1. Introduction

According to the Intergovernmental Panel on Climate Change [

1], emission reduction at the city level is an inevitable requirement to ensure that GHG are reduced to national target levels [

2]. To accurately report GHG emissions and to provide reliable data for both policymaking and recommendation formulation to achieve individual activity emission reduction, an accurate and complete city-level GHG emission inventory is necessary [

3]. In fulfilling the Paris Agreement, city authorities should establish a GHG emission inventory such that they can monitor and design strategies to reduce GHG emissions [

4,

5].

With the rapid development of urbanization and industrialization, the Municipal Solid Waste (MSW) amount increasing rapidly in the world. The waste sector’s GHG emission inventories are commonly supported by available estimation methodologies and accessible software and hardware. In the last decades, landfill, compost, thermal conversion methods (incineration, pyrolysis, gasification), and biological conversion method (anaerobic digestion) were the most common waste treatment methods [

6]. A city-level GHG emission inventory of waste sector should possess the following features: (1) it must facilitate the development of appropriate global warming mitigation recommendations and enable urban planning involving efficient urban supply chains and low-carbon civil construction at the governmental level [

7,

8]; (2) it must support city designers in determining GHG emission sources and analyzing the accurate proportion of city emissions [

9]; (3) it must be replicable and easily adaptable to different data sets [

10]; (4) it must be timely in its approach through the application of the latest activity data and avoid double counting, thus ensuring data source consistency [

11]. However, currently, most community-level inventories are limited by data availability and reporting consistency [

2].

Previous studies have applied top-down [

12,

13,

14] and bottom-up [

15,

16] methods in the development of a city-level GHG emission inventory. The bottom-up method divides and solves the problem based on small and practical parts, which considers a finer spatial scale [

17]. In addition, studies on low-carbon community contains a variety of contents that includes industry, agriculture, waste, business, and carbon market [

18,

19]. There have been a variety of studies focusing on different contents of MSW, such as sludge [

20,

21], food waste [

22], wastepaper, and social community trust [

23]. In addition, the MSW treatment evaluation includes environment performances such as GHG emission reduction and economic impacts, technology and its application, integrated MSW treatment systems [

24,

25]. In addition, energy recovery from waste is a significant process of the treatment [

26]. Waste-to-energy (WTE) processes recover the energy from the waste, that have been widely used in the MSW treatment. Therefore, the improvement of energy recovery efficiency from MSW has taken on great importance [

27,

28]. In addition, more and more researchers began to discuss the combination of system and integration with other industrial processes [

29]. However, the scope framework and top-down method has not been suitably applied in previous studies, which are about analysis working toward waste in low carbon community.

The main objective of this study is to estimate the GHG emissions of the waste treatment sector using a bottom-up approach. This study considered the incineration, residential wastewater, and transport of the waste. The Honjo Waseda community in Japan, in which emissions are increasing, was used as a case study community. This study follows Global Protocol for Community-Scale Greenhouse Gas Emission Inventories (GPC) guidelines [

1], and quantity analyses were conducted through Statistical Product and Service Solutions (SPSS) software. After estimating the GHG emissions, mitigation reductions were analyzed for three case settings. Case 1 was a scenario in which all municipal solid waste (MSW) was incinerated. Case 2 was the combination of the incineration of combustible waste and the bio-gasification of food waste. In Case 2, automated sorting technology was applied to separate the two different types of waste. Case 3 was mechanical biological treatment (MBT), which combined refuse-derived solid recovered fuel (SRF) and the bio-gasification of food waste through the application of automated sorting technology.

This study comprises five sections.

Section 1 provides an overview of the global trends in the GHG emission inventory development of waste treatment.

Section 2 presents GHG emission accounting methods and data sources.

Section 3 contains a demonstration of a waste sector GHG emission inventory outcome at the community level and offers proposals to reduce these GHG emissions.

Section 4 contains the discussion.

Section 5 contains the conclusion of the study.

