Design and Operation of a Polygeneration System in Spanish Climate Buildings under an Exergetic Perspective

Abstract

:1. Introduction

- They have a better performance than separate generation and, therefore, they save primary energy and reduce the energy bill.

- They serve to implement actions for the efficient use of waste heat, improving the competitiveness of the system.

- Partial or complete independence from the electricity supply is achieved and transmission and distribution losses are reduced.

- Polygeneration enhances energy diversity [4].

- Among the disadvantages we can mention the following:

- A need for greater investment.

- A strong dependence on regulations and, therefore, a higher risk of regulatory change [5].

- A risk of increased local pollution.

- A risk of instability in the electrical grid and added technical risks.

- Thermal characterization of the office envelope components, both opaque and semi-transparent, are considered. Energy demand for the indoor air quality and thermal requirements are taken into account.

- In order to cover the demands, the facility, which consists of polygeneration and renewable components, is defined. The operation and the energy performance of the facility is also analyzed, based on energy and exergy indicators.

- Ventilation, air movement and thermal comfort are checked from an exergetic point of view, facilitating a deep energy and exergy analysis of the air-handling unit components.

2. Materials and Methods

2.1. Energy and Exergy Analysis of a Thermal Installation

- Physical-specific enthalpy and exergy of humid air:

- Physical enthalpy and exergy of incompressible fluids:

- Energy and exergy for a work flow:

- Chemical exergy of fuels:

- Specific exergy radiation per unit of area:

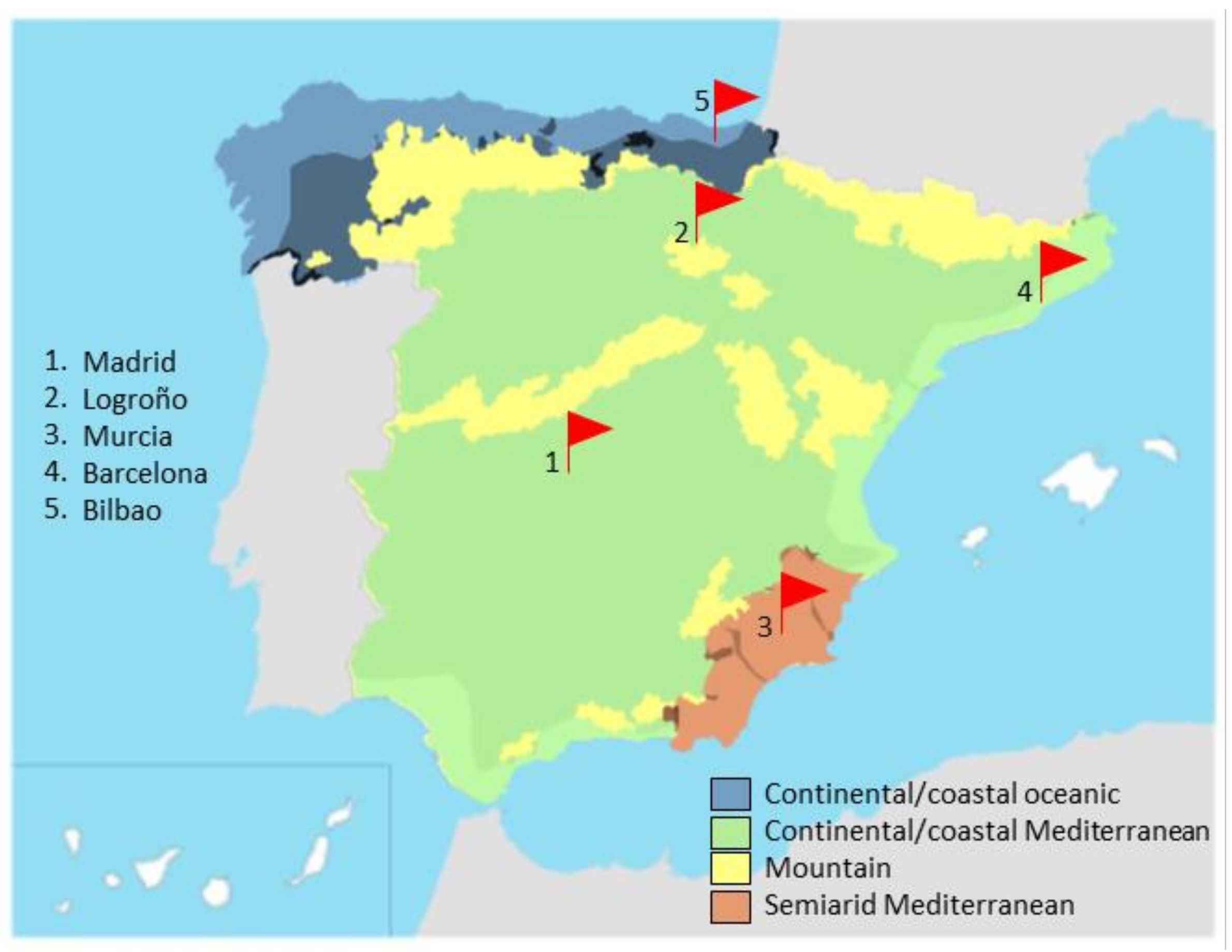

2.2. Defining the Case Study

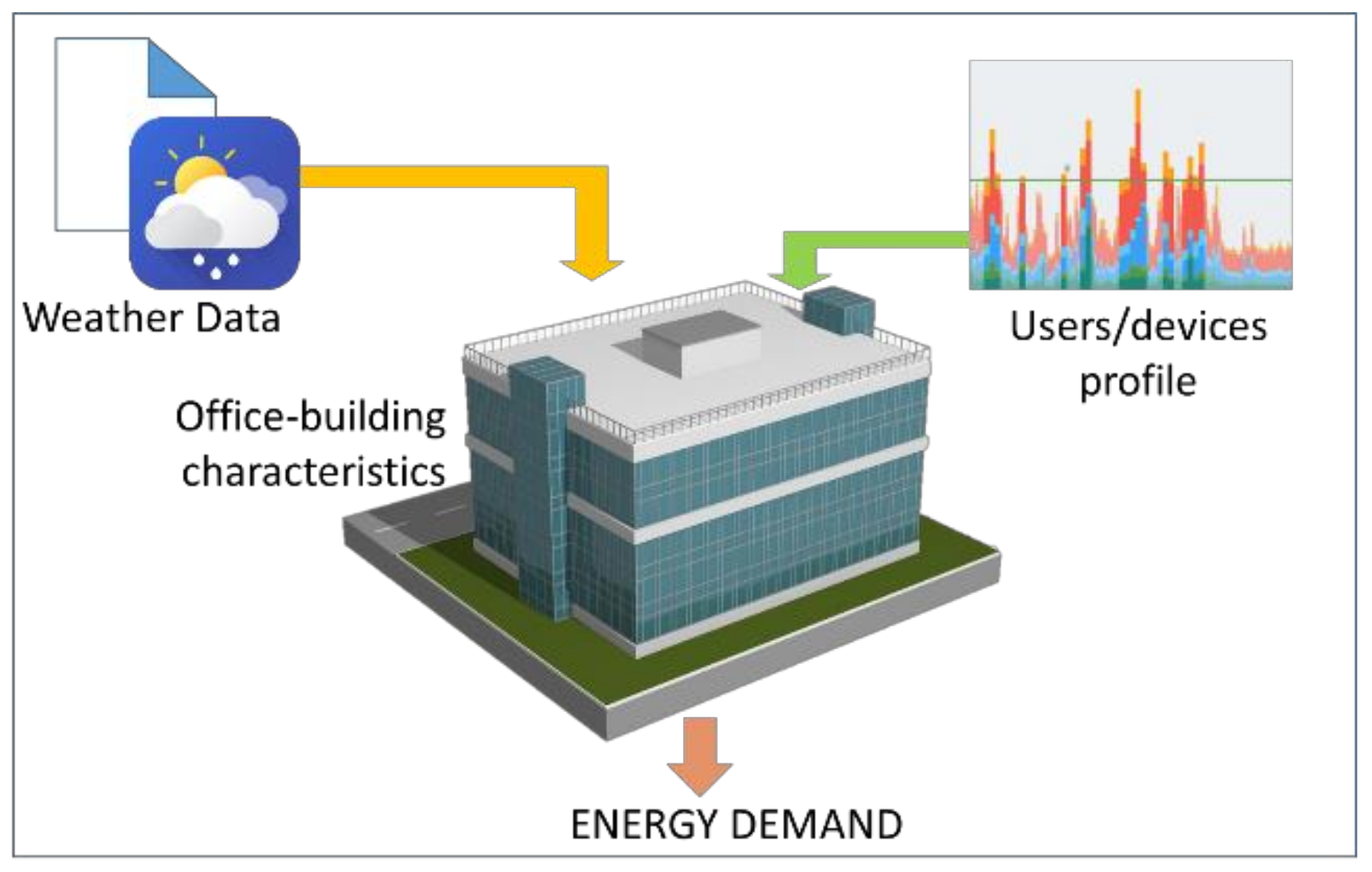

2.3. Energy Demand

- Building architectonics and thermal characteristics of the envelop components, defining the orientations, sizes, façade composition, non-opaque zones, etc.

