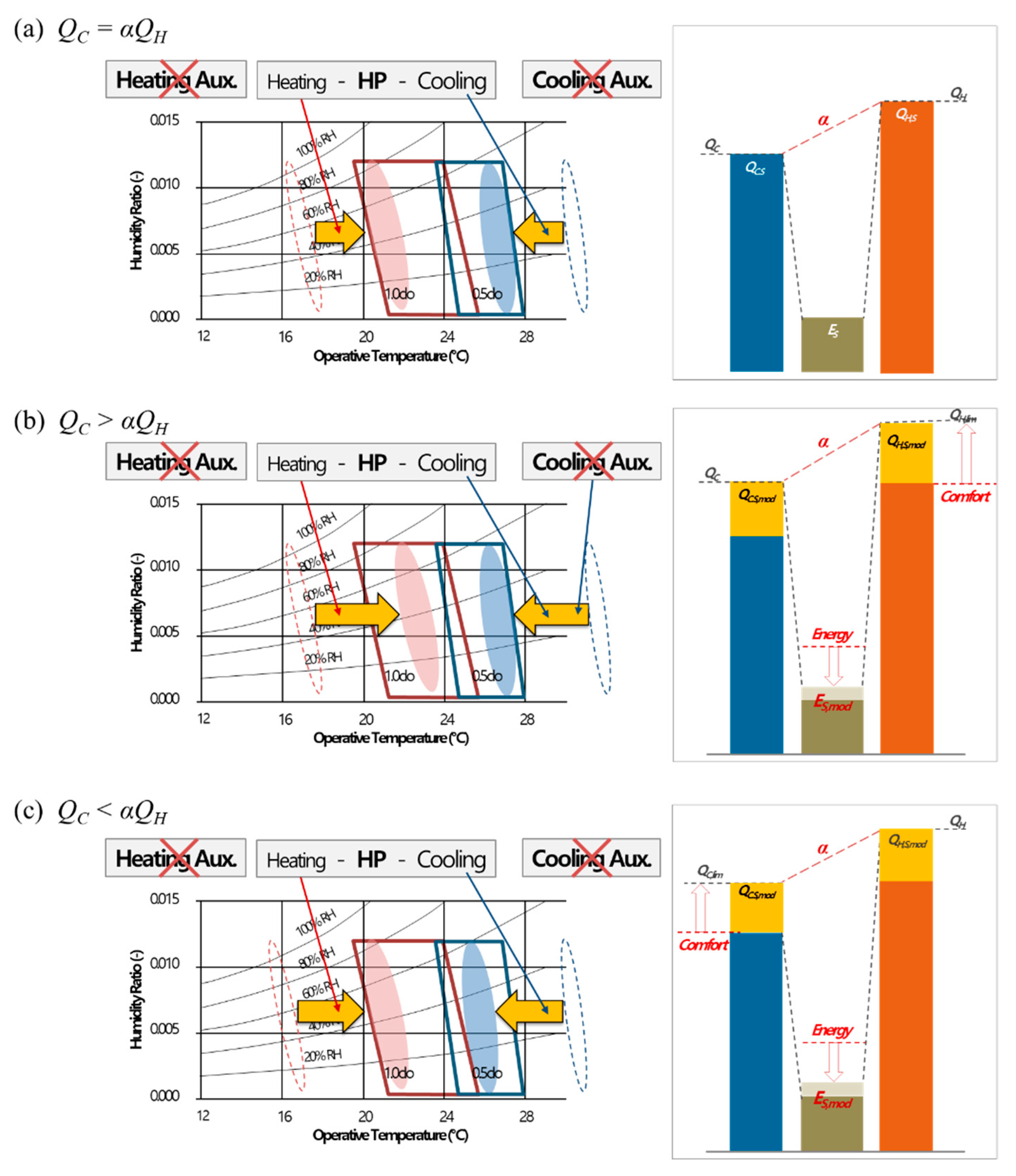

2.2.2. Energy Consumption of the SHCs with Load Balancing (LB)

2.3. General Method vs. Load Balancing Method

2.3.1. Energy Saving When Using the LB Method

2.3.2. Energy Saving When Set Temperature Changes in Real Time

2.3.3. Simulation Condition

3. Results and Discussion

3.1. Energy Saving When Using the LB Method

3.2. Energy Saving When Set Temperature Changes in Real Time

4. Conclusions

- (1)

- Simultaneous cooling and heating systems using heat pumps can be effectively utilized in buildings where heating and cooling loads occur simultaneously. When combined with a heat storage tank, more loads can be removed, even when loads do not occur simultaneously. An auxiliary heat source such as an air source can be applied when the amount of load is different. However, the efficiency is generally lower than that of simultaneous heating and cooling using a water-to-water heat pump. Therefore, maximizing simultaneous heating and cooling can improve the overall system efficiency.

