Abstract

The disposal of olive wastes and their wastewater is a major problem worldwide. An important recycling chain can be formed through biogas production and energy conversion from olive waste. This study developed an efficient and effective sustainable model for biogas production using anaerobic digestion conditions with the co-digestion of pretreated olive waste. The sample used was hard olive pomace, which was dried in an oven before being crushed to fine particles with a mortar and pestle. The sample was analyzed by a CE-440 Elemental Analyzer, and Fourier Transform Infrared Spectrophotometer (FTIR) analysis was performed using Shimadzu IRTracer-100. Through the analysis, a substantial amount of electrical energy of 769 kWh/t was found to be generated per ton of olive pomace due to the high volatile solid (VS) percentage of organic waste material incorporated during the calculation. Reduced land area for landfilling olive waste was calculated to be 108 m2 per year, whereas the potential to reduce landfill leachate production was evaluated to be 0.32 m3 per year.

1. Introduction

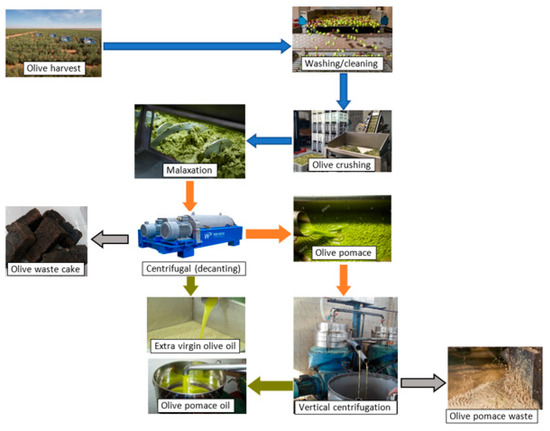

Cultivation of olive trees, scientifically known as Olea europaea, is one of the oldest processes in the world, with an estimated global cultivation area of 9 million hectares [1]. The world’s largest modern olive farm is located in Saudi Arabia, where olive trees are grown on a large scale for the production of olive oil to meet consumer demand. Olive oil extraction occurs via the traditional pressing and centrifugal processes, and this extraction process generates massive quantities of waste [2]. Different processes are included in olive oil extraction, as shown in Figure 1. The physicochemical properties and magnitude of the generated waste and effluents are contingent on the extraction procedure implemented. The extraction of olive oil produces two streams: one is solid waste known as olive pomace (OP), and the other, olive mill wastewater (OMWW) [3]. Both of these falls into the category of high pollutants and phytotoxic wastes. The disposal costs of these wastes are very high, and because they are produced by small enterprises, they are not treated properly due to financial limitations.

Figure 1.

A flow process diagram of olive pomace waste generation.

Olive waste is a by-product formed from a process called tree-pruning, which is a step of olive oil production, the source of which is olive leaves [1]. Olive leaves have a polyphenolic composition for which they can be applied in multiple processes. OMWW has the potential of being economically valuable and can be treated to be used as valued antioxidants agents and fertilizers, and to fulfil fatty acid requirements in the human diet. OP also has potential economic value as it can be a renewable energy source and a good alternative to fossil fuels, having an energy density of 23 MJ/kg [3]. Residual solids and treated OMWW can be utilized for soil amendment, which significantly contributes to the agriculture sector. Olive leaves comprise lignocellulosic compounds such as cellulose, hemicellulose, and lignin in different concentrations. When treated, olive leaves have many applications, such as cattle food, pharmaceutical, new materials, fertilizer and compost production, food products, and energy generation. They can be treated biochemically and thermochemically for energy generation. OMWW can be treated in multiple ways, such as biological treatment, composting, membrane filtration, chemical-physical treatment, and these treatment processes release important products such as biogas [4]. Anaerobic treatment of OMWW can convert this waste into biogas.

The olive oil industry produces a large amount of waste, which releases odors and ammonia into the environment, causing environmental problems. These wastes are produced in a short time and contain an average of 28.5% water, 21.5% pulp, 41.5% hull, and 8.5% oil in semi-solids, with a high humidity level and a high organic load [5]. Organic waste decomposes and releases methane and carbon dioxide (CO2) into the environment. This natural process results in environmental contamination, as methane has a global warming potential 20 times greater than that of carbon dioxide [6]. The disposal of olive waste may degrade soil and water quality, posing a severe environmental threat to Saudi Arabia’s aquatic and land ecosystems. However, olive mill wastes are not reusable, and therefore a sustainable approach to transferring energy from waste is required to reduce pollution. Renewable energy sources, such as bioethanol, biodiesel, solar, biogas, and wind, can significantly reduce greenhouse gas (GHG) emissions [7]. Olive mill waste is one of these sources that may be utilized to generate high-quality renewable fuels, such as biogas [8]. Olive wastes include substantial amounts of fat, protein, and carbohydrates [9], making them ideal for biogas generation. Moreover, the digest produced during biogas generation is used as a source of organic fertilizer [10]. In addition to bioenergy production, the most significant benefit of the recovery process is the reduction in waste volume, the reduction in waste disposal negatives in different sectors, and the reduction in land use for waste disposal [11].

