1. Introduction

The introduction of intermittent and unpredictable energy sources, such as wind and solar power, compromises the stability of the electrical grid and leads hydroelectric turbines to work for longer periods of time at non-optimal operating points. These working conditions can cause complex flows, such as von Kármán’s vortices, to appear along the hydraulic circuit, which can result in unwanted periodic excitation forces.

Vortex shedding behind solid bodies located in a fluid stream has attracted the attention of researchers since 1878, when Strouhal observed this phenomenon experimentally for the first time [

1]. The vortex shedding is a consequence of the boundary layer detachment on both the upper and lower surfaces of the solid body. Above a critical Reynolds number, these detachments form a periodic array of discrete vortices referred to as von Karman’s vortex street [

2,

3,

4,

5]. Due to the asymmetric formation of these vortices, the body experiences an oscillating lift force [

6].

When the oscillation frequency of the lift force lies in the vicinity of a body’s natural frequency, resonance can occur, which often results in potentially dangerous vibration amplitudes [

7,

8]. Vortex shedding as a mechanism of premature failure has been reported in a wide range of structures [

9]. For instance, structural damage has specifically been observed on stay vanes and runner blades of hydraulic turbines, and is often attributed to severe fatigue loading [

10,

11,

12,

13,

14]. It is therefore of paramount importance to predict the vibration amplitude of hydrofoils under resonance conditions in order to avoid catastrophic failures and to estimate their life expectancy.

As long as the hydrofoil is not under a resonance condition, the vortex shedding frequency varies linearly with the free stream velocity, often referred to as lock-off regime [

1]. In the case of resonance, the vortex shedding frequency has a constant value for a specific range of free stream velocities, the so-called lock-in regime. It is observed that the lock-in of the vortex shedding frequency around a cantilever hydrofoil occurs for the first torsional mode [

6].

Many researchers have focused their investigations on the prediction of the vortex shedding frequency. For instance, Vu et al. [

15] first developed a numerical methodology to predict the von Kármán vortex shedding frequency of a turbine stay vane. They predicted the frequency using 2D unsteady flow simulations with the Shear Stress Transport (SST) turbulence model. The difference observed between the computed and the experimentally measured frequencies was about 18%. Nevertheless, Alexandre et al. [

16] were not able to capture the vortex wake correctly with Unsteady Reynolds Averaged Navier Stokes (URANS) equations. They obtained more realistic results using the Detached Eddy Simulation (DES) model. Nowadays, the accuracy for the numerical computation of the vortex shedding frequency is about 10% [

17].

When pressure falls below vapor pressure in a liquid, cavitation occurs. Due to the high vorticity taking place in the centers of the vortices, sharp decreases in pressure are expected to occur. As a result, these regions are more prone to develop vortex cavitation [

18,

19].

Both the vortex shedding frequency and vortex formation length have been observed to be sensitive to the extent of wake cavitation. For example, Young et al. [

20] experimentally studied the vortex shedding frequency behind a 2D triangular wedge. They observed an increase in the frequency when wake cavitation was developed. Later, Belahadji et al. [

21] also concluded that wake cavitation changed the flow dynamics and led to an increase in the vortex shedding frequency. Ausoni et al. [

6] experimentally confirmed that the wake cavitation is responsible for the increase in the vortex shedding frequency behind a truncated NACA 0009 hydrofoil. Chen et al. [

22] simulated the cavitating flow around a 2D NACA 0009 hydrofoil. They predicted an increase in the vortex shedding frequency of about 14% for a cavitation number around 40% of the incipient one.

Concerning the vortex formation length, Gerrard et al. [

4] concluded that a larger vortex formation region leads to a decrease in the vortex frequency for single-phase flows. In the same direction, Ausoni et al. [

6] reached the same conclusion after conducting experiments, again for cavitation-free regimes. Nevertheless, no experimental measurements were reported when cavitation occurred. On the other hand, Ramamurthy et al. [

23] concluded that the higher the degree of the wake cavitation, the larger the vortex formation length. This conclusion was reached through experiments carried out on different geometries such as a cylinder and a two-dimensional triangular wedge. These results highlighted the fact that wake cavitation makes this phenomenon more complex.

The study of fluid-structure interaction (FSI) phenomena requires considering the flow behavior at the wake of hydrofoils and the structure dynamic response. In this sense, Zeng et al. [

24] studied the dynamic response of the first bending mode of a blunt trailing-edge hydrofoil in a fluid stream through two-way FSI simulations. They concluded that this approach is suitable for the prediction of the vibration amplitude with a maximum deviation of around 8.82% for the hydrodynamic damping. Liaghat et al. [

25] also studied the dynamic response of the first bending mode of a hydrofoil by using two-way FSI simulations. They numerically found the linear relationship between the hydrodynamic damping and the free-stream velocity. They reported that the deviation from experimentally obtained hydrodynamic damping ratios was around 12%. Like in the previous studies, Zeng et al. [

26] numerically studied the dynamic response of a hydrofoil bending mode through two-way FSI simulations. They concluded that despite the usefulness of this approach, the numerical damping could induce uncertainty in the results. However, they also captured the linear dependency between the free-stream velocity and the hydrodynamic damping.

The prediction of hydrofoil vibration amplitudes under lock-in conditions has received far less attention than under lock-off conditions. In this sense, Alexandre et al. [

27] studied the lift force, the vibration amplitude, and the frequency value of a hydrofoil under a lock-in condition. They modelled the torsional mode as a single degree of freedom system and coupled it to a CFD simulation. They concluded that this method can capture the increase of vibration amplitude in lock-in conditions. Miyagawa et al. [

28] also modelled the resonant mode of vibration as a single degree of freedom oscillator. They included it in a CFD simulation in order to predict the vibration amplitudes in lock-in conditions. Additionally, they computed the hydrodynamic damping corresponding to different values of the reduced velocity. In particular, a decrease in the hydrodynamic damping was found when large amplitudes of vibration occurred. They concluded that the drop in the damping was a result of a self-excitation mechanism. Nennemann et al. [

17] predicted the vibration amplitude of hydraulic profiles under a torsional lock-in regime through an alternative methodology usually referred to as modal work approach. This method was validated by comparing the numerically predicted and the experimentally measured maximum vibration amplitudes of two different hydrofoils under lock-in conditions. For a truncated NACA 0009 profile, the deviation of the simulation result was nearly 0%, while the vibration amplitude was about 30% over-predicted for the other hydrofoil. This discrepancy was attributed to either the existence of an acoustic damping or to the incorrect transposition from measured strains to displacements.

Most research has been focused on lock-in conditions for free wake cavitation regimes, whilst there is a lack of investigations when wake cavitation occurs with few available bibliography resources. For example, Ausoni et al. [

6] experimentally studied the impact of the wake cavitation on the formation process of the vortex street. They concluded that wake cavitation should be considered as an active agent in the process since they observed a drop in the vibration amplitude of a hydrofoil under torsional lock-in conditions when wake cavitation occurred.

In summary, most of the literature related to the study of hydrofoils under vortex shedding flows deals with: (i) the prediction of the vortex shedding frequency for free-wake cavitation conditions [

12,

15,

16,

29,

30,

31,

32], (ii) the influence of the wake cavitation on the vortex shedding dynamic behavior [

4,

20,

21,

22,

23], and (iii) the prediction of the vibration amplitudes of hydrofoil under lock-off and lock-in conditions when no wake cavitation occurs [

17,

24,

25,

26,

27,

28]. However, solely Ausoni et al. [

6] experimentally studied the interaction between wake cavitation and the dynamic response of a hydrofoil under a lock-in condition. For this reason, it is of paramount importance to conduct further research on this topic with the aim of predicting vibration amplitudes with good accuracy when wake cavitation occurs to understand the phenomena involved in the interaction between wake cavitation and lock-in conditions.

In the present article, the modal work approach proposed by Nennemann et al. [

17] was firstly used to calculate the vibration modal amplitude of a NACA 0009 profile under a torsional lock-in condition and to assess its suitability not only for free-wake cavitation regimes, but also for incipient wake cavitation conditions. Secondly, the obtained results were analyzed to understand the mechanism responsible for the experimentally observed drop in the hydrofoil vibration amplitude when wake cavitation is developed.

The present paper starts with a review of studies on hydrofoils under vortex shedding flows. In the following section, a detailed explanation of the modal work approach applied to a NACA 0009 profile as well as an overview of the numerical model are provided. The results section is divided into, first, the validation of the numerical simulations, in which a comparison between experimental and numerical results is shown, and second, the discussion, in which the results employed to study the mechanism responsible for the drop in the vibration amplitude are presented. Finally, a summary of the most relevant findings is given in the conclusions.

2. Methodology

2.1. Modal Work Approach

Von Karman vortices formed on the trailing edge exert a dynamic loading on hydrofoils under lock-in conditions that transfer energy from the fluid to the vibrating structure in the form of work. On the other hand, the structural deformation and the displacement of the hydrofoil surfaces within the fluid domain can be also understood as another transfer of energy, but in this case from the structure to the fluid. According to the “Energy consideration” concept described by Naudascher et al. [

7], the energy transfers from the structure to the fluid and from the fluid to the structure tend to be in balance for one cycle of vibration in a lock-in condition.

The idea of the modal work approach resides in finding the vibration amplitude which results in zero energy exchanged between the displacement of the structure within the flow and the surrounding fluid during one cycle of vibration. This calculation is carried out through an iterative process of simulations in which the hydrofoil surface’s periodic motion imposed in the CFD by an initial assumed modal amplitude is updated according to the value of the computed exchanged energy after each iteration until convergence to zero work is achieved.

Under lock-in conditions, the hydrofoil vibration oscillates periodically according to the mode shape of the excited resonance. In this case, the vector of surface displacements can be expressed as follows:

where

is the displacement vector of the structural surface,

is the normalized mode of vibration,

q is the vibration modal amplitude, and

the natural frequency of the mode.

It is noticeable that with the vibration modal amplitude, q, and the normalized mode shape, , the vibration amplitude of any point of the structural surface can be computed through Equation (1). Moreover, it can be seen that the maximum vibration amplitude of the structural surface is equal to q.

To reproduce the lock-in condition in the CFD simulation,

,

and an estimated modal amplitude,

, are imposed in the solid boundary in order to define the hydrofoil surface periodic motion. Subsequently, the energy exchange between the structure and the fluid can be computed from:

where

is the pressure,

is the shear stress,

is the velocity of the structure surface in the normal direction when vibrating under the resonant condition, and

is the modal work performed by the structure on the fluid.

