The Effects of the Length and Conductivity of Artificial Fracture on Gas Production from a Class 3 Hydrate Reservoir

Abstract

:1. Introduction

2. Methodology

2.1. Reservoir Specification

2.2. Numerical Model Establishment

2.2.1. Simulator

2.2.2. Artificial Fracture Model

2.2.3. Relative Permeability and Capillary Pressure

2.2.4. Initial Conditions

2.2.5. Production Strategy

3. Results and Discussion

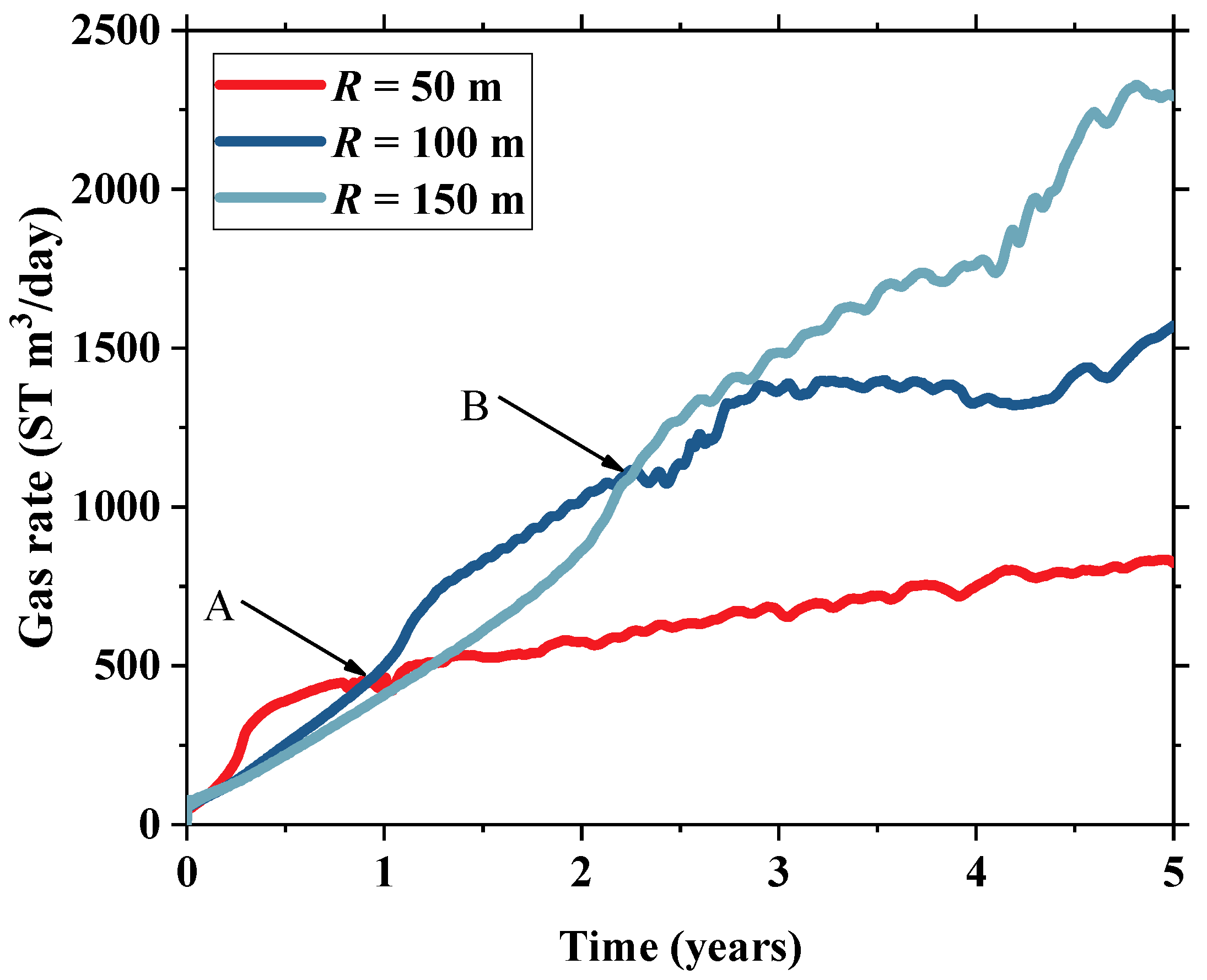

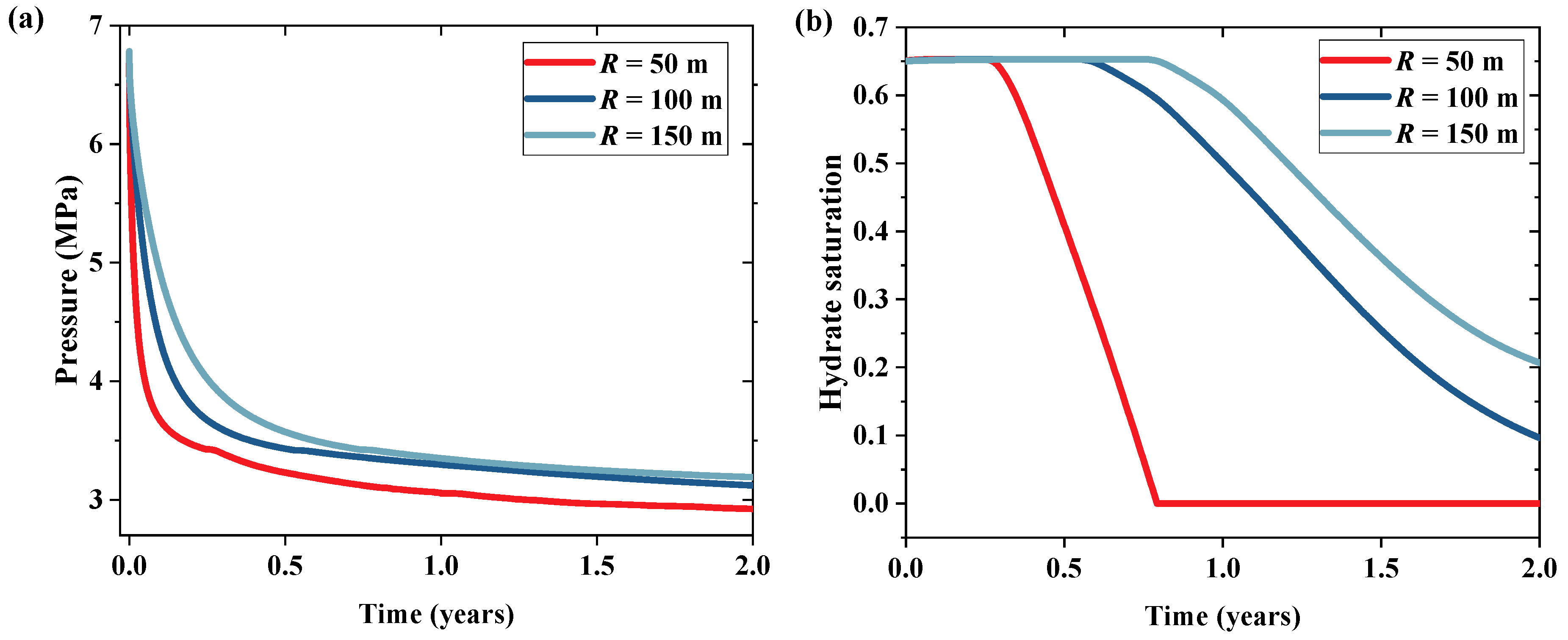

3.1. Effect of Fracture Length on Production

3.1.1. Gas Production

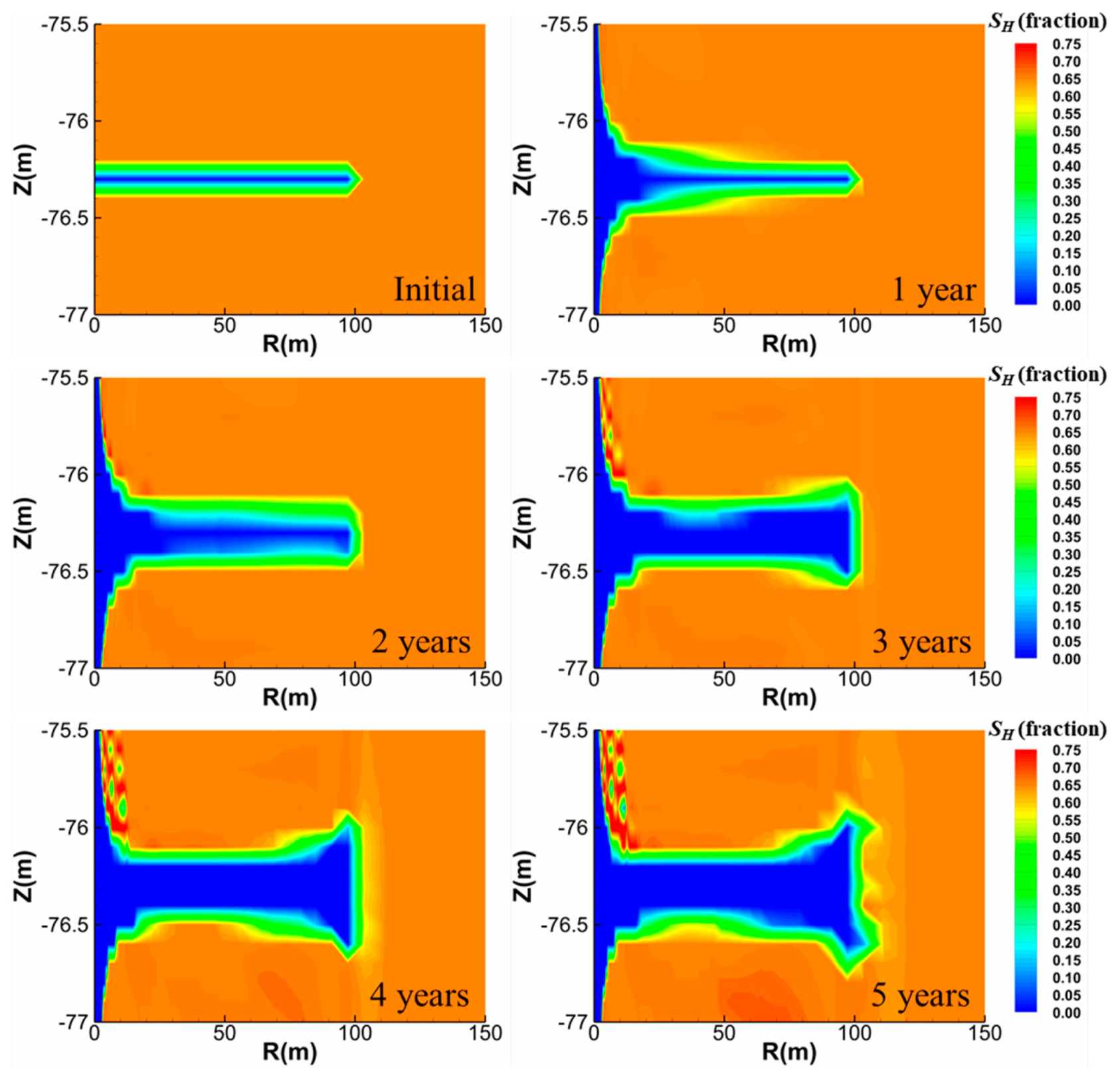

3.1.2. Evolution of Physical Property Distribution in Production Process

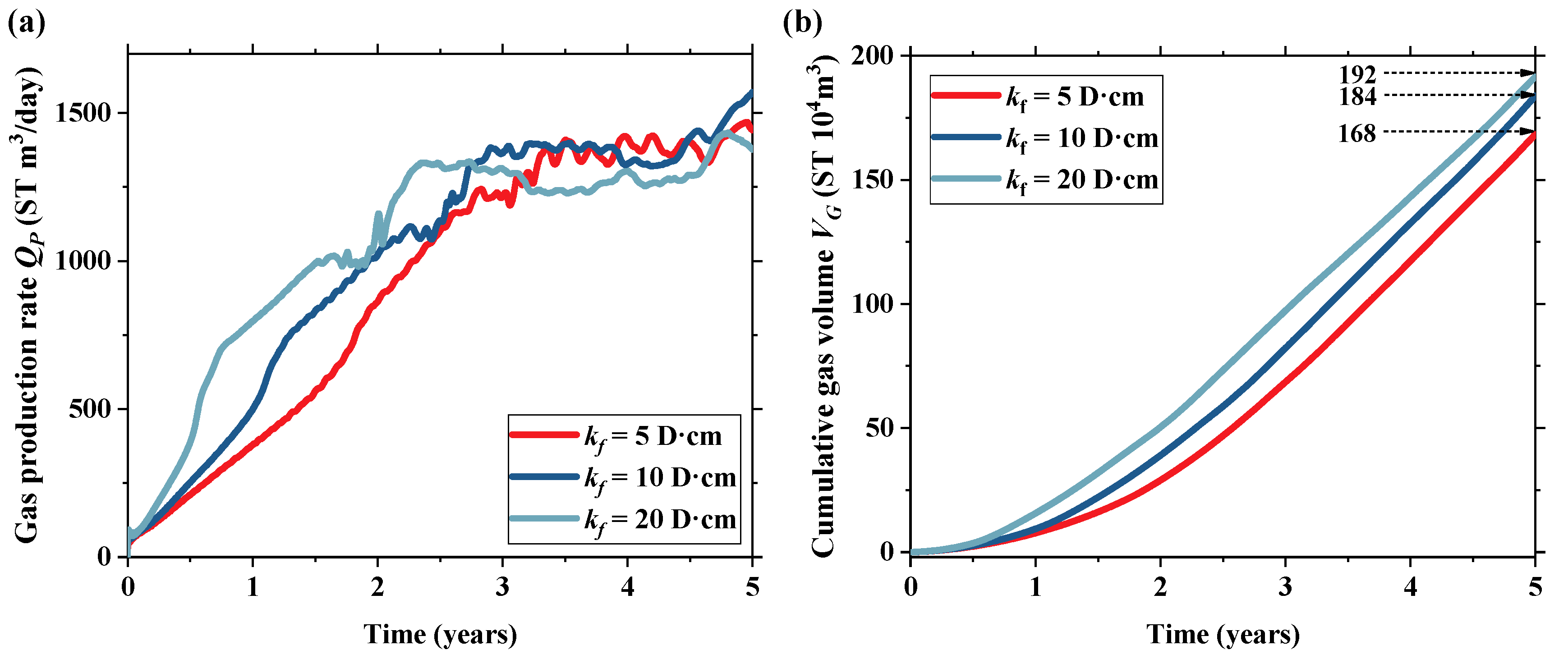

3.2. Effect of Fracture Conductivity on Production Performance

