Web-Based Simulation Environment for Vehicular Electrical Networks

Abstract

1. Introduction

2. Simulation Engine Architecture

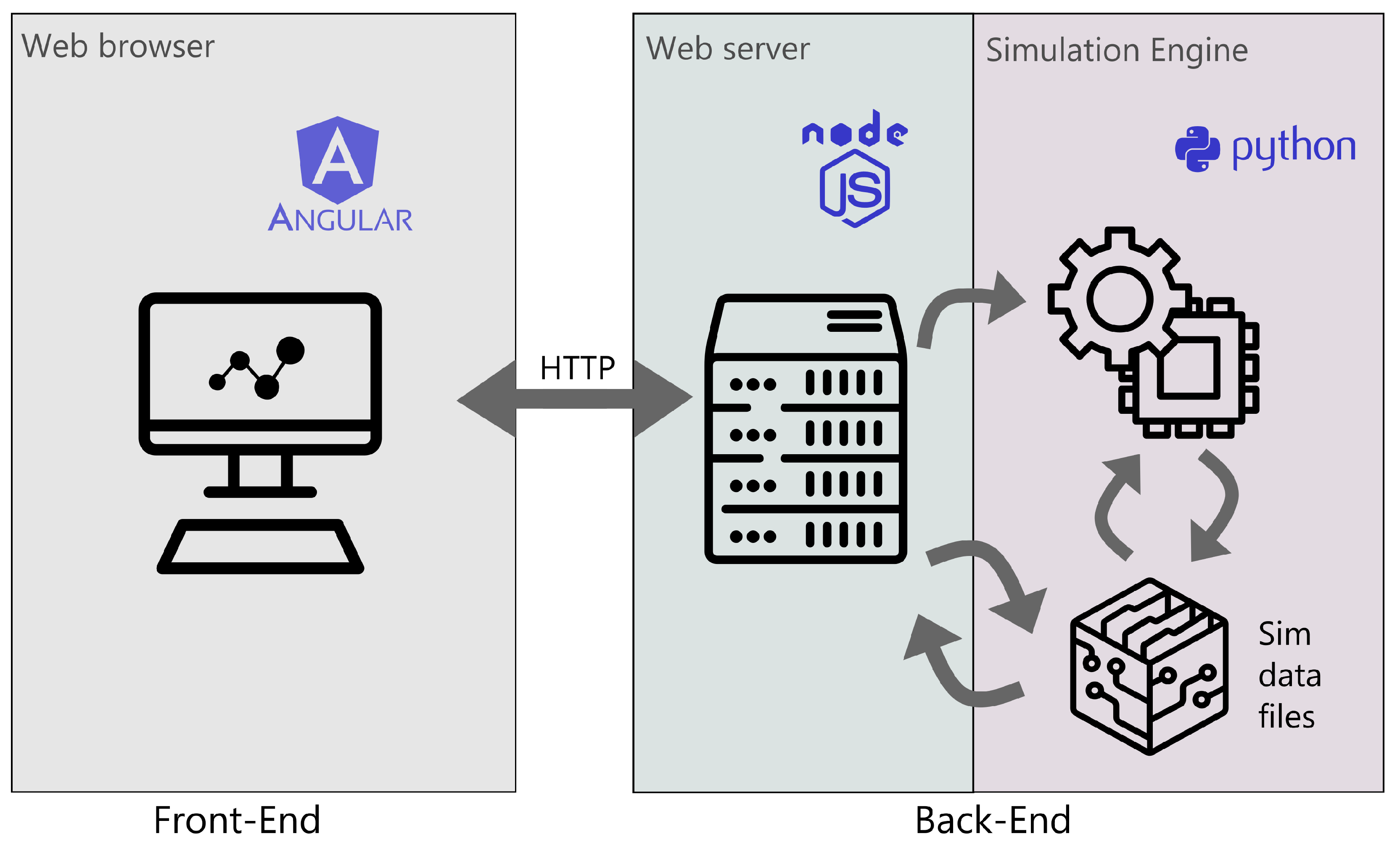

2.1. Web-Based Framework

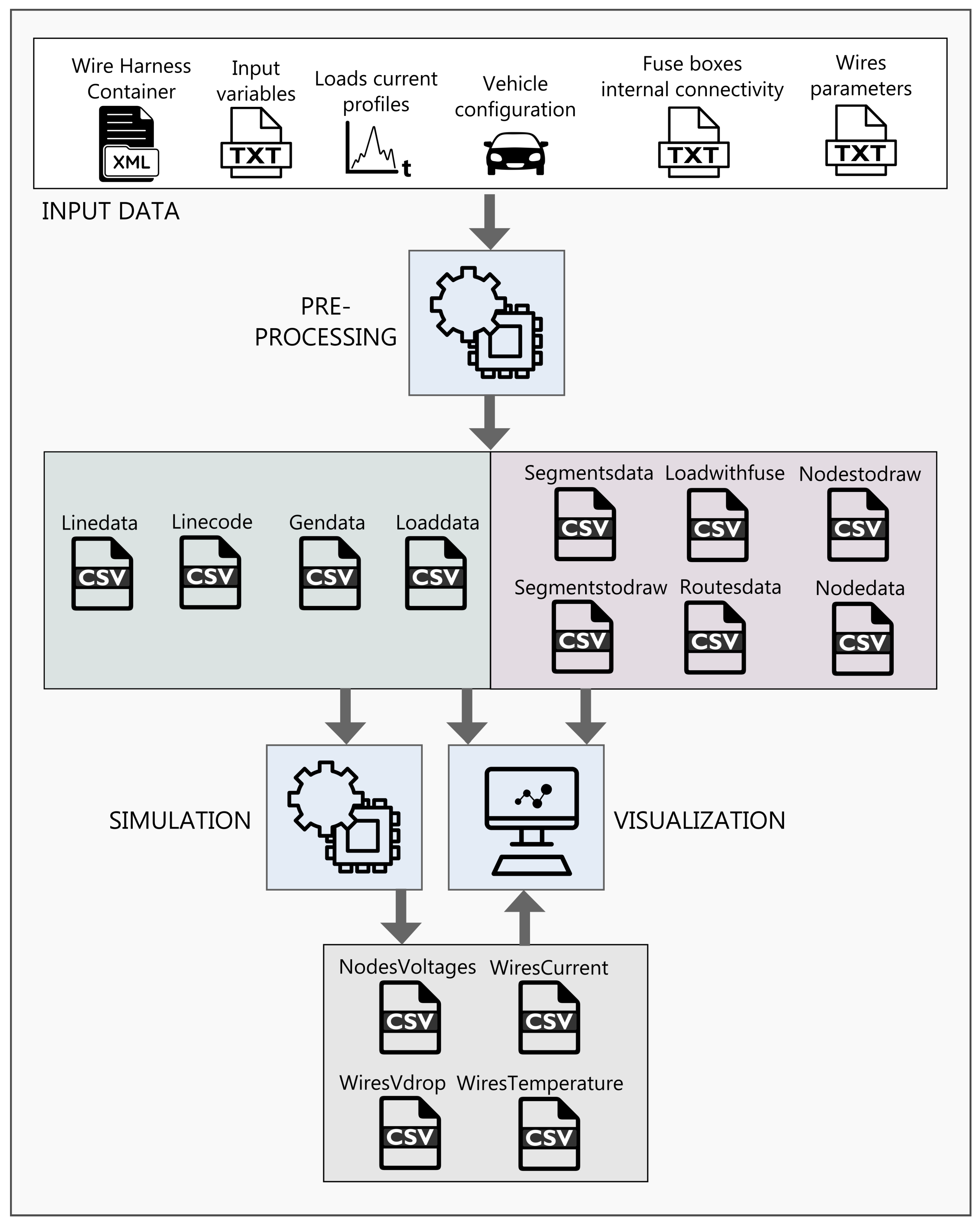

2.2. Data Preprocessing

3. Automatic Generation of Electrical Layouts for Vehicular EDS

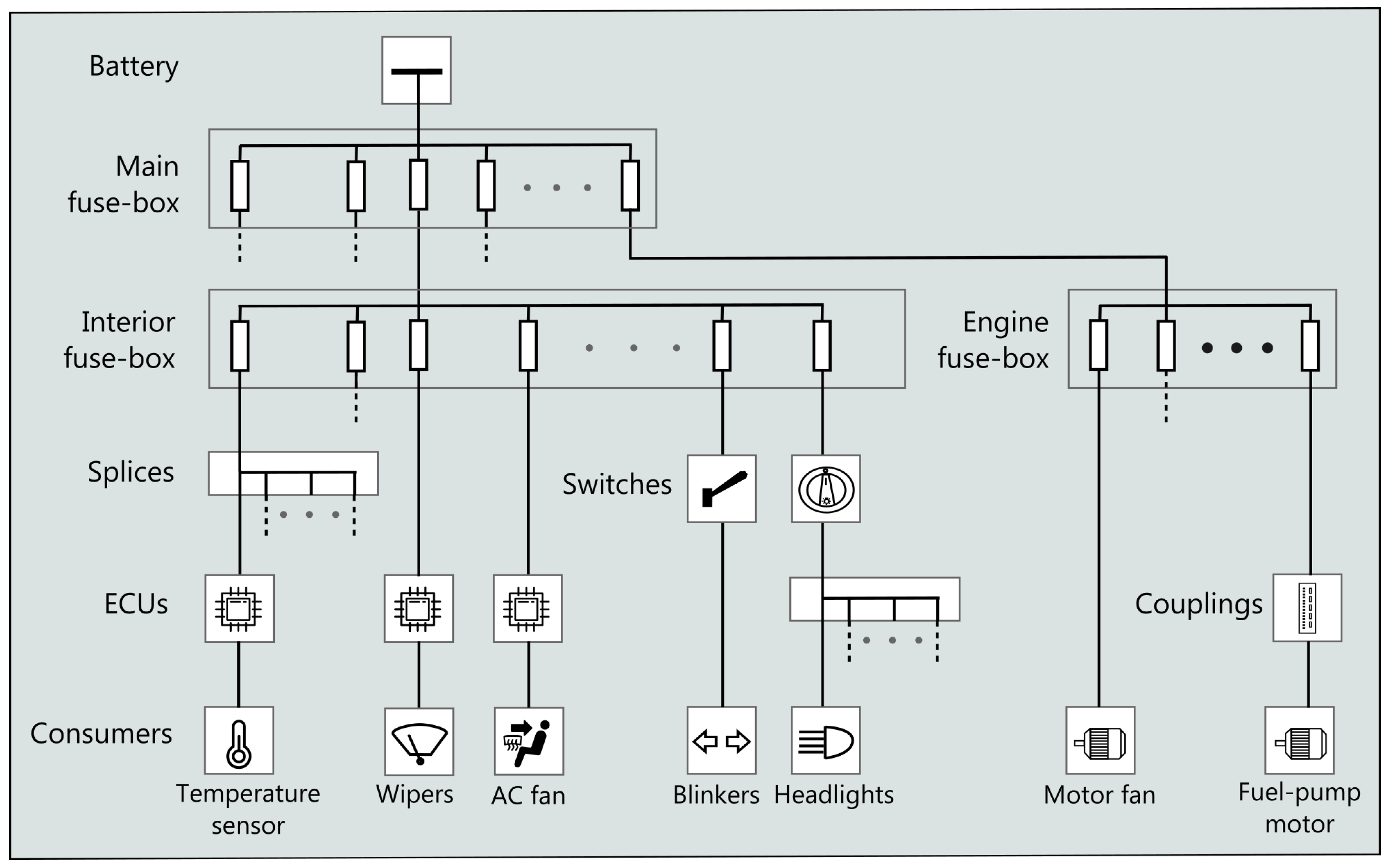

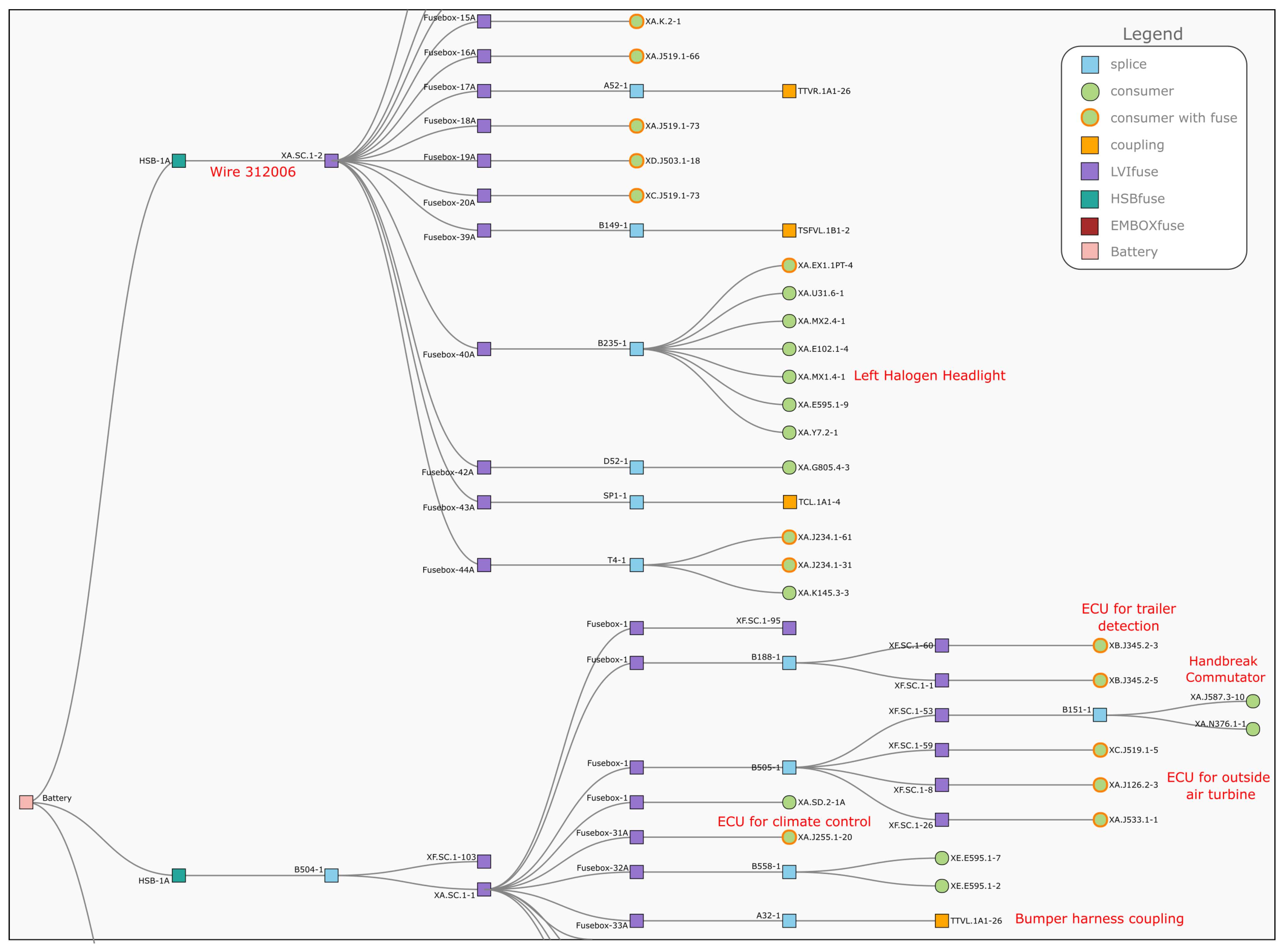

3.1. The General View

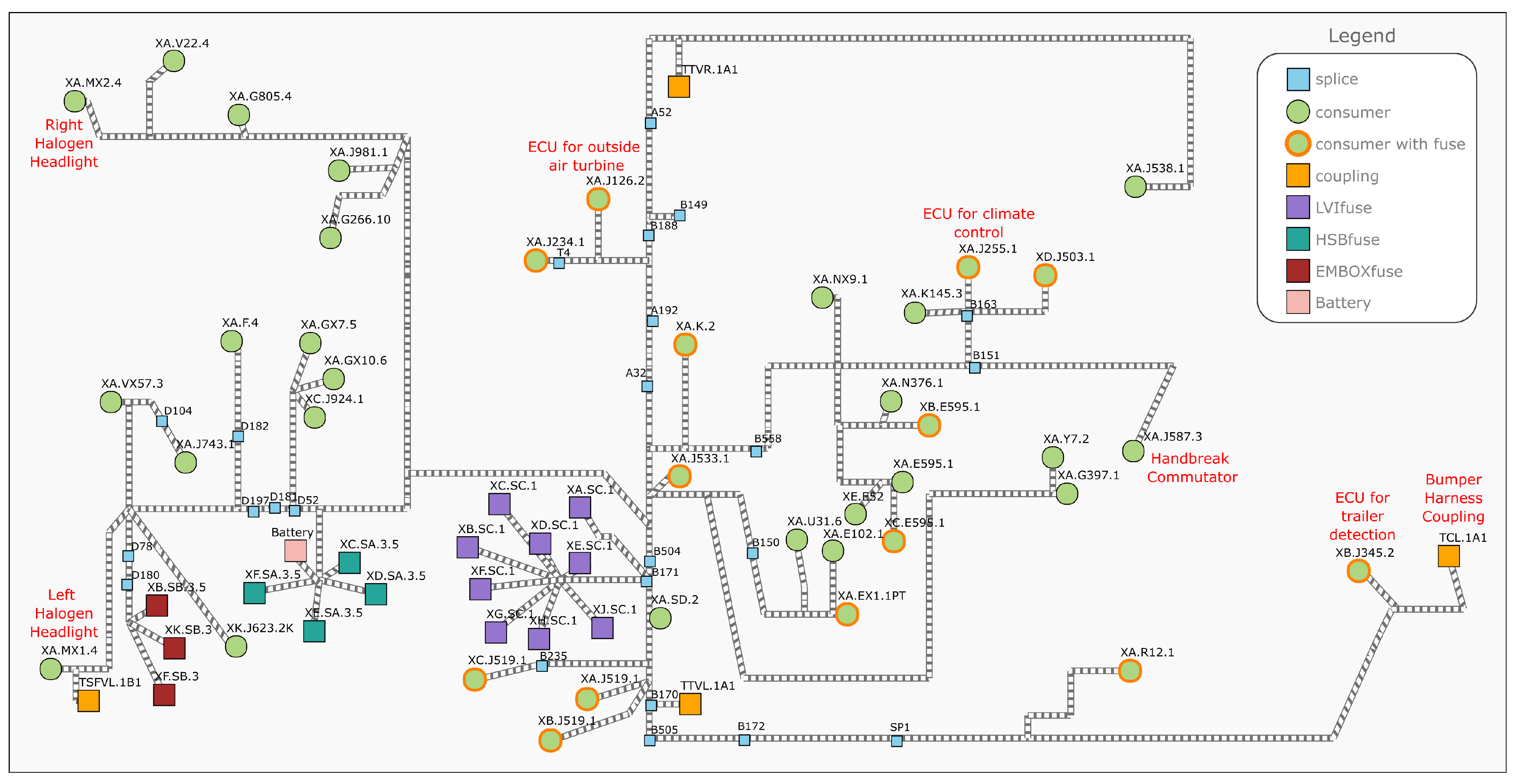

3.2. The Detailed View

| Algorithm 1: General and Detailed Views Generation. |

| Require: .CSV files resulting from the preprocessing stage (e.g.: Gendata, Nodedata, Nodestodraw, Segmentsdata, Loaddata, Linedata ...) |

