Effect of Microwave Pulses on the Morphology and Development of Spark-Ignited Flame Kernel

Abstract

:1. Introduction

- The transient spark discharge energy and mean microwave pulse energy are measured under different conditions.

- It is the first time in MAI research that the deformation degree of flame kernel is quantitively described by introducing deformation index. Based on it, the microwave-caused flow is related to the microwave enhancing regime.

- The influencing regimes of both microwave power and pulse repetition frequency are discussed from the perspectives of both flow and energy accumulation.

- Regimes of microwave-induced wrinkles and flame deformation under different microwave parameters are related to the plasma instability and discussed deeply.

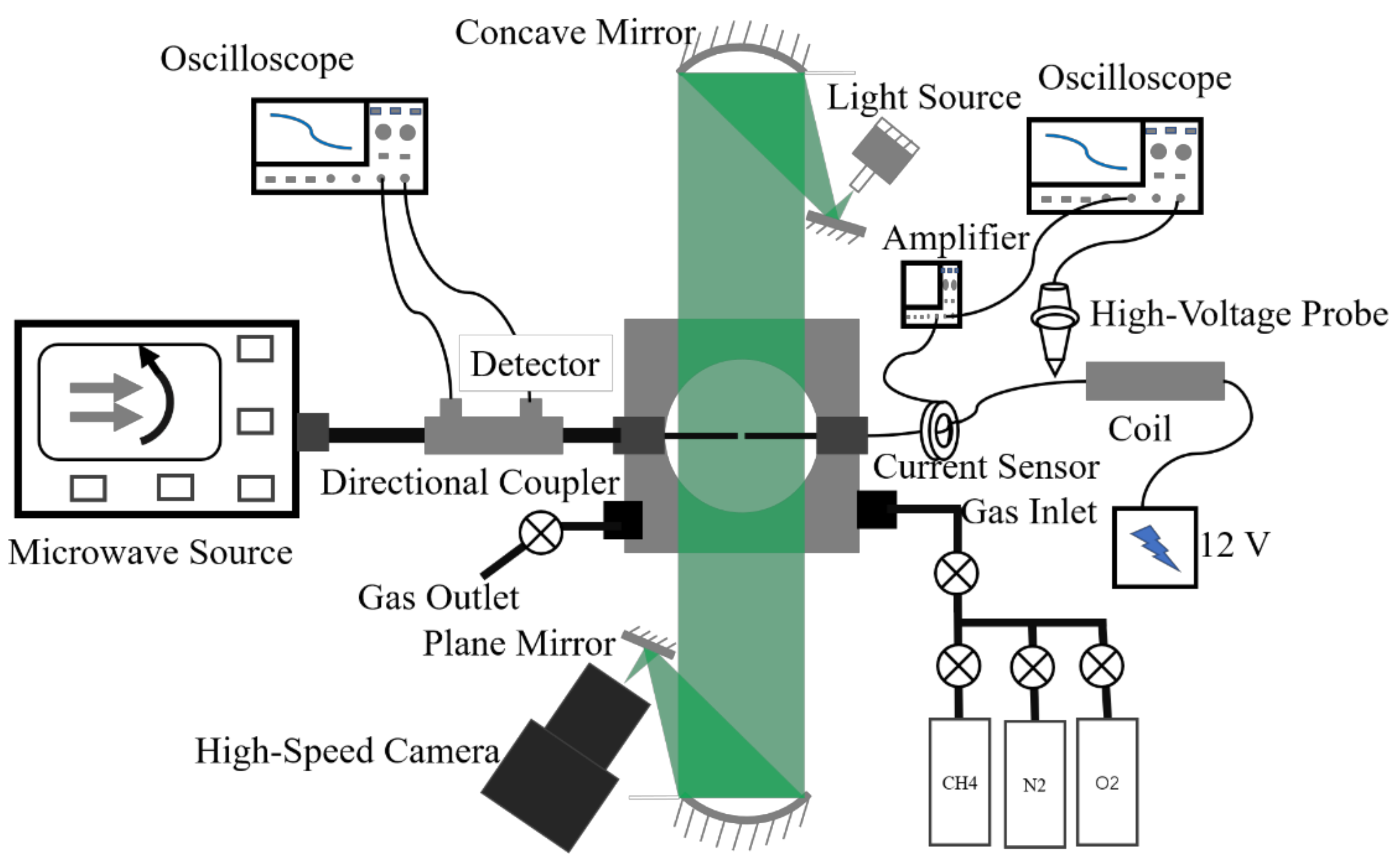

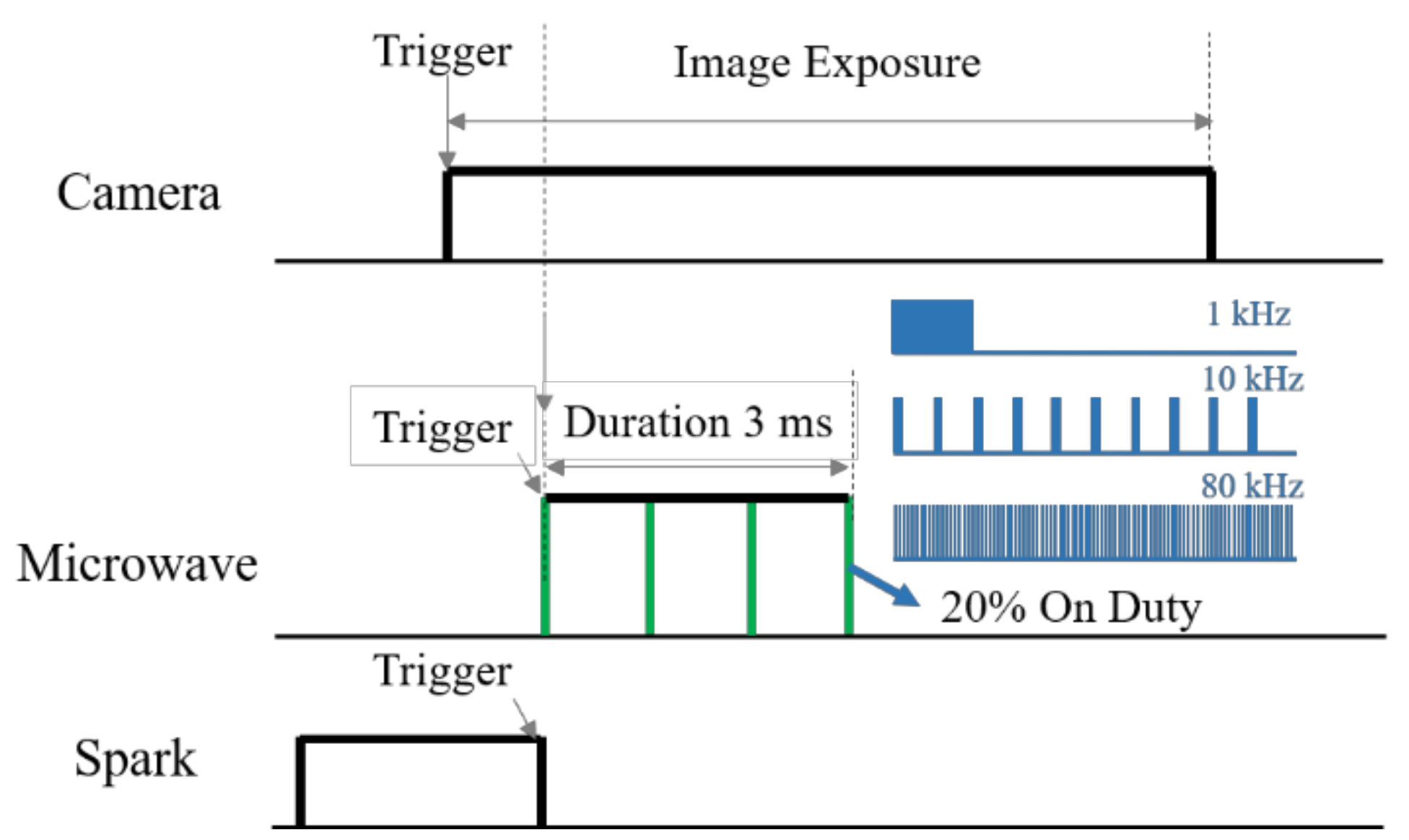

2. Experimental Setup and Methods

2.1. Microwave-Assisted CVCC System

