Robust Scheduling for Pumping in a Water Distribution System under the Uncertainty of Activating Regulation Reserves

Abstract

:1. Introduction

- Robust operational planning model under the uncertainty of activating regulation reserves: The proposed model is sufficiently robust to maintain the water volume in the reservoir within the constraints and to maintain a stable water supply when there is uncertainty about whether the regulation reserves provided to the power system will be activated. Because the proposed optimal operational planning model is formulated as an MILP, it can be solved by many commercial solvers and is highly practical.

- Determination of water pump operation based on electrical energy prices and incentive prices: In the proposed model, it is possible to optimize the water pump operation plan according to the electrical energy prices and the incentive prices for each time slot to provide regulation reserves presented in advance by the retail electric utilities and aggregators.

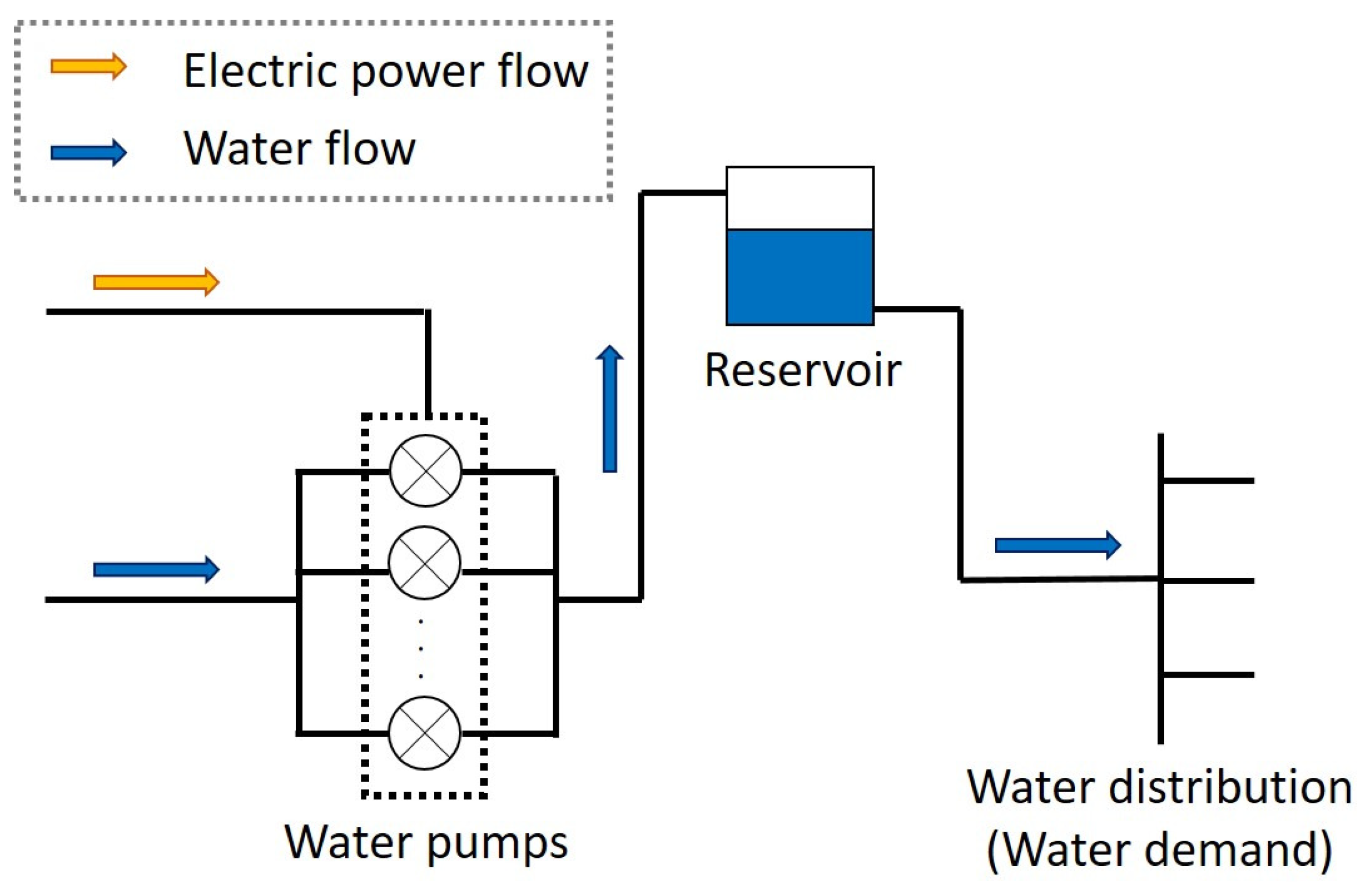

2. Assumed Environment

2.1. Water Distribution System

2.2. Price Information

2.3. Regulation Reserves

- Compensation is paid by the contractor based on the incentive price for the regulation reserve capacity provided during each time slot. In this case, the occurrence of the consideration does not depend on whether the regulation reserves are triggered during actual operation.

- In actual operation, the final volume of provision is determined through transactions with retail electricity providers and aggregators. In this paper, the amount that can be provided in the plan is treated as the amount provided.

- The time and amount of the activation of the provided regulation reserves are random.

- The imbalance from the demand plan caused by activating regulation reserves is settled between transmission and distribution companies based on the imbalanced price. The imbalance is not treated in the optimal operation planning model.