4. Conclusions

- (1)

- An artificial fracture can enhance the gas production rate, and the enhancement effect will be more pronounced with increasing fracture length. However, the effect of fracture length on production is closely related to the time frame of production, and the benefits from larger fracture length are not presented at the early production stage.

- (2)

- The enhancement effect of artificial fracture results from the extra flow channels provided by the fractures. The fracture acts as a flow channel, and the hydrate dissociation is accelerated with increased permeability of hydrate-bearing sediments in the dissociation area.

- (3)

- New flow channels for gas and water migration are generated in the area adjacent to artificial fracture, which helps gas migrate into the wellbore.

- (4)

- It is found that the secondary hydrate formation is absent in the artificial fracture, and its high conductivity will not be compromised during the entire simulation period.

- (5)

- The effect of the artificial fracture conductivity is limited in enhancing the gas production rate. As a result, fracture length and conductivity should be designed properly in practical production projects to balance cost and benefit.

Author Contributions

Funding

Conflicts of Interest

References

- Sloan, E.D. Fundamental principles and applications of natural gas hydrates. Nature 2003, 426, 353–359. [Google Scholar] [CrossRef]

- Koh, C.A. Towards a fundamental understanding of natural gas hydrates. Chem. Soc. Rev. 2002, 31, 157–167. [Google Scholar] [CrossRef]

- Decourt, B.; Alias, S.; Debarre, R.; Askew, P. Taking the heat out of the burning-ice debate: Potential and future of gas hydrates. In Proceedings of the SPE Asia Pacific Unconventional Resources Conference and Exhibition, Brisbane, Australia, 9–11 November 2015. [Google Scholar]

- Ruppel, C.D.; Kessler, J.D. The interaction of climate change and methane hydrates. Rev. Geophys. 2017, 55, 126–168. [Google Scholar] [CrossRef]

- Liu, L.P.; Sun, Z.L.; Zhang, L.; Wu, N.Y.; Qin, Y.C.; Jiang, Z.Z.; Geng, W.; Cao, H.; Zhang, X.L.; Zhai, B.; et al. Progress in Global Gas Hydrate Development and Production as a New Energy Resource. Acta Geol. Sin. 2019, 93, 731–755. [Google Scholar] [CrossRef]