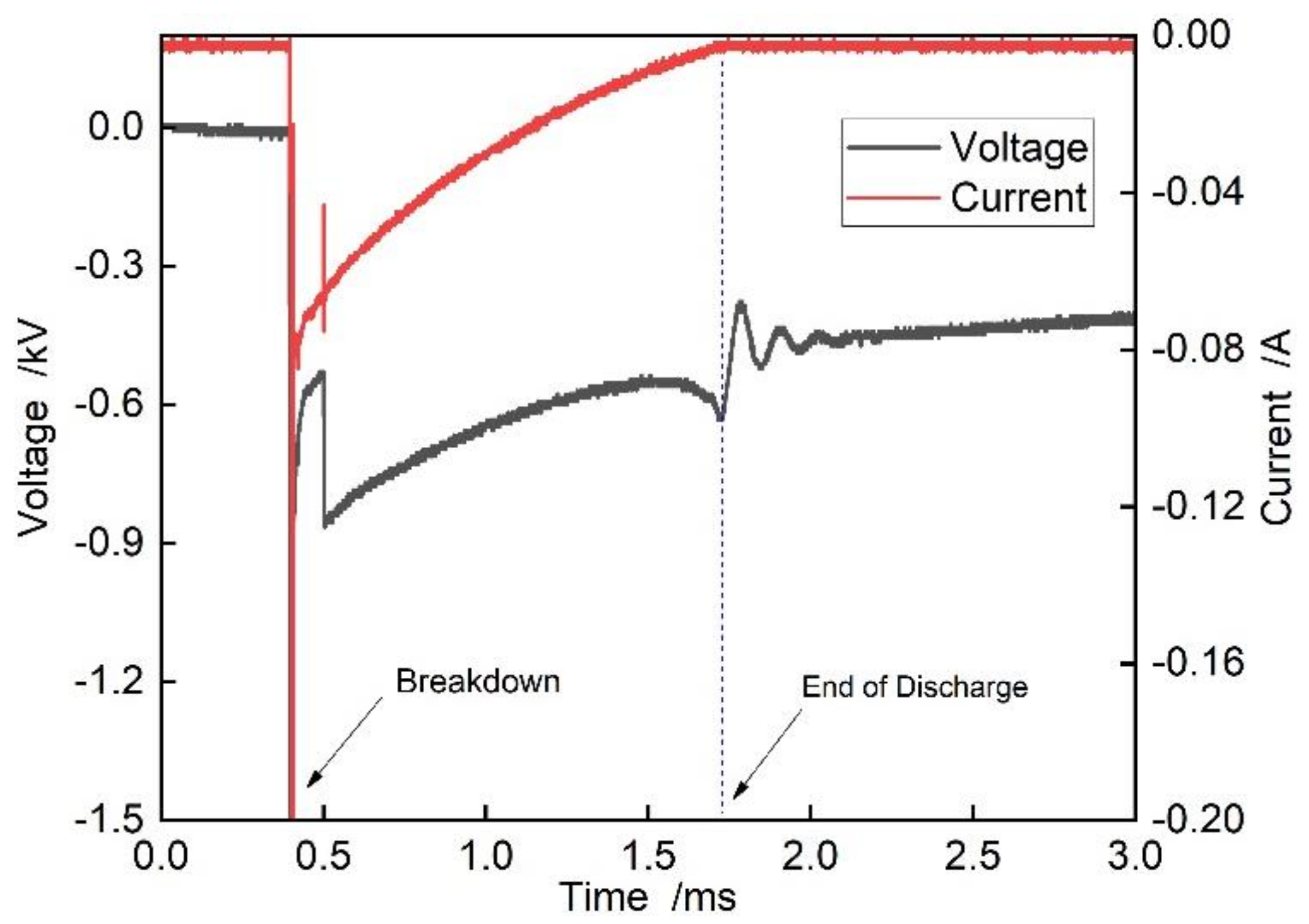

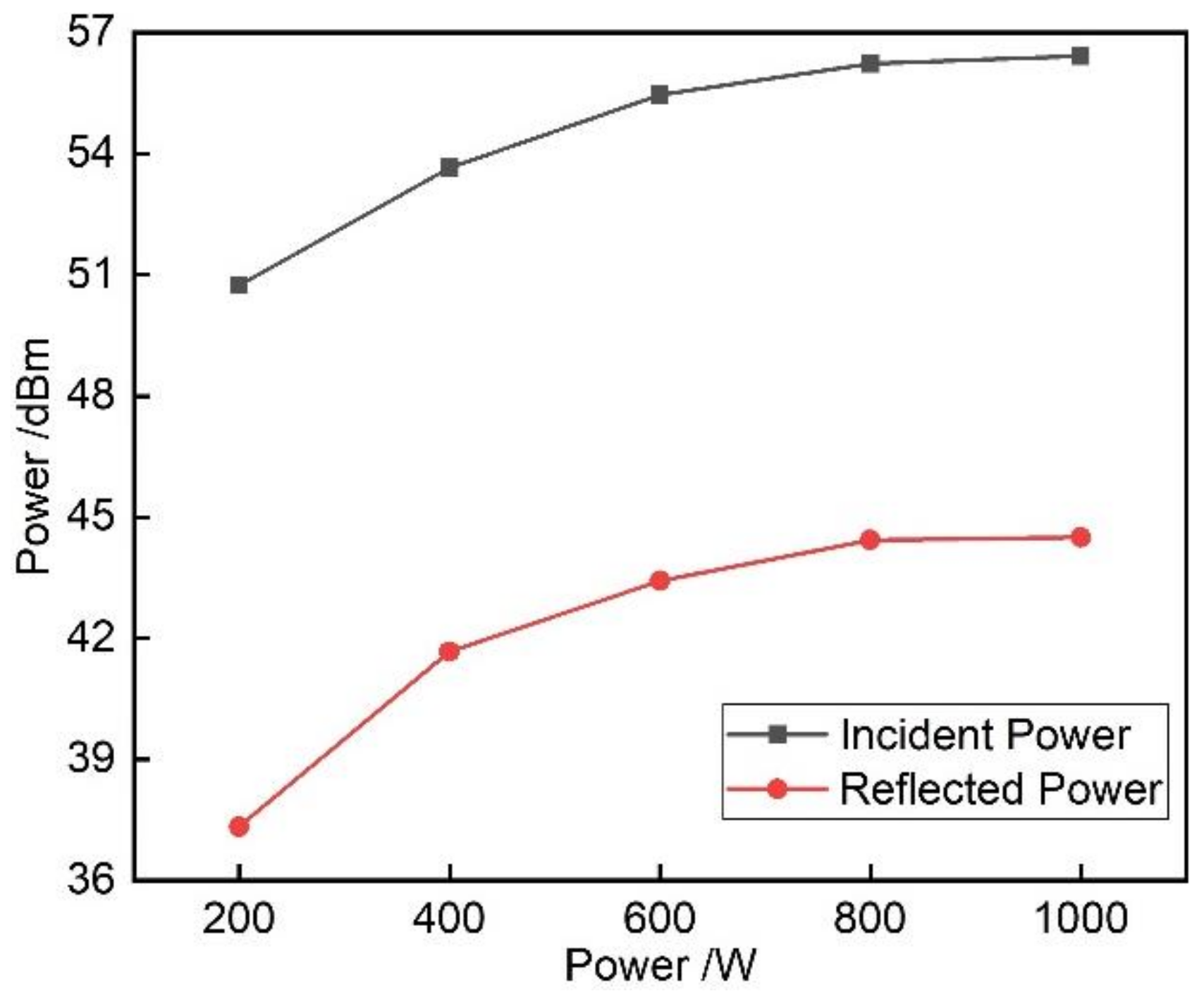

2.2. Discharge Energy and Microwave Pulse Energy

2.3. Experimental Procedure

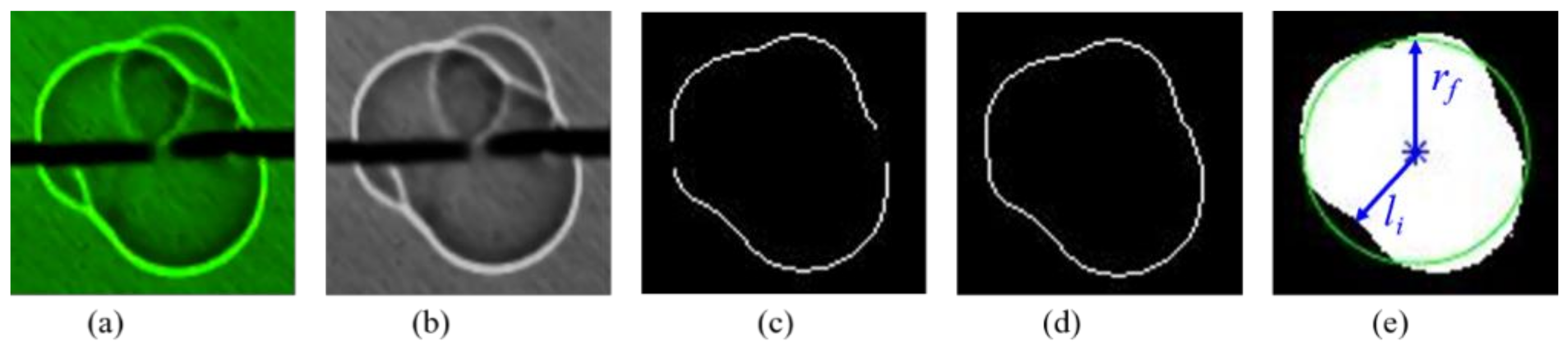

2.4. Image Processing

3. Results and Discussion

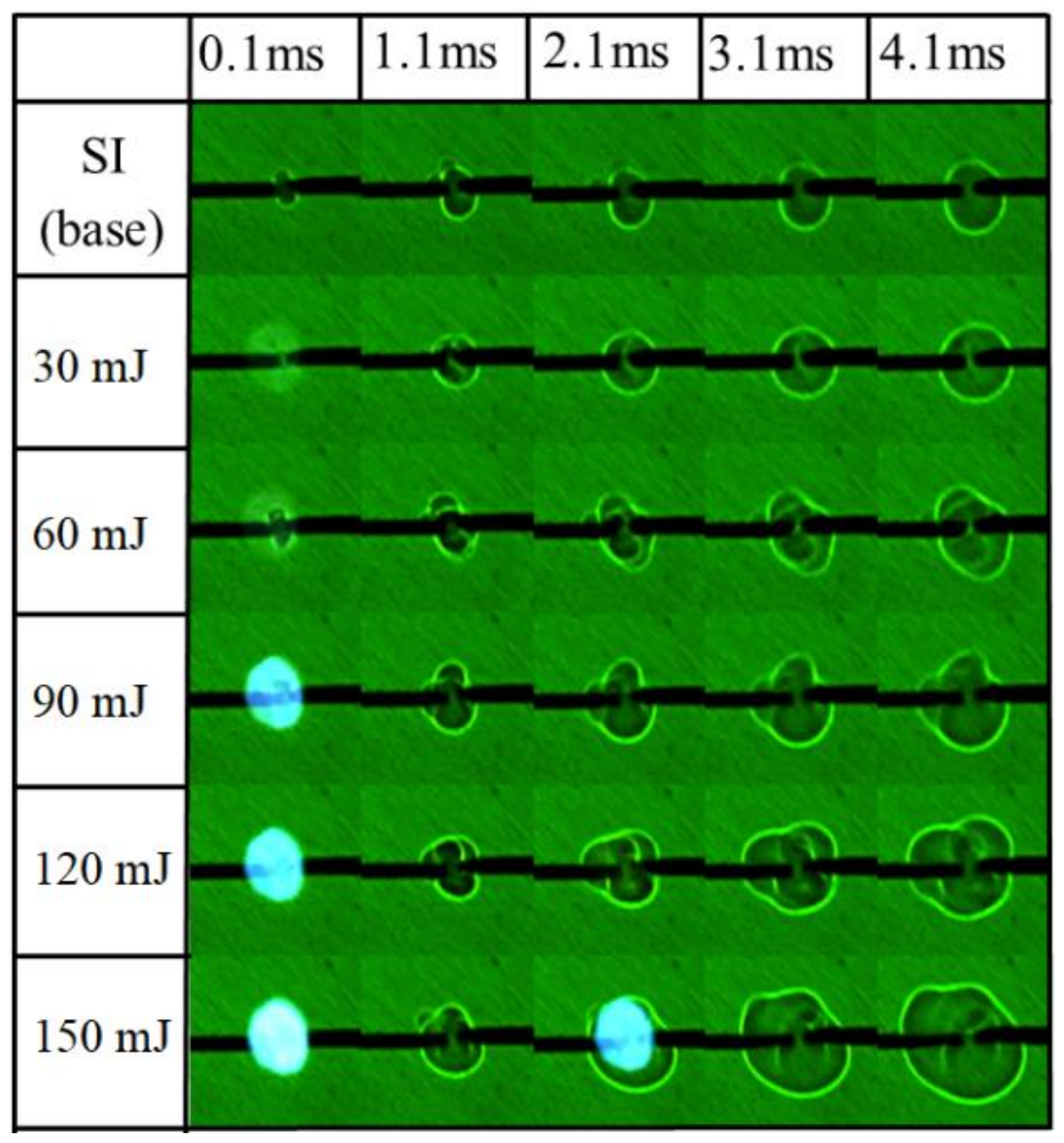

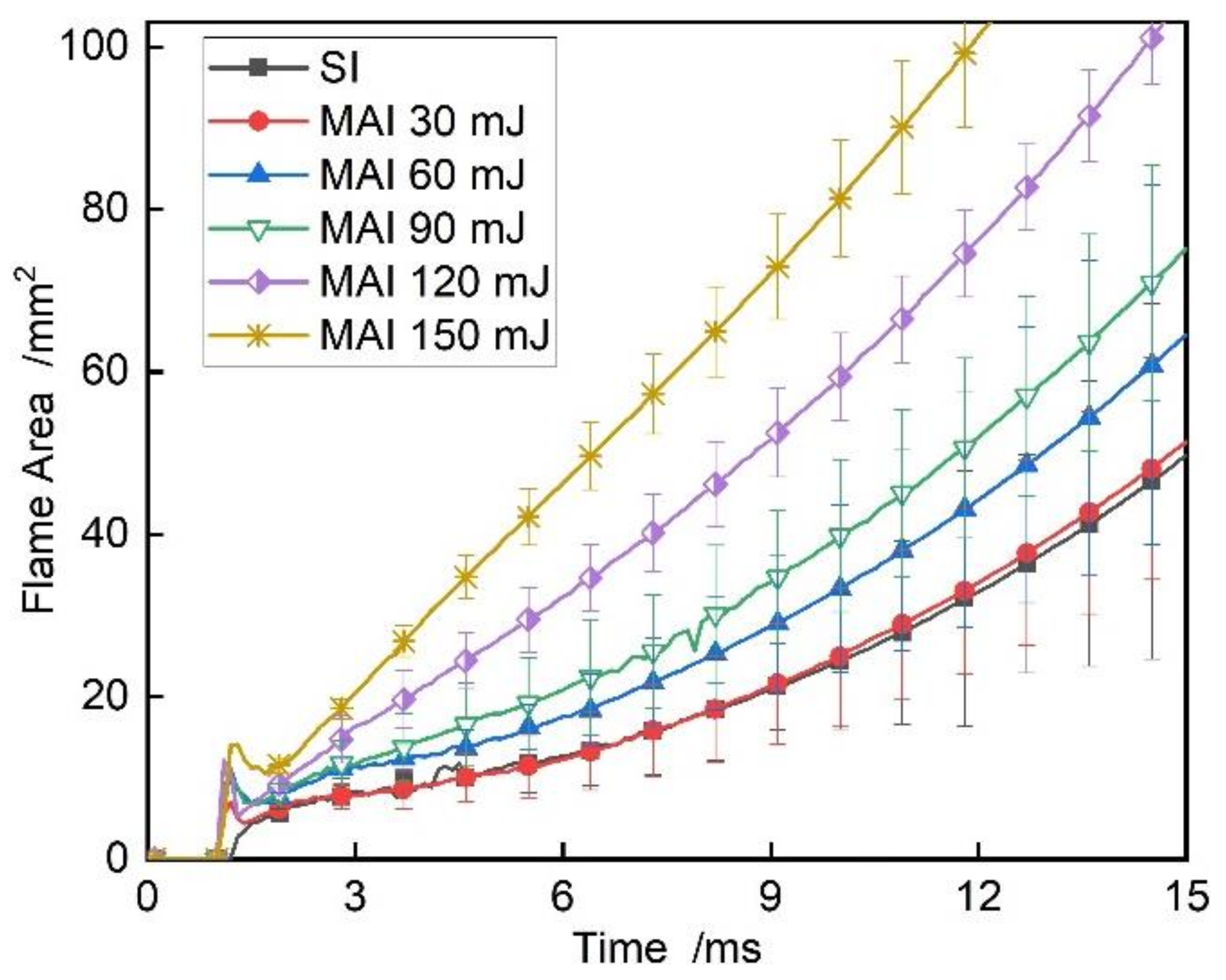

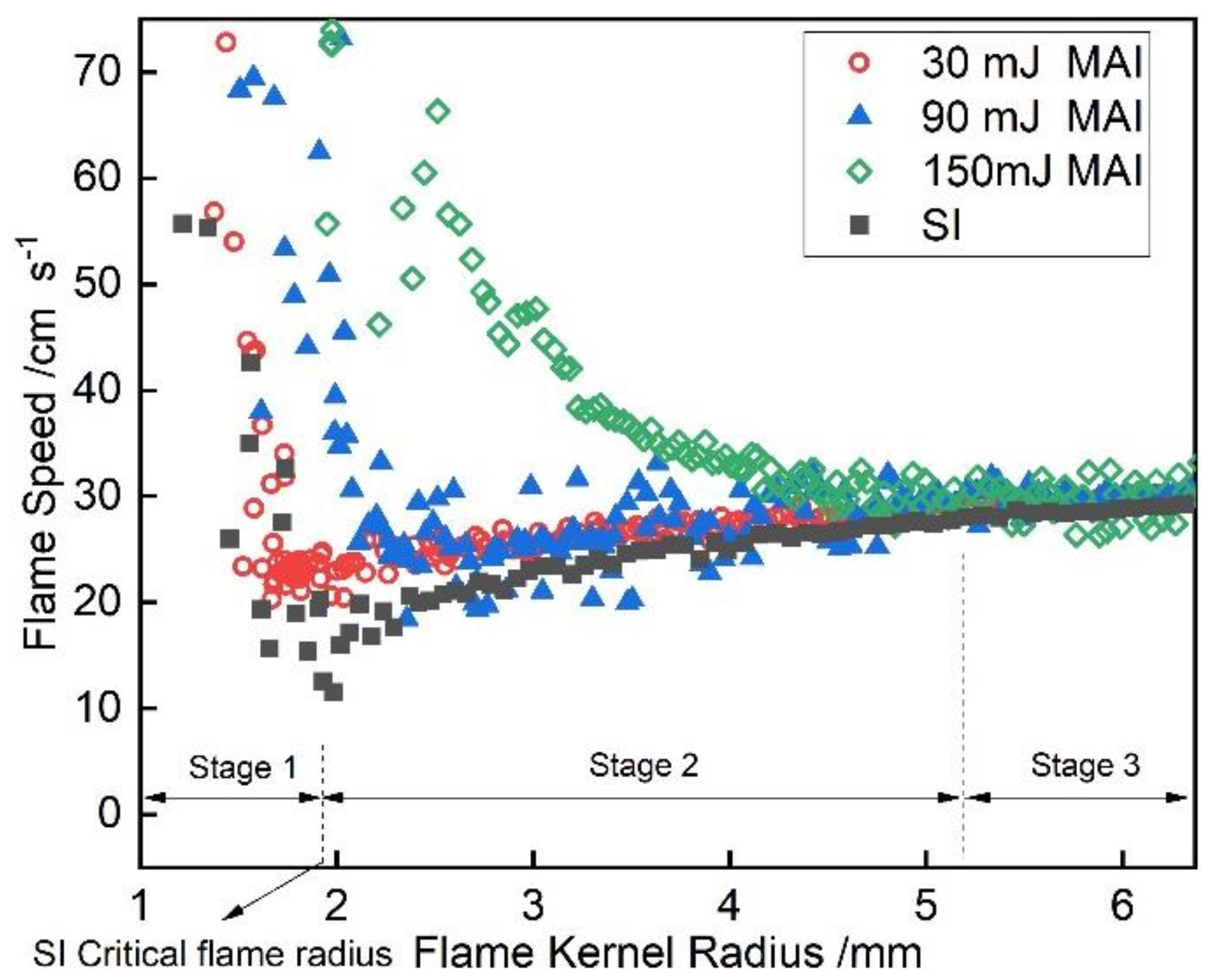

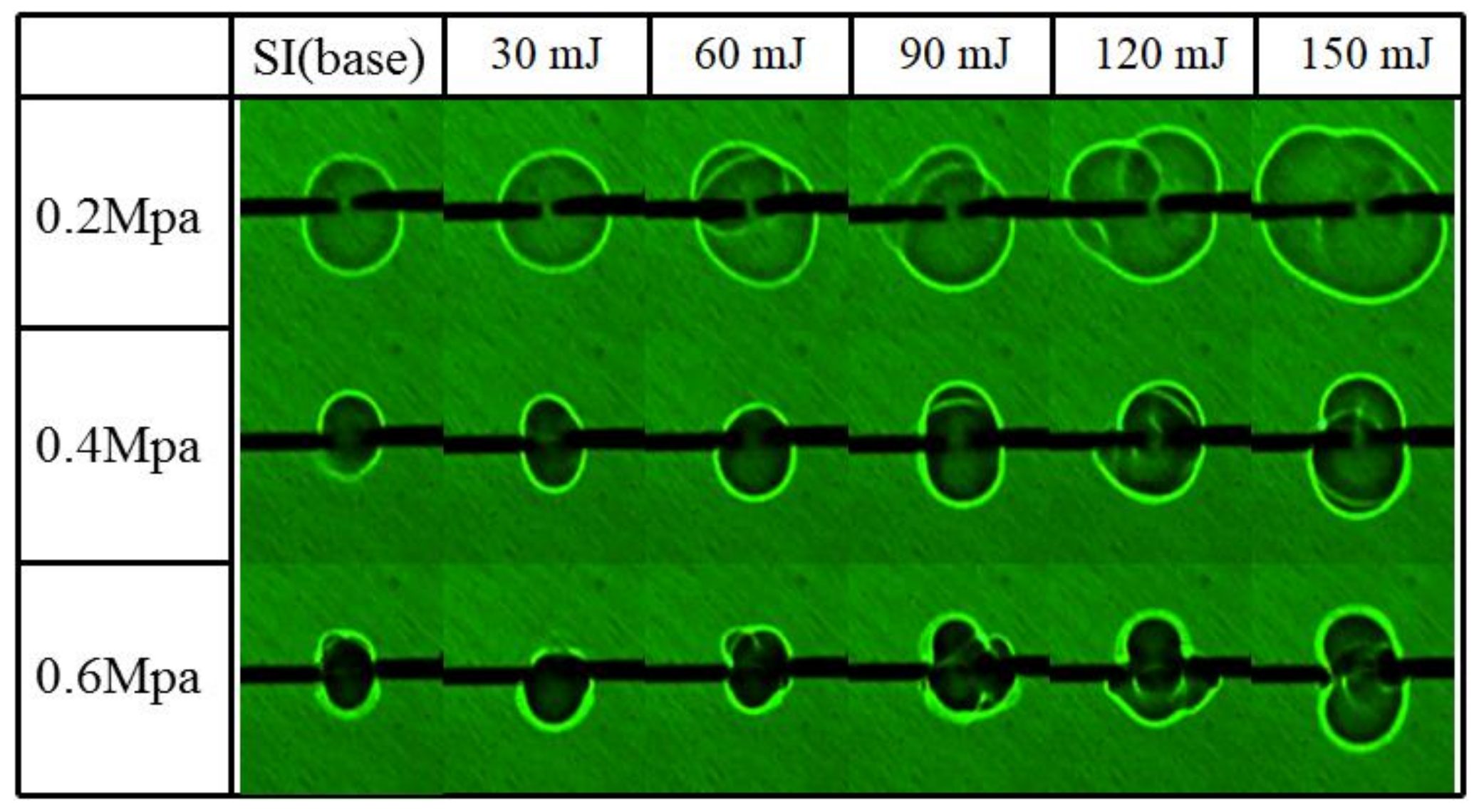

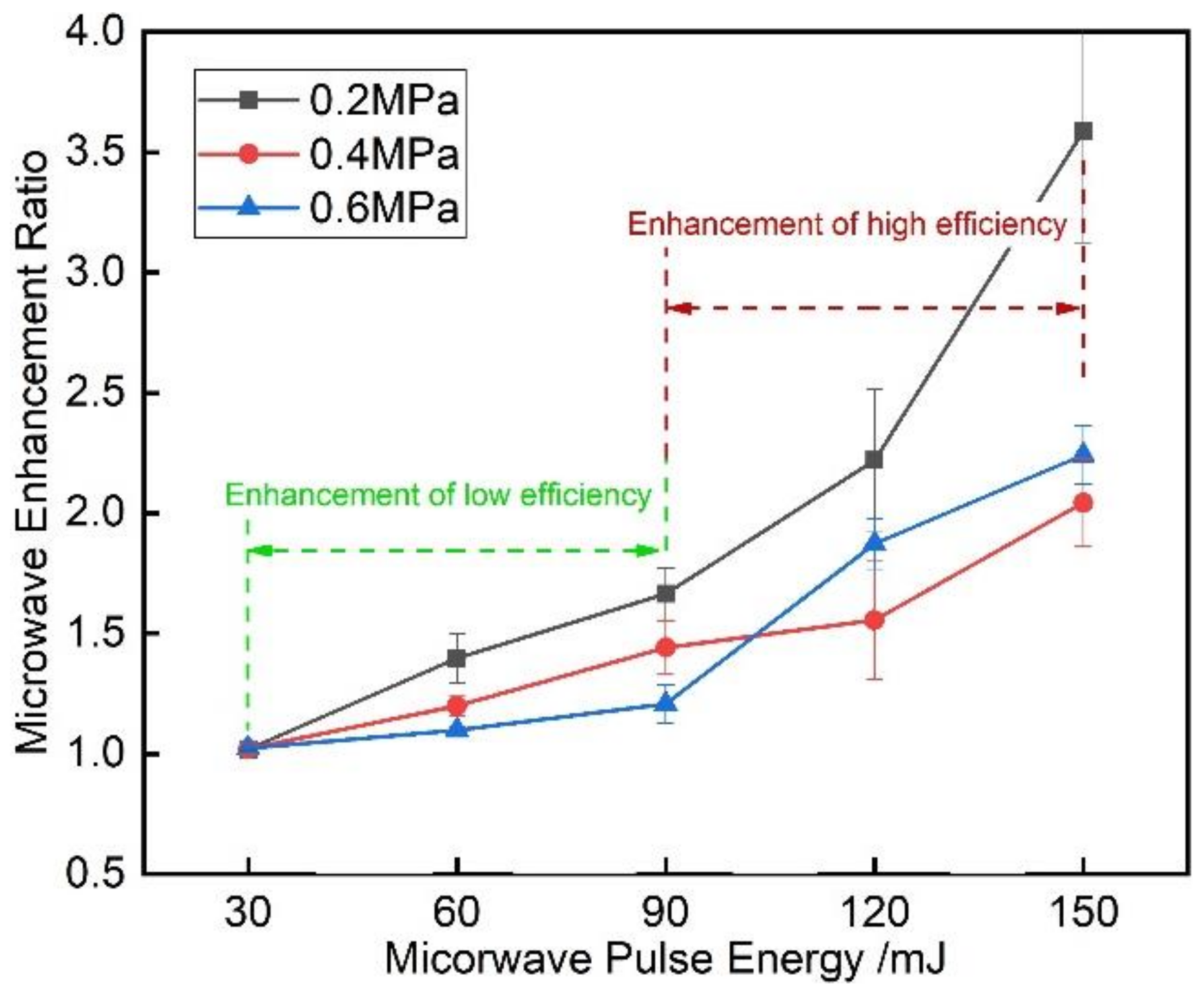

