4.1. Description and Parameters of Possible Waste Heat Sources

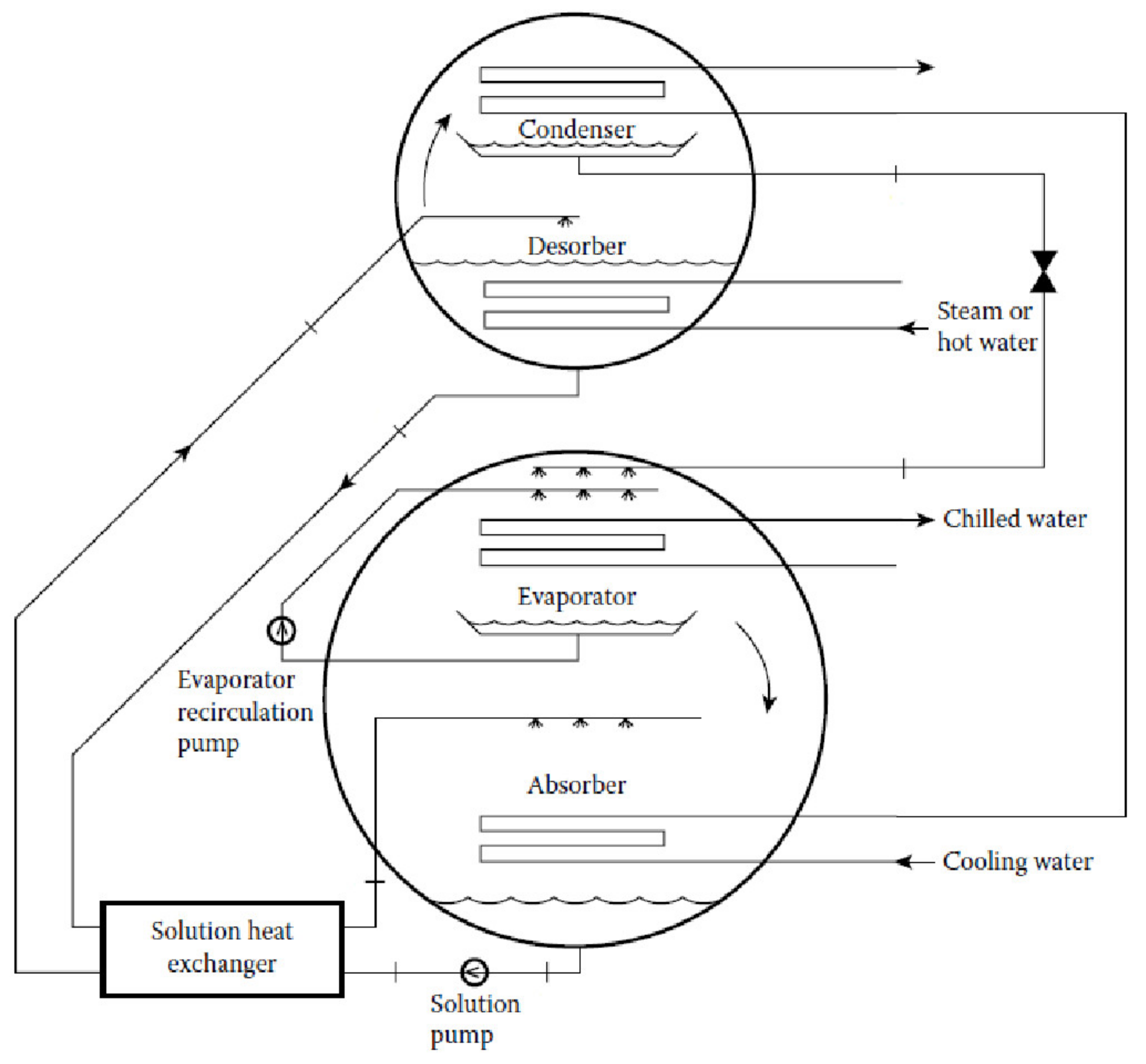

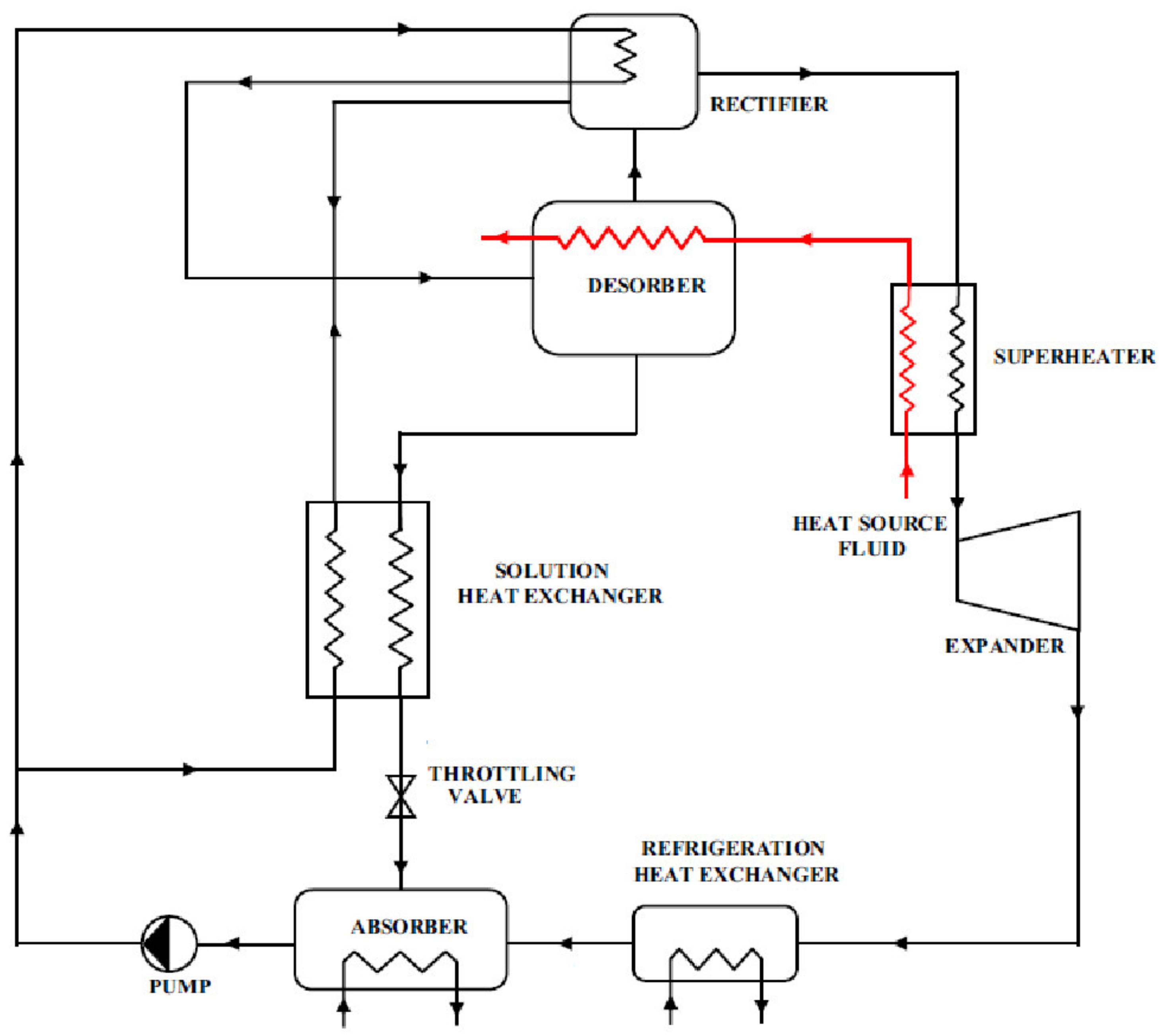

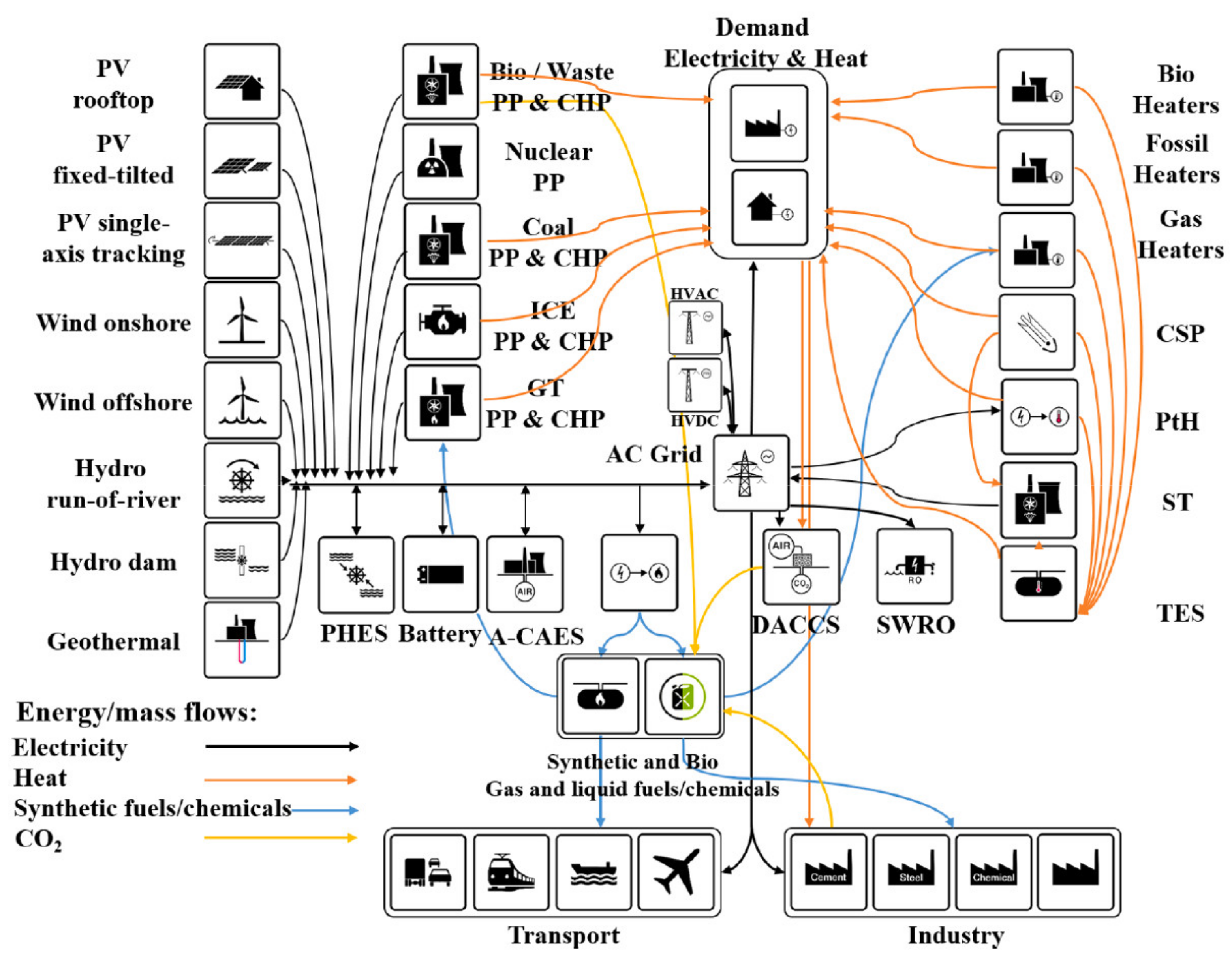

Despite the integration of sectors through bridging technologies, as introduced in

Section 3, each energy sector within the LUT model has its characteristics, infrastructure, and processes. For that reason, it is possible to find different potential waste heat sources not only when making comparisons between sectors but also within each sector. By way of examples, in the power sector, it is possible to find photovoltaic thermal panels, the charging/discharging processes within PV batteries (PVB), and waste heat from CSP plants. The heat sector has large CHP plants and thermal storage technologies [

71]. Within the transportation sector, the exhaust gases from heavy-duty ICE-driven vehicles might be considered a good example. In the case of the industry sector, it depends mainly on the subsegment, but cement, steel, and aluminum are great energy consumers and, therefore, have a higher potential to release larger amounts of waste. However, in the context of feeding small–medium CHP technologies, not every waste heat source has the potential to drive them, at least from the point of its temperature level.

In order to evaluate the potential of a given heat source feed a small–medium CHP plant, this paper adopts the following methodology, divided into two steps. First, it is necessary to define a parameter that is used to evaluate a specific waste heat. For this work, it is temperature level. Second, gather the data of the feeding temperature level of the CHP technologies, presented in

Section 2, with their respective output values. Therefore,

Table 5 presents the waste heat sources selected in

Section 3.5 with their respective parameters for evaluation. These parameters are not provided by the LUT model. It is defined, selected, and reviewed by this work.

As can be observed in

Table 5, for PVB, the selected parameter was the battery temperature, i.e., the temperature level resulted from charging/discharging processes. PVT panels provide an output temperature, which is from the heated water coming from a set of pipes underneath the solar PV panel. Geothermal (GTH) power plants have the condensate or brine reinjection temperature, that is, the temperature of the geothermal fluid right before being reinjected into the well. For SWH, which have an intuitive name, the water output temperature from the water tank was selected. For steam turbine (ST) based power plants, the selected parameter was the turbine output temperature. The designated parameters for gas turbines (GT) were the turbine output temperature and the HRSG (Heat Recovery Steam Generator) output temperature. Generally, GT output temperature is relatively high (around 500 to 600 °C) and, for that reason, GT is commonly part of a large CHP plant that uses this high temperature to feed other systems, as for example, ST-based cycles. ICE-based CHP plants are considered here since they can also be powered by renewable fuels, such as bio and synthetic gas. Its parameter is the temperature of the exhaust gases and, in some cases, the coolant water temperature. The values reviewed for each parameter of

