Spraying of Composite Liquid Fuels Based on Types of Coal Preparation Waste: Current Problems and Achievements: Review

Abstract

:1. Introduction

1.1. Relevance of Composite Liquid Fuels

- -

- lower cost as compared with fuel oil or coal in its pure form;

- -

- minimal emissions of harmful substances into the air due to complete combustion of fuel;

- -

- a possibility to recover a large group of combustible waste as fuel components;

- -

- reduced fire and explosion hazard at power plants due to the presence of water in the composite fuel composition.

1.2. CLF Atomization in the Combustion Chambers of Power Plants

2. Prospective Components of Composite Liquid Fuels

2.1. Coal–Water and Organic-Coal–Water Suspensions

2.2. Anhydrous Composite Liquid Fuels

3. Primary Atomization of Composite Liquid Fuels

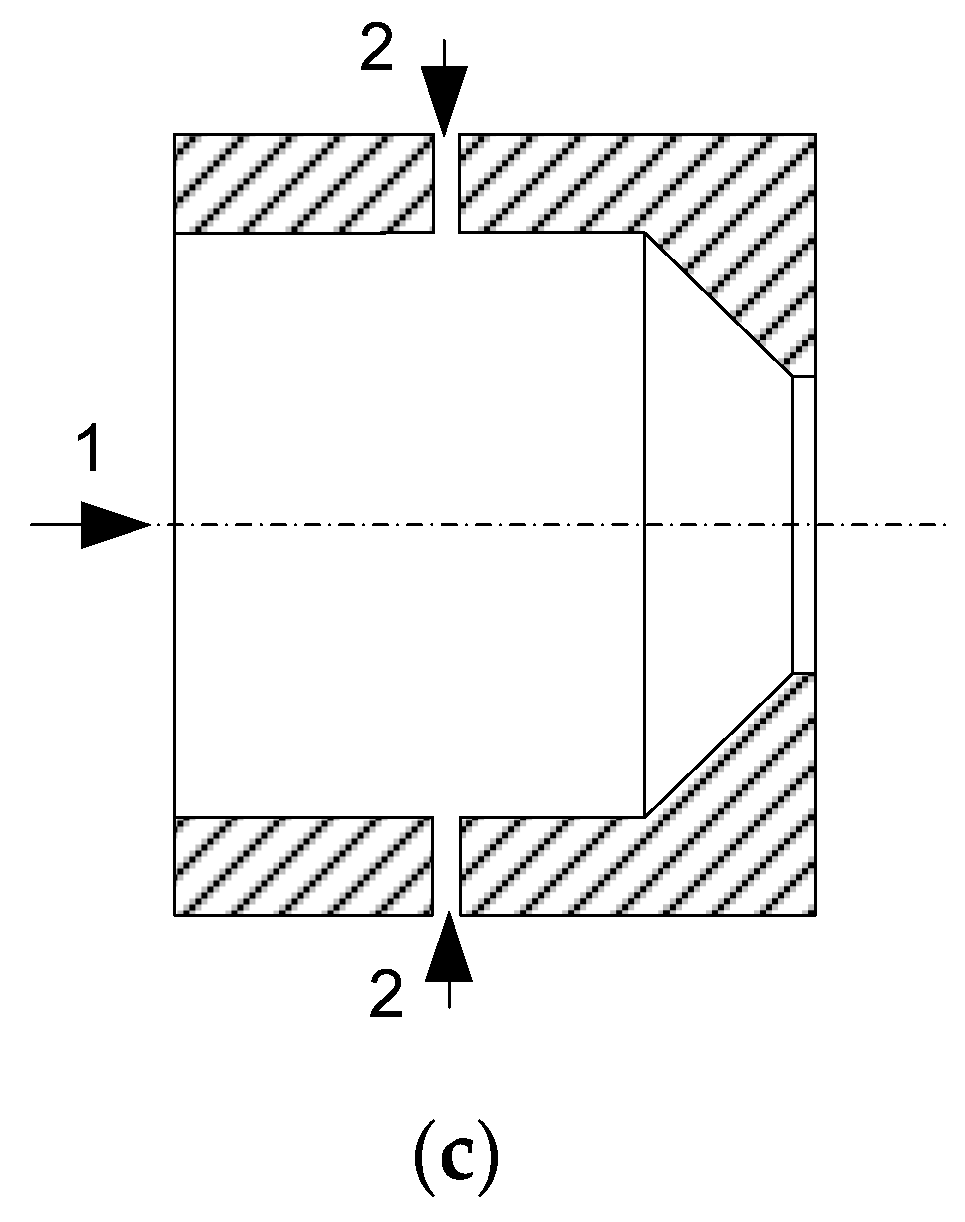

