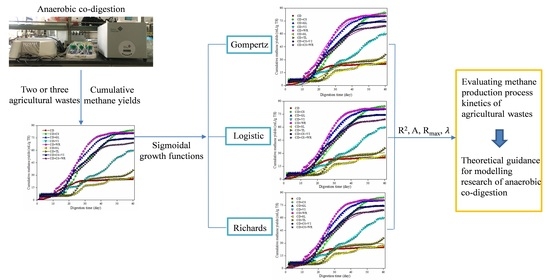

Modeling the Methane Production Kinetics of Anaerobic Co-Digestion of Agricultural Wastes Using Sigmoidal Functions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Agricultural Wastes Substrates Characterization

2.2. Experimental Conditions

2.3. Models Description

2.4. Data Analysis

3. Results

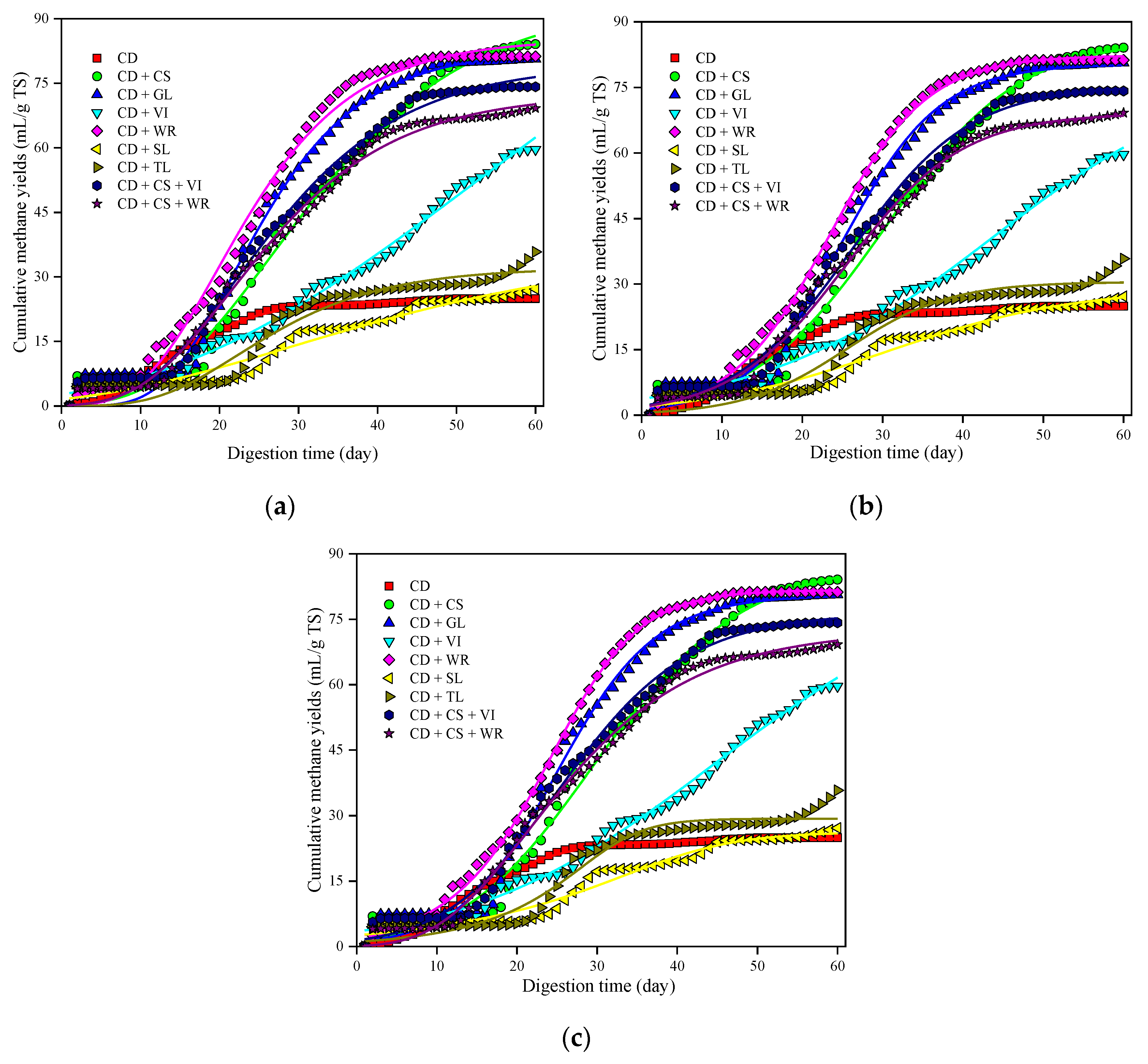

3.1. Methane Yields of Anaerobic Digestion with Different Feedstocks

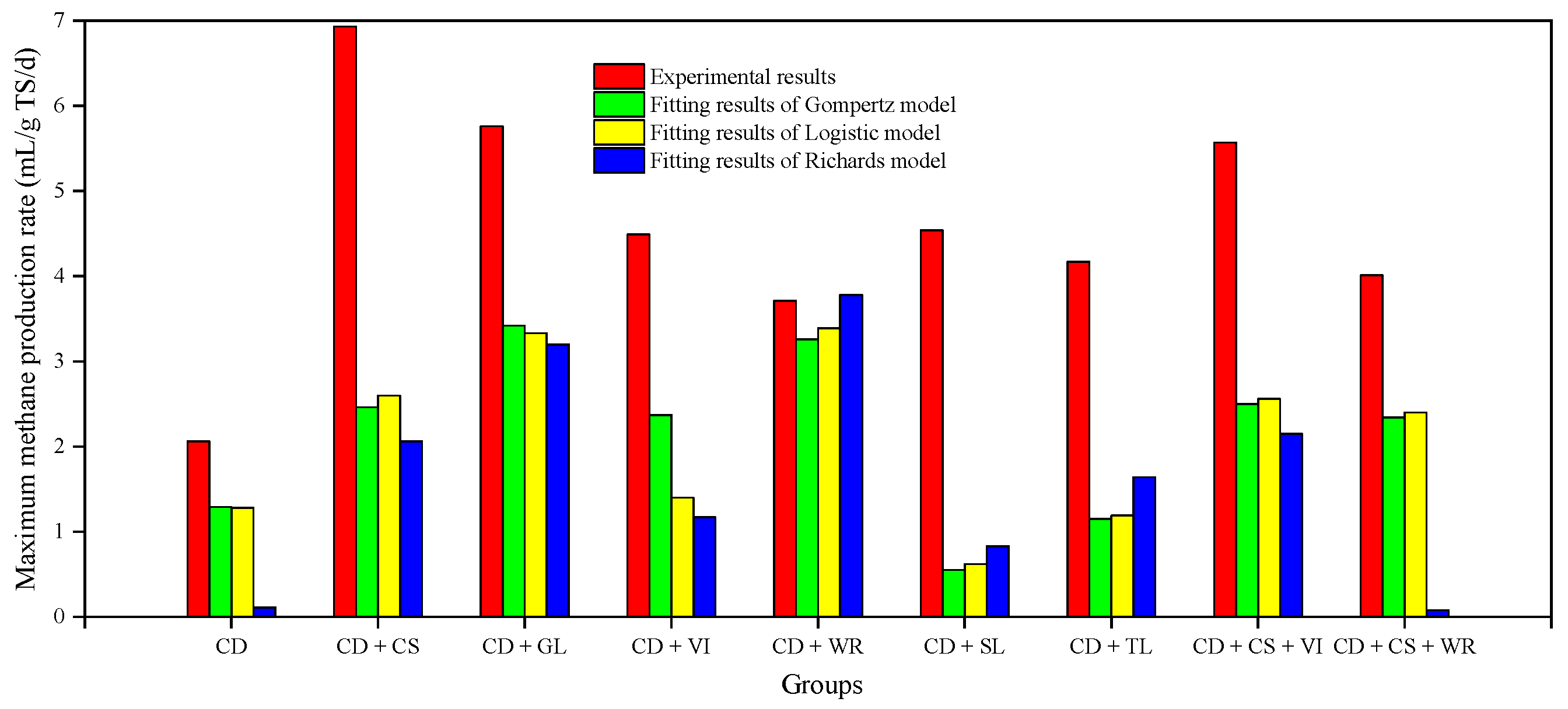

3.2. Modeling Methane Production Kinetics Using Modified Gompertz Model

3.3. Modeling Methane Production Kinetics Using Modified Logistic Model

3.4. Modeling Methane Production Kinetics Using Modified Richards Model

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bożym, M.; Florczak, I.; Zdanowska, P.; Wojdalski, J.; Klimkiewicz, M. An analysis of metal concentrations in food wastes for biogas production. Renew. Energy 2015, 77, 467–472. [Google Scholar] [CrossRef]

