Multi-Virtual-Vector Model Predictive Current Control for Dual Three-Phase PMSM

Abstract

:1. Introduction

2. VV-MPC for DTP-PMSM

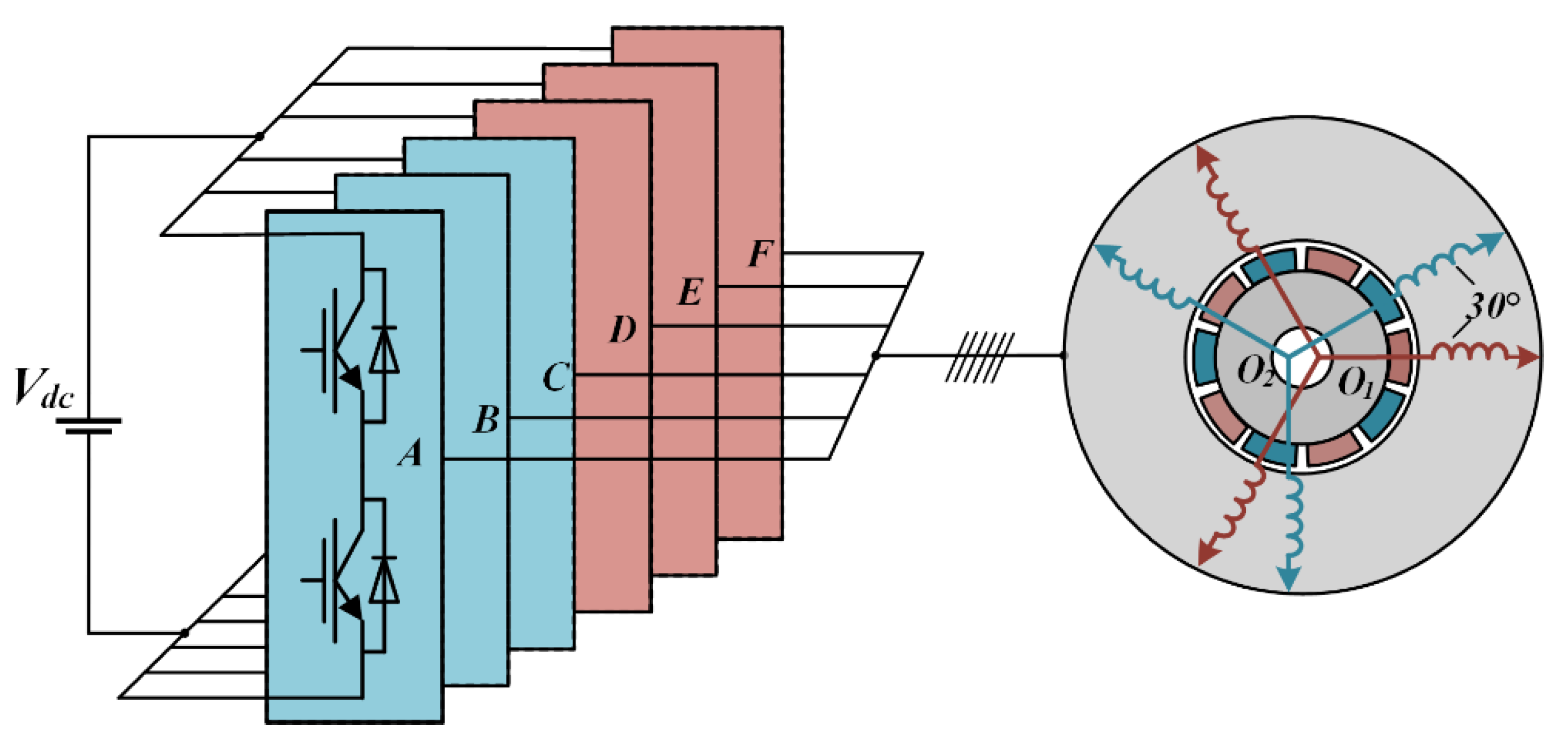

2.1. Dual Three-Phase PMSM Drive

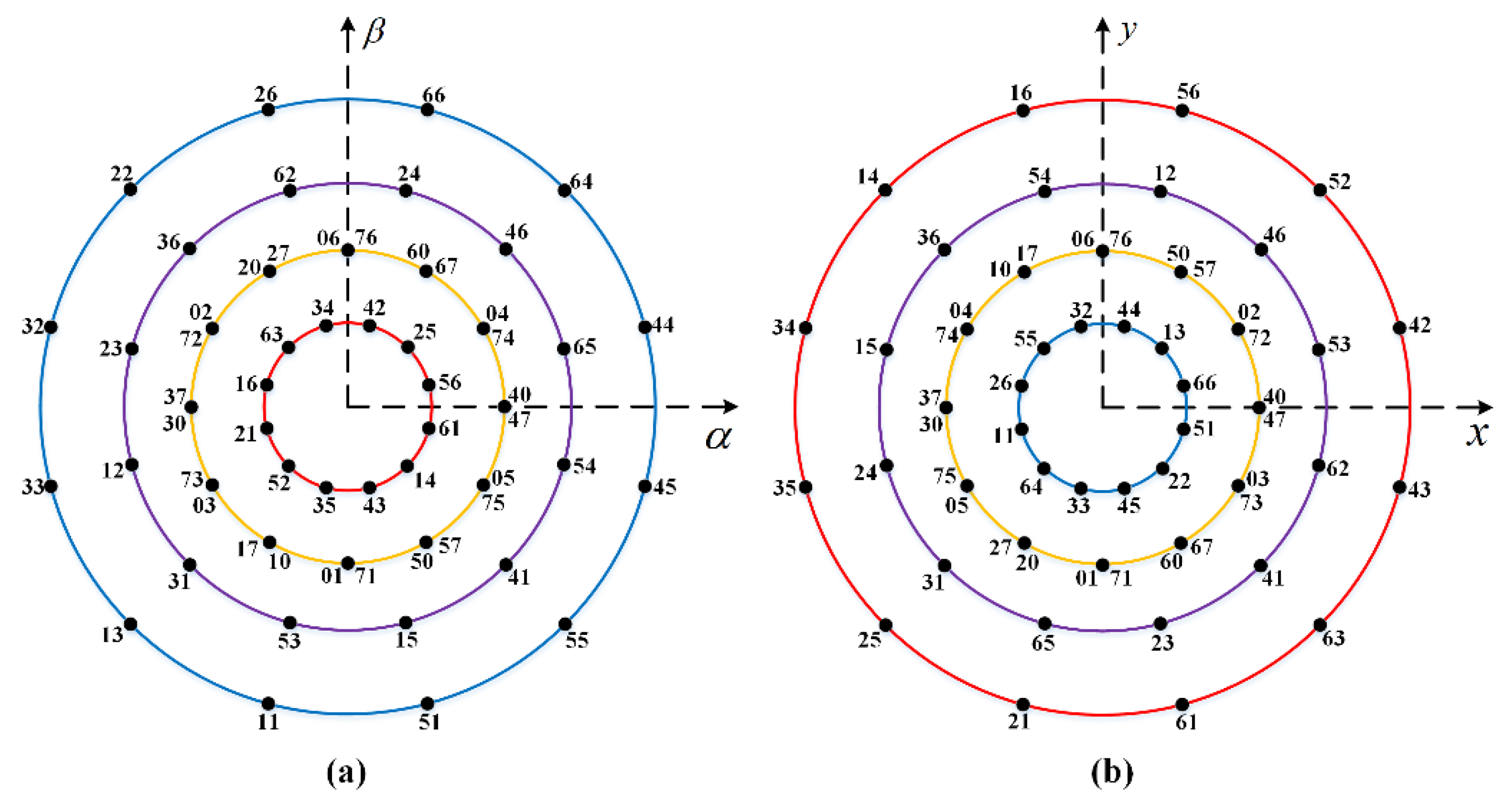

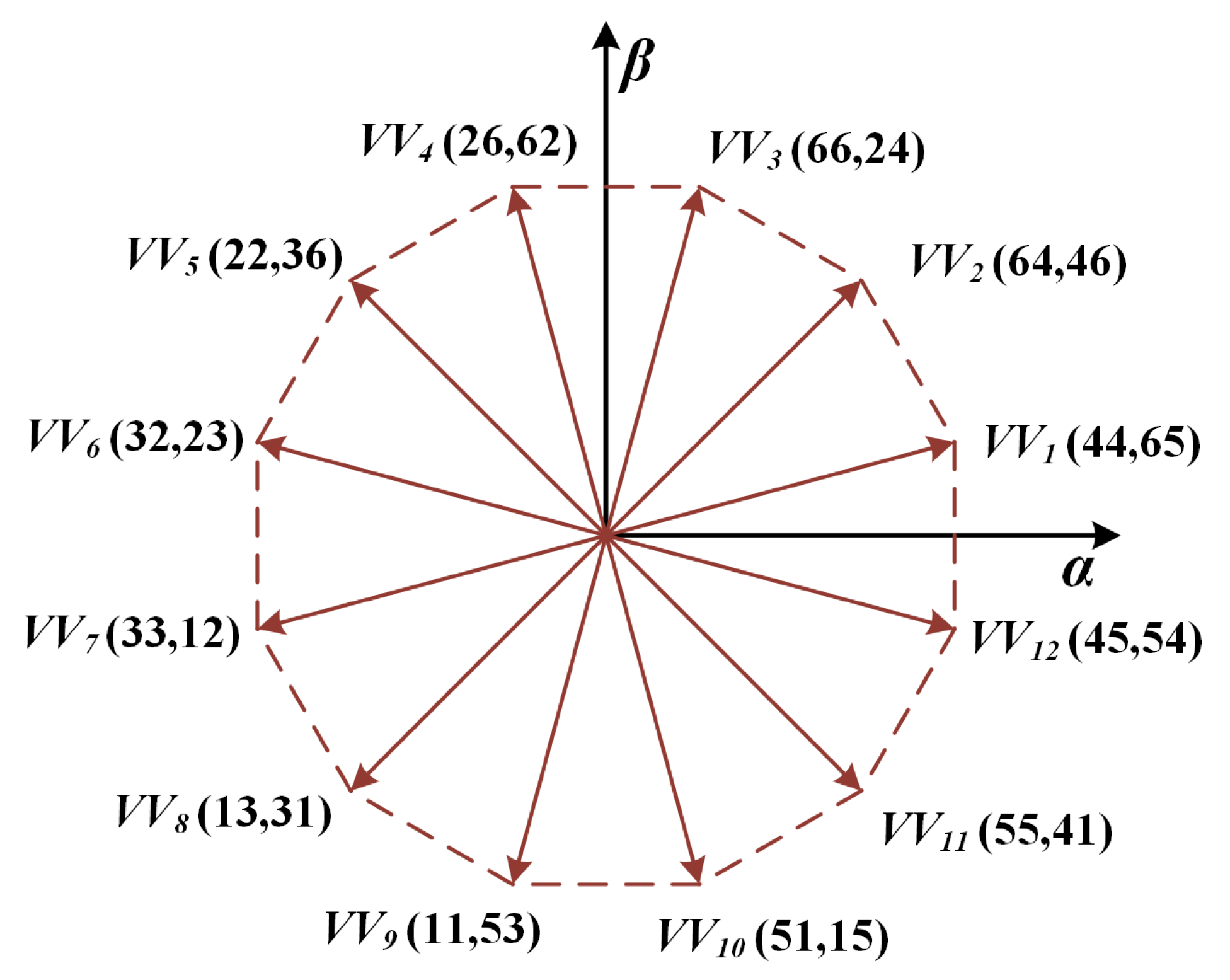