3. Results and Proposals

3.1. Results

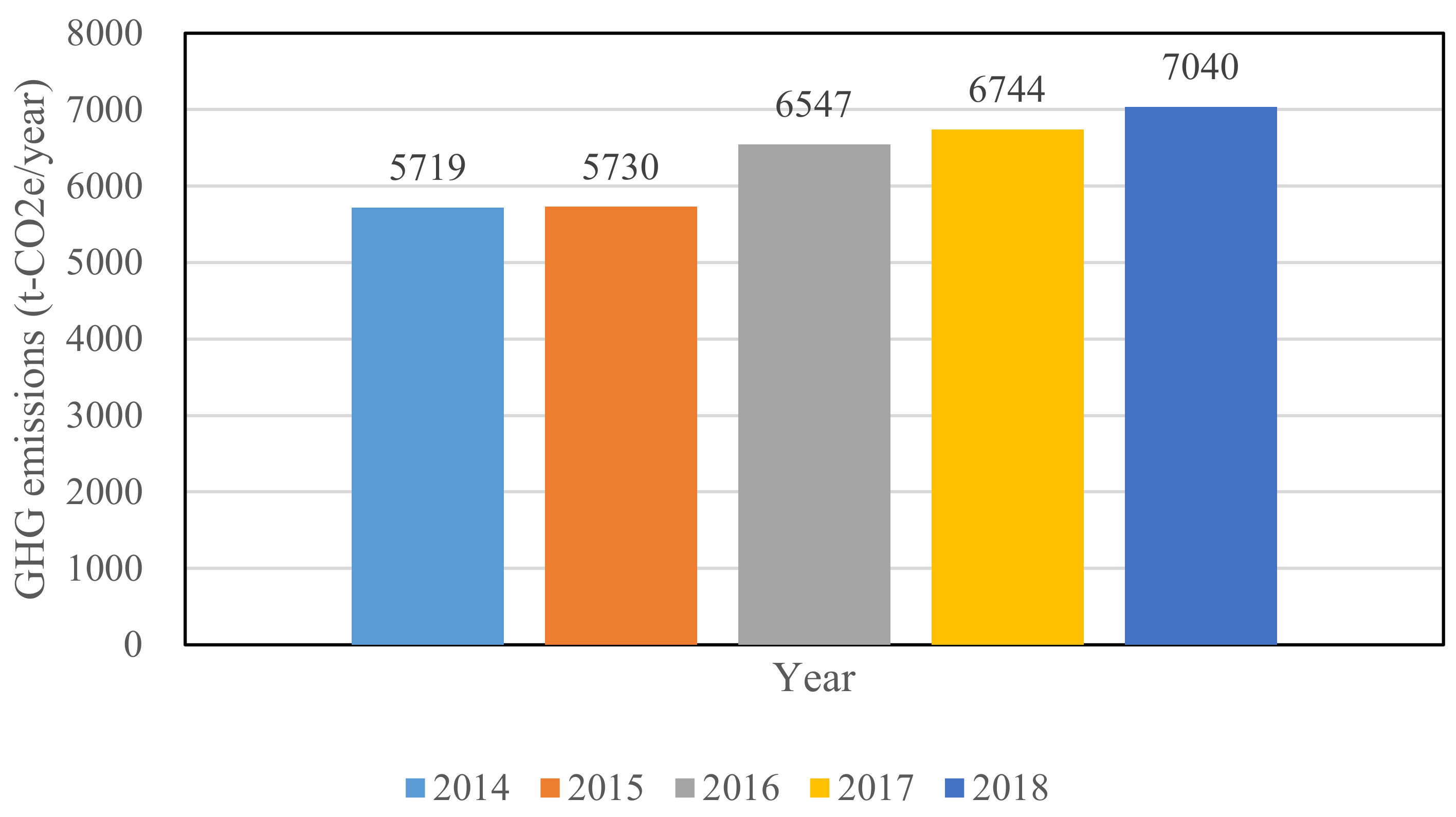

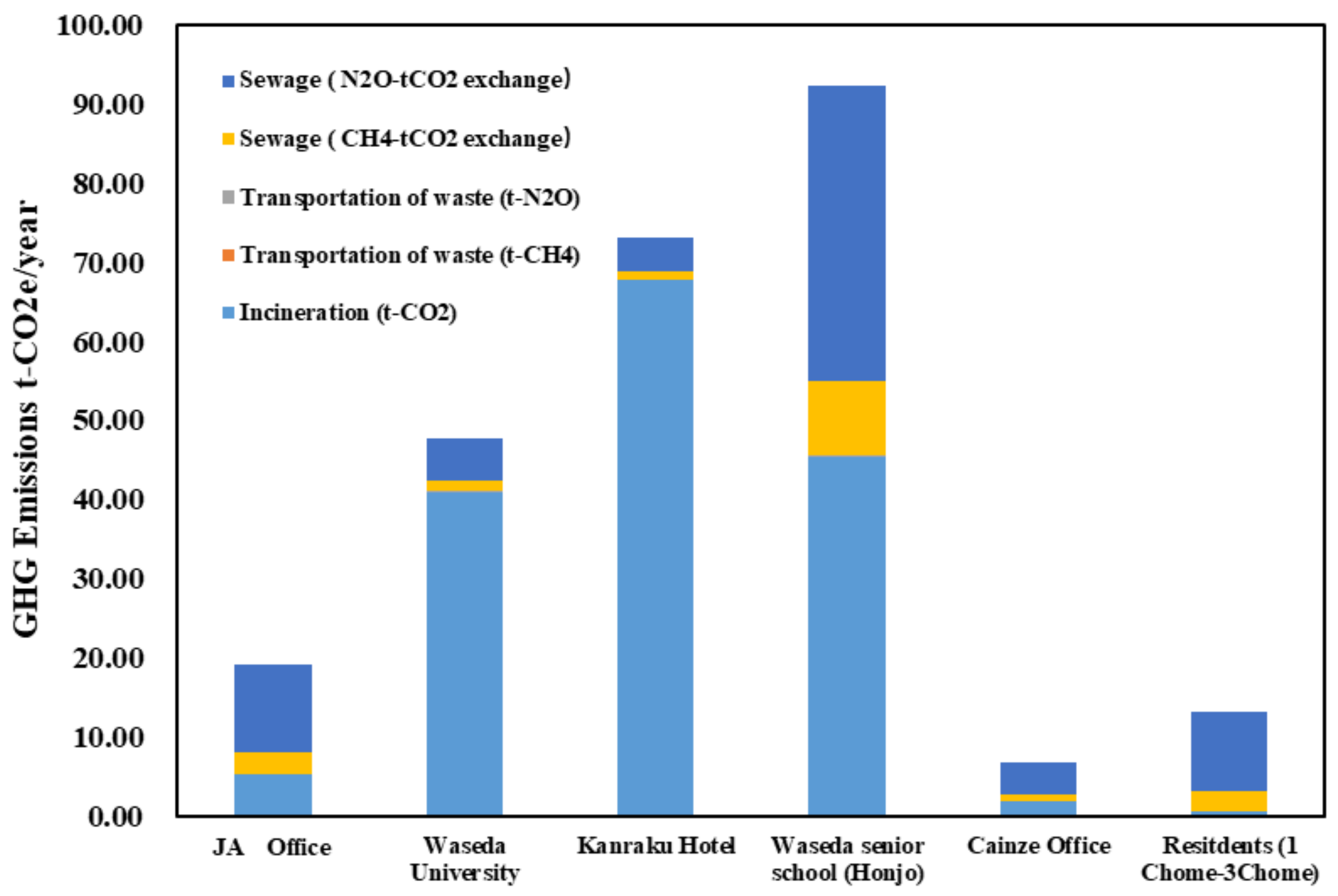

Beisiagate supermarket produced the most GHG emissions due to waste treatment because of its high garbage emissions. In details, as illustrated in

Figure 2, the Beisiagate supermarket (1466 t-CO

2e/year) was followed by Honjo Senior High School (92 t-CO

2e/year), Kanraku Hotel (73 t-CO

2e/year), Waseda University (48 t-CO

2e/year), JA office (19 t-CO

2e/year), residents (13 t-CO

2e/year) and Cainz (7 t-CO

2e/year). Among all emissions, it was found that the CO

2-biomass carbon natural and CO

2 -non-biomass occupied around 49.4%, including food waste, paper, and wood, while CH

4 and N

2O occupied 0.2% and 1.0%, respectively.

With regard to incineration, Beisiagate supermarket ranked the highest (21.8t-CO

2e/day), followed by Honjo Senior High School, Waseda campus, and Kanraku hotel. As illustrated in

Table 8, it was found that paper was the largest GHG emitter for Cainz office, JA office, Waseda campus, and Honjo Senior High School. Moreover, food waste was the largest emitter for Beisiagate supermarket and Kanraku Hotel.

For residential wastewater, the annual CH

4 (890 t-CO

2e) emissions were higher than the annual N

2O (239 t-CO

2e) emissions. Combined processing produced the most emissions, accounting for 57% of CH

4 and 74% of N

2O; details are illustrated in

Table 9.

