Abstract

During the last decade, the application of pretreatment has been investigated to enhance methane production from lignocellulosic biomass such as wheat straw (WS). Nonetheless, most of these studies were conducted in laboratory batch tests, potentially hiding instability problems or inhibition, which may fail in truly predicting full-scale reactor performance. For this purpose, the effect of an alkaline pretreatment on process performance and methane yields from WS (0.10 g NaOH g−1 WS at 90 °C for 1 h) co-digested with fresh wastewater sludge was evaluated in a pilot-scale reactor (20 L). Results showed that alkaline pretreatment resulted in better delignification (44%) and hemicellulose solubilization (62%) compared to untreated WS. Pilot-scale study showed that the alkaline pretreatment improved the methane production (261 ± 3 Nm3 CH4 t−1 VS) compared to untreated WS (201 ± 6 Nm3 CH4 t−1 VS). Stable process without any inhibition was observed and a high alkalinity was maintained in the reactor due to the NaOH used for pretreatment. The study thus confirms that alkaline pretreatment is a promising technology for full-scale application and could improve the overall economic benefits for biogas plant at 24 EUR t−1 VS treated, improve the energy recovery per unit organic matter, reduce the digestate volume and its disposal costs.

1. Introduction

Currently, the demand for energy is continuously increasing due to worldwide population growth and rapid industrialization. Although fossil fuels are the main energy source, they are expensive and their reserves are slowly depleting, making the development of renewable energies an important step for worldwide sustainable development. For this purpose, the European Union has set the objective of achieving a 20% share of renewable energy in its overall energy consumption by 2020 (Directive 2009/28/CE, 2009). Among the renewable energy technologies, anaerobic digestion (AD) technology has gained interest during the last few decades as a robust technology that allows treatment of a large range of organic waste as sludges, agricultural residues, organic fraction of municipal solid wastes, algae, etc. [1,2]. The perspective of a low-cost process that turns organic wastes into biogas (composed primarily of methane and carbon dioxide), a source of renewable energy and profit, has certainly increased the interest around this technology [3]. Biogas can be further used for heat production, biofuels, or injected into the natural gas grid. At farm-scale, due to the geolocalization of the AD plant, biogas is generally converted into heat and electricity through a combined heat and power (CHP) plant. If the electricity is sold to the national public grid, the heat valorization at farm-scale is not optimal as part of the heat is lost to the ambient environment and can be therefore used for the pretreatment step [4].

Recently, to potentially improve methane production and reactor stability in the agricultural sector, anaerobic digestion of various substrates referred as “co-digestion process” has attracted attention. Previously, several co-digestion studies investigated treating different organic wastes such as agricultural wastes and wastewater sludges [5,6]. In particular, mixing of different organic substrates can result in a feed mixture with an optimal carbon to nitrogen (C/N) ratio of 20–30:1, and may supply nutrients that are missing from a single substrate and/or dilute toxic compounds from a single substrate to below the toxic thresholds for anaerobic microorganisms [5,7].

Nevertheless, AD of lignocellulosic substrates is often limited by the hydrolysis step, which converts the complex organic molecules into simpler molecules; for this purpose part of the organic matter, especially cellulose and lignin, are not degraded during the AD process [8,9]. As a result, only between 40% and 50% of the feedstock will be converted to biogas and the remaining biomass leaves the reactor undegraded, which will reduce the profitability of the AD plants, leading to further treatment/disposal [8]. For this purpose, the application of a pretreatment upstream from the anaerobic reactor to improve lignocellulose biodegradability and to optimize the methane production recovery has been investigated [1,10]. Pretreatments are generally classified as physical, thermochemical, biological, or a combination of them [2]. Many studies have been reported in the literature about the impact of lignocellulosic biomass pretreatment and in particular thermochemical pretreatment has been shown to improve the production of biogas [3,11]. Indeed, thermoacid pretreatments are used to solubilize carbohydrates, and alkaline pretreatment are known to be more effective in delignification and partial solubilization of hemicelluloses [3,11]. For instance, Sambusiti et al. (2013) reported a methane enhancement of 48% and 67%, respectively, with 1% and 10% NaOH (w/w TS) pretreatment of wheat straw at 100 °C [12]. Furthermore, thermochemical pretreatment of lignocellulosic residues at farm-scale could utilize the waste heat from the CHP plant the pretreatment.

Currently, most of these studies have been performed at batch-scale in BMP tests [2]. Although this method is useful and effective for determining methane potential at optimal conditions, it is risky to extrapolate the results to full-scale, as potential inhibition or instability cannot be detected [2]. To date, insufficient experimental data, especially using a laboratory-scale continuous reactor, are available in the literature to draw a clear conclusion on the economic feasibility and potential integration of thermoalkaline pretreatments at full industrial scale [11,13]. Therefore, process performance and methane yield during anaerobic co-digestion of sludge with alkaline-pretreated wheat straw (WS) was investigated in a pilot-scale mesophilic reactor. A sufficiently large-scale digester of 20 L was chosen to represent the real full-scale biogas plant. Finally, a preliminary energetic and economic assessment of the co-digestion process was also performed.

2. Materials and Methods

2.1. Raw Material

Wheat straw samples were collected from a farm in South of France. WS samples were first cut into 1–5 cm pieces by using a plant shredder (Viking GE250, Kufstein, Austria) and then milled to 0.75 mm particle size with a centrifugal mill (Retsch ZM 200, Haan, Germany). Finally, milled WS was stored at 6 ± 2 °C until further use.