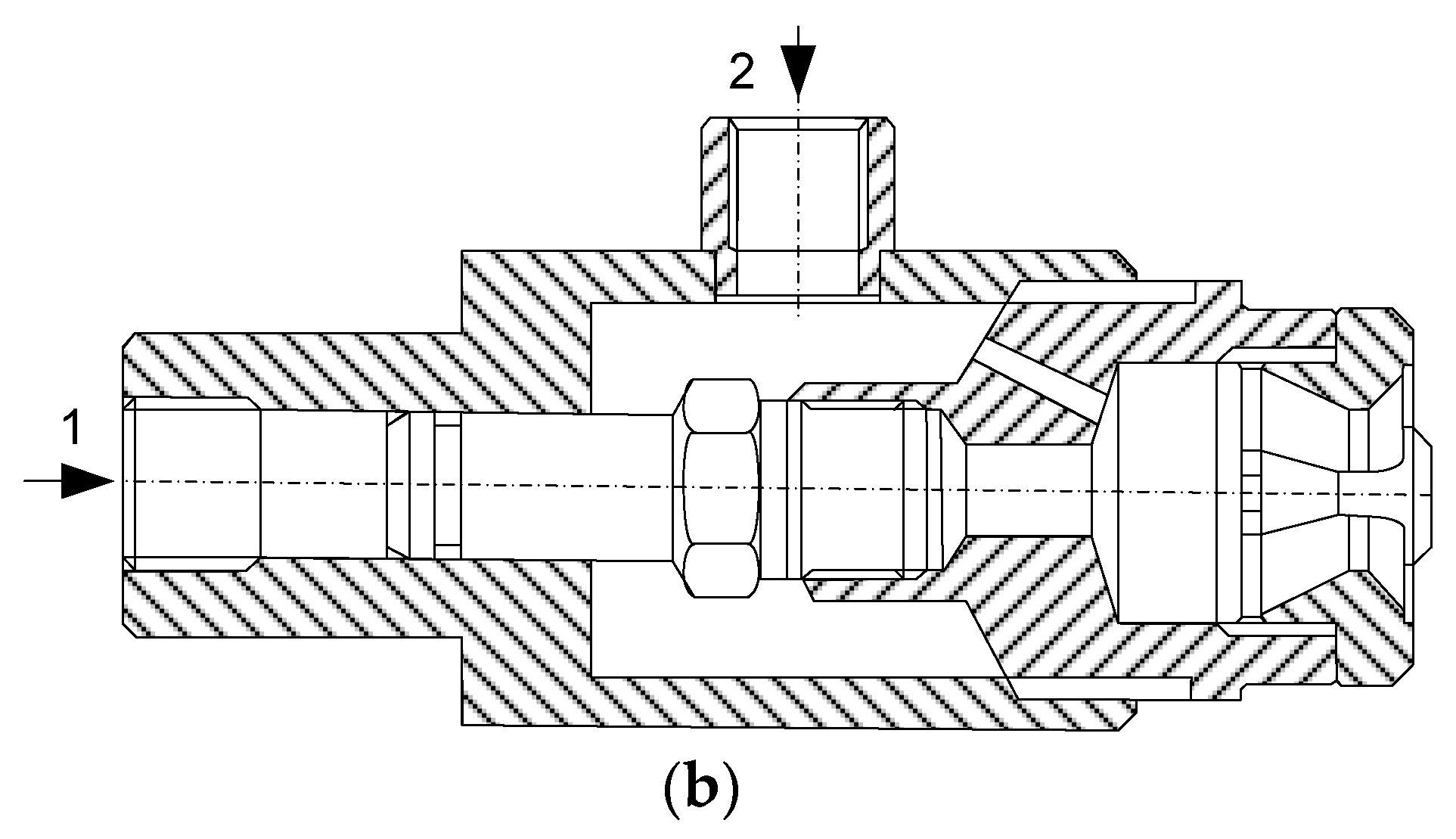

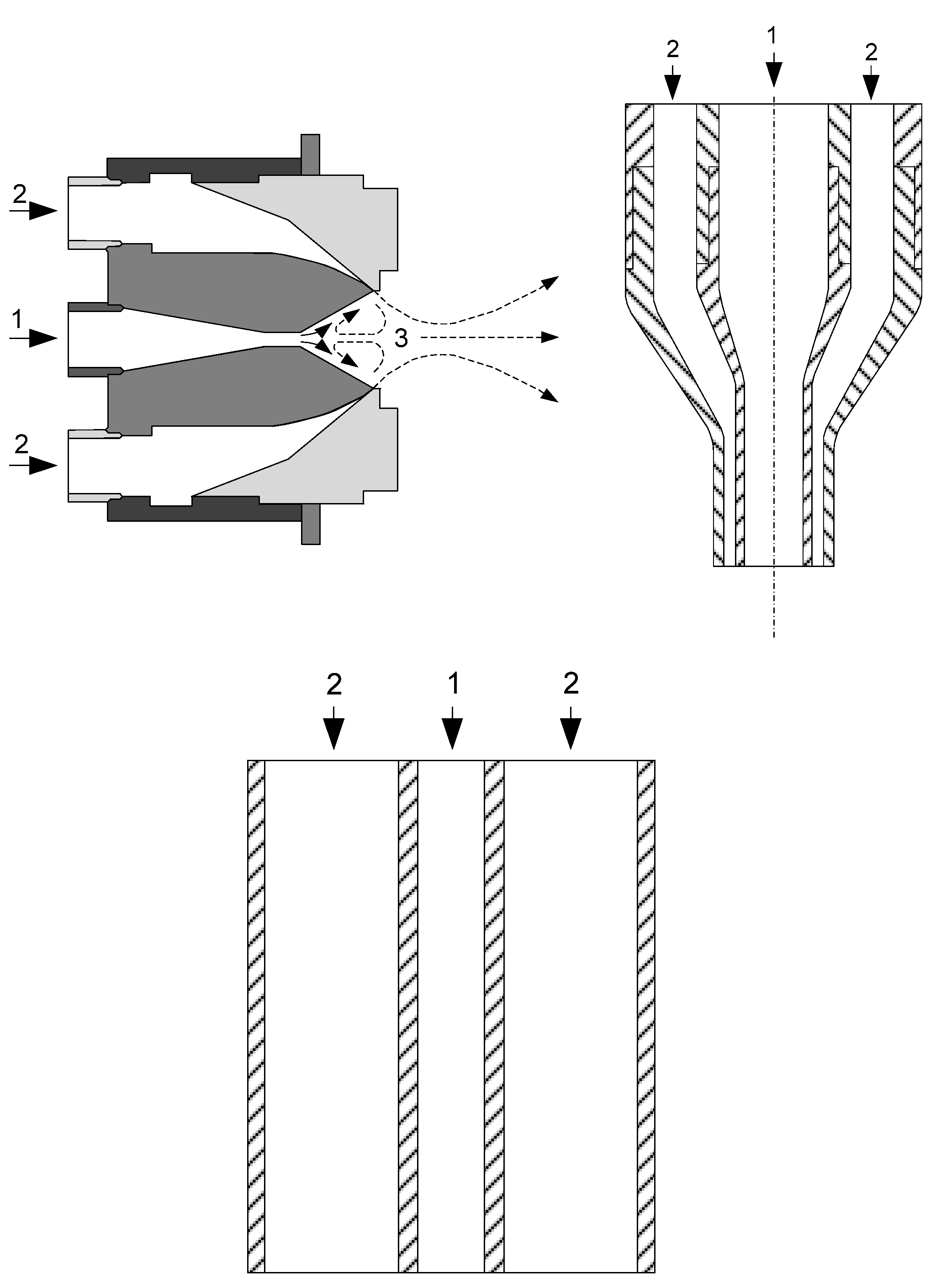

3.1. Injectors with Internal Mixing

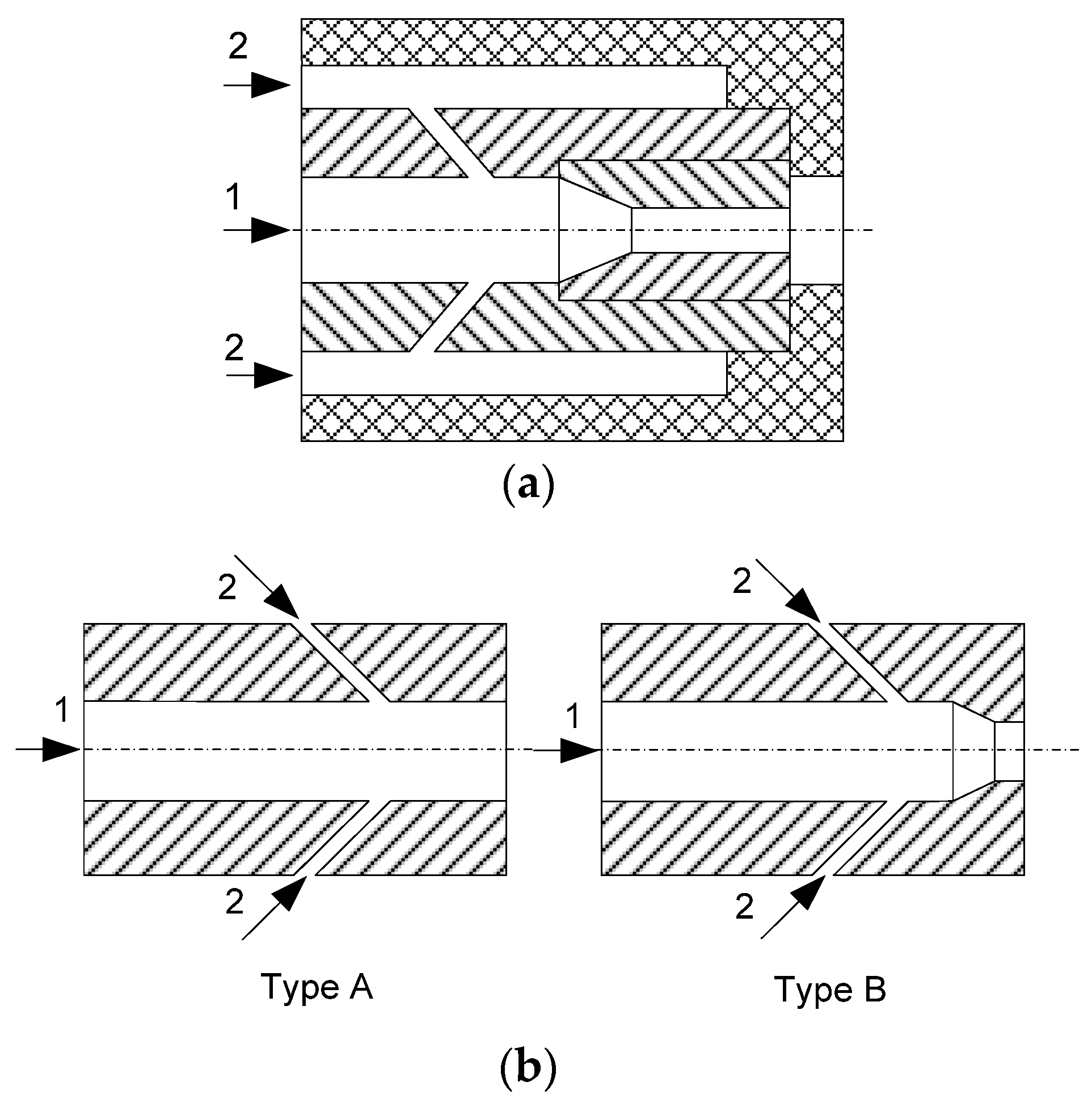

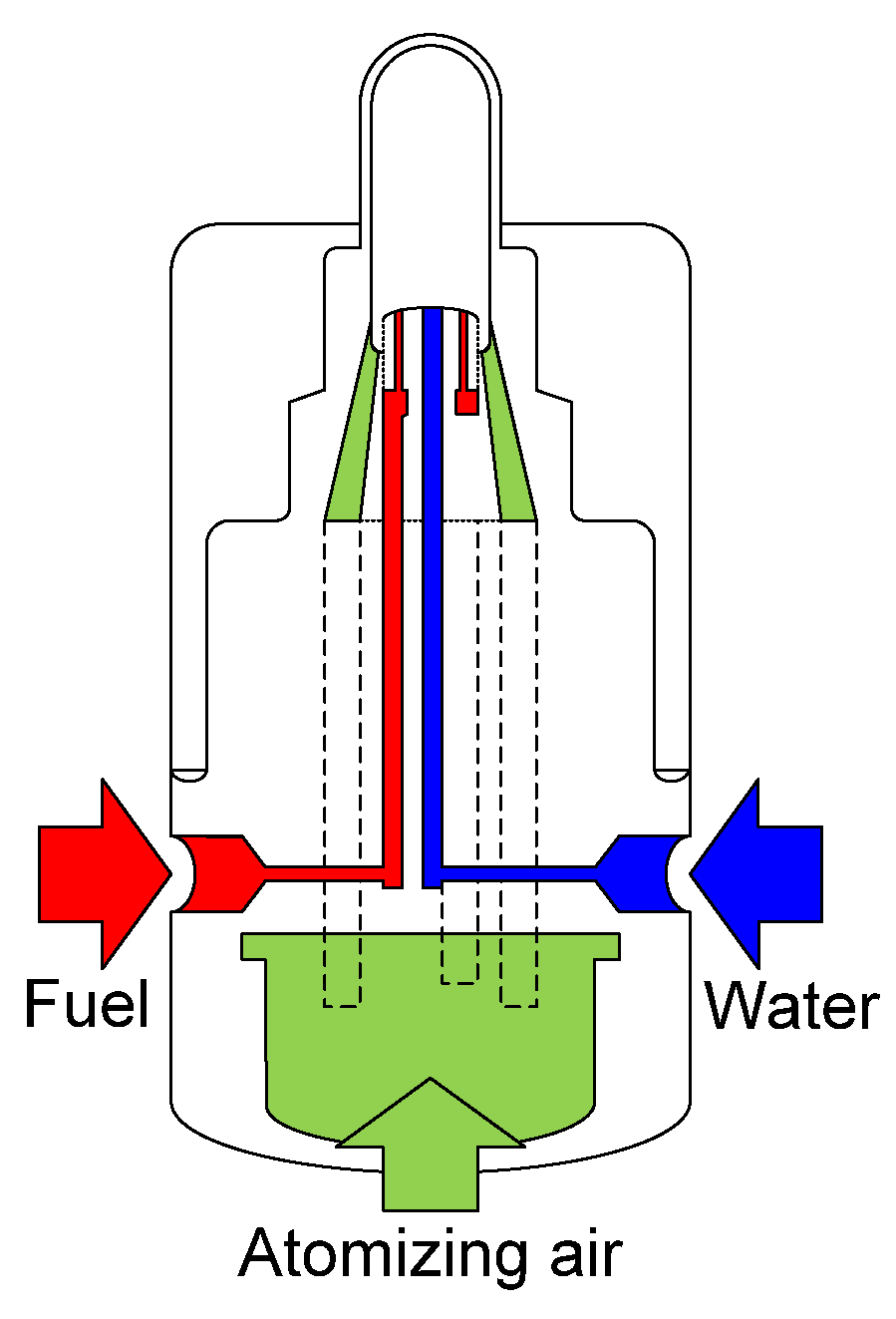

3.2. Injectors with Multi-Stage Mixing

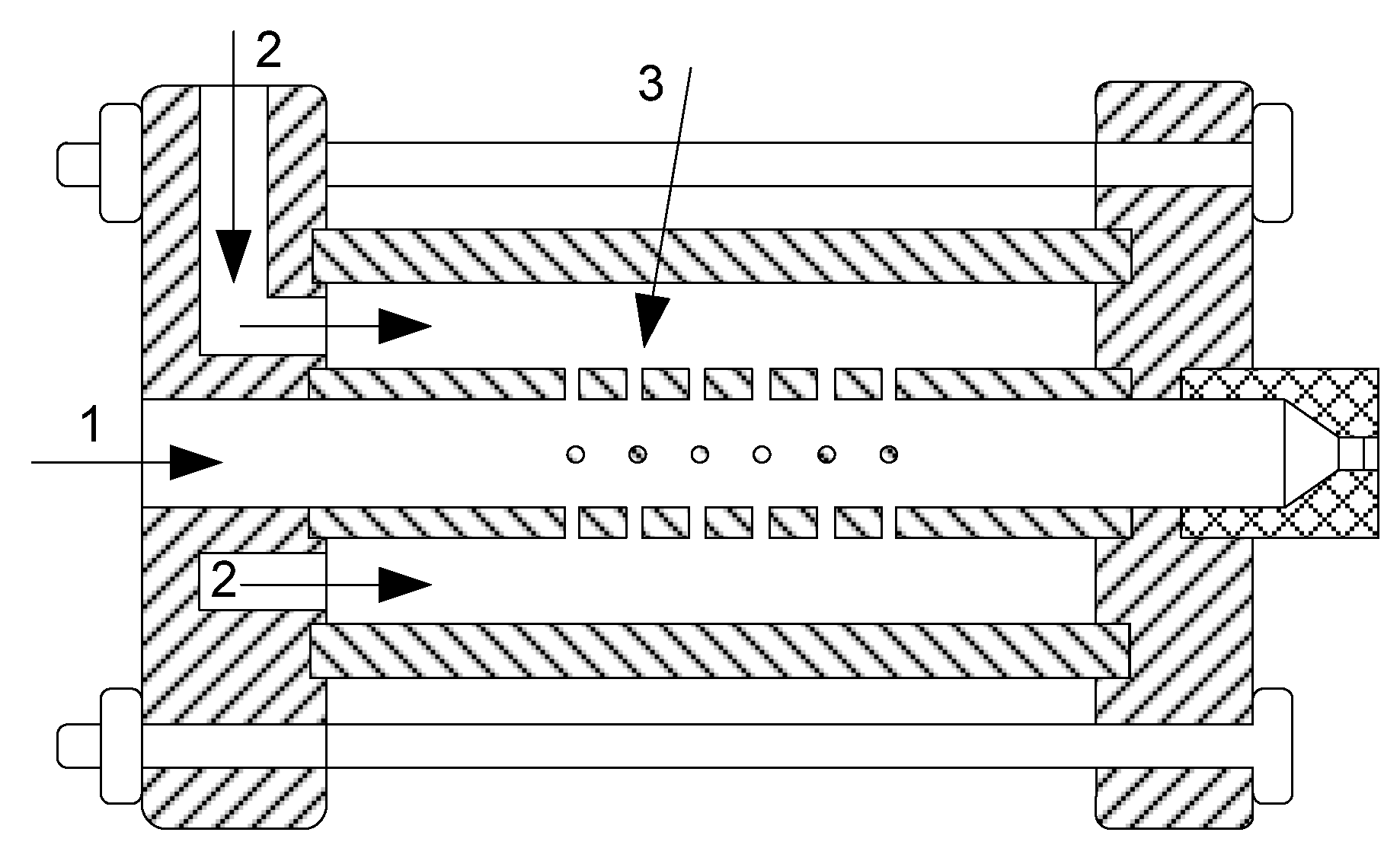

3.3. Bubble Injectors

3.4. Coaxial Injectors

4. Secondary Atomization of Composite Liquid Fuels

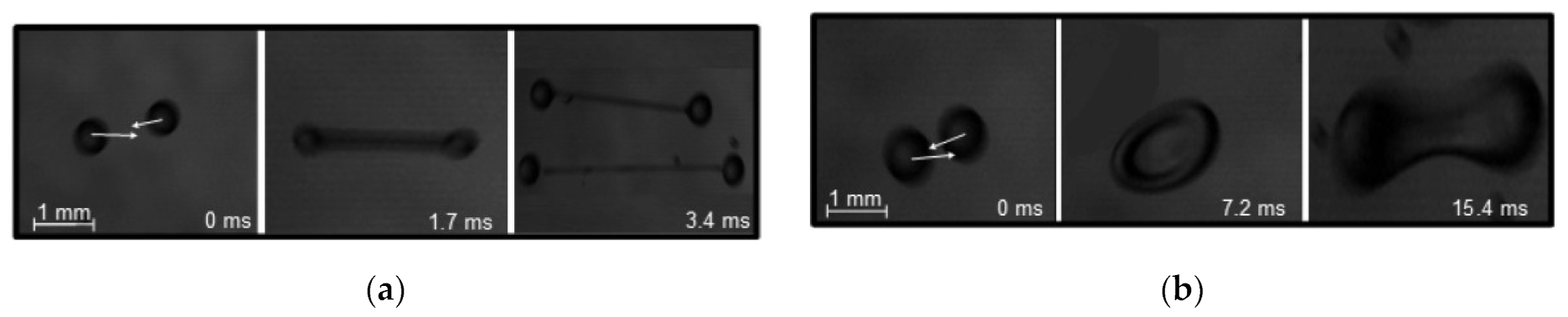

4.1. Aerodynamic Mechanism of Secondary Atomization

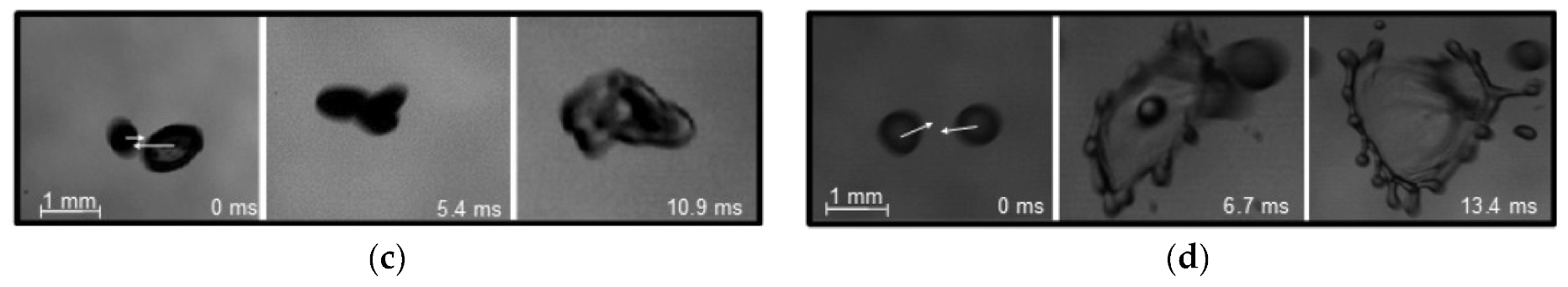

4.2. Thermal Mechanism of Secondary Atomization

5. Conclusions

- Based on the analysis of modern trends in the development of technologies for the atomization of composite liquid fuels, it can be concluded that the most effective formation of a polydisperse flux of fuel suspensions requires the simultaneous use of primary