Table 5 are presented from

Table 6,

Table 7,

Table 8,

Table 9,

Table 10 and

Table 11.

Table 6 presents battery temperature values from various references. The maximum temperature was 55 °C [

72] and the lowest 25 °C [

79], which are quite low temperature levels when considering power small CHP heat recovery technologies. Besides, almost all papers reported battery issues when raising its temperature. For that reason, the heat released by PVB would not be an option for the proposed analysis of this work. A similar situation happened to PVT (

Table 7) and solar water heater (

Table 8). For PVT, the highest water output temperature was 80 °C; however, the authors state that the higher this temperature, the lower the electrical efficiency. Thus, from PVT references, it can reach an average water output temperature of 46 °C, which is also quite low for small CHP heat recovery technologies.

Solar water heaters achieved a slightly higher average water output temperature of 58 °C, but its exergy content is still very poor, even if the time variation in the environmental temperature were taken into account in the exergy calculations [

82,

83]. Therefore, the exploitation of this waste heat for power production or for feeding some small CHP technologies is not feasible in practice. In some cases, depending on the demand constraints, it could feed a space heating system [

84].

Table 7.

Literature review of the values for PVT selected parameter.

Table 7.

Literature review of the values for PVT selected parameter.

| Reference | Water Output Temperature (°C) | Notes |

|---|

| Fudholi et al., 2014 [85] | 53.6 | Maximum achieved among three analyzed types |

| Kumar et al., 2015 [86] | From 30 to 80 | However, electrical efficiency drops for higher temperatures |

| Liang et al., 2015 [87] | 38 | Maximum achieved in a typical day |

| Yazdanpanahi et al., 2015 [88] | 27 | Ambient temperature around 17 °C |

| Fudholi et al., 2014 [89] | 45 | The highest achieved for a PVT air collector |

| Kazemian et al., 2019 [90] | 55 | Maximum achieved through a CFD analysis |

| Al-Musawi et al., 2019 [91] | 35 | In combination with Phase Change Materials |

| Islam et al., 2021 [92] | 46 | At the lower flow rate and with Phase Change Materials |

| Kazemian et al., 2021 [93] | 42 | For an improved PVT configuration |

| Alsalame et al., 2021 [94] | 43.4 | Maximum achieved among three studied cases |

As mentioned before, the selected parameter for the geothermal heat source was the brine reinjection temperature (BRT). The temperature of the brine, right before its reinjection back into the well, represents an exergy level that could be used for something else, depending on that level. Of course, it should be noted here that it was considered that a major percentage of the brine exergy content was already used throughout the geothermal power plant and that the technical feasibility of recovering the brine reinjection temperature was neglected in this study.

