Travel Dynamics Analysis and Intelligent Path Rectification Planning of a Roadheader on a Roadway

Abstract

:1. Introduction

2. Roadway Conditions and Roadheader’s Motion Performance

2.1. Road Conditions and Resistance Analysis

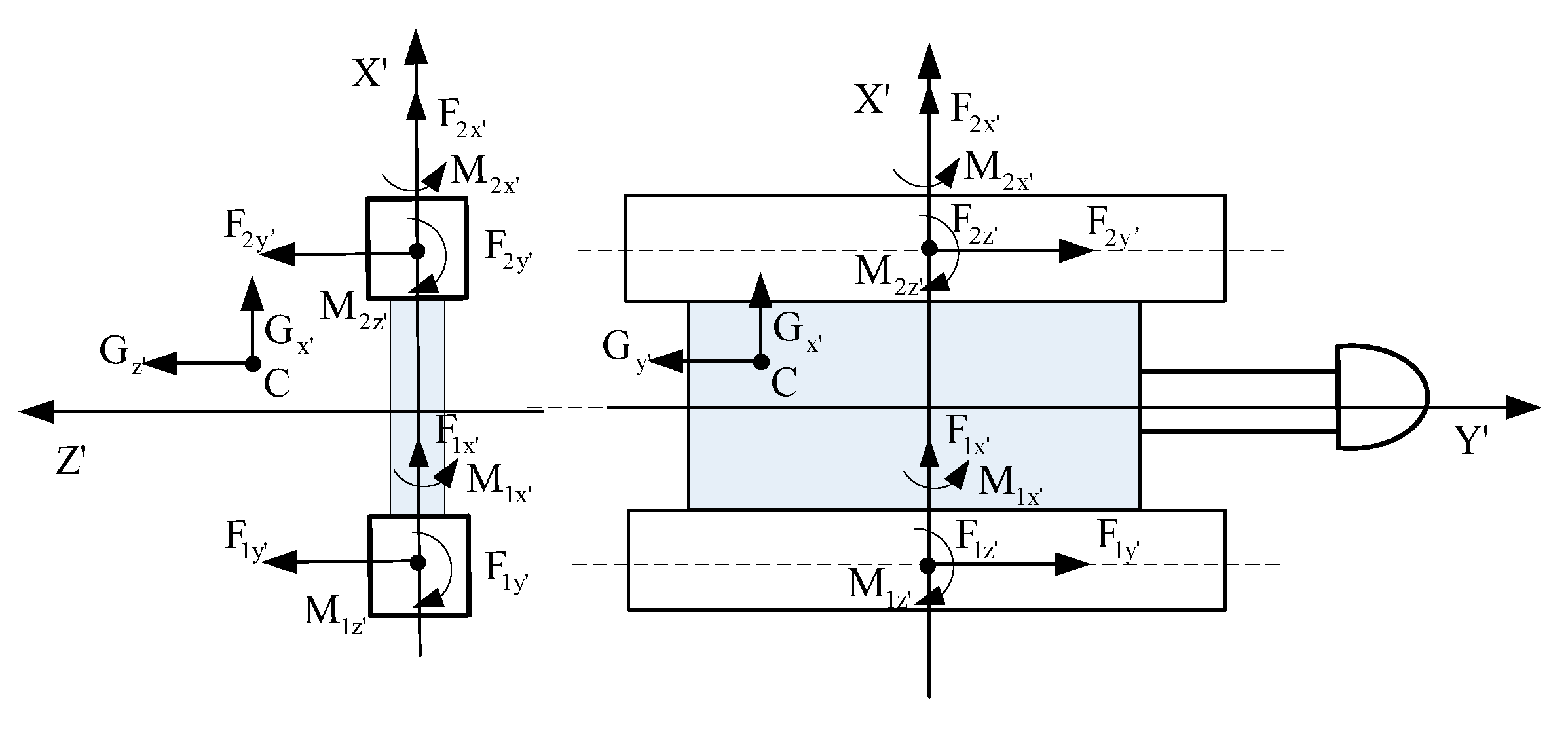

2.1.1. Compaction and Bulldozing Resistance

2.1.2. Steering Resistance

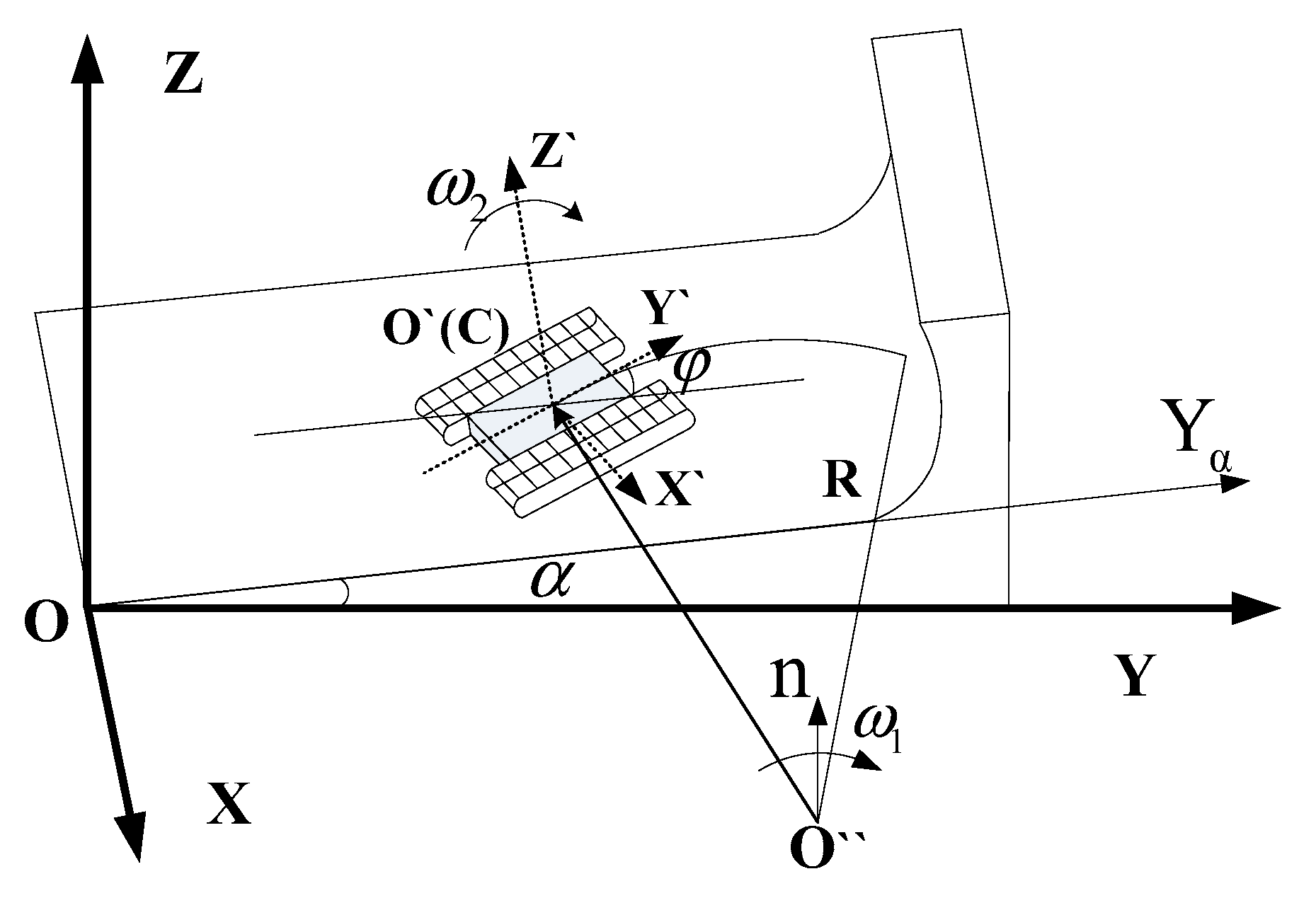

2.2. Kinematic Analysis of Rectifying Machine in a Complex Roadway