- (2)

- The energy saved by the LB method is proportional to the energy limit that can be additionally input to the simultaneous heating and cooling, and the ratio of the COP difference between the simultaneous heating and cooling and the auxiliary and COP of the auxiliary heat source. That is when more energy is input to the simultaneous heating and cooling, or the auxiliary heat source COP is smaller than the simultaneous heating and cooling COP, the energy saving is greater.

- (3)

- The LB method is advantageous, not only in terms of energy savings, but also in terms of comfort by removing more loads. In particular, in the case of setting the set point at the boundary of the comfort zone, it was found that energy savings were greater when the LB method was used than when the general method was used. Thus, when the temperature is set as the boundary of the comfort range in a building (e.g., a public institution) with restrictions on the set-point temperature, both the comfort increase and energy saving can be satisfied if the simultaneous heating and cooling system and LB methods are applied.

- (4)

- When a heat storage tank with an ideal capacity is installed, approximately 60% of the energy can be saved compared to the case where the heat storage tank is not installed. Additionally, in the case of LB, by changing the set room temperature of both the hot and cold zones in real-time by predicting the indoor load, more energy can be saved than in the LB method, which changes only one load.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Nomenclature

| Latin letters: | |

| A | Surface area (m2) |

| COP | Coefficient of performance (−) |

| E | Consumed energy (W) |

| K | K-value (W/m2K) |

| LB | Load Balancing |

| N | Number of ventilation (1/h) |

| Q | Thermal load (W) |

| SHC | Simultaneous Heating and Cooling |

| T | Temperature (°C) |

| V | Volume (m3) |

| c | Specific heat (kJ/kgK) |

| Greek letters: | |

| Ratio of COPs (−) | |

| Density (kg/m3) | |

| Subscripts: | |

| A | Auxiliary heat source |

| C | Cooling |

| G | General |

| H | Heating |

| L | Load Balancing |

| O | Outside |

| S | Simultaneous heating and cooling |

| add | Additional |

| int | Internal |

| lim | limit |

| mod | Modified |

| p | Static pressure |

| set | Set point |

| sol | Solar |

References

- Byrne, P.; Miriel, J.; Lénat, Y. Design and simulation of a heat pump for simultaneous heating and cooling using HFC or CO2 as a working fluid. Int. J. Refrig. 2009, 32, 1711–1723. [Google Scholar] [CrossRef] [Green Version]

- Shin, D.U.; Leigh, T.H.; Joe, G.S.; Kim, M.G.; Yeo, M.S.; Kim, K.W. Energy performance of balanced heat recovery systems with load-balancing. Energy Procedia 2015, 78, 2445–2451. [Google Scholar] [CrossRef] [Green Version]

- Chapter 9 Applied heat pump and heat recovery systems. In ASHRAE Handbook—HVAC Systems and Equipment; ASHRAE: Peachtree Corners, GA, USA, 2020.

- Sarkar, J.; Bhattacharyya, S.; Gopal, M.R. Simulation of a transcritical CO2 heat pump cycle for simultaneous cooling and heating applications. Int. J. Refrig. 2006, 29, 735–743. [Google Scholar] [CrossRef]

- Kang, H.; Joo, Y.; Chung, H.; Kim, Y.; Choi, J. Experimental study on the performance of a simultaneous heating and cooling multi-heat pump with the variation of operation mode. Int. J. Refrig. 2009, 32, 1452–1459. [Google Scholar] [CrossRef]

- Byrne, P.; Miriel, J.; Lénat, Y. Experimental study of an air-source heat pump for simultaneous heating and cooling—Part 1: Basic concepts and performance verification. Appl. Energy 2011, 88, 1841–1847. [Google Scholar] [CrossRef] [Green Version]