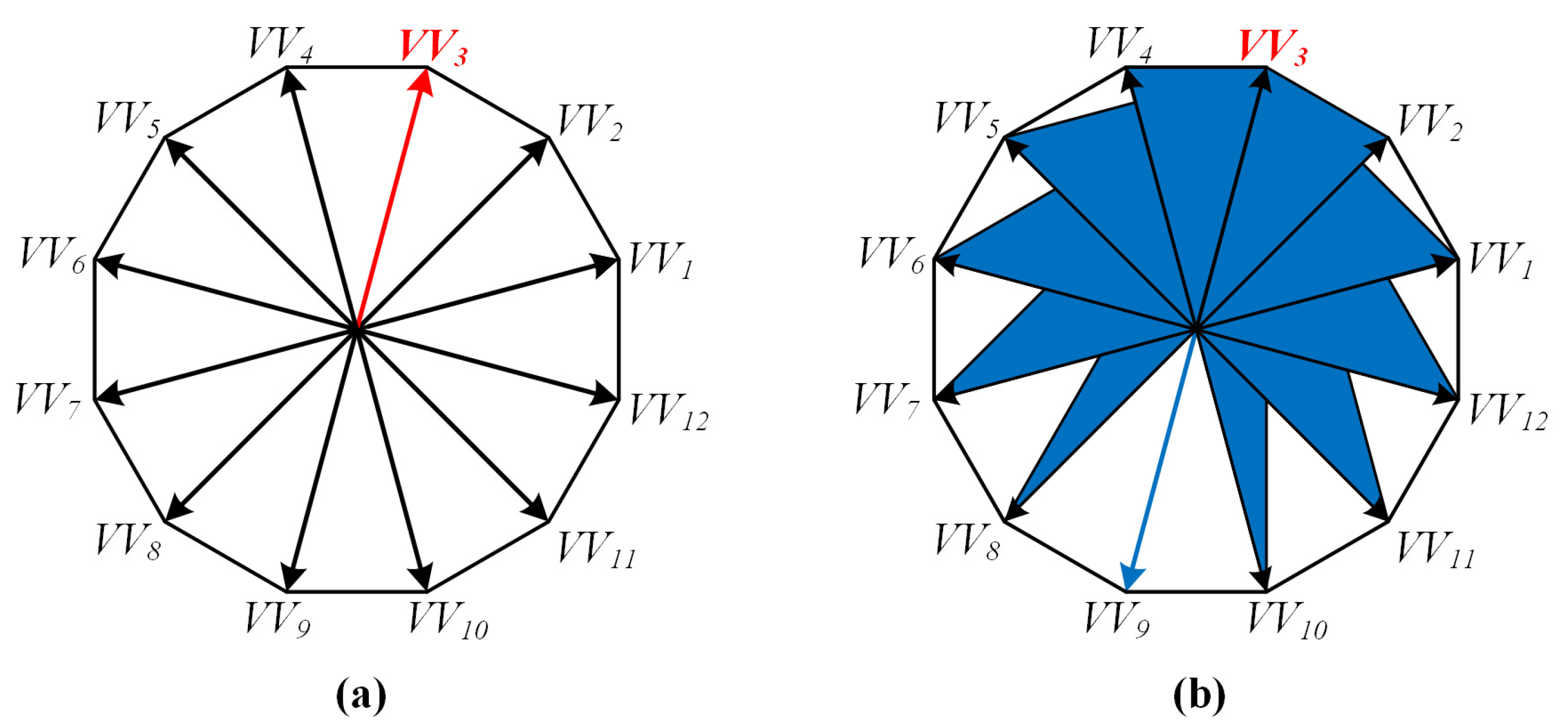

2.2. Virtual Voltage Vector

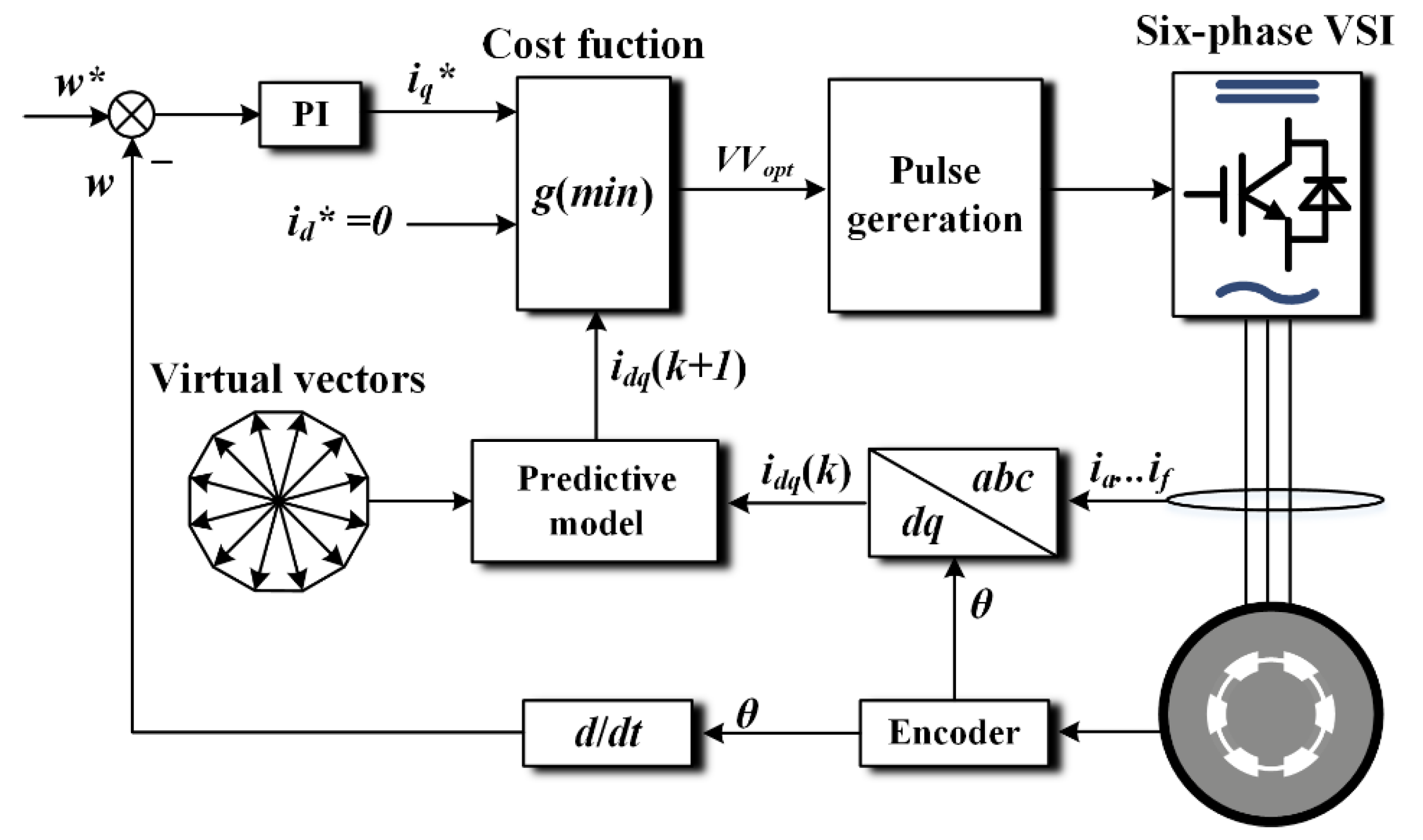

2.3. MPC Based on Virtual Vectors

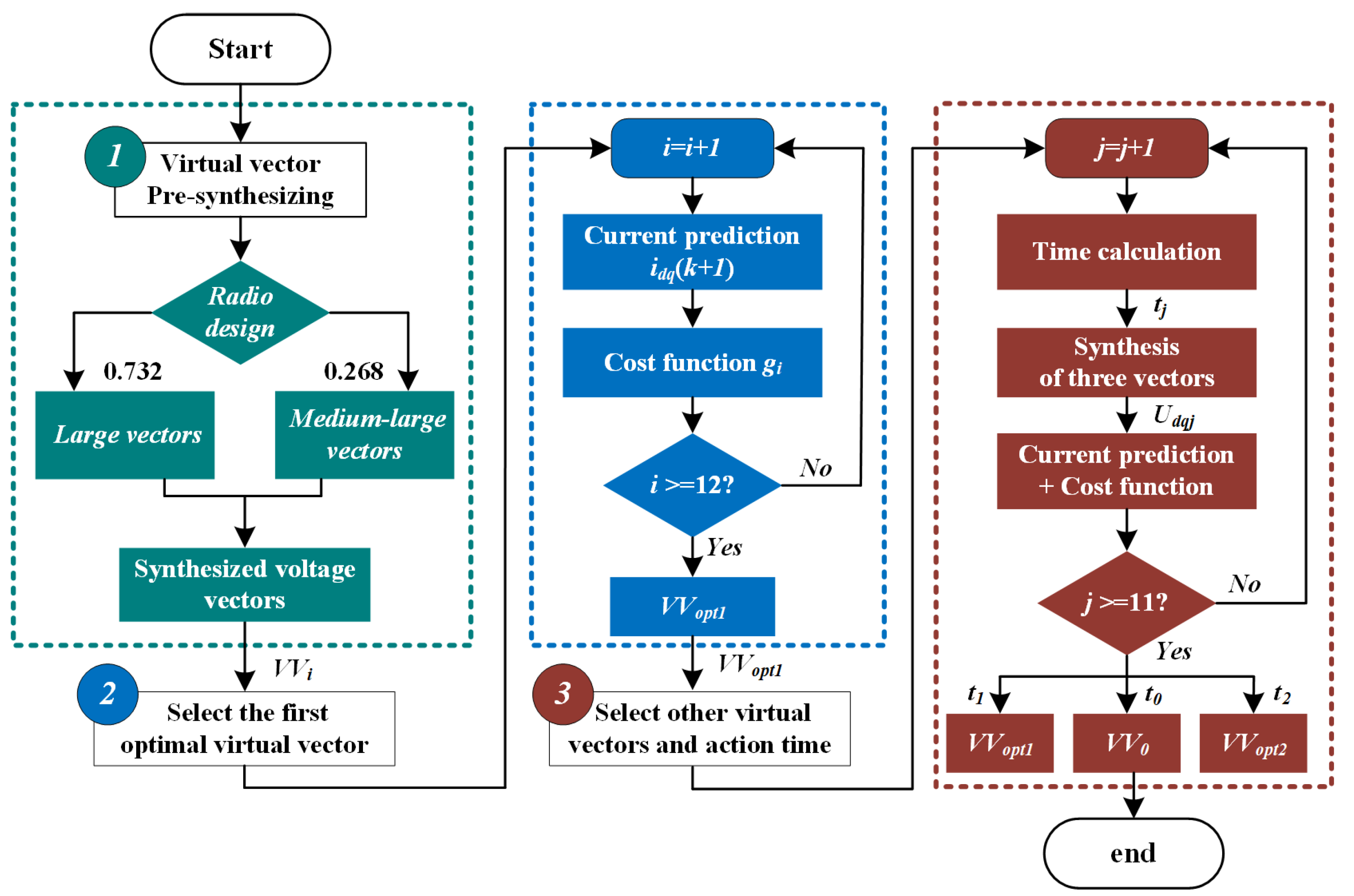

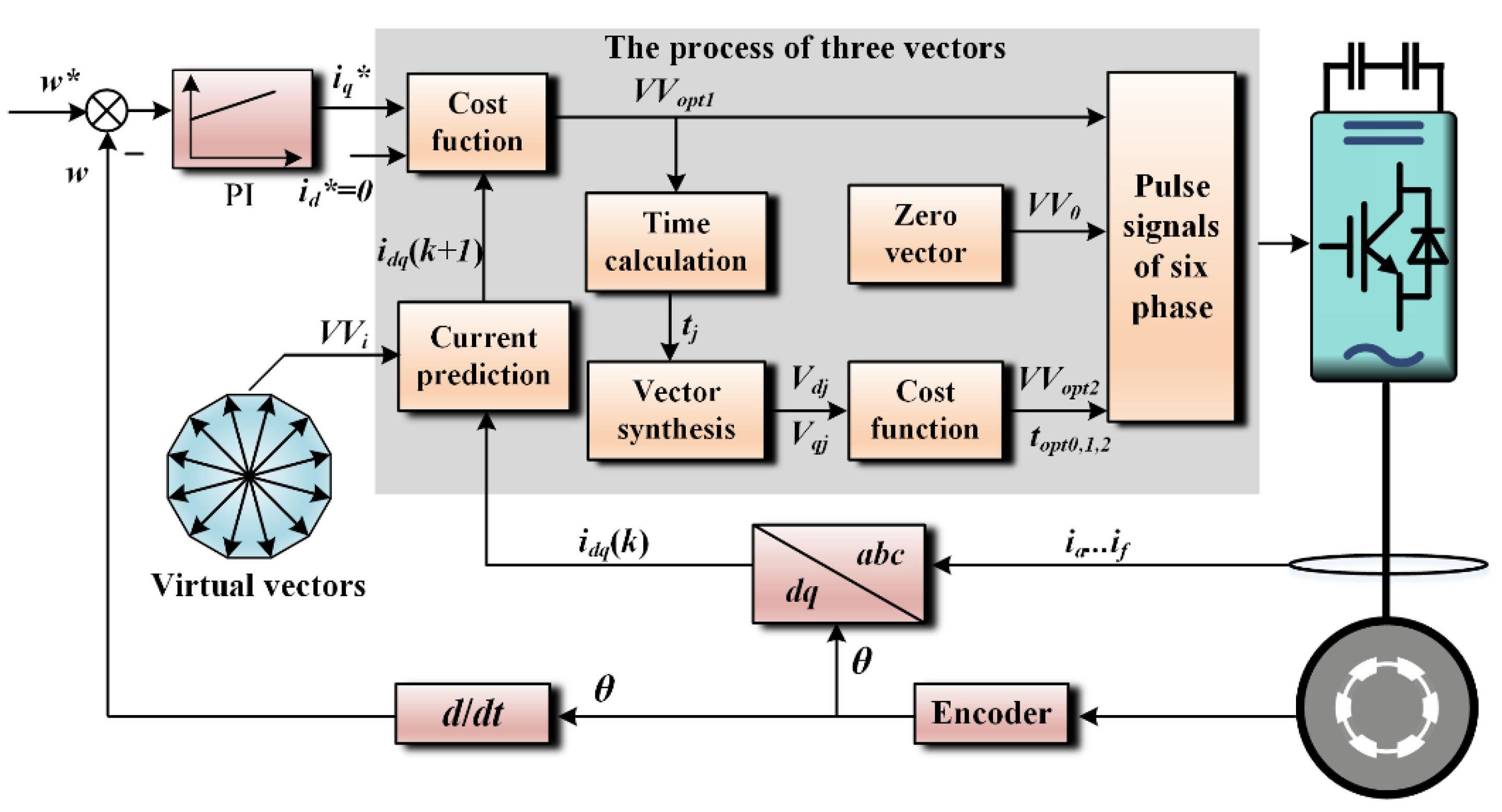

3. Proposed MVV-MPC Scheme