and secondary atomization modes. It is not possible to develop a universal scheme for the injection of CLFs into the combustion chamber due to a wide variety of fuel components, stabilizing additives, and their ratios in the composition.

- Based on the analysis of modern achievements of the global scientific community, it is possible to formulate conclusions regarding primary atomization modes:

- Injector devices with simple internal mixing allow for the formation of an effective polydisperse flux. However, they are sensitive to the presence of large inclusions of solid particles. When preparing composite liquid fuels with solid additives in industrial volumes, it is difficult to completely exclude the occurrence of such agglomerates.

- Multistage injectors are more resistant to the presence of large particles. However, their performance and polydisperse flux parameters strongly depend on the ratio between the flow rates of the fuel and the atomizing agent. This requires the use of highly sensitive control systems.

- It is not advisable to use bubbling injectors for atomizing composite liquid fuels with solid components. However, this type of atomization can be used for suspensions based on liquid components, including those with non-Newtonian properties.

- Coaxial injectors demonstrate excellent efficiency in the formation of finely dispersed fluxes due to a high degree of turbulence. At the same time, their main disadvantage is high resulting flow rates, including supersonic ones.

- When analyzing the methods of secondary atomization of composite liquid fuel droplets, it is substantiated that, for the best use of the aerodynamic mechanism of secondary fragmentation, optimal ranges of motion velocities and mutual trajectories of droplet fluxes should be chosen. In this regard, it is necessary to note that the development of aerodynamic fragmentation mode maps is highly relevant, and these maps can only be obtained from experimental research findings. For the effective implementation of the thermal mechanism of secondary fragmentation, it is necessary to aim for the occurrence of micro-explosive disintegration. The main favorable factors include: the presence of solid inclusions (a clear phase boundary) in the droplets; a significant difference in the volatility of liquid components; and the presence of microcenters where boiling centers nucleation takes place.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ruhe, C.H.W. Statistical Review. JAMA J. Am. Med. Assoc. 1973, 225, 299–306. [Google Scholar] [CrossRef]