| Ensure: Harness General and Detailed Views |

| 1. Create the web-interface elements and components using the Angular framework |

| 2. Parse input .CSV files |

| 3. Convert input files into data objects (e.g.: NodedataObj, LinedataObj, SegmentsdataObj... ) |

| 4. Correlate nodes with consumers and their protection fuses matching LoaddataObj, LoadtitlewithfuseObj and NodedataObj |

| 5. Correlate harness segments with the wires and their routing using SegmentsdataObj, RoutesdataObj and LinedataObj |

| 6. Infer nodes and segments to draw considering NodestodrawObj and SegmentstodrawObj |

| 7. Create the SVG containers and configure their functionalities such as zoom and panning |

| 8. if The General View is required then |

| 9. Scale down the XY positioning of nodes from NodedataObj considering the available screen size |

| 10. Use D3 library to draw nodes, segments, patterns, texts and others |

| 11. end if |

| 12. if The Detailed View is required then |

| 13. Infer child-parent correlation in LinedafirstneighObj for main harnesses and LinedaObj for secondary harnesses |

| 14. Use D3.tree to give tree-hierarchy structure to the data |

| 15. Use base D3 library to draw nodes, links, texts and others |

| 16. Detect and individually draw redundant links |

| 17. end if |

| 18. Assign colors and styles to the different elements |

| 19. Create and setup additional elements and interface functionalities (e.g.: interactive legend, tooltips, mouse-over highlighting, elements search-box, contextual menus, draggable nodes, correlation between views, simulation results export) |

4. Visual Analytics Strategies

- 1

- Automate the integration of all the necessary information. Once the user inserts the necessary factory input data files, the platform preprocess, derives and organizes all the information required for visualization and electrical simulation of the harness as the previous section elaborated.