Table 8.

Literature review of the values for Solar Water Heater selected parameter.

Table 8.

Literature review of the values for Solar Water Heater selected parameter.

| Reference | Water Output Temperature (°C) | Notes |

|---|

| Liu et al., 2012 [95] | 65 | Configuration with eight tanks connected in series |

| Fazilati and Alemrajabi 2013 [96] | 50 | On average and using Phase Change Materials |

| Sathyamurthy et al., 2015 [97] | 60 and 65 | Maximum during winter and summer, respectively |

| Xue 2016 [98] | 40 | Maximum and using Phase Change Materials |

| Assari et al., 2018 [99] | 49 | Maximum achieved among seven studied cases |

| Mandal et al., 2020 [100] | 61.8 | Maximum and using Phase Change Materials |

| Mandal et al., 2020 [101] | 74.7 | Performance investigation of an improved configuration |

Table 9.

Literature review of the values for geothermal selected parameter.

Table 9.

Literature review of the values for geothermal selected parameter.

| Reference | Brine Reinjection Temperature (°C) | Notes |

|---|

| Britvin et al., 2000 [102] | 50 | - |

| Kanoglu et al., 2008 [103] | 90 | Binary geothermal power plant |

| Keçebaş et al., 2011 [104] | 50 | Geothermal district heating for building application |

| Gabbrielli 2012 [105] | 70 | Binary geothermal power plant with an ORC |

| Srinivas et al., 2014 [106] | 45 | Integration of geothermal and biomass power plant |

| Clarke and McLeskey 2015 [107] | 90 | Optimization of a binary geothermal power plant |

| Sinaga and Manik 2018 [108] | 39 | Optimization through simulating wet bulb temperature fluctuation |

| Prananto et al., 2018 [109] | 113 | Configuration using Kalina as a bottoming cycle |

| Song et al., 2019 [110] | 25 | Geothermal integration to district heating substations |

| Garapati et al., 2020 [111] | 50 and 100 | Lowest and highest values achieved for a hybrid geothermal power plant |

Table 9 shows the values of brine reinjection temperature found in the literature. As one can see, the average brine reinjection temperature was 67 °C, which means that in some cases, it is possible to feed just a space heating system, but in other ones, it is possible to power a small size heat recovery CHP technology. That would be the case of Prananto et al. [

109] with the brine reinjection temperature at 113 °C. However, when it comes to geothermal brine, some problems might arise if its temperature is lowered beyond a certain threshold. For instance, scaling problems [

105] would hamper the heat exchange rate, and the decline of geothermal well temperature [

107] would affect the long-term plant effectiveness. Hence, recovering the brine reinjection temperature would be possible in some cases, despite being complicated from a practical point of view, even though it is considered in the analysis of

Section 4.2.

Table 10 indicates the selected parameters for GT and ST and gathers generation and cogeneration power plants powered by different sources, such as natural gas, biomass, heat recovery, solar, and hydrogen. In the case of GT, the selected parameter is the output temperature of the exhaust gases. As indicated, GT output temperature values demonstrate that this waste heat source has a substantially high temperature level (average of 567.7 °C). For that reason, this is commonly used to feed another thermal system in order to increase the overall efficiency; however, it is a too-high temperature level for small–medium CCHP technologies. Therefore, GT output temperature is not considered in the analysis of

Section 4.2. On the other hand, a plausible source of waste heat is the exhaust gas of an HRSG system, which is usually integrated into a GT system and operates with the same exhaust gases from the GT output. The average temperature of the HRSG output reviewed by this work was 131 °C, which is also a promising temperature level for small CCHP heat recovery technologies. When it comes to ST, the selected parameter was the output temperature of the working fluid stream. It was identified an average value of about 102 °C, which is a favorable temperature level capable of driving small CCHP heat recovery technologies. Therefore, from

Table 10, only HRSG output temperature and ST output temperature are considered in the analysis of

Section 4.2.

There are two important aspects to keep in mind in this analysis: first, it is worth noting that the literature [

92,

100,

103] has reported problems with corrosion if the exhaust temperature becomes lower than a certain threshold, a fact that would limit the amount of exergy allowed to be recovered. Second, even in cases in which the waste heat recovery is common, in practice, the waste heat was regarded as a potential input for CCHP systems as well, consistently with the idea of highlighting the potential role of those systems in the future 100% RE scenario.

ICE technologies can still be considered within the 100% RE scenario since they can be powered by renewable fuels, such as Biodiesel, hydrogen, alcohol, and synthetic fuels (such as Fischer–Tropsch petrol or diesel) [

112].

Table 10.

Literature review of the values for gas and steam turbine selected parameters.

Table 10.

Literature review of the values for gas and steam turbine selected parameters.

| Reference | Cycle Description | Fuel | GT Output Temperature (°C) | ST Output Temperature (°C) | HRSG Output Temperature (°C) |

|---|

| Anozie and Odejobi 2011 [113] | ST | NG or Oil | - | 51 | - |

| Kaviri et al., 2013 [114] * | GT/ST | NG | 550 | - | 151 |

| Choi et al., 2014 [115] | GT/ST | NG | 645 | 126 | - |

| Aguilar et al., 2014 [116] * | GT/ST | - | 555 | 187 | - |

| Gebreeg et al., 2014 [117] | ST | BM | - | 125 | - |

| Athari et al., 2015 [118] * | GT | BM | 577 | - | - |

| Ganjehkaviri et al., 2015 [119] | ST | HR | - | 70 | - |

| Ibrahim et al., 2017 [120] * | GT | NG | 602 | - | - |

| Ziółkowski et al., 2019 [121] | GT/ST | NG | 520 | 143 | 100 |

| Omar et al., 2020 [122] | ST | CSP | - | 70 | - |

| Parvez and Khan 2020 [123] * | GT/ST | BM | 612 | 41 | 127 |

| Koç et al., 2020 [124] | GT | - | 450 | - | - |

| Niu et al., 2021 [125] * | ST | BM | 598 | - | 147 |

Table 11.

Literature review of the values for Internal Combustion Engine selected parameters.

Table 11.

Literature review of the values for Internal Combustion Engine selected parameters.

| Reference | Fuel | ICE-ET (°C) | ICE-FET (°C) | JW-OT (°C) | Notes |

|---|

| Zhao et al., 2010 [126] | NG | 530 | 140 * | 98 | Combined with an AHP |

| Rabovitser et al., 2013 [127] | ** | 487 | - | - | The mix of gases was one of the varied parameters |

| Zhao et al., 2014 [128] | NG | 510 | 170* | 110 | Combined with an AHP |

| Wang et al., 2014 [129] | - | 500 | - | - | Waste heat used by a CO2 thermodynamic cycle |

| Maheswari et al., 2015 [130] | DSL | 410 | 120 | - | Waste heat for desalination purposes |

| Scaccabarozzi et al., 2017 [131] | DSL | 350 | - | - | For optimization of heat recovery ORCs |

| Frigo and Spazzafumo 2018 [132] | NG

H2 | 880 | - | - | Temperature achieved when using H2. (620 °C for NG) |

| Mohammadkhani and Yari 2019 [133] | DSL | 525 | 120 | 87 | Feeding a transcritical dual loop ORC |

| Kim et al., 2020 [134] | CH4 | 587 | 66 | - | ICE in combination with a SOFC |

| Choi and Song 2020 [135] | NG | 600 | - | 110 *** | ICE in combination with a SOFC |

Table 11 brings the selected parameters for ICE technologies. Three types of potential parameters were identified in the literature: ICE exhaust temperature (ICE-ET, right after the ICE exhaust exit), ICE final exhaust temperature (ICE-FET, after it had been used in any upstream process), and jacket water output temperature (JW-OT, the ICE coolant water output). ICE-ET has a substantially high exergy level content, and, especially in the case of stationary ICEs, it is used to feed another thermal system. With an average ICE-ET of 537.9 °C, it is able to feed, for instance, high temperature absorption heat pumps [

126], desalination systems [

130], and organic Rankine cycles [

133]. For that reason, ICE-ET is not considered in the evaluation of

Section 4.2 since its temperature level is too high for small–medium CHP technologies. An average temperature of 123.2 °C was encountered for the ICE-FET, which is also a good potential waste heat to drive small CHP heat recovery technologies. Some papers also analyze the use of the JW-OT together with the ICE-ET to make better use of the primary energy. The average JW-OT found in the literature was 101.2 °C and, together with ICE-FET, is also considered for the

Section 4.2 analysis.