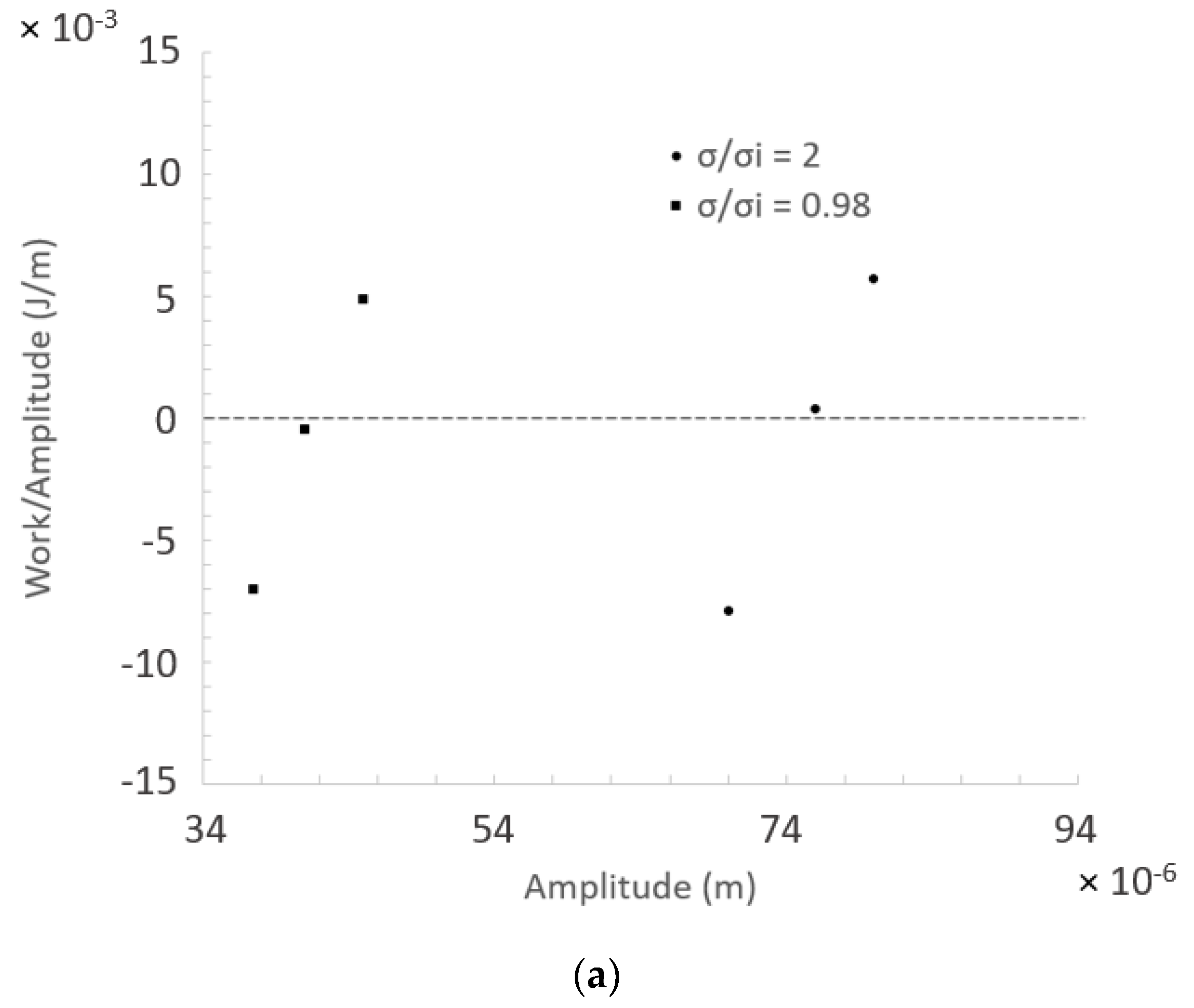

Based on the assumption described by Naudascher et al. [

7], a positive value of

W indicates that the needed vibration modal amplitude,

q, is smaller than the estimated vibration modal amplitude,

. Conversely,

q is larger than

if

W is negative. In the case that

W = 0, when

q equals

, the energy exchange is in balance and thus the lock-in condition is well characterized and simulated.

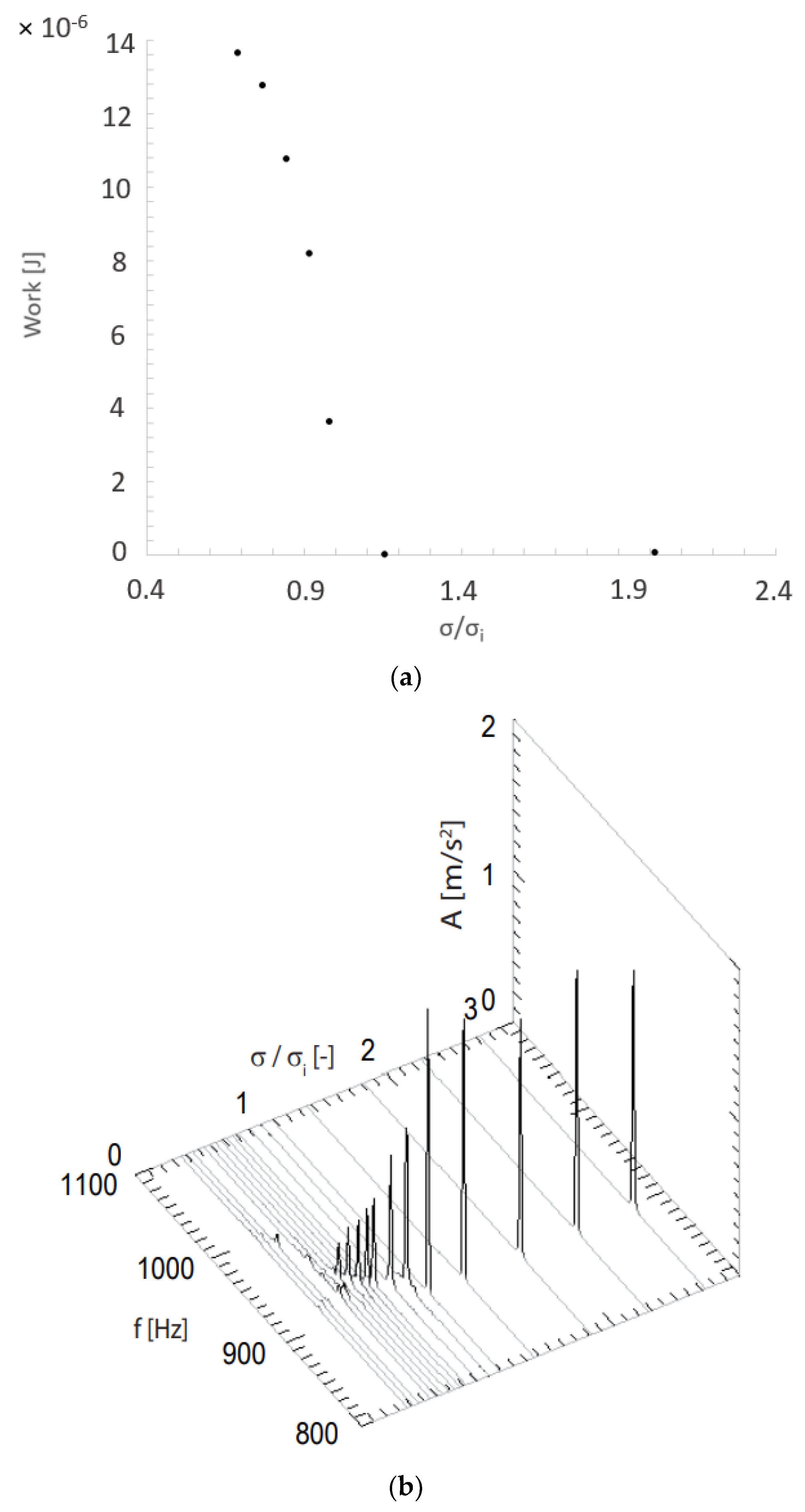

In the present work, the modal work approach was employed to calculate the vibration modal amplitudes, q, for no cavitation and incipient cavitation conditions in addition to studying the trend of q as a function of the cavitation number, deduced from the tendency of W.

To begin with, the normalized mode shape,

, and the natural frequency,

, corresponding to the 3D torsion mode were determined through a coupled acoustic-structural modal analysis. This method accounts for the reduction of natural frequencies when structures are submerged in a dense fluid owing to the added mass effect. This methodology has been proven to give reasonably accurate results in the past [

33,

34,

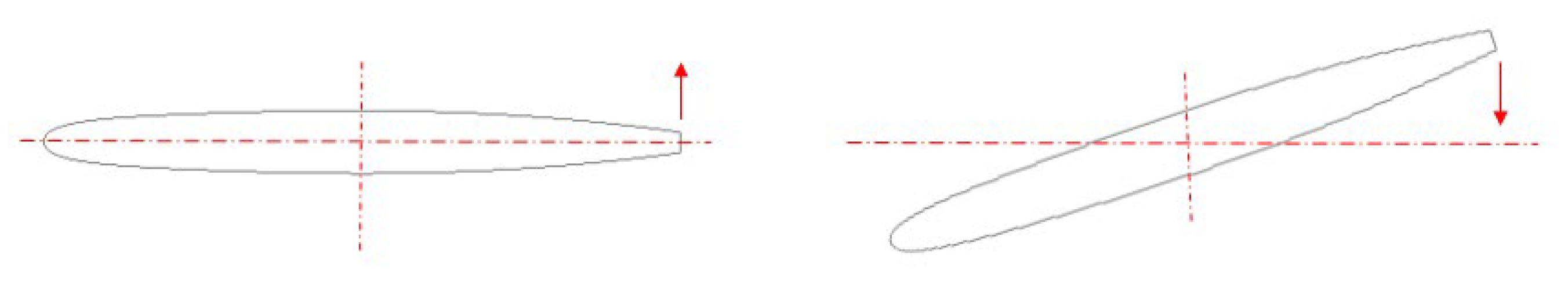

35]. The displacement of the hydrofoil in a section close to the tip, where the maximum displacement takes place, was then selected and imported in the CFD model as shown in