- 2

- Provide the user with a functional user-friendly interface. This was fulfilled by means of the following features:

- Intuitive electrical diagrams via the already mentioned broad (General View) and wire-by-wire (Detailed View) schematics.

- Elements highlighting and tooltips on mouse-over actions to ease the visualization and understanding of the selected items.

- Interactive nodes legend to highlight in the schematic all the elements of the selected node type.

- Preprocessing and simulation pop-up messages to keep the user informed along the process.

- Pan and zoom options for a proper navigation into the electrical diagrams.

- Shape and color coding of nodes, wires and harness segments to favor a prompt distinction of elements and risky simulation outcomes such as excessive temperatures.

- Elements search box to rapidly locate specific wires and nodes in the network. When the desired element is found, it is highlighted and the screen is zoomed close to it.

- Contextual menus via right-click over elements to download datasheets (consumers) or see troublesome temperature conditions after simulation (harness segments). On the latter, once the user clicks the contextual menu related to the problematic wire in the General View, the tool automatically shifts to the Detailed View to represent the risky condition in a wire-by-wire basis.

- Draggable consumer nodes in the General View to permit the user a cleaner visualization of the network.

- Option to export simulation results in a spreadsheet.

- 3

- Facilitate the understanding of the electrical behavior of the network via simulation, including the following:

- Static or time-dependent power flow simulations where the user can add personalized current profiles for the loads.

- Simulation logs exposing undesired conditions (wires over temperatures and fuses mismatches) as well as different tables detailing all the simulation results regarding voltages, currents and temperatures in wires.

- Simulations with parameters variations where the user can modify the length, section and ambient temperature of wires.

- Time plots to visualize electrical variables when consumers current profiles are inserted.

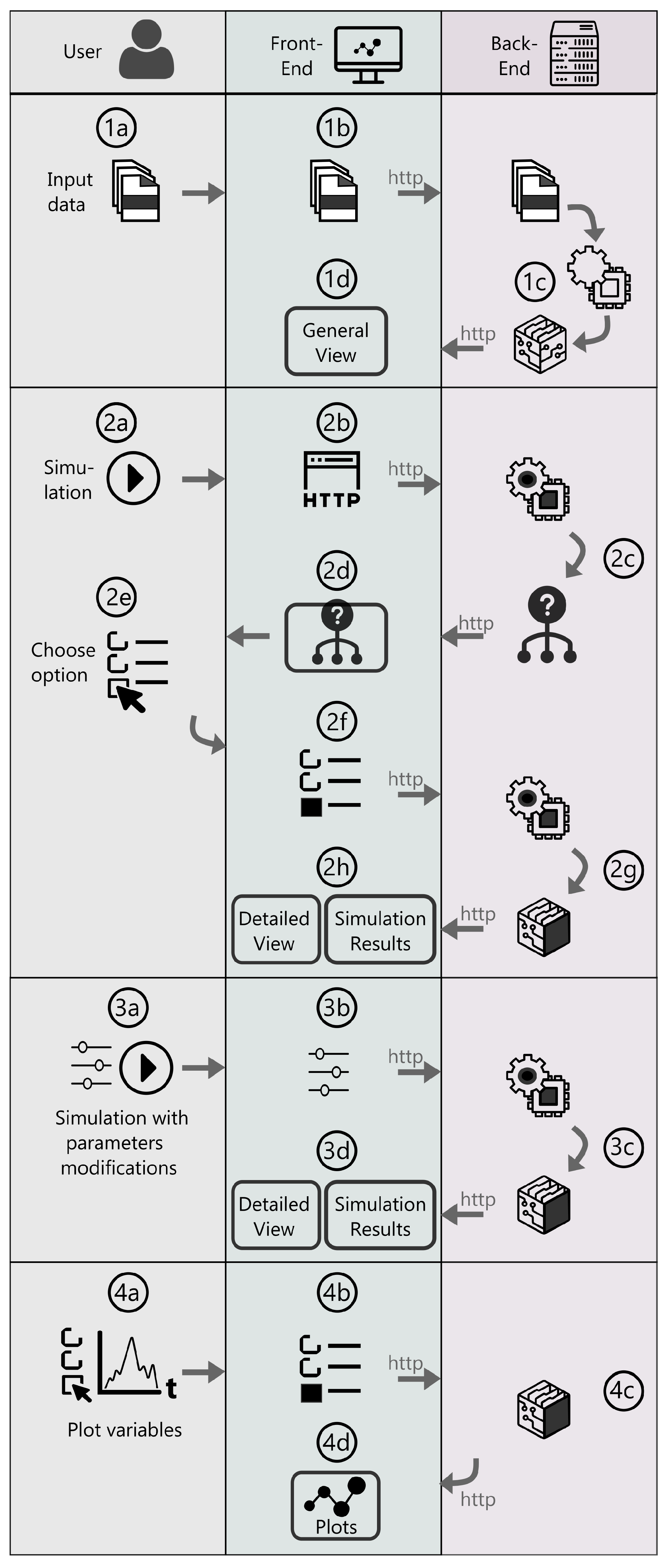

5. Simulation Workflow

- The user inserts the corresponding input data files as specified in Section 3, for this case study this is the data related to the SEAT Ibiza main harness. As a time-dependent simulation will be conducted, the consumers have been assigned different time-varying current profiles.