- Zhang, Z.; Gonzalez, A.M.; Davies, E.G.R.; Liu, Y. Agricultural wastes. Water Environ. Res. 2012, 84, 1386–1406. [Google Scholar] [CrossRef]

- Farhat, A.; Manai, I.; Gtari, M.; Bouallagui, H. Effect of enhancing nutrient balance in anaerobic digester feedstock by co-substrate addition on the microbial diversity and energy production from municipal sewage sludge. J. Biosci. Bioeng. 2018, 126, 497–506. [Google Scholar] [CrossRef] [PubMed]

- Herrmann, C.; Kalita, N.; Wall, D.; Xia, A.; Murphy, J.D. Optimised biogas production from microalgae through co-digestion with carbon-rich co-substrates. Bioresour. Technol. 2016, 214, 328–337. [Google Scholar] [CrossRef]

- Astals, S.; Musenze, R.S.; Bai, X.; Tannock, S.; Tait, S.; Pratt, S.; Jensen, P.D. Anaerobic co-digestion of pig manure and algae: Impact of intracellular algal products recovery on co-digestion performance. Bioresour. Technol. 2015, 181, 97–104. [Google Scholar] [CrossRef] [Green Version]

- Tian, Y.; Zhang, H.; Chai, Y.; Wang, L.; Mi, X.; Zhang, Y.; Ware, M.A. Biogas properties and enzymatic analysis during anaerobic fermentation of Phragmites australis straw and cow dung: Influence of nickel chloride supplement. Biodegradation 2017, 28, 15–25. [Google Scholar] [CrossRef]

- Matheri, A.N.; Ndiweni, S.N.; Belaid, M.; Muzenda, E.; Hubert, R. Optimising biogas production from anaerobic co-digestion of chicken manure and organic fraction of municipal solid waste. Renew. Sustain. Energy Rev. 2017, 80, 756–764. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, L.; Mi, X.; Zhang, H.; Chai, Y. Effect of ferrous chloride on biogas production and enzymatic activities during anaerobic fermentation of cow dung and Phragmites straw. Biodegradation 2016, 27, 69–82. [Google Scholar]

- Martín, M.A.; Fernández, R.; Gutiérrez, M.C.; Siles, J.A. Thermophilic anaerobic digestion of pre-treated orange peel: Modelling of methane production. Process Saf. Environ. Prot. 2018, 117, 245–253. [Google Scholar] [CrossRef]

- Zwietering, M.H.; Jongenburger, I.; Rombouts, F.M.; van ’t Riet, K. Modeling of the bacterial growth curve. Appl. Environ. Microbiol. 1990, 56, 1875–1881. [Google Scholar] [CrossRef] [Green Version]

- Tian, Y.; Yang, K.; Zheng, L.; Han, X.; Xu, Y.; Li, Y.; Li, S.; Xu, X.; Zhang, H.; Zhao, L. Modelling biogas production kinetics of various heavy metals exposed anaerobic fermentation process using sigmoidal growth functions. Waste Biomass Valori. 2019, 11, 4837–4848. [Google Scholar] [CrossRef]

- Ware, A.; Power, N. Modelling methane production kinetics of complex poultry slaughterhouse wastes using sigmoidal growth functions. Renew. Energy 2017, 104, 50–59. [Google Scholar] [CrossRef]

- Li, X.; Huang, J.; Liu, Y.; Maurer, C.; Kranert, M. Effects of salt on anaerobic digestion of food waste with different component characteristics and fermentation concentrations. Energies 2019, 12, 3571. [Google Scholar] [CrossRef] [Green Version]

- Gaur, R.Z.; Suthar, S. Anaerobic digestion of activated sludge, anaerobic granular sludge and cow dung with food waste for enhanced methane production. J. Clean. Prod. 2017, 164, 557–566. [Google Scholar] [CrossRef]