- Kurihara, M.; Sato, A.; Funatsu, K.; Ouchi, H.; Yamamoto, K.; Numasawa, M.; Ebinuma, T.; Narita, H.; Masuda, Y.; Dallimore, S.R.; et al. Analysis of production data for 2007/2008 Mallik gas hydrate production tests in Canada. In Proceedings of the International Oil and Gas Conference and Exhibition in China, China, Beijing, 8–10 June 2010. [Google Scholar]

- Boswell, R.; Schoderbek, D.; Collett, T.S.; Ohtsuki, S.; White, M.; Anderson, B.J. The Iġnik Sikumi field experiment, Alaska North Slope: Design, operations, and implications for CO2-CH4 exchange in gas hydrate reservoirs. Energy Fuels 2017, 31, 140–153. [Google Scholar] [CrossRef]

- Konno, Y.; Fujii, T.; Sato, A.; Akamine, K.; Naiki, M.; Masuda, Y.; Yamamoto, K.; Nagao, J. Key findings of the world’s first offshore methane hydrate production test off the coast of Japan: Toward future commercial production. Energy Fuels 2017, 31, 2607–2616. [Google Scholar] [CrossRef]

- Yamamoto, K.; Wang, X.X.; Tamaki, M.; Suzuki, K. The second offshore production of methane hydrate in the Nankai Trough and gas production behavior from a heterogeneous methane hydrate reservoir. RSC Adv. 2019, 9, 25987–26013. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Ye, J.; Qin, X.; Qiu, H.; Wu, N.; Lu, H.; Xie, W.; Lu, J.; Peng, F.; Xu, Z.; et al. The first offshore natural gas hydrate production test in South China Sea. China Geol. 2018, 1, 5–16. [Google Scholar] [CrossRef]

- Ye, J.; Qin, X.; Xie, W.; Lu, H.; Ma, B.; Qiu, H.; Liang, J.; Lu, J.; Kuang, Z.; Lu, C.; et al. The second natural gas hydrate production test in the South China Sea. China Geol. 2020, 3, 197–209. [Google Scholar] [CrossRef]

- Wang, D.; Wang, C.; Li, C.; Liu, C.; Lu, H.; Wu, N.; Hu, G.; Liu, L.; Meng, Q. Effect of gas hydrate formation and decomposition on flow properties of fine-grained quartz sand sediments using X-ray CT based pore network model simulation. Fuel 2018, 226, 516–526. [Google Scholar] [CrossRef]

- Wang, L.; Gu, L.; Lu, H. Sediment permeability change on natural gas hydrate dissociation induced by depressurization. China Geol. 2020, 3, 221–229. [Google Scholar] [CrossRef]

- Mayerhofer, M.J.; Lolon, E.; Warpinski, N.R.; Cipolla, C.L.; Walser, D.W.; Rightmire, C.M. What Is Stimulated Reservoir Volume? SPE Prod. Oper. 2010, 25, 89–98. [Google Scholar] [CrossRef]

- Chen, L.; Yamada, H.; Kanda, Y.; Okajima, J.; Komiya, A.; Maruyama, S. Investigation on the dissociation flow of methane hydrate cores: Numerical modeling and experimental verification. Chem. Eng. Sci. 2017, 163, 31–43. [Google Scholar] [CrossRef]

- Too, J.L.; Cheng, A.; Khoo, B.C.; Palmer, A.; Linga, P. Hydraulic fracturing in a penny-shaped crack. Part I: Methodology and testing of frozen sand. J. Nat. Gas Sci. Eng. 2018, 52, 609–618. [Google Scholar] [CrossRef]

- Too, J.L.; Cheng, A.; Khoo, B.C.; Palmer, A.; Linga, P. Hydraulic fracturing in a penny-shaped crack. Part II: Testing the frackability of methane hydrate-bearing sand. J. Nat. Gas Sci. Eng. 2018, 52, 619–628. [Google Scholar] [CrossRef]

- Liu, X.; Sun, Y.; Guo, T.; Rabiei, M.; Qu, Z.; Hou, J. Numerical Simulations of Hydraulic Fracturing in Methane Hydrate Reservoirs Based on the Coupled Thermo-Hydrologic-Mechanical-Damage (THMD) Model. Energy 2021, 122054. [Google Scholar] [CrossRef]