- Additionally, indoor appliances were included, defining the usage profile of the computers and lighting devices, worker presence profile, and the specific usage of the office building.

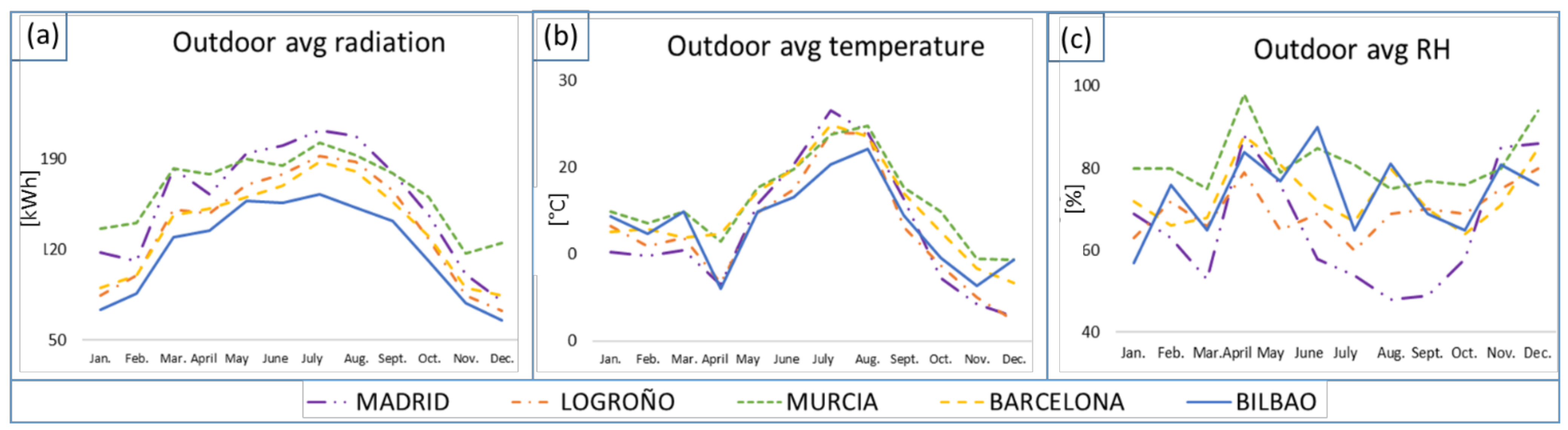

- Weather data, such as dry-bulb temperature, humidity, radiation, etc., of the location.

- According to the Spanish norm, offices require an IDA2 quality of indoor air, which means a minimum ventilation rate of or if the room is empty [12]. In addition, the operative temperature during wintertime needs to be between 21 and 23 °C and between 23 and 25 °C during summer [13], while the relative humidity should be between 45 and 55% and 40 and 60%, respectively.