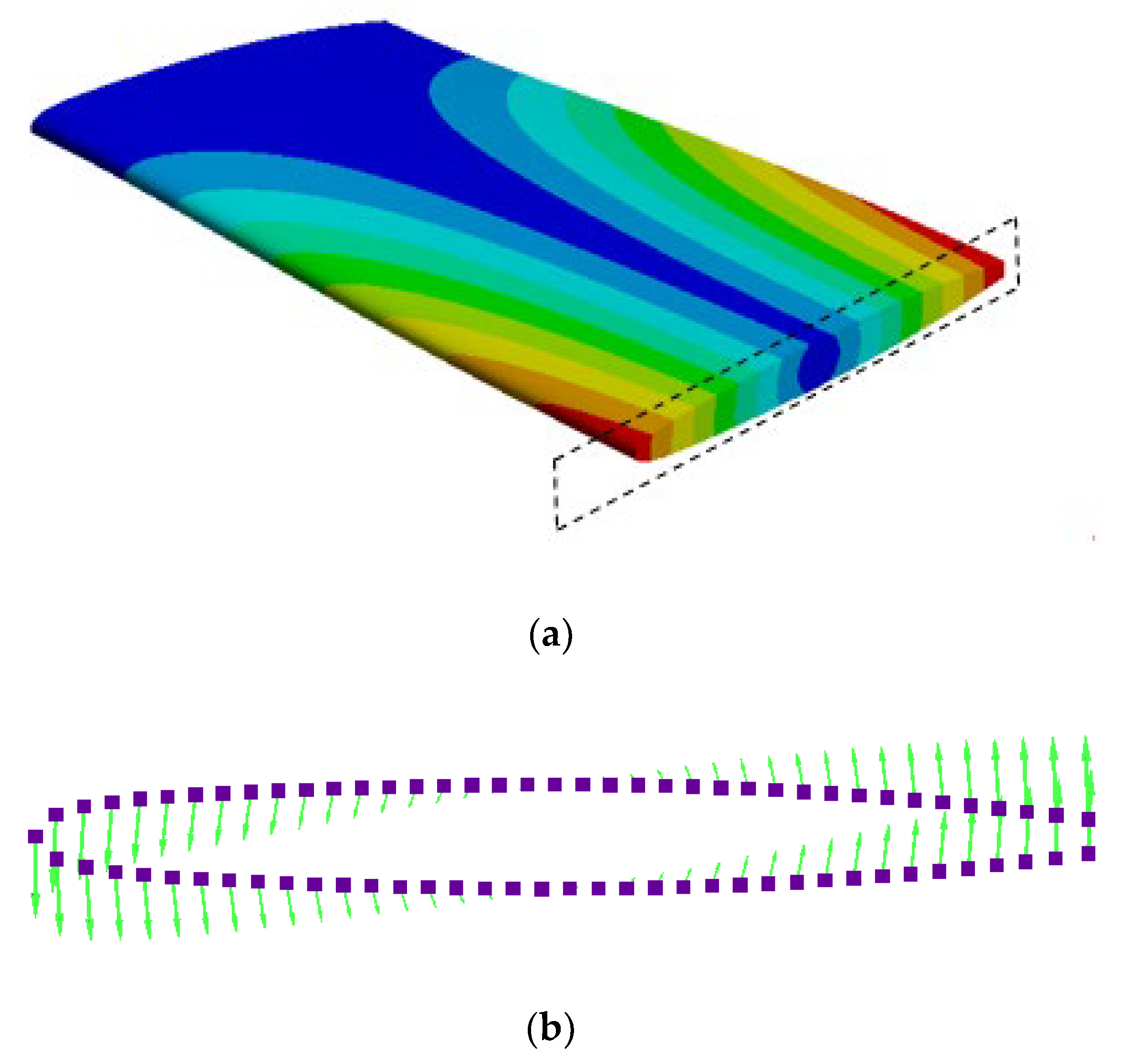

Figure 1. The method has been tested with different 2D sections of the torsion mode and proven to be insensitive to displacement levels.

Subsequently, the hydrofoil surface periodic motion was defined in a CFD simulation based on

,

and with an initially assumed vibration modal amplitude,

. The corresponding boundary conditions were a uniform velocity at the inlet and an average static pressure at the outlet. Finally, from the CFD simulations, the modal work,

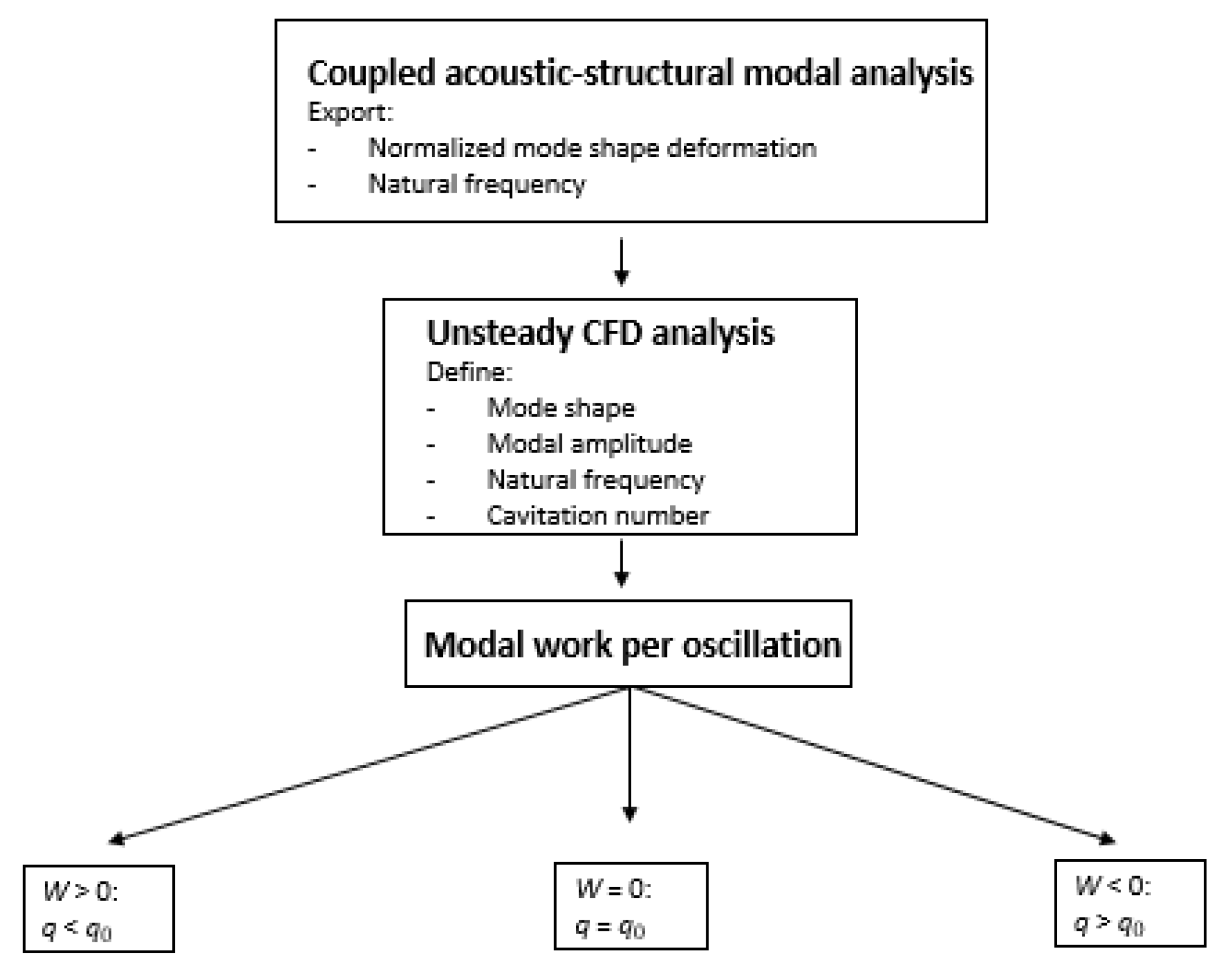

W, was computed. A flow chart of the methodology is shown in

Figure 2.