- Byrne, P.; Miriel, J.; Lénat, Y. Experimental study of an air-source heat pump for simultaneous heating and cooling—Part 2: Dynamic behaviour and two-phase thermosiphon defrosting technique. Appl. Energy 2011, 88, 3072–3078. [Google Scholar] [CrossRef] [Green Version]

- Byrne, P.; Miriel, J.; Lénat, Y. Modelling and simulation of a heat pump for simultaneous heating and cooling. Build. Simul. 2012, 5, 219–232. [Google Scholar] [CrossRef] [Green Version]

- Ghoubali, R.; Byrne, P.; Miriel, J.; Bazantay, F. Study of a heat pump for simultaneous heating and cooling working with R290 or R1234yf and coupled to a building. ASHRAE Trans. 2013, 119, 1–8. [Google Scholar]

- Ghoubali, R.; Byrne, P.; Miriel, J.; Bazantay, F. Simulation study of a heat pump for simultaneous heating and cooling coupled to buildings. Energy Build. 2014, 72, 141–149. [Google Scholar] [CrossRef] [Green Version]

- Fricker, J.; Zoughaib, A. Simultaneous heating and cooling production devices composed by reverse cycle systems under variable loads. Int. J. Refrig. 2015, 55, 1–16. [Google Scholar] [CrossRef]

- Shin, D.U.; Ryu, S.R.; Kim, K.W. Simultaneous heating and cooling system with thermal storage tanks considering energy efficiency and operation method of the system. Energy Build. 2019, 205, 109518. [Google Scholar] [CrossRef]

- Diaby, A.T.; Byrne, P.; Mare, T. Simulation of heat pumps for simultaneous heating and cooling using CO2. Int. J. Refrig. 2019, 106, 616–627. [Google Scholar] [CrossRef]

- Joo, Y.; Kang, H.; Ahn, J.; Lee, M.; Kim, Y. Performance characteristics of a simultaneous cooling and heating multi-heat pump at partial load conditions. Int. J. Refrig. 2011, 34, 893–901. [Google Scholar] [CrossRef]

- Byrne, P.; Ghoubali, R. Exergy analysis of heat pumps for simultaneous heating and cooling. Appl. Therm. Eng. 2019, 149, 414–424. [Google Scholar] [CrossRef]

- Standard 55. Thermal Environmental Conditions for Human Occupancy; ASHRAE: Peachtree Corners, GA, USA, 2017. [Google Scholar]

- Shin, D.U.; Leigh, T.H.; Joe, G.S.; Kim, M.G.; Yeo, M.S.; Kim, K.W. Energy performance of balanced heat recovery systems with different terminal systems. In Proceedings of the IBPSA Asia Conference 2014, Nagoya, Japan, 28–29 November 2014. [Google Scholar]

- Shin, D.U.; Lee, S.J.; Joe, G.S.; Park, S.J.; Yeo, M.S.; Kim, K.W. Development of evaluation method for Energy Balancing System in super-large complex buildings. In Proceedings of the ISES 2011 Solar World Congress, Kassel, Germany, 28 August–2 September 2011. [Google Scholar]

- Klein, S.A.; Beckman, W.A.; Mitchell, J.W.; Duffie, J.A.; Duffie, N.A.; Freeman, T.L.; Kummer, J.P. TRNSYS 17 A Transient System Simulation Program; University of Wisconsin-Madison: Madison, WI, USA, 2009. [Google Scholar]

| Case | Set Temp. (°C) | |

|---|---|---|

| Hot Zone | Cold Zone | |

| Case 1-1 | 28 | 18 |

| Case 1-2 | 26 | 20 |

| Case 1-3 | 24 | 22 |

| Case | Set Temp. (°C) | |

|---|---|---|

| Heating COP | Cooling COP | |

| Case 1-2-1 | 2 | 1 |

| Case 1-2-2 | 3 | 2 |

| Case 1-2-3 | 4 | 3 |

| Case 1-2-4 | 5 | 4 |

| Case 1-2-5 | 6 | 5 |

| Case 1-2-6 | 7 | 6 |

| Case 1-2-7 | 8 | 7 |

| Case 1-2-8 | 9 | 8 |

| Case 1-2-9 | 10 | 9 |

| Case | Set Temp. (°C) | |

|---|---|---|

| Hot Zone | Cold Zone | |

| Case 2-1 | 28 | 18 |

| Case 2-2 | 26 | 20 |

| Case 2-3 | 24 | 22 |

| Case 2-4 | 28, 26, 24 | 18, 20, 22 |

| Contents | Dimension | Internal Load (W) | Wall/Window Type | |

|---|---|---|---|---|

| Building | Hot zone | 8.1 m(W) × 6 m(D) × 2.7 m(H) | 1840 (for all time) |

|

| Cold zone | 8.1 m(W) × 3 m(D) × 2.7 m(H) | 0 |

| |

| Material |

| |||

| Location | Seoul, Republic of Korea | Period | 1 month: from 21 January to 10 February (Timestep: 1 s) | |