For high temperature waste heat (about 400 °C, or higher) and sizes above 5 MW, a bottom steam Rankine cycle is the first option to be evaluated [

37]. For significantly smaller sizes and lower temperatures, ORC groups are preferred. Note that both steam units and ORC units can easily operate as cogeneration systems with heat production (in the form of saturated steam or hot water) at temperatures between 40 °C and 110 °C and, in some cases, even higher. These thermal levels may be suitable for many technological uses [

136], but certainly for space heating. The quantities of heat available in this way are potentially important, given that power plants hardly have an electrical efficiency greater than 50%, which means that about 50% of the energy stored in chemical form is not converted back into electricity, but it is still available in the form of heat.

If other forms of accumulation of excess electrical power were preferred, reducing the expected contribution from power-to-chemical-to-power systems, the integration of low temperature heat in local distribution networks is expected to be even more interesting and would offer the option of connecting such systems with solar thermal systems, according to the SDH concept. Even in a highly electrified context, this solution is expected to improve the energy performance of the entire system. For the exploitation of heat at even lower temperatures, from 80 °C to 140 °C, the use of ORC is still possible but with modest yields. In the lower part of the range, technologies based on the absorption process become competitive, in particular the Absorption Power Cycles, which, in such conditions, have slightly better yields than the ORC cycles [

137]. The integration of low temperature heat (as low as about 40 °C) in local distribution networks can still be useful, according to the concept of low temperature DH [

138].

4.2. Integration between Waste Heat Sources and CHP Technologies

As explained in the last section, this section gathers, presents, and confronts all the data collected until this point. Following the adopted methodology, the first step here is to bring together and present a summary of the data related to the reviewed parameters of all potential waste heat sources (selected in

Section 4.1) and of all CHP technologies reviewed in

Section 2. The second step is to cross both sets of data to see which heat source is a potential source for each CHP technology.

Table 12 presents the data related to the reviewed parameters of all potential waste heat sources, showing the minimum and maximum temperatures found in the literature for each heat source as well as the respective average temperature for each range.

Table 13 presents the feeding temperature range and the respective output capacity range for the selected CHP technologies, reviewed in

Section 2.

Confronting

Table 12 and

Table 13, it is possible to observe that, as stated in the last section, PVBT, PVT-WOT, and SWH-WOT have quite low temperature levels and do not have the potential to feed the CHP technologies reviewed in

Section 2. On the other hand, and following a similar analysis, one can note that all the heat sources from BRT to HRSG-ET have the potential of feeding the CHP technologies presented in

Table 13 since their temperature ranges overlap at some points. Even though GT-OT and ICE-ET heat sources have a substantially high potential for feeding secondary thermal systems, they are not considered since their temperature levels are quite high and do not overlap the temperature ranges of the CHP technologies at any point. A more detailed analysis is presented in

Figure 4,

Figure 5,

Figure 6 and

Figure 7.