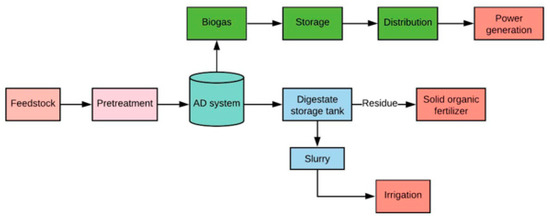

Biogas generation from olive mills is a viable approach for reducing the environmental effect of olive oil industry effluent. Biogas can be utilized to generate heat or electricity and renewable transportation fuel [12]. A general process flowchart of a biogas plant is shown in Figure 2. There are several environmental benefits and improvements from the utilization of biogas [13]. Biogas production creates novel opportunities for integrating nutrient recycling and energy production, maximizing underutilized resources’ utilization. It can also help to reduce CO2 emissions and substitute chemical fertilizers [14]. However, there are some disadvantages of biogas utilization, such as fewer technological advancements, economic infeasibility, formation of toxic intermediate composites, low production of biogas, and unstable nature of biogas [15,16]. There has been less technological progress made in making biogas production more cost-effective and feasible on a large scale due to a dearth of investors [17]. Amplification of digestion plant treatment capacity is required to counterbalance the high operational and installation costs [15]. Furthermore, biogas becomes flammable and can cause explosions when it comes into contact with O2. The key factors influencing the environmental and public health impacts of biogas systems depend on raw material selection, the final application of the biogas and digestate, and the production process [12,18].

Figure 2.

General process flowchart of a biogas plant (Liu et al., 2011).

Pretreatment is a critical step in the bioconversion of olive biomass for use in biorefineries, both technically and economically. The characteristics and properties of the material have a significant impact on the selection of the most appropriate pretreatment method. It has been reported that Fenton pretreatment increases the amount of biogas produced from olive waste by a significant amount [19]. The biogas generation was investigated by Al Afif and Linke [20] from three-phase olive mill solid waste under mesophilic and thermophilic conditions. The results revealed that biogas yield increased by 8% under thermophilic conditions in comparison with mesophilic conditions, while the presence of the enzyme in thermophilic conditions increased methane yield by 10%. When Al-Addous [21] examined the biogas production potential of olive pomace, it was found that the produced amount was only 20–40% of that traditionally generated by substrates. However, mixing feedstock can be an effective solution to maximize heat and biogas production. Valenti [22] generated biogas from biomass via a system based on sustainable intensification of crop rotation and utilization of by-products derived from the concept of BIOGASDONERIGHT. Olive pomace was considered a by-product for this study to find a way to reduce the environmental burdens that occur due to waste disposal by residues of olive oil industries. According to the findings of this study, the whole amount of accessible olive pomace can theoretically yield 1.9 million Nm3 biogas. This proves the high potential of olive pomace to be converted into a renewable energy source. The experimental research of [23] employed a simple and easy pretreatment process using hydrogen peroxide in alkaline conditions in the absence of the catalyst. This process improves the ability to anaerobically treat wet olive wastes, resulting in a methane production of 0.328 LCH4/gCODremoved on processed waste.

Anaerobic digestion (AD) is a well-known and viable technique for biogas generation [24]. It produces biogas by utilizing organic waste from farms and agriculture [25]. Therefore, it has been presented as a potential technique for producing biogas from olive oil waste. This is because the anaerobic digesters are designed and operated in a relatively low cost and simple manner [26]. Numerous studies [27,28,29,30] investigated various anaerobic digestion techniques for olive mill wastewater. Several technologies and different pretreatment techniques were explored for assessing their impact on the digestive process. Alagöz et al. [27] reported that treatment of olive pomace and wastewater sludge in the anaerobic digestion process increased biomethane production when compared to microwave and ultrasonic pretreatment. In another study conducted by Gunay and Karadag [28], a co-digestion approach was proposed to enhance the generation of biomethane with olive effluent pretreatment. Up-flow sludge blanket reactors were found to be highly effective in treating high-strength olive mill wastes and highly adaptable to changing operating conditions. Agriculture waste streams co-digested in two-stage anaerobic systems produced good treatment efficiency and energy generation. Carlini et al. [26] analyzed the potential of bio-methane from the anaerobic digestion of olive mill waste with inoculum, in addition to the co-digestion of olive mill waste with the substrates cattle slurry and cattle manure. The analysis comprised pollutant waste generated through olive oil processing using centrifugation systems of three-phase. To evaluate the biogas yield, a batch stirred tank reactor was employed under mesophilic conditions (38 °C). The olive mill waste with pit performed better when employed in co-digestion with different substrates. The optimum mixture was found to be 72.10% cattle slurry, 4.65% cattle manure, and 23.25% olive mill waste, with total solid composition of 14%.