- Zaidi, A.A.; Feng, R.; Yue, S.; Khan, S.Z.; Mushtaq, K. Nanoparticles augmentation on biogas yield from microalgal biomass anaerobic digestion. Int. J. Hydrogen Energy 2018, 43, 14202–14213. [Google Scholar] [CrossRef]

- Zhu, M.R. Fitting Gompertz Model and Logistic Model. Math. Pract. Theory 2002, 32, 705–709. [Google Scholar]

- Altaş, L. Inhibitory effect of heavy metals on methane-producing anaerobic granular sludge. J. Hazard. Mater. 2009, 162, 1551–1556. [Google Scholar] [CrossRef]

- Dhamodharan, K.; Kumar, V.; Kalamdhad, A.S. Effect of different livestock dungs as inoculum on food waste anaerobic digestion and its kinetics. Bioresour. Technol. 2015, 180, 237–241. [Google Scholar] [CrossRef]

- Basak, B.; Fatima, A.; Jeon, B.H.; Ganguly, A.; Chatterjee, P.K.; Dey, A. Process kinetic studies of biohydrogen production by co-fermentation of fruit-vegetable wastes and cottage cheese whey. Energy Sustain. Dev. 2018, 47, 39–52. [Google Scholar] [CrossRef]

- Bakhov, Z.K.; Korazbekova, K.U.; Lakhanova, K.M. The kinetics of methane production from co-digestion of cattle manure. Pak. J. Biol. 2014, 17, 1023–1029. [Google Scholar] [CrossRef]

- Boni, M.R.; Sbaffoni, S.; Tuccinardi, L. The influence of iron concentration on biohydrogen production from organic waste via anaerobic fermentation. Environ. Technol. 2014, 35, 3000–3010. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Zhang, H.; Mi, X.; Wang, L.; Zhang, L.; Ai, Y. Research on anaerobic digestion of corn stover enhanced by dilute acid pretreatment: Mechanism study and potential utilization in practical application. J. Renew. Sustain. Energy 2016, 8, 023103. [Google Scholar] [CrossRef]

- Sun, W.; Qu, Y.; Yu, Q. Adsorption of organic pollutants from coking and papermaking wastewaters by bottom ash. J. Hazard. Mater. 2008, 154, 595–601. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Zhang, H. Producing biogas from agricultural residues generated during phytoremediation process: Possibility, threshold, and challenges. Int. J. Green Energy 2016, 13, 1556–1563. [Google Scholar] [CrossRef]

- Lao, J.; Chen, X.; Qi, M.; Ji, B. Soil Agrochemical Analysis Manual; Lao, J., Ed.; Agriculture Press: Beijing, China, 1988. [Google Scholar]

- Zhang, P.; Zeng, G.; Zhang, G.; Li, Y.; Zhang, B.; Fan, M. Anaerobic co-digestion of biosolids and organic fraction of municipal solid waste by sequencing batch process. Fuel Process. Technol. 2008, 89, 485–489. [Google Scholar] [CrossRef]

- Bakraoui, M.; Karouach, F.; Ouhammou, B.; Lahboubi, N.; Gnaoui, Y.E.; Kerrou, O.; Aggour, M.; Bari, H.E. Kinetics study of methane production from anaerobic digestion of sludge and wastewater recycled pulp and paper. Conf. Ser. Mater. Sci. Eng. 2020, 946, 27–29. [Google Scholar] [CrossRef]

- Veluchamy, C.; Kalamdhad, A.S. Enhanced methane production and its kinetics model of thermally pretreated lignocellulose waste material. Bioresour. Technol. 2017, 241, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; He, Q.; Zhao, X.; Wu, D.; Wang, X.; Peng, X. Anaerobic digestion of food waste: Correlation of kinetic parameters with operational conditions and process performance. Biochem. Eng. J. 2017, 130, 1–9. [Google Scholar] [CrossRef]

- Blasius, J.P.; Contrera, R.C.; Maintinguer, S.I.; de Castro, M.C.A.A. Effects of temperature, proportion and organic loading rate on the performance of anaerobic digestion of food waste. Biotechnol. Rep. 2020, 27, e00503. [Google Scholar] [CrossRef]