| Hot Zone | Cold Zone | |||||

|---|---|---|---|---|---|---|

| Set temperature (°C) | 28 | 26 | 24 | 18 | 20 | 22 |

| Transmittance load (W) | −1038 | −967 | −897 | −882 | −971 | −1060 |

| Solar load (W) | 0 | 0 | 0 | 70 | 70 | 70 |

| Internal load (W) | 1840 | 1840 | 1840 | 0 | 0 | 0 |

| Total load (W) | 802 | 873 | 943 | −812 | −901 | −990 |

| Total amount of load (kJ) | 1,454,663 | 1,583,165 | 1,711,666 | −1,474,050 | −1,635,170 | −1,796,290 |

| Case | General | Load Balancing | |||

|---|---|---|---|---|---|

| Hot Zone | Cold Zone | Hot Zone | Cold Zone | ||

| Case 1-1 | Set Temp. (°C) | 28 | 18 | 28(0) | 22 (+4) |

| Load (kJ) | 1,454,663 | −1,474,050 | 1,454,663 (0) | −1,795,304 (−321,254) | |

| SHC: 1,179,240 Aux.: 275,423 | SHC: −1,474,050 Aux.: 0 | SHC: 1,436,243 Aux.: 18,420 | SHC: −1,795,304 Aux.: 0 | ||

| Energy (kJ) | 570,233 | 377,481 (−192,752) | |||

| SHC: 294,810 Aux.: 275,423 | SHC: 359,061 Aux.: 18,420 | ||||

| Case 1-2 | Set Temp. (°C) | 26 | 20 | 26(0) | 22 (+2) |

| Load (kJ) | 1,583,165 | −1,635,170 | 1,583,165 (0) | −1,795,797 (−96,376) | |

| SHC: 1,308,136 Aux.: 275,029 | SHC: −1,635,170 Aux.: 0 | SHC: 1,436,638 Aux.: 146,527 | SHC: −1,795,797 Aux.: 0 | ||

| Energy (kJ) | 602,063 | 505,687 (−96,376) | |||

| SHC: 327,034 Aux.: 275,029 | SHC: 359,159 Aux.: 146,527 | ||||

| Case 1-3 | Set Temp. (°C) | 24 | 22 | 24(0) | 22 (0) |

| Load (kJ) | 1,711,666 | −1,796,290 | 1,711,666 (0) | −1,796,290 (0) | |

| SHC: 1,437,032 Aux.: 274,634 | SHC: −1,796,290 Aux.: 0 | SHC: 1,437,032 Aux.: 274,634 | SHC: −1,796,290 Aux.: 0 | ||

| Energy (kJ) | 633,892 | 633,892 (0) | |||

| SHC: 359,258 Aux.: 275,029 | SHC: 359,258 Aux.: 274,634 | ||||

| Case | General | Load Balancing | |||

|---|---|---|---|---|---|

| Hot Zone | Cold Zone | Hot Zone | Cold Zone | ||

| Case 1-2-1 | Set Temp. (°C) | 26 | 20 | 26(0) | 22 (+2) |

| Load (kJ) | 1,583,165 | −1,635,170 | 1,583,165 (0) | −1,796,290 (−161,120) | |

| SHC: 817,585 Aux.: 765,580 | SHC: −1,635,170 Aux.: 0 | SHC: 898,145 Aux.: 685,020 | SHC: −1,796,290 Aux.: 0 | ||

| Energy (kJ) | 1,583,165 | 1,583,165 (0) | |||

| SHC: 817,585 Aux.: 765,580 | SHC: 898,145 Aux.: 685,020 | ||||

| Case 1-2-2 | Set Temp. (°C) | 26 | 20 | 26(0) | 22 (+2) |

| Load (kJ) | 1,583,165 | −1,635,170 | 1,583,165 (0) | −1,796,290 (−161,120) | |

| SHC: 1,090,113 Aux.: 493,051 | SHC: −1,635,170 Aux.: 0 | SHC: 1,197,527 Aux.: 385,638 | SHC: −1,796,290 Aux.: 0 | ||