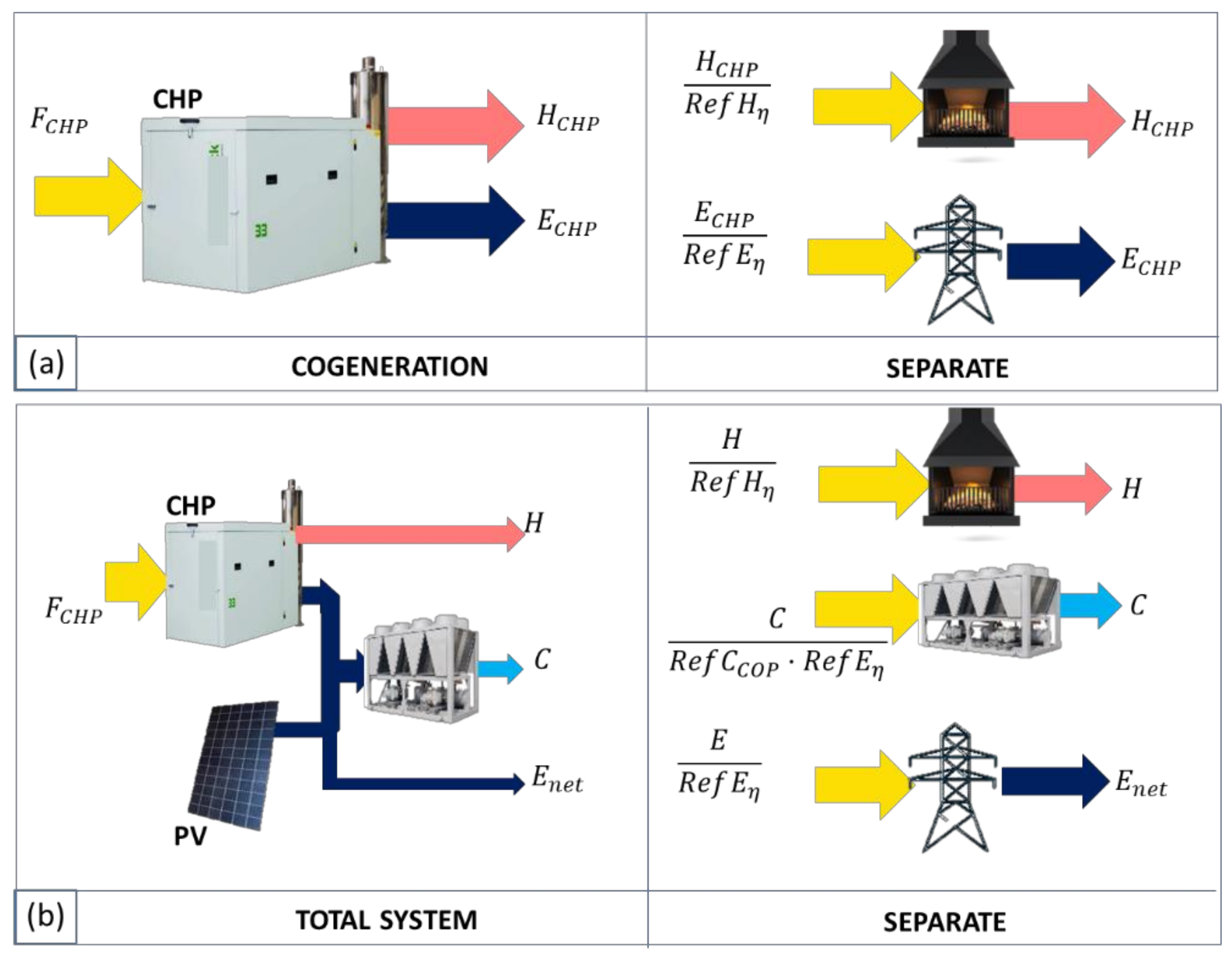

2.4. Characteristics of the Polygeneration Facility

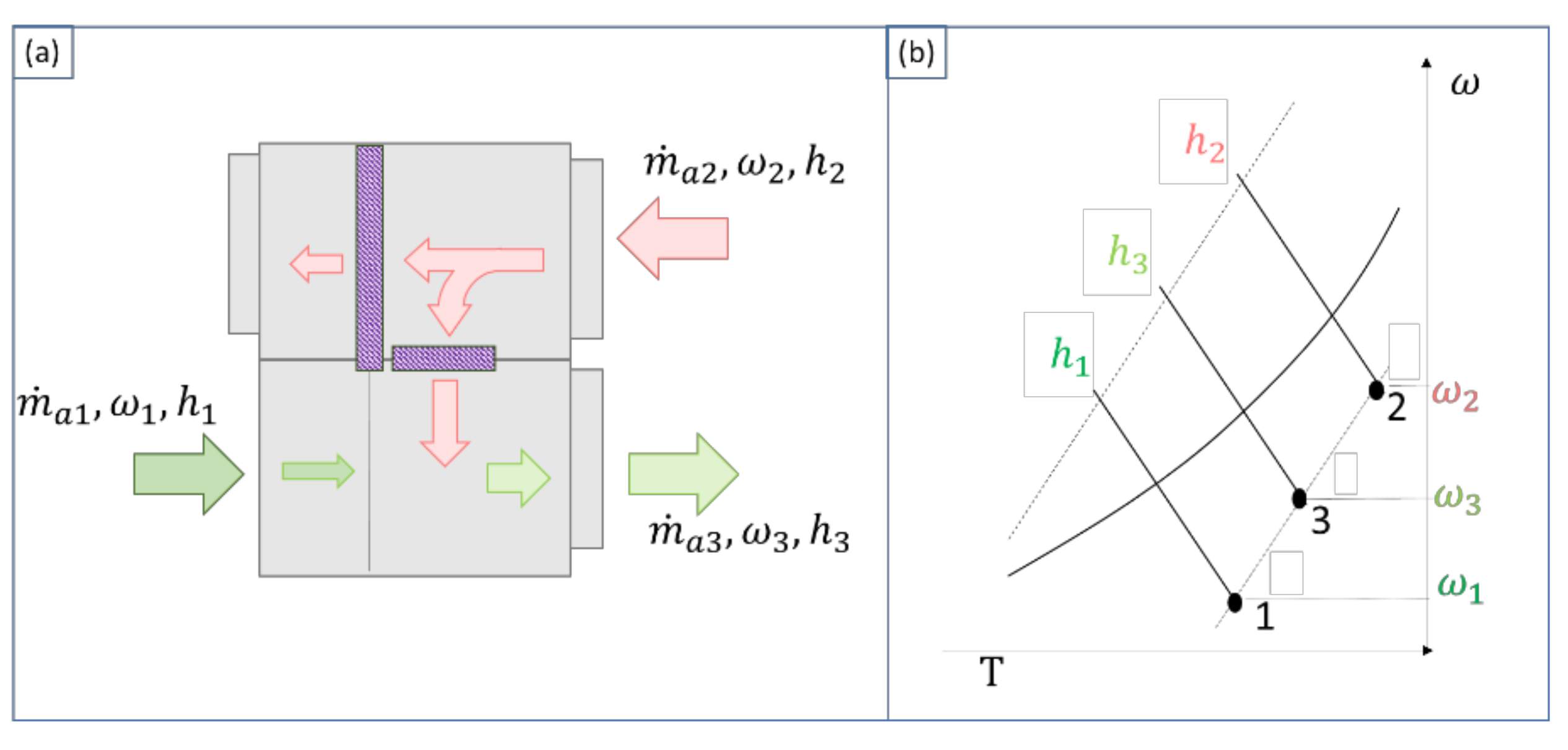

2.5. Energy and Exergy Analysis of the Air-Handling Unit (AHU)

- Pre-conditioning the intake air by exchanging heat with the exhaust air and partially mixing it with the extracted indoor air.

- Increasing or decreasing the temperature of the air by means of sensible heating or cooling.

- Decreasing or increasing the humidity of the incoming air by means of cooling dehumidification or humidification by adding water.