3. Optimal Operation Planning Model for Water Pumping

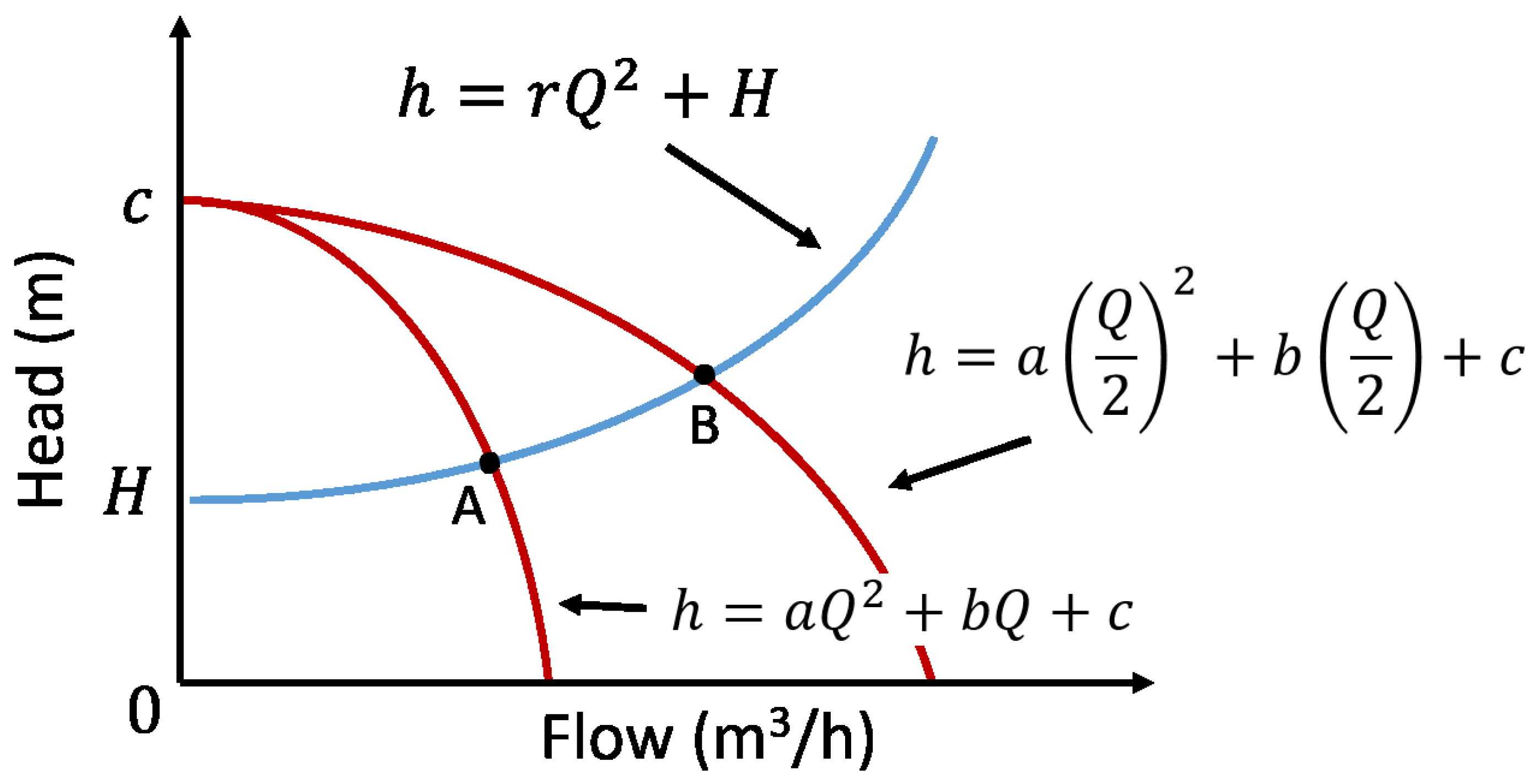

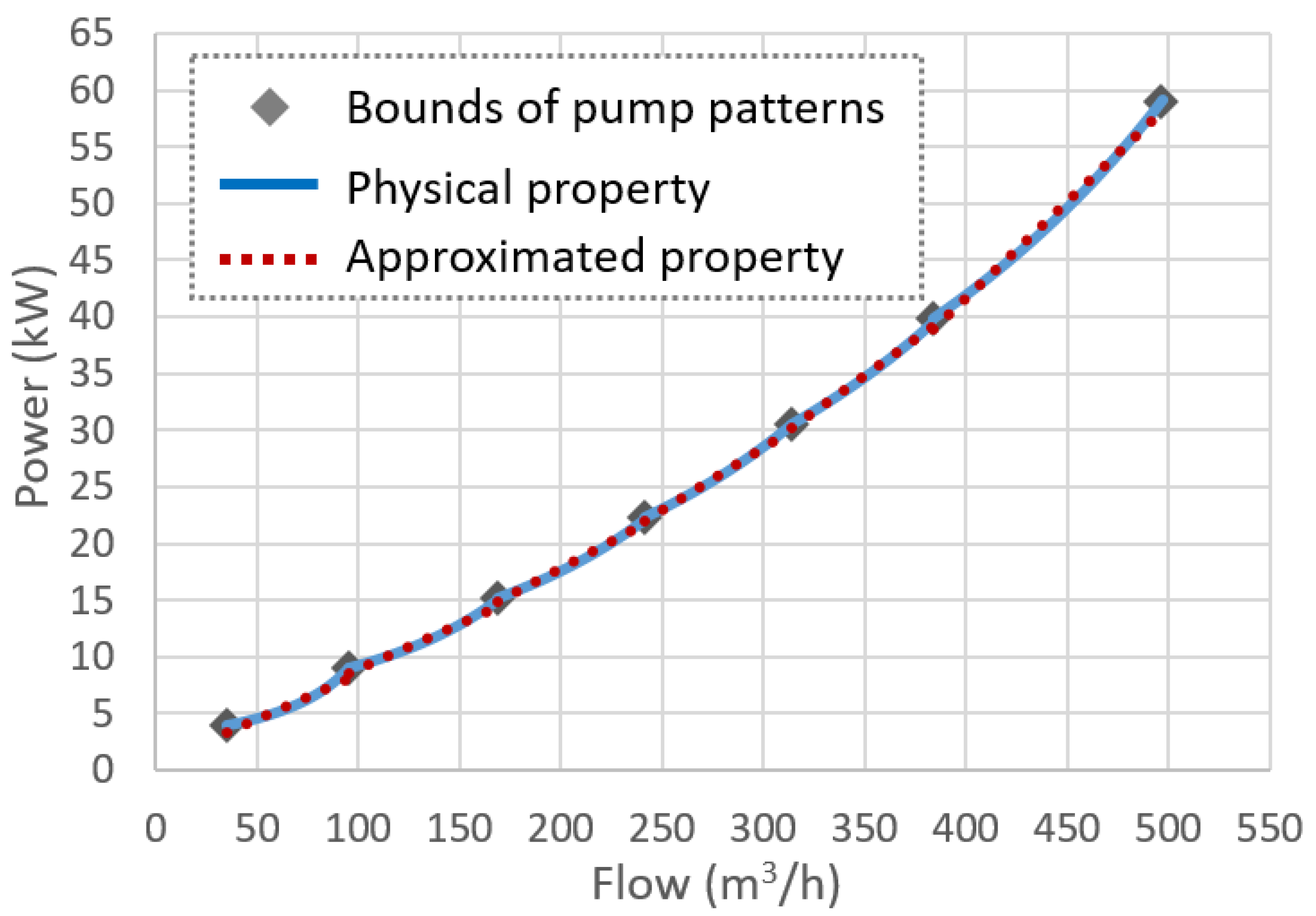

3.1. Power Consumption Characteristic Model of Water Pumps