| Energy (kJ) | 1,038,108 | 984,402 (−53,707) | |||

| SHC: 545,075 Aux.: 493,051 | SHC: 598,763 Aux.: 385,638 | ||||

| Case 1-2-3 | Set Temp. (°C) | 26 | 20 | 26(0) | 22 (+2) |

| Load (kJ) | 1,583,165 | −1,635,170 | 1,583,165 (0) | −1,796,290 (−161,120) | |

| SHC: 1,226,378 Aux.: 356,787 | SHC: −1,635,170 Aux.: 0 | SHC: 1,347,218 Aux.: 235,947 | SHC: −1,796,290 Aux.: 0 | ||

| Energy (kJ) | 765,580 | 685,020 (−80,560) | |||

| SHC: 408,793 Aux.: 356,787 | SHC: 449,073 Aux.: 235,947 | ||||

| Case 1-2-4 | Set Temp. (°C) | 26 | 20 | 26(0) | 22 (+2) |

| Load (kJ) | 1,583,165 | −1,635,170 | 1,583,165 (0) | −1,795,797 (−160,627) | |

| SHC: 1,308,136 Aux.: 275,029 | SHC: −1,635,170 Aux.: 0 | SHC: 1,436,638 Aux.: 146,527 | SHC: −1,795,797 Aux.: 0 | ||

| Energy (kJ) | 602,063 | 505,687 (−96,376) | |||

| SHC: 327.034 Aux.: 275,029 | SHC: 359,159 Aux.: 146,527 | ||||

| Case 1-2-5 | Set Temp. (°C) | 26 | 20 | 26(0) | 22 (+2) |

| Load (kJ) | 1,583,165 | −1,635,170 | 1,583,165 (0) | −1,789,372 (−154,202) | |

| SHC: 1,362,642 Aux.: 220,523 | SHC: −1,635,170 Aux.: 0 | SHC: 1,491,143 Aux.: 92,022 | SHC: −1,789,372 Aux.: 0 | ||

| Energy (kJ) | 493,051 | 390,250 (−102,801) | |||

| SHC: 272.528 Aux.: 220,523 | SHC: 298,229 Aux.: 92,022 | ||||

| Case 1-2-6 | Set Temp. (°C) | 26 | 20 | 26(0) | 22 (+2) |

| Load (kJ) | 1,583,165 | −1,635,170 | 1,583,165 (0) | −1,785,089 (−149,918) | |

| SHC: 1,401,574 Aux.: 181,590 | SHC: −1,635,170 Aux.: 0 | SHC: 1,530,076 Aux.: 53,089 | SHC: −1,785,089 Aux.: 0 | ||

| Energy (kJ) | 415,186 | 308,102 (−107,085) | |||

| SHC: 233.596 Aux.: 181,590 | SHC: 255,013 Aux.: 53,089 | ||||

| Case 1-2-7 | Set Temp. (°C) | 26 | 20 | 26(0) | 22 (+2) |

| Load (kJ) | 1,583,165 | −1,635,170 | 1,583,165 (0) | −1,782,029 (−146,859) | |

| SHC: 1,430,774 Aux.: 152,391 | SHC: −1,635,170 Aux.: 0 | SHC: 1,559,275 Aux.: 23,889 | SHC: −1,782,029 Aux.: 0 | ||

| Energy (kJ) | 356,787 | 246,643 (−110,144) | |||

| SHC: 204.396 Aux.: 152,391 | SHC: 222,754 Aux.: 23,889 | ||||

| Case 1-2-8 | Set Temp. (°C) | 26 | 20 | 26(0) | 22 (+2) |

| Load (kJ) | 1,583,165 | −1,635,170 | 1,583,165 (0) | −1,779,734 (−144,564) | |

| SHC: 1,453,485 Aux.: 129,680 | SHC: −1,635,170 Aux.: 0 | SHC: 1,581,986 Aux.: 1,179 | SHC: −1,779,734 Aux.: 0 | ||