- Mohanty, J.K.; Guru, S.R.; Dash, P.; Pradhan, P.K. Fly Ash Management and Condition Monitoring of Ash Pond. Earth Syst. Environ. 2020, 5, 445–457. [Google Scholar] [CrossRef]

- Gonzalez-Salazar, M.A.; Kirsten, T.; Prchlik, L. Review of the operational flexibility and emissions of gas- and coal-fired power plants in a future with growing renewables. Renew. Sustain. Energy Rev. 2018, 82, 1497–1513. [Google Scholar] [CrossRef]

- Guttikunda, S.K.; Jawahar, P. Atmospheric emissions and pollution from the coal-fired thermal power plants in India. Atmos. Environ. 2014, 92, 449–460. [Google Scholar] [CrossRef]

- Wang, G.; Xu, Y.; Ren, H. Intelligent and ecological coal mining as well as clean utilization technology in China: Review and prospects. Int. J. Min. Sci. Technol. 2019, 29, 161–169. [Google Scholar] [CrossRef]

- Bogomolov, A.; Valiullin, T.; Vershinina, K.; Shevyrev, S.; Shlegel, N. Igniting Soaring Droplets of Promising Fuel Slurries. Energies 2019, 12, 208. [Google Scholar] [CrossRef] [Green Version]

- Zhou, L.; Li, X.; Zhang, R.; Zhou, W.; Jin, J.; Wang, C.; Tian, Y.; Zhang, K. New method for utilizing waste tire pyrolysis residue to prepare slurry fuel: Adsorption and slurry characteristics. Powder Technol. 2021, 386, 236–246. [Google Scholar] [CrossRef]

- Ra, H.W.; Mun, T.Y.; Hong, S.J.; Chun, D.H.; Lee, H.T.; Yoon, S.M.; Moon, J.H.; Park, S.J.; Lee, S.H.; Yang, J.H.; et al. Indirect coal liquefaction by integrated entrained flow gasification and Rectisol/Fischer–Tropsch processes for producing automobile diesel substitutes. Energy 2021, 219, 119597. [Google Scholar] [CrossRef]

- Meng, Z.; Yang, Z.; Yin, Z.; Li, Y.; Ju, X.; Yao, Y.; Long, J. Interaction between dispersant and coal slime added in semi-coke water slurry: An experimental and DFT study. Appl. Surf. Sci. 2021, 540, 148327. [Google Scholar] [CrossRef]

- Cui, L.; An, L.; Jiang, H. A novel process for preparation of an ultra-clean superfine coal–oil slurry. Fuel 2008, 87, 2296–2303. [Google Scholar] [CrossRef]

- Shui, H.; Cai, Z.; Xu, C. Recent Advances in Direct Coal Liquefaction. Energies 2010, 3, 155. [Google Scholar] [CrossRef]

- Kong, Z.; Dong, X.; Xu, B.; Li, R.; Yin, Q.; Song, C. EROI Analysis for Direct Coal Liquefaction without and with CCS: The Case of the Shenhua DCL Project in China. Energies 2015, 8, 786–807. [Google Scholar] [CrossRef] [Green Version]

- Shadrin, E.Y.; Anufriev, I.S.; Butakov, E.B.; Kopyev, E.P.; Alekseenko, S.V.; Maltsev, L.I.; Sharypov, O.V. Coal-water slurry atomization in a new pneumatic nozzle and combustion in a low-power industrial burner. Fuel 2021, 303, 121182. [Google Scholar] [CrossRef]

- Singh, A.; Kumar, H.; Kumar, S. Analysis of Tribological Performance of HVOF Sprayed Composite Coatings on Pipeline Material; AIP Publishing: Melville, NY, USA, 2021. [Google Scholar]

- Larionov, K.B.; Zenkov, A.V.; Yankovsky, S.A.; Ditc, A.A. Change of coal-water fuel rheological properties by rotary flows modulation. In Proceedings of the 2016 11th International Forum on Strategic Technology (IFOST), Novosibirsk, Russia, 1–3 June 2016; pp. 568–571. [Google Scholar] [CrossRef]

- Al-lwayzy, S.H.; Yusaf, T.; Saleh, K.; Yousif, B. The Influence of Emulsified Water Fuel Containing Fresh Water Microalgae on Diesel Engine Performance, Combustion, Vibration and Emission. Energies 2019, 12, 2546. [Google Scholar] [CrossRef] [Green Version]

- Long, J.M.; Boyette, M.D. Analysis of Micronized Charcoal for Use in a Liquid Fuel Slurry. Energies 2016, 10, 25. [Google Scholar] [CrossRef] [Green Version]

- Lu, P.; Zhang, M. Experimental investigation on atomizing characteristics of coal–water paste for pressurized fluidized bed. Fuel 2004, 83, 2109–2114. [Google Scholar] [CrossRef]

- Alekseenko, S.V.; Anufriev, I.S.; Dekterev, A.A.; Kuznetsov, V.A.; Maltsev, L.I.; Minakov, A.V.; Chernetskiy, M.Y.; Shadrin, E.Y.; Sharypov, O.V. Experimental and numerical investigation of aerodynamics of a pneumatic nozzle for suspension fuel. Int. J. Heat Fluid Flow 2019, 77, 288–298. [Google Scholar] [CrossRef] [Green Version]

- Deng, J.; Ding, Z.; Zhou, H.; Tan, Y. Performance and wear characteristics of ceramic, cemented carbide, and metal nozzles used in coal–water–slurry boilers. Int. J. Refract. Met. Hard Mater. 2009, 27, 919–926. [Google Scholar] [CrossRef]

- Zhao, H.; Hou, Y.B.; Liu, H.F.; Tian, X.S.; Xu, J.L.; Li, W.F.; Liu, Y.; Wu, F.Y.; Zhang, J.; Lin, K.F. Influence of rheological properties on air-blast atomization of coal water slurry. J. Nonnewton. Fluid Mech. 2014, 211, 1–15. [Google Scholar] [CrossRef]

- Yu, H.; Zhang, C.; Liu, J.; Cen, K. Experimental Study of the Atomizing Performance of a New Type of Nozzle for Coal Water Slurry. Energy Fuels 2008, 22, 1170–1173. [Google Scholar] [CrossRef]