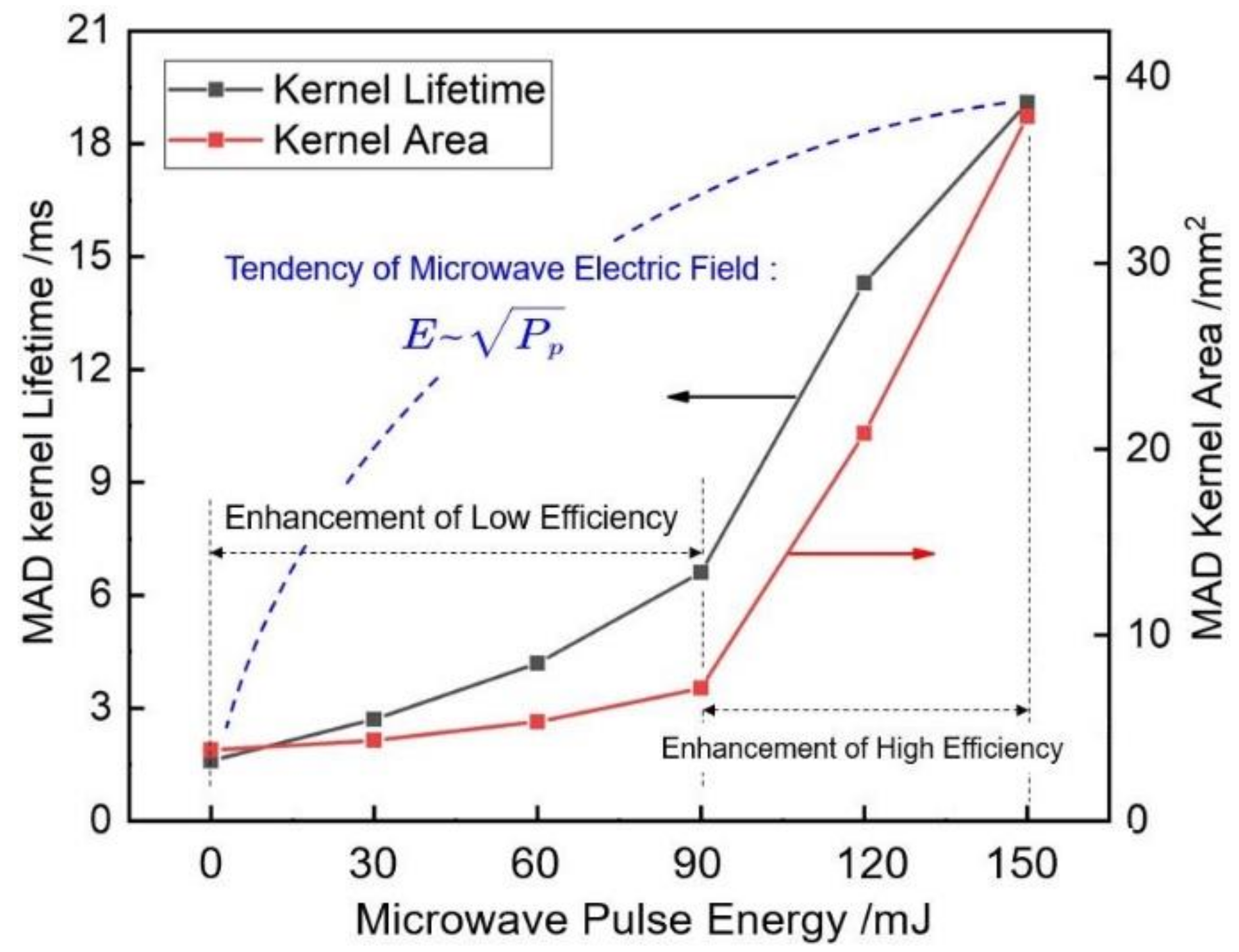

3.1. Threshold Process of Flame Development with Increasing Pulse Energy

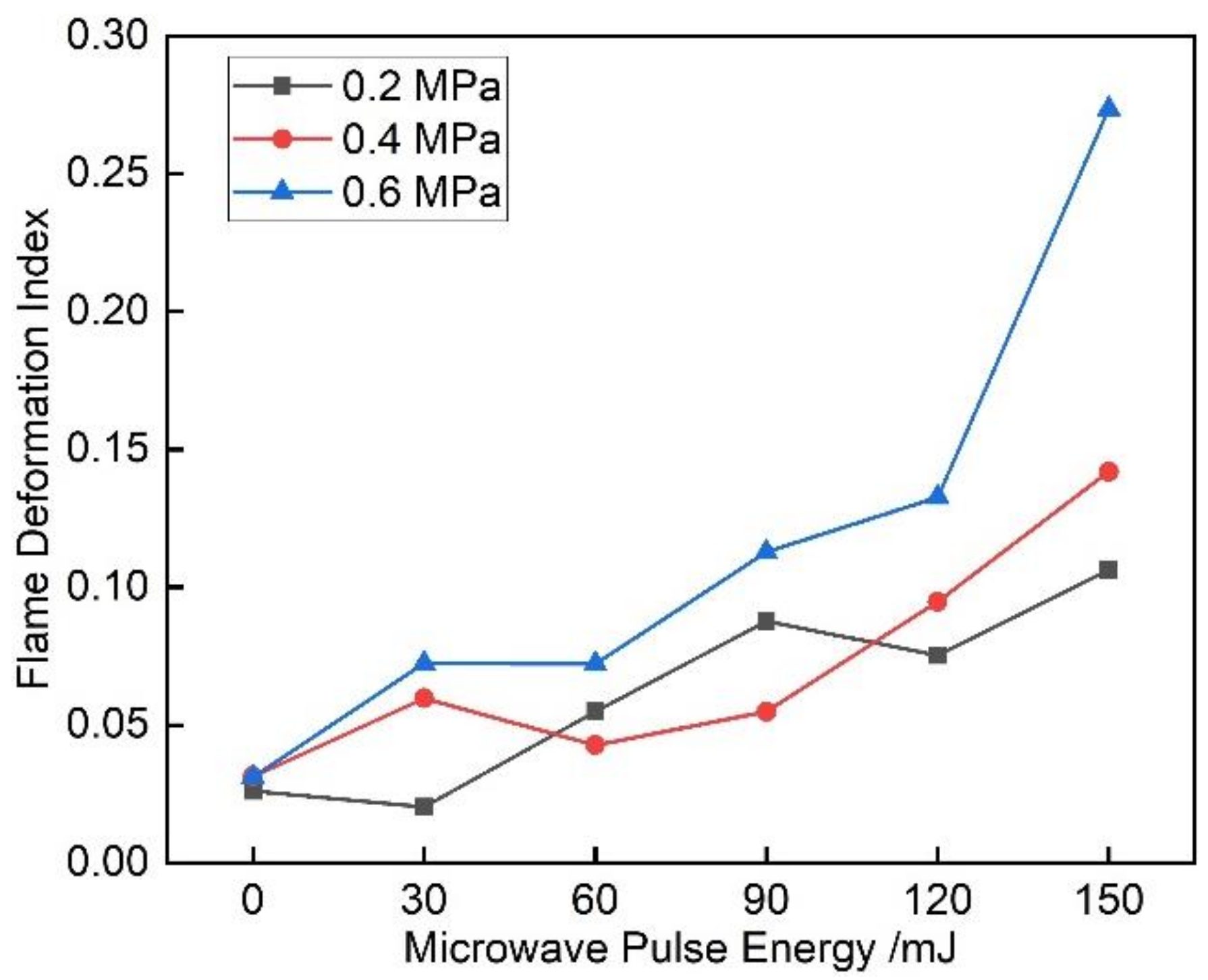

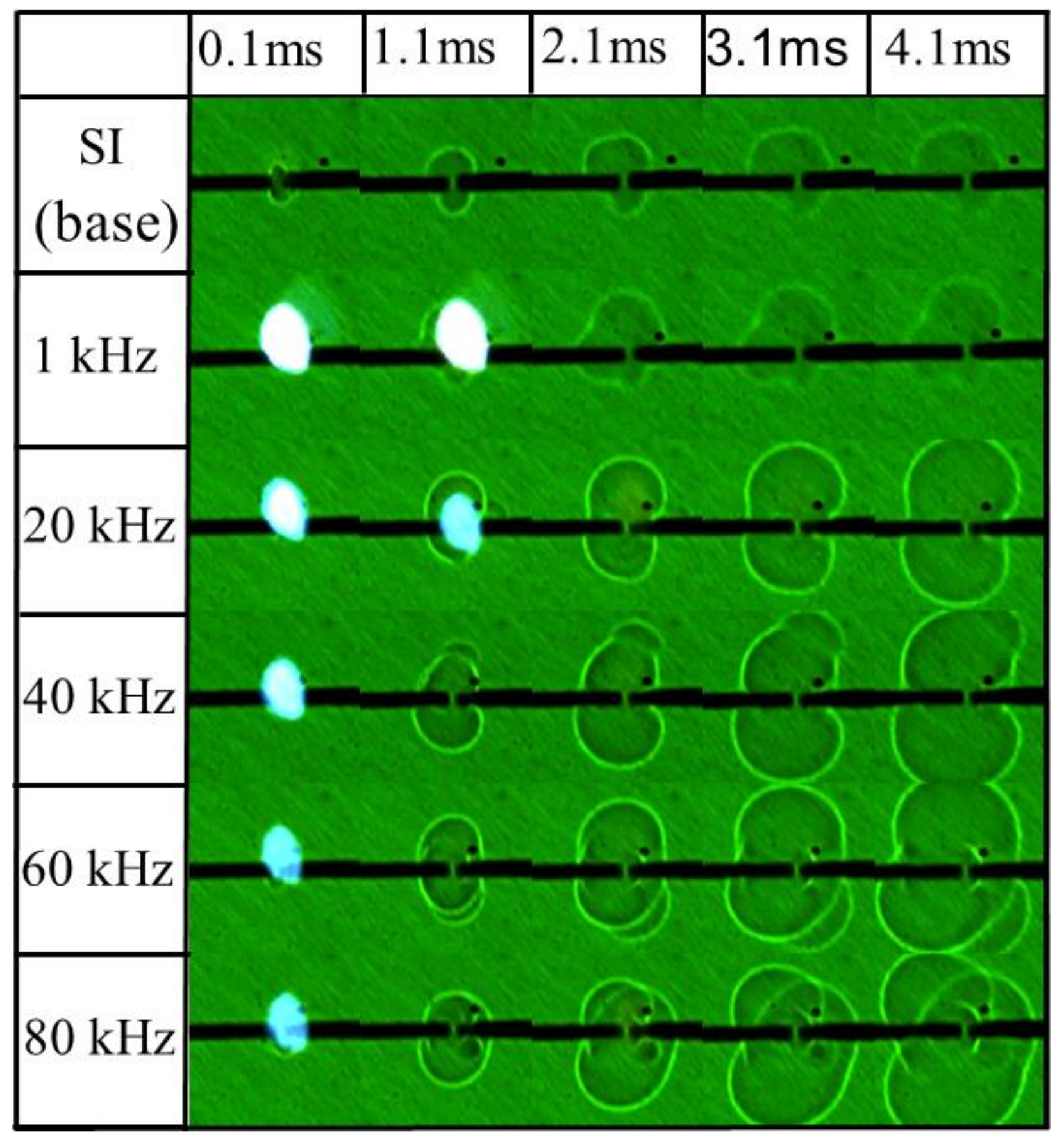

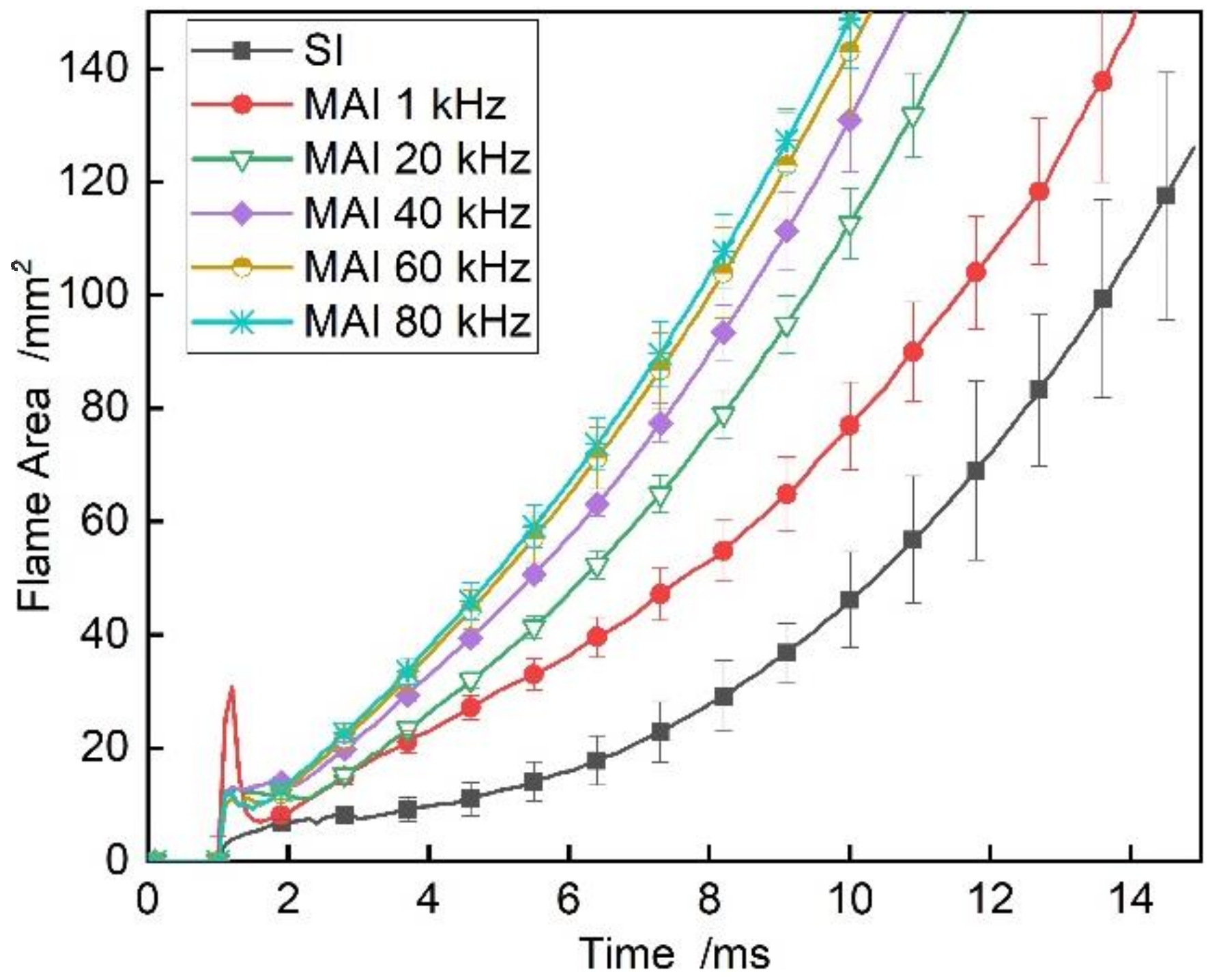

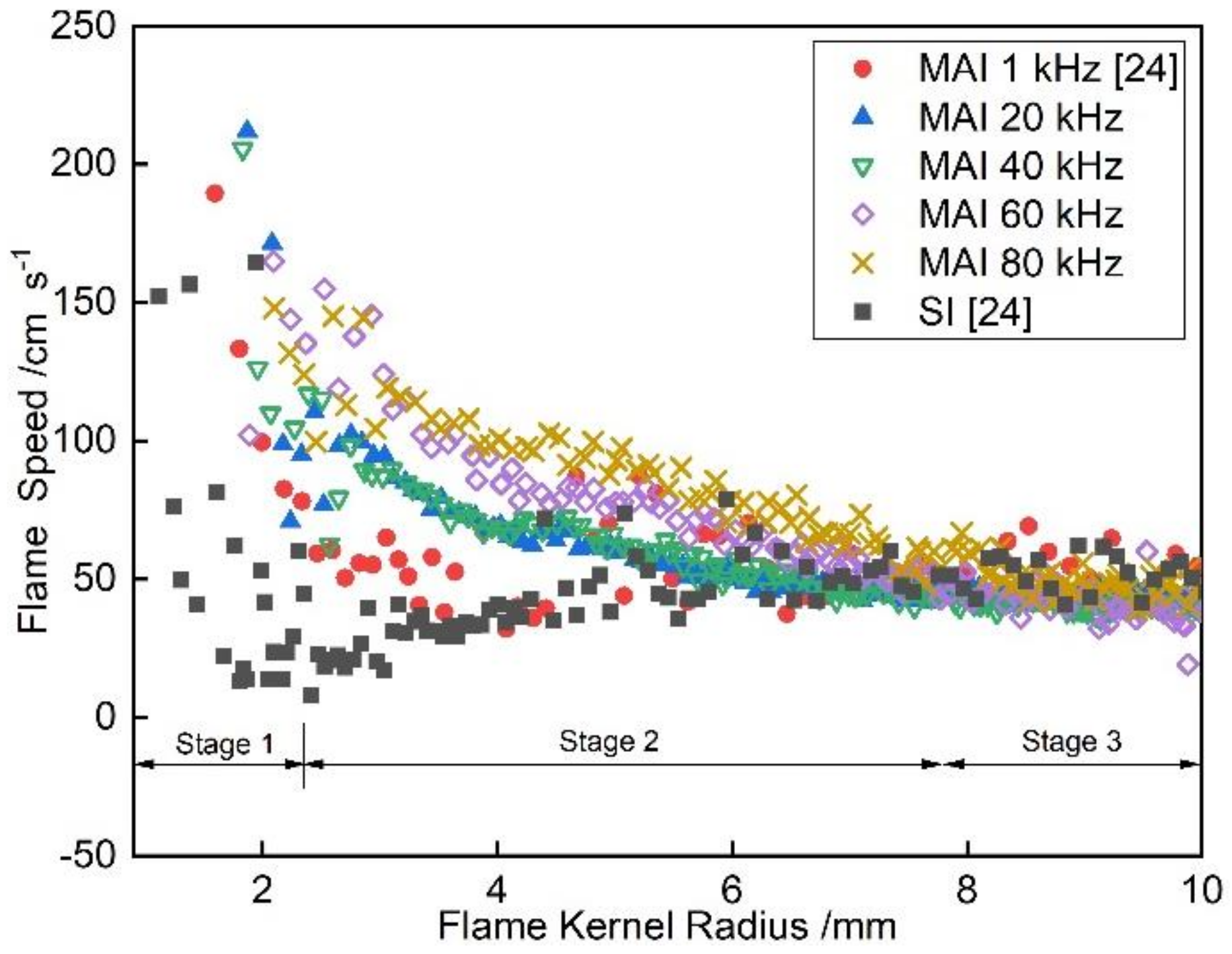

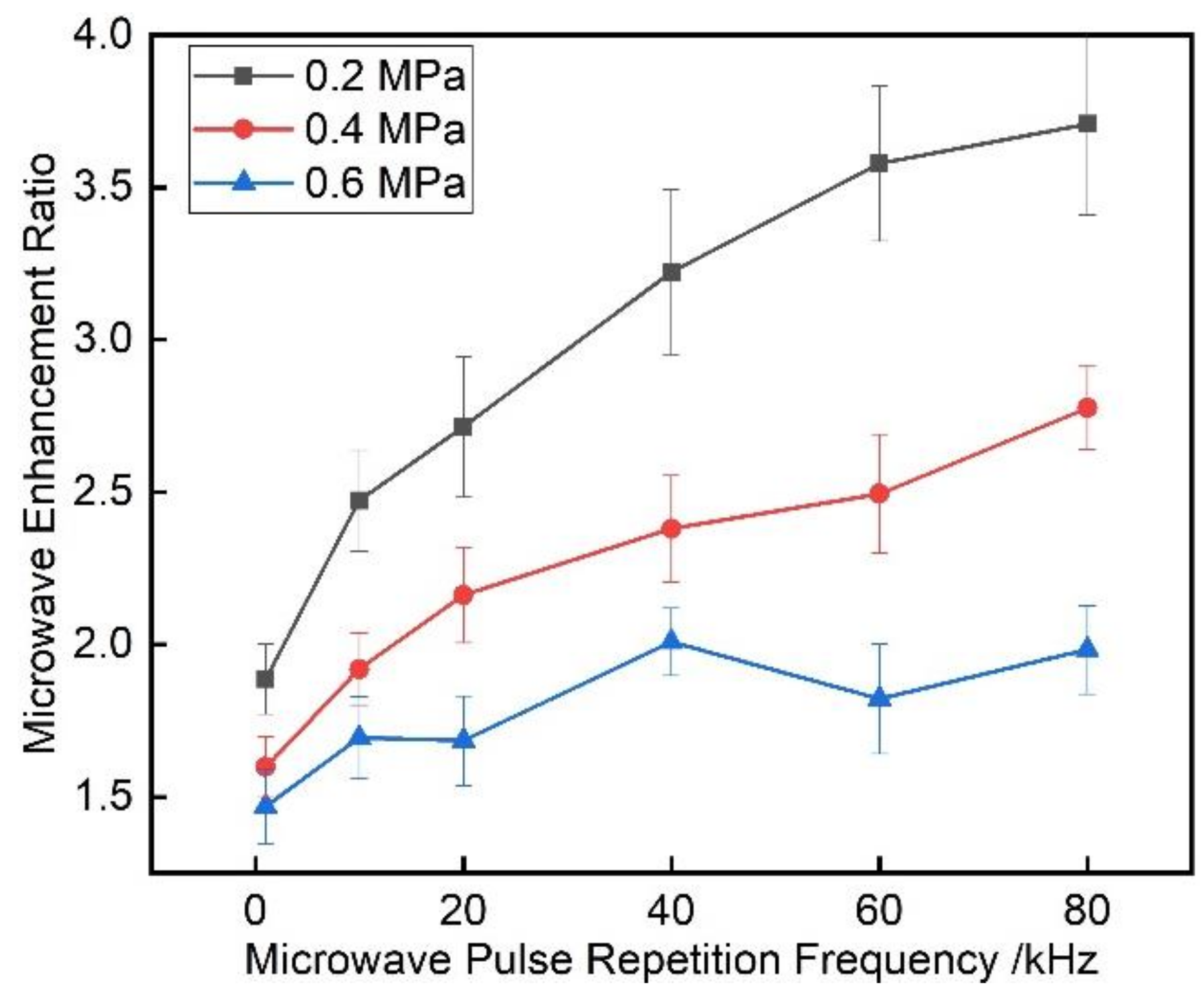

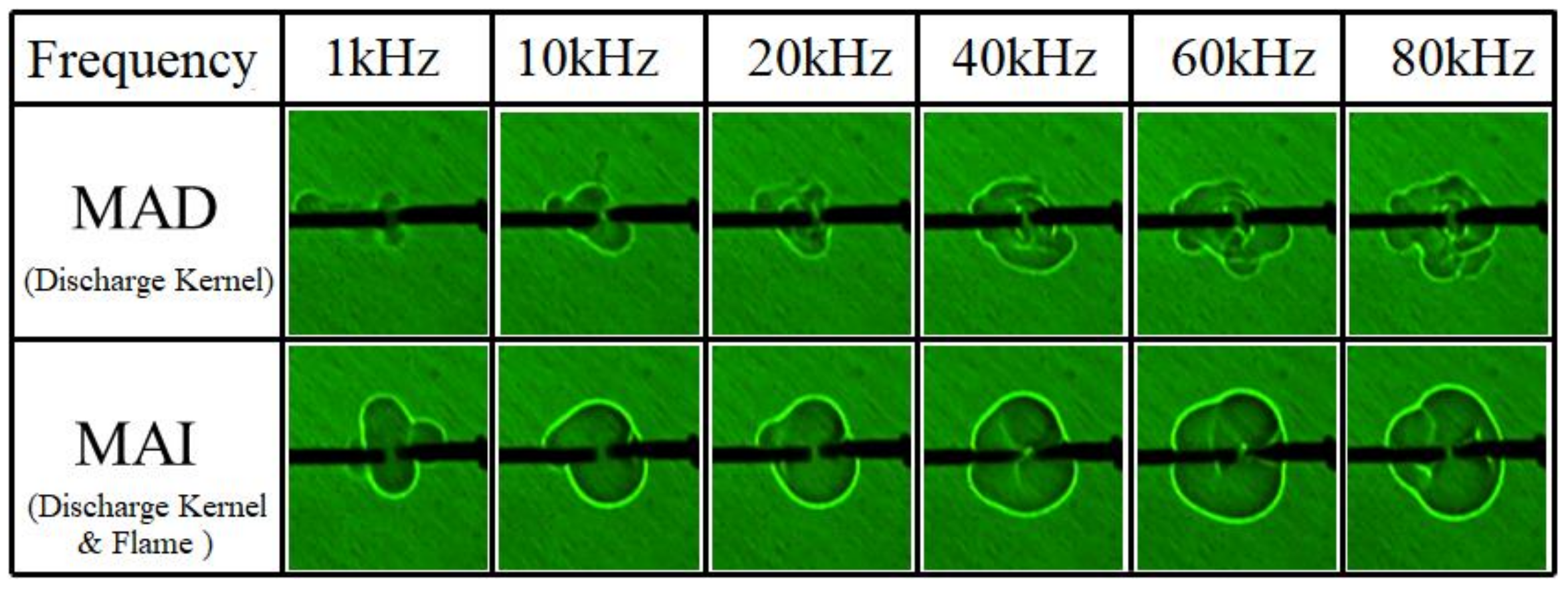

3.2. Flame Deformation with Various PRF

3.3. Mechanism of the Wrinkles