In the efficacy of anaerobic digestion, temperature is one of the most important technological factors [31]. Mesophilic (30–35 °C) and thermophilic (55–60 °C) circumstances were used as frequently as possible under various anaerobic digestive conditions [23]. Compared to mesophilic temperature, thermophilic operation improved performance because of its faster biochemical reaction and higher degradation rate of organic matter [30]. In comparison to two-phase olive mill waste, co-digestion increased the amount of accumulated methane (L) by 264–319%, the methane output by 293–351% (LCH4/kgVSadded), and the volatile solids consumed by 312–342% (LCH4/kgVSremoved). As a result, there is huge potential for improving biogas production from olive mill waste through anaerobic digestion; however, this has not been investigated in Saudi Arabia yet. Therefore, the present study aimed to maximize the energy produced by bioenergy products derived from olive wastes. Based on anaerobic digestion conditions with the co-digestion process of pretreated olive wastes, an efficient and effective sustainable model was developed for producing biogas. Thermophilic conditions can be maintained in anaerobic digestion to produce biogas from olive mill wastes by utilizing Saudi Arabia’s plentiful solar energy. Saudi Arabia is endowed with both solar energy and olive mill wastes as biomass, both of which are used to improve the techno-economic potential of the country.

2. Material and Methodology

2.1. Data Collection

The hard olive pomace sample was collected from the Hill-Zafran company, Jouf, Saudi Arabia, and then crushed with a mortar and pestle to produce fine particles for testing. Ultimate analysis of the sample was undertaken using a CE-440 Elemental Analyzer and Fourier Transform Infrared Spectrophotometer (FTIR) analysis was performed using a Shimadzu IRTracer-100. Taking a basis of 1-ton olive pomace as feed and using the ultimate analysis data, the biogas quality and quantity was theoretically assessed from various equations as outlined in the following section. The local area data such as annual rainfall and landfill depth were also collected from online sources [32,33].

2.2. Calculations and Projections

2.2.1. Biogas Constituents

The proportion of the biogas components (methane to carbon dioxide) was determined by Equations (1) and (2) [34], which were revised from the method of Buswell and Mueller [35]:

where and represent the proportion of CH4 and CO2 respectively; wt.% of the elements, namely carbon, hydrogen, oxygen, nitrogen, and sulfur are derived from ultimate analysis data and denoted by C, H, O, N, and S, correspondingly. These values were, in turn, calculated using Equation (3).

where Ei represents the wt.% of the individual elements, Eult stands for respective proportions from ultimate analysis data, and Mi denotes individual molecular weights of the elements.

2.2.2. Biogas and Methane Gas Yield

The amount of CH4 and VM was determined by Equation (4) [34,36], and the aggregate volume of biogas, Vbio, was evaluated from Equation (5) using the values of VM and :

where VM defines the volume of the pure methane yield (m3/day), VS represents the volatile solid amount of organic waste, c is the constant for biogas production (taken as 0.375 g carbon/g volatile solid) with a 75% VS degradation, MC denotes the molecular weight of carbon (12 g/mol), VI = one mol gas volume at STP (22.4 L), MMSW signifies the mass (incoming) of the organic waste stream (kg/day), and Vbio represents the yield of biogas volume (m3/day).

2.2.3. Estimated Potential of Biofertilizer and Bioenergy

The production of electrical energy from biogas was estimated by Equation (6) [34]. The electrical power output, PEbio, in Equation (7) was then evaluated from the electrical energy, EEbio.

where EEbio denotes electrical energy output (MWh day−1), VM gives the volume of methane yield (m3 day−1), EC stands for methane energy constant (taken as 10 kWh/m3), η represents electrical effectiveness of the biogas engine (taken as 40%), and PEbio is the electrical power output (MWh).

Equation (8) was used to calculate the amount of biofertilizer produced from digested olive pomace [36]. Biogas output for the organic fraction of MSW constitutes 75% of the entire VS content [37]. The remaining portion of the VS was used to estimate biofertilizer output.

where BF gives the biofertilizer output (ton day−1), DM represents the dry mass % of organic solids, VS stands for volatile solids % and indicates the fraction of DM converted into biogas, and MMSW denotes the organic waste input (kg day−1).