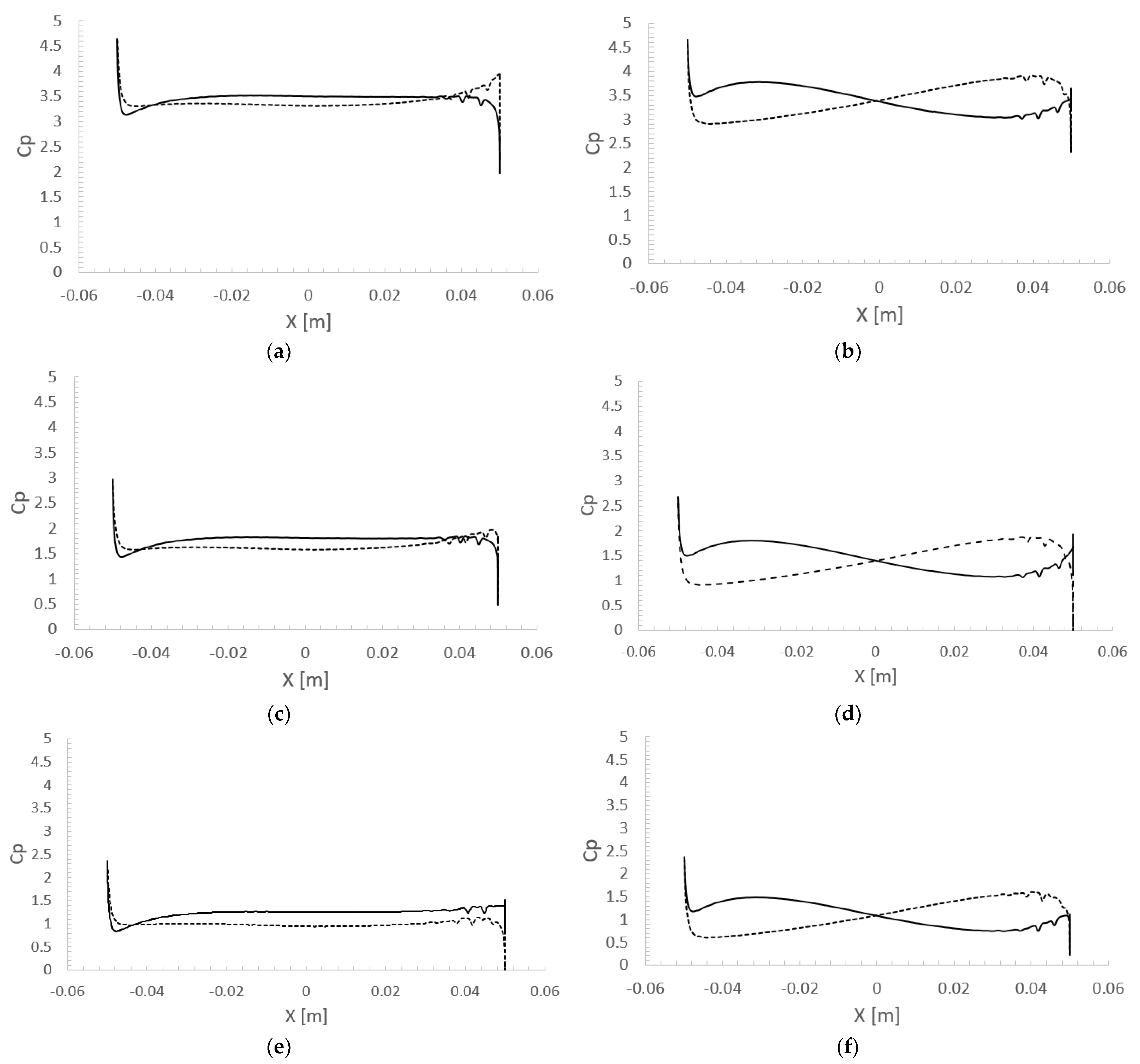

On the one hand, in order to calculate the q corresponding to a specific cavitation condition, the average static pressure at the outlet of the flow was fixed in the CFD, while the assumed vibration modal amplitude, , was updated after each simulation. Specifically, the sign and value of W after each computation were considered to iterate a new value of , i.e., a positive W implies a reduction of whereas a negative W implies an increase of . This iterative process continued until reaching a , which results in W being approximately null. In this article, W was considered null when . W was divided by in order to eliminate its dependency on and to make possible the comparison of W/ between cases in which different were assumed.

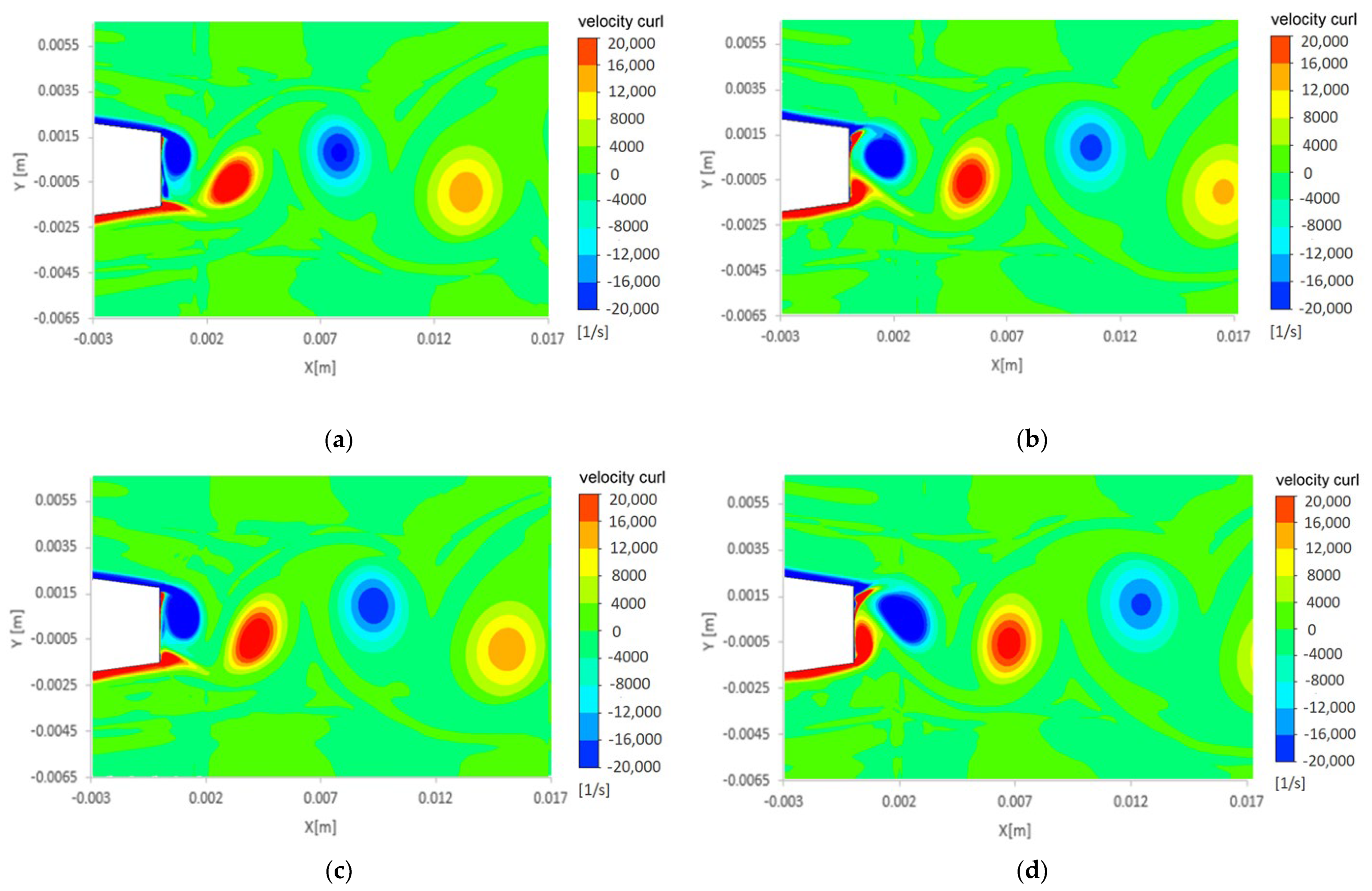

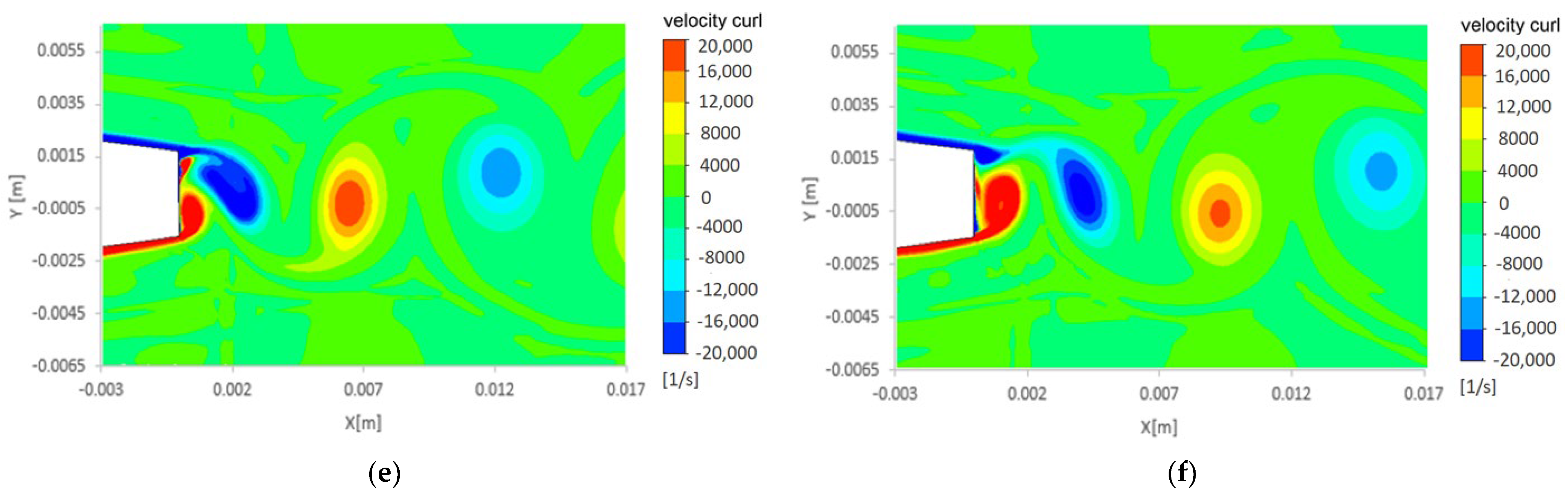

On the other hand, in order to study the evolution of q as a function of the cavitation number, the assumed was fixed in the CFD whilst the average static pressure at the outlet of the flow was gradually reduced in a series of simulations, where W is calculated. Finally, from the tendency of W as a function of the cavitation number, the evolution of q can be deduced, i.e., an increase of W means that the variable q is reduced while a decrease in W means that it is increased.

2.2. Numerical Setup

The experimental results obtained by Ausoni et al. [

6] were used as a reference for the present paper. These experiments were carried out with a NACA 0009 hydrofoil with chord length,

c, and span,

sp, of 100 and 150 mm, respectively, inside a rectangular test section with dimensions of 150 × 150 × 750 mm of the EPFL high-speed cavitation tunnel. They observed the lock-in of the first torsional mode of vibration at a free-stream velocity of about 12 m/s. The vortex-induced vibration for this condition was measured with a laser vibrometer located at a distance of 80 mm in the chordwise direction and 112.5 mm in the spanwise direction.