2.3. Driving Performance Analysis of the Roadheader

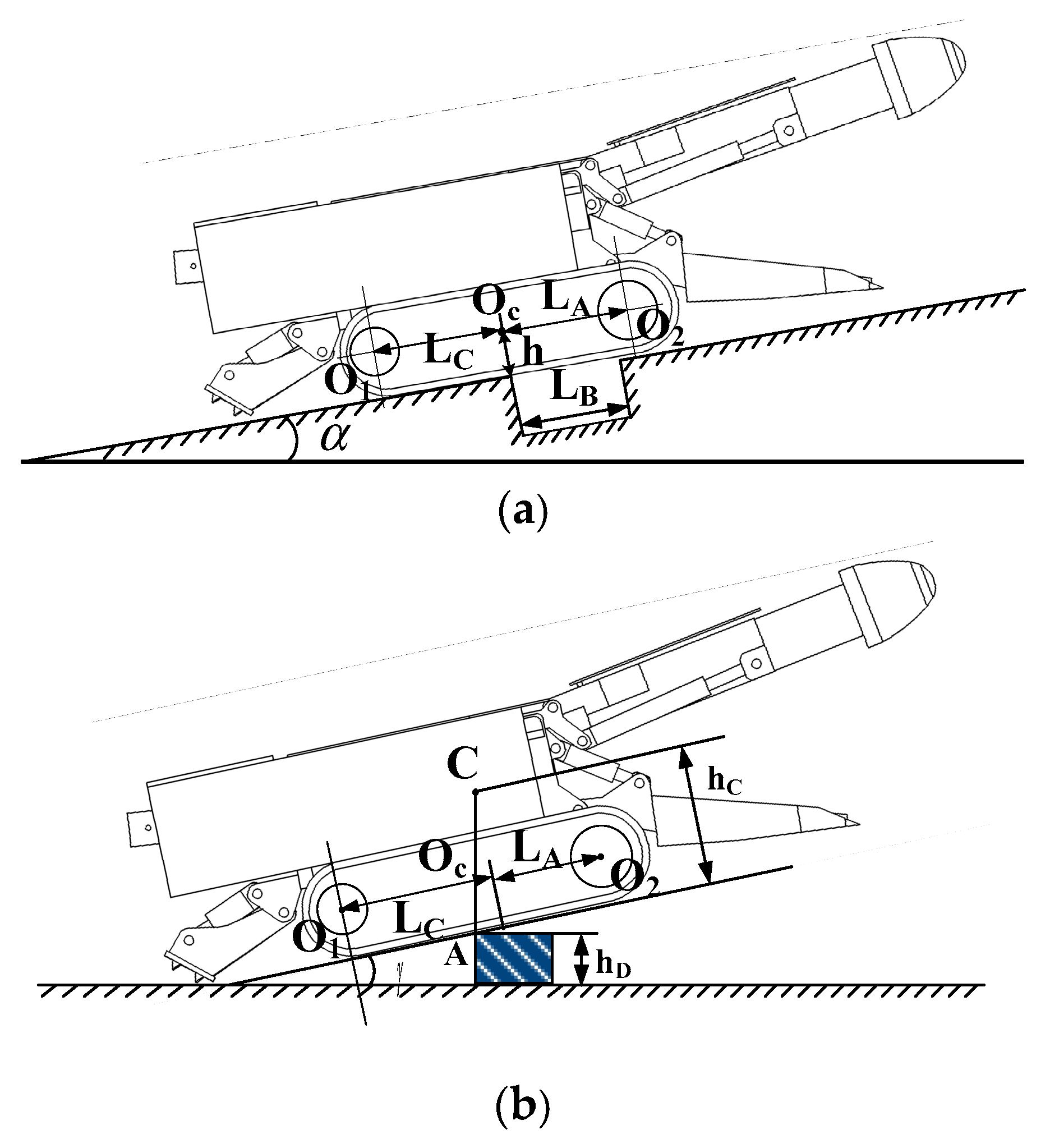

2.3.1. Trench-Crossing Capability of the Roadheader

2.3.2. Analysis of Obstacle-Crossing Capability of the Roadheader

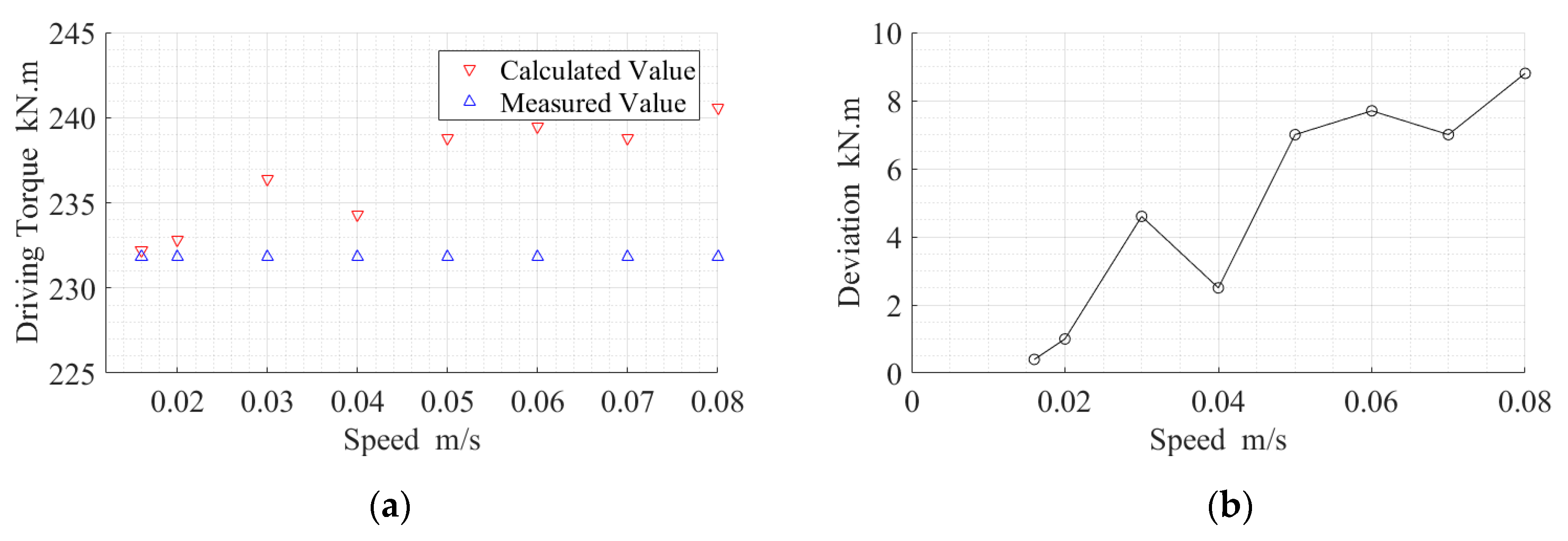

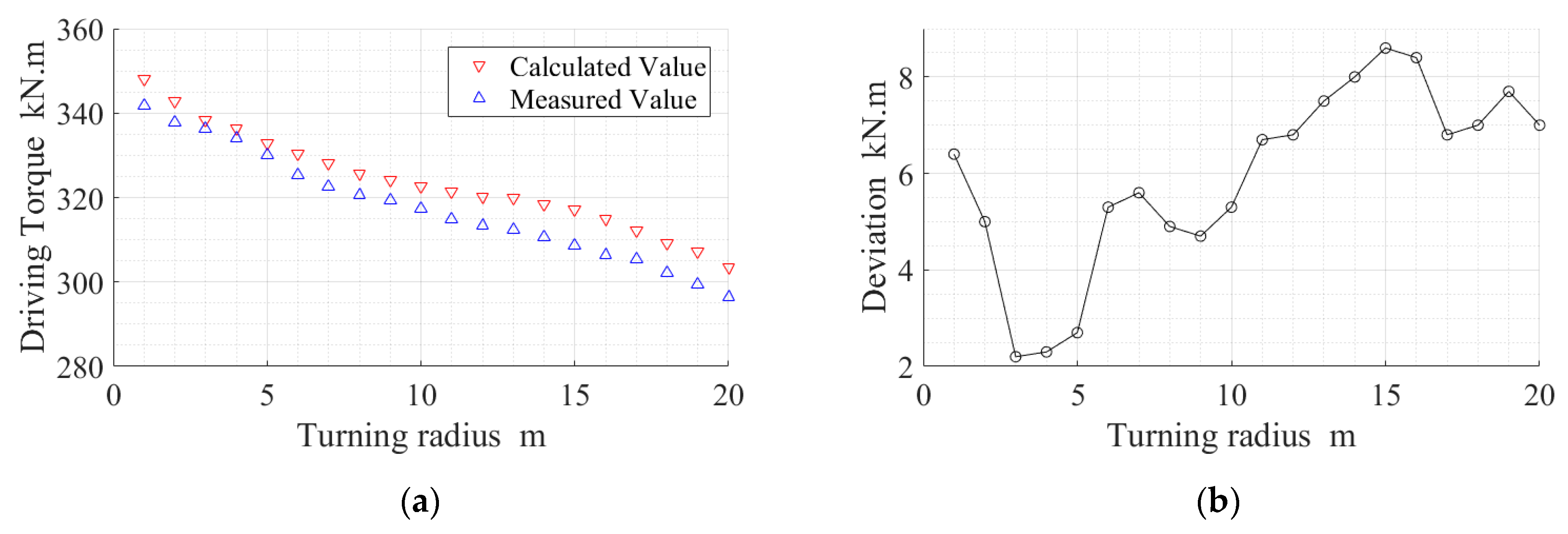

2.4. Experimental Verification

3. Automatic Rectification Planning Algorithm for the Roadheader