2.2.4. Contribution to Environmental Protection

CO2 emissions avoidance was calculated using Equation (9) [38], whereas Equations (10) and (11) were used to measure the landfill area reduction and leachate circumvention [39], respectively:

where represents carbon dioxide circumvention (t day−1), XC indicates the base factor for offsetting CO2 by generating electricity from renewable energy (kg MWh−1), and EEbio denotes the electrical energy output (MWh day−1).

where LAMSW is the requisite organic waste landfill area (m2 day−1); MMSW, the waste feed mass (kg day−1); CD, the compressed density of waste (t m−3); and HL, the of landfill depth (m).

where VLD is the leachate ejection volume (m3 day−1); AR, the yearly rainfall (m); and LAMSW, the requisite organic waste landfill area (m2 day−1).

3. Results and Discussion

3.1. Characterisation of Olive Waste

3.1.1. Composition and Yield of Biogas

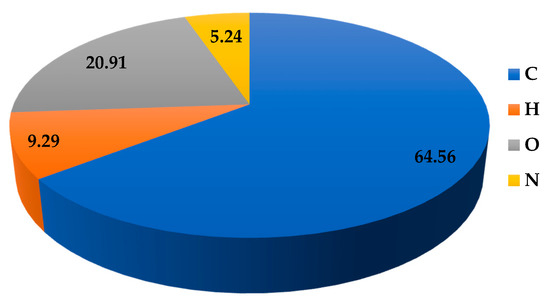

The ultimate analysis of olive waste indicates that the waste contains 64.56% carbon, 9.29% hydrogen, 5.24% nitrogen, and 20.91% oxygen (Figure 3). Based on ultimate analysis data, the amounts of CH4 and CO2 were calculated to be 62.90 and 37.10%, respectively [40], which were within the limit of conventional biogas compositions, with methane accounting for around 60–65% and CO2 accounting for 35–40% [41,42]. The outputs of pure CH4 and biogas from 1 ton olive pomace input were 192.2 and 305.5 m3 day−1, respectively. In addition, around 330.24 L of pure methane was estimated to be produced per kg of VS, which falls within the typical limits (250–550 L CH4/kg VS) found in many on-field functions of solid waste anaerobic digesters (AD) installed in various countries worldwide [43,44,45,46].

Figure 3.

Elemental composition of the Olive pomace using CE-440 Elemental Analyzer.

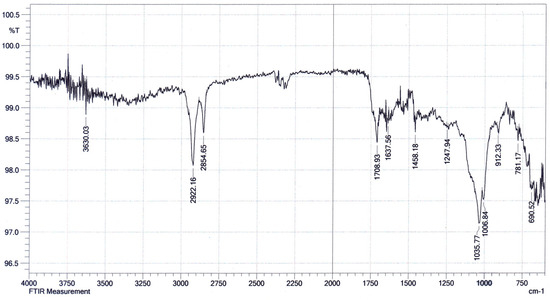

3.1.2. FTIR Analysis

Electromagnetic radiation, via absorption, transmission, reflection, dispersion, or photoluminescence, can reveal a large amount about a substance’s molecular composition and energy level shift [47]. The collected sample of olive pomace was analyzed through a Fourier Transform Infrared (FTIR) Spectrophotometer. When a small amount of olive waste is placed in the path of an infrared beam, it absorbs and transmits light, which then passes through the sample to the detector. The detector monitors the amount of radiation that enters a sample, in addition to the amount of radiation that passes through it. A computer converts its output as a function of time into a plot of transmittance against wavenumber using the Fourier transform method, as illustrated in Figure 4. The graph shows multiple visible peaks in the diagnostic region (1500–3000 cm−1), indicating the presence of several functional groups [48,49,50]. The sample has C=C stretching at a wavenumber of around 1600–1650 representing alkene compounds, C=O stretching at a wavenumber around 1700–1850 indicative of carbonyl compounds, C≡N at a wavenumber of approximately 2200–2250 representing nitrile compounds, N-H at a wavenumber of about 2600–2700 representing amines, C-H at a wavenumber of approximately 2900–3100 for alkanes, O-H at a wavenumber of around 3200–3500 for alcohols, etc. [48,49]. Using the spectrophotometric data and irAnalyze-RAMalyze (version 7.0.4.0) software, the main functional groups identified to be present in the sample were aliphatic nitrile, carbonyl, metal carbonyl, aliphatic amine, aliphatic isonitrile, aliphatic cyanate, aromatic amino acid, a tertiary alcohol, and aromatic rings.

Figure 4.

FTIR analysis of the olive waste.