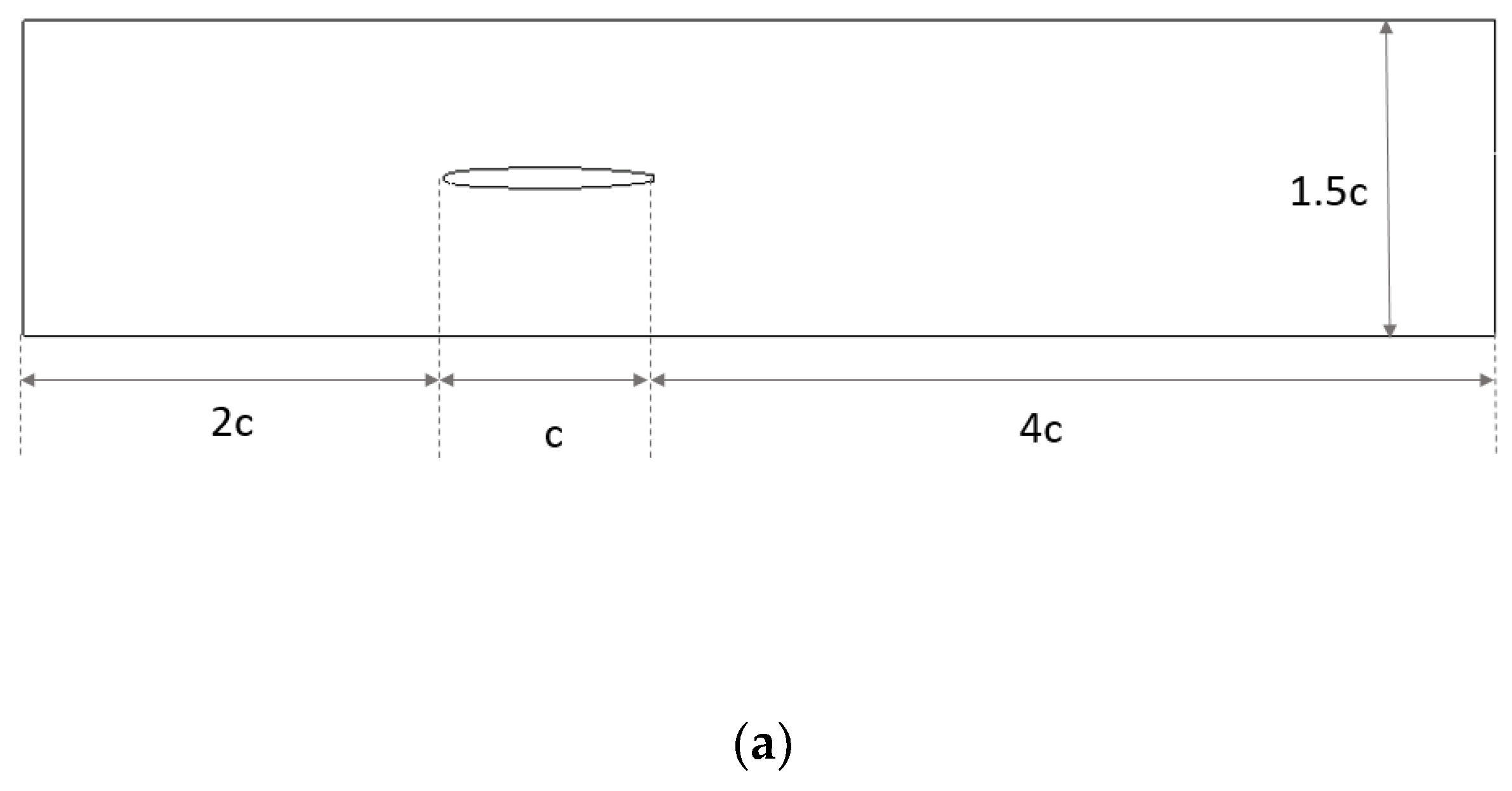

Figure 3 presents the dimensions and boundary conditions of the CFD domain corresponding to the lock-in condition observed experimentally by Ausoni et al. [

6]. The top and bottom boundaries in addition to the hydrofoil surface were set with no slip wall condition. At the inlet, a uniform free-stream velocity of 12 m/s perpendicular to the inlet boundary with a 5% of turbulence intensity was imposed, whereas an average static pressure was employed at the outlet boundary. Symmetry conditions were considered at both lateral surfaces in the spanwise direction. This 2D assumption was previously applied with reasonable accuracy by Alexandre et al. [

27] and Miyagawa et al. [

28]. Finally, the hydrofoil surface periodic motion was defined through the torsion mode shape, a

of 887.5 Hz corresponding to the torsion natural frequency, and an assumed

.

With regard to the turbulence modelling, the transition SST model was employed. For cavitation simulation, a homogeneous mixture model was considered which neglects the velocity differences between the liquid and the vapor phases by considering a single fluid with mixture properties. Thus, the mixture density and viscosity were calculated from a summation of their corresponding amounts in liquid and vapor states weighted by the volume fraction of each state, respectively. In particular, the Zwart-Gerber-Belamri cavitation mass transfer model was used to calculate the mass transfer rate between liquid and vapor and thus to derive the vapor volume fraction. In this model, the following parameters were considered: (i) a saturated vapor pressure of 2000 Pa, (ii) an initial value of the bubble radius of 1 µm, (iii) a nucleation site of the volume fraction of 0.0005, (iv) an empirical condensation coefficient of 0.01, and (v) an empirical vaporization coefficient of 50.

Regarding the solution methods, a time step of 0.000028 s was considered with the high-resolution advection scheme, the second-order backward Euler transient scheme, and the high-resolution turbulence numeric to solve the flow.

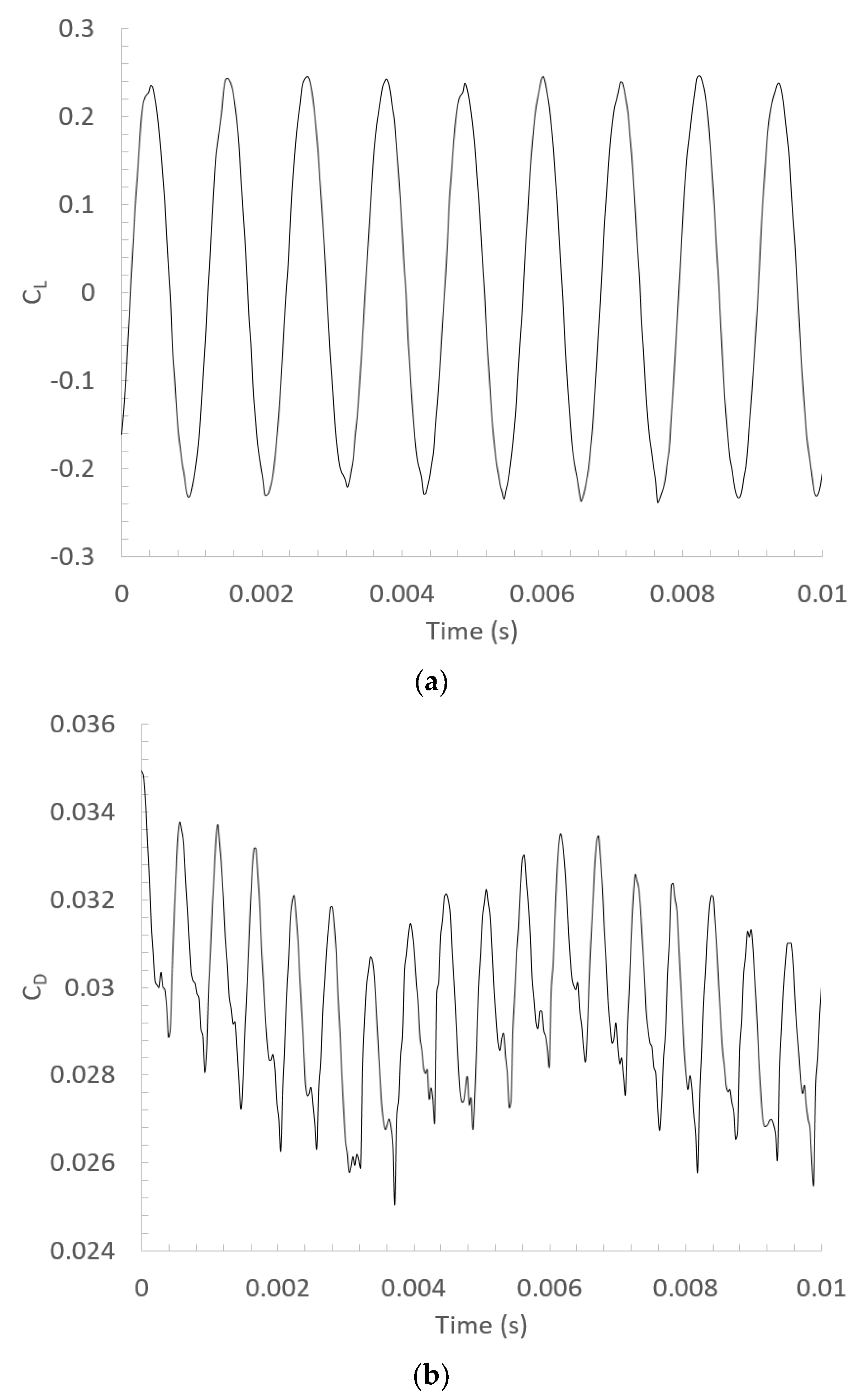

Under lock-in conditions, the vortex shedding frequency can be derived from the temporal evolution of the lift and the drag coefficients,

CL and

CD. The expressions used to calculate the

CL and

CD are presented as follows:

where

is the water density,

is the inlet velocity,

is the reference area considered,

is the fluid force perpendicular to the free-stream velocity, and

is the force parallel to the free-stream velocity.