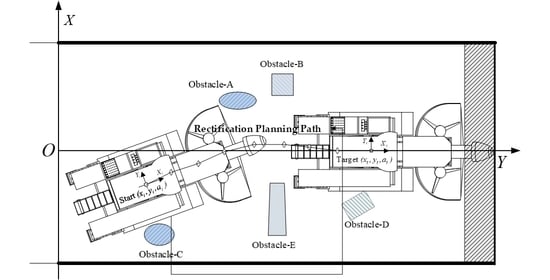

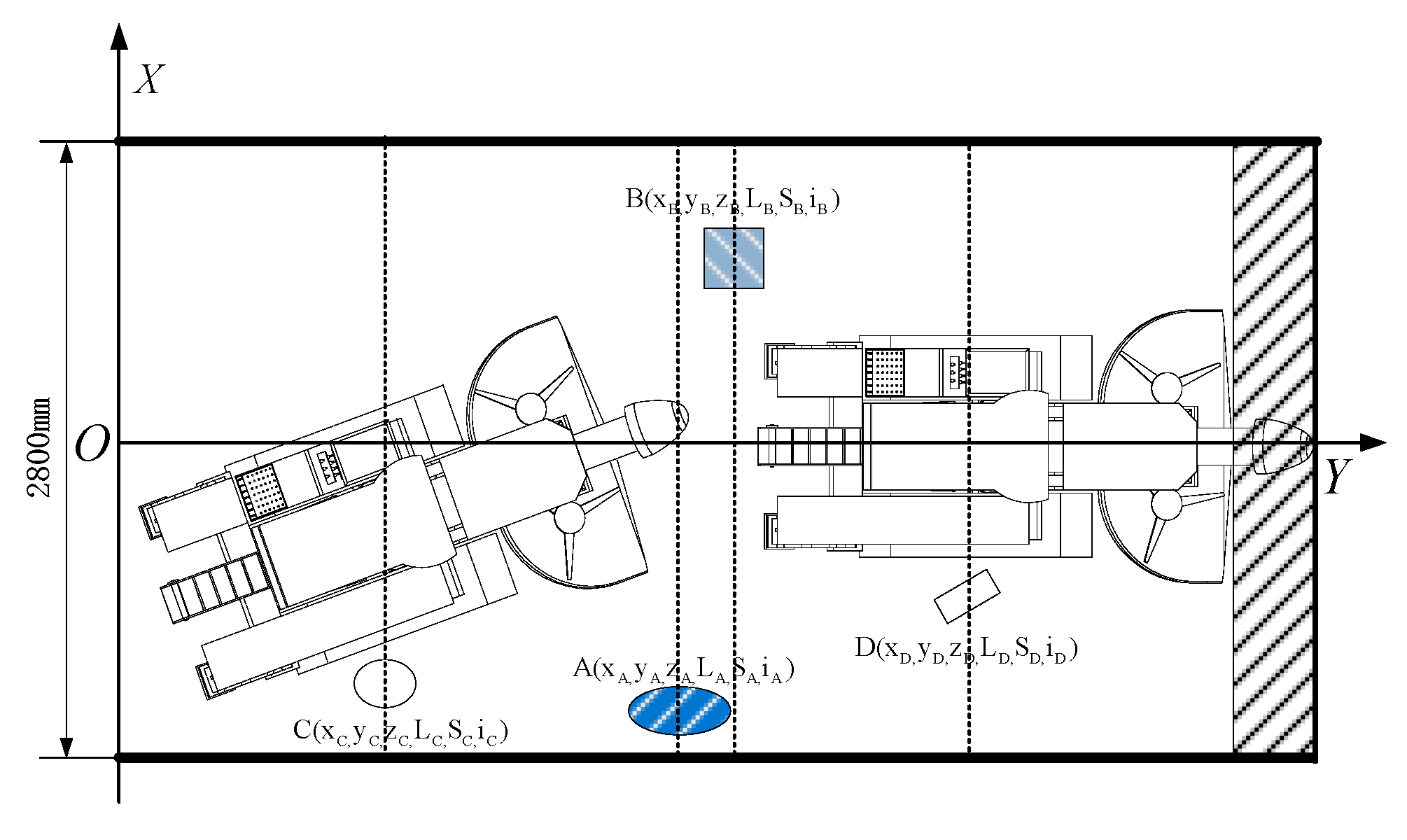

3.1. Roadway Environment Modeling

3.2. Rectification Impact Degree (RID) of the Roadheader

3.2.1. Automatic Rectification Impact Degree (RID) of the Roadheader

3.2.2. Simplified Roadway Grid Model

- When is less than the minimum and other values are within the value range, this grid must be reserved and marked as an impassable area.

- When and are greater than their maximum values and , this grid must be retained as a passable area.

- When is greater than the maximum and other values are within its value range, this grid must be retained and the area cannot be traversed.

- In addition to the above, a threshold value is proposed. When the rectification influence degree is greater than this threshold, the grid should be reserved or otherwise deleted.