3.2. Electrical Potential and Biofertilizer Output

The electrical energy generated by biogas (EEbio) and the capacity or output power of a biogas-based power plant (PEbio) were calculated using Equations (6) and (7), as summarized in Table 1. The biogas engine efficiency was set at 40%, considering typical industrial gas engine efficiency as a reference. The final values for EEbio and PEbio were found to be 0.769 MWh per day and 0.032 MW, respectively. Electrical energy of 769 kWh was generated per ton of olive pomace, which was found to be greater than the reported literature values of around 200–400 kWh/t [51,52]. This may be because of the high VS content considered in the calculation.

Table 1.

Electricity potential from the generated biogas.

The biofertilizer yield (BF) was projected to be 0.2735 t/day for the input using Equation (8). A similar study found that nutrient content (e.g., nitrogen, potassium, phosphorus) of liquid and solid biofertilizers generated from AD meets biofertilizer standards, whereas hazardous content such as heavy metals, in addition to other pathogenic bacteria, are within the tolerable limits [53].

3.3. Environmental Aspects

In Saudi Arabia, renewable electricity generated from olive pomace can save around 0.53 tons of CO2 per day for a one-ton waste feed, resulting in a cumulative savings of approximately 190 tons CO2. Table 2 summarizes CO2 reduction, leachate avoidance, and landfilling area minimization. The factor XC (taken as 694.0 kg CO2 per MWh) is used as the base for CO2 emissions when generating 1 MWh of energy in the form of electricity [38]. It represents the total greenhouse gas released into the atmosphere by fossil fuel-based power plants, which can be offset by generating electricity and distributing it via sustainable energy sources such as solar, biomass, and biogas. The typically compressed waste density (CD) was taken as 270 kgm−3 for landfilling [54], whereas the depth of the landfill (HL) was 12 m [32]. It is noted that the recent average annual precipitation in Saudi Arabia’s Al Jawf Province was calculated as 0.02 m [33]. Using these values in Equations (10) and (11), the potential for reducing the land area required for landfilling olive waste per day was 0.3086 m2, whereas the potential for reducing landfill leachate production was 0.0009 m3 per day. These values are approximately 108 m2 and 0.32 m3 respectively on an annual basis.

Table 2.

Contribution to environmental protection.

4. Conclusions

Despite the abundance of marketable wastes in urban markets, such as olive waste, initiatives to convert waste to energy remain minimal. These types of wastes have very high disposal costs, and because they are generated by small enterprises, they are not effectively processed due to financial constraints. The potential for renewable energy in Saudi Arabia’s green markets is enormous, but the actual implementation is inadequate. As a result, employing anaerobic digestion conditions with the co-digestion of processed olive waste, the present study developed an efficient and feasible model for biogas production. To develop the model, the hard olive pomace sample was collected, dried in an oven, crushed to fine particles, and analyzed using Fourier Transform Infrared Spectrophotometer analysis. Due to the high volatile solid (VS) percentage of organic waste material incorporated throughout the calculation, a significant amount of electrical energy of 769 kWh/t was found to be generated per ton of olive pomace. In addition, the land area required for landfilling olive waste could be reduced by 0.3086 m2 per day, whereas landfill leachate generation could be reduced by 0.0009 m3 per day. Mixing feedstock can be an effective solution to maximize biogas production.

The initial investment cost is a significant barrier to biogas uptake in South Arabia, regardless of government support schemes for renewable energy technologies. Although biogas production technology has the potential to meet the energy needs of Saudi Arabia, particularly those of rural residents, the design and installation of digesters are costly. Numerous biogas digesters fail due to a lack of substrates, and therefore the amount of substrate entering the digesters should be stable for long-term functioning. There are also other drawbacks of biogas utilization, including a lack of technological advancements, economic infeasibility, the formation of toxic intermediate composites, limited biogas production, and the unstable nature of biogas. Furthermore, Saudi Arabia has a dearth of biogas research, despite the fact that digesters are being constructed. There is also a lack of available scientific literature on biogas digesters and laboratory batch digesters. A lack of awareness programs is another challenge to the advancement of biogas technology. It is necessary to educate society about biogas technology’s health, environmental, economic, and social benefits to establish a sustainable and feasible biogas system.

Author Contributions

M.A.U.: Conceptualization, Writing—original draft, sample collection; S.Y.A.S.: Writing—original draft and methodology; S.F.A.: Writing—original draft and validation; Z.I.R.: Writing—review and editing; M.A.K.C.: Data analysis; M.M.: Writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

The authors extend their appreciation to the Deanship of Scientific Research at Jouf University for funding this work through research grant no (DSR2020-02-2604).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

There is no known conflict of interests.