3.1. The Selection of Virtual Vector

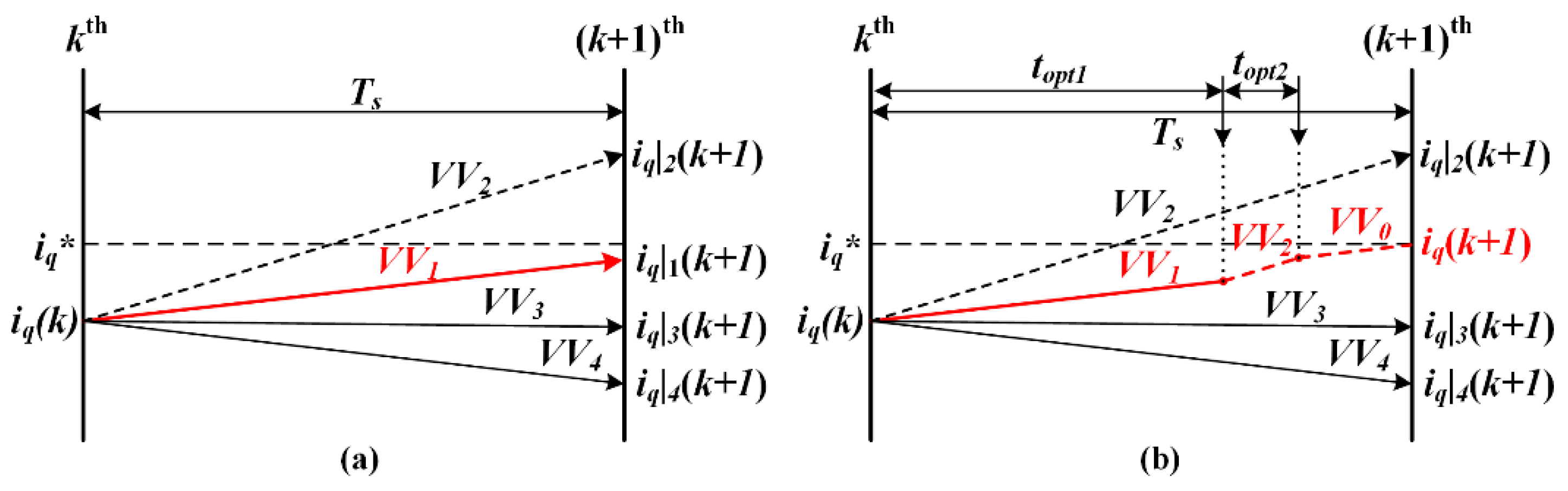

3.2. The Calculation of Virtual Vector Duration Time

- (1)

- When t1 < 0 or t2 < 0, this vector combination will not be adopted.

- (2)

- When t1 + t2 > Ts, the duration time will be reallocated as:

3.3. The Strategy Analysis of MVV-MPC

4. Results

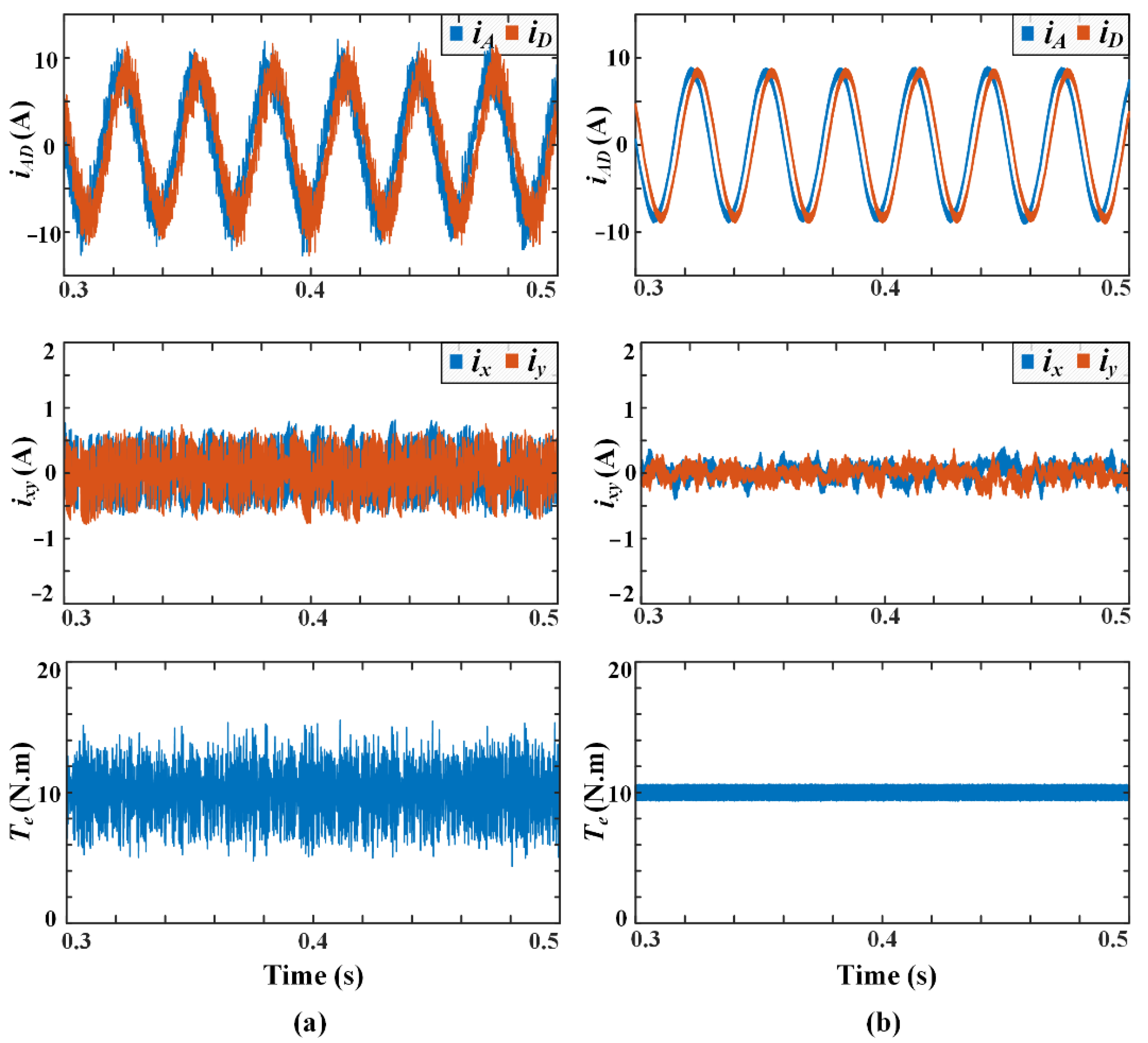

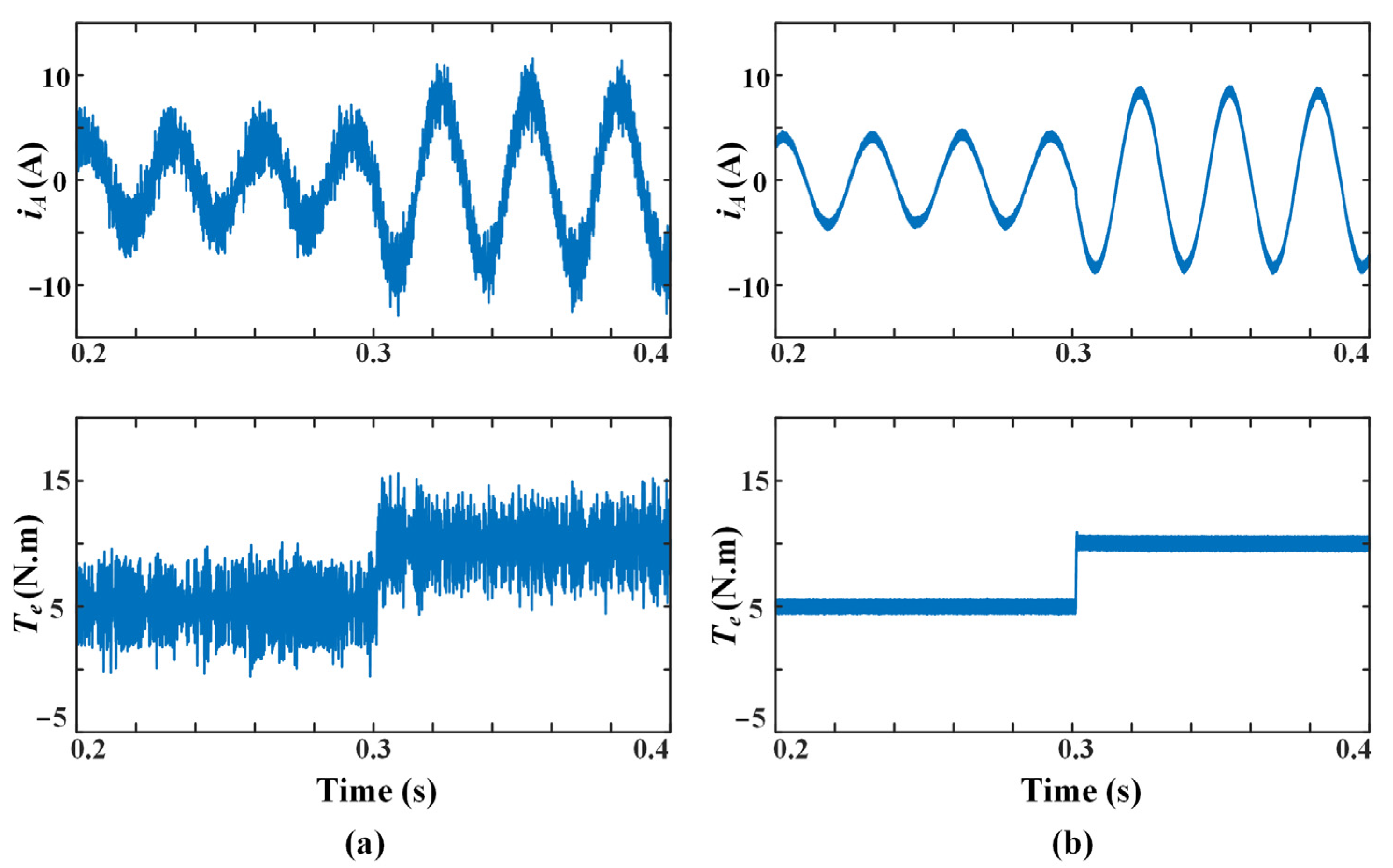

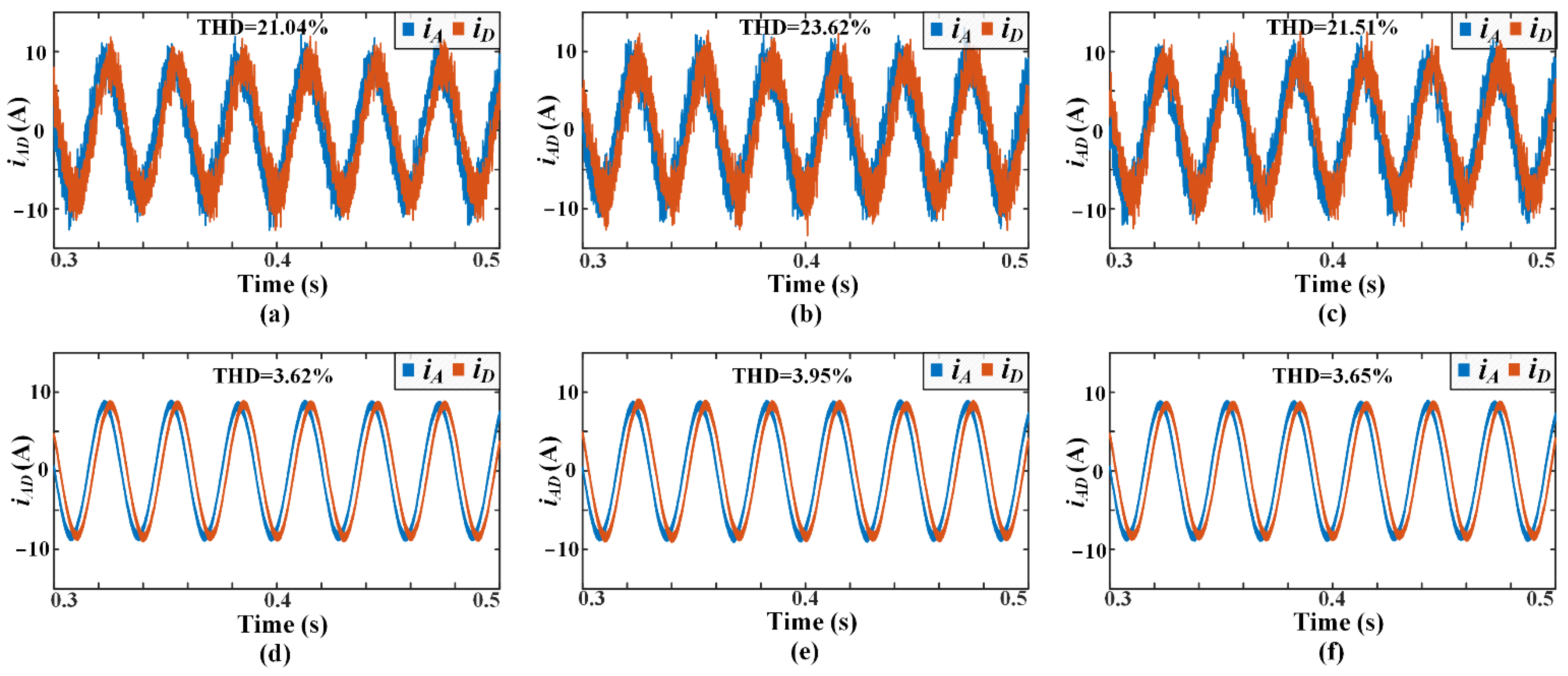

4.1. Simulated Results

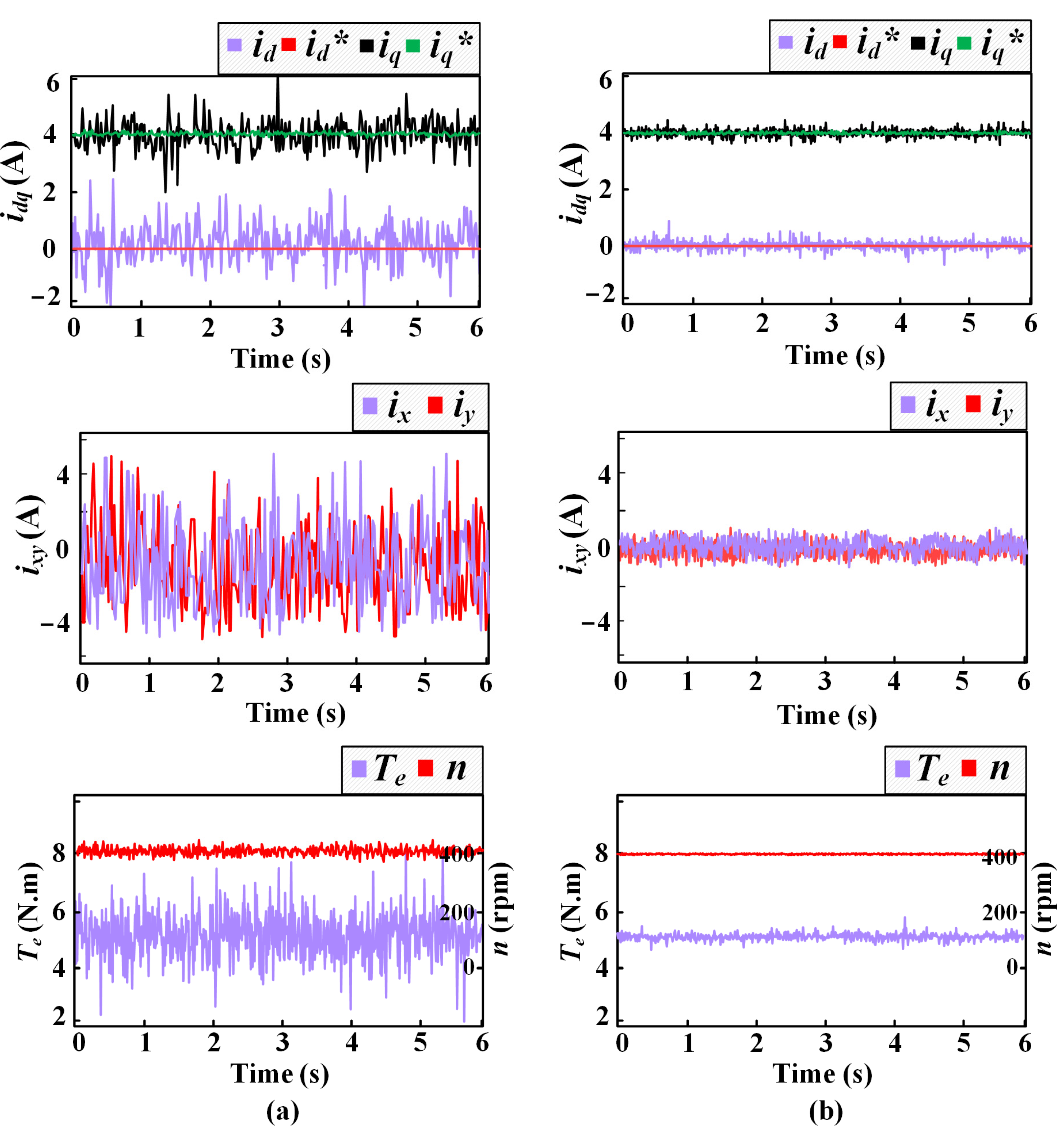

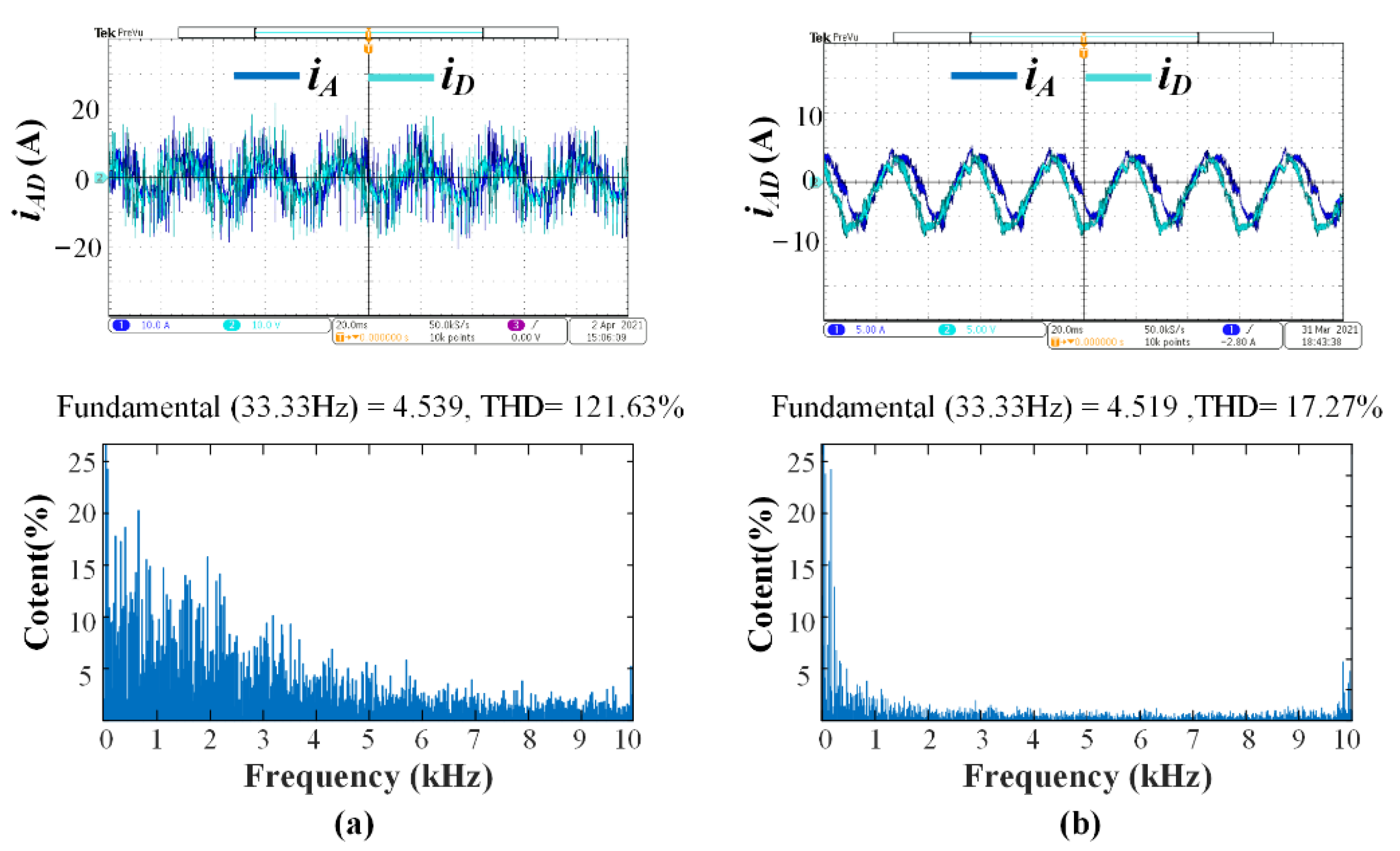

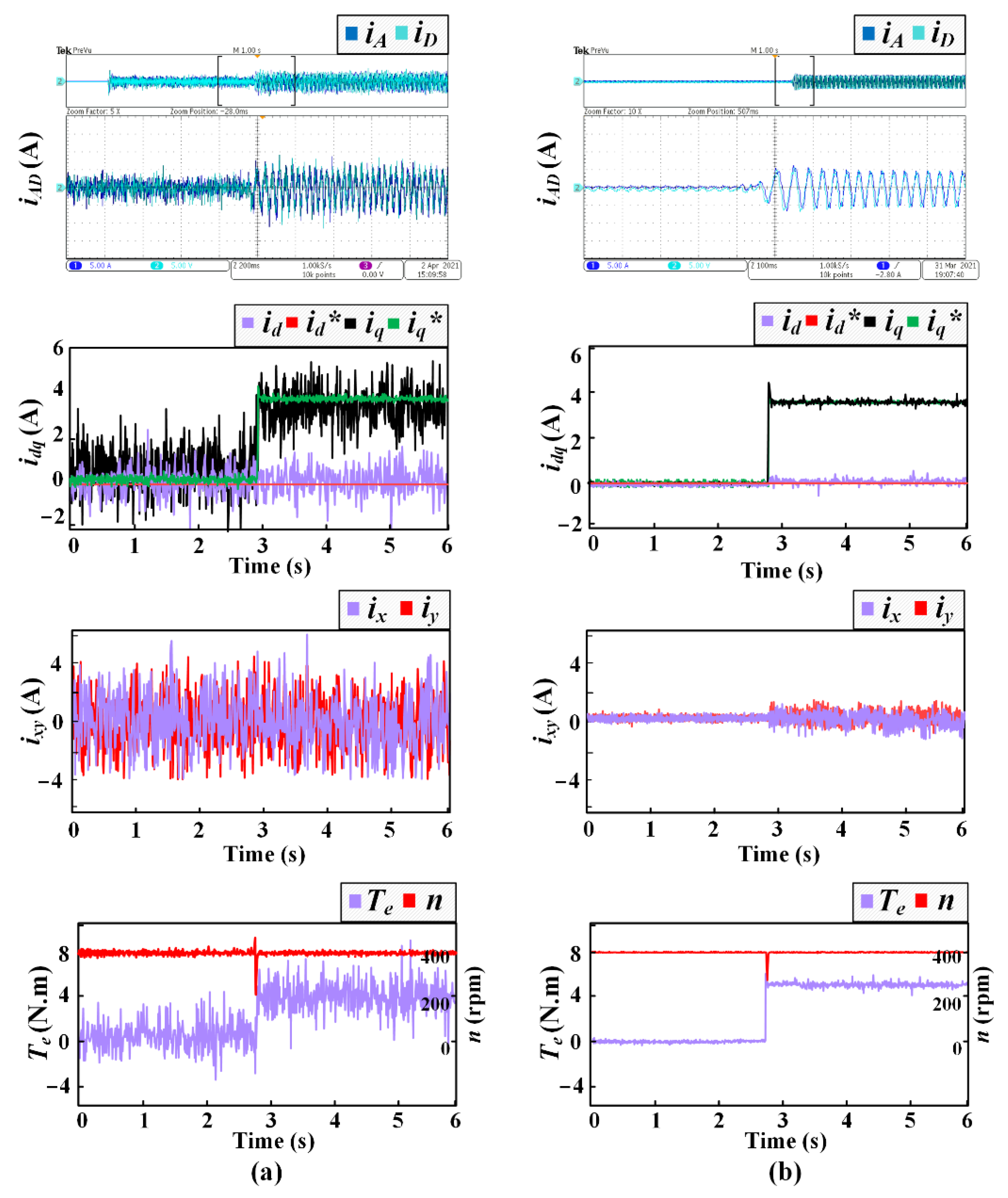

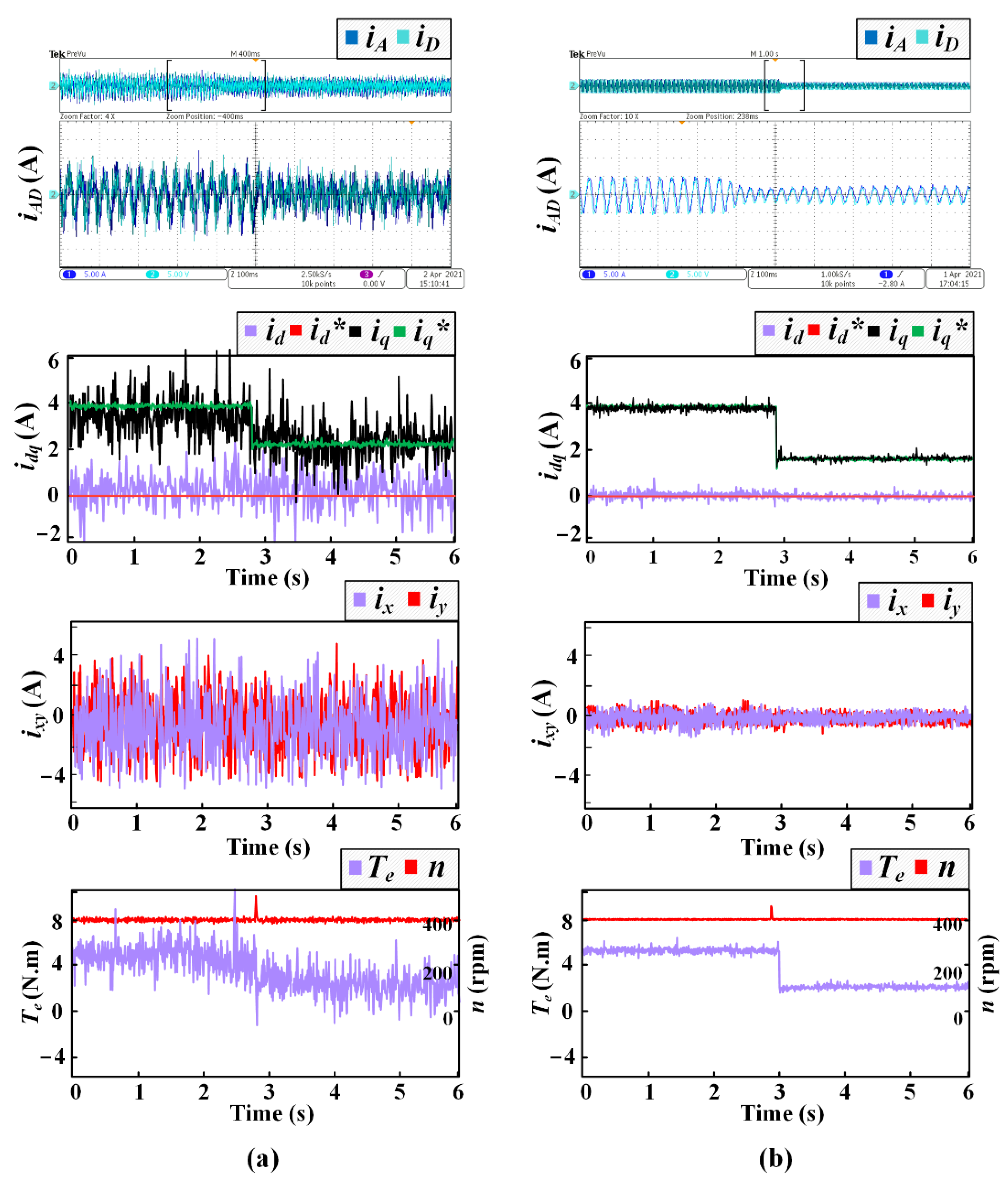

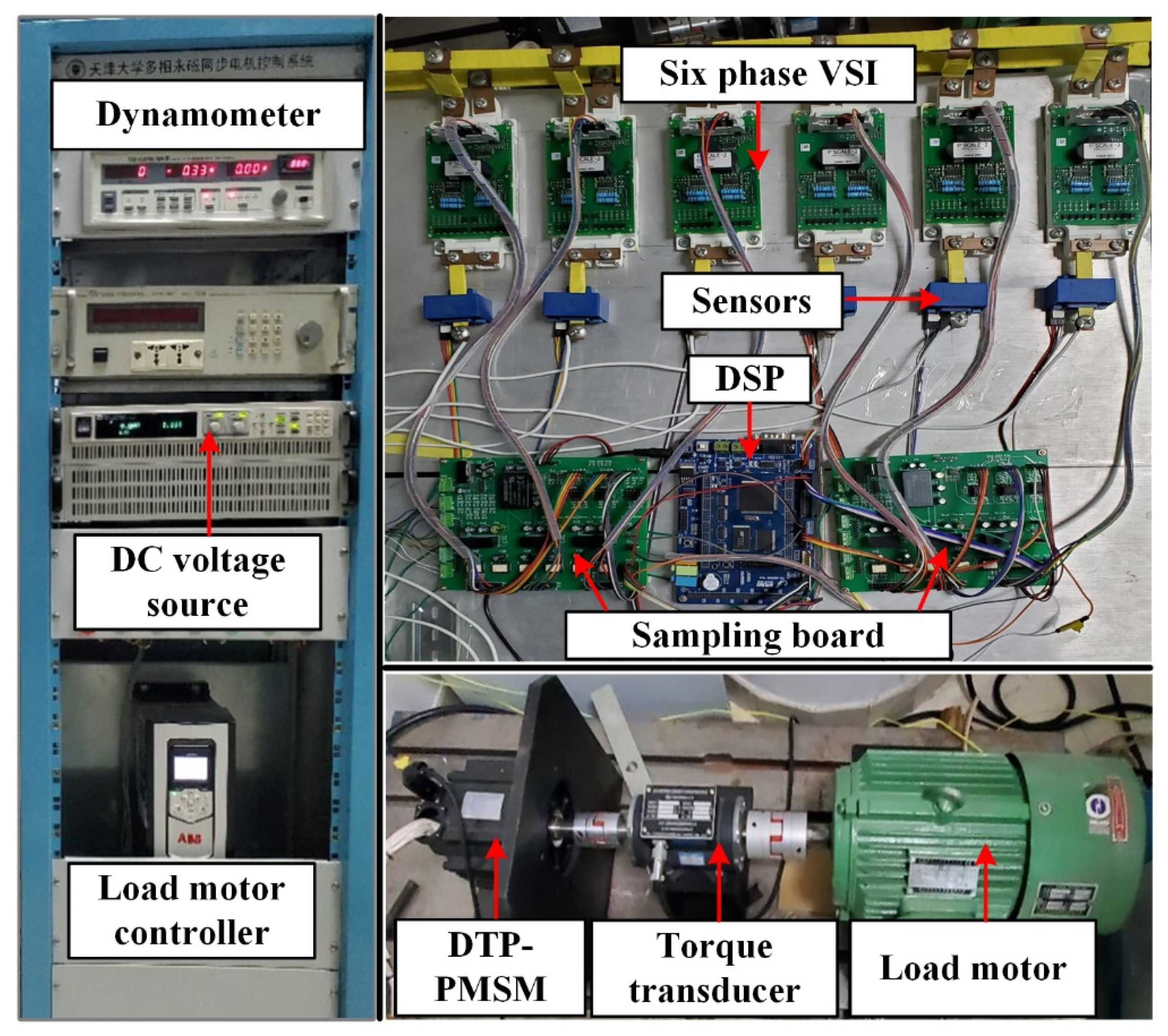

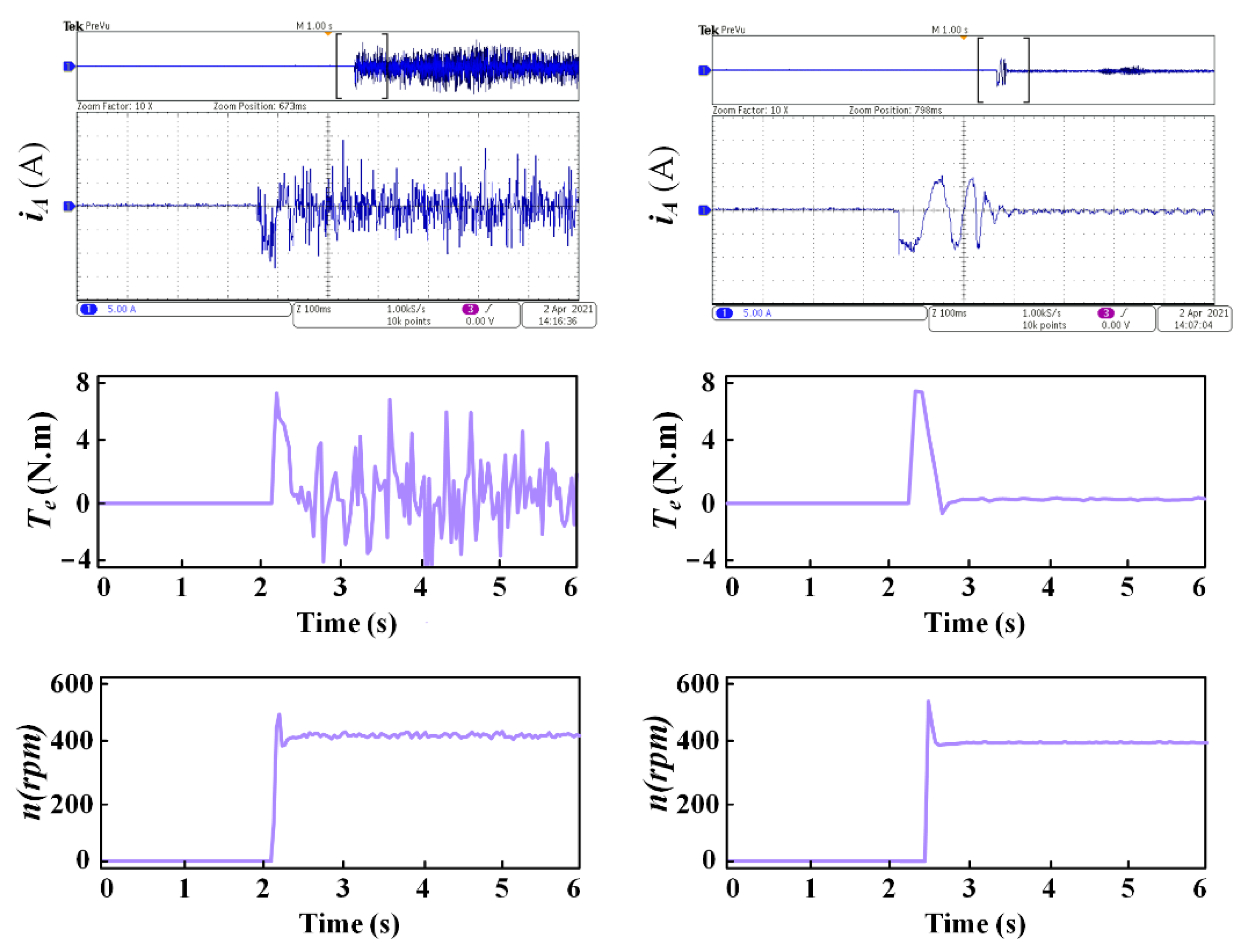

4.2. Experimental Results

5. Conclusions

- (1)

- The virtual vectors are pre-synthesized by large vectors and medium-large vectors, which aim to eliminate the components in harmonic subspace.

- (2)

- Two active virtual vectors and a zero vector are applied in this method according to the principle of deadbeat, thus the currents in fundamental subspace are also well regulated.

- (3)

- Through two traversals of the virtual vector, the optimal combination that ensures a minimum cost function could be selected.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tu, W.; Luo, G.; Chen, Z.; Cui, L.; Kennel, R. Predictive cascaded speed and current control for PMSM drives with multi-timescale Optimization. IEEE Trans. Power Electron. 2019, 34, 11046–11061. [Google Scholar] [CrossRef]

- Kakosimos, P.; Abu-Rub, H. Predictive speed control with short prediction horizon for permanent magnet synchronous motor drives. IEEE Trans. Power Electron. 2018, 33, 2740–2750. [Google Scholar] [CrossRef]