3.2.3. Rectification Cost (RC) of the Roadheader

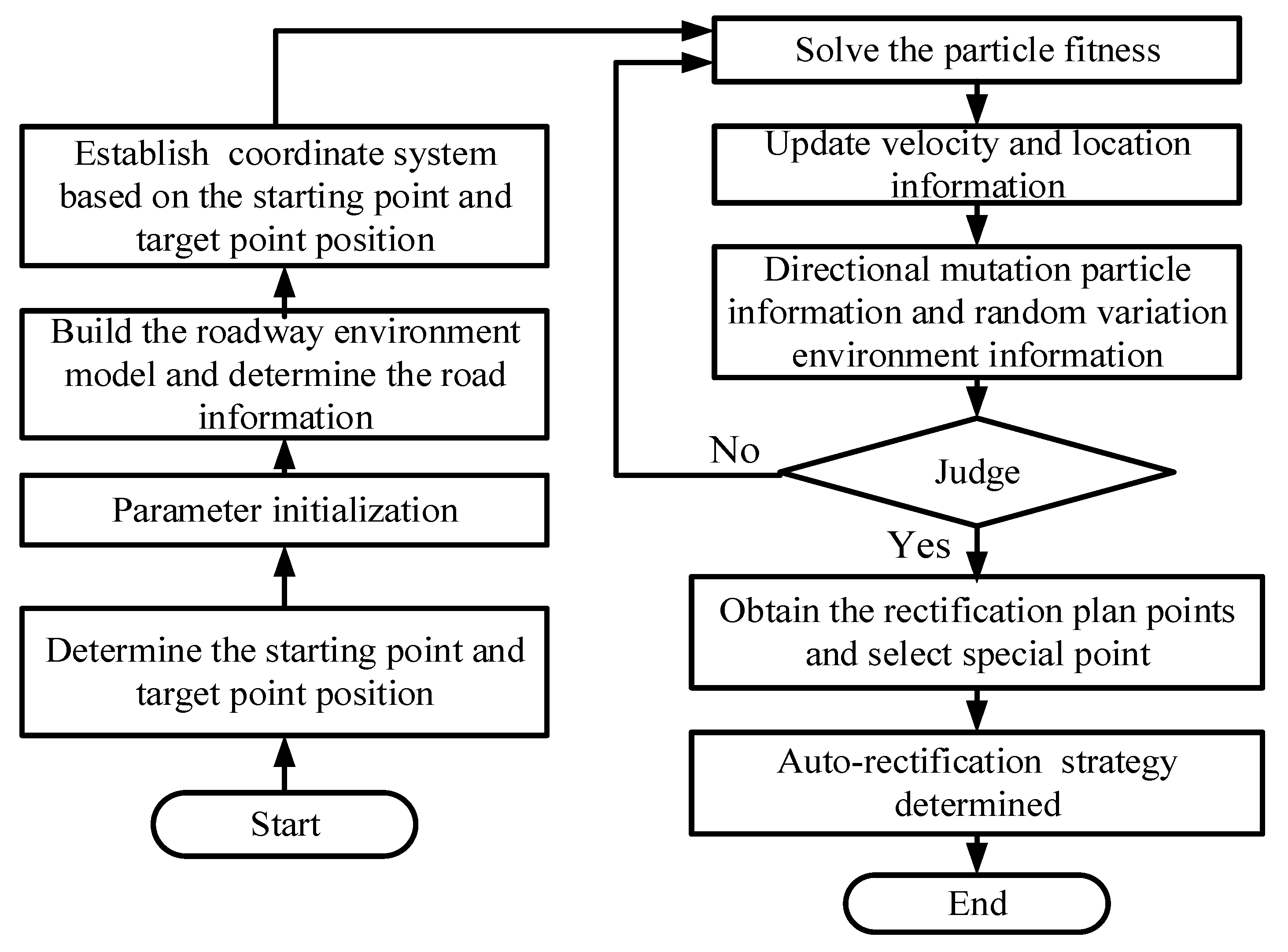

3.3. Rectification Plan Algorithm for the Roadheader

3.3.1. Mutation Particle Swarm Optimization Rectification Algorithm (PSO) for the Roadheader

- When the rectification angle is smaller than 5°, the ECI of the roadheader is calculated according to the motion model in Section 2.1. Therefore, is calculated according to Formula (9): .

- When the rectification angle is large or operating at variable speed is required, the ECI of the roadheader is calculated according to the motion model in Section 2.2. Therefore, is calculated according to Formula (21). The grid model in Section 3.2 does not take into account the change of pitch angle and roll angle during the operation of the roadheader:

- The first category is in the safe area and the cost is less than the rectification cost threshold P.

- The second category is passing a non-traversable area.

- The third category is a safe area but the cost is greater than the threshold.