References

- Espeso, J.; Isaza, A.; Lee, J.Y.; Sörensen, P.M.; Jurado, P.; Avena-Bustillos, R.D.J.; Olaizola, M.; Arboleya, J.C. Olive Leaf Waste Management. Front. Sustain. Food Syst. 2021, 5, 162. [Google Scholar] [CrossRef]

- Souilem, S.; El-Abbassi, A.; Kiai, H.; Hafidi, A.; Sayadi, S.; Galanakis, C.M. Olive oil production sector: Environmental effects and sustainability challenges. Olive Mill Waste Recent Adv. Sustain. Manag. 2017, 1–28. [Google Scholar]

- Khdair, A.; Abu-Rumman, G. Sustainable environmental management and valorization options for olive mill byproducts in the Middle East and North Africa (MENA) region. Processes 2020, 8, 671. [Google Scholar] [CrossRef]

- Doula, M.K.; Moreno-Ortego, J.L.; Tinivella, F.; Inglezakis, V.J.; Sarris, A.; Komnitsas, K. Olive mill waste: Recent advances for the sustainable development of olive oil industry. Olive Mill Waste Recent Adv. Sustain. Manag. 2017, 29–56. [Google Scholar]

- Tekin, A.R.; Dalgıç, A.C. Biogas production from olive pomace. Resour. Conserv. Recycl. 2000, 30, 301–313. [Google Scholar] [CrossRef]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef] [PubMed]

- Ong, H.C.; Masjuki, H.H.; Mahlia, T.M.I.; Silitonga, A.S.; Chong, W.T.; Yusaf, T. Engine performance and emissions using Jatropha curcas, Ceiba pentandra and Calophyllum inophyllum biodiesel in a CI diesel engine. Energy 2014, 69, 427–445. [Google Scholar] [CrossRef]

- Maghanaki, M.M.; Ghobadian, B.; Najafi, G.; Galogah, R.J. Potential of biogas production in Iran. Renew. Sustain. Energy Rev. 2013, 28, 702–714. [Google Scholar] [CrossRef]

- Rodríguez, G.; Lama, A.; Rodríguez, R.; Jiménez, A.; Guillén, R.; Fernández-Bolaños, J. Olive stone an attractive source of bioactive and valuable compounds. Bioresour. Technol. 2008, 99, 5261–5269. [Google Scholar] [CrossRef] [PubMed]

- Nasir, I.M.; Ghazi, T.I.M.; Omar, R.; Idris, A. Anaerobic digestion of cattle manure: Influence of inoculums concentration. Int. J. Engin. Technol. 2013, 10, 22–26. [Google Scholar]

- Khalil, M.; Berawi, M.A.; Heryanto, R.; Rizalie, A. Waste to energy technology: The potential of sustainable biogas production from animal waste in Indonesia. Renew. Sustain. Energy Rev. 2019, 105, 323–331. [Google Scholar] [CrossRef]

- Kuo, J.; Dow, J. Biogas production from anaerobic digestion of food waste and relevant air quality implications. J. Air Waste Manag. Assoc. 2017, 67, 1000–1011. [Google Scholar] [CrossRef]

- Siddiki, S.Y.A.; Mofijur, M.; Kumar, P.S.; Ahmed, S.F.; Inayat, A.; Kusumo, F.; Badruddin, I.A.; Khan, T.M.Y.; Nghiem, L.D.; Ong, H.C.; et al. Microalgae biomass as a sustainable source for biofuel, biochemical and biobased value-added products: An integrated biorefinery concept. Fuel 2022, 307, 121782. [Google Scholar] [CrossRef]

- Herrero, M.; Laca, A.; Laca, A.; Díaz, M. Application of Life Cycle Assessment to Food Industry Wastes; Elsevier: Amsterdam, The Netherlands, 2020; pp. 331–353. [Google Scholar]

- Ellacuriaga, M.; García-Cascallana, J.; Gómez, X. Biogas Production from Organic Wastes: Integrating Concepts of Circular Economy. Fuels 2021, 2, 144–167. [Google Scholar] [CrossRef]

- Pramanik, S.K.; Suja, F.B.; Zain, S.M.; Pramanik, B.K. The anaerobic digestion process of biogas production from food waste: Prospects and constraints. Bioresour. Technol. Rep. 2019, 8, 100310. [Google Scholar] [CrossRef]

- Bhardwaj, S.; Das, P. A Review: Advantages and Disadvantages of Biogas. Int. Res. J. Eng. Technol. 2017, 4, 890–893. [Google Scholar]

- Huttunen, S.; Manninen, K.; Leskinen, P. Combining biogas LCA reviews with stakeholder interviews to analyse life cycle impacts at a practical level. J. Clean. Prod. 2014, 80, 5–16. [Google Scholar] [CrossRef]