- Mulyaningtyas, A.; Sediawan, W.B. Effect of combined pretreatment of lignocellulose and the kinetics of its subsequent bioconversion by Aspergillus niger. Biocatal. Agric. Biotechnol. 2019, 21, 101292. [Google Scholar] [CrossRef]

- Fang, W.; Zhang, P.; Zhang, T.; Requeson, D.C.; Poster, M. Upgrading volatile fatty acids production through anaerobic co-fermentation of mushroom residue and sewage sludge: Performance evaluation and kinetics analysis. J. Environ. Manag. 2019, 241, 612–618. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Wang, Y.; Qian, P.; Gu, J. Optimization of phthalic acid batch biodegradation and the use of modified Richards model for modelling degradation. Int. Biodeter. Biodegr. 2004, 53, 57–63. [Google Scholar] [CrossRef]

| Feedstocks | CD 1 | CS 2 | GL 3 | VI 4 | WR 5 | SL 6 | TL 7 |

|---|---|---|---|---|---|---|---|

| TS 9 (%Dry weight) | 17.42 | 92.86 | 86.95 | 91.59 | 88.06 | 91.04 | 90.51 |

| VS 10 (%TS) | 85.06 | 90.56 | \ 8 | 90.18 | 84.31 | 86.34 | \ |

| TOC 11 (%TS) | 0.17 | 16.53 | 28.28 | 37.78 | 38.73 | 30.43 | 40.03 |

| TN 12 (%TS) | 0.15 | 0.34 | 0.23 | 0.53 | 0.16 | 0.62 | 0.64 |

| TP 13 (%TS) | 0.003 | 0.01 | 0.004 | 0.005 | 0.01 | 0.001 | 0.02 |

| Soluble sugar (%TS) | 0.004 | 0.15 | 0.44 | 0.46 | 3.58 | 6.00 | 4.74 |

| Starch (%TS) | 0.0002 | 0.24 | \ | 0.56 | 0.31 | 0.30 | 0.37 |

| Protein (%TS) | 0.45 | 0.27 | 0.60 | 0.65 | 0.12 | 0.31 | 0.27 |

| Lipid (%TS) | 0.78 | 5.86 | 7.48 | 3.88 | 6.92 | 5.34 | 9.86 |

| Cellulose (%TS) | 34.63 | 35.94 | 26.41 | 32.57 | 43.13 | 28.42 | 34.58 |

| Hemicellulose (%TS) | 19.46 | 23.11 | 23.36 | 33.67 | 11.45 | 13.57 | 15.10 |

| Lignin (%TS) | 28.64 | 21.25 | 28.81 | 17.37 | 17.19 | 22.79 | 24.28 |

| Groups | The Feedstocks and Dry Weights |

|---|---|

| 1 | CD 1 16 g |

| 2 | CD 16 g + CS 2 8 g |

| 3 | CD 16 g + GL 3 8 g |

| 4 | CD 16 g + VI 4 8 g |

| 5 | CD 16 g + WR 5 8 g |

| 6 | CD 16 g + SL 6 8 g |

| 7 | CD 16 g + TL 7 8 g |

| 8 | CD 16 g + CS 4 g + VI 4 g |

| 9 | CD 16 g + CS 4 g + WR 4 g |

| Groups | A 8 (mL/g∙TS) | Rmax 9 (mL/g∙TS/day) | λ 10 (days) | R2 11 | ||

|---|---|---|---|---|---|---|

| Fitting Results | Experimental Results | Fitting Results | Experimental Results | |||

| CD 1 | 24.76 | 24.98 | 1.29 | 2.06 | 5.03 | 0.9978 |

| CD + CS 2 | 94.38 | 84.09 | 2.46 | 6.93 | 12.38 | 0.9899 |

| CD + GL 3 | 82.68 | 80.64 | 3.42 | 5.76 | 12.79 | 0.9896 |

| CD + VI 4 | 142.93 | 59.63 | 1.37 | 4.49 | 14.51 | 0.9927 |

| CD + WR 5 | 85.27 | 81.23 | 3.26 | 3.71 | 10.03 | 0.9938 |

| CD + SL 6 | 37.24 | 27.19 | 0.55 | 4.54 | 3.86 | 0.9503 |

| CD + TL 7 | 32.12 | 35.83 | 1.15 | 4.17 | 12.01 | 0.9445 |

| CD + CS + VI | 79.51 | 74.17 | 2.50 | 5.57 | 10.33 | 0.9918 |

| CD + CS + WR | 72.56 | 69.18 | 2.34 | 4.01 | 10.02 | 0.9947 |

| Groups | A 8 (mL/g∙TS) | Rmax 9 (mL/g∙TS/day) | λ 10 (days) | R2 11 | ||

|---|---|---|---|---|---|---|

| Fitting Results | Experimental Results | Fitting Results | Experimental Results | |||