- The web-browser packs the information and send it to the Back-End attached to the HTTP request.

- As detailed in Section 3, the preprocessing takes place over the input data executing different Python scripts that extract and arrange the electrical information in CSV files. The latter are now sent to the Front-End via an HTTP response.

- The General View is generated as in Algorithm 1 and the user can interact with it.

- The user clicks the corresponding simulation button.

- An HTTP request is sent to the Back-End with the simulation demand.

- A first stage of the power flow simulation, related to connectivity analysis, takes place. As in some cases the use of the input data itself is not enough to determine all the connection paths lying downstream from the main fusebox, the possible connectivity options for the isolated nodes are sent to the Front-End.

- The interface displays a pop-up dialog that lists the connectivity alternatives.

- The user chooses the corresponding connectivity options for the isolated nodes.

- The interface sends the selected items to the Back-End.

- The second part of the power flow algorithm is executed. The simulation results are organized in different CSV files, some of these are related to voltages and currents in the consumers, while the others are associated to the nodes and lines in the network. The latter (see Figure 3) are sent to the Front-End.

- The interface shows a pop-up dialog exposing the simulation log where troublesome conditions (such as fuses mismatches and over temperatures in wires) are highlighted. The new incoming files are then processed to create the Detailed View and an additional tab containing all the simulation results related to voltages in nodes as well as currents, voltage drops and temperatures in wires.

- The required modifications are selected by the user in a tab designed for this purpose.

- The modifications list is sent to the Back-End.

- The entire power flow simulation takes place as the main fusebox connectivity was already given by the user in the former process. The new simulation files are issued to the Front-End.

- The electrical schematics and tables are updated according to the new incoming files.

- In the corresponding tab, the user selects the variables to plot for the consumers (voltage, current, power) as well as for the wires (voltage drop, current).

- The list of variables to plot are sent to the Back-End.

- The server sends back the simulation files related to the selected variables. This approach was employed to make the process more fluid by delivering on-demand only the desired simulation results. Given the large amount of electrical variables that can exist in a harness simulation, delivering all the results at once would be counterproductive.

- At the web-browser, after parsing the received files, time-plots like in Figure 9 are generated using the D3 library. There we can see, for a given simulation scenario, that when the Left Halogen Headlight (see down-left part of Figure 5) is demanding power according to a profile predefined by the user, its voltage correlates with the current flow in an upstream cable that feeds this consumer’s branch, namely wire 312006 (see top-left part of Figure 6).

6. Case Study Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhou, L.; Ren, L.; Laili, L. Modeling and Simulation in Intelligent Manufacturing. Comput. Ind. 2019, 112, 103123. [Google Scholar]

- Dominguez, X.; Arboleya, P.; Mantilla-Perez, P.; El-Sayed, I.; Gimenez, N.; Millan, M.A.D. Visual Analytics-Based Computational Tool for Electrical Distribution Systems of Vehicles. In Proceedings of the 2019 IEEE Vehicle Power and Propulsion Conference (VPPC), Hanoi, Vietnam, 14–17 October 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Sajjad, M.; Irfan, M.; Muhammad, K.; Ser, J.D.; Sanchez-Medina, J.; Andreev, S.; Ding, W.; Lee, J.W. An Efficient and Scalable Simulation Model for Autonomous Vehicles With Economical Hardware. IEEE Trans. Intell. Transp. Syst. 2021, 22, 1718–1732. [Google Scholar] [CrossRef]

- Jiang, D.; Huo, L.; Zhang, P.; Lv, Z. Energy-Efficient Heterogeneous Networking for Electric Vehicles Networks in Smart Future Cities. IEEE Trans. Intell. Transp. Syst. 2021, 22, 1868–1880. [Google Scholar] [CrossRef]

- Pokhrel, S.R. Software Defined Internet of Vehicles for Automation and Orchestration. IEEE Trans. Intell. Transp. Syst. 2021, 22, 3890–3899. [Google Scholar] [CrossRef]

- Mantilla-Pérez, P.; Pérez-Rúa, J.; Millán, M.A.D.; Domínguez, X.; Arboleya, P. Power Flow Simulation in the Product Development Process of Modern Vehicular DC Distribution Systems. IEEE Trans. Veh. Technol. 2020, 69, 5025–5040. [Google Scholar] [CrossRef]

- Dominguez, X.; Arboleya, P.; Mantilla-Perez, P.; El-Sayed, I.; Gimenez, N.; Millan, M.A.D. Development of a Computer Platform for Visualization and Simulation of Vehicular DC Distribution Systems. IET Electr. Syst. Transp. 2020, 10, 341–350. [Google Scholar] [CrossRef]

- Mantilla-Pérez, P.; Domínguez, X.; Gimenez, N.; Mohamed, B.; Millán, M.A.D.; Arboleya, P. Vehicular Electrical Distribution System Simulation Employing a Current-injection Algorithm. IEEE Trans. Transp. Electrif. 2021. [Google Scholar] [CrossRef]

- Xie, J.; Wang, X.; Yang, Z.; Hao, S. An Integrated Cloud CAE Simulation System for Industrial Service Applications. IEEE Access 2019, 7, 21429–21445. [Google Scholar] [CrossRef]

- Xiaocheng, L.; Qiang, H.; Xiaogang, Q.; Bin, C.; Kedi, H. Cloud-based Computer Simulation: Towards Planting Existing Simulation Software Into the Cloud. Simul. Model. Pract. Theory 2012, 26, 135–150. [Google Scholar]

- Multisim Live Online Simulator. Available online: www.multisim.com (accessed on 1 June 2021).

