Degradation Mechanism of Pressure-Assisted Sintered Silver by Thermal Shock Test

Abstract

:1. Introduction

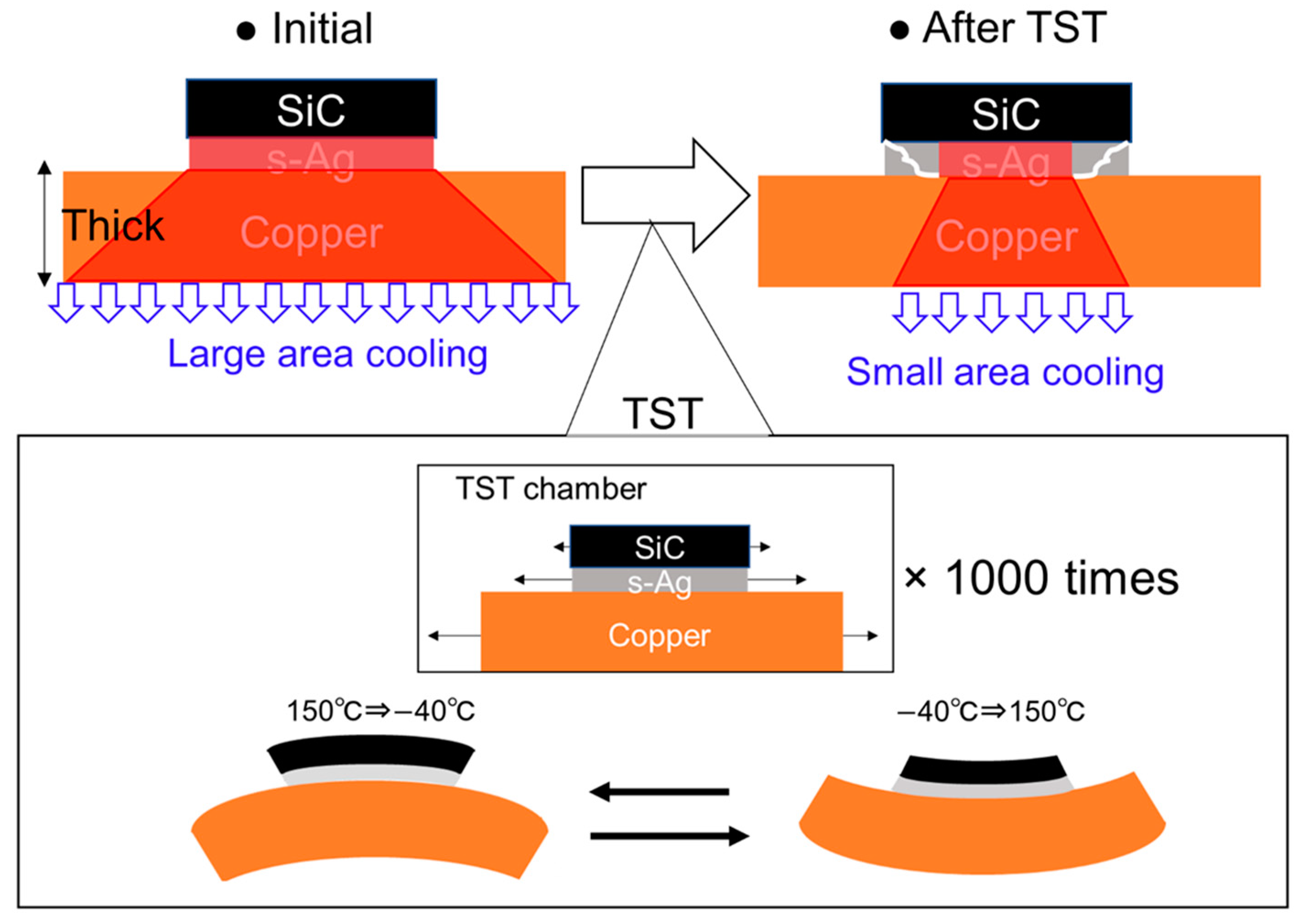

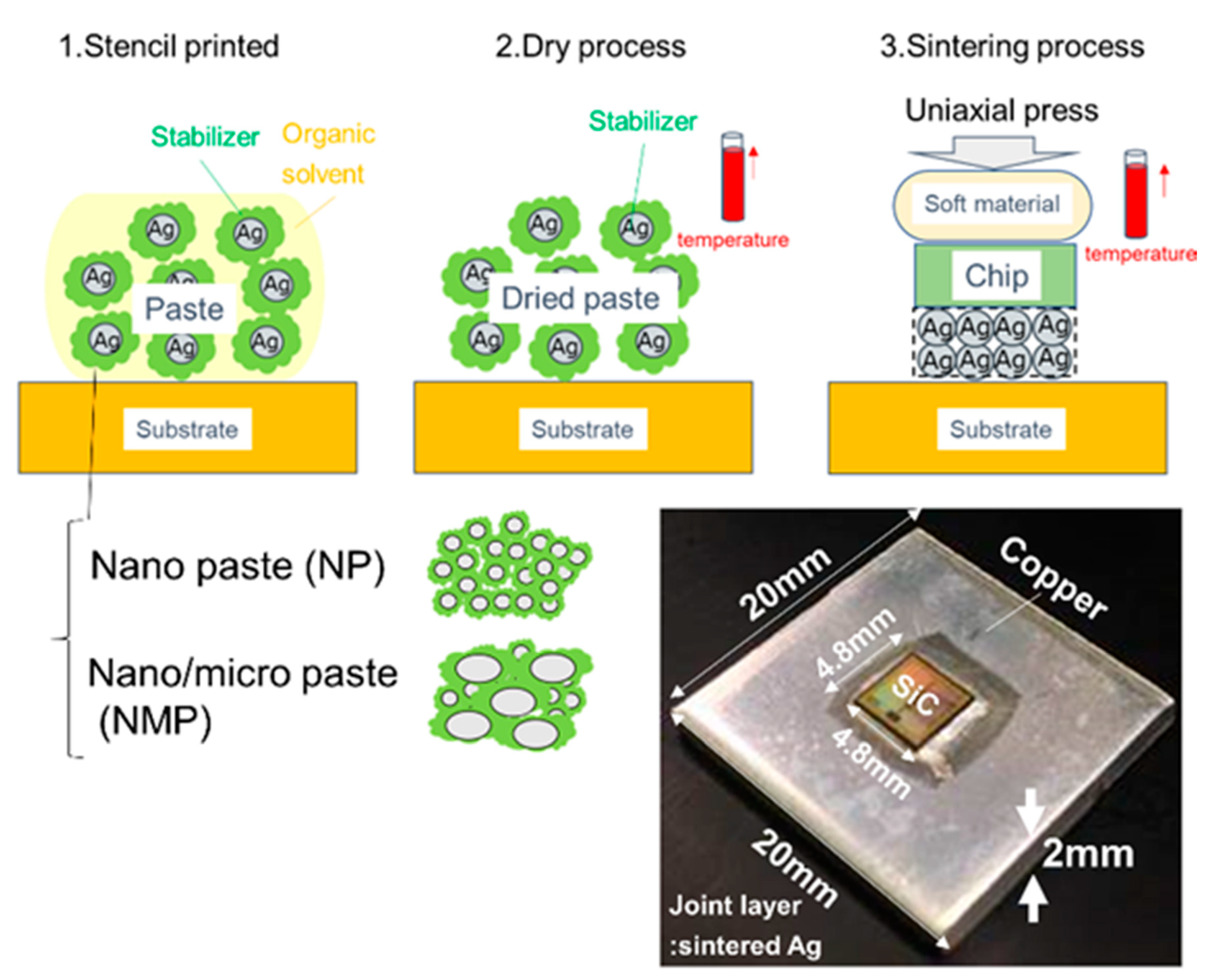

2. Materials and Methods

3. Results

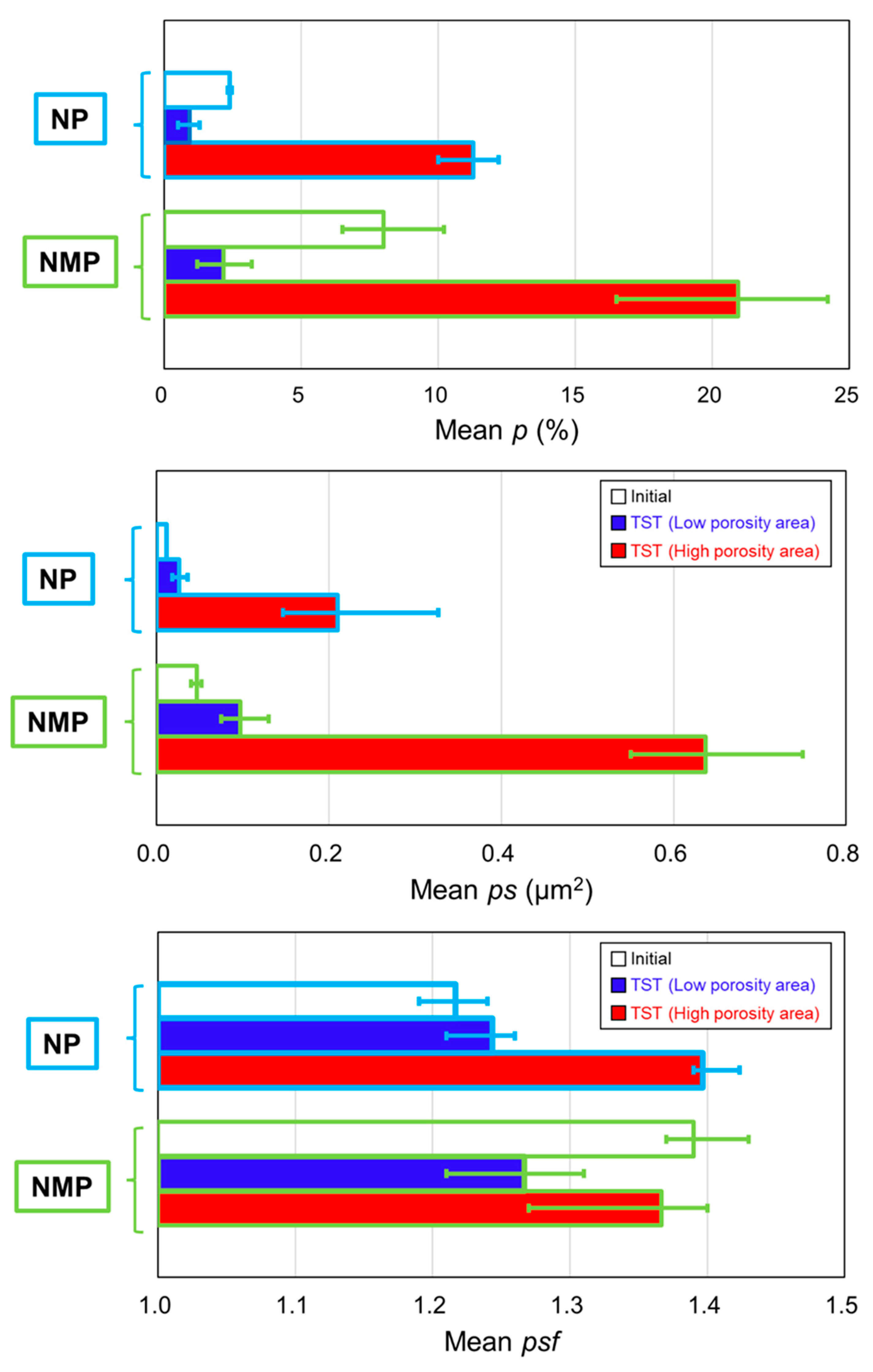

3.1. Microporous Structure of s-Ag

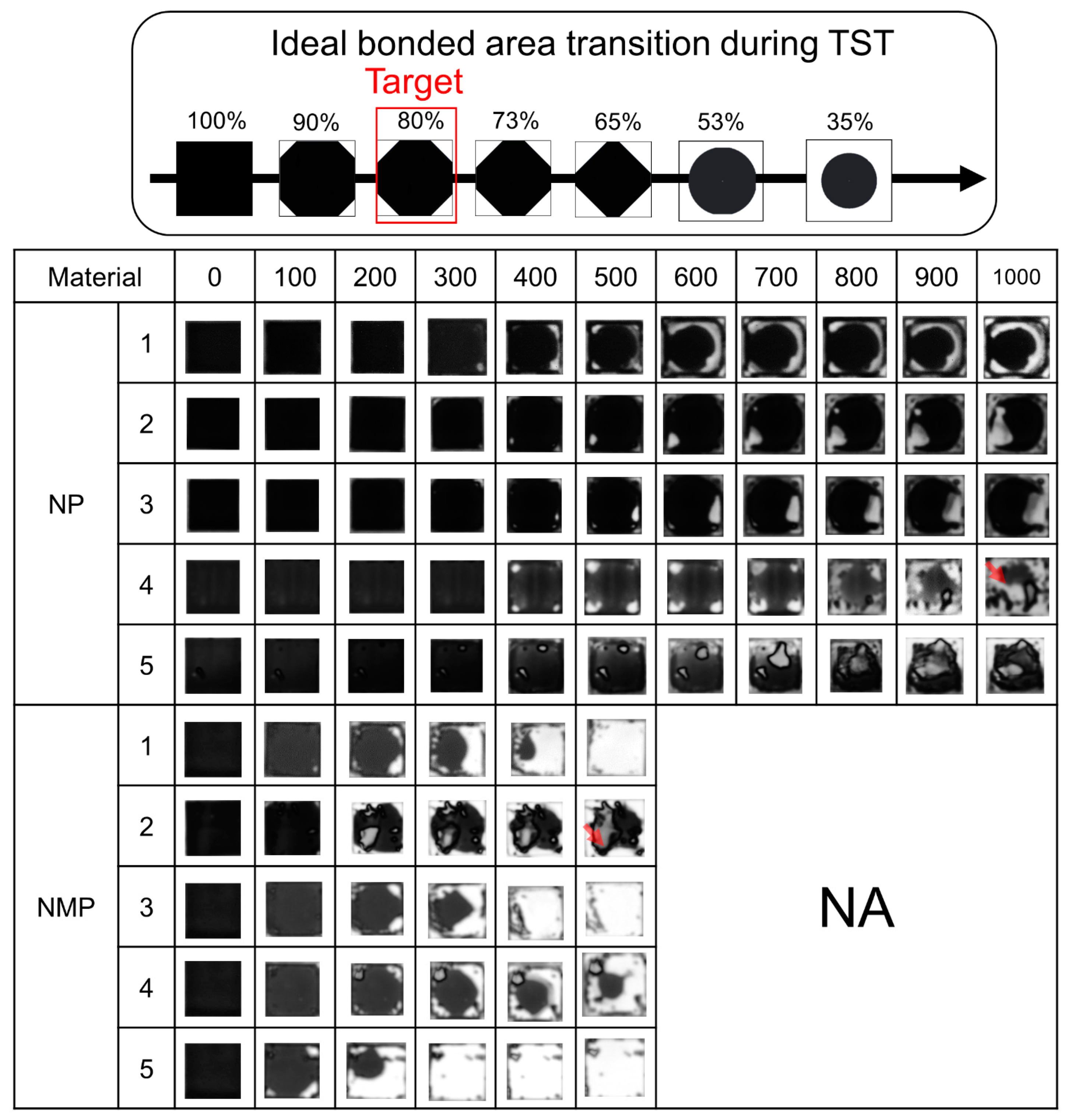

3.2. Thermal Shock Test Results with Scanning Acoustic Tomography Images

4. Discussion

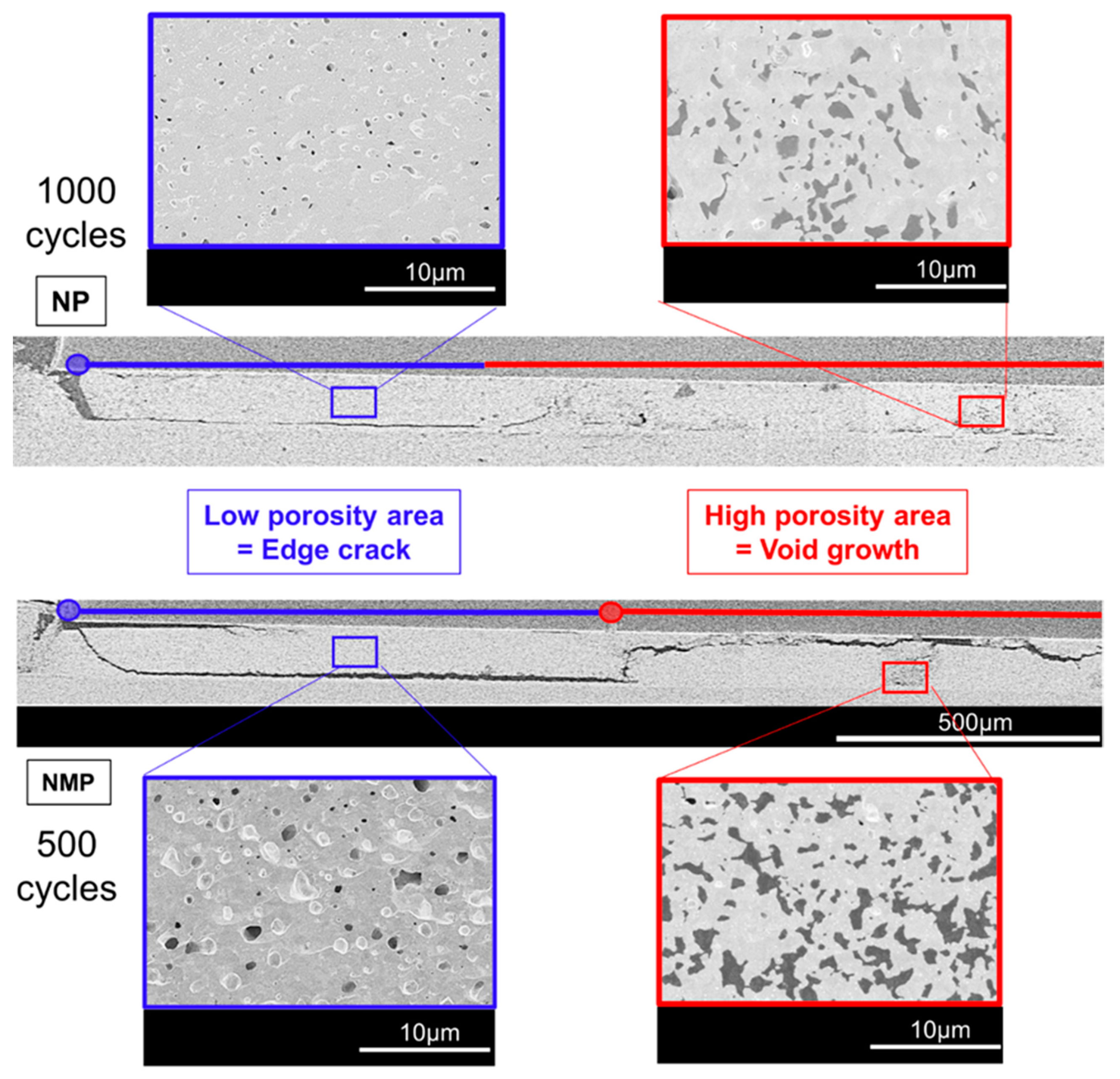

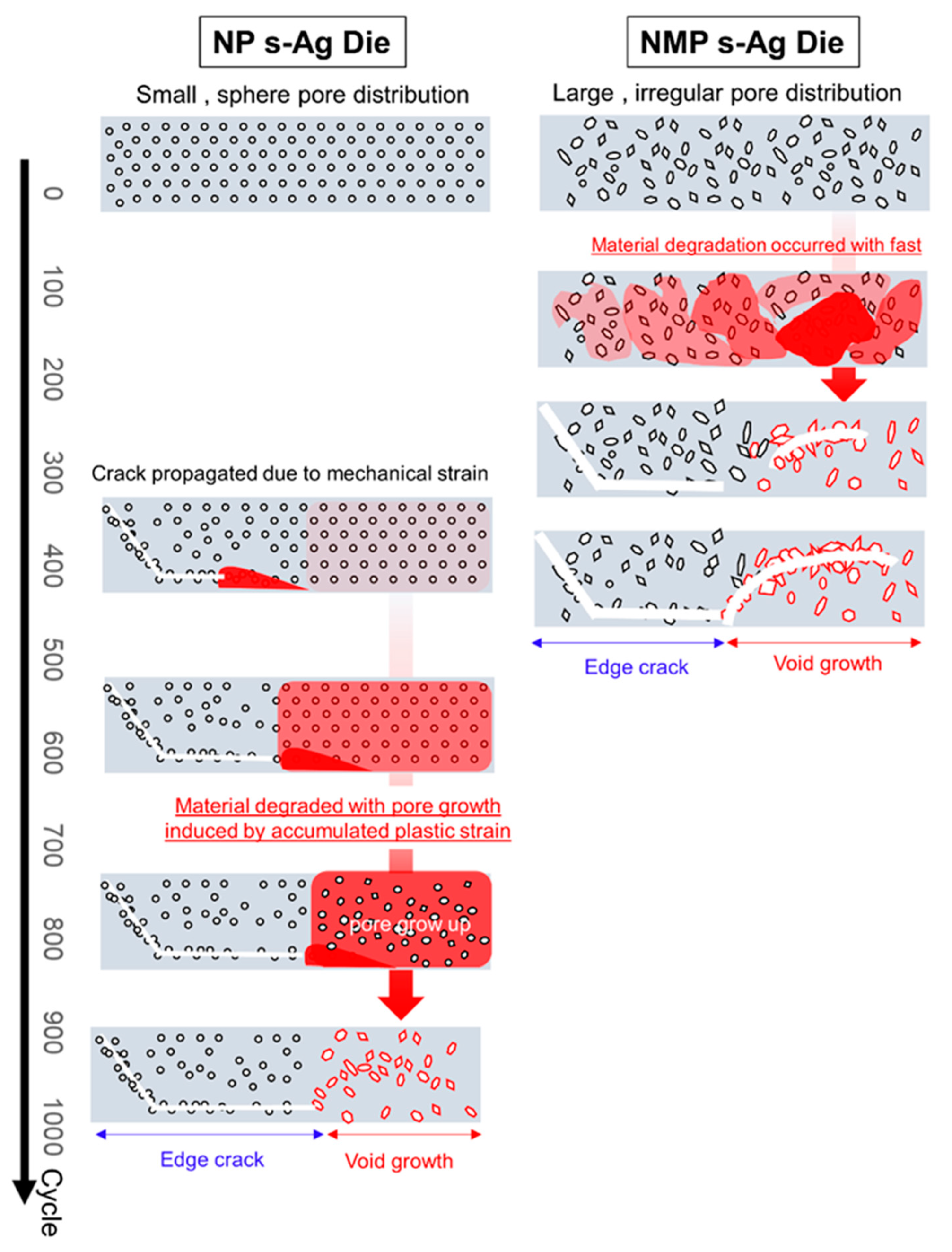