3.2. Approximation of the Power Consumption Characteristics of the Water Pumps

3.3. Optimal Operational Planning Model

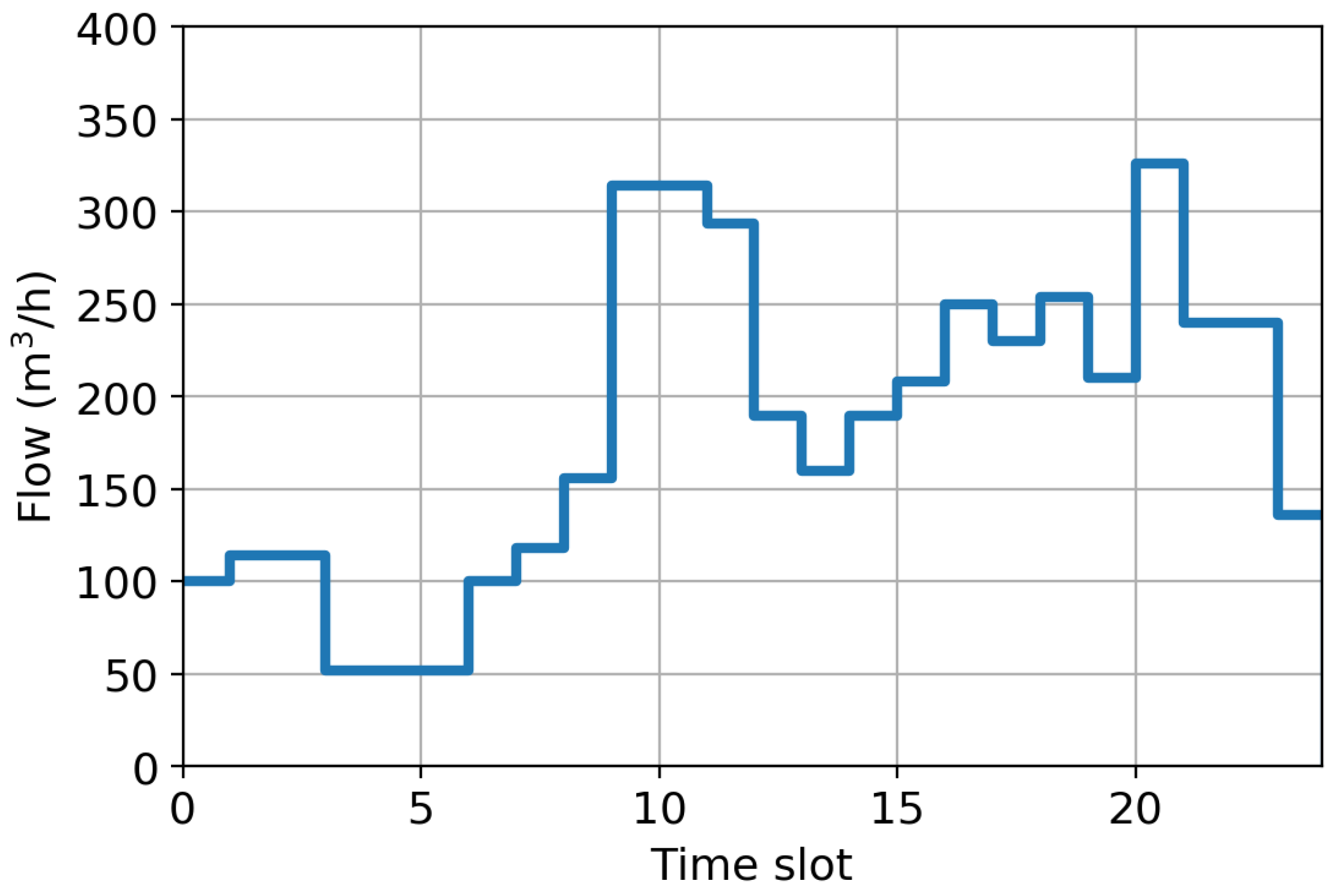

4. Numerical Experiment