- Autodesk Tinkercad. Available online: www.tinkercad.com (accessed on 1 June 2021).

- CircuitLab Online Circuit Simulator. Available online: www.circuitlab.com (accessed on 1 June 2021).

- Partsim Circuit Simulation. Available online: www.partsim.com (accessed on 1 June 2021).

- Sousa, J.; Coury, D.; Fernandes, R. A Survey on Cloud Computing Applications in Smart Distribution Systems. Electr. Power Compon. Syst. 2018, 46, 1554–1569. [Google Scholar] [CrossRef]

- Byrne, J.; Heavey, C.; Byrne, P. A Review of Web-based Simulation and Supporting Tools. Simul. Model. Pract. Theory 2010, 18, 253–276. [Google Scholar] [CrossRef]

- Internet Technology Based Power System Simulator (InterPSS). Available online: https://sites.google.com/a/interpss.org/interpss/Home (accessed on 8 June 2021).

- MATPOWER Simulator. Available online: https://matpower.org (accessed on 8 June 2021).

- Neplan 360 Cloud Simulator. Available online: https://www.neplan.ch/neplanproduct/en-neplan-360-cloud/ (accessed on 8 June 2021).

- Simulink Online. Available online: https://es.mathworks.com/products/simulink-online.html (accessed on 8 June 2021).

- Huang, Q.; Zhou, M.; Zhang, Y.; Wu, Z. Exploiting Cloud computing for Power System Analysis. In Proceedings of the 2010 International Conference on Power System Technology, Hangzhou, China, 24–28 October 2010; pp. 1–6. [Google Scholar] [CrossRef]

- Leijiao, G.; Shouxiang, W.; Xianjun, G. Framework Design of Cloud Computing Technology Application in Power System Transient Simulation. In Proceedings of the 2014 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Hong Kong, China, 7–10 December 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Anderson, K.; Du, J.; Narayan, A.; Gamal, A.E. GridSpice: A Distributed Simulation Platform for the Smart Grid. IEEE Trans. Ind. Inform. 2014, 10, 2354–2363. [Google Scholar] [CrossRef]

- Fang, X.; Yang, D.; Xue, G. Evolving Smart Grid Information Management Cloudward: A Cloud Optimization Perspective. IEEE Trans. Smart Grid 2013, 4, 111–119. [Google Scholar] [CrossRef]

- Maheshwari, K.; Lim, M.; Wang, L.; Birman, K.; van Renesse, R. Toward a Reliable, Secure and Fault Tolerant Smart Grid State Estimation in the Cloud. In Proceedings of the 2013 IEEE PES Innovative Smart Grid Technologies Conference (ISGT), Washington, DC, USA, 24–27 February 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Agamah, S.; Ekonomou, L. Agamah, S.; Ekonomou, L. A Methodology for Web-Based Power Systems Simulation and Analysis Using PHP Programming. In Electricity Distribution: Intelligent Solutions for Electricity Transmission and Distribution Networks; Springer: Berlin, Germany, 2016; pp. 1–25. [Google Scholar]

- Ma, F.; Luo, X.; Litvinov, E. Cloud Computing for Power System Simulations at ISO New England—Experiences and Challenges. IEEE Trans. Smart Grid 2016, 7, 2596–2603. [Google Scholar] [CrossRef]

- Luo, X.; Zhang, S.; Litvinov, E. Practical Design and Implementation of Cloud Computing for Power System Planning Studies. In Proceedings of the 2019 IEEE Power Energy Society General Meeting (PESGM), Atlanta, GA, USA, 4–8 August 2019; p. 1. [Google Scholar] [CrossRef]

- Liu, Y.; Song, Y.; Yu, Z.; Shen, C.; Chen, Y. Modeling and Simulation of Hybrid AC-DC System on a Cloud Computing Based Simulation Platform—CloudPSS. In Proceedings of the 2018 2nd IEEE Conference on Energy Internet and Energy System Integration (EI2), Beijing, China, 20–22 October 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Ramos, M.; Valente, M.T.; Terra, R. AngularJS Performance: A Survey Study. IEEE Softw. 2018, 35, 72–79. [Google Scholar] [CrossRef]

- El-Sayed, I.; Mohamed, B.; Arboleya, P. Web-based Software-Suite for DC Railway Simulation and Analysis: Architecture, Data Management and Visualization. In Proceedings of the 2020 IEEE Vehicle Power and Propulsion Conference (VPPC), Gijón, Spain, 26–29 October 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Bostock, M.; Ogievetsky, V.; Heer, J. D3: Data-Driven Documents. IEEE Trans. Vis. Comput. Graph. 2011, 17, 2301–2309. [Google Scholar] [CrossRef]