3.3.2. Marking and Tracking of the Roadheader’s Rectification Points

4. Simulation and Experiment of the Roadheader’s Rectification Plan

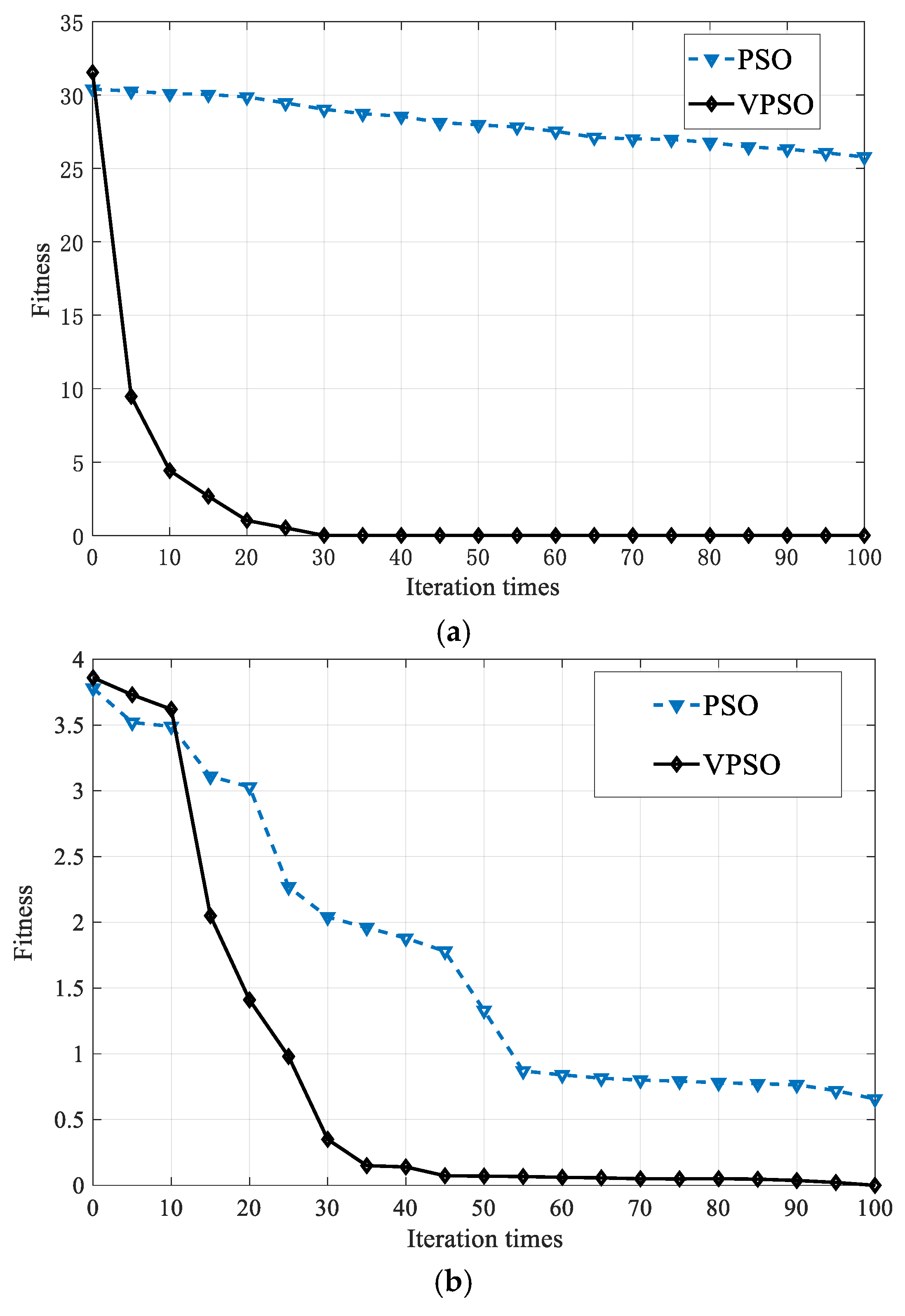

4.1. Rectification Plan Algorithm Simulation

4.1.1. The Simulation of the Roadheader’s Rectification Plan Algorithm

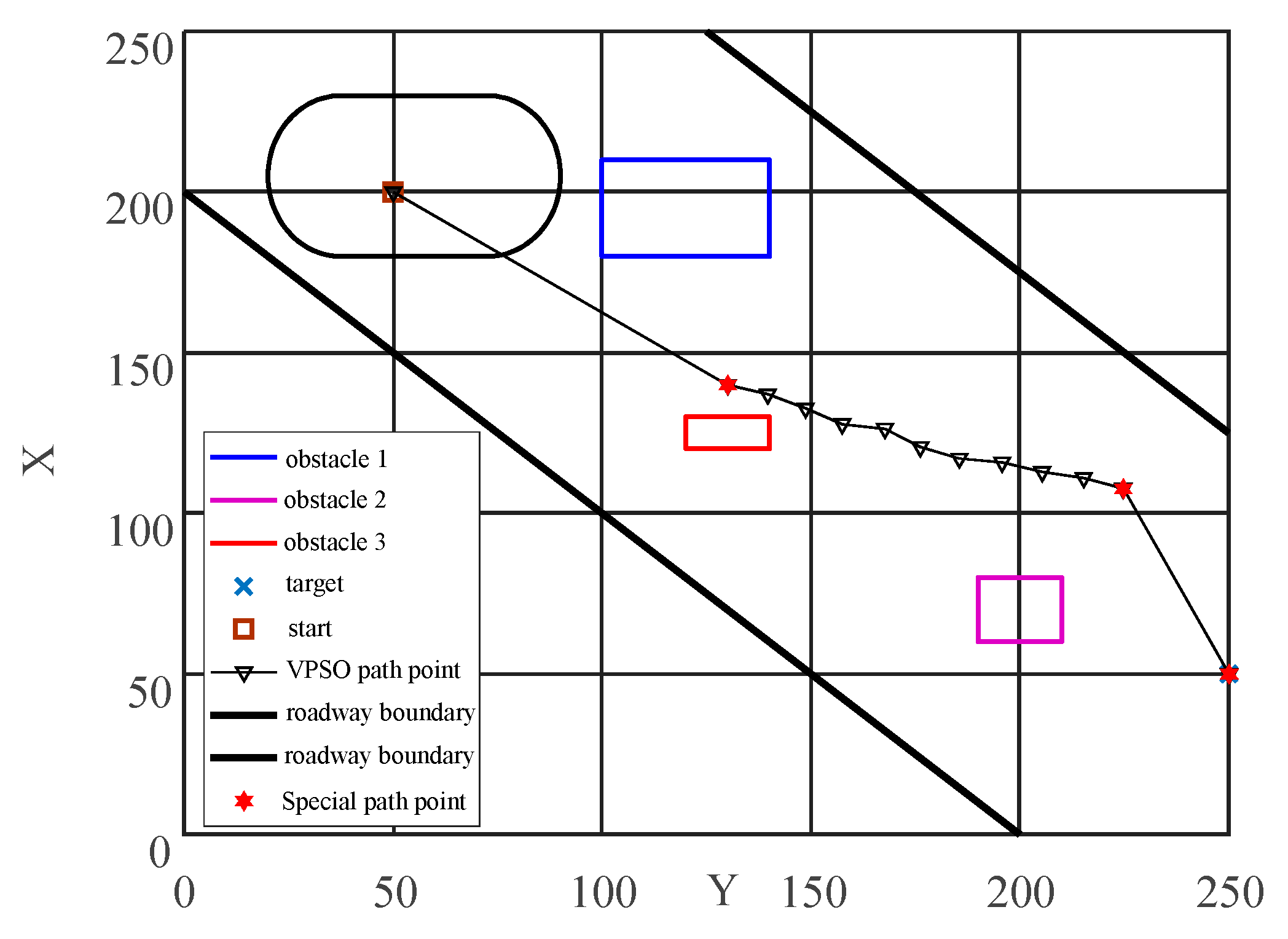

4.1.2. Simulation Analysis of the Roadheader’s Rectification Plan

4.1.3. Simulation of the Roadheader Rectifying Point Tracking

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Janarthan, B.; Padmanabhan, C.; Sujatha, C. Longitudinal dynamics of a tracked vehicle: Simulation and experiment. J. Terramech. 2012, 49, 63–72. [Google Scholar] [CrossRef]

- Zang, F.Y.; Liu, D.; Lv, F.Y. Study on anti-skid control of roadheaders on roadways floors with varied dipangles. Coal Sci. Technol. 2019, 47, 30–36. [Google Scholar]