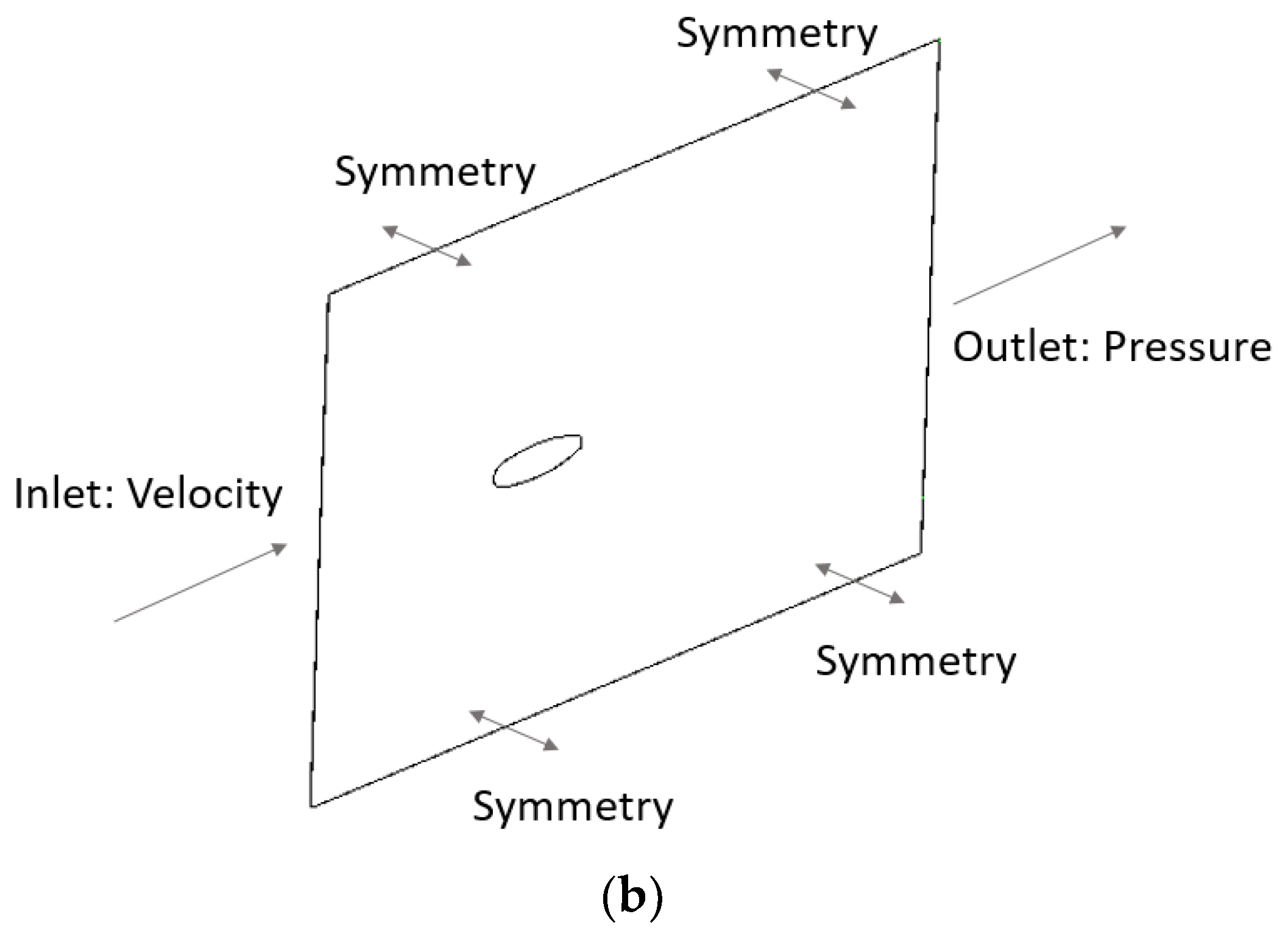

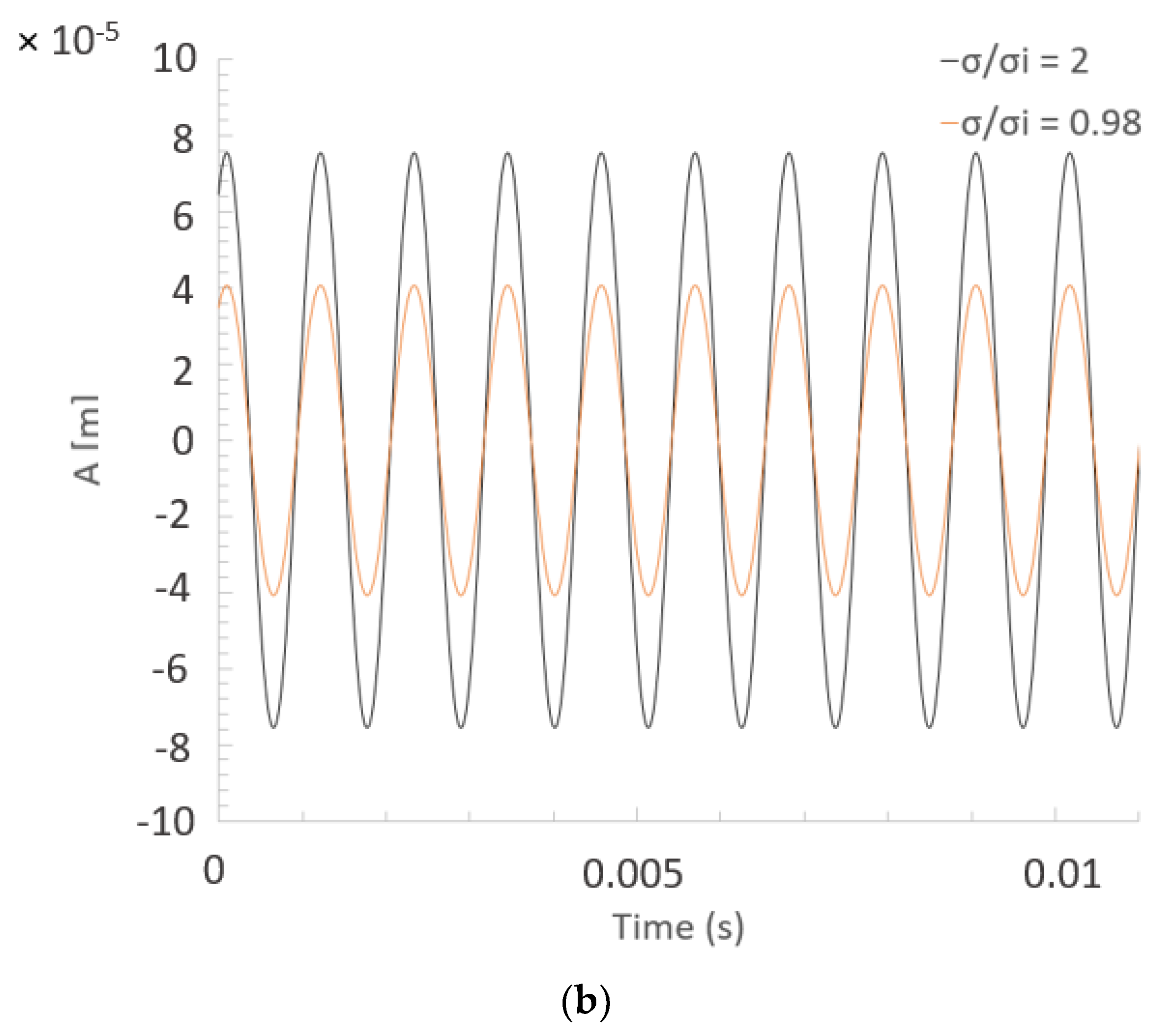

Figure 4 shows an example of the time histories of the

CL and

CD for a cavitating condition.

The validation of the grid independence was carried out under non-cavitating conditions and with four (4) different mesh refinement levels. Specifically, the vortex shedding frequency calculated from the time history of the lift coefficient was considered as the verification variable. The results obtained with the different refined meshes are listed in

Table 1.

The grid convergence index (GCI) methodology was employed in order to verify that the solution was insensitive to the grid resolution [

36]. In this case, the vortex shedding frequency was chosen as a parameter indicative of the grid convergence (

ɸ). Both mesh refinement ratios,

r21 and

r43, being greater than 1.3, met the GCI requirements.

Table 2 shows that the extrapolated value (

ɸ31ext) was 882 Hz, the approximate relative error (

ɸ31a_E) and the extrapolated relative error (

ɸ31ext_E) were 2.2% and 0.68% respectively, and the GCI was 0.84%.

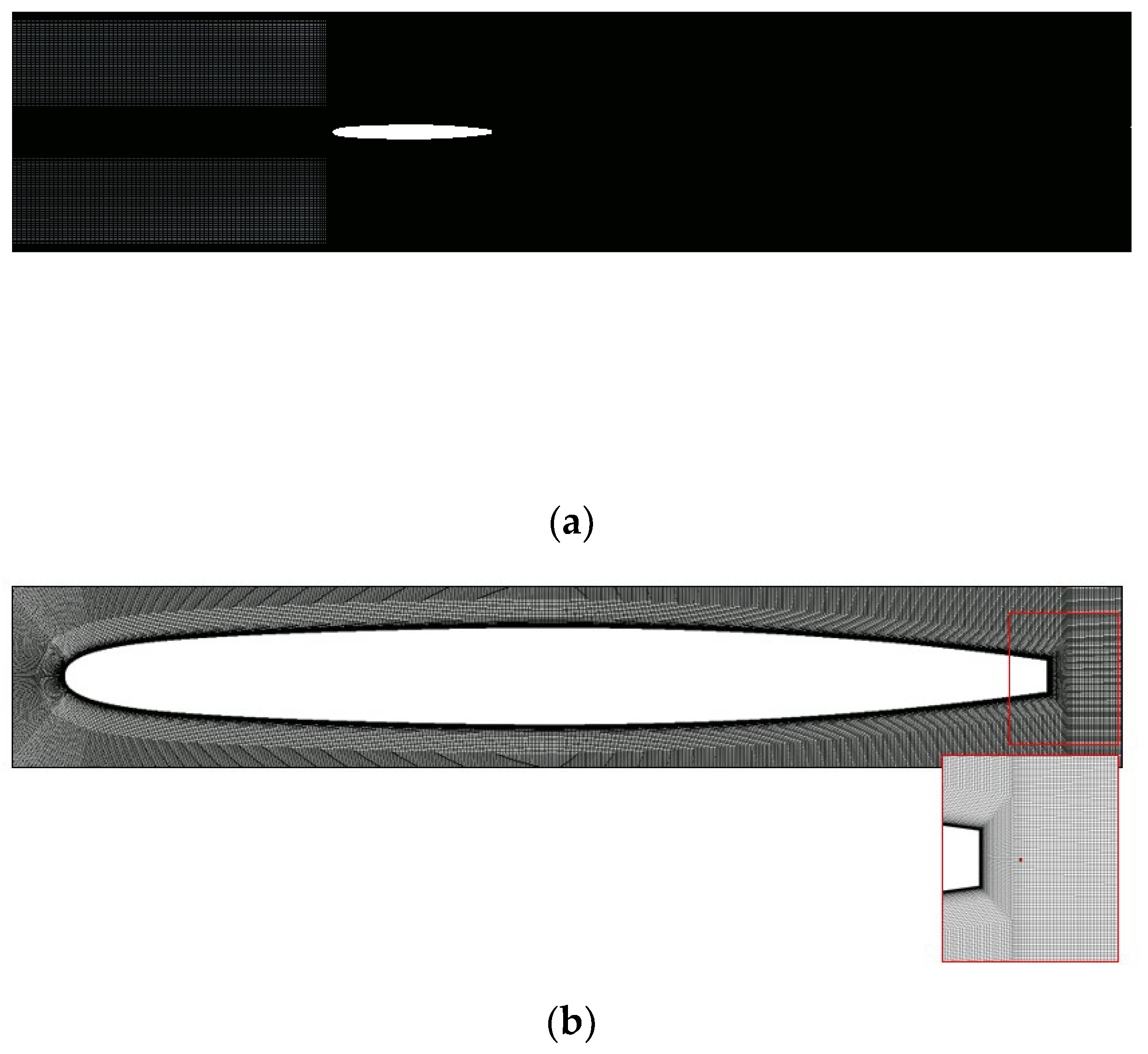

In

Figure 5, the selected mesh (

N1) as well as a detail of the trailing edge are presented:

The cavitation number is defined as follows:

where

is the reference outlet pressure and

is the vapor pressure.