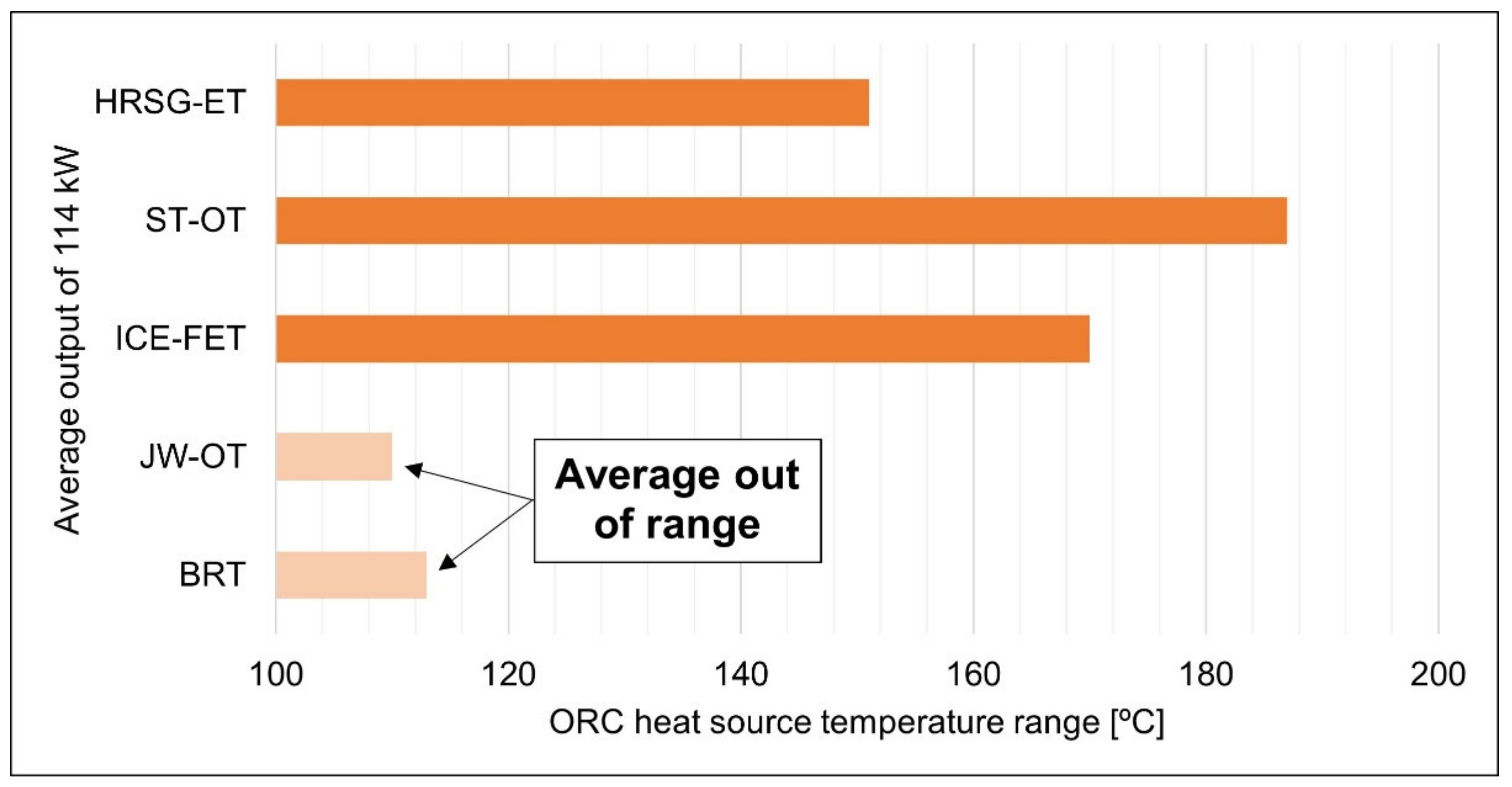

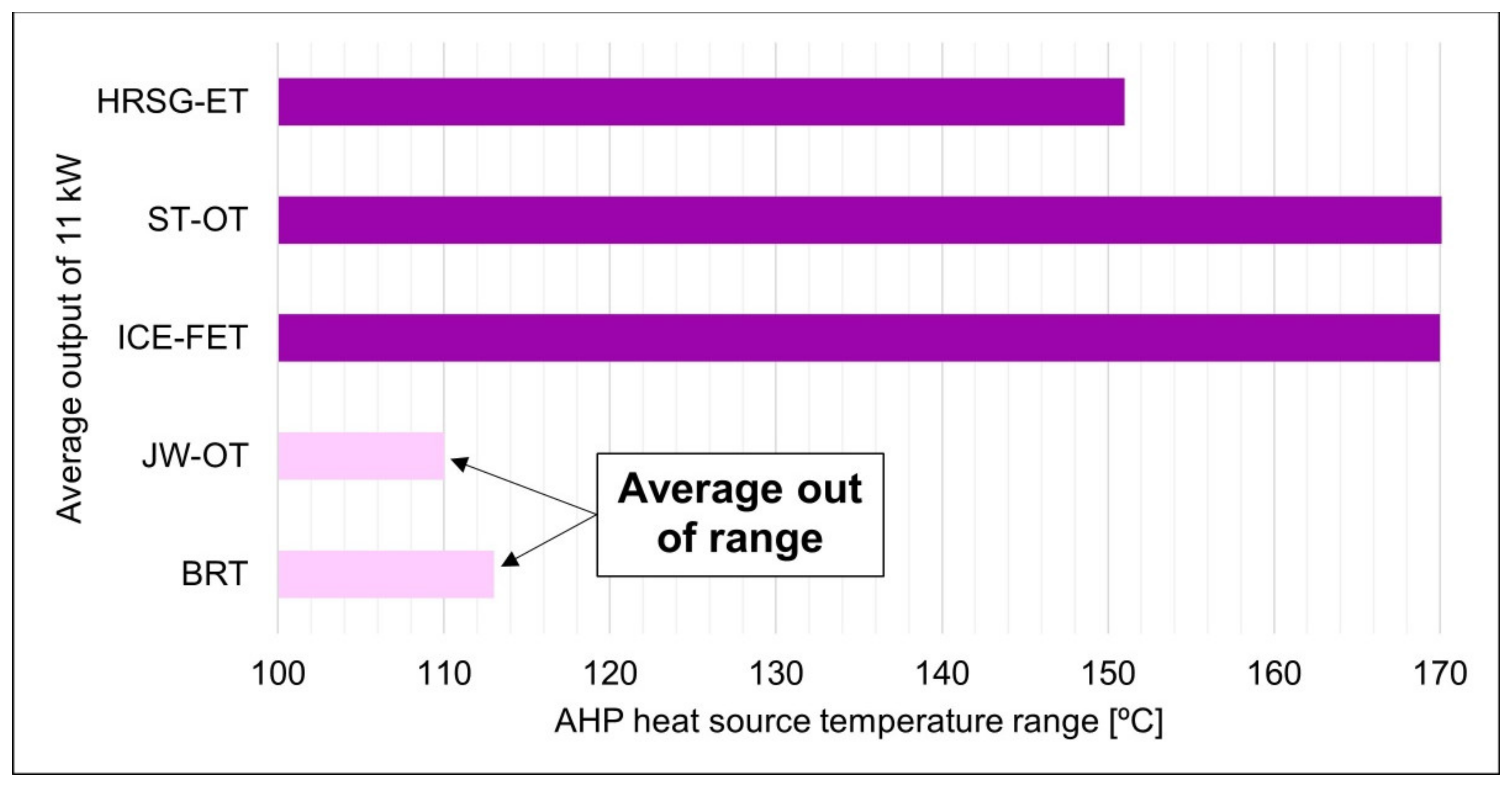

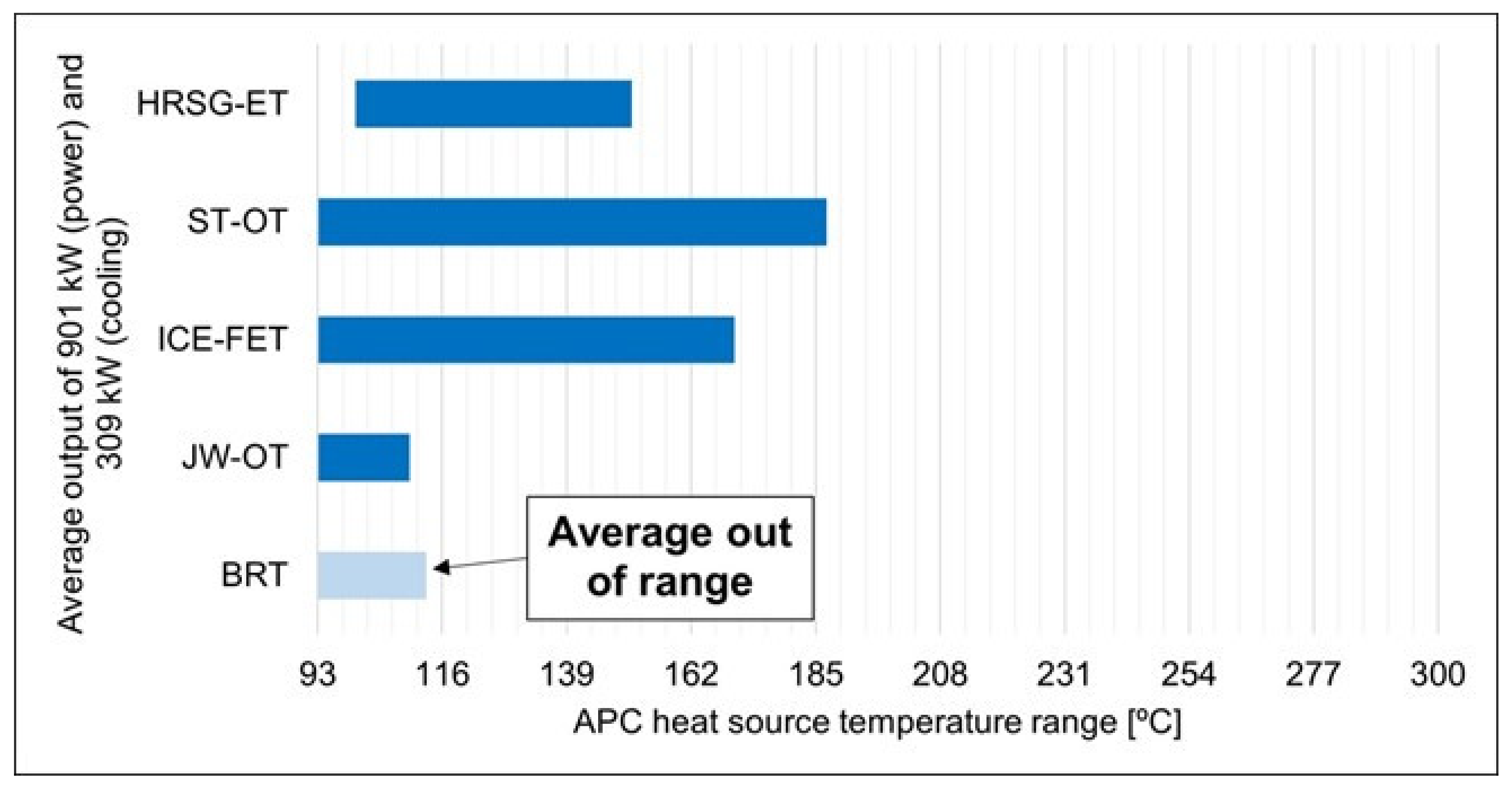

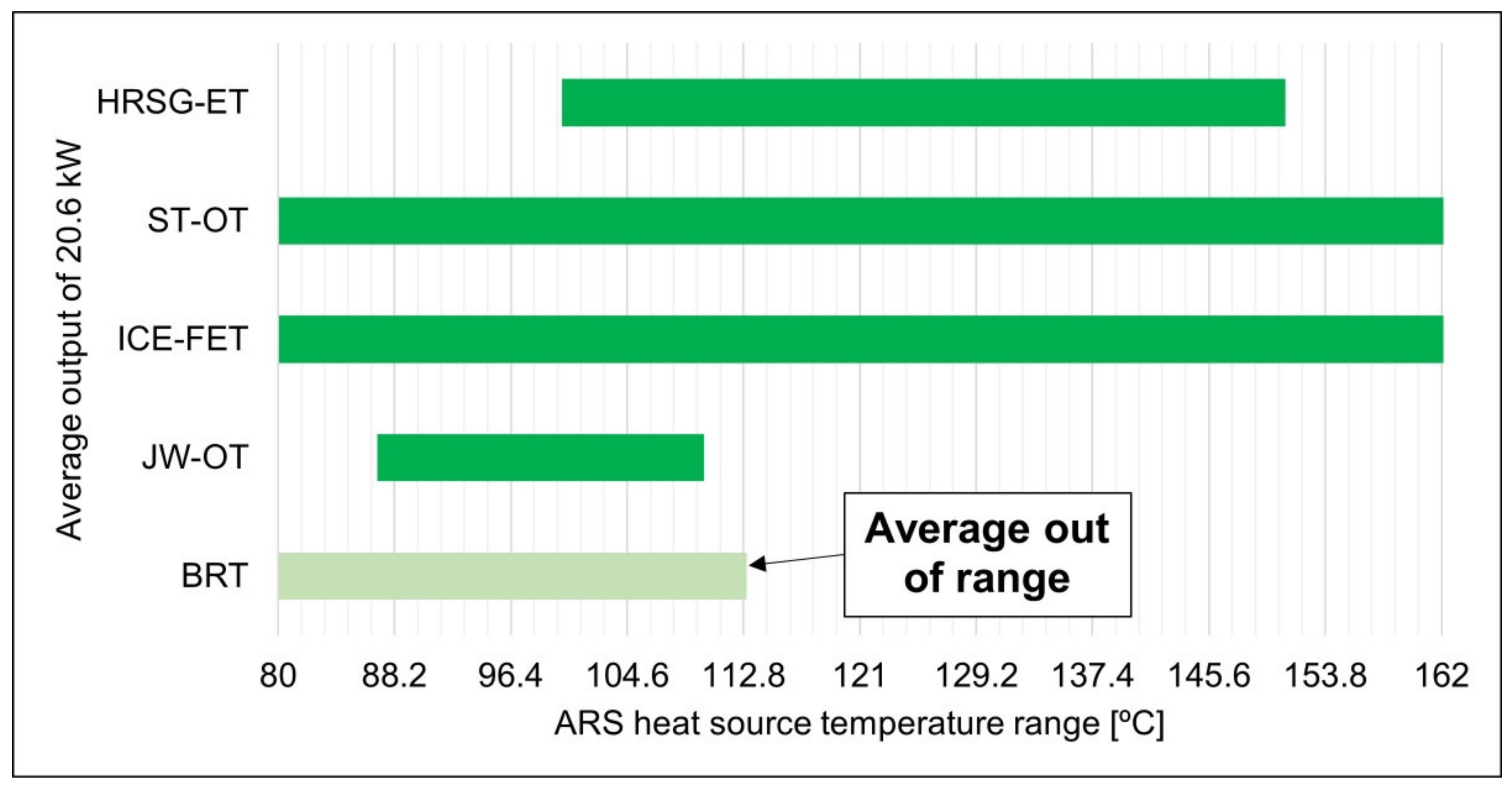

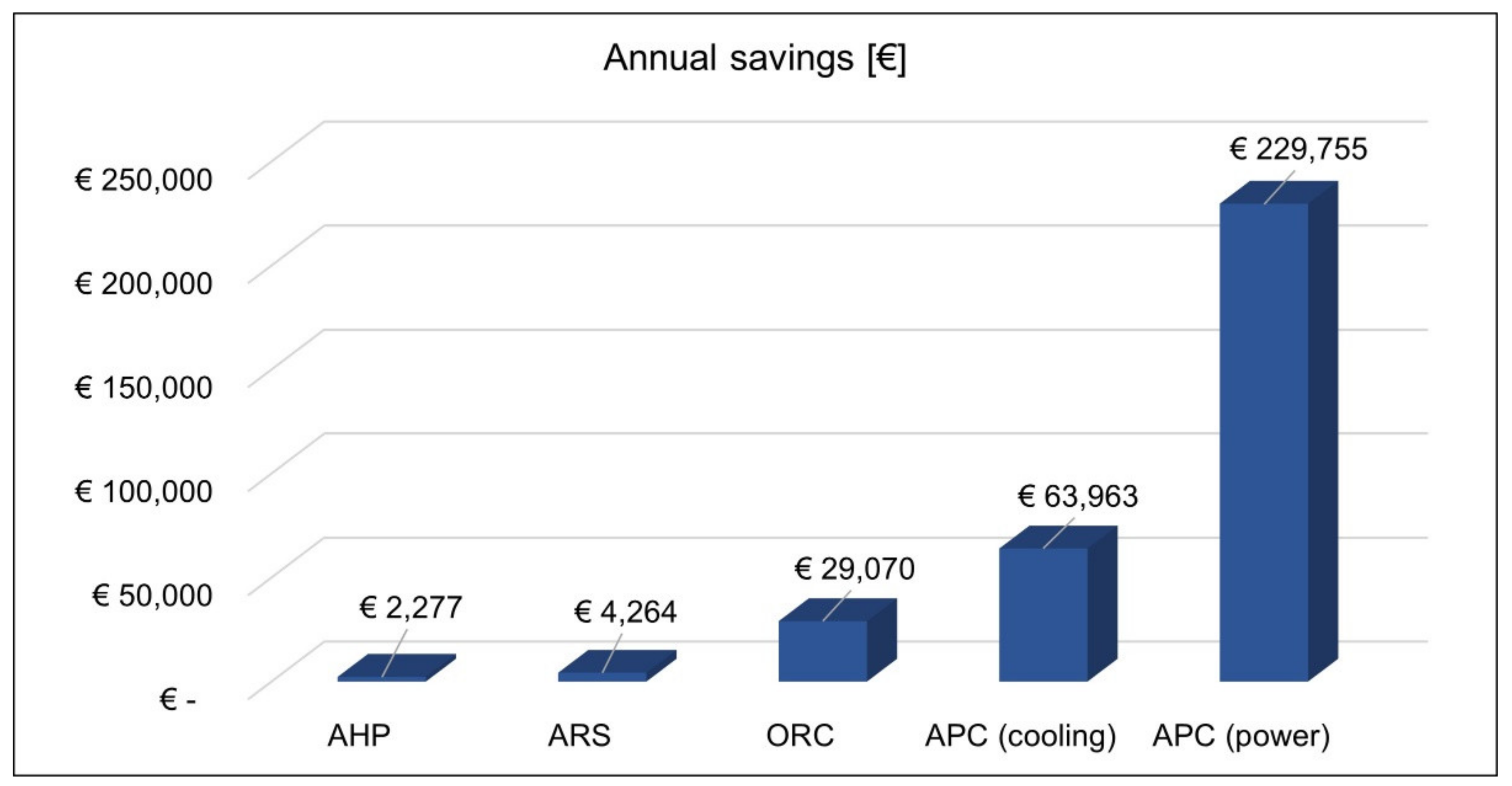

The next set of charts (

Figure 4,

Figure 5,

Figure 6 and

Figure 7) presents the data intersection concerning the heat sources from BRT to HRSG-ET (

Table 12) and the technologies presented in

Table 13. Following

Table 13,

Figure 4 shows the feeding temperature range for the ORC systems reviewed in

Section 2. The horizontal bars represent the temperature range for the reviewed parameters of the five selected heat sources mentioned in the last paragraph, according to

Table 12. As observed in

Figure 4, in this case, only the HRSG-ET, ST-OT, and ICE-FET heat sources are considered to be suitable for feeding ORC systems since their average temperatures are inside the ORC temperature range and the largest part of their temperature ranges overlap. Some cases of the JW-OT and BRT heat sources are suitable for feeding ORC systems as well; however, their average temperatures are outside the temperature range of the ORC systems, and the largest part of their temperature ranges do not overlap. For that reason, they are not considered as potential heat sources for ORC systems. According to

Table 13, the reviewed ORC systems have the potential to deliver an average output of 114 kW of power within this feeding temperature range. With similar results,