4.1. Cross-Section SEM Images after TST

4.2. Strain Distribution by Finite Element Analysis

4.3. Fracture Mechanism

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, F.C.; van Wyk, J.D.; Boroyevich, D.; Lu, G.Q.; Liang, Z.; Barbosa, P. Technology Trends Toward a System-in-a-module in Power electronics. IEEE Circuits Syst. Mag. 2002, 2, 4–22. [Google Scholar] [CrossRef]

- Tolbert, L.M.; King, T.J.; Ozpineci, B.; Campbell, J.B.; Muralidharan, G.; Rizy, G.; Sabau, D.T.; Zhang, A.S.; Zhang, H.W.; Xu, Y.; et al. Power Electronics for Distributed Energy Systems and Transmission and Distribution Applications; Techincal report No. ORNL/TM-2005/230; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2005. [Google Scholar]

- Siow, K.S. Are Sintered Silver Joints Ready for Use as Interconnect Material in Microelectronic Packaging? J. Elec. Mat. 2014, 43, 947–963. [Google Scholar] [CrossRef] [Green Version]

- Siow, K.S. Mechanical properties of nano-silver joints as die attach materials. J. Alloy. Compounds 2012, 514, 6–19. [Google Scholar] [CrossRef]

- Peng, P.; Hu, A.; Gerlich, A.P.; Zou, G.; Liu, L.; Zhou, Y.N. Joining of Silver Nanomaterials at Low Tempertures: Processes, Properties, and Applications. Appl. Mater. Interfaces 2015, 7, 12597–12618. [Google Scholar] [CrossRef] [PubMed]

- Bai, J.G.; Calata, J.N.; Lu, G.Q. Processing and Characterization of Nanosilver Pastes for Die-Attaching SiC Devices. IEEE Trans. Electron. Packag. Technol. 2007, 30, 241–245. [Google Scholar] [CrossRef]

- Wereszczak, A.A.; Vuono, D.J.; Wang, H.; Ferber, M.K.; Liang, Z.X. Properties of Bulk Sintered Silver as a Function of Porosity; Techincal report No. ORNL/TM-2012/130; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2012. [Google Scholar]

- Ordonez-Miranda, J.; Hermans, M.; Nikitin, I.; Kouznetsova, V.G.; van der Sluis, O.; Ras, M.A.; Reparaz, J.S.; Wagner, M.R.; Sledzinska, M.; Gomis-Bresco, J.; et al. Measurement and modeling of the effective thermal conductivity of sintered silver pastes. Int. J. Therm. Sci. 2016, 108, 185–194. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.J.; Chen, C.M.; Horng, R.H.; Wu, D.S.; Hong, J.S. Thermal management and interface properties in high-power GaN-based light-emitting diodes employing diamond-added Sn -3 wt.% Ag -0.5 wt.% Cu solder as a die-attach material. J. Elec. Mat. 2010, 39, 2618–2626. [Google Scholar] [CrossRef] [Green Version]

- Thomas, M. Die-attach materials and processes—A lead-free solution for power and high-power applications. Adv. Packag. 2007, 39, 32–34. [Google Scholar]