4.1. Experimental Conditions

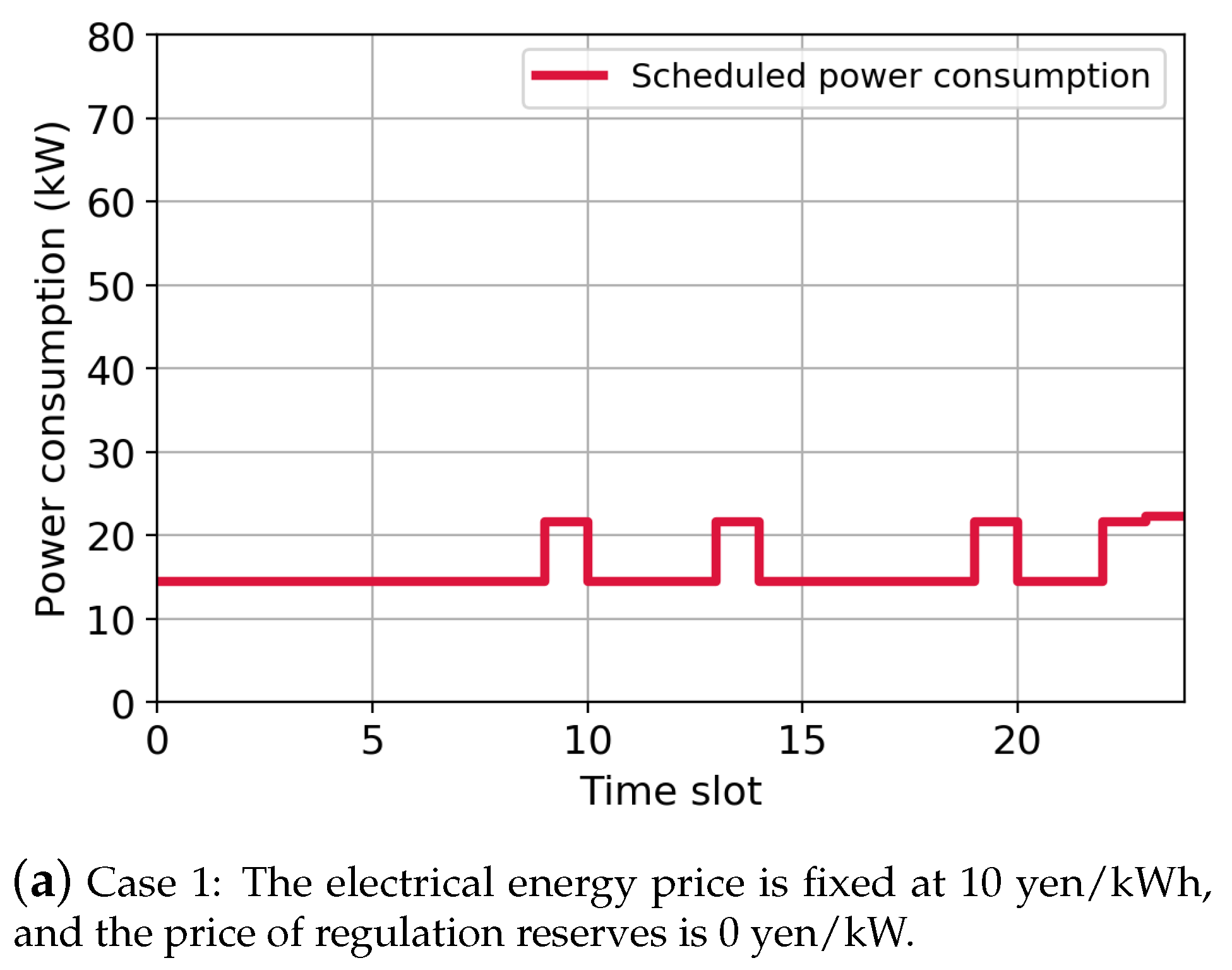

- Case 1: The electrical energy price is fixed at 10 yen/kWh, and the price of regulation reserves is 0 yen/kW.