- Lu, Y.; Xiao, S.; Ge, Z.; Zhou, Z.; Deng, K. Rock-breaking properties of multi-nozzle bits for tree-type drilling in underground coal mines. Energies 2016, 9, 249. [Google Scholar] [CrossRef] [Green Version]

- Chao, D.; Kai, C.; Xueliang, G.; Yuan, X.; Zhaoyin, D. Tracked vehicle skid steer performance analysis under the influence of centrifugal force. J. Vib. Meas. Diagn. 2017, 37, 76–83. [Google Scholar]

- Qinglu, S.; Fengchun, S. Study on steering stability of tracked vehicles and ramp. Trans. Chin. Soc. Agric. Mach. 2007, 38, 22–26. [Google Scholar]

- Zeng, Y.H.; Zhou, Y.C.; Liu, D.C.; Zuo, Q.S. A smart calibration model on track’s pressure–sinkage characteristic of a tracked vehicle moving on soft seabed sediments. J. Cent. South Univ. 2013, 20, 9112–9917. [Google Scholar] [CrossRef]

- Thueer, T. Mobility evaluation of wheeled all-terrain robots. J. Robot. Auton. Syst. 2010, 58, 508–519. [Google Scholar] [CrossRef]

- Keiji, N.; Dadisuke, E.; Kazuya, Y. Improvement of the odometry accuracy of a crawler vehicle with consideration of slippage. In Proceedings of the 2007 IEEE International Conference on Robotics and Automation, Roma, Italy, 10–14 April 2007; pp. 2752–2757. [Google Scholar]

- Feng, C. Study on Deep Seabed Mining Robot Vehicle Motion Modeling and Control. Ph.D. Thesis, Central South University, Changsha, China, 2005. [Google Scholar]

- Yihui, Z. Research on the Mechanical of Running Behavior Tracked Vehicle Collector in the Soft Sediment and Simulation Test. Ph.D. Thesis, Central South University, Changsha, China, 2013. [Google Scholar]

- Haohan, S. Reseach on Path Planing of Tracked Unmanned Platform in Dynamic Environment. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2020. [Google Scholar]

- Chen, S.; Niu, J.; Wen, S.; Chen, Y. Measurement Method of Navigation System of Self-propelled Underground Tunneling Robots. J. Beijing Univ. Technol. 2014, 40, 1091–1098. [Google Scholar]

- Zhizhong, L. Research on Mechanism Design and Analysis for Robotization of Coal Road Driving Equipment for Soft and Outburst Coal Seam. Ph.D. Thesis, Northeastern University, Boston, MA, USA, 2015. [Google Scholar]

- Hong, S.; Choi, J.S.; Kim, H.W.; Won, M.C.; Shin, S.C.; Rhee, J.S.; Park, H.U. A path tracking control algorithm for underwater mining vehicles. J. Mech. Sci. Technol. 2009, 23, 2030–2037. [Google Scholar] [CrossRef]

- Yuanyuan, Q.; Linke, S.; Xiaodong, J. Study on path planning and tracking of the underground mining roadheader. J. Min. Sci. Technol. 2020, 5, 194–202. [Google Scholar] [CrossRef]

- Wu, J.; Shen, Y.; Ji, X.; Wang, P.; Jiang, H.; Zheng, W.; Li, Y. Trajectory and deviation perception method of boom-type roadheader. J. China Coal Soc. 2021, 46, 2046–2056. [Google Scholar]

- Yang, J.; Tang, Z.; Wang, X.; Wang, Z.; Yin, B.; Wu, M. Research on environment modeling and excavation obstacle detection method of mine roadway. Coal Sci. Technol. 2020, 48, 12–18. [Google Scholar]

- Minjun, Z.; Rong, C.; Yu, Z.; Ming, Z.; Fuyu, Z.; Miao, W. Study on roadheader rectification running performance and control in the incline coalmine roadway. J. China Coal Soc. 2021, 46, 310–320. [Google Scholar] [CrossRef]

- Cheluszka, P. Optimization of the Cutting Process Parameters to Ensure High Efficiency of Drilling Tunnels and Use the Technical Potential of the Boom-Type Roadheader. Energies 2020, 13, 6597. [Google Scholar] [CrossRef]

- Joostberens, J.; Pawlikowski, A.; Prostański, D.; Nieśpiałowski, K. Method for Assessment of Operation of Analog Filters Installed in the Measuring Lines for Electrical Quantities of a Mining Machine’s Converter Power Supply System. Energies 2021, 14, 2384. [Google Scholar] [CrossRef]

- Wong, J.Y.; Chiang, C.F. A general theory for skid steering of tracked vehicles on firm ground. J. Automob. Eng. 2001, 21, 52–57. [Google Scholar] [CrossRef]

- Kejian, Z. Terrain Vehicle Mechanics; Duo, Y., Ma, C., Eds.; National Defence Industry Press: Beijing, China, 2002; ISBN 711802564X. [Google Scholar]

- Acaroglu, O.; Erdogan, C. Stability analysis of roadheaders with mini-disc. Tunn. Undergr. Space Technol. 2017, 68, 187–195. [Google Scholar] [CrossRef]

- Suraj, D.; Raina, A.K.; Murthy, V.M.S.R.; Trivedi, R.; Vajre, R. Roadheader-A comprehensive review. Tunn. Undergr. Space Technol. 2020, 95, 103148.1–103148.12. [Google Scholar]

- Guofa, W.; Desheng, Z. Innovation practice and development prospect of intelligent fully mechanized technology for coal mining. J. China Univ. Min. Technol. 2018, 47, 459–467. [Google Scholar]

- Huang, Z.; Zhang, Z.; Li, Y.; Song, G.; He, Y. Nonlinear dynamic analysis of cutting head-rotor-bearing system of the roadheader. J. Mech. Sci. Technol. 2019, 33, 1033–1043. [Google Scholar] [CrossRef]