- McCluskey, F.P.; Dash, M.; Wang, Z.; Huff, D. Reliability of high temperature solder alternatives. Microelectron. Reliab. 2006, 39, 1910–1914. [Google Scholar] [CrossRef]

- Mohn, F.; Liu, C.; Schuderer, J. Reliable Interconnection Technologies for High-Temperature Operation of SiC MOSFETs. In Proceedings of the International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 16–18 May 2017. [Google Scholar]

- Gillot, C.; Schaeffer, C.; Massit, C.; Meysenc, L. Double-Sided Cooling for High Power IGBT Modules Using Flip Chip Technology. IEEE Trans. Comp. Packag. Technol. 2001, 24, 698–704. [Google Scholar] [CrossRef]

- Chabonaeu, B.C.; Wang, F.; Wyk, J.D.V.; Boroyevich, D. Double-Sided Liquid Cooling for Power Semiconductor Devices Using Embedded Power Packaging. IEEE Trans. Ind. Appl. 2005, 44, 1645–1655. [Google Scholar]

- Ishino, H.; Watanabe, T.; Tsuruta, K. 6-in-1 Silicon Carbide Power Module for High Performance of Power Electronics Systems. In Proceedings of the 26th International Symposium on Power Semiconductor Devices and Ics (ISPSD), Waikoloa, HI, USA, 15–19 June 2014. [Google Scholar]

- Yang, F.; Liang, Z.; Wang, Z.J.; Wang, F. Design of a low parasitic inductance SiC power module with double-sided cooling. In Proceedings of the 10th Annual IEEE Conference on Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 26–30 March 2017. [Google Scholar]

- Hussein, K.; Ishihara, M.; Miyamoto, N.; Nakata, Y.; Nakano, T. New Compact, High Performance 7th Generation IGBT Module with Direct Liquid Cooling for EV/HEV Inverters. In Proceedings of the 8th Annual IEEE Conference on Applied Power Electronics Conference and Exposition (APEC), Charlotte, NC, USA, 15–19 March 2015. [Google Scholar]

- Lee, H.; Smet, V.; Tummala, R. A Review of SiC Power Module Packaging Technologies: Challenges, Advances, and Emerging Issues. J. Emerg. Sel. Top. Electronics. 2020, 8, 239–255. [Google Scholar] [CrossRef]

- Schaal, M.; Klingler, M.; Metais, B.; Gruninger, R.; Hoffman, S.; Wunderle, B. Reliability Assessment of Ag Sintered Joints Using a SiC Semiconductor and Determination of Failure Mechanism in the Field of Power Electronics. In Proceedings of the 21st International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Cracow, Poland, 5–8 July 2020. [Google Scholar]

- Herboth, T.; Fruh, C.; Gunther, M.; Wilde, J. Assessment of Thermo-Mechanical Stresses in Low Temperature Joining Technology. In Proceedings of the 13th International Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems, Cascais, Portugal, 16–18 April 2012. [Google Scholar]

- Zabihzadeh, S.; Petegem, S.V.; Duarte, L.I.; Mokso, R.; Cervellino, A.; Swygenhoven, H.V. Deformation behavior of sintered nanocrystalline silver layers. Acta Mater. 2015, 97, 116–123. [Google Scholar] [CrossRef]

- Zabihzadeh, S.; Petegem, S.V.; Holler, M.; Diaz, A.; Duarte, L.I.; Swygenhoven, H.V. Deformation behavior of nanoporous polycrystalline silver. Part I: Microstructure and mechanical properties. Acta Mater. 2017, 131, 467–474. [Google Scholar] [CrossRef]

- Gadaud, P.; Caccuri, V.; Bertheau, D.; Carr, J.; Milhet, X. Aging sintered silver: Relationship between tensile behavior, mechanical properties and the nanoporous structure evolution. Mater. Sci. Eng. A 2016, 669, 379–386. [Google Scholar] [CrossRef]

- Suzuki, T.; Terasaki, T.; Kawana, Y.; Ishikawa, D.; Nishimura, M.; Nakako, H.; Kurafuchi, K. Effect of Manufacturing Process on Micro-Deformation Behavior of Sintered-Silver Die-Attach Material. IEEE Trans. Device Mater. Reliab. 2016, 16, 588–593. [Google Scholar] [CrossRef]

- Takesue, M.; Watanabe, T.; Tanaka, K.; Nakajima, N. Mechanical Properties and Reliability of Pressureless Sintered Silver Materials for Power Devices. In Proceedings of the International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 5–7 June 2018. [Google Scholar]