- Luo, G.; Zhang, R.; Chen, Z.; Tu, W.; Zhang, S.; Kennel, R. A novel nonlinear modeling method for permanent-magnet synchronous motors. IEEE Trans. Ind. Electron. 2016, 63, 6490–6498. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, L.; Zhang, Y. Model predictive current control for PMSM drives with parameter robustness improvement. IEEE Trans. Power Electron. 2019, 34, 1645–1657. [Google Scholar] [CrossRef]

- Mariethoz, S.; Morari, M. Explicit model-predictive control of a PWM inverter with an LCL filter. IEEE Trans. Ind. Electron. 2009, 56, 389–399. [Google Scholar] [CrossRef]

- Casadei, D.; Profumo, F.; Serra, G.; Tani, A. FOC and DTC: Two viable schemes for induction motors torque control. IEEE Trans. Power Electron. 2002, 17, 779–787. [Google Scholar] [CrossRef] [Green Version]

- Holtz, J. Advanced PWM and predictive control—An overview. IEEE Trans. Ind. Electron. 2016, 63, 3837–3844. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Jung, J. Finite control set model predictive control to guarantee stability and robustness for surface-mounted PM synchronous motors. IEEE Trans. Ind. Electron. 2018, 65, 8510–8519. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, H. Model predictive torque control of induction motor drives with optimal duty cycle control. IEEE Trans. Power Electron. 2014, 29, 6593–6603. [Google Scholar] [CrossRef]