Sludge from a wastewater treatment plant was collected after the centrifuge step at the wastewater treatment plant. The chemical composition of the sludge was as follows: VS/TS of 77.3 (±1)% and a pH of 7.8 ± 0.2. Sludge had an average methane potential of 205 ± 18 NmL CH4 g−1 VS.

2.2. Thermoalkaline Pretreatment

Thermoalkaline pretreatment was performed on the milled WS. WS was loaded in a glass reactor at a solid loading of 80 g straw/L and the solution was heated at 90 °C in a water bath for 1 h (upon the designed temperature reached). It should be noted that no external pressure was applied during the pretreatment. Approximately 30 min was required to attain the designed temperature of 90 °C. NaOH concentration of 10 g/100 g straw was used. Our conditions are in line with methodology of Sambusiti et al. [12], who reported that the typical pretreatment conditions for the thermoalkaline pretreatment of lignocellulosic biomass are 8–12% NaOH (based on dry matter content), 80 °C to 120 °C, and 30 min to 60 min. Pretreated WS was then used for BMP and semi-continuous pilot-scale reactor studies without pH adjustment. Furthermore, part of the pretreated WS was centrifuged (4500 rpm for 10 min) to obtain solid and liquid fractions for further chemical analysis.

2.3. Physicochemical Analysis

The untreated and pretreated samples were analyzed for total solids (TS) and volatile solids (VS) according to the APHA standard methods [14]; pH was monitored by using a WTW pH meter model Multi 340i. Fiber analysis was determined by the standard Van Soest method [15]. All analyses were performed in duplicate. Through this extractive process, soluble organic compounds, hemicelluloses, cellulose, and lignin and cutin were determined. Finally, the solubilized fraction during pretreatment was evaluated as the difference between the amount of organic matter present in the untreated WS and that found in the solid fraction of the pretreated WS. Total volatile fatty acids (TVFAs) and bicarbonates were determined according to the protocol published elsewhere [16]. Briefly, samples were collected from the pilot-scale reactor twice a week. They were prepared by diluting a 2 g sample with 50 g of distilled water; pH was adjusted to 5.1 first and then to 3.5 with 0.1 M sulfuric acid. Quantities of acid were used to estimate the TVFAs and bicarbonate concentrations. Ammonia was determined by spectrophotometric kits using a photometer PhotoLab S6 WTW. Elemental composition of WS was determined by an elemental analyzer (varioMicro V4.0.2, Elementar®, Langenselbold, Germany).

2.4. Biochemical Methane Potential

Untreated and pretreated WS samples were digested in 1 L glass bottles with a working volume of 600 mL. The substrate was mixed with an inoculum acclimated in the laboratory using a mixture of grass and sludge. The inoculum had a TS content of 3.7% with VS accounting for 65.5% ± 0.3 of TS. The pH and VFA content of the inoculum was 7.8 and 0.2 geq acetate/L, respectively. Each assay was loaded with 6 gVS substrate/L of inoculum. Tap water was used to achieve the desired working volume of 600 mL. Hydrochloric acid was used to adjust the pH to 7.5. Headspace in the assays was flushed with pure nitrogen (99.9%) to create anaerobic conditions and the bottles were hermetically sealed with butyl rubber stoppers and aluminum crimps. Assays were prepared in triplicate and incubated statically under mesophilic conditions (38 °C) in a thermostatically controlled water batch. Assays with inoculum alone were used as controls. Methane produced from the control assays were subtracted from the sample assays. Assays were mixed manually 5 days/week. Each assay was connected to a liquid-filled column containing an acidified water solution to quantify the biogas production by liquid displacement. The biogas composition (N2, H2S, O2, CH4, and CO2) was measured by infrared gas analyzer (Model Biogas Check de Geotechnical Instruments, United Kingdom).

To quantify the kinetic advantage of the pretreatment on anaerobic methane production, the first order kinetic constants were calculated by using least-squares fit of methane production data during time (t) to the following equation:

where B(t) is the volume of methane produced at time t(d), expressed in mL CH4 g−1 VS, Bo is the maximum producible methane volume (mL CH4 g−1 VS), and k is the hydrolysis kinetics constant (d−1). Bo and k were determined by using Microsoft Excel’s Solver function. The analysis of variance (ANOVA) method was used to analyze the impact of pretreatments; the confidence level considered was 95%.

B(t) = Bo (1 − e−kt)

2.5. Continuous Reactor Study

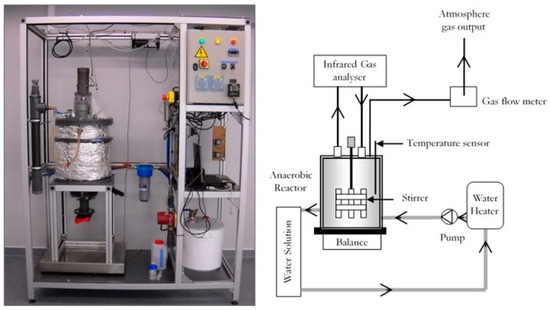

A pilot-scale continuously stirred tank reactor of 20 L working volume was operated under mesophilic condition (Figure 1). The reactor was placed on a metal frame and equipped with a balance for feed rate control, a stirring system, and a temperature control. The reactor temperature was maintained by circulation of hot water in the reactor jacket. The reactor contents were mixed by a mechanical stirrer connected to a motor. Stirrer speed, mixing duration, and frequency (80 rpm, 15 min h−1) were controlled by a programming module.

Figure 1.

Schematic view of the anaerobic digester pilot.