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, X.; Guo, Z.; Sun, P.; Wang, S.; Li, A.; Yang, H.; Li, Z.; Liu, Z.; Li, J.; Shang, Z. Investigation of combustion and emissions of an SI engine with ethanol port injection and gasoline direct injection under lean burn conditions. Energy 2019, 189, 116231. [Google Scholar] [CrossRef]

- Zhuang, Y.; Qian, Y.; Hong, G. Lean Burn Performance of a Spark Ignition Engine with an Ethanol–Gasoline Dual Injection System. Energy Fuels 2018, 32, 2855–2868. [Google Scholar] [CrossRef]

- Collin-Bastiani, F.; Vermorel, O.; Lacour, C.; Lecordier, B.; Cuenot, B. DNS of spark ignition using Analytically Reduced Chemistry including plasma kinetics. Proc. Combust. Inst. 2019, 37, 5057–5064. [Google Scholar] [CrossRef]

- Sjerić, M.; Kozarac, D.; Tatschl, R. Modelling of early flame kernel growth towards a better understanding of cyclic combustion variability in SI engines. Energy Convers. Manag. 2015, 103, 895–909. [Google Scholar] [CrossRef]

- Imamura, O.; Chen, B.; Nishida, S.; Yamashita, K.; Tsue, M.; Kono, M. Combustion of ethanol fuel droplet in vertical direct current electric field. Proc. Combust. Inst. 2011, 33, 2005–2011. [Google Scholar] [CrossRef]

- Kim, G.T.; Park, D.G.; Cha, M.S.; Park, J.; Chung, S.H. Flow instability in laminar jet flames driven by alternating current electric fields. Proc. Combust. Inst. 2017, 36, 4175–4182. [Google Scholar] [CrossRef]