- Davari, S.A.; Khaburi, D.A.; Kennel, R. An improved FCS–MPC algorithm for an induction motor with an imposed optimized weighting factor. IEEE Trans. Power Electron. 2012, 27, 1540–1551. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, H. Torque ripple reduction of model predictive torque control of induction motor drives. In Proceedings of the IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; pp. 1176–1183. [Google Scholar]

- Zhang, Y.; Yang, H. Generalized two-vector-based model-predictive torque control of induction motor drives. IEEE Trans. Power Electron. 2015, 30, 3818–3829. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, H. Two-vector-based model predictive torque control without weighting factors for induction motor drives. IEEE Trans. Power Electron. 2016, 31, 1381–1390. [Google Scholar] [CrossRef]

- Zhang, Y.; Peng, Y.; Yang, H. Performance improvement of two-vectors-based model predictive control of PWM rectifier. IEEE Trans. Power Electron. 2016, 31, 6016–6030. [Google Scholar] [CrossRef]

- Kang, S.; Soh, J.; Kim, R. Symmetrical three-vector-based model predictive control with deadbeat solution for IPMSM in rotating reference frame. IEEE Trans. Ind. Electron. 2020, 67, 159–168. [Google Scholar] [CrossRef]

- Zhao, Y.; Lipo, T. Space vector PWM control of dual three-phase induction machine using vector space decomposition. IEEE Trans. Ind. Appl. 1995, 31, 1100–1109. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, Z.; Wang, X.; Cheng, M. Predictive current control method for dual three-phase PMSM drives with reduced switching frequency and low-computation burden. IET Electr. Power Appl. 2020, 14, 668–677. [Google Scholar] [CrossRef]