The reactor was operated at an organic loading rate (OLR) of 3 kg VS.m−3.d−1 and the hydraulic retention time (HRT) of 25 days. The feed was composed of sludge and WS (untreated or pretreated) at a ratio of 58–42% VS. This ratio was chosen according the previous studies reported in the literature [7]. Tap water was used to obtain a solid content of 10%wt TS to simulate a wet anaerobic digestion process. During the initial start-up, the reactor was operated with a mixture of wastewater sludge and milled straw for 4 weeks at an OLR increasing from 2 to 3 kg VS.m−3.d−1. Thereafter, the experiment was run in two stages.

- First stage (Phase 1): Feed composed of sludge and milled WS with an increase in OLR from 2 to 3 kg VS.m−3.d−1 (from week 1 to 4) and then to 3 kg VS.m−3.d−1 (from week 5 to 8) with an HRT of 25 days.

- Second stage (Phase 2): Feed composed of sludge and alkaline-pretreated WS with an OLR of 3 kg VS.m−3.d−1 (from week 9 to 15) and HRT of 24 days.

Each phase was operated for 2.5 HRT and is in agreement with previous studies [11,17]. The energy balance was calculated based on the results obtained during the last HRT of each operational phase.

2.6. Preliminary Energy Balance and Economic Analyses

A preliminary energy balance and economic analyses was carried out by comparing the extra operational energy/costs for the substrate pretreatment with that of the extra methane produced due to the thermoalkaline pretreatment of WS (Scenario 1) and was compared with untreated WS (Scenario 2). As a preliminary assumption, the electric energy consumption of the equipment/machines normally used to ground the substrates was not considered in this analysis, as it was assumed that these machines can be used even when untreated substrates are used.

The specific heat requirements (Eheat) to treat 1 ton of VS during thermoalkaline-pretreated WS from 25 to 70 °C were calculated as follows:

where Eheat (kWh t−1 VS) is the heat required for the thermal pretreatment of the substrate; m (kg) is the mass of water; Cp is the specific heat capacity of the mixture, assumed equal to the specific heat capacity of water (4.18 kJ kg−1 °C−1); Ta (°C) is the initial temperature of the substrate suspension, assumed as 25 °C; Tp (°C) is the final temperature of the substrate suspension, as 90° C; and 3600 is the conversion factor between kJ and kWh. In our calculation, it was considered that the thermoalkaline pretreatment is applied only on WS fraction accounting for 42% of the organic matter of the feeding. It was also assumed that the biogas produced is utilized for electricity and heat production in a CHP system with an electricity and thermal efficiency of 40% and 50%, respectively. A heat autoconsumption of 15% from the heat produced (150 kWh t−1 VS) was assumed based on literature data of a full-scale agricultural AD plant [13]. Normally, the electric energy produced by the CHP system is sold to the public grid at a fixed rate. For this purpose, a government incentive policy of 0.18 EUR kWhel−1 was considered for France. As for the cost of the chemical pretreatment, the European cost of the sodium hydroxide was used (420 EUR/ton ICIS).

Eheat, pretreatment = [m ∗ Cp ∗ (Tp − Ta)]/3600

3. Results and Discussion

3.1. Chemical Composition of Untreated and Pretreated Wheat Straw

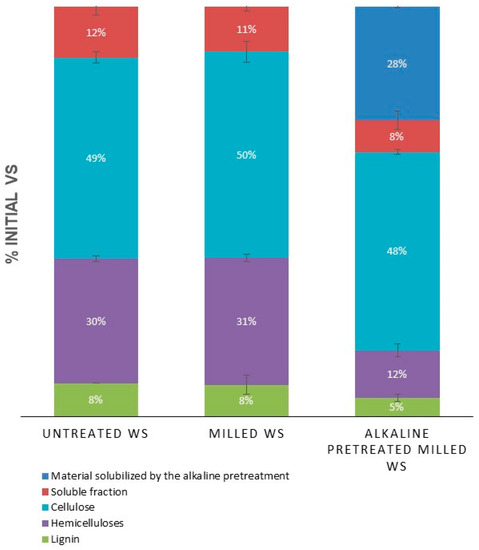

The WS samples had a VS/TS ratio of 95.9%. The WS was composed of 13% of soluble fraction, 30% of hemicelluloses, 49% of cellulose, and 8% of lignin and cutin. The C and N content in WS was 41% of TS and 0.6% of TS, respectively. The effects of the alkaline pretreatment on the chemical composition (% VS initial) of WS are presented in Figure 2.

Figure 2.

Chemical composition determined by Van Soest fractionation for untreated WS, milled WS, and alkaline-pretreated milled WS, expressed in terms of % initial VS. Values correspond to mean ± standard deviation of measurement performed in duplicate.

Untreated WS had a cellulose content of 49.1%, hemicellulose around 30.4%, lignin and cutin around 8.1%, and soluble fraction of 12.5% of initial VS. The corresponding values for milled WS were 50.3%, 31%, 7.7%, and 11.1% of initial VS. These results are in agreement with previous studies that demonstrated that mechanical fractionation of lignocellulosic biomass does not affect the chemical composition but affects the physical structure such as crystallinity and accessible surface area [18,19]. In contrast, alkaline pretreatment had a profound effect on the chemical composition of the milled WS. During the pretreatment, 26% of the VS was solubilized or reduced to small particle size. This is attributed mainly due to the solubilization of hemicelluloses and lignin [20,21]. Indeed, during the alkaline pretreatment, the decreases in lignin and hemicellulose fractions were 63% and 42% for the hemicelluloses fractions, respectively. On the contrary, the cellulose content remained more or less unchanged after the pretreatment. Alkaline pretreatments have shown to be efficient in lignin removal by preserving most of the carbohydrates, in particular cellulose [21,22]. The results are in accordance with previous studies that highlighted the efficiency of alkaline pretreatment in solubilizing a part of hemicelluloses [15,23]. Previously, alkaline pretreatment (24 h, 55 °C, 4% NaOH w/w TS) was shown to improve solubilization of lignin (by 36%) in sunflower stalks [15]. Similarly, Sun et al. [24] studied the effectiveness of different alkaline dosage on WS and reported that pretreatment of WS with 1.5% NaOH at 20 °C for 144 h had resulted in 60% and 80% of lignin and hemicelluloses removal, respectively.