- Ma, X.; Duan, Y.; Liu, M. Atomization of petroleum-coke sludge slurry using effervescent atomizer. Exp. Therm. Fluid Sci. 2013, 46, 131–138. [Google Scholar] [CrossRef]

- Yuan, K.; Chen, L.; Wu, C. Study on characteristics of different types of nozzles for coal-water slurry atomization. J. Therm. Sci. 2001, 10, 331–335. [Google Scholar] [CrossRef]

- Volkov, R.S.; Kuznetsov, G.V.; Strizhak, P.A. Analysis of the Characteristics of the Retardation and Entrainment of Droplets in a Polydisperse Water Flow by High-Temperature Gases Under Conditions of Intense Phase Transformations. J. Eng. Phys. Thermophys 2015, 88, 937–947. [Google Scholar] [CrossRef]

- Solomatin, Y.; Shlegel, N.E.; Strizhak, P.A. Atomization of promising multicomponent fuel droplets by their collisions. Fuel 2019, 255, 115751. [Google Scholar] [CrossRef]

- Zhao, H.; Wu, Z.W.; Li, W.F.; Xu, J.L.; Liu, H.F. Transition Weber number between surfactant-laden drop bag breakup and shear breakup of secondary atomization. Fuel 2018, 221, 138–143. [Google Scholar] [CrossRef]

- Breitenbach, J.; Kissing, J.; Roisman, I.V.; Tropea, C. Characterization of secondary droplets during thermal atomization regime. Exp. Therm. Fluid Sci. 2018, 98, 516–522. [Google Scholar] [CrossRef]

- Ashikhmin, A.E.; Khomutov, N.A.; Piskunov, M.V.; Yanovsky, V.A. Secondary Atomization of a Biodiesel Micro-Emulsion Fuel Droplet Colliding with a Heated Wall. Appl. Sci. 2020, 10, 685. [Google Scholar] [CrossRef] [Green Version]

- Ismael, M.A.; Heikal, M.R.; Aziz, A.R.A.; Crua, C.; El-Adawy, M.; Nissar, Z.; Baharom, M.B.; Zainal A., E.Z.; Firmansyah. Investigation of Puffing and Micro-Explosion of Water-in-Diesel Emulsion Spray Using Shadow Imaging. Energies 2018, 11, 2281. [Google Scholar] [CrossRef] [Green Version]

- Watanabe, H.; Shoji, Y.; Yamagaki, T.; Hayashi, J.; Akamatsu, F.; Okazaki, K. Observation of droplet behavior of emulsified fuel in secondary atomization in flame. J. Therm. Sci. Technol. 2014, 9, JTST0009–JTST0009. [Google Scholar] [CrossRef] [Green Version]

- Watanabe, H.; Okazaki, K. Visualization of secondary atomization in emulsified-fuel spray flow by shadow imaging. Proc. Combust. Inst. 2013, 34, 1651–1658. [Google Scholar] [CrossRef]

- Antonov, D.V.; Kuznetsov, G.V.; Strizhak, P.A. Fragmentation of heated droplets of coal-water slurries containing petrochemicals. Appl. Therm. Eng. 2021, 195, 117190. [Google Scholar] [CrossRef]

- Mukhtar, M.N.A.; Hagos, F.Y.; Noor, M.M.; Mamat, R.; Abdullah, A.A.; Abd Aziz, A.R. Tri-fuel emulsion with secondary atomization attributes for greener diesel engine—A critical review. Renew. Sustain. Energy Rev. 2019, 111, 490–506. [Google Scholar] [CrossRef]

- Suzuki, Y.; Harada, T.; Watanabe, H.; Shoji, M.; Matsushita, Y.; Aoki, H.; Miura, T. Visualization of aggregation process of dispersed water droplets and the effect of aggregation on secondary atomization of emulsified fuel droplets. Proc. Combust. Inst. 2011, 33, 2063–2070. [Google Scholar] [CrossRef]

- Rao, D.C.K.; Karmakar, S. Crown formation and atomization in burning multi-component fuel droplets. Exp. Therm. Fluid Sci. 2018, 98, 303–308. [Google Scholar] [CrossRef]

- Faik, A.M.D.; Zhang, Y. Liquid-phase dynamics during the two-droplet combustion of diesel-based fuel mixtures. Exp. Therm. Fluid Sci. 2020, 115, 110084. [Google Scholar] [CrossRef]

- Watanabe, H.; Shoji, Y.; Yamagaki, T.; Hayashi, J.; Akamatsu, F.; Okazaki, K. Secondary atomization and spray flame characteristics of carbonated W/O emulsified fuel. Fuel 2016, 182, 259–265. [Google Scholar] [CrossRef]

- Gvozdyakov, D.; Zenkov, A. Improvement of atomization characteristics of coal-water slurries. Energy 2021, 230, 120900. [Google Scholar] [CrossRef]

- Cheng, J.; Zhou, J.; Li, Y.; Liu, J.; Cen, K. Effects of pore fractal structures of ultrafine coal water slurries on rheological behaviors and combustion dynamics. Fuel 2008, 87, 2620–2627. [Google Scholar] [CrossRef]

- Egorov, R.I.; Zaitsev, A.S.; Salgansky, E.A. Activation of the Fuels with Low Reactivity Using the High-Power Laser Pulses. Energies 2018, 11, 3167. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Huang, R.; Huang, S.; Zhang, Y.; Xu, S.; Wang, Z. Experimental investigation on the effect of n-pentanol blending on spray, ignition and combustion characteristics of waste cooking oil biodiesel. Energy Convers. Manag. 2017, 148, 440–455. [Google Scholar] [CrossRef]

- Jiang, L.; Liang, J.; Yuan, X.; Li, H.; Li, C.; Xiao, Z.; Huang, H.; Wang, H.; Zeng, G. Co-pelletization of sewage sludge and biomass: The density and hardness of pellet. Bioresour. Technol. 2014, 166, 435–443. [Google Scholar] [CrossRef] [PubMed]