Figure 5 illustrates the crossing data between the temperature range of the considered heat sources and the feeding temperature range for absorption heat pumps (100–170 °C). The heat sources considered suitable for feeding AHP systems were also HRSG-ET, ST-OT, and ICE-FET for the same reasons stressed out for ORC systems. According to

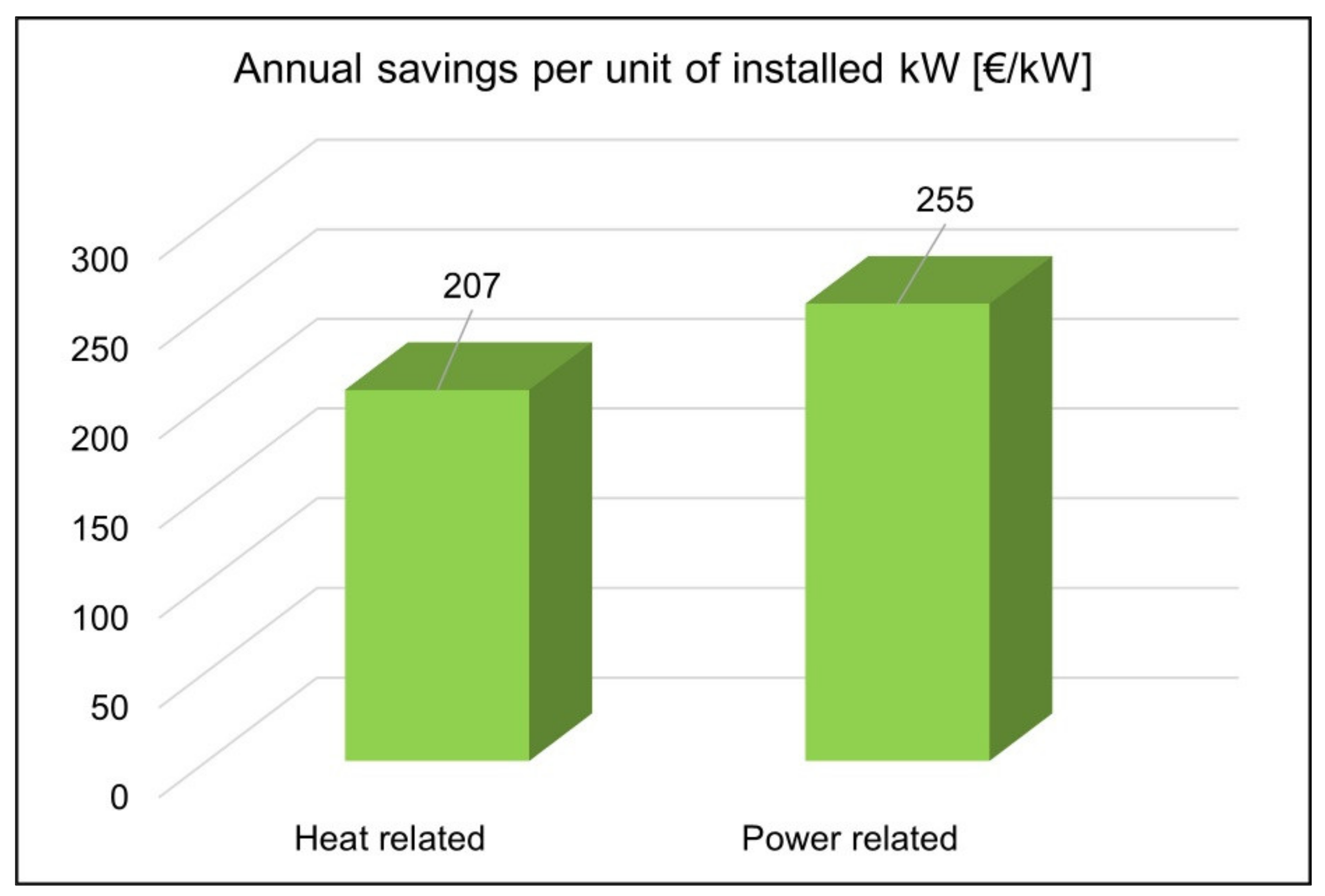

Table 13, within the reviewed feeding temperature range, each AHP unit is capable of delivering an average output of 11 kW of heat.

Figure 6 illustrates the feeding temperature range for the APC systems reviewed in

Section 2. For this type of system, it was found a broader feeding temperature range, from 93 to 300 °C. Besides the same heat sources suitable for ORC systems (HRSG-ET, ST-OT, and ICE-FET), JW-OT was also appropriate for APC systems since its average temperature is inside the APC temperature range and the largest part of their temperature ranges overlap. From the reviewed APC studies, an average output of 901 kW for power and 309 kW for cooling was found. As can be inferred from the chart, the temperature ranges of each suitable heat source are overlapping just the first half of the feeding temperature range of APC systems. Therefore, it might be expected that, with those heat sources, the designed APC system will deliver lower output levels. Comparable results were found for Absorption Refrigeration Systems, i.e., the suitable heat sources were also HRSG-ET, ST-OT, ICE-FET, and JW-OT (

Figure 7). However, the review of the feeding temperature range for ARS resulted in a narrower range of temperatures (80–162 °C). Within this range, ARS is expected to deliver 20.6 kW of cooling output, which is quite achievable for all four suitable heat sources mentioned since they occupy almost the entire feeding temperature range for ARS.

4.4. Perspectives on the Carbon Footprint within the Presented Scenario

As stressed in the introduction, the growing energy demand caused by the social-economic development of the world has resulted in higher rates of GHG emissions. This has led to higher amounts of carbon footprint for the energy sector since it is currently fed by high rates of fossil fuels [

2]. For that reason, this section aims to succinctly approach the perspective of carbon footprint for what concerns the 100% RE scenario and the proposed CHP/CCHP integration.