- Sokkanathan, G.; Sharmila, V.G.; Kaliappan, S.; Banu, J.R.; Yeom, I.T.; Rani, R.U. Combinative treatment of phenol-rich retting-pond wastewater by a hybrid upflow anaerobic sludge blanket reactor and solar photofenton process. J. Environ. Manag. 2018, 206, 999–1006. [Google Scholar] [CrossRef] [PubMed]

- Al Afif, R.; Linke, B. Biogas production from three-phase olive mill solid waste in lab-scale continuously stirred tank reactor. Energy 2019, 171, 1046–1052. [Google Scholar] [CrossRef]

- Al-Addous, M.; Alnaief, M.; Class, C.; Nsair, A.; Kuchta, K.; Alkasrawi, M. Technical possibilities of biogas production from olive and date waste in Jordan. BioResources 2017, 12, 9383–9395. [Google Scholar] [CrossRef]

- Valenti, F.; Arcidiacono, C.; Chinnici, G.; Cascone, G.; Porto, S.M.C. Quantification of olive pomace availability for biogas production by using a GIS-based model. Biofuels Bioprod. Biorefining 2017, 11, 784–797. [Google Scholar] [CrossRef]

- Siciliano, A.; Stillitano, M.; De Rosa, S. Biogas production from wet olive mill wastes pretreated with hydrogen peroxide in alkaline conditions. Renew. Energy 2016, 85, 903–916. [Google Scholar] [CrossRef]

- Nunes, N.S.P.; Ansilago, M.; de Oliveira, N.N.; Leite, R.S.R.; da Paz, M.F.; Fonseca, G.G. Biofuel Production; Academic Press: Cambridge, MA, USA, 2021; pp. 145–171. [Google Scholar]

- Appels, L.; Lauwers, J.; Degrève, J.; Helsen, L.; Lievens, B.; Willems, K.; Van Impe, J.; Dewil, R. Anaerobic digestion in global bio-energy production: Potential and research challenges. Renew. Sustain. Energy Rev. 2011, 15, 4295–4301. [Google Scholar] [CrossRef]

- Mahmudul, H.M.; Rasul, M.G.; Akbar, D.; Narayanan, R.; Mofijur, M. A comprehensive review of the recent development and challenges of a solar-assisted biodigester system. Sci. Total Environ. 2021, 753, 141920. [Google Scholar] [CrossRef] [PubMed]

- Alagöz, B.A.; Yenigün, O.; Erdinçler, A. Enhancement of anaerobic digestion efficiency of wastewater sludge and olive waste: Synergistic effect of co-digestion and ultrasonic/microwave sludge pre-treatment. Waste Manag. 2015, 46, 182–188. [Google Scholar] [CrossRef]

- Gunay, A.; Karadag, D. Recent developments in the anaerobic digestion of olive mill effluents. Process Biochem. 2015, 50, 1893–1903. [Google Scholar] [CrossRef]

- Carlini, M.; Castellucci, S.; Moneti, M. Anaerobic Co-digestion of Olive-mill Solid Waste with Cattle Manure and Cattle Slurry: Analysis of Bio-methane Potential. Energy Procedia 2015, 81, 354–367. [Google Scholar] [CrossRef] [Green Version]

- Rubio, J.A.; Romero, L.I.; Wilkie, A.C.; García-Morales, J.L. Mesophilic Anaerobic Co-digestion of Olive-Mill Waste with Cattle Manure: Effects of Mixture Ratio. Front. Sustain. Food Syst. 2019, 3, 9. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Mofijur, M.; Tarannum, K.; Chowdhury, A.T.; Rafa, N.; Nuzhat, S.; Kumar, P.S.; Vo, D.-V.N.; Lichtfouse, E.; Mahlia, T.M.I. Biogas upgrading, economy and utilization: A review. Environ. Chem. Lett. 2021, 19, 4137–4164. [Google Scholar] [CrossRef]

- Osra, F.A.; Kajjumba, G.W. Landfill site selection in Makkah using geographic information system and analytical hierarchy process. Waste Manag. Res. 2019, 38, 245–253. [Google Scholar] [CrossRef]

- World Weather & Climate Information. Climate and Average Weather in Al Jawf Province, Saudi Arabia. 2021. Available online: https://weather-and-climate.com/average-monthly-Rainfall-Temperature-Sunshine-region-al-jawf-province-sa,Saudi-Arabia (accessed on 15 October 2021).

- Banks, C. Anaerobic Digestion and Energy-Valorgas. 2009. Available online: http://www.valorgas.soton.ac.uk/Pub_docs/JyU%20SS%202011/CB%204.pdf (accessed on 15 October 2021).