2.5.1. Adiabatic Mixing of Two Flow Rates

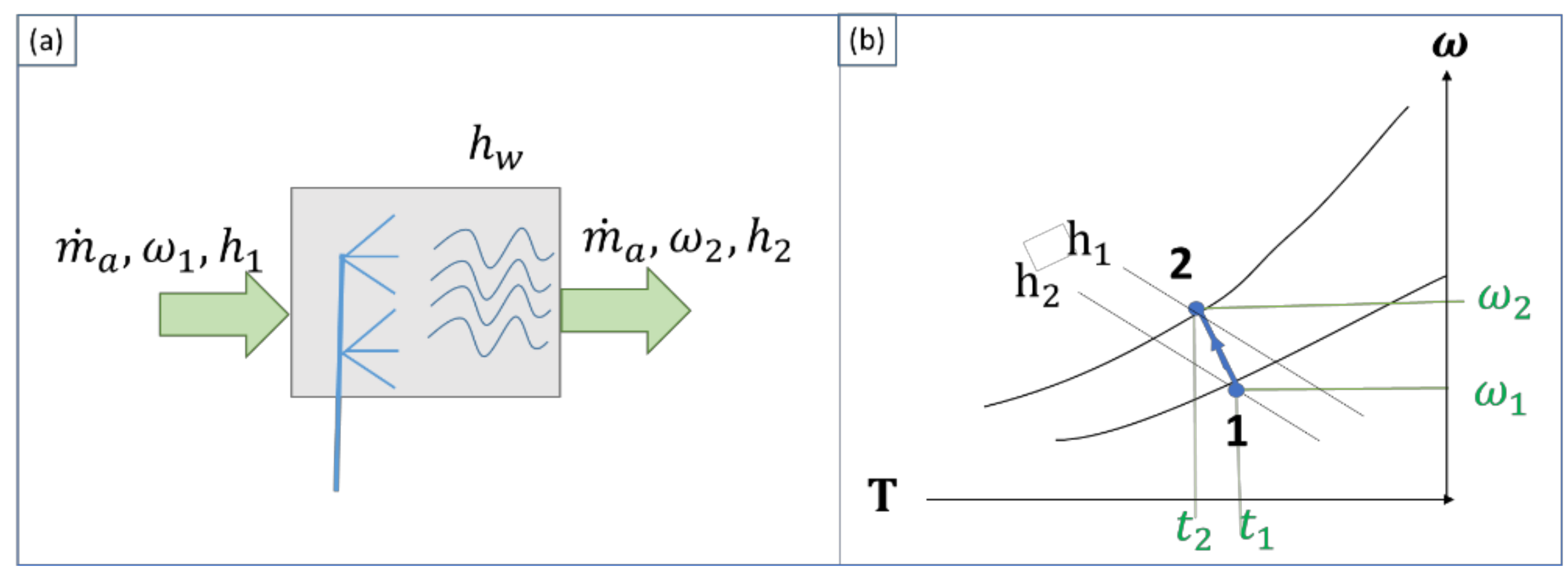

2.5.2. Sensible Heating or Cooling of the Air

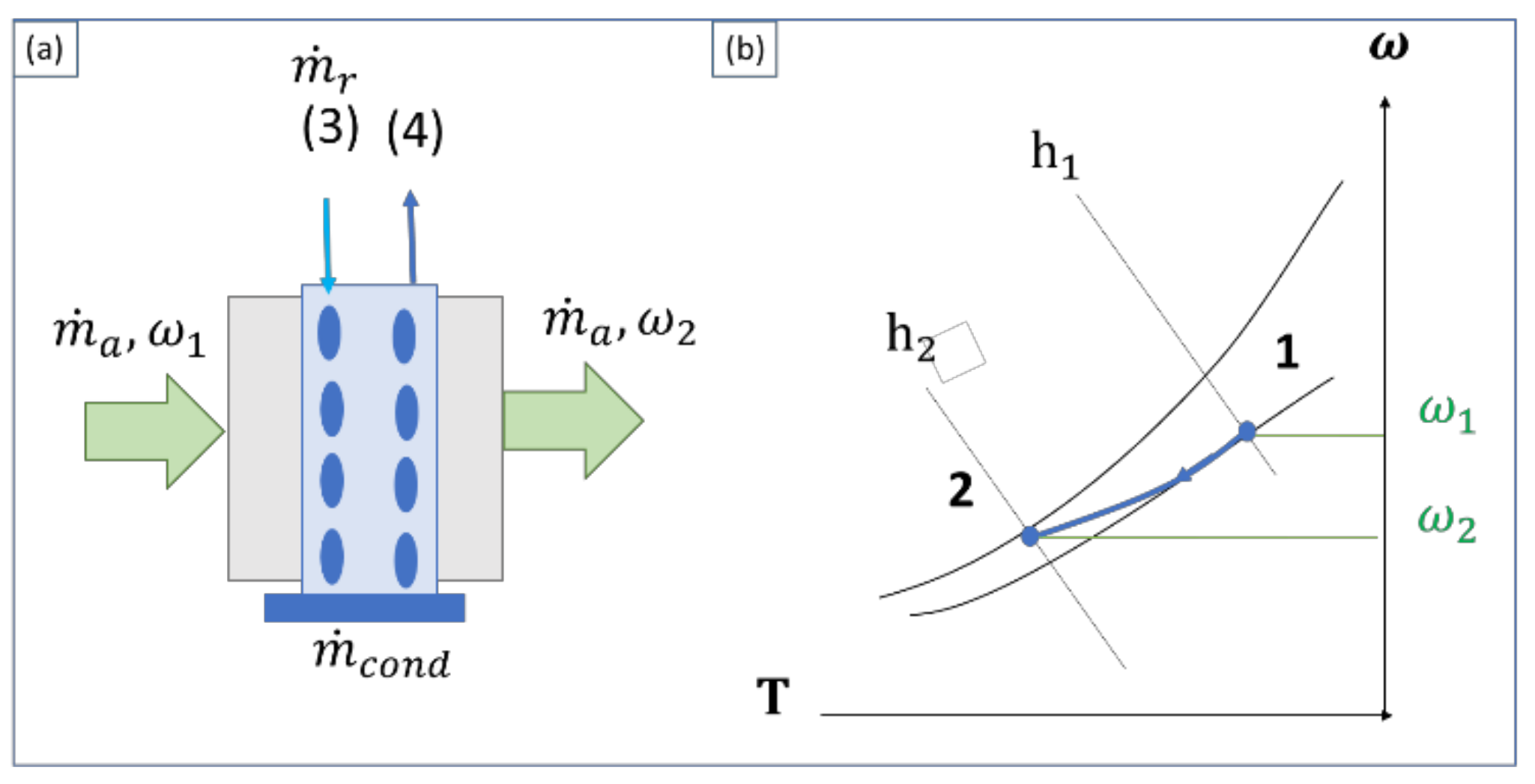

2.5.3. Cooling and Dehumidification

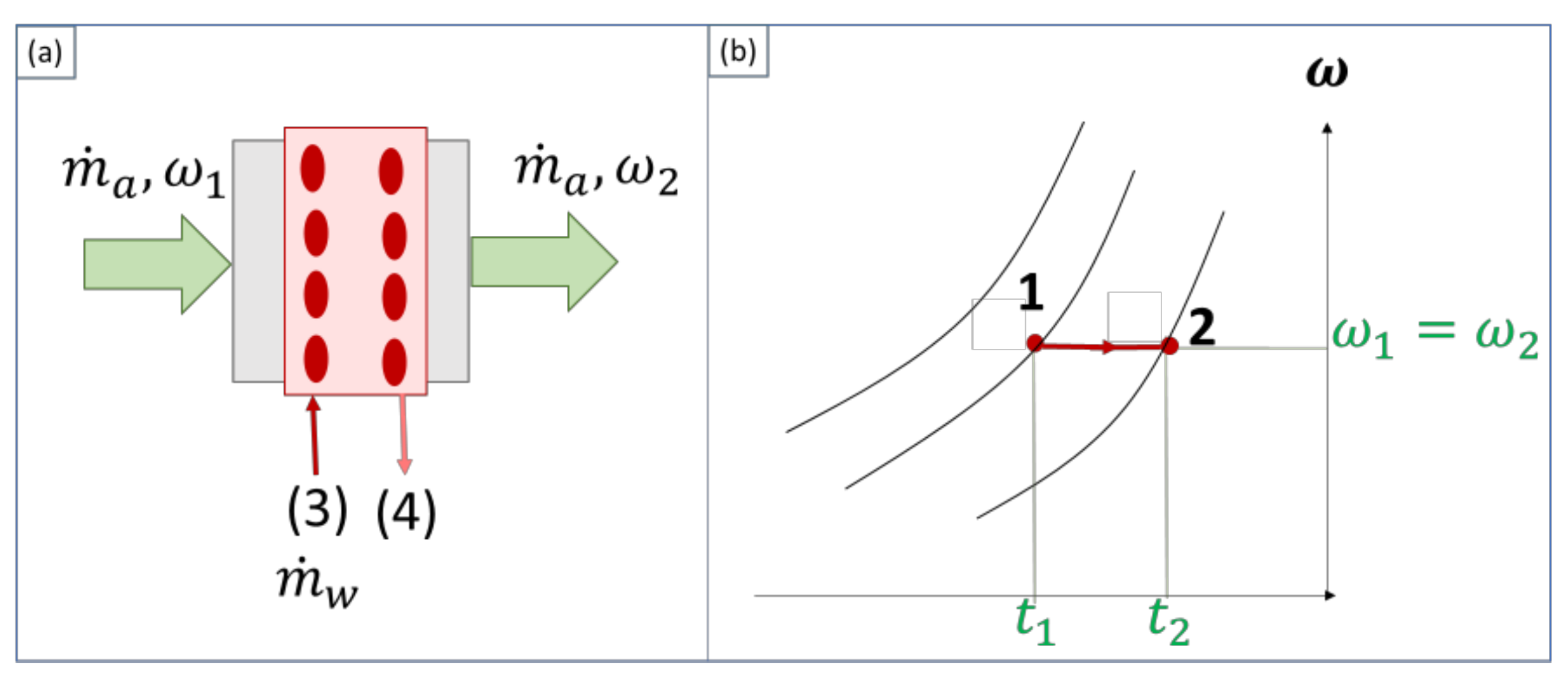

2.5.4. Humidification or Dehumidification by Mixing with Water

3. Results

3.1. Case Study

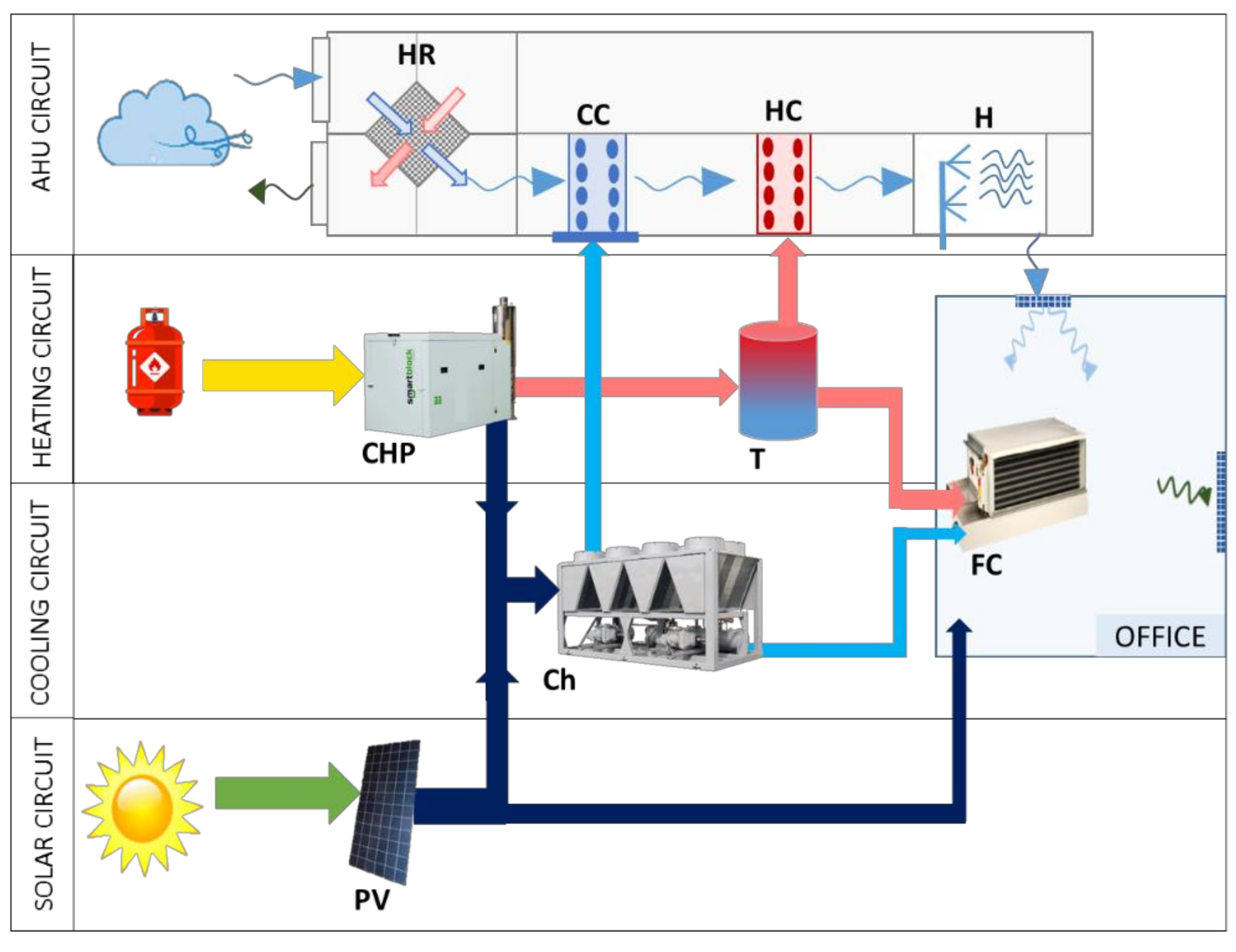

3.2. Description of the Complete Installation

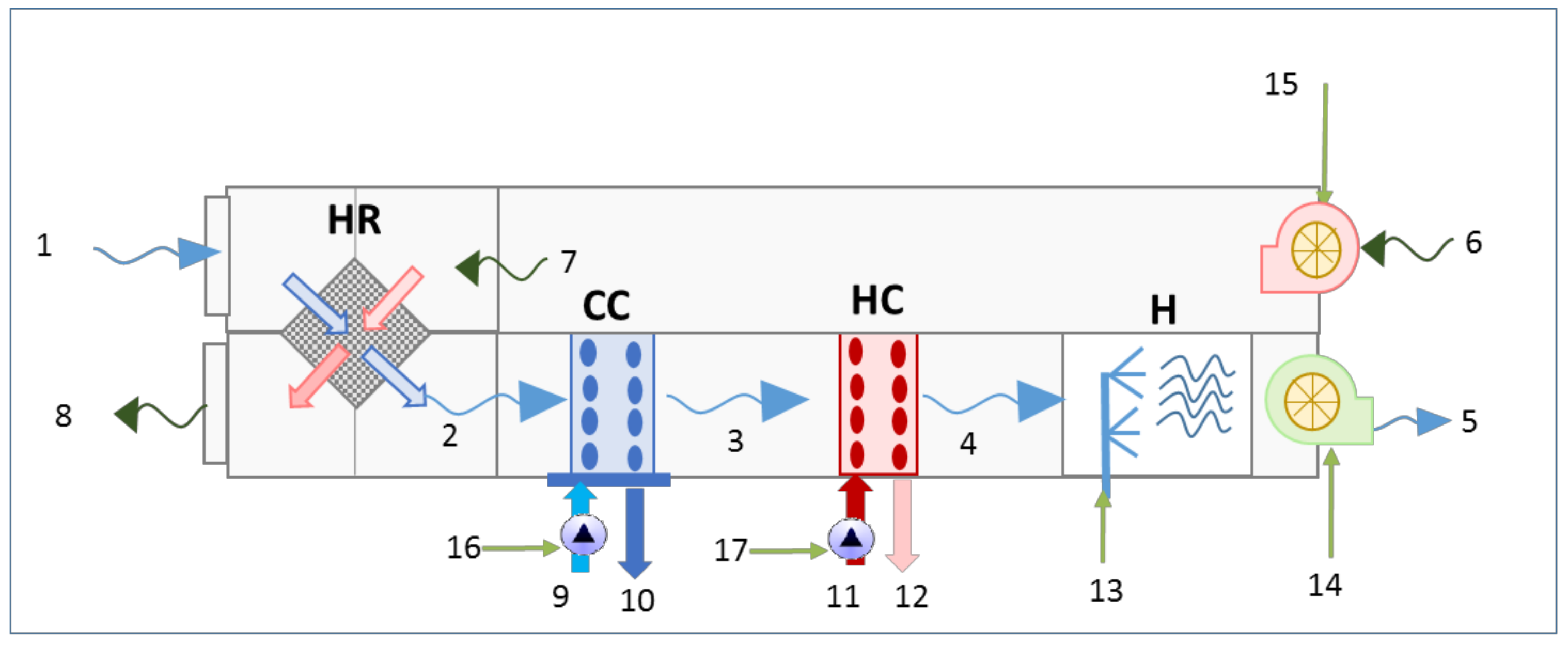

- AHU circuit: which consists of the heat recovery (HR), a cooling coil (CC), a heating coil (HC) and a humidifier (H) to condition the intake air; this circuit provides the required ventilation for IDA2 indoor quality.

- Heating circuit: formed by two natural gas internal combustion cogeneration engines (CHP) of 50 kWe electric power and 87.7 kWt thermal nominal power each. A 2500 L thermal storage tank introduces the inertia to the circuit and feeds the HC and the fan coils (FC) with hot water to satisfy the heating demand.

- Cooling circuit: the cogenerated electricity and the photovoltaic panels (PV) feed a 110 kW chiller (Ch); when self-produced electricity is not enough, it is taken from the net. The chiller provides cold water to the CC and to the FC, to satisfy the cooling demand.

- Solar circuit: PV panels with 60 m2 total area that generate electricity for the Ch and/or the office lighting.

- The control system has the following schedule:

- In wintertime, programmed between 1 November and 15 May, heating is provided, if required. Summertime is between 16 May and 31 October, and cooling is provided to the building in this period.

- Ventilation (provided by the AHU system) is activated during the whole year following the IDA 2 requirement.

- The indoor air temperature is maintained between 19 and 23 °C in winter and between 21 and 25 °C in summer. In addition, the relative humidity is between 45 and 66% in winter and 40 and 60% in summer.

3.3. Facility Operation Analysis

- The adequacy of the indoor air control is checked in all the Spanish locations of the office building.

- An energy analysis of the total system is performed over the year in a dynamic way for the different locations of the office buildings and the main polygeneration indicators are calculated.

- Finally, an exergy analysis is carried out focusing on the AHU components.