3.2. Biochemical Methane Potential of Untreated and Alkaline-Pretreated WS

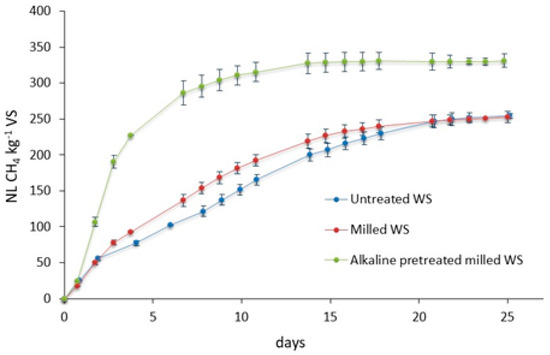

The impact of alkaline pretreatment on WS methane yields was studied in BMP tests. Figure 3 shows the cumulative methane production during BMP tests of untreated and alkaline-pretreated WS.

Figure 3.

Cumulative methane production (NL CH4 kg−1 VS) during BMP tests of untreated WS, milled WS, and alkaline-pretreated milled WS.

The methane yield from untreated WS was 251 NmL CH4 g−1 VS. Similar methane yields were also obtained with milled straw. However, no significant difference (<2%) in methane yields was noticed between untreated and milled WS. These results suggested that the mechanical fractionation did not affect the methane yields of WS. These results are in agreement with previous results where grinding WS from 759 to 48 µm had no influence on the methane yields of WS [25]. On the contrary, an increase in methane yield from 285 to 334 NmL CH4 g−1 VS with decrease in particle size from 5 to 0.2 cm of WS was reported [26]. Such discrepancy in methane yields could be attributed to the difference in mechanical size reduction process and/or WS variety used, which can influence the biodegradability of the pretreated biomass.

Pretreated WS had a methane yield of 330 ± 5 NmL CH4 g−1 VS and the yield was 31% higher than the yield obtained from untreated WS (Figure 3). This result agrees with previous studies reported in the literature [12,15,27]. For instance, Di Girolamo et al. [27] studied the effect of mild alkaline pretreatment for enhancing the methane yields of biomass crops and residues. The results from this study showed that the most recalcitrant substrate (giant reed) resulted in the highest increase (30%) in cumulative methane yield with NaOH 0.15 N compared with untreated giant reed (190 NmL CH4 g−1 VS) [27]. Conversely, the least recalcitrant substrate (sorghum fibers) resulted in the lowest increase (10%) (248 NmL CH4 g−1 VS) followed by 15% increase for an intermediate response of barley straw (232 NmL CH4 g−1 VS). Similarly, Monlau et al. [15] also studied the effect of various thermochemical pretreatments on sunflower stalks. Highest methane yields in this study (259 ± 6 NmL CH4 g−1 VS) was achieved when sunflower stalks were pretreated with 4% NaOH (w/w TS) at 55 °C for 24 h compared with 192 ± 2 NmL CH4 g−1 VS obtained for untreated sunflower stalks [15]. Recently, Chen et al. [28] investigated the effect of alkaline pretreatment (35 °C, 120 °C, 6% NaOH w/w TS) on asparagus stem and reported an increase in methane yields by 38% compared with untreated biomass [28]. Such results clearly demonstrate that the physicochemical modifications (reduction of lignin, improved organic matter solublization) generated by alkaline pretreatments facilitate to significantly improve the methane yields of WS.

Milling of WS did not significantly improve the hydrolysis kinetics, with values of 0.073 and 0.08 d−1 for milled and pretreated WS, respectively. Nonetheless, biogas production kinetics were significantly improved by NaOH pretreatment. Indeed, hydrolysis constants of 0.073 and 0.25 d−1 were obtained for untreated and pretreated WS (ANOVA p value < 0.05), respectively. Approximately 80% of the total biogas was produced within 12.5 days for the untreated and milled straw. The corresponding value for pretreated milled WS was 7.5 days. Therefore, alkaline pretreatment significantly increased the kinetics of anaerobic digestion. Improved biodegradability can further decrease the HRT or size of the reactor required to treat the same quantity of feedstock. Similar results have been reported during the alkaline pretreatment of lignocellulosic biomass [3,15]. For instance, an increase in the hydrolysis constants by 86% and 12% was reported for alkaline pretreatment of horse manure [3] and sunflower stalks [15].

3.3. Pilot-Scale Studies on the Effects of Alkaline Pretreatment on the Methane Production from WS

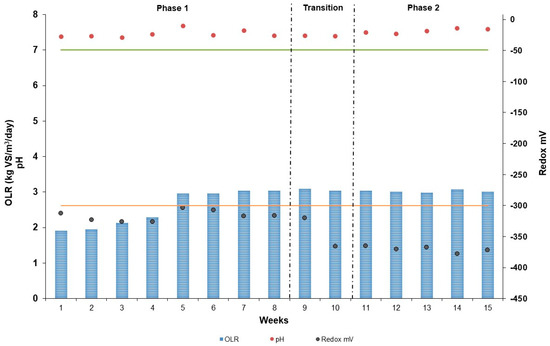

The effect of alkaline pretreatment on process performance and methane yields during the semi-continuous pilot-scale reactor studies was studied for 5 months and the results are presented in Figure 4, Figure 5 and Figure 6. Both quantity and the quality of the biogas produced during the pilot-scale experiment are presented for the two phases. Weeks 9 to 11 (Phase 2) are considered as weeks of transition between Phases 1 and 2. The results obtained during these two weeks were not included in the calculations of average values and standard deviations of the various chemical parameters that are presented below. For the calculation of the Phase 1, Weeks 5 to 8 were retained and for the Phase 2, Weeks 12 to 15 were retained (Figure 4).