- Bi, H.; Wang, C.; Lin, Q.; Jiang, X.; Jiang, C.; Bao, L. Combustion behavior, kinetics, gas emission characteristics and artificial neural network modeling of coal gangue and biomass via TG-FTIR. Energy 2020, 213, 118790. [Google Scholar] [CrossRef]

- Yu, Y. Experimental study on effects of ethanol-diesel fuel blended on spray characteristics under ultra-high injection pressure up to 350 MPa. Energy 2019, 186, 115768. [Google Scholar] [CrossRef]

- Kim, H.J.; Suh, H.K.; Park, S.H.; Lee, C.S. An Experimental and Numerical Investigation of Atomization Characteristics of Biodiesel, Dimethyl Ether, and Biodiesel−Ethanol Blended Fuel. Energy Fuels 2008, 22, 2091–2098. [Google Scholar] [CrossRef]

- Sun, D.; Cai, W.; Li, C.; Lu, J. Experimental study on atomization characteristics of high-energy-density fuels using a fuel slinger. Energy 2021, 234, 121222. [Google Scholar] [CrossRef]

- Jin, Y.; Dou, S.; Yang, Q.; Xu, X.; Fu, Q.; Pan, L. Performance characteristics of a scramjet engine using JP-10 fuel containing aluminum nanoparticles. Acta Astronaut. 2021, 185, 70–77. [Google Scholar] [CrossRef]

- Li, S.; Zhuo, Z.; He, L.; Huang, X. Atomization characteristics of nano-Al/ethanol nanofluid fuel in electrostatic field. Fuel 2019, 236, 811–819. [Google Scholar] [CrossRef]

- Klein-Douwel, R.J.H.; Frijters, P.J.M.; Somers, L.M.T.; de Boer, W.A.; Baert, R.S.G. Macroscopic diesel fuel spray shadowgraphy using high speed digital imaging in a high pressure cell. Fuel 2007, 86, 1994–2007. [Google Scholar] [CrossRef]

- Sparacino, S.; Berni, F.; D’Adamo, A.; Krastev, V.K.; Cavicchi, A.; Postrioti, L. Impact of the Primary Break-Up Strategy on the Morphology of GDI Sprays in 3D-CFD Simulations of Multi-Hole Injectors. Energies 2019, 12, 2890. [Google Scholar] [CrossRef] [Green Version]

- Mohd Arshad, A.S.; Nada, Y.; Kidoguchi, Y.; Asao, D.; Yoshimura, S. Rapid emulsification of a fuel–water rapid internal mixing injector for emulsion fuel combustion. Energy 2019, 167, 35–46. [Google Scholar] [CrossRef]

- Daviault, S.G.; Ramadan, O.B.; Matida, E.A.; Hughes, P.M.; Hughes, R. Atomization performance of petroleum coke and coal water slurries from a twin fluid atomizer. Fuel 2012, 98, 183–193. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, H.F.; Xu, J.L.; Li, W.F.; Cheng, W. Breakup and atomization of a round coal water slurry jet by an annular air jet. Chem. Eng. Sci. 2012, 78, 63–74. [Google Scholar] [CrossRef]

- Rao, D.C.K.; Karmakar, S.; Basu, S. Atomization characteristics and instabilities in the combustion of multi-component fuel droplets with high volatility differential. Sci. Rep. 2017, 7, 8925. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tavangar, S.; Hashemabadi, S.H.; Saberimoghadam, A. CFD simulation for secondary breakup of coal–water slurry drops using OpenFOAM. Fuel Process. Technol. 2015, 132, 153–163. [Google Scholar] [CrossRef]

- Xue, Z.; Gong, Y.; Guo, Q.; Wang, F.; Yu, G. Visualization study on breakup modes of coal water slurry in an impinging entrained-flow gasifier. Fuel 2019, 244, 40–47. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, H.F.; Xu, J.L.; Li, W.F. Secondary breakup of coal water slurry drops. Phys. Fluids 2011, 23, 113101. [Google Scholar] [CrossRef]

- Minakov, A.V.; Shebeleva, A.A.; Strizhak, P.A.; Chernetskiy, M.Y.; Volkov, R.S. Study of the Weber number impact on secondary breakup of droplets of coal water slurries containing petrochemicals. Fuel 2019, 254, 115606. [Google Scholar] [CrossRef] [Green Version]

- Zuzio, D.; Estivalezes, J.L.; Villedieu, P.; Blanchard, G. Numerical simulation of primary and secondary atomization. Comptes Rendus Mécanique 2013, 341, 15–25. [Google Scholar] [CrossRef]

- Antonov, D.V.; Nyashina, G.S.; Strizhak, P.A.; Romanov, D.S. Micro-explosive droplet fragmentation of environmentally promising coal-water slurries containing petrochemicals. Fuel 2021, 283, 118949. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Volkov, R.; Valiullin, T.; Vysokomornaya, O. Spraying of Composite Liquid Fuels Based on Types of Coal Preparation Waste: Current Problems and Achievements: Review. Energies 2021, 14, 7282. https://doi.org/10.3390/en14217282

Volkov R, Valiullin T, Vysokomornaya O. Spraying of Composite Liquid Fuels Based on Types of Coal Preparation Waste: Current Problems and Achievements: Review. Energies. 2021; 14(21):7282. https://doi.org/10.3390/en14217282

Chicago/Turabian StyleVolkov, Roman, Timur Valiullin, and Olga Vysokomornaya. 2021. "Spraying of Composite Liquid Fuels Based on Types of Coal Preparation Waste: Current Problems and Achievements: Review" Energies 14, no. 21: 7282. https://doi.org/10.3390/en14217282

APA StyleVolkov, R., Valiullin, T., & Vysokomornaya, O. (2021). Spraying of Composite Liquid Fuels Based on Types of Coal Preparation Waste: Current Problems and Achievements: Review. Energies, 14(21), 7282. https://doi.org/10.3390/en14217282