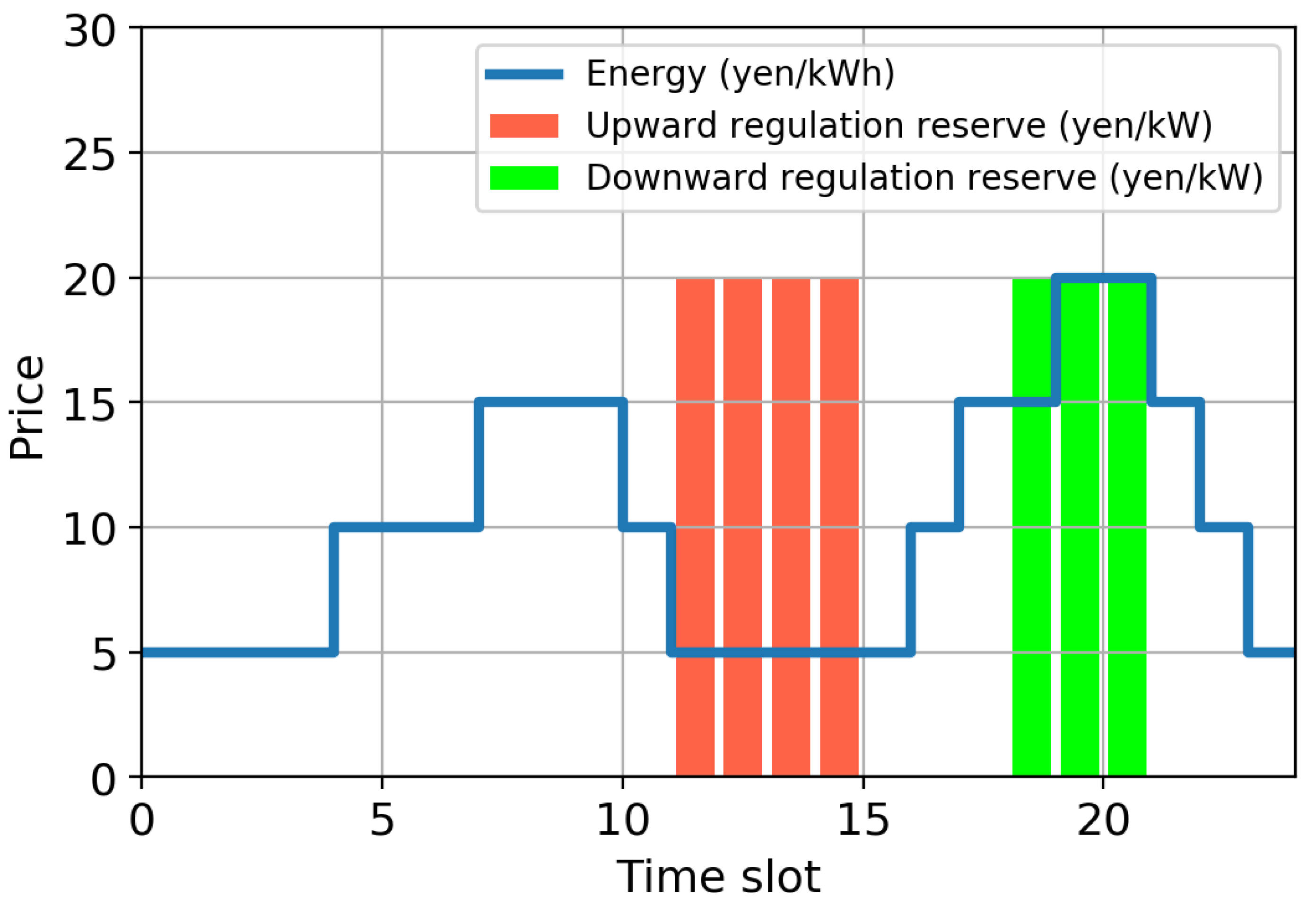

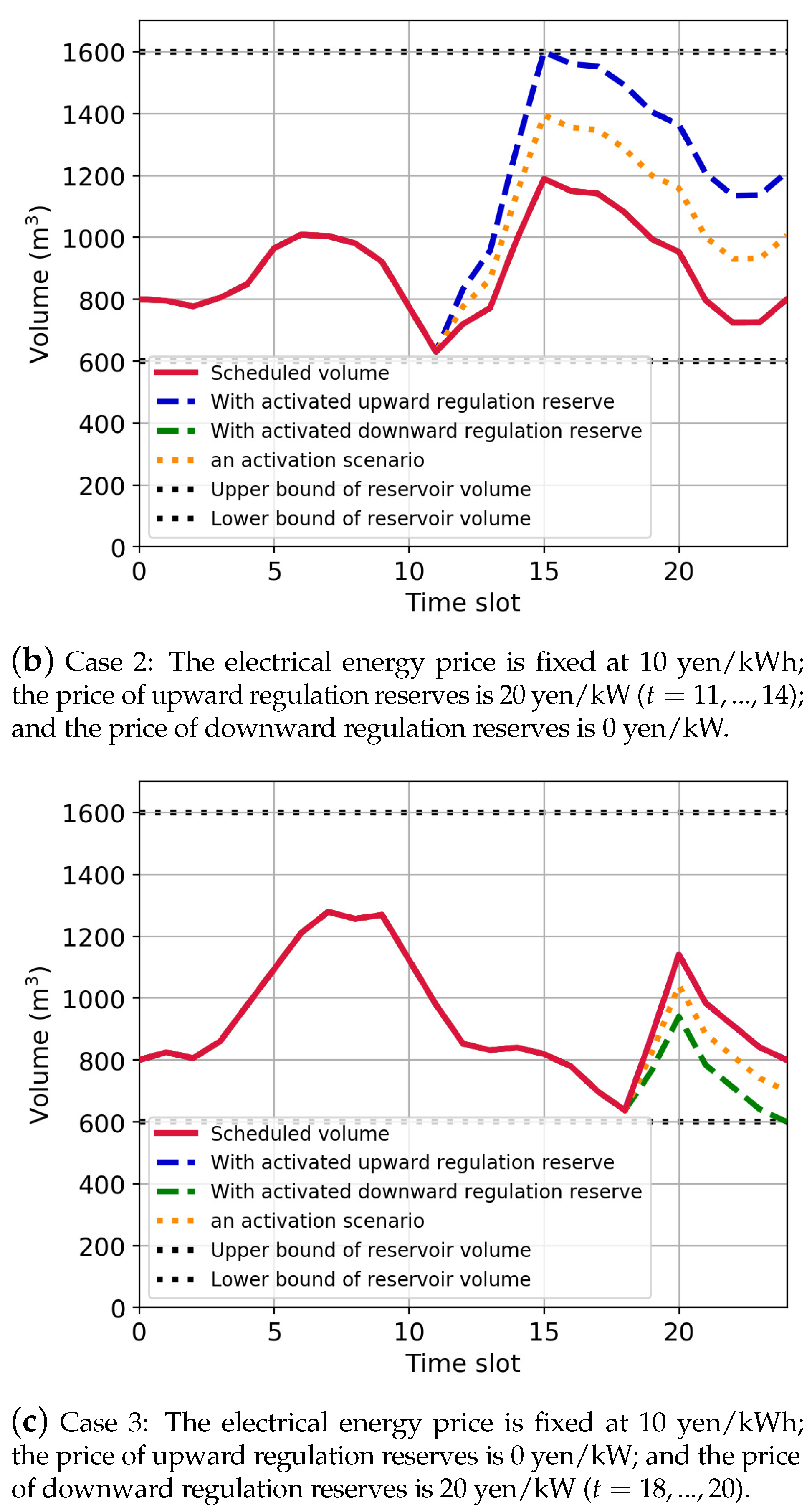

- Case 2: The electrical energy price is fixed at 10 yen/kWh; the price of upward regulation reserves is 20 yen/kW (); and the price of downward regulation reserves is 0 yen/kW.