- Bai, J.G.; Chang, Z.Z.; Calata, J.N.; Lu, G.Q. Low-Temperature Sintered Nanoscale Silver as a novel Semiconductor Device-Metallized Substrate Interconnect Material. IEEE Trans. Device Mater. Reliab. 2006, 29, 589–595. [Google Scholar] [CrossRef]

- Wakamoto, K.; Mochizuki, Y.; Otsuka, T.; Nakahara, K.; Namazu, T. Tensile Mechanical properties of sintered porous silver films and their dependence on porosity. Jpn. J. Appl. Phys. 2019, 58, SDDL08-1–SDDL08-5. [Google Scholar] [CrossRef]

- Herboth, T.; Guenther, M.; Fix, A.; Wilde, J. Failure Mechanisms of Sintered Silver Interconnections for Power Electronic Applications. In Proceedings of the 63rd Electronic Components and Technology Conference, Las Vegas, NV, USA, 28–31 May 2013. [Google Scholar]

- Webber, C.; Dijk, M.V.; Walter, H.; Hutter, M.; Witter, O.; Lang, K.D. Combination of experimental and simulation methods for analysis of sintered Ag joints for high temperature applications. In Proceedings of the 66th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 31 May–3 June 2016. [Google Scholar]

- Wakamoto, K.; Mochizuki, Y.; Otsuka, T.; Nakahara, K.; Namazu, T. Temperature Dependence on Tensile Mechanical Properties of Sintered Silver Film. Materials 2020, 13, 4061. [Google Scholar] [CrossRef]

- Wakamoto, K.; Mochizuki, Y.; Otsuka, T.; Nakahara, K.; Namazu, T. The Influence of Mechanical Property on the Heat-Cycle Reliablity of Sintered Silver Die Attach. In Proceedings of the 32nd International Symposium on Power Semiconductor Devices and ICs (ISPSD), Vienna, Austria, 13–18 September 2020. [Google Scholar]

- Santopa, M.; Russo, S.; Torrsi, M.; Renna, M.; Sitta, A.; Calabretta, M. Fast transient thermomechanical stress to set a pressure-assisted sintering process. In Proceedings of the 15th Conference on Ph.D Research in Microelectronics and Electronics (PRIME), Lausanne, Switzerland, 15–18 July 2019. [Google Scholar]

- Calabretta, M.; Sitta, A.; Oliveri, S.M.; Sequenzia, G. Silver Sintering for Silicon Carbide Die Attach: Process Optimization and Structual Modeling. Appl. Sci. 2021, 11, 7012. [Google Scholar] [CrossRef]

- Calabretta, M.; Renna, M.; Vinciguerra, V.; Messina, A.A. Power Packages Interconnections for High Reliability Automotive Applications. In Proceedings of the 49th European Solid-State Device Research Conference (ESSDERC), Cracow, Poland, 23–26 September 2019. [Google Scholar]

- Anselmetti, F.S.; Luthi, S.; Eberli, G.P. Quantitative characterization of carbonate pore systems by digital image analysis. AAPG Bull. 1998, 82, 1815–1836. [Google Scholar]

| Material | Young’s Modulus (GPa) | Poisson’s Ratio | CTE (×10−6) |

|---|---|---|---|

| SiC | 412 | 0.17 | 3 |

| Copper | 118 | 0.35 | 16.8 |

| s-Ag (NP, NMP) |  | 0.35 | 19.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wakamoto, K.; Otsuka, T.; Nakahara, K.; Namazu, T. Degradation Mechanism of Pressure-Assisted Sintered Silver by Thermal Shock Test. Energies 2021, 14, 5532. https://doi.org/10.3390/en14175532

Wakamoto K, Otsuka T, Nakahara K, Namazu T. Degradation Mechanism of Pressure-Assisted Sintered Silver by Thermal Shock Test. Energies. 2021; 14(17):5532. https://doi.org/10.3390/en14175532

Chicago/Turabian StyleWakamoto, Keisuke, Takukazu Otsuka, Ken Nakahara, and Takahiro Namazu. 2021. "Degradation Mechanism of Pressure-Assisted Sintered Silver by Thermal Shock Test" Energies 14, no. 17: 5532. https://doi.org/10.3390/en14175532

APA StyleWakamoto, K., Otsuka, T., Nakahara, K., & Namazu, T. (2021). Degradation Mechanism of Pressure-Assisted Sintered Silver by Thermal Shock Test. Energies, 14(17), 5532. https://doi.org/10.3390/en14175532