Figure 4.

Organic loading rate (OLR), pH, and potential redox of the pilot scale reactor during the various running phases.

Figure 5.

Methane production and methane yield at pilot-scale with the three different phases (phase 1, transition, phase 2).

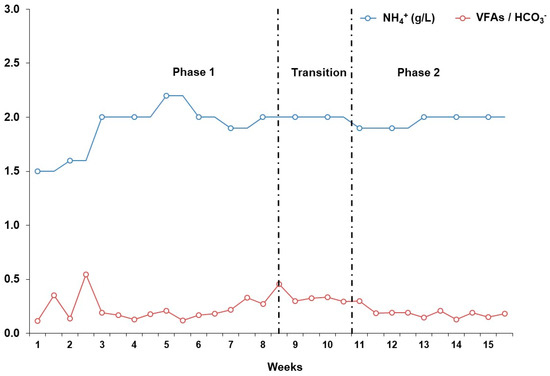

Figure 6.

Ammonium (NH4+) content and VFAs/HCO3− ratio during the different phases of the continuous pilot assay.

The methane content of the biogas increased slightly during the test run, ranging from 56.6% during Phase 1 to 60.1% during Phase 2. The average methane production for each phase was 201 ± 6 Nm3 CH4 t−1 VS (Phase 1) and 261 ± 3 Nm3 CH4 t−1 VS (Phase 2). The results clearly show an increase of the methane production by 30% for alkaline pretreatment.

Currently, only a few studies are available in the literature on the effect of pretreatment on process performance and methane yields in continuous reactors [2]. Sambusiti et al. [11] reported a 25% increase in methane yields after an alkaline pretreatement (0.10 g NaOH g−1 TS at 40 °C for 24 h) of sorghum forage. Similarly, Monlau et al. [13] reported a 26% increase in methane yields from alkaline-pretreated sunflower stalks in laboratory-scale CSTR reactors compared to control. Co-digestion of sewage sludge and enzymatic pretreated rice straw (1:0.5 TS basis) in continuous reactors (1.8 L) enhanced methane yields by 10% compared to the yields obtained from control containing sewage sludge and grinding rice straw [17]. Finally, Ahring et al. [8] reported an 357% increase in methane yields during the thermophilic anaerobic digestion of wet exploded feedlot manure in CSTR with an HRT of 10 days.

Figure 6 presents the measured ratio of the concentrations of TVFAs and bicarbonate during the experimentation. Feeding with alkaline-pretreated WS had resulted in an increase in bicarbonate content. The presence of soda allowed for maintaining a high alkalinity in the reactor. TVFAs/alkalinity ratio can be used as a measure of process stability—when TVFA/alkalinity ratio is less than 0.3–0.4, the process is considered to be stable without acidification risk [11]. In our study, the ratio TVFAs/HCO3− has decreased during the trial from 0.32 for Phase 1 to 0.17 for Phase 2. The ratio was lower or equal to 0.3 throughout the experimental run for both Phase 1 and 2. Similarly, Sambusiti et al. [11] reported a ratio TVFAs/alkalinity of 0.1 during the anaerobic digestion of alkaline-pretreated sorghum forage. The ammonia concentration of 2.1 ± 0.2 g NH4–N L−1 (Phase 1) and 2.0 ± 0.1 g NH4–N L−1 (Phase 2) were high but below the threshold levels reported to cause process inhibition (higher than 2.5 g NH4–N L−1) [11,29].

Table 1 presents the process performance during the steady-state of Phase 1 and 2 of the experimental run. The increased methane yield with pretreated WS was evident from the higher VS removal (51%) than without pretreatment (46%). As shown in Figure 4, pH was between 7.1 and 8.7 through the experimental run with an average value of 7.4 ± 0.2 for Phase 1 and 7.6 ± 0.1 for Phase 2. These results suggest that sodium hydroxide in the feed does not affect the pH of the reactor and is in agreement with the observation made by Sambusiti et al. [11]. Furthermore, the potential redox remained below −300 mV throughout the run, suggesting ideal conditions for the anaerobic digestion process and growth of anaerobic microbes.

Table 1.

Steady-state performances of the digesters (mean ± standard deviation) and organic matter removal during Phases 1 and 2.

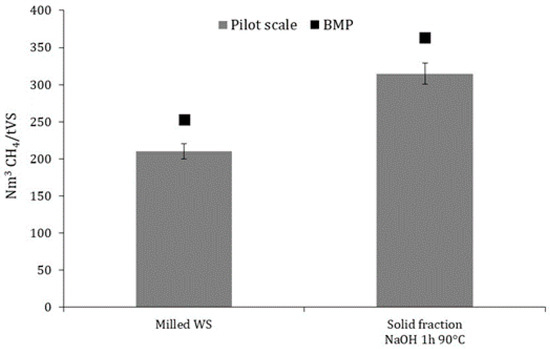

The comparison of the methane yields obtained from pilot-scale and laboratory-scale BMP studies is presented in Figure 7. Interestingly, theoretical methane production calculated from the results of BMP allowed a good estimation of methane produced from the pilot-scale reactor. For both process conditions, theoretical methane production calculated from the BMP values overestimated the experimental values of the pilot-scale trial. Indeed, methane production obtained from the pilot-scale reactor represented 83% and 88% of the BMP yields, respectively, for untreated and pretreated WS co-digested with sludge. Thus, it can be concluded that the BMP tests can accurately assess the methane production rates and yields of different organic wastes. Similarly, Sambusiti et al. [11] demonstrated that the methane yields obtained from a pilot-scale reactor were 86% and 88% of the BMP potential for untreated and pretreated sorghum forage, respectively.