For waste transport, it was found that the amount of CH4 emissions for (round tripper vehicle per time) t-CO2e conversion was 0.03 t-CO2e. In addition, the amount of N2O emissions for (round tripper vehicle per time) t-CO2e conversion was 1.14 t-CO2e.

3.2. GHG Reduction Proposal for the Waste Treatment Sector

This research evaluated waste treatments from the waste collection and recycling, transport, and treatment perspectives through a bottom-up method. Honjo Waseda community was used as a case study to offer proposals. A life cycle assessment (LCA) was applied for the assessment of CO2 emissions and the primary energy consumption. Furthermore, a series of MSW processes were evaluated that ranged from collection and recycling to final use and disposal treatments. An environmental load evaluation database of incineration and melting (including the input and output amounts at different treatment scales and power generation efficiency) was compiled based on the plant maker’s design and estimated values. This enabled the calculation of indices for the recycling rate, energy expended in the recycling process, and final disposal treatment for different evaluation scenarios.

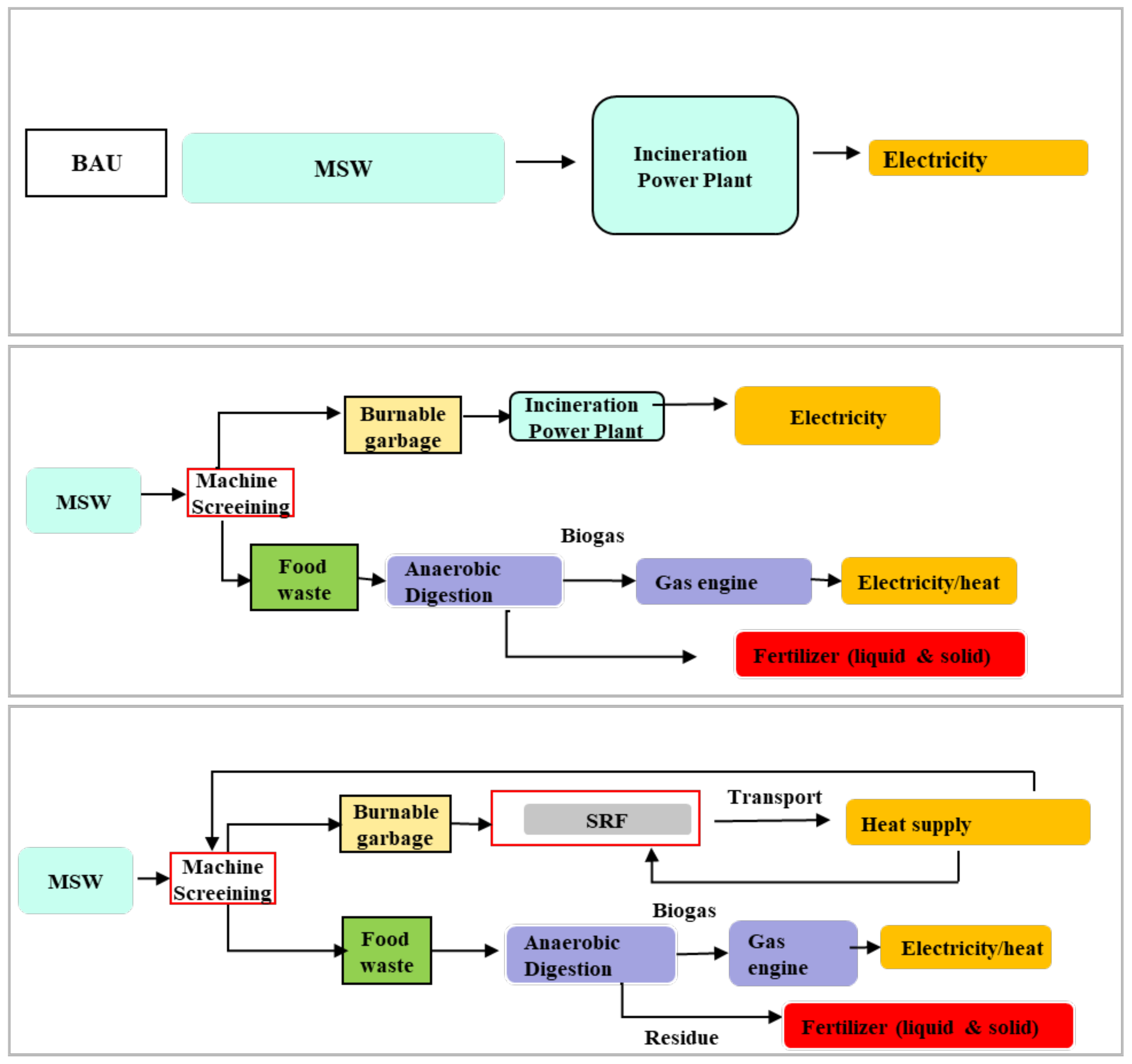

In order to reduce GHG emissions generated by incineration and achieve zero-waste for building low carbon cities, this study proposed three cases for comparison and provided an overview of the current situation of MSW and food waste treatment in Honjo Waseda community. Case 1 was business as usual (BAU), in which it was assumed that there was no difference between Case 1 and the current waste treatment system. Case 2 proposed an option that combined the incineration of combustible waste and bio-gasification for food waste treatment. In this case, automated sorting technology was applied to separate two different types of waste.