- Duran, M.J.; Prieto, J.; Barrero, F.; Toral, S. Predictive current control of dual three-phase drives using restrained search techniques. IEEE Trans. Ind. Electron. 2011, 58, 3253–3263. [Google Scholar] [CrossRef]

- Xue, C.; Song, W.; Feng, X. Finite control-set model predictive current control of five-phase permanent-magnet synchronous machine based on virtual voltage vectors. IET Electr. Power Appl. 2017, 11, 836–846. [Google Scholar] [CrossRef]

- Gonzalez-Prieto, I.; Duran, M.J.; Aciego, J.J.; Martin, C.; Barrero, F. Model predictive control of six-phase induction motor drives using virtual voltage vectors. IEEE Trans. Ind. Electron. 2018, 65, 27–37. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, C. Elimination of harmonic currents using a reference voltage vector based-model predictive control for a six-phase PMSM motor. IEEE Trans. Power Electron. 2019, 34, 6960–6972. [Google Scholar] [CrossRef]

- Aciego, J.J.; Prieto, I.G.; Duran, M.J. Model predictive control of six-phase induction motor drives using two virtual voltage vectors. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 7, 321–330. [Google Scholar] [CrossRef]

| Item | Value |

|---|---|

| Stator resistance (R) | 0.45 Ω |

| Inductance of d-axis (Ld) | 1.4 mH |