- Ito, T.; Igarashi, A.; Suzuki, K.; Nagakubo, S.; Matsuzawa, M.; Yamamoto, K. Laboratory Study of Hydraulic Fracturing Behavior in Unconsolidated Sands for Methane Hydrate Production. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2008. [Google Scholar]

- Ito, T.; Narita, H. Laboratory Study for Pore Water Effect on Hydraulically-induced Fracture Behavior in Unconsolidated Sands. In Proceedings of the 48th U.S. Rock Mechanics/Geomechanics Symposium, Minneapolis, MN, USA, 18 August 2014. [Google Scholar]

- Konno, Y.; Jin, Y.; Yoneda, J.; Uchiumi, T.; Shinjou, K.; Nagao, J. Hydraulic fracturing in methane-hydrate-bearing sand. RSC Adv. 2016, 6, 73148–73155. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Yang, L.; Jia, R.; Sun, Y.; Guo, W.; Chen, Y.; Li, X. Simulation Study on the Effect of Fracturing Technology on the Production Efficiency of Natural Gas Hydrate. Energies 2017, 10, 1241. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, L.; Suzuki, A.; Kogawa, T.; Okajima, J.; Komiya, A.; Maruyama, S. Enhancement of gas production from methane hydrate reservoirs by the combination of hydraulic fracturing and depressurization method. Energy Convers. Manage. 2019, 184, 194–204. [Google Scholar] [CrossRef]

- Adachi, J.; Siebrits, E.; Peirce, A.; Desroches, J. Computer simulation of hydraulic fractures. Int. J. Rock Mech. Min. Sci. 2007, 44, 739–757. [Google Scholar] [CrossRef]

- Konno, Y.; Masuda, Y.; Akamine, K.; Naiki, M.; Nagao, J. Sustainable gas production from methane hydrate reservoirs by the cyclic depressurization method. Energy Convers. Manag. 2016, 108, 439–445. [Google Scholar] [CrossRef]

- Moridis, G.J.; Collett, T.; Boswell, R.; Kurihara, M.; Reagan, M.T.; Koh, C.; Sloan, E.D. Toward Production From Gas Hydrates: Current Status, Assessment of Resources, and Simulation-Based Evaluationof Technology and Potential. SPE Reserv. Eval. Eng. 2009, 12, 745–771. [Google Scholar] [CrossRef] [Green Version]

- Moridis, G.J. Numerical Studies of Gas Production From Class 2 and Class 3 Hydrate Accumulations at the Mallik Site, Mackenzie Delta, Canada. SPE Reserv. Eval. Eng. 2004, 7, 175–183. [Google Scholar] [CrossRef]

- Anderson, B.; Hancock, S.; Wilson, S.; Enger, C.; Collett, T.; Boswell, R.; Hunter, R. Formation pressure testing at the Mount Elbert Gas Hydrate Stratigraphic Test Well, Alaska North Slope: Operational summary, history matching, and interpretations. Mar. Pet. Geol. 2011, 28, 478–492. [Google Scholar] [CrossRef]

- Anderson, B.J.; Kurihara, M.; White, M.D.; Moridis, G.J.; Wilson, S.J.; Pooladi-Darvish, M.; Gaddipati, M.; Masuda, Y.; Collett, T.S.; Hunter, R.B.; et al. Regional long-term production modeling from a single well test, Mount Elbert Gas Hydrate Stratigraphic Test Well, Alaska North Slope. Mar. Pet. Geol. 2011, 28, 493–501. [Google Scholar] [CrossRef]

- Kurihara, M.; Sato, A.; Funatsu, K.; Ouchi, H.; Masuda, Y.; Narita, H.; Collett, T.S. Analysis of formation pressure test results in the Mount Elbert methane hydrate reservoir through numerical simulation. Mar. Pet. Geol. 2011, 28, 502–516. [Google Scholar] [CrossRef]

- Winters, W.; Walker, M.; Hunter, R.; Collett, T.; Boswell, R.; Rose, K.; Waite, W.; Torres, M.; Patil, S.; Dandekar, A. Physical properties of sediment from the Mount Elbert Gas Hydrate Stratigraphic Test Well, Alaska North Slope. Mar. Pet. Geol. 2011, 28, 361–380. [Google Scholar] [CrossRef] [Green Version]