- Case 3: The electrical energy price is fixed at 10 yen/kWh; the price of upward regulation reserves is 0 yen/kW; and the price of downward regulation reserves is 20 yen/kW ().

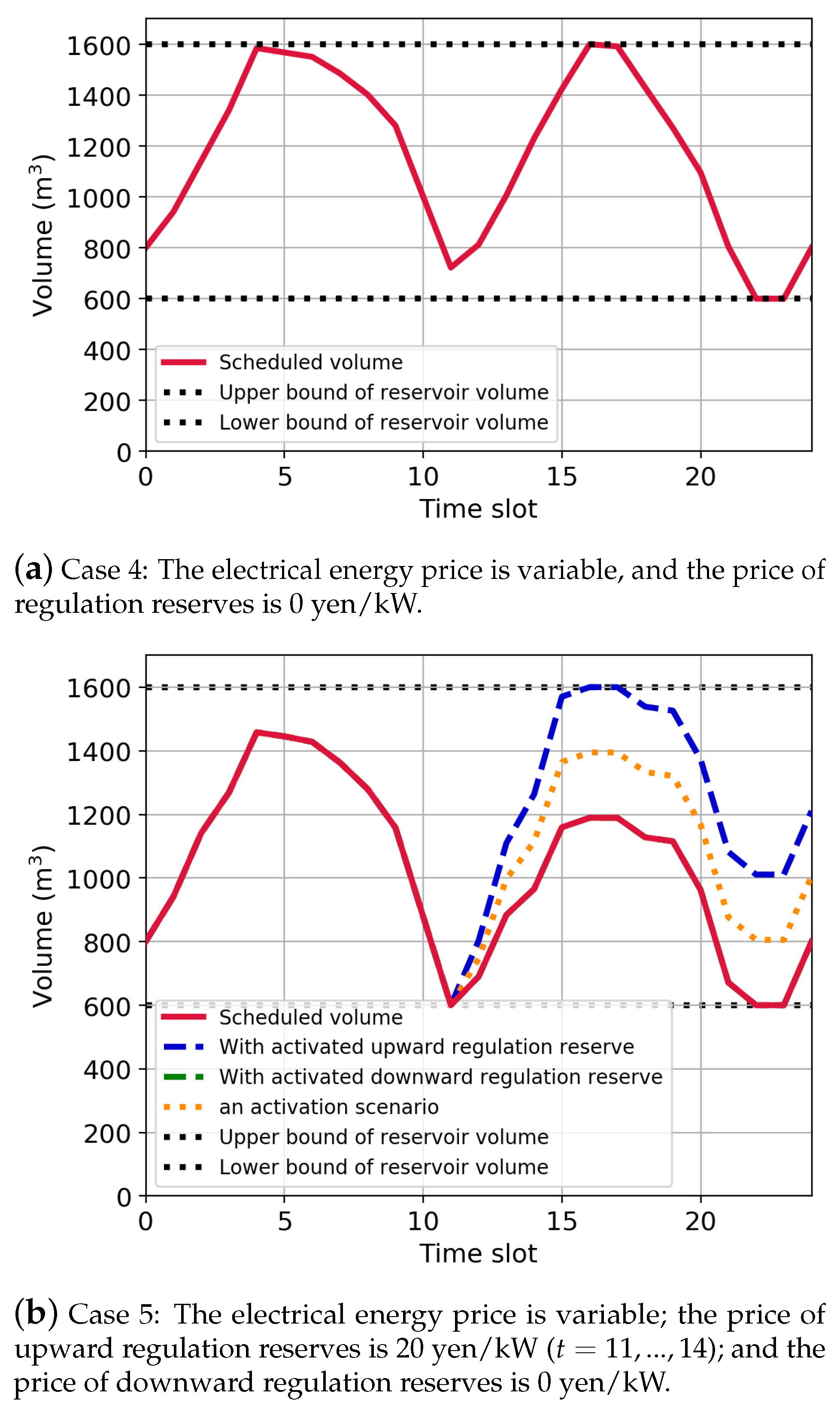

- Case 4: The electrical energy price is variable, and the price of regulation reserves is 0 yen/kW.

- Case 5: The electrical energy price is variable; the price of upward regulation reserves is 20 yen/kW (); and the price of downward regulation reserves is 0 yen/kW.