This application was able to effectively connect a bio-gasification system and sewage treatment facilities in order to solve the following issues: (1) creating a connection between sewage treatment and the cement factory; (2) the collection of food waste in the areas with a centralized system; and (3) creating the heat supply from both biogas and waste plastic after waste treatment. Case 3 was the combination of SRF and bio-gasification in food waste treatment, namely an MBT system. In this case, the SRF was used to replace fossil fuel, such as coal, and the food waste was separated, collected, and treated using fermentation. The MBT system is a type of waste processing facility that combines a sorting facility with a form of biological treatment such as composting or anaerobic digestion. MBT plants are designed to process mixed household waste as well as commercial and industrial wastes. After separation and machine selection, food waste is used for power generation through fermentation, while other waste plastic becomes SRF for heat use in cement manufacturing factories. The generated electricity in these cases will be used in the city.

Figure 3 describes the treatment processes for the four MSW treatment scenarios.

3.3. Outcome of Proposals of Case Studies

The waste incineration amount and primary energy consumption were estimated using the LCA method. The details of the energy conversion index are illustrated in

Table 9. For energy consumption, it was found that the SRF in Case 3 contributed the most for energy recovery. The energy conversion index and GHG factors, with references that were applied in this study, are applied in

Table 10 and

Table 11, respectively. Furthermore, waste amount of each case in Honjo Waseda community and primary energy consumption are illustrated in

Table 12 and

Table 13.