- Tilkov, S.; Vinoski, S. Node.js: Using JavaScript to Build High-Performance Network Programs. IEEE Internet Comput. 2010, 14, 80–83. [Google Scholar] [CrossRef]

- Koirala, A.; Suarez-Ramon, L.; Mohamed, B.; Arboleya, P. Non-synthetic European Low Voltage Test System. Int. J. Electr. Power Energy Syst. 2020, 118, 105712. [Google Scholar] [CrossRef]

- Birchfield, A.B.; Overbye, T.J. Techniques for Drawing Geographic One-Line Diagrams: Substation Spacing and Line Routing. IEEE Trans. Power Syst. 2018, 33, 7269–7276. [Google Scholar] [CrossRef]

- Mota, A.d.A.; Mota, L.T.M. Drawing Meshed One-Line Diagrams of Electric Power Systems Using a Modified Controlled Spring Embedder Algorithm Enhanced with Geospatial Data. J. Comput. Sci. 2011, 7, 234–241. [Google Scholar] [CrossRef][Green Version]

- Lendak, I.; Erdeljan, A.; Capko, D.; Vukmirovic, S. Algorithms in Electric Power System One-line Diagram Creation: The Soft Computing Approach. In Proceedings of the 2010 IEEE International Conference on Systems, Man and Cybernetics, Istanbul, Turkey, 10–13 October 2010; pp. 2867–2873. [Google Scholar] [CrossRef]

- Lendak, I.; Vidacs, A.; Erdeljan, A. Electric Power System One-line Diagram Generation with Branch and Bound Algorithm. In Proceedings of the 2012 IEEE International Energy Conference and Exhibition, ENERGYCON 2012, Florence, Italy, 9–12 September 2012; pp. 947–951. [Google Scholar] [CrossRef]

- Reingold, E.; Tilford, J. Tidier Drawings of Trees. IEEE Trans. Softw. Eng. 1981, SE-7, 223–228. [Google Scholar] [CrossRef]

- Keim, E.D.; Kohlhammer, J.; Ellis, G. Mastering the Information Age: Solving Problems with Visual Analytics; Eurographics Association: Goslar, Germany, 2010. [Google Scholar]

- Huang, X.; Zhao, Y.; Ma, C.; Yang, J.; Ye, X.; Zhang, C. TrajGraph: A Graph-Based Visual Analytics Approach to Studying Urban Network Centralities Using Taxi Trajectory Data. IEEE Trans. Vis. Comput. Graph. 2016, 22, 160–169. [Google Scholar] [CrossRef] [PubMed]

- Kalamaras, I.; Zamichos, A.; Salamanis, A.; Drosou, A.; Kehagias, D.D.; Margaritis, G.; Papadopoulos, S.; Tzovaras, D. An Interactive Visual Analytics Platform for Smart Intelligent Transportation Systems Management. IEEE Trans. Intell. Transp. Syst. 2018, 19, 487–496. [Google Scholar] [CrossRef]

- Sedlmair, M.; Isenberg, P.; Baur, D.; Mauerer, M.; Pigorsch, C.; Butz, A. Cardiogram: Visual Analytics for Automotive Engineers. In Proceedings of the SIGCHI Conference on Human Factors in Computing Systems, Vancouver, BC, Canada, 7–12 May 2011; ACM: New York, NY, USA, 2011; pp. 1727–1736. [Google Scholar]

- Sedlmair, M.; Bernhold, C.; Herrscher, D.; Boring, S.; Butz, A. MostVis: An Interactive Visualization Supporting Automotive Engineers in MOST Catalog Exploration. In Proceedings of the 2009 13th International Conference Information Visualisation, Barcelona, Spain, 14–19 July 2009; pp. 173–182. [Google Scholar] [CrossRef]

| Feature | Number |

|---|---|

| Mechanical and electrical nodes | 732 |

| Electrical nodes | 175 |

| Harness segments | 369 |

| Lines | 180 |

| Consumers | 46 |

| Fuses | 25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dominguez, X.; Mantilla-Pérez, P.; Gimenez, N.; El-Sayed, I.; Díaz Millán, M.A.; Arboleya, P. Web-Based Simulation Environment for Vehicular Electrical Networks. Energies 2021, 14, 6087. https://doi.org/10.3390/en14196087

Dominguez X, Mantilla-Pérez P, Gimenez N, El-Sayed I, Díaz Millán MA, Arboleya P. Web-Based Simulation Environment for Vehicular Electrical Networks. Energies. 2021; 14(19):6087. https://doi.org/10.3390/en14196087

Chicago/Turabian StyleDominguez, Xavier, Paola Mantilla-Pérez, Nuria Gimenez, Islam El-Sayed, Manuel Alberto Díaz Millán, and Pablo Arboleya. 2021. "Web-Based Simulation Environment for Vehicular Electrical Networks" Energies 14, no. 19: 6087. https://doi.org/10.3390/en14196087

APA StyleDominguez, X., Mantilla-Pérez, P., Gimenez, N., El-Sayed, I., Díaz Millán, M. A., & Arboleya, P. (2021). Web-Based Simulation Environment for Vehicular Electrical Networks. Energies, 14(19), 6087. https://doi.org/10.3390/en14196087