- Asadi, A.; Abbasi, A.; Bagheri, A. Prediction of Roadheader Bit Consumption Rate in Coal Mines Using Artifificial Neural Networks. In 3rd Nordic Rock Mechanics Symposium-NRMS International Society for Rock Mechanics and Rock Engineering; OnePetro: Richardson, TX, USA, 2017; p. 12. [Google Scholar]

- Minjun, Z.; Miao, W. Analysis of Vibration of Roadheader Rotary Table Based on Finite Element Method and Data from Underground Coalmine. Shock Vib. 2018, 3, 1–9. [Google Scholar]

- Park, B.; Choi, J.; Wan, K.C. Sampling-based retraction method for improving the quality of mobile robot path plan. Int. J. Control Autom. Syst. 2012, 10, 982–991. [Google Scholar] [CrossRef]

- Karlsen, H.H.; Vinter, B. Minimum intrusion Grid-The Simple Model. In Proceedings of the Workshop on Enabling Technologies Infrastructure for Collaborative Enterprises Wet Ice, Linkoping, Sweden, 13–15 June 2005; pp. 305–310. [Google Scholar]

- Wen, X.M.; Zhao, W.; Meng, F.X. Research of Grid Scheduling Algorithm Based on P2P_Grid Model. In Proceedings of the 2009 International Conference on Electronic Commerce and Business Intelligence, Beijing, China, 6–7 June 2009. [Google Scholar]

- Heitkoetter, W.; Medjroubi, W.; Vogt, T.; Agert, C. Comparison of Open Source Power Grid Models—Combining a Mathematical, Visual and Electrical Analysis in an Open Source Tool. Energies 2019, 12, 4728. [Google Scholar] [CrossRef] [Green Version]

- Jiang, J.J.; Wei, W.X.; Shao, W.L.; Liang, Y.F.; Qu, Y.Y. Research on Large-Scale Bi-Level Particle Swarm Optimization Algorithm. IEEE Access 2021, 9, 56364–56375. [Google Scholar] [CrossRef]

- Li, R.; Zhang, M.; Wang, P.; Shen, Y.; Wu, M. Research on autonomous navigation method for crawler support vehicle based on regional grid. J. Min. Sci. Technol. 2020, 5, 423–434. [Google Scholar]

- Viet, D.T.; Phuong, V.V.; Duong, M.Q.; Tran, Q.T. Models for Short-Term Wind Power Forecasting Based on Improved Artificial Neural Network Using Particle Swarm Optimization and Genetic Algorithms. Energies 2020, 13, 2873. [Google Scholar] [CrossRef]

- Lei, H. A review of particle swarm optimization algorithms. Mech. Eng. Autom. 2010, 5, 197–199. [Google Scholar]

- Jian-Hu, F.; Ting-Yu, Z.; Shuo, F.; Bao-Juan, Z. Improved Particle Swarm Optimization Algorithm for Robot Path Planning. Mach. Des. Manuf. 2021, 9, 291–298. [Google Scholar]

- Guanghui, G. Ultra-wideband Positioning Method Based on Particle Swarm Optimization for Tunneling Support Bracket. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2019. [Google Scholar]

| Parameter | Measuring Point of Maximum Driving Torque | Measuring Point of Maximum Deviation | ||

|---|---|---|---|---|

| Driving Torque (KN·m) | Speed (m/s) | Driving Torque (KN·m) | Speed (m/s) | |

| Calculated value | 231.8150 | 0.08 | 231.8150 | 0.08 |

| Measured value | 241.2238 | 0.0786 | 241.2238 | 0.0786 |

| Deviation | 9.6088 | 0.0014 | 9.6088 | 0.0014 |

| Parameter | Measuring Point of Maximum Driving Torque | Measuring Point of Maximum Deviation | ||

|---|---|---|---|---|

| Driving Torque (KN·m) | Radius (m) | Driving Torque (KN·m) | Radius (m) | |

| Calculated value | 341.659 | 1 | 308.544 | 15 |

| Measured value | 348.324 | 1.08 | 317.268 | 15.42 |

| Deviation | 7.57 | 0.08 | 8.72 | 0.42 |

| Algorithm | A Function | G Function | ||

|---|---|---|---|---|

| Average Iterations | Minimum Fitness | Average Iterations | Minimum Fitness | |

| PSO | 100 | 57.6 | 10 | |

| VPSO | 28.4 | 2 × 10−7 | 35.6 | 0.0047 |

| Path Plan Performance Parameters | VPSO | PSO |

|---|---|---|

| Sum of centroid displacements (mm) | 2570.89 | 2388.73 |

| Total angle (rad) | 1.7091 | 1.5938 |

| Safety index(mm) | 280.293 | 245.29 |

| Total cost | 0.3096 | 0.3415 |

| Parameter | Original Points Track | Marked Points Track |

|---|---|---|

| Total distance(mm) | 2570.89 | 2097.14 |

| Total angular rotation (rad) | 1.7091 | 1.5777 |

| Safety index (mm) | 280.293 | 280.293 |

| cost index | 0.3096 | 0.3368 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, X.; Zhang, M.; Qu, Y.; Jiang, H.; Wu, M. Travel Dynamics Analysis and Intelligent Path Rectification Planning of a Roadheader on a Roadway. Energies 2021, 14, 7201. https://doi.org/10.3390/en14217201

Ji X, Zhang M, Qu Y, Jiang H, Wu M. Travel Dynamics Analysis and Intelligent Path Rectification Planning of a Roadheader on a Roadway. Energies. 2021; 14(21):7201. https://doi.org/10.3390/en14217201

Chicago/Turabian StyleJi, Xiaodong, Minjun Zhang, Yuanyuan Qu, Hai Jiang, and Miao Wu. 2021. "Travel Dynamics Analysis and Intelligent Path Rectification Planning of a Roadheader on a Roadway" Energies 14, no. 21: 7201. https://doi.org/10.3390/en14217201

APA StyleJi, X., Zhang, M., Qu, Y., Jiang, H., & Wu, M. (2021). Travel Dynamics Analysis and Intelligent Path Rectification Planning of a Roadheader on a Roadway. Energies, 14(21), 7201. https://doi.org/10.3390/en14217201