| CD 1 | 24.39 | 24.98 | 1.28 | 2.06 | 5.56 | 0.9936 |

| CD + CS 2 | 86.07 | 84.09 | 2.60 | 6.93 | 13.82 | 0.9909 |

| CD + GL 3 | 80.33 | 80.64 | 3.33 | 5.76 | 13.05 | 0.9924 |

| CD + VI 4 | 80.55 | 59.63 | 1.40 | 4.49 | 14.68 | 0.9930 |

| CD + WR 5 | 82.32 | 81.23 | 3.39 | 3.71 | 11.24 | 0.9988 |

| CD + SL 6 | 29.07 | 27.19 | 0.62 | 4.54 | 7.11 | 0.9604 |

| CD + TL 7 | 30.48 | 35.83 | 1.19 | 4.17 | 12.85 | 0.9573 |

| CD + CS + VI | 75.42 | 74.17 | 2.56 | 5.57 | 11.37 | 0.9933 |

| CD + CS + WR | 69.10 | 69.18 | 2.40 | 4.01 | 11.17 | 0.9946 |

| Groups | A 8 (mL/g∙TS) | Rmax 9 (mL/g∙TS/day) | λ 10 (days) | v 11 | R2 12 | ||

|---|---|---|---|---|---|---|---|

| Fitting Results | Experimental Results | Fitting Results | Experimental Results | ||||

| CD 1 | 24.74 | 24.98 | 0.11 | 2.06 | 5.04 | 0.03 | 0.9977 |

| CD + CS 2 | 88.47 | 84.09 | 2.06 | 6.93 | 13.20 | 0.59 | 0.9913 |

| CD + GL 3 | 80.53 | 80.64 | 3.20 | 5.76 | 12.97 | 0.89 | 0.9923 |

| CD + VI 4 | 90.06 | 59.63 | 1.17 | 4.49 | 14.21 | 0.65 | 0.9930 |

| CD + WR 5 | 81.71 | 81.23 | 3.78 | 3.71 | 11.73 | 1.39 | 0.9990 |

| CD + SL 6 | 26.28 | 27.19 | 0.83 | 4.54 | 10.18 | 2.81 | 0.9644 |

| CD + TL 7 | 29.32 | 35.83 | 1.64 | 4.17 | 14.95 | 2.75 | 0.9607 |

| CD + CS + VI | 76.43 | 74.17 | 2.15 | 5.57 | 10.95 | 0.65 | 0.9936 |

| CD + CS + WR | 72.49 | 69.18 | 0.08 | 4.01 | 10.03 | 0.01 | 0.9947 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; An, D.; Cao, Y.; Tian, Y.; He, J. Modeling the Methane Production Kinetics of Anaerobic Co-Digestion of Agricultural Wastes Using Sigmoidal Functions. Energies 2021, 14, 258. https://doi.org/10.3390/en14020258

Zhang H, An D, Cao Y, Tian Y, He J. Modeling the Methane Production Kinetics of Anaerobic Co-Digestion of Agricultural Wastes Using Sigmoidal Functions. Energies. 2021; 14(2):258. https://doi.org/10.3390/en14020258

Chicago/Turabian StyleZhang, Huayong, Di An, Yudong Cao, Yonglan Tian, and Jinxian He. 2021. "Modeling the Methane Production Kinetics of Anaerobic Co-Digestion of Agricultural Wastes Using Sigmoidal Functions" Energies 14, no. 2: 258. https://doi.org/10.3390/en14020258

APA StyleZhang, H., An, D., Cao, Y., Tian, Y., & He, J. (2021). Modeling the Methane Production Kinetics of Anaerobic Co-Digestion of Agricultural Wastes Using Sigmoidal Functions. Energies, 14(2), 258. https://doi.org/10.3390/en14020258