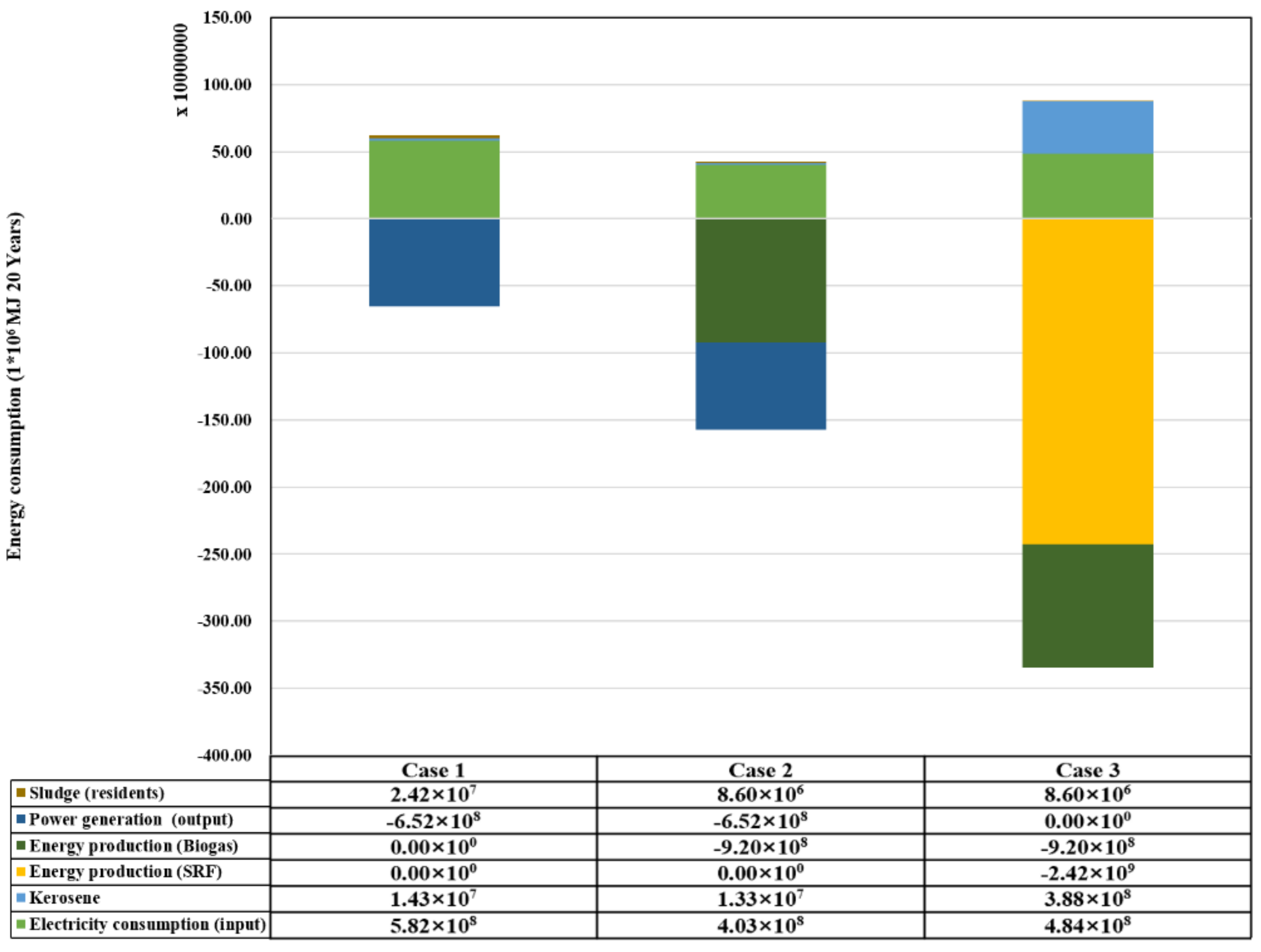

It was found that the incineration amount was largely reduced by applying the MBT (Case 2) system. In Case 1 (the BAU scenario), the electricity consumption was 582 GJ, the kerosene consumption was 14.3 GJ, the incineration power generation was −652 GJ, and the electricity consumption was 582 GJ. Details are illustrated in

Table 10. In this study, the waste treatment facilities are assumed to operate 280 days/year and work for 20 years.

For the energy consumption outcomes, the output of Case 3 was the largest, and was generated mainly by the energy production of SRF (