Energy and Exergy Analysis of the AHU

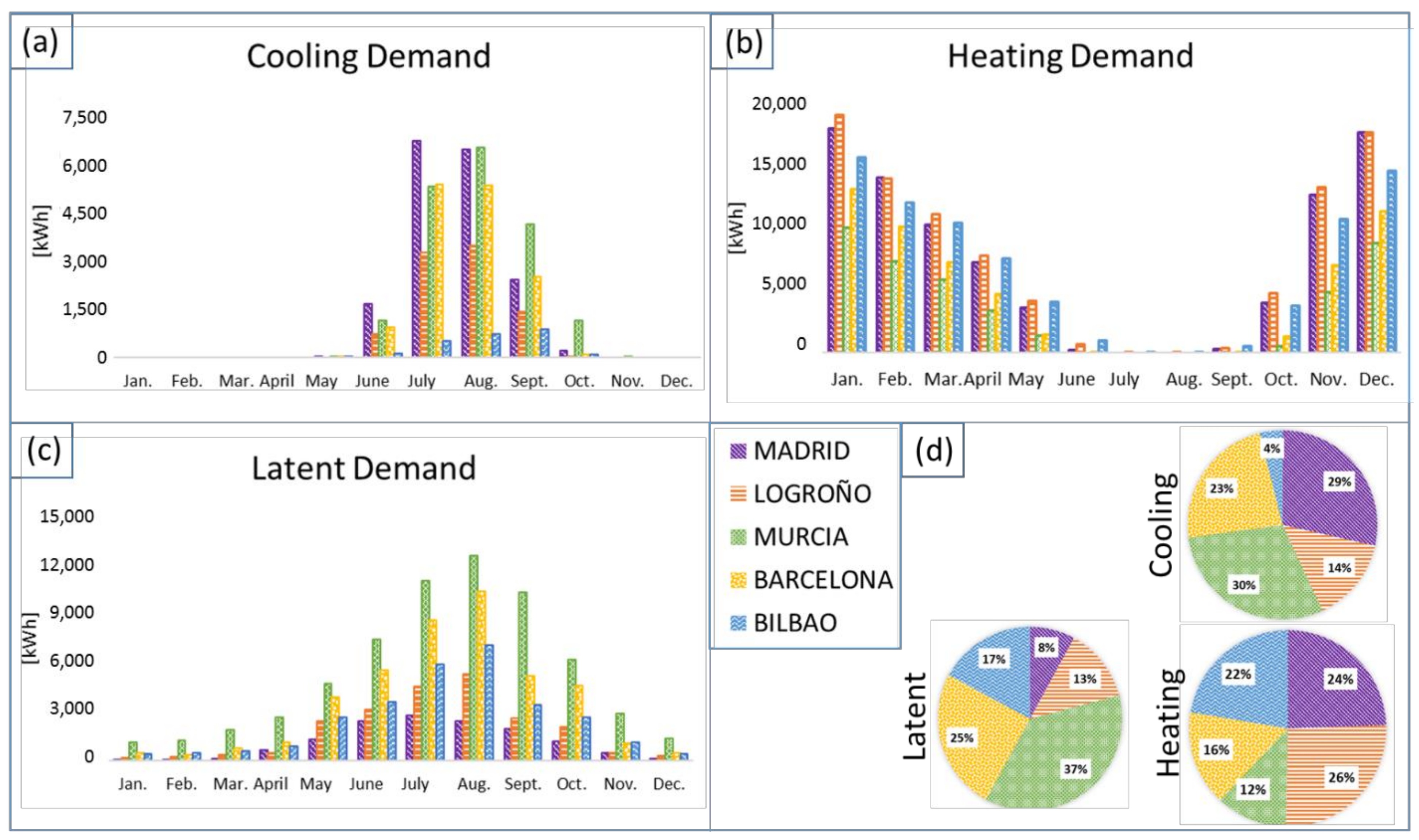

3.4. Numerical Results for Heating and Cooling Demands in Different Climates

3.5. Numerical Results of Facility Operation Results

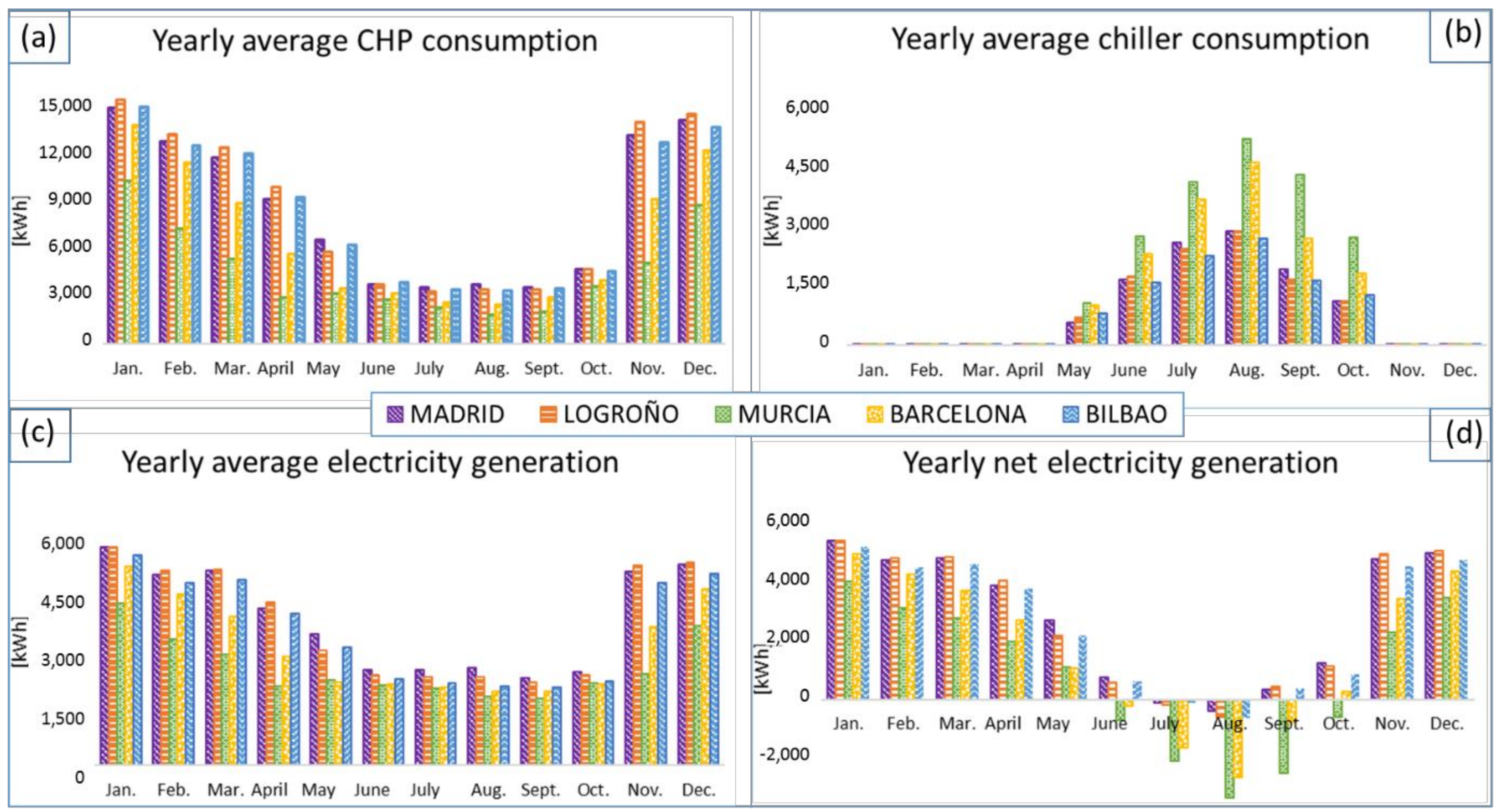

3.5.1. Energy Analysis Results

- During the whole year, the CHP or the PV cells supply the electricity consumed by the chiller in Bilbao, whereas in the rest of the cities, electricity from the grid is needed in the warmest months. Therefore, the facility in Bilbao can be considered a complete polygeneration that consumes only natural gas in the CHP.

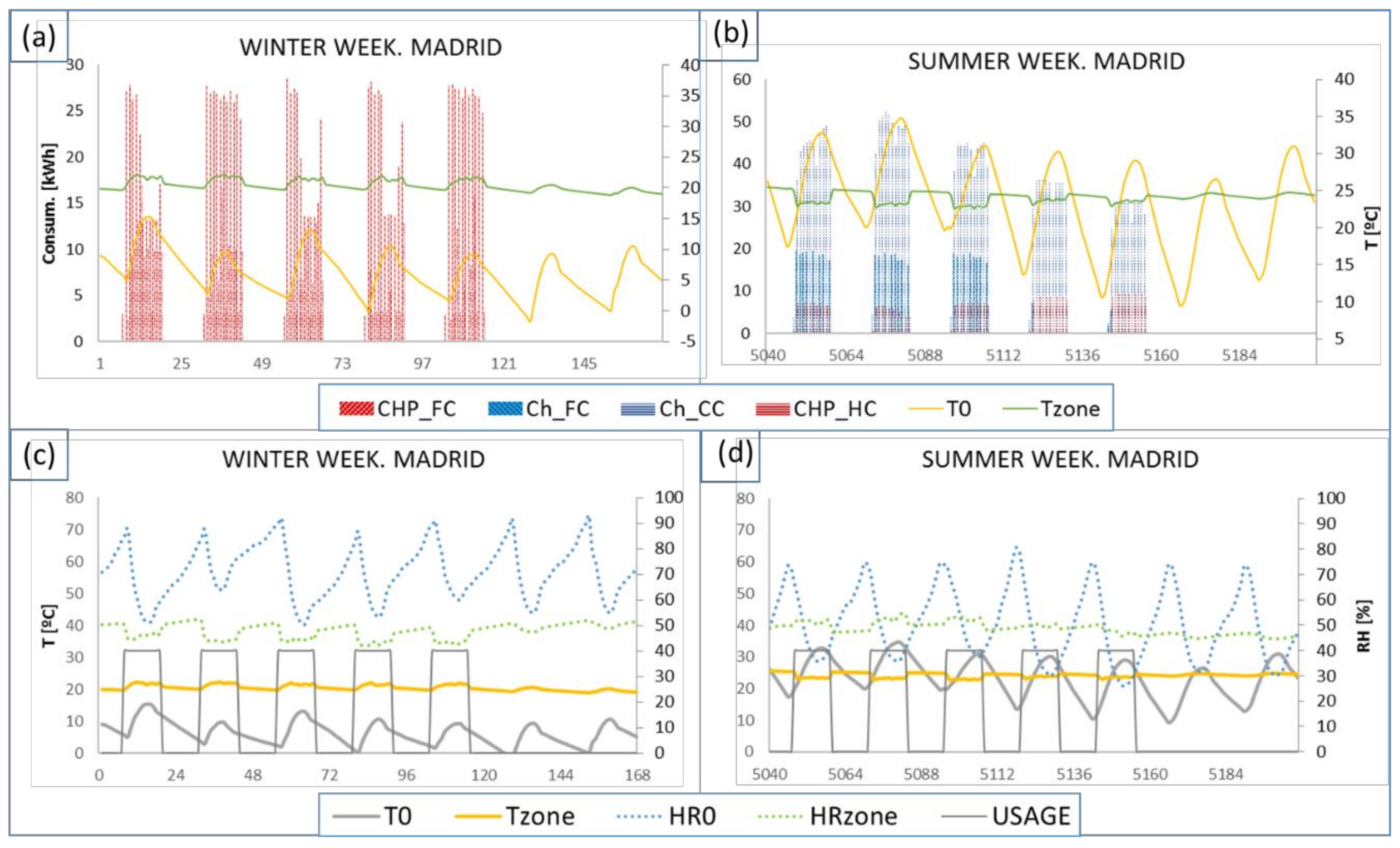

- In winter, the chiller is turned off (Ch_FC and Ch_CC are null), part of the heating is provided by the fan coil supported by the CHP (CHP_FC) and the rest by the AHU heating coil (CHP_HC) in order to provide the appropriate RH indoor conditions. On weekends, the heating system is off (Figure 15a).