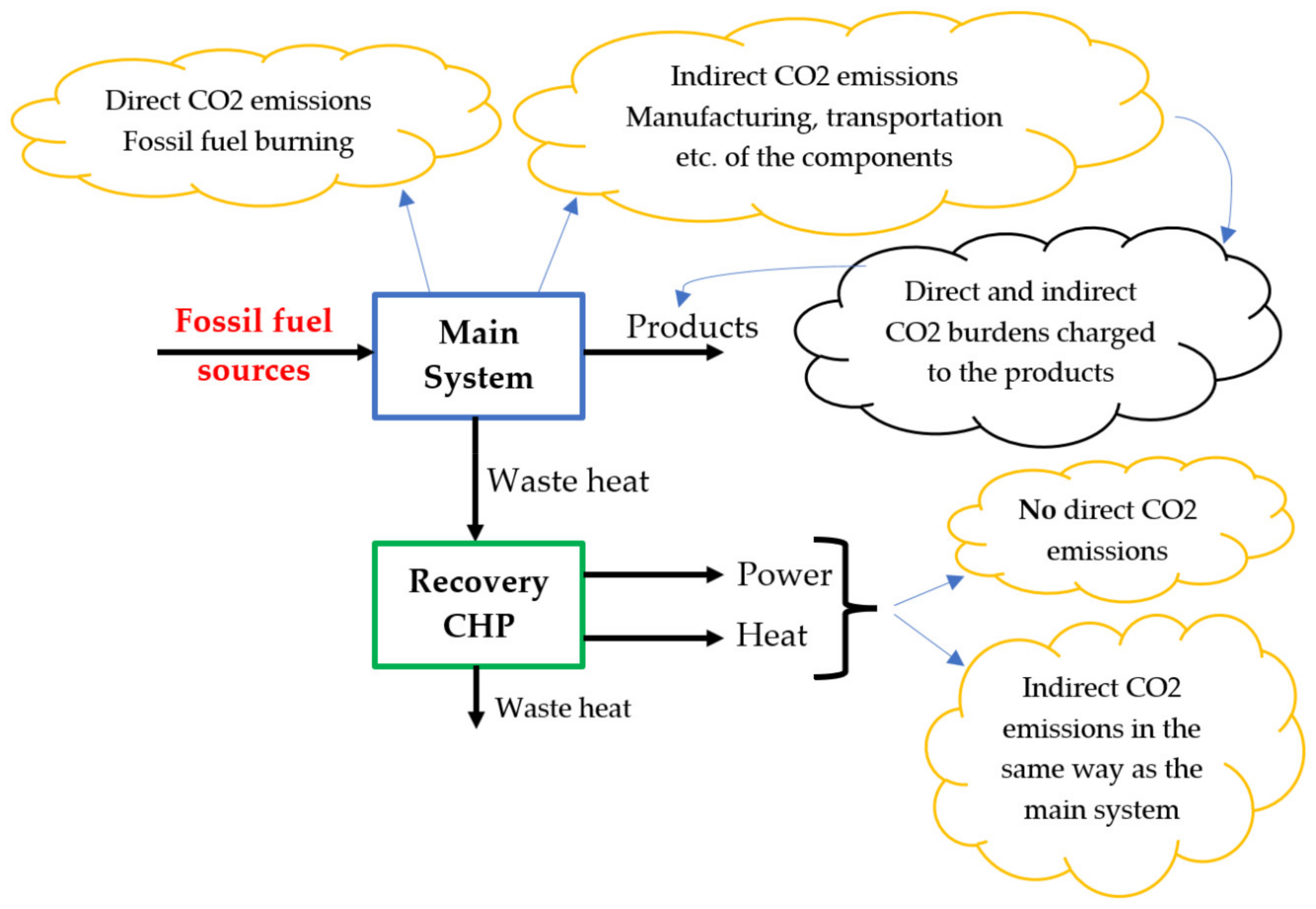

In order to discuss such perspective, it is crucial to keep in mind two main aspects: first, this paper has dealt with a proposal that has the potential to improve even further the economic and environmental positive characteristics of the energy system within the 100% RE scenario, through the integration of small–medium CHP/CCHP systems as shown in the previous sections; second, the direct and indirect CO

2 emission concepts. Direct emissions are those resulting from directly burning fossil fuels, while indirect emissions are those regarded to the entire life cycle of a given product, such as manufacturing, transportation, installation, and maintenance [

139].

With the high rates of fossil fuels in the current primary energy sources scenario, the technologies integrating current energy systems contribute to both direct and indirect CO

2 emissions. For instance, supposing that the main system, pictured in

Figure 10, is a GT fed by natural gas, the total CO

2 emissions by this system will comprise the direct CO

2 emissions from burning natural gas plus CO

2 emissions resulted from all processes that need to be performed to manufacturing a GT, from raw materials extraction to its disposal. Once all CO

2 burden is charged on the main system’s products, the waste heat that will feed the recovery CHP/CCHP system will be free of CO

2 burdens [

140]. However, the products from the recovery system are not free of CO

2 burdens since the recovery system’s components were manufactured in a scenario far from being 100% RES, as reported by WEO 2019 [

2], which claimed that the share of RES on the world electricity generation was about 25%.

Still bearing the current energy scenario in mind and assuming that the main system in

Figure 10 is now a system fed by RES (such as a solar PV power plant or a wind turbine), it is easy to infer that the products from those systems still bear CO

2 carbon footprint since they were (most likely) manufactured and transported by fossil fuels fed means. For instance, in the investigation developed by Wild-Scholten [

141], they studied the carbon footprint of different types of commercial PV systems. The carbon footprint for such systems ranged from 15.8 to 38.1 g CO

2-eq/kWh with the consideration that, when the manufacturing process was assumed to be in China, these values increased by a factor of around two. Stylos and Koroneos [

142] also performed a study about the carbon footprint of photovoltaic systems. Their investigation approached the problem through four different scenarios based on the characteristics of the manufacturing process. The result was a carbon footprint ranging from 12.28 to 58.81 g CO

2/kWh. In a review performed by Kaldellis and Apostolou [

143], they made a comparison between the carbon footprint of onshore and offshore wind energy. The lower value encountered in the literature was for onshore (~4.5 g CO

2/kWh), while the higher value was for bottom-fixed offshore (32 g CO

2/kWh). Xie et al. [

144] analyzed three types of wind turbines operating in the region of Taiwan and found an average carbon footprint of 3.9 g CO

2/kWh for its entire life cycle. Thus, in the current energy scenario, the carbon footprint of CHP/CCHP systems feed by recovered waste heat is expected to be in line with that of system fed by RES, i.e., about from 4 to 40 g CO

2-eq/kWh, depending on the location and the manufacturing technology adopted for component production.

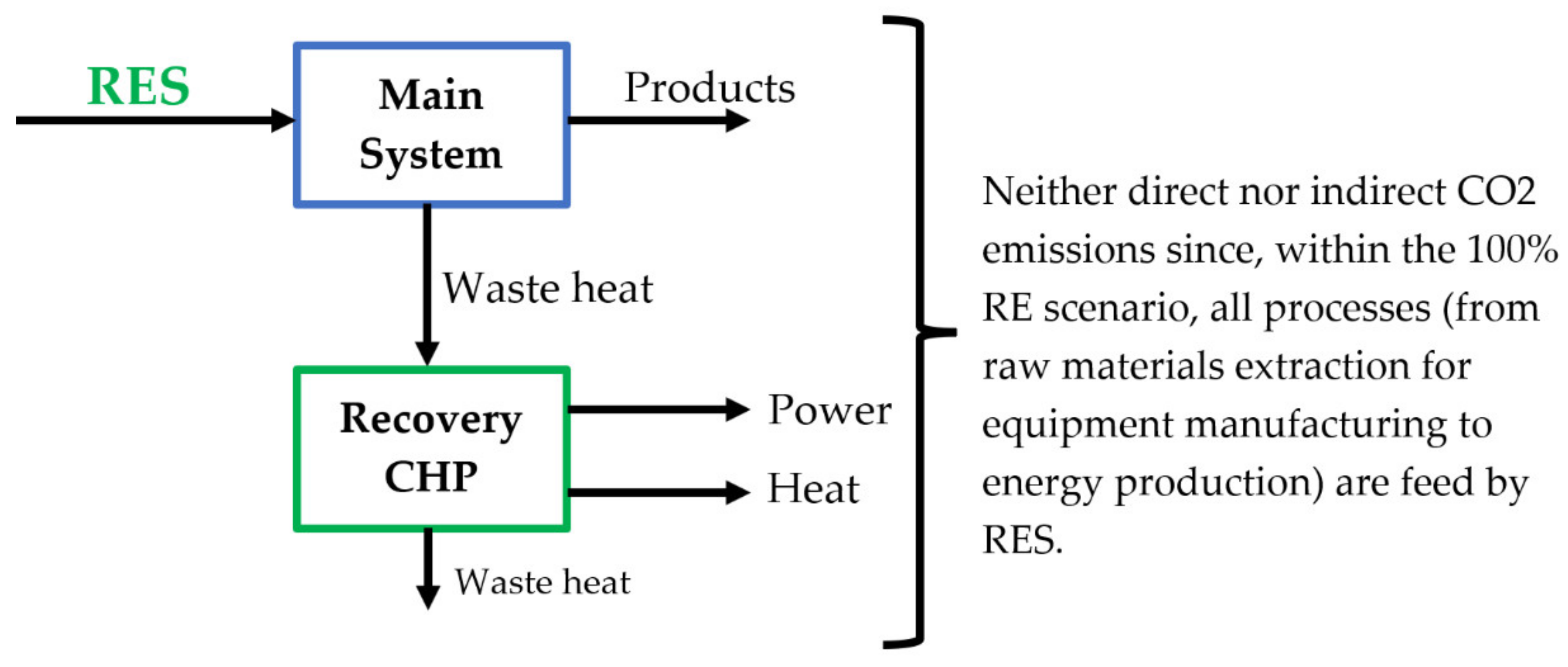

On the other hand, now considering the future scenario of 100% RES, it means that all energy consumption (direct and indirect) comes from renewable sources. For that reason, the carbon footprint of all products (

Figure 11) would be zero. In that case, the comparison should be made on the basis of the amount of RES required for certain energy production.