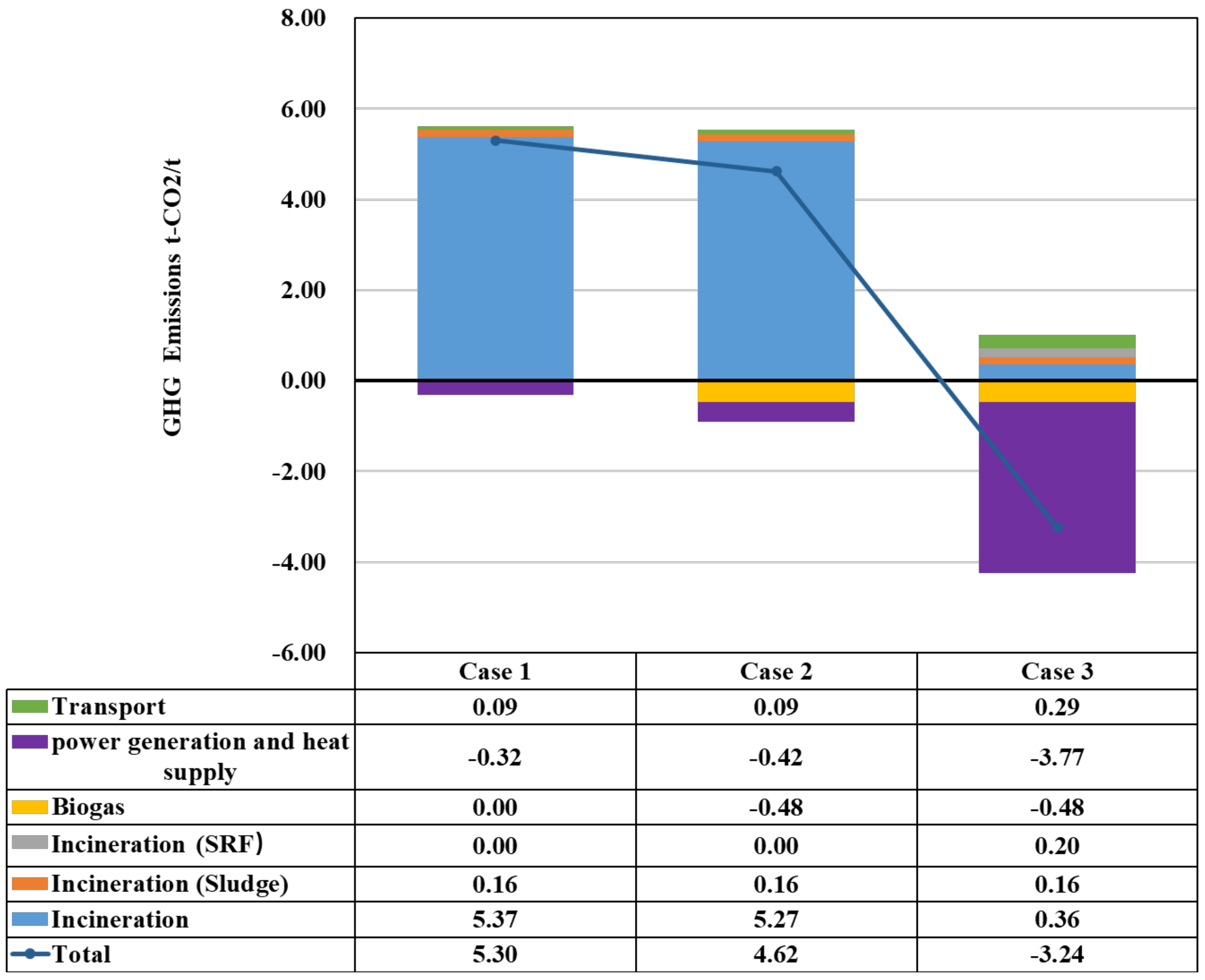

Figure 4). It was found that the energy input and output of current situation (Case 1) are almost equal. Regarding the GHG emissions, as shown in

Figure 5, it was found that Case 3 contributed to GHG reduction most, while incineration accounted for a large proportion of the emissions in Case 1 and Case 2.

To improve energy efficiency and further reduce GHG emissions, this study also analyzed the changes in power generation efficiency. The estimation was based on applying the calorific value, energy conversion index, and GHG emission factor of waste. It was found that the GHG reduction ranged from 5% to 20% depending on power generation efficiency. When compared with heat supply, the GHG reductions generated from SRF power generation were higher than SRF heat supply when the efficiency changed (

Table 14). Therefore, we recommend using SRF for heat supply rather than power generation.

After applying the bottom-up methodology in the case study area (Honjo community), it was found that the developed methodology filled the research gaps of the community GHG inventory. It is shown that the developed energy consumption-based methodology enabled calculation of GHG emissions within and without the community. Furthermore, it was proven that the developed bottom-up methodology is applicable for providing an essential basis and waste GHG emission outcome for policy making through proposals and performed case analyses toward zero-waste.

4. Discussion

In this study, we estimated GHG emission, which included waste incineration, sewage, and transport. Through applying the bottom-up method, it was found that the highest emissions were from Beisiagate supermarket and that the CO2-biomass carbon neutral emissions reached approximately 50% of the total emissions. The Beisiagate supermarket emitted 21.8t-CO2e/day for waste incineration. For waste transport, it was found that the emissions (round trip) for t-CO2e conversion was 1.16 t-CO2e/year, CH4 was 0.0285 t-CO2e (CO2 conversion), and N2O was 1.14 t-CO2e (CO2 conversion). In addition, for residential wastewater, the CH4 emissions (890 t-CO2e) were higher than the N2O emissions (239 t-CO2e) annually.