| Inductance of q-axis (Lq) | 1.4 mH |

| Leakage inductance (Lxy) | 1.1 mH |

| Permanent magnet flux (ψ) | 0.08 wb |

| Numbers of pole pairs (P) | 5 |

| Rotational inertia (J) | 0.0023 kg·m2 |

| DC bus voltage (Vdc) | 100 V |

| Rated speed (n) | 2000 rpm |

| Rated torque (T) | 10 N.m |

| Sample frequency (f) | 10 kHz |

| Equipment | Type |

|---|---|

| Current sensors | HAS-50S |

| DC power | IT6535C |

| VSI | FF300R12ME4 |

| Drive board of VSI | 2SP0115T2C0-12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luan, T.; Wang, Z.; Long, Y.; Zhang, Z.; Li, Q.; Zhu, Z.; Liu, C. Multi-Virtual-Vector Model Predictive Current Control for Dual Three-Phase PMSM. Energies 2021, 14, 7292. https://doi.org/10.3390/en14217292

Luan T, Wang Z, Long Y, Zhang Z, Li Q, Zhu Z, Liu C. Multi-Virtual-Vector Model Predictive Current Control for Dual Three-Phase PMSM. Energies. 2021; 14(21):7292. https://doi.org/10.3390/en14217292

Chicago/Turabian StyleLuan, Tianjiao, Zhichao Wang, Yang Long, Zhen Zhang, Qi Li, Zhihao Zhu, and Chunhua Liu. 2021. "Multi-Virtual-Vector Model Predictive Current Control for Dual Three-Phase PMSM" Energies 14, no. 21: 7292. https://doi.org/10.3390/en14217292

APA StyleLuan, T., Wang, Z., Long, Y., Zhang, Z., Li, Q., Zhu, Z., & Liu, C. (2021). Multi-Virtual-Vector Model Predictive Current Control for Dual Three-Phase PMSM. Energies, 14(21), 7292. https://doi.org/10.3390/en14217292