| Energy (kJ) | 311,366 | 198,927 (−112,439) | |||

| SHC: 181.686 Aux.: 129,680 | SHC: 197,748 Aux.: 1,179 | ||||

| Case 1-2-9 | Set Temp. (°C) | 26 | 20 | 25.7(−0.3) | 22 (+2) |

| Load (kJ) | 1,583,165 | −1,635,170 | 1,600,155 (0) | −1,777,950 (−142,779) | |

| SHC: 1,471,653 Aux.: 111,512 | SHC: −1,635,170 Aux.: 0 | SHC: 1,600,155 Aux.: 0 | SHC: −1,777,950 Aux.: 0 | ||

| Energy (kJ) | 275,029 | 177,795 (−97,234) | |||

| SHC: 163,517 Aux.: 111,512 | SHC: 177,795 Aux.: 0 | ||||

| Hot Zone | Cold Zone | |||||

|---|---|---|---|---|---|---|

| Set temperature (°C) | 28 | 26 | 24 | 18 | 20 | 22 |

| Total amount of load (kJ) | 1,523,263 | 1,656,212 | 1,788,559 | −1,457,951 | −1,654,205 | −1,852,610 |

| Difference between loads (%) | 1.1 | 1.2 | 3.1 | 4.7 | 4.6 | 4.5 |

| Case | General | ||

|---|---|---|---|

| Hot Zone | Cold Zone | ||

| Case 2-1 | Set Temp. (°C) | 28 | 18 |

| Load (kJ) | 1,523,263 | −1,457,951 | |

| SHC: 1,092,716 Aux.: 430,548 | SHC: −1,365,894 Aux.: −92,056 | ||

| Energy (kJ) | 795,783 | ||

| SHC: 273,179 Cooling Aux.: 430,548 Heating Aux.: 92,056 | |||

| Case 2-2 | Set Temp. (°C) | 26 | 20 |

| Load (kJ) | 1,656,212 | −1,654,205 | |

| SHC: 1,329,288 Aux.: 416,924 | SHC: −1,549,110 Aux.: −105,095 | ||

| Energy (kJ) | 831,841 | ||

| SHC: 309,822 Cooling Aux.: 416,924 Heating Aux.: 105,0956 | |||

| Case 2-3 | Set Temp. (°C) | 24 | 22 |

| Load (kJ) | 1,788,559 | −1,852,610 | |

| SHC: 1,386,166 Aux.: 402,393 | SHC: −1,732,707 Aux.: −119,903 | ||

| Energy (kJ) | 868,838 | ||

| SHC: 346,541 Cooling Aux.: 402,393 Heating Aux.: 119,903 | |||

| Case 2-4 | Set Temp. (°C) | 28, 26, 24 | 18, 20, 22 |

| Load (kJ) | 1,600,875 | −1,721,002 | |

| SHC: 1,351,652 Aux.: 249,223 | SHC: −1,669,565 Aux.: −31,437 | ||

| Energy (kJ) | 618,573 | ||

| SHC: 337,913 Cooling Aux.: 249,223 Heating Aux.: 31,437 | |||

| Heating Set Temperature (°C) | Number of Settings | Ratio (%) | Cooling Set Temperature (°C) | Number of Settings | Ratio (%) |

|---|---|---|---|---|---|

| 18 | 8886 | 29.38 | 28 | 18,090 | 59.82 |

| 20 | 2443 | 8.08 | 26 | 4999 | 16.53 |

| 22 | 18,912 | 62.54 | 24 | 7152 | 23.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, D.-U.; Jeong, C.-H. Energy Savings of Simultaneous Heating and Cooling System According to Indoor Set Temperature Changes in the Comfort Range. Energies 2021, 14, 7691. https://doi.org/10.3390/en14227691

Shin D-U, Jeong C-H. Energy Savings of Simultaneous Heating and Cooling System According to Indoor Set Temperature Changes in the Comfort Range. Energies. 2021; 14(22):7691. https://doi.org/10.3390/en14227691

Chicago/Turabian StyleShin, Dae-Uk, and Chang-Ho Jeong. 2021. "Energy Savings of Simultaneous Heating and Cooling System According to Indoor Set Temperature Changes in the Comfort Range" Energies 14, no. 22: 7691. https://doi.org/10.3390/en14227691

APA StyleShin, D.-U., & Jeong, C.-H. (2021). Energy Savings of Simultaneous Heating and Cooling System According to Indoor Set Temperature Changes in the Comfort Range. Energies, 14(22), 7691. https://doi.org/10.3390/en14227691