Different from relevant studies, this study estimates the GHG emissions of the waste treatment sector at a community level. In addition, compared with other studies that apply the top-down approach, this study estimated the wastes emissions from incineration, residential wastewater and waste transport through a bottom-up approach, which is more accurate and based on field data. Moreover, mitigation reductions were analyzed for three case settings in this study. Meanwhile, compared with other communities in Japan, the waste recycling rate of Honjo Waseda community was much lower, especially the food waste. Traditional solid waste treatment has formed a relatively complete recycling industry chain, and the wastepaper, waste plastic, and other varieties of domestic waste had a high recycling rate. However, waste glass [

34,

35], waste batteries [

36,

37], and other varieties of waste had a considerably lower recycling rate with low added value.

This study proposes the introduction of automated sorting technology in order to accelerate the MBT system. Therefore, machine screening as source sorting [

38,

39] and waste reduction are the first priorities. Increasing the rate of source sorting will also increase the classification and profitable recycling of waste materials. Furthermore, this research also suggests each community to adapt to local conditions and combine national special planning to further promote the reduction of MSW generation, reduce and control the environmental impacts of the MSW treatment process, and optimize the waste collection, transportation, and disposal process from the perspective of the entire life cycle. Moreover, this study recommends that municipalities consider other factors that influence decision making in planning as well as the zero-waste policy in future years. For instance, the financial situation of the current municipalities, the projected electricity sale price and population trends.

In addition, zero waste has been recognized as an essential strategy according to the Circular Economy Vision 2020 by the Ministry of Economy, Trade and Industry (METI, Japan, 2020) [

40]. The virtuous cycle of the environment is significant for promoting the 3Rs (reuse, reduce, recycle) toward building zero-waste cities. In addition, five areas that need special attention in terms of the 3Rs are plastics, fibers, carbon fiber reinforced polymers, batteries, and solar panels. It is estimated that, by Japan’s Ministry of Environment on Japan’s environmental industry, this market has reached a record size of approximately 105.3 trillion JPY in 2017 [

41].

Regarding building a zero-waste city, the policy implications of global carbon emission reduction, including applying renewable energy such as photovoltaic, wind, nuclear, hydropower, chemical energy storage, and carbon capture utilization and storage (CCUS), [

42,

43] are expected. Furthermore, the improvement of the incineration rate and the application of a centralized incineration system will increase the power generation efficiency and reduce GHG emissions in the community. Moreover, with the waste separation policy, food waste will contribute to the MTB (combined methane fermentation and SRF) system implementation in cities. Bio-gasification has improved, and the capacity is much higher than in some developed communities.

5. Conclusions

This study estimated and analyzed GHG emissions working toward zero-waste and its indication to low carbon city at a community level. Unlike existing studies, this study aimed to fill the research gaps from the following perspectives: (1) this research provided a variety of analyses and offered proposals for the development of GHG estimation at the community level in the waste sector through a bottom-up method; (2) this study designed estimation methods that included emissions within and without the community; (3) this study provided a detailed inventory and proposals for each building type through a bottom-up methodology and performed case analyses.

Through estimating and analyzing GHG emission from waste incineration, sewage, and transport, the outcome demonstrated that the highest emissions were produced by the Beisiagate supermarket, and the CO2-biomass carbon neutral emissions reached approximately 50% of the total emissions. For incineration, the Beisiagate supermarket ranked the highest (2.18 × 101 t-CO2e/day), and for residential wastewater, the CH4 emissions (890 t-CO2e) were higher than the N2O emissions (239 t-CO2e), annually. Moreover, for waste transport, it was found that the emissions (round trip) per time was 0.02 t-CO2e, and annual emissions of the community was 2.33 t-CO2e. Furthermore, because most waste was treated using incineration, this study conducted a case study and offered proposals for its reduction of incineration. In detail, case 1 was the current situation, case 2 was incineration + a bio-gasification system, and case 3 was SRF + a bio-gasification system (MBT). It was shown that the SRF contributed the most GHG reduction, and Case 3 resulted in the highest energy recovery.

To expand upon the results of this study, future research will include other communities with different characteristics in order to conduct comparative analyses and apply other technological options for GHG reduction. Furthermore, data visualization and database creation for software application and urban policy assessments will be conducted. Moreover, different local factors such as culture and resource endowments should be considered. Other topics, such as regional collaboration among surrounding communities, more detailed economic feasibility studies of innovative options, urban-industrial symbiosis, and the effect of consumer behavior on GHG emissions with the aim of zero waste, deserve further study. Furthermore, the cost–benefit perspective of waste treatment facility construction costs will be considered.