Figure 7.

Comparison of methane potential (BMP vs. pilot-scale).

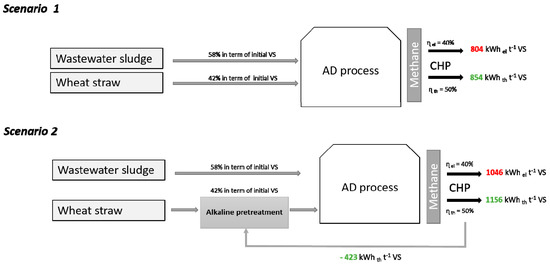

3.4. Energy and Economical Assessment

The economic and energy assessment of semi-continuous pilot-scale process was carried out and the results presented in Table 2 and in Figure 8. As shown in Table 2, a total energy of 2009 and 2614 kWh t VS−1 was obtained for S1 and S2, respectively. Use of biogas for generation of electricity and heat in a combined heat and power (CHP) system was evaluated. This option is consistent with the current practice across farm-scale biogas plants in Europe.

Table 2.

Energy and economical balances between Scenario S1 (control WS) and S2 (alkaline-pretreated WS).

Figure 8.

Energy and economical balances between Scenario S1 (control WS) and S2 (alkaline-pretreated WS).

Results showed that Scenario 2 generated surplus electricity of 242 kWhel t VS−1 compared with Scenario 1, where no pretreatment was used. The corresponding value for surplus heat production in Scenario 1 compared to Scenario 2 was 302 kWhth t VS−1. Thus, it is important to verify whether the surplus heat obtained in Scenario 1 was sufficient for the heat energy required for alkaline pretreatment. The calculated heat energy required for the pretreatment step in Scenario 2 was 423 kWhth t VS−1. In contrast, the heat energy required for the pretreatment with heat recovery was only 64 kWhth t VS−1. Thus, heat energy required for pretreatment can be covered by the heat produced from the CHP system. However, the heat energy required for pretreatment depended on the operational conditions such as temperature and solid loading (80 g/L in this study). Low heat energy requirement was noticed at the highest solid loading. Moreover, in the case of thermal pretreatment, it was demonstrated that part of the heat could be recovered when cooling down the biomass to heat the digester [30] or to preheat raw substrate suspension [31]. Such an option can be realized by means of a heat exchanger, with an efficiency of 85% [32]. Thus, surplus heat energy of 239 kWhth t VS−1 can be recovered in Scenario 2 (Table 2).

The economics of thermoalkaline-pretreatment implementation were considered and presented for Scenario 1 and Scenario 2 in Table 2. As the heat produced was sufficient to cover the heat energy requirements for pretreatment, the cost of heat energy for pretreatment in Scenario 2 was assumed as zero. The net economic gain for Scenario 2 was calculated by considering the NaOH cost and the sale of surplus electricity in Scenario 2 compared to Scenario 1. Considering these assumptions, an estimated net economic benefit of 24 EUR t−1 VS was obtained for Scenario 2. Besides the economic benefit, thermoalkaline pretreatment also improved the energy recovery per unit mass of organic matter, reducing the digestate produced and thus its disposal costs. However, the net economic benefit obtained in the present study was lower than that reported by Sambusiti et al. [11], who reported a net gain of 122 EUR t−1 VS with alkaline pretreatment (10% NaOH at 90 °C for 30 min) of WS. Such differences are mainly attributed to the difference in the government incentives and policies, e.g., with an Italian incentive of 0.28 EUR kWhel−1, and due to the higher methane yields obtained from the WS variety used in the above study. Thus, the net economic gain can vary among countries due to the differences in government incentives, biomass composition, pretreatment conditions, biogas process conditions, increased methane yields from the pretreatment, and the cost of the chemicals used in the study. In our study, the high cost of sodium hydroxide used in pretreatment could explain the low economic benefit. In the future, the possibility of sodium hydroxide recycling or to replace part of sodium hydroxide with a less expensive chemical such as calcium hydroxide will be assessed.

In the future, it will be also interesting to evaluate the digestate quality (in terms of heavy metals and potential emerging organic contaminants) and to assess potential phytotoxicity due to the pretreatment technology applied, as only few studies were reported in this direction [7,33,34]. It would also be interesting to investigate the impact of alkaline pretreatment on the potential shift in microbial communities in the anaerobic digester, as this has not been reported in the literature [7,35].

4. Conclusions

The effect of alkaline pretreatment on process performance and methane yield from wheat straw co-digested with sludge was investigated at pilot-scale. Results showed that alkaline pretreatment could improve the methane yield from pretreated WS. Methane yield of 261 ± 3 Nm3 CH4 t VS−1 was obtained from pretreated WS compared to 201 ± 6 Nm3 CH4 tVS−1 obtained from untreated WS. Furthermore, no inhibition was observed during the study. However, a high alkalinity was maintained in the reactor due to the NaOH used for pretreatment. Preliminary results on the energy balance and economical gain showed that the alkaline pretreatment for improving the methane yields from WS is feasible with better energy recovery per unit of WS. Furthermore, improved solubilization of organic matter also reduced the digestate volume and the costs associated for its disposal.