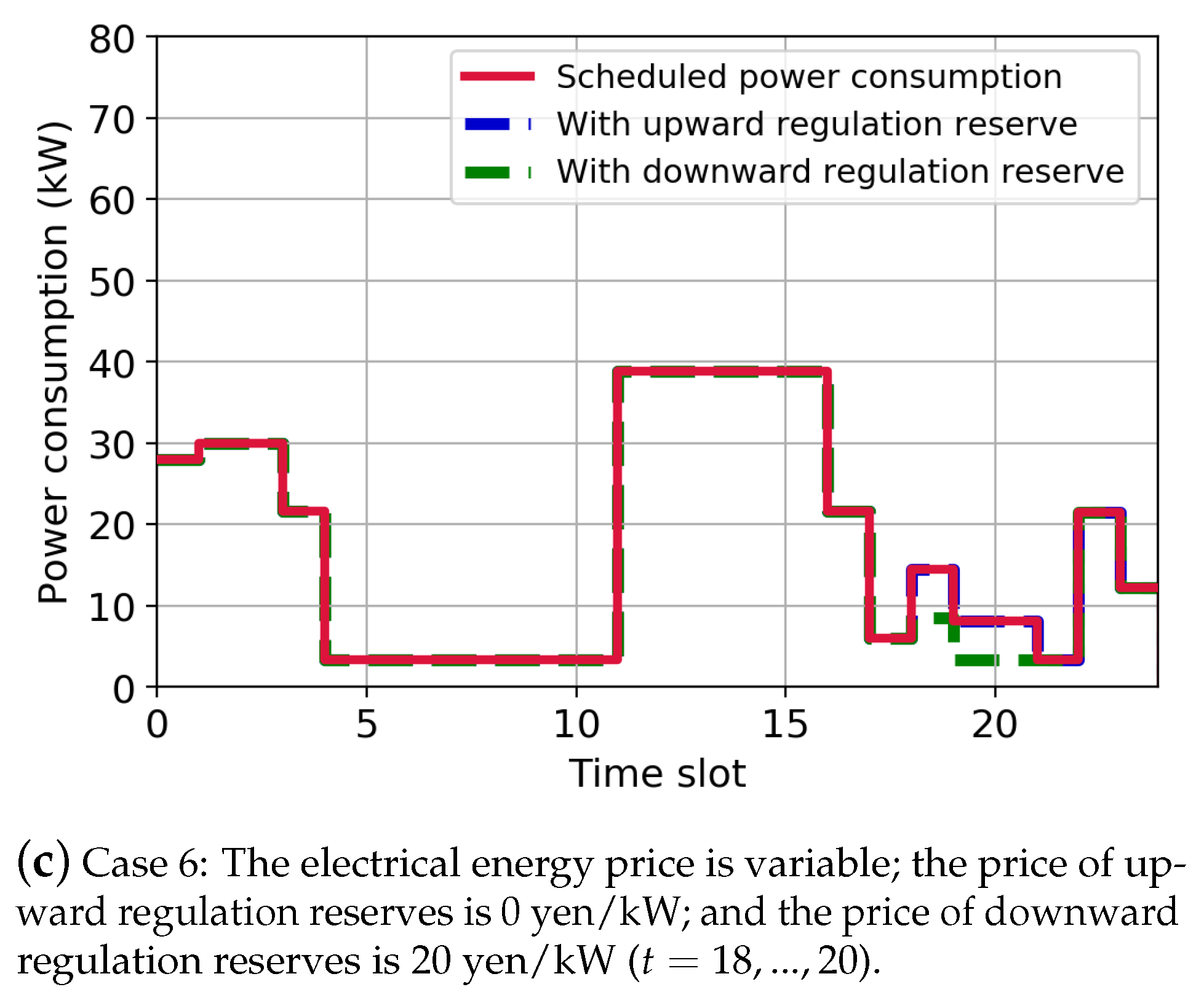

- Case 6: The electrical energy price is variable; the price of upward regulation reserves is 0 yen/kW; and the price of downward regulation reserves is 20 yen/kW ().

4.2. Results

4.2.1. In the Case of Fixed Electrical Energy Prices

4.2.2. Variable Electrical Energy Price

4.2.3. Comparison of Operational Costs

5. Conclusions

- For the optimal operation planning problem of the water pumps that provides regulation reserves, a method to ensure that the water storage volume in the reservoir is within the constraints and to maintain a stable water distribution under the uncertainty of the activation of the provided regulation reserves was proposed.

- Based on electrical energy and incentive prices for the provision of regulation reserves, a model was proposed that allows drawing an operation plan for water pumps that minimizes the net energy cost.

- As a case study, a numerical experiment was conducted on changing the electrical energy and incentive prices. The results confirmed the time shift in power consumption with the electrical energy price as a control signal. To maximize the revenues from the provision of regulation reserves, an operational plan was obtained that adjusts the planned water storage volume for the time slots when regulation reserves were required.

- Through a comparison of the objective function values obtained as a result of the numerical experiments, a net operating cost reduction in water pump operation was achieved by establishing a new source of income: the use of water pumps to provide regulation reserves to the power system.

Author Contributions

Funding

Conflicts of Interest

References

- Water Supply Division, Health Bureau, Ministry of Health, Labour and Welfare. Guide to Environmental Measures in Water Supply Projects (Revised Edition). 2009. Available online: https://www.mhlw.go.jp/za/0723/c02/c02-02.html (accessed on 15 April 2019).

- Health Bureau, Ministry of Health, Labour and Welfare. New Water Supply Vision. 2013. Available online: https://www.mhlw.go.jp/seisakunitsuite/bunya/topics/bukyoku/kenkou/suido/newvision/1_0_suidou_newvision.htm (accessed on 15 April 2019).

- American Water Works Association. Computer Modeling of Water Distribution Systems: AWWA Manual of Water Supply Practice, 3rd ed.; American Water Works Association: Denver, CO, USA, 2012. [Google Scholar]

- Arai, Y.; Horie, T.; Koizumi, A.; Inakazu, T.; Masuko, A.; Tamura, S.; Yamamoto, T. Minimizing Power Usage in Water Distribution System Using Mixed Integer Linear Programming. J. Jpn. Soc. Civ. Eng. Ser. G 2012, 68, II273–II281. (In Japanese) [Google Scholar]

- Takahashi, S.; Koibuchi, H.; Adachi, S.; Takemoto, T.; Koizumi, K. Pump Operation Scheduling for Power Demand Response in Water Transmission Systems. IEEJ Trans. EIS 2016, 136, 1200–1208. (In Japanese) [Google Scholar] [CrossRef]

- Chang, Y.; Choi, G.; Kim, J.; Byeon, S. Energy Cost Optimization for Water Distribution Networks Using Demand Pattern and Storage Facilities. Sustainability 2018, 10, 1118. [Google Scholar] [CrossRef] [Green Version]