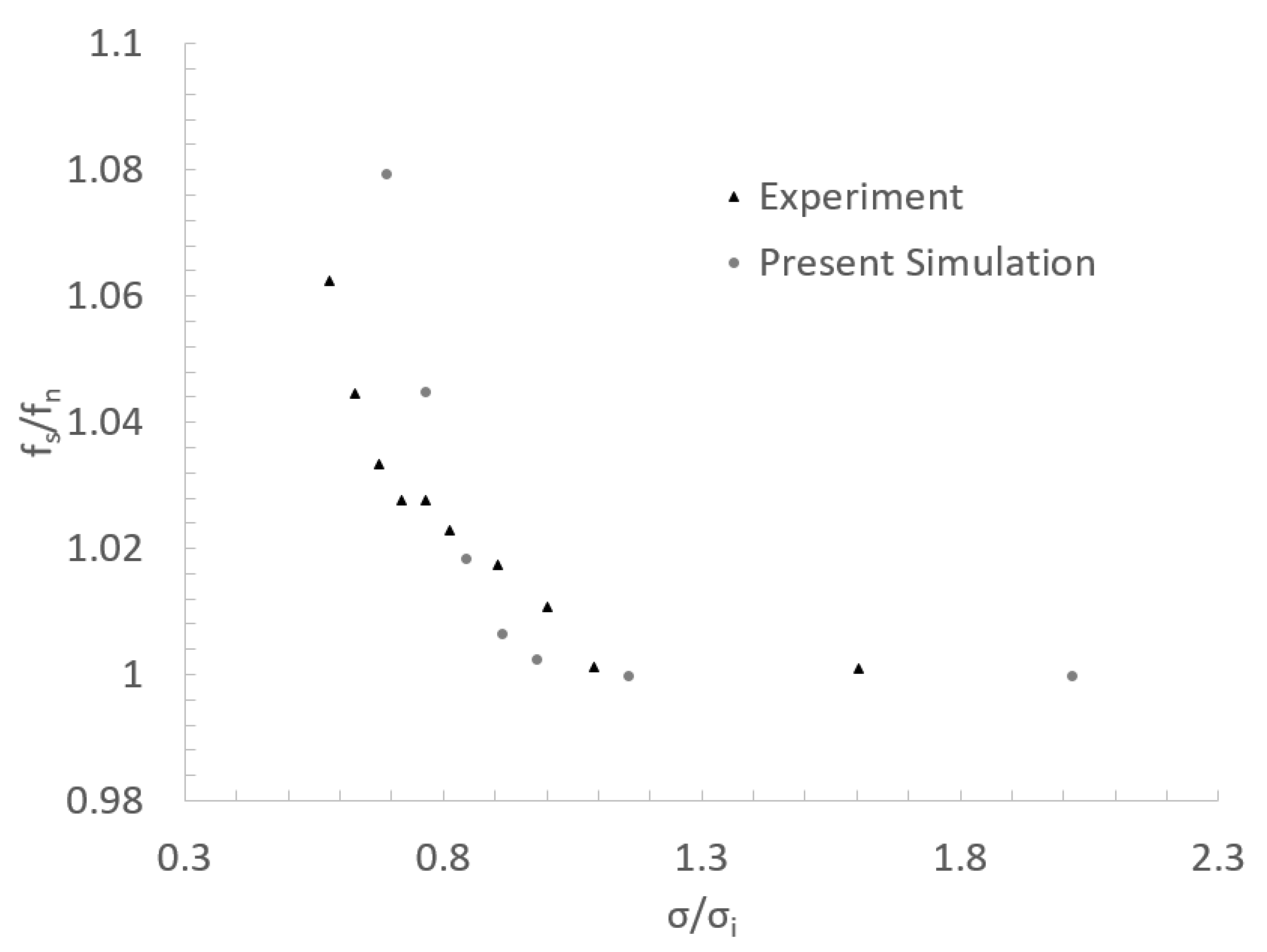

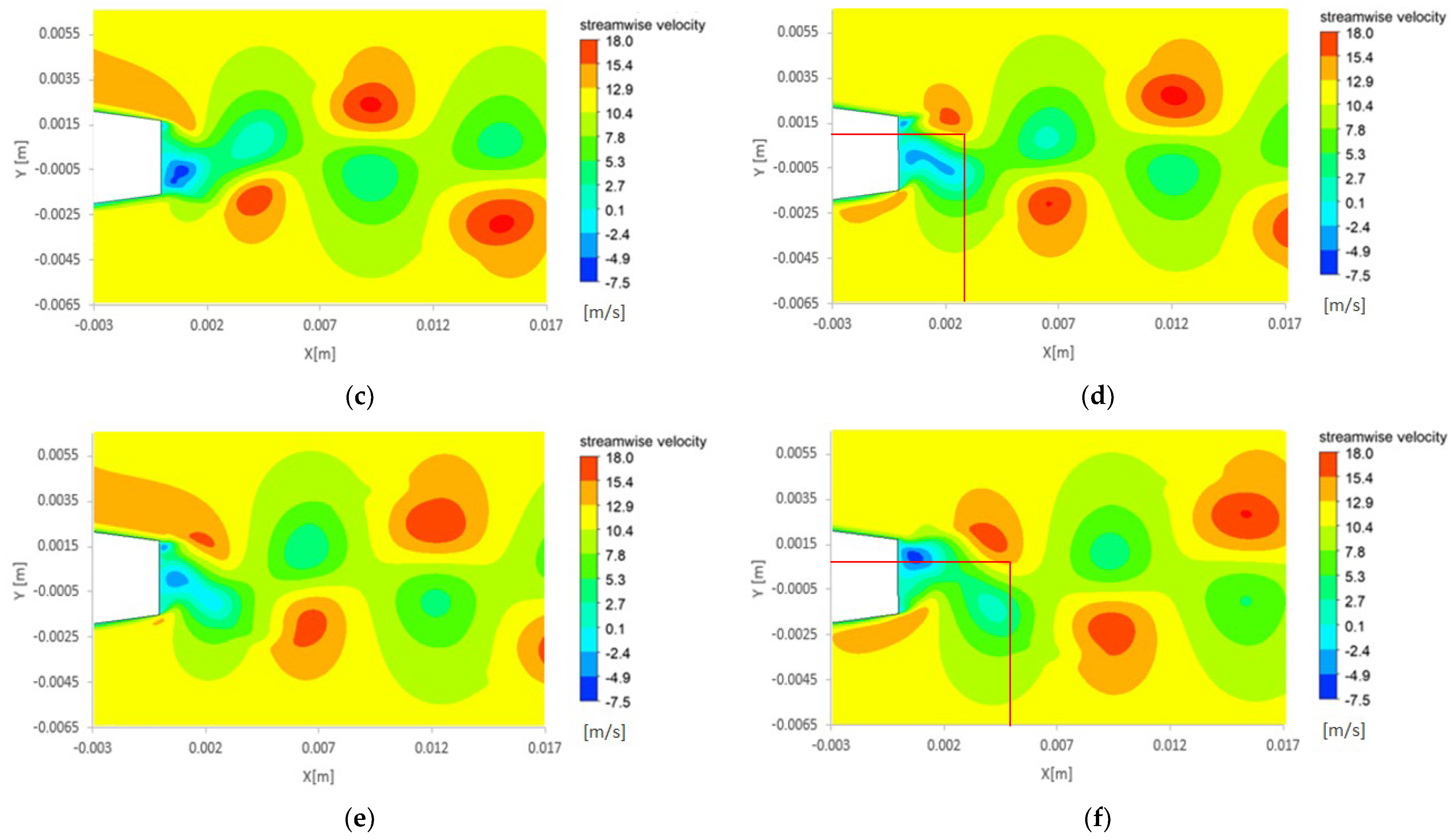

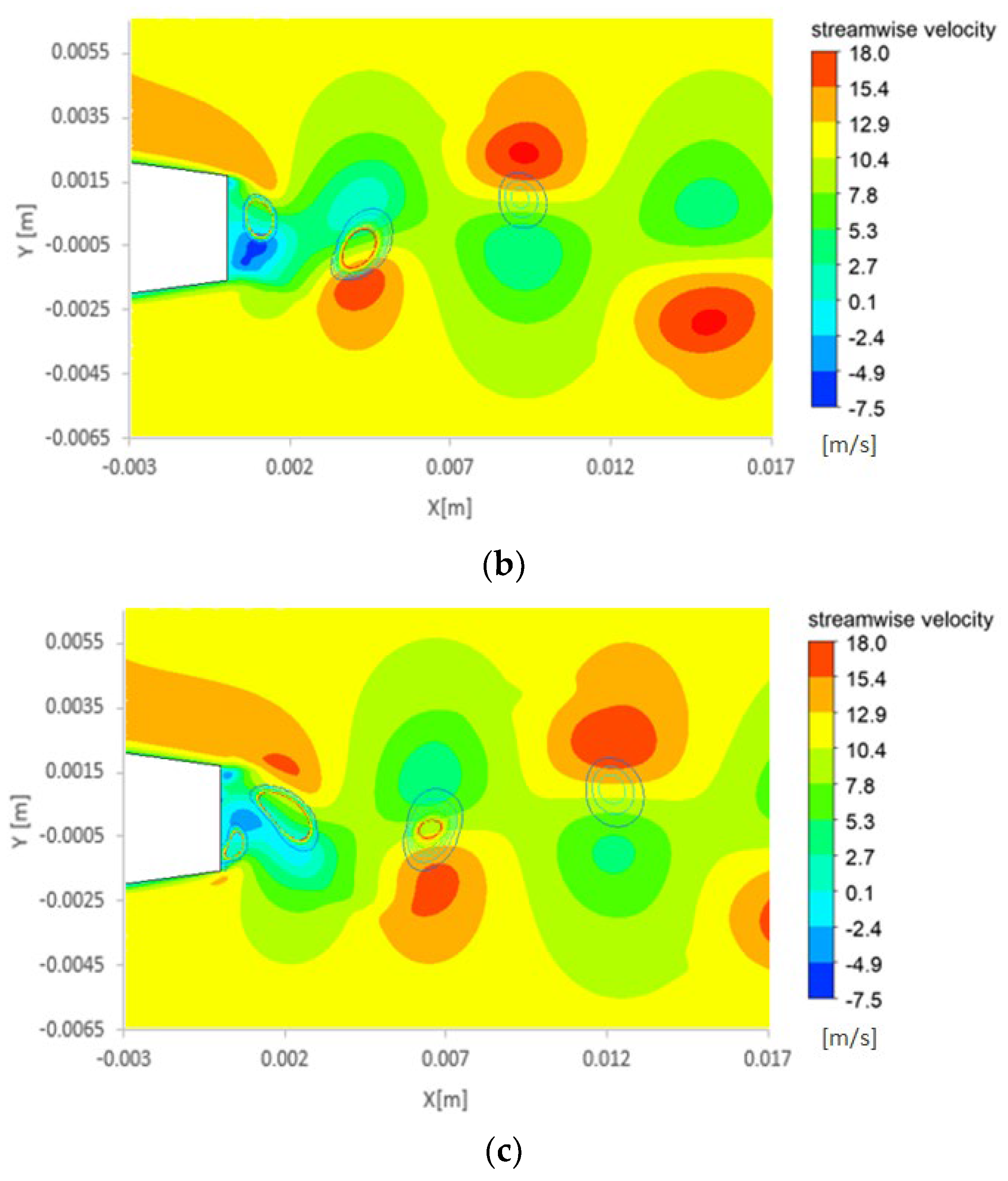

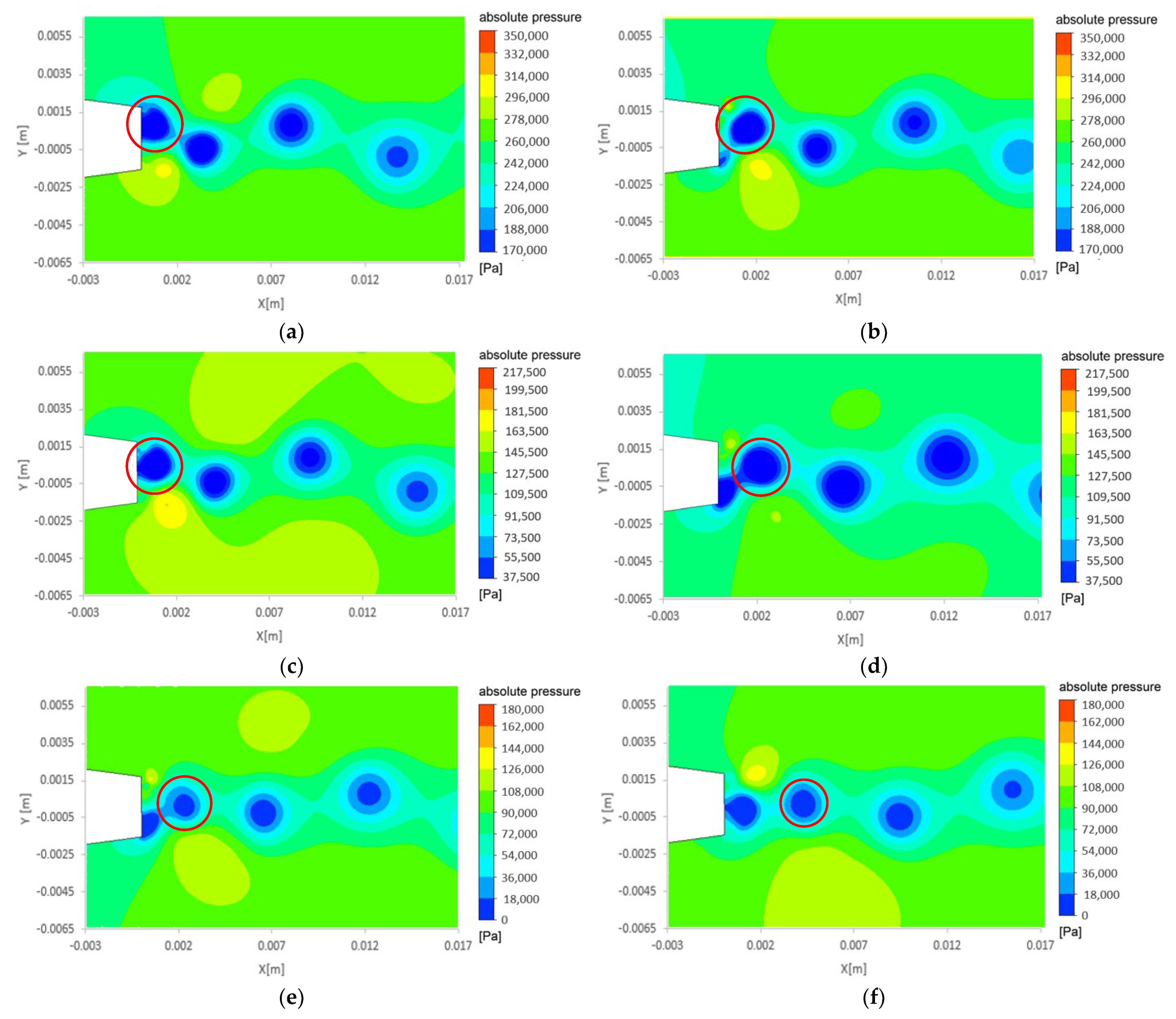

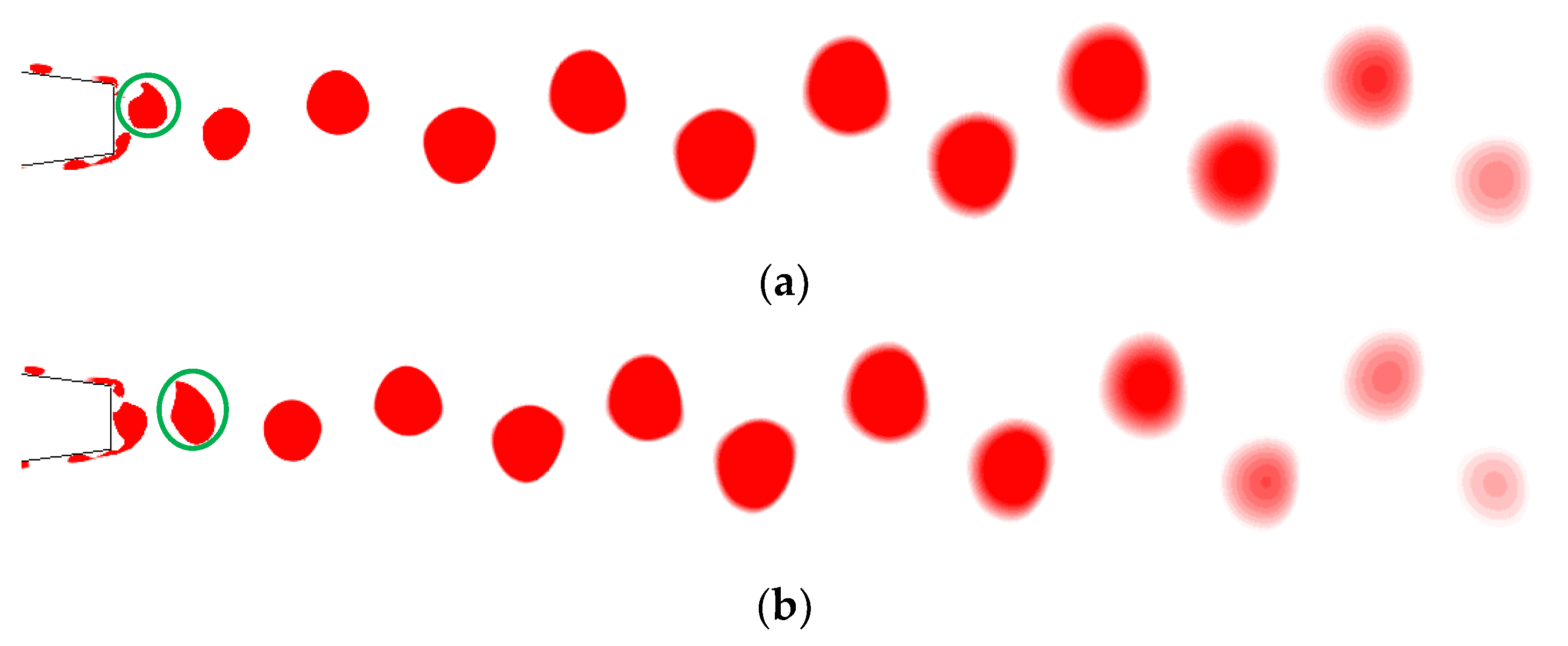

The occurrence of the wake cavitation for the first time was identified numerically when the outlet absolute pressure was around 130,000 Pa based on the observation of: (i) vapor volume fractions higher than zero and (ii) pressure levels around the vapor pressure at the wake of the blade. This condition is referred to as cavitation incipient number, , and in the present paper it took a value of 1.77.

Table 3 presents the

and the ratio of the cavitation number relative to the incipient cavitation number,

, employed in the simulations. In the first simulation group (1), the hydrofoil surface periodic motion was not included in the CFD. In this case, the vortex shedding frequency was computed for different cavitation conditions with the objective of verifying whether the model accounts for the increase in the vortex shedding frequency when wake cavitation occurs. In the second (2) and third (3) simulation groups, the values of

q corresponding to a wake-cavitation-free regime,

, and to an incipient cavitation condition,

, were calculated with an iterative process of simulations. During these computations, the suitability of the modal work approach in order to calculate vibration modal amplitudes was assessed. Finally, in the fourth simulation group (4), the

q computed previously for

was considered in a series of CFD simulations in which the cavitation number was gradually reduced. Then, from the evolution of the calculated

W, the tendency of

q as a function of the cavitation number was studied and thus also the mechanism responsible for the drop in the vibration modal amplitude when wake cavitation was developed.