- Buswell, A.M.; Mueller, H.F. Mechanism of Methane Fermentation. Ind. Eng. Chem. 1952, 44, 550–552. [Google Scholar] [CrossRef]

- Ngumah, C.; Ogbulie, J.; Orji, J.; Amadi, E. Potential of organic waste for biogas and biofertilizer production in Nigeria. Environ. Res. Eng. Manag. 2013, 63, 60–66. [Google Scholar] [CrossRef] [Green Version]

- Deublein, D.; Steinhauser, A. Biogas from Waste and Renewable Resources: An Introduction; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Yong, Z.J.; Bashir, M.J.K.; Hassan, M.S. Biogas and biofertilizer production from organic fraction municipal solid waste for sustainable circular economy and environmental protection in Malaysia. Sci. Total Environ. 2021, 776, 145961. [Google Scholar] [CrossRef]

- Tengku Ibrahim, T.N.; Mahmood, N.; Othman, F. Estimation of leachate generation from msw landfills in selangor. Asian J. Microbiol. Biotechnol. Environ. Sci. 2016, 19, 43–48. [Google Scholar]

- Sert, M.; Selvi Gökkaya, D.; Cengiz, N.; Ballice, L.; Yüksel, M.; Sağlam, M. Hydrogen production from olive-pomace by catalytic hydrothermal gasification. J. Taiwan Inst. Chem. Eng. 2018, 83, 90–98. [Google Scholar] [CrossRef]

- Bong, C.P.C.; Lim, L.Y.; Lee, C.T.; Klemeš, J.J.; Ho, C.S.; Ho, W.S. The characterisation and treatment of food waste for improvement of biogas production during anaerobic digestion—A review. J. Clean. Prod. 2018, 172, 1545–1558. [Google Scholar] [CrossRef]

- Jutidamrongphan, W. Sustainable Waste Management and Waste to Energy Recovery in Thailand. In Advances in Biofuels and Bioenergy; IntechOpen: London, UK, 2018. [Google Scholar]

- Bautista Angeli, J.R.; Morales, A.; LeFloc’h, T.; Lakel, A.; Andres, Y. Anaerobic digestion and integration at urban scale: Feedback and comparative case study. Energy Sustain. Soc. 2018, 8, 29. [Google Scholar] [CrossRef] [Green Version]

- Fisgativa, H.; Tremier, A.; Dabert, P. Characterizing the variability of food waste quality: A need for efficient valorisation through anaerobic digestion. Waste Manag. 2016, 50, 264–274. [Google Scholar] [CrossRef]

- Negri, C.; Ricci, M.; Zilio, M.; D’Imporzano, G.; Qiao, W.; Dong, R.; Adani, F. Anaerobic digestion of food waste for bio-energy production in China and Southeast Asia: A review. Renew. Sustain. Energy Rev. 2020, 133, 110138. [Google Scholar] [CrossRef]

- Xu, F.; Li, Y.; Ge, X.; Yang, L.; Li, Y. Anaerobic digestion of food waste–Challenges and opportunities. Bioresour. Technol. 2018, 247, 1047–1058. [Google Scholar] [CrossRef]

- Munajad, A.; Subroto, C. Fourier Transform Infrared (FTIR) Spectroscopy Analysis of Transformer Paper in Mineral Oil-Paper Composite Insulation under Accelerated Thermal Aging. Energies 2018, 11, 364. [Google Scholar] [CrossRef] [Green Version]

- Nandiyanto, A.B.D.; Oktiani, R.; Ragadhita, R. How to Read and Interpret FTIR Spectroscope of Organic Material. Indones. J. Sci. Technol. 2019, 4, 97–118. [Google Scholar] [CrossRef]

- Merck. IR Spectrum Table & Chart. 2021. Available online: https://www.sigmaaldrich.com/BD/en/technical-documents/technical-article/analytical-chemistry/photometry-and-reflectometry/ir-spectrum-table#ir-spectrum-table-by-range (accessed on 15 October 2021).

- Coates, J. Interpretation of Infrared Spectra, A Practical Approach. In Encyclopedia of Analytical Chemistry; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Thi, N.B.D.; Lin, C.-Y.; Kumar, G. Electricity generation comparison of food waste-based bioenergy with wind and solar powers: A mini review. Sustain. Environ. Res. 2016, 26, 197–202. [Google Scholar] [CrossRef] [Green Version]

- Surroop, D.; Mohee, R. Technical and economic assessment of power generation from biogas. Int. Conf. Environ. Sci. Technol. IPCBEE 2012, 30, 108–112. [Google Scholar]

- Ma, Y.; Shen, Y.; Liu, Y. Food Waste to Biofertilizer: A Potential Game Changer of Global Circular Agricultural Economy; ACS Publications: Washington, DC, USA, 2020. [Google Scholar]

- Hamed, O.; Foad, Y.; Hamed, E.M.; Al-Hajj, N.J.B. Cellulose powder from olive industry solid waste. BioResources 2012, 7, 4190–4201. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).