- In winter, although the outside relative humidity RH0 is high and the temperature T0 is low, the indoor RH and T are maintained within the comfort range. The usage of the building is limited from Monday to Friday (Figure 15c).

- In summer, the cooling demand is provided partly by the fan coil supported by the Ch (Ch_FC) and the rest by the cooling coil of the AHU (Ch_CC). The CHP is turned on in order to dehumidify the incoming outdoor air until the indoor comfort conditions are reached (Figure 15b,d).

3.5.2. Polygeneration Indicators

- is positive in all the places over the whole year, so polygeneration creates savings related to the separate generation of heating, cooling and electricity (Figure 16a).

- The equivalent electric fuel consumption in summer () is lower since less electricity is cogenerated (because heating demand is lower) and cooling demand is high (Figure 16b).

3.5.3. Energy and Exergy Analysis of IAQ Components

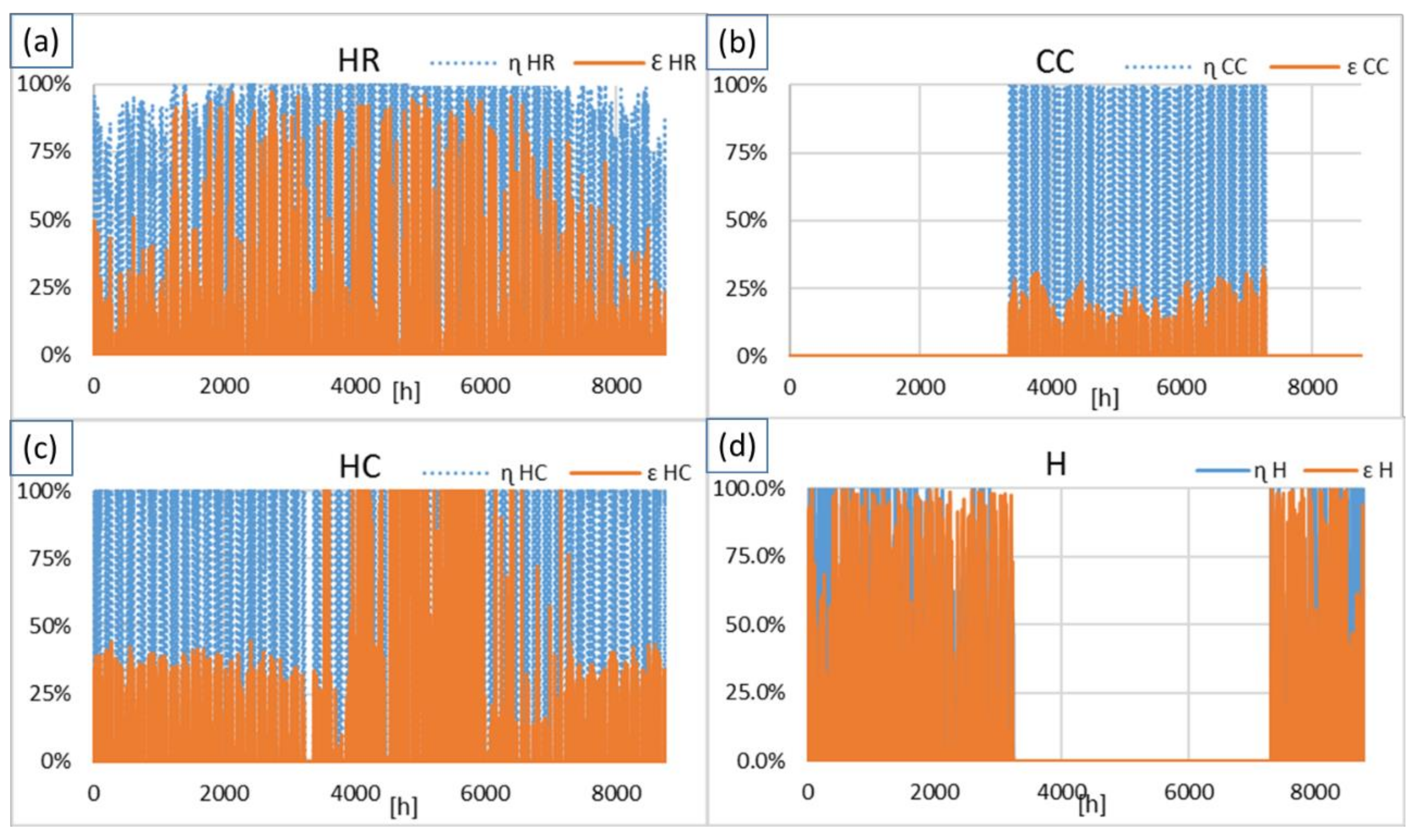

- HR energy efficiency is close to the ideal value, with a yearly average efficiency of 90%, while the exergetic efficiency is much lower, with a yearly average value of 25%, due to the exergy destruction because of the mixing of flows at different temperature levels (Figure 17a).

- CC only works in summer. Its average energy efficiency is 95%, while the exergy efficiency is 15%. There is a high exergy destruction in the process since the exergy of the airflow (sum of the physical and chemical components) barely changes in comparison with the decrease in exergy of the refrigerant water (Figure 17b).

- HC preheats the air during the winter but bypasses it in summer. Therefore, the average energy efficiency is 89% during the winter and its average exergy efficiency is 23% (Figure 17c).

- H is only switched on in winter with an average energy efficiency of 90% and an average exergy efficiency of 57% (Figure 17d).

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Mathematic Nomenclature | ||

| physical exergy of incompressible fluids | ||

| chemical exergy of fuels | ||

| physical-specific exergy of humid air | ||

| chemical-specific exergy of humid air | ||

| specific heat at constant pressure | ||

| exergy destruction rate | ||

| exergy efficiency | ||

| energy efficiency | ||

| h | specific enthalpy | |

| mass flow rate | ||

| heat exchange | ||

| reference efficiency of local X fuel type generation | ||

| T | temperature | |

| effective temperature of the sun | ||

| absolute humidity | ||

| w | work | |

| Subindexes | ||

| 0 | reference environment | |

| a | air | |

| CHP | combined heat and power | |

| cond | condensate | |

| E | electricity | |

| net | net electricity production | |

| sep | separate generation | |

| TOT | total | |

| v | vapor | |

| w | water | |

| Acronym | ||

| IAQ | indoor air quality | |

| AHU | air-handling units | |

| C | cooling | |

| CC | cooling coil | |

| CCHP | combined cooling, heating and power | |

| Ch | chiller | |

| CHP | combined heat and power | |

| COP | coefficient of performance | |

| CTE | Spanish Technical Building Code | |

| DHW | domestic hot water | |

| E | electricity | |

| EEE | equivalent electrical efficiency | |

| EExE | equivalent electrical exergy efficiency | |

| ES | energy savings | |

| F | resource consumption | |

| FC | Fan coils | |

| G | incident irradiation | |

| H | heating | |

| H | humidifier | |

| HC | heating coil | |

| HR | heat recovery | |

| IDA2 | air quality 2nd classification | |

| LHV | lower heating value | |

| PES | percentage of energy savings | |

| PExS | percentage of exergy savings | |

| PV | photovoltaic panels | |

| QF | quality factor of the fuel | |

| RE | reference environment | |

| TRNSYS | Transient System Simulation Tool | |

References

- Buckley, N.; Mills, G.; Reinhart, C.; Berzolla, Z.M. Using Urban Building Energy modelling (UBEM) to support the new European Union’s Green Deal: Case study of Dublin Ireland. Energy Build. 2021, 247, 111115. [Google Scholar] [CrossRef]