Author Contributions

C.P.: investigation, methodology, conceptualization, data curation, writing—review and editing; A.B.: conceptualization, writing—review and editing; C.L.: investigation, methodology, data curation; P.K.: writing—review and editing, supervision; F.M.: conceptualization, data curation, writing—review and editing, project administration, supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Nouvelle Aquitaine region, grant number 19R04.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We are grateful to the Nouvelle Aquitaine region for its financial support through the FEDER program, which allowed us to perform this assay.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| AD | Anaerobic digestion |

| BMP | Biochemical Methane Potential |

| CHP | Co-generation Heat and Power system |

| OLR | Organic Loading Rate |

| TS | Total Solids |

| TVFAs | Total Volatile Fatty Acids |

| VS | Volatile Solids |

| WS | Wheat Straw |

References

- Atelge, M.R.; Atabani, A.E.; Banu, J.R.; Krisa, D.; Kaya, M.; Eskicioglu, C.; Kumar, G.; Lee, C.; Yildiz, Y.Ş.; Unalan, S.; et al. A critical review of pretreatment technologies to enhance anaerobic digestion and energy recovery. Fuel 2020, 270, 117494. [Google Scholar] [CrossRef]

- Carrere, H.; Antonopoulou, G.; Affes, R.; Passos, F.; Battimelli, A.; Lyberatos, G.; Ferrer, I. Review of feedstock pretreatment strategies for improved anaerobic digestion: From lab-scale research to full-scale application. Bioresour. Technol. 2016, 199, 386–397. [Google Scholar] [CrossRef] [PubMed]

- Peyrelasse, C.; Kaparaju, P.; Lallement, A.; Marques, M.; Monlau, F. Reduction of the environmental footprint of thermo-alkali pretreatment by reusing black liquor during anaerobic digestion of lignocellulosic biomasses. Biofuels Bioprod. Biorefin. 2021, 15, 657–670. [Google Scholar] [CrossRef]

- Antoniou, N.; Monlau, F.; Sambusiti, C.; Ficara, E.; Barakat, A.; Zabaniotou, A. Contribution to Circular Economy options of mixed agricultural wastes management: Coupling anaerobic digestion with gasification for enhanced energy and material recovery. J. Clean. Prod. 2019, 209, 505–514. [Google Scholar] [CrossRef]

- Aboudi, K.; Gómez-Quiroga, X.; Álvarez-Gallego, C.J.; Romero-García, L.I. Insights into anaerobic co-digestion of ligno-cellulosic biomass (sugar beet by-products) and animal manure in long-term semi-continuous assays. Appl. Sci. 2020, 10, 5126. [Google Scholar] [CrossRef]

- Chow, W.L.; Chong, S.; Lim, J.W.; Chan, Y.J.; Chong, M.F.; Tiong, T.J.; Chin, J.K.; Pan, G.-T. Anaerobic Co-Digestion of Wastewater Sludge: A Review of Potential Co-Substrates and Operating Factors for Improved Methane Yield. Processes 2020, 8, 39. [Google Scholar] [CrossRef] [Green Version]

- Elalami, D.; Carrere, H.; Monlau, F.; Abdelouahdi, K.; Oukarroum, A.; Barakat, A. Pretreatment and co-digestion of wastewater sludge for biogas production: Recent research advances and trends. Renew. Sustain. Energy Rev. 2019, 114, 109287. [Google Scholar] [CrossRef]

- Ahring, B.K.; Biswas, R.; Ahamed, A.; Teller, P.J.; Uellendahl, H. Making lignin accessible for anaerobic digestion by wet-explosion pretreatment. Bioresour. Technol. 2015, 175, 182–188. [Google Scholar] [CrossRef]

- Santi, G.; Proietti, S.; Moscatello, S.; Stefanoni, W.; Battistelli, A. Anaerobic digestion of corn silage on a commercial scale: Differential utilization of its chemical constituents and characterization of the solid digestate. Biomass Bioenergy 2015, 83, 17–22. [Google Scholar] [CrossRef]

- Millati, R.; Wikandari, R.; Ariyanto, T.; Putri, R.U.; Taherzadeh, M.J. Pretreatment technologies for anaerobic digestion of lignocelluloses and toxic feedstocks. Bioresour. Technol. 2020, 304, 122998. [Google Scholar] [CrossRef]

- Sambusiti, C.; Ficara, E.; Malpei, F.; Steyer, J.P.; Carrère, H. Benefit of sodium hydroxide pretreatment of ensiled sorghum forage on the anaerobic reactor stability and methane production. Bioresour. Technol. 2013, 144, 149–155. [Google Scholar] [CrossRef] [PubMed]

- Sambusiti, C.; Monlau, F.; Ficara, E.; Carrère, H.; Malpei, F. A comparison of different pre-treatments to increase methane production from two agricultural substrates. Appl. Energy 2013, 104, 62–70. [Google Scholar] [CrossRef]

- Monlau, F.; Kaparaju, P.; Trably, E.; Steyer, J.-P.; Carrere, H. Alkaline pretreatment to enhance one-stage CH4 and two-stage H2/CH4 production from sunflower stalks: Mass, energy and economical balances. Chem. Eng. J. 2015, 260, 377–385. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater, 21st ed.; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- Monlau, F.; Barakat, A.; Steyer, J.P.; Carrere, H. Comparison of seven types of thermo-chemical pretreatments on the structural features and anaerobic digestion of sunflower stalks. Bioresour. Technol. 2012, 120, 241–247. [Google Scholar] [CrossRef]