- Lu, H.; Lorenson, T.D.; Moudrakovski, I.L.; Ripmeester, J.A.; Collett, T.S.; Hunter, R.B.; Ratcliffe, C.I. The characteristics of gas hydrates recovered from the Mount Elbert Gas Hydrate Stratigraphic Test Well, Alaska North Slope. Mar. Pet. Geol. 2011, 28, 411–418. [Google Scholar] [CrossRef] [Green Version]

- Moridis, G.J.; Kowalsky, M.B.; Pruess, K. TOUGH+Hydrate v1.0 User’s Manual: A Code for the Simulation of System Behavior in Hydrate-Bearing Geologic Media; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2008.

- White, M.D.; Kneafsey, T.J.; Seol, Y.; Waite, W.F.; Uchida, S.; Lin, J.S.; Myshakin, E.M.; Gai, X.; Gupta, S.; Reagan, M.T.; et al. An international code comparison study on coupled thermal, hydrologic and geomechanical processes of natural gas hydrate-bearing sediments. Mar. Pet. Geol. 2020, 120, 104566. [Google Scholar] [CrossRef]

- Yin, Z.; Moridis, G.; Tan, H.K.; Linga, P. Numerical analysis of experimental studies of methane hydrate formation in a sandy porous medium. Appl. Energy 2018, 220, 681–704. [Google Scholar] [CrossRef] [Green Version]

- Bei, K.; Xu, T.; Shang, S.; Wei, Z.; Yuan, Y.; Tian, H. Numerical Modeling of Gas Migration and Hydrate Formation in Heterogeneous Marine Sediments. J. Mar. Sci. Eng. 2019, 7, 348. [Google Scholar] [CrossRef] [Green Version]

- Zhu, H.; Xu, T.; Zhu, Z.; Yuan, Y.; Tian, H. Numerical modeling of methane hydrate accumulation with mixed sources in marine sediments: Case study of Shenhu Area, South China Sea. Mar. Geol. 2020, 423, 106142. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, L.; Ning, F.; Lei, H.; Liu, T.; Hu, G.; Lu, H.; Lu, J.; Liu, C.; Jiang, G.; et al. Production potential and stability of hydrate-bearing sediments at the site GMGS3-W19 in the South China Sea: A preliminary feasibility study. Mar. Pet. Geol. 2017, 86, 447–473. [Google Scholar] [CrossRef]

- Reagan, M.T.; Queiruga, A.F.; Moridis, G.J. Simulation of Gas Production from Multilayered Hydrate-Bearing Media with Fully Coupled Flow, Thermal, Chemical and Geomechanical Processes Using TOUGH+Millstone. Part 3: Production Simulation Results. Transp. Porous Media 2019, 129, 179–202. [Google Scholar] [CrossRef] [Green Version]

- Kowalsky, M.B.; Moridis, G.J. Comparison of kinetic and equilibrium reaction models in simulating gas hydrate behavior in porous media. Energy Convers. Manag. 2007, 48, 1850–1863. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhang, J.; Yuan, B.; Yin, S. In-situ stresses controlling hydraulic fracture propagation and fracture breakdown pressure. J. Pet. Sci. Eng. 2018, 164, 164–173. [Google Scholar] [CrossRef]

- Lin, M.; Chen, S.; Ding, W.; Chen, Z.; Xu, J. Effect of Fracture Geometry on Well Production in Hydraulic-Fractured Tight Oil Reservoirs. J. Can. Pet. Technol. 2015, 54, 183–194. [Google Scholar] [CrossRef]

- Rubin, B. Accurate Simulation of Non Darcy Flow in Stimulated Fractured Shale Reservoirs. In Proceedings of the SPE Western Regional Meeting, Anaheim, CA, USA, 1 January 2010. [Google Scholar]

- van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Leung, J.Y. Numerical Investigation of Coupling Multiphase Flow and Geomechanical Effects on Water Loss during Hydraulic-Fracturing Flowback Operation. SPE Reserv. Eval. Eng. 2016, 19, 520–537. [Google Scholar] [CrossRef]

- Song, H.; Yu, M.; Zhu, W.; Wu, P.; Lou, Y.; Wang, Y.; Killough, J. Numerical investigation of gas flow rate in shale gas reservoirs with nanoporous media. Int. J. Heat Mass Transf. 2015, 80, 626–635. [Google Scholar] [CrossRef]