- Economidou, M.; Todeschi, V.; Bertoldi, P.; Agostino, D.D.; Zangheri, P.; Castellazzi, L. Review of 50 years of EU energy efficiency policies for buildings. Energy Build. 2020, 225, 110322. [Google Scholar] [CrossRef]

- Hani, M.R.; Mahidin, M.; Erdiwansyah, E.; Husin, H.; Khairil, K.; Hamdani, H. An overview of polygeneration as a sustainable energy solution in the future. J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 74, 85–119. [Google Scholar] [CrossRef]

- Pinto, E.S.; Serra, L.M.; Lázaro, A. Economic and environmental assessment of renewable energy and energy storage integration in standalone polygeneration systems for residential buildings. In Proceedings of the International Conference on Solar Heating and Cooling for Buildings and Industry 2019, Santiago, Chile, 4–7 November 2019. [Google Scholar]

- Pina, E.A.; Lozano, M.A.; Serra, L.M. Assessing the influence of legal constraints on the integration of renewable energy technologies in polygeneration systems for buildings. Renew. Sustain. Energy Rev. 2021, 149, 111382. [Google Scholar] [CrossRef]

- Prada, M.; Prada, I.F.; Cristea, M.; Popescu, D.E.; Bungău, C.; Aleya, L.; Bungău, C.C. New solutions to reduce greenhouse gas emissions through energy efficiency of buildings of special importance–Hospitals. Sci. Total Environ. 2020, 718, 137446. [Google Scholar] [CrossRef] [PubMed]

- FENERCOM; Community of Madrid; Ministry of Economy, Employment and Finance. Guide to Saving and Energy Efficiency in Offices and Offices; Mares Ideas Publicitarias S.L: Madrid, Spain, 2017. [Google Scholar]

- Sala-Lizarraga, J.M.; Picallo-Perez, A. Exergy Analysis and Thermoeconomics of Buildings: Design and Analysis for Sustainable Energy Systems; Butterworth-Heinemann: Oxford, UK, 2019. [Google Scholar]

- Picallo-Perez, A.; Sala-Lizarraga, J.M.; Odriozola-Maritorena, M.; Hidalgo-Betanzos, J.M.; Gomez-Arriaran, I. Ventilation of buildings with heat recovery systems: Thorough energy and exergy analysis for indoor thermal wellness. J. Build. Eng. 2021, 39, 102255. [Google Scholar] [CrossRef]

- Government of Spain, CSIC for the General Directorate of Urban Agenda and Architecture of the Ministry of Transport, Mobility and Urban Agenda. Technical Building Code. Available online: https://www.codigotecnico.org/DocumentosCTE/parte1.html (accessed on 8 November 2021).

- Picallo-Perez, A.; Lazzaretto, A.; Sala, J.M. Overview and implementation of dynamic thermoeconomic & diagnosis analyses in HVAC&R systems. J. Build. Eng. 2020, 32, 101429. [Google Scholar]

- Calama-González, C.M.; León-Rodríguez, Á.L.; Suárez, R. Indoor air quality assessment: Comparison of ventilation scenarios for retrofitting classrooms in a hot climate. Energies 2019, 12, 4607. [Google Scholar] [CrossRef] [Green Version]

- IDAE (Institute for Energy Diversification and Saving. Government of Spain). Thermal Comfort in an Air-Conditioned Space; 2019. Available online: https://www.idae.es/articulos/bienestar-termico-en-un-espacio-climatizado (accessed on 8 November 2021).

- Beckman, W.A.; Broman, L.; Fiksel, A.; Klein, S.A.; Lindberg, E.; Schuler, M.; Thornton, J. TRNSYS The most complete solar energy system modeling and simulation software. Renew. Energy 1994, 5, 486–488. [Google Scholar] [CrossRef]

- Remund, J.; Kunz, S. Meteonorm Version 5. METEOTEST. 2003. Available online: www.meteotest.com (accessed on 8 November 2021).

- Zhao, X.; Wang, C.; Li, F.; Liang, J.; Zhou, Y.; Xiao, W. Research on energy saving evaluation index of combined heat and power generation system. In Proceedings of the 10th International Conference on Measuring Technology and Mechatronics Automation (ICMTMA), Changsha, China, 10–11 February 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 159–162. [Google Scholar]

- IDAE (Institute for Energy Diversification and Saving. Government of Spain). Technical Guide for the Measurement and Determination of Useful Heat, Electricity and Primary Energy Savings of High-Efficiency Cogeneration; IDEA: Madrid, Spain, 2008.

- DIRECTIVE 2004/8/EC of the European Parlament and of the Council of 11 February 2004 on the Promotion of Cogeneration Based on a Useful Heat Demand in the Internal Energy Market and Amending Directive 92/42/EEC; BOE: Madrid, Spain, 2004; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32004L0008&from=DE (accessed on 1 November 2021).

- Ministry of Industry, Energy and Tourism. Royal Decree 413/2014, of June 6, which Regulates the Activity of Electricity Production from Renewable Energy Sources, Cogeneration and Waste; BOE: Madrid, Spain, 2014.

- Picallo-Perez, A.; Catrini, P.; Piacentino, A.; Sala, J.M. A novel thermoeconomic analysis under dynamic operating conditions for space heating and cooling systems. Energy 2019, 180, 819–837. [Google Scholar] [CrossRef]

- Picallo-Perez, A.; Sala, J.M.; Hernández, A. Application of thermoeconomics in HVAC systems. Appl. Sci. 2020, 10, 4163. [Google Scholar] [CrossRef]

| LOCATION | Tmax [°C] | Tmin [°C] | RHmax [%] | RHmin [%] |

|---|---|---|---|---|

| Madrid | 36.79 | −5.87 | 100 | 26.05 |

| Logroño | 37.20 | −4.57 | 100 | 33.00 |

| Murcia | 31.99 | −0.67 | 100 | 51.00 |

| Barcelona | 31.29 | 0.43 | 100 | 39.05 |

| Bilbao | 33.70 | −2.77 | 100 | 36.00 |

| T avg Winter [°C] | T avg Summer [°C] | RH avg Winter [%] | RH avg Summer [%] | |

| Madrid | 8.36 | 20.35 | 72.32 | 59.16 |

| Logroño | 8.48 | 18.96 | 75.84 | 67.97 |

| Murcia | 12.66 | 21.74 | 81.05 | 79.13 |

| Barcelona | 11.96 | 21.27 | 71.96 | 73.46 |

| Bilbao | 10.31 | 18.54 | 74.42 | 73.15 |

| LOCATION | Max Heat Pow. [kW] | Max Cool Pow. [kW] |

|---|---|---|

| Madrid | 134 | 109 |

| Logroño | 141 | 118 |

| Murcia | 97 | 121 |

| Barcelona | 111 | 102 |

| Bilbao | 128 | 104 |

| LOCATION | ||||

| Madrid | 33% | 1.45 | 16% | 0.70 |

| Logroño | 31% | 1.38 | 15% | 0.69 |

| Murcia | 22% | 1.24 | 6% | 0.67 |

| Barcelona | 24% | 1.22 | 6% | 0.63 |

| Bilbao | 30% | 1.32 | 12% | 0.66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Picallo-Perez, A.; Sala-Lizarraga, J.M. Design and Operation of a Polygeneration System in Spanish Climate Buildings under an Exergetic Perspective. Energies 2021, 14, 7636. https://doi.org/10.3390/en14227636

Picallo-Perez A, Sala-Lizarraga JM. Design and Operation of a Polygeneration System in Spanish Climate Buildings under an Exergetic Perspective. Energies. 2021; 14(22):7636. https://doi.org/10.3390/en14227636

Chicago/Turabian StylePicallo-Perez, Ana, and Jose Maria Sala-Lizarraga. 2021. "Design and Operation of a Polygeneration System in Spanish Climate Buildings under an Exergetic Perspective" Energies 14, no. 22: 7636. https://doi.org/10.3390/en14227636

APA StylePicallo-Perez, A., & Sala-Lizarraga, J. M. (2021). Design and Operation of a Polygeneration System in Spanish Climate Buildings under an Exergetic Perspective. Energies, 14(22), 7636. https://doi.org/10.3390/en14227636