- Anderson, G.K.; Yang, G. Determination of bicarbonate and total volatile acid concentration in anaerobic digesters using a simple titration. Water Environ. Res. 1992, 64, 53–59. [Google Scholar] [CrossRef]

- Komatsu, T.; Kudo, K.; Inoue, Y.; Himeno, S. Anaerobic codigestion of sewage sludge and rice straw. In Proceedings of the Moving Forward Wastewater Biosolids Sustainability: Technical, Managerial, and Public Synergy, Moncton, NB, Canada, 24–27 June 2007; pp. 495–501. [Google Scholar]

- Barakat, A.; De Vries, H.; Rouau, X. Dry fractionation process as an important step in current and future lignocellulose biorefineries: A review. Bioresour. Technol. 2013, 134, 362–373. [Google Scholar] [CrossRef]

- Barakat, A.; Mayer-Laigle, C.; Solhy, A.; Arancon, R.A.D.; de Vries, H.; Luque, R. Mechanical pretreatments of lignocellulosic biomass: Towards facile and environmentally sound technologies for biofuels production. RSC Adv. 2014, 4, 48109–48127. [Google Scholar] [CrossRef]

- Monlau, F.; Barakat, A.; Trably, E.; Dumas, C.; Steyer, J.-P.; Carrère, H. Lignocellulosic Materials into Biohydrogen and Biomethane: Impact of Structural Features and Pretreatment. Crit. Rev. Environ. Sci. Technol. 2013, 43, 260–322. [Google Scholar] [CrossRef]

- Taherzadeh, M.J.; Karimi, K. Pretreatment of Lignocellulosic Wastes to Improve Ethanol and Biogas Production: A Review. Int. J. Mol. Sci. 2008, 9, 1621–1651. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Wan, C.; Li, Y. Enhanced solid-state anaerobic digestion of corn stover by alkaline pretreatment. Bioresour. Technol. 2010, 101, 7523–7528. [Google Scholar] [CrossRef]

- Xie, S.; Frost, J.P.; Lawlor, P.G.; Wu, G.; Zhan, X. Effects of thermo-chemical pre-treatment of grass silage on methane production by anaerobic digestion. Bioresour. Technol. 2011, 102, 8748–8755. [Google Scholar] [CrossRef]

- Sun, R.; Lawther, J.M.; Banks, W.B. Influence of alkaline pre-treatments on the cell wall components wheat straw. Ind. Crop Prod. 1995, 4, 127–145. [Google Scholar] [CrossRef]

- Dumas, C.; Silva Ghizzi Damasceno, G.S.; Barakat, A.; Carrere, H.; Steyer, J.-P.; Rouau, X. Effects of grinding processes on anaerobic digestion of wheat straw. Ind. Crop Prod. 2015, 74, 450–456. [Google Scholar] [CrossRef] [Green Version]

- Menardo, S.; Airoldi, G.; Balsari, P. The effect of particle size and thermal pre-treatment on the methane yield of four agricultural by-products. Bioresour. Technol. 2012, 104, 708–714. [Google Scholar] [CrossRef] [PubMed]

- Di Girolamo, G.; Bertin, L.; Capecchi, L.; Ciavatta, C.; Barbanti, L. Mild alkaline pre-treatments loosen fibre structure enhancing methane production from biomass crops and residues. Biomass Bioenergy 2014, 71, 318–329. [Google Scholar] [CrossRef]

- Chen, X.; Gu, Y.; Zhou, X.; Zhang, Y. Asparagus stem as a new lignocellulosic biomass feedstock for anaerobic digestion: Increasing hydrolysis rate, methane production and biodegradability by alkaline pretreatment. Bioresour. Technol. 2014, 164, 78–85. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Cheng, J.J.; Creamer, K.S. Inhibition of anaerobic digestion process: A review. Bioresour. Technol. 2008, 99, 4044–4064. [Google Scholar] [CrossRef] [PubMed]

- Zábranská, J.; Dohányos, M.; Jeníček, P.; Kutil, J. Disintegration of excess activated sludge—Evaluation and experience of full-scale applications. Water Sci. Technol. 2006, 53, 229–236. [Google Scholar] [CrossRef]

- Bougrier, C.; Delgenès, J.P.; Carrère, H. Impacts of thermal pre-treatments on the semi-continuous anaerobic digestion of waste activated sludge. Biochem. Eng. J. 2007, 34, 20–27. [Google Scholar] [CrossRef]

- Passos, F.; Ferrer, I. Microalgae Conversion to Biogas: Thermal Pretreatment Contribution on Net Energy Production. Environ. Sci. Technol. 2014, 48, 7171–7178. [Google Scholar] [CrossRef]

- Luste, S.; Heinonen-Tanski, H.; Luostarinen, S. Co-digestion of dairy cattle slurry and industrial meat-processing by-products—Effect of ultrasound and hygienization pre-treatments. Bioresour. Technol. 2012, 104, 195–201. [Google Scholar] [CrossRef] [PubMed]

- Misson, G.; Mainardis, M.; Incerti, G.; Goi, D.; Peressotti, A. Preliminary evaluation of potential methane production from anaerobic digestion of beach-cast seagrass wrack: The case study of high-adriatic coast. J. Clean. Prod. 2020, 254, 120131. [Google Scholar] [CrossRef]

- Misson, G.; Mainardis, M.; Marroni, F.; Peressotti, A.; Goi, D. Environmental methane emissions from seagrass wrack and evaluation of salinity effect on microbial community composition. J. Clean. Prod. 2021, 285, 125426. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).