- Afshar, A.; Massoumi, F.; Afshar, A.; Marino, M.A. State of the art review of ant colony optimization applications in water resource management. Water Resour. Manag. 2015, 29, 3891–3904. [Google Scholar] [CrossRef]

- Luna, T.; Ribau, J.; Figueiredo, D.; Alves, R. Improving energy efficiency in water supply systems with pump scheduling optimization. J. Clean. Prod. 2019, 213, 342–356. [Google Scholar] [CrossRef]

- Gleixner, A.; Held, H.; Huang, W.; Vigerske, S. Towards globally optimal operation of water supply networks. Numer. Algebr. Control Optim. 2012, 2, 695–711. [Google Scholar] [CrossRef]

- Burgschweiger, J.; Gnadig, B.; Steinbach, M.C. Optimization models for operative planning in drinking water networks. Optim. Eng. 2008, 10, 43–73. [Google Scholar] [CrossRef]

- Menke, R.; Abraham, E.; Parpas, P.; Stoianov, I. Demonstrating demand response from water distribution system through pump scheduling. Appl. Eng. 2016, 170, 377–387. [Google Scholar] [CrossRef] [Green Version]

- Hirano, T.; Ashida, Y.; Lu, Y.; Izukura, S.; Nishioka, I.; Fujimaki, R. Stable and Energy Efficient Operation in a Large-scale Water Distribution Network. IPSJ Trans. Math. Model. Appl. 2017, 10, 33–42. [Google Scholar]

- Zimmermann, B.; Gardian, H.; Rohrig, K. Cost-Optimal Flexibilization of Drinking Water Pumping and Treatment Plants. Water 2018, 10, 857. [Google Scholar] [CrossRef] [Green Version]

- Fooladivanda, D.; Taylor, J.A. Energy-Optimal Pump Scheduling and Water Flow. IEEE Trans. Control Netw. Syst. 2018, 5, 1016–1026. [Google Scholar] [CrossRef]

- Fracasso, P.T.; Barnes, F.S.; Costa, A.H.R. Energy Cost Optimization in Water Distribution Systems using Markov Decision Processes. In Proceedings of the 2013 International Green Computing Conference, Arlington, VA, USA, 27–29 June 2013; pp. 1–6. [Google Scholar]

- EPANET. Available online: https://www.epa.gov/water-research/epanet (accessed on 20 April 2020).

- GUROBI Optimizer. Available online: https://www.gurobi.com/ (accessed on 6 March 2020).

- CPLEX. Available online: https://www.ibm.com/jp-ja/analytics/cplex-optimizer (accessed on 6 March 2020).

- Takahashi, M. Study on Possibility of Fast Demand Response Mitigating Grid Balancing Challenges in Japanese Power System with Large-scale Renewable Energy Integration. CRIEPI Res. Rep. 2016, Y13030, 16–18. (In Japanese) [Google Scholar]

- Negishi, S.; Ikegami, T. A Water Pumping Scheduling Method in Water Distribution System with Providing Balancing Reserves to Power System. IEEJ Trans. Power Energy 2019, 139, 757–766. (In Japanese) [Google Scholar] [CrossRef]

- Investigating R&D Committee on New Development of Computational Intelligence Techniques and Their Applications to Industrial Systems. Optimization Benchmark Problems for Industrial Applications. IEEJ Tech. Rep. 2013, 1287, 13–17. (In Japanese) [Google Scholar]

| Sum of time slots T | 24 |

| Time step (h) | 1.0 |

| Sum of pump patterns | 6 |

| Upper bound of volume of the reservoir (m) | 1600 |

| Lower bound of volume of the reservoir (m) | 600 |

| Initial volume of the reservoir (m) | 800 |

| Parameter of pumps a | −0.005 |

| Parameter of pumps b | 0.064 |

| Parameter of pumps c | 50 |

| Parameter of pumps d | −0.0002 |

| Parameter of pumps e | 0.0286 |

| Parameter of pumps f | −0.03 |

| Pipeline resistance r (h/m) | 0.00005 |

| Gross pump head H (m) | 30 |

| Pump Patterns l | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Regression coefficient | 0.0778 | 0.0803 | 0.0934 | 0.1097 | 0.1281 | 0.1705 |

| Regression coefficient | 0.6938 | 0.9017 | −0.8533 | −4.4538 | −9.953 | −26.6 |

| Upper bound of flow rate (m/h) | 95.37 | 168.64 | 241.46 | 313.54 | 383.91 | 496.80 |

| Lower bound of flow rate (m/h) | 34.79 | 95.37 | 168.64 | 241.46 | 313.54 | 383.91 |

| Case | Objective Function Value (yen) |

|---|---|

| Case 1 | 3835 |

| Case 2 | 2686 |

| Case 3 | 3388 |

| Case 4 | 2806 |

| Case 5 | 1795 |

| Case 6 | 2679 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Negishi, S.; Ikegami, T. Robust Scheduling for Pumping in a Water Distribution System under the Uncertainty of Activating Regulation Reserves. Energies 2021, 14, 302. https://doi.org/10.3390/en14020302

Negishi S, Ikegami T. Robust Scheduling for Pumping in a Water Distribution System under the Uncertainty of Activating Regulation Reserves. Energies. 2021; 14(2):302. https://doi.org/10.3390/en14020302

Chicago/Turabian StyleNegishi, Shintaro, and Takashi Ikegami. 2021. "Robust Scheduling for Pumping in a Water Distribution System under the Uncertainty of Activating Regulation Reserves" Energies 14, no. 2: 302. https://doi.org/10.3390/en14020302

APA StyleNegishi, S., & Ikegami, T. (2021). Robust Scheduling for Pumping in a Water Distribution System under the Uncertainty of Activating Regulation Reserves. Energies, 14(2), 302. https://doi.org/10.3390/en14020302