- Mao, X.; Chen, Q.; Rousso, A.C.; Chen, T.Y.; Ju, Y. Effects of controlled non-equilibrium excitation on H2/O2/He ignition using a hybrid repetitive nanosecond and DC discharge. Combust. Flame 2019, 206, 522–535. [Google Scholar] [CrossRef]

- Kuhl, J.; Seeger, T.; Zigan, L.; Will, S.; Leipertz, A. On the effect of ionic wind on structure and temperature of laminar premixed flames influenced by electric fields. Combust. Flame 2017, 176, 391–399. [Google Scholar] [CrossRef]

- Park, D.G.; Chung, S.H.; Cha, M.S. Bidirectional ionic wind in non-premixed counterflow flames with DC electric fields. Combust. Flame 2016, 168, 138–146. [Google Scholar] [CrossRef]

- Park, D.G.; Chung, S.H.; Cha, M.S. Visualization of ionic wind in laminar jet flames. Combust. Flame 2017, 184, 246–248. [Google Scholar] [CrossRef]

- Leonov, S.B. Electrically Driven Supersonic Combustion. Energies 2018, 11, 1733. [Google Scholar] [CrossRef] [Green Version]

- Ikeda, Y.; Nishiyama, A.; Kaneko, M. Microwave Enhanced Ignition Process for Fuel Mixture at Elevated Pressure of 1 MPa. In Proceedings of the 47th AIAA Aerospace Sciences Meeting including The New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009. [Google Scholar] [CrossRef]

- Ikeda, Y.; Nishiyama, A.; Katano, H.; Kaneko, M.; Jeong, H. Research and Development of Microwave Plasma Combustion Engine (Part II: Engine Performance of Plasma Combustion Engine); SAE 2009-01-1049; SAE: Warrendale, PA, USA, 2009. [Google Scholar]

- Ikeda, Y.; Nishiyama, A.; Wachi, Y.; Kaneko, M. Research and Development of Microwave Plasma Combustion Engine (Part I: Concept of Plasma Combustion and Plasma Generation Technique); SAE 01-1050; SAE: Warrendale, PA, USA, 2009. [Google Scholar]

- Rapp, V.H.; DeFilippo, A.; Saxena, S.; Chen, J.Y.; Dibble, R.W.; Nishiyama, A.; Moon, A.; Ikeda, Y. Extending Lean Operating Limit and Reducing Emissions of Methane Spark-Ignited Engines Using a Microwave-Assisted Spark Plug. J. Combust. 2012, 2012, 927081. [Google Scholar] [CrossRef] [Green Version]

- Nishiyama, A.; Ikeda, Y. Improvement of Lean Limit and Fuel Consumption Using Microwave Plasma Ignition Technology; SAE Technical Paper Series 2012-01-1139; SAE: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Wolk, B.; DeFilippo, A.; Chen, J.-Y.; Dibble, R.; Nishiyama, A.; Ikeda, Y. Enhancement of flame development by microwave-assisted spark ignition in constant volume combustion chamber. Combust. Flame 2013, 160, 1225–1234. [Google Scholar] [CrossRef]

- Hwang, J.; Bae, C.; Park, J.; Choe, W.; Cha, J.; Woo, S. Microwave-assisted plasma ignition in a constant volume combustion chamber. Combust. Flame 2016, 167, 86–96. [Google Scholar] [CrossRef]

- Starikovskaia, S.M. Plasma assisted ignition and combustion. J. Phys. D Appl. Phys. 2006, 39, R265–R299. [Google Scholar] [CrossRef]

- Ju, Y.; Sun, W. Plasma assisted combustion Dynamics and chemistry. Prog. Energy Combust. Sci. 2015, 48, 21–83. [Google Scholar] [CrossRef]

- Duan, H.; Wu, X.; Hou, J.; Zhang, C.; Gao, Z. Experimental study of lean premixed CH4/N2/O2 flames under low-frequency alternating-current electric fields. Fuel 2016, 181, 1011–1019. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Wu, H.; Liu, C.; Cheng, X.; Chen, J.-Y. Propulsive effect of microwave-induced plasma jet on spark ignition of CO2-diluted CH4-air mixture. Combust. Flame 2021, 229, 111400. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Huang, S.; Wu, H.; Jin, B.; Cheng, X. Experimental Study of CH4-Air Premixed Spherical Expanding Flames with Microwave Assisted Ignition. Trans. CSICE 2020, 38, 226–233. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Wu, H.; Zhou, D.; Huang, S.; Cheng, X.; Chen, J.-Y. Experimental study of microwave assisted spark ignition on expanding C2H2-Air spherical flames. Combust. Flame 2020, 222, 111–122. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Zhou, D.; Wu, H.; Cheng, X.; Jin, B.; Chen, J.-Y. Strengthening effect of microwave on spark ignited spherical expanding flames of methane-air mixture. Energy Convers. Manag. 2020, 224, 113368. [Google Scholar] [CrossRef]

- Cha, M.S.; Lee, Y. Premixed Combustion Under Electric Field in a Constant Volume Chamber. IEEE Trans. Plasma Sci. 2012, 40, 3131–3138. [Google Scholar] [CrossRef]

- Chen, Z.; Burke, M.P.; Ju, Y. On the critical flame radius and minimum ignition energy for spherical flame initiation. Proc. Combust. Inst. 2011, 33, 1219–1226. [Google Scholar] [CrossRef]

- Kim, H.H.; Won, S.H.; Santner, J.; Chen, Z.; Ju, Y. Measurements of the critical initiation radius and unsteady propagation of n-decane/air premixed flames. Proc. Combust. Inst. 2013, 34, 929–936. [Google Scholar] [CrossRef]

- Huang, S.; Zhang, Y.; Huang, R.; Xu, S.; Ma, Y.; Wang, Z.; Zhang, X. Quantitative characterization of crack and cell’s morphological evolution in premixed expanding spherical flames. Energy 2019, 171, 161–169. [Google Scholar] [CrossRef]

- Huang, S.; Huang, R.; Zhang, Y.; Zhou, P.; Wang, Z.; Yin, Z. Relationship between cellular morphology and self-acceleration in lean hydrogen-air expanding flames. Int. J. Hydrog. Energy 2019, 44, 31531–31543. [Google Scholar] [CrossRef]

- Starikovskiy, A.; Aleksandrov, N. Plasma-assisted ignition and combustion. Prog. Energy Combust. Sci. 2013, 39, 61–110. [Google Scholar] [CrossRef] [Green Version]

- Rao, X.; Hemawan, K.; Wichman, I.; Carter, C.; Grotjohn, T.; Asmussen, J.; Lee, T. Combustion dynamics for energetically enhanced flames using direct microwave energy coupling. Proc. Combust. Inst. 2011, 33, 3233–3240. [Google Scholar] [CrossRef]

- Stockman, E.S.; Zaidi, S.H.; Miles, R.B.; Carter, C.D.; Ryan, M.D. Measurements of combustion properties in a microwave enhanced flame. Combust. Flame 2009, 156, 1453–1461. [Google Scholar] [CrossRef]

- Chen, F.F. Introduction to Plasma Physics and Controlled Fusion, 3rd ed.; Springer: Cham, Switzerland, 2015; pp. 200–249. [Google Scholar] [CrossRef]

- Gu, X.; Li, Q.; Huang, Z.; Zhang, N. Measurement of laminar flame speeds and flame stability analysis of tert-butanol–air mixtures at elevated pressures. Energy Convers. Manag. 2011, 52, 3137–3146. [Google Scholar] [CrossRef]

- Colin, O.; Ritter, M.; Lacour, C.; Truffin, K.; Mouriaux, S.; Stepanyan, S.; Lecordier, B.; Vervisch, P. DNS and LES of spark ignition with an automotive coil. Proc. Combust. Inst. 2019, 37, 4875–4883. [Google Scholar] [CrossRef] [Green Version]

- Jankowski, K.J.; Reszke, E. Chapter 1, An Introduction to Microwave Plasma Spectrometries. In Microwave Induced Plasma Analytical Spectrometry; The Royal Society of Chemistry: London, UK, 2011; pp. 1–22. [Google Scholar] [CrossRef]

- Dysthe, K.B. A thermal oscillating two-stream instability. Phys. Fluids 1983, 26, 146–158. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, X.; Zhang, X.; Wang, Z.; Wu, H.; Wang, Z.; Chen, J.-Y. Effect of Microwave Pulses on the Morphology and Development of Spark-Ignited Flame Kernel. Energies 2021, 14, 6205. https://doi.org/10.3390/en14196205

Cheng X, Zhang X, Wang Z, Wu H, Wang Z, Chen J-Y. Effect of Microwave Pulses on the Morphology and Development of Spark-Ignited Flame Kernel. Energies. 2021; 14(19):6205. https://doi.org/10.3390/en14196205

Chicago/Turabian StyleCheng, Xiaobei, Xinhua Zhang, Zhaowen Wang, Huimin Wu, Zhaowu Wang, and Jyh-Yuan Chen. 2021. "Effect of Microwave Pulses on the Morphology and Development of Spark-Ignited Flame Kernel" Energies 14, no. 19: 6205. https://doi.org/10.3390/en14196205

APA StyleCheng, X., Zhang, X., Wang, Z., Wu, H., Wang, Z., & Chen, J.-Y. (2021). Effect of Microwave Pulses on the Morphology and Development of Spark-Ignited Flame Kernel. Energies, 14(19), 6205. https://doi.org/10.3390/en14196205