- Davies, D.R.; Kuiper, T.O.H. Fracture Conductivity in Hydraulic Fracture Stimulation. J. Pet. Technol. 1988, 40, 550–552. [Google Scholar] [CrossRef]

- Rutqvist, J.; Moridis, G.J. Numerical Studies on the Geomechanical Stability of Hydrate-Bearing Sediments. SPE J. 2009, 14, 267–282. [Google Scholar] [CrossRef]

- Shang, S.; Gu, L.; Lu, H. Numerical study of gas production from a methane hydrate reservoir by depressurization with multi-wells. Acta Geol. Sin. 2021, 95, 928–936. [Google Scholar] [CrossRef]

- Shang, S.; Gu, L.; Zhan, L.; Qiu, H.; Lu, H. Application of horizontal well to gas production from a hydrate reservoir with free gas and high irreducible water. J. Nat. Gas Sci. Eng. 2021, 94, 104102. [Google Scholar] [CrossRef]

| Reservoir Location | Alaska North Slope, USA |

|---|---|

| Reservoir classification | Class 3 hydrate reservoir |

| Reservoir depth | ~650 m |

| Lithology | Coarse-grained sand sediment |

| Initial pressure (MPa) | 6.78 at the middle of hydrate-bearing layer |

| Initial temperature (°C) | 2.95 at the middle of hydrate-bearing layer |

| Intrinsic permeability (mD) | Hydrate-bearing layer: 1000 (radial direction), 100 (vertical direction); Hydrate-free layer: 0 (both radial and vertical direction) |

| Hydrate-bearing permeability (mD) | Hydrate-bearing layer: 0.12 (radial direction), 0.012 (vertical direction) |

| Porosity | Hydrate-free layer: 0.10, Hydrate-bearing layer: 0.35 |

| Initial saturation | Hydrate-free layer: water saturation = 1.0; Hydrate-bearing layer: water saturation = 0.35, hydrate saturation = 0.65 |

| Gas component | Pure methane |

| Parameters | Symbols | Sediments | Fracture |

|---|---|---|---|

| Irreducible water saturation | 0.248 | 0.000 | |

| Irreducible gas saturation | 0.000 | 0.000 | |

| Relative permeability index for water | 4.52 | 1.00 | |

| Relative permeability index for gas | 3.16 | 1.00 | |

| Gas entry pressure | 985.2 Pa | 0 Pa | |

| Capillary pressure index | 0.7744 | – | |

| Maximum of water saturation | 1.0 | – |

| Group | Case | Fracture Length | Fracture Conductivity | Phase in Fracture | Remarks |

|---|---|---|---|---|---|

| A | A1 | 50 m | 1 × 10−13 m3 (10 ) | = 1.0 | Fracture length effects |

| A2 (base case) | 100 m | 1 × 10−13 m3 (10 ) | = 1.0 | ||

| A3 | 150 m | 1 × 10−13 m3 (10 ) | = 1.0 | ||

| B | B1 | 100 m | 5 × 10−14 m3 (5 ) | = 1.0 | Fracture conductivity effects |

| B2 | 100 m | 1 × 10−13 m3 (10 ) | = 1.0 | ||

| B3 | 100 m | 2 × 10−13 m3 (20 ) | = 1.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, S.; Gu, L.; Lu, H. The Effects of the Length and Conductivity of Artificial Fracture on Gas Production from a Class 3 Hydrate Reservoir. Energies 2021, 14, 7513. https://doi.org/10.3390/en14227513

Shang S, Gu L, Lu H. The Effects of the Length and Conductivity of Artificial Fracture on Gas Production from a Class 3 Hydrate Reservoir. Energies. 2021; 14(22):7513. https://doi.org/10.3390/en14227513

Chicago/Turabian StyleShang, Shilong, Lijuan Gu, and Hailong Lu. 2021. "The Effects of the Length and Conductivity of Artificial Fracture on Gas Production from a Class 3 Hydrate Reservoir" Energies 14, no. 22: 7513. https://doi.org/10.3390/en14227513

APA StyleShang, S., Gu, L., & Lu, H. (2021). The Effects of the Length and Conductivity of Artificial Fracture on Gas Production from a Class 3 Hydrate Reservoir. Energies, 14(22), 7513. https://doi.org/10.3390/en14227513