Effects of Water Injection Strategies on Oxy-Fuel Combustion Characteristics of a Dual-Injection Spark Ignition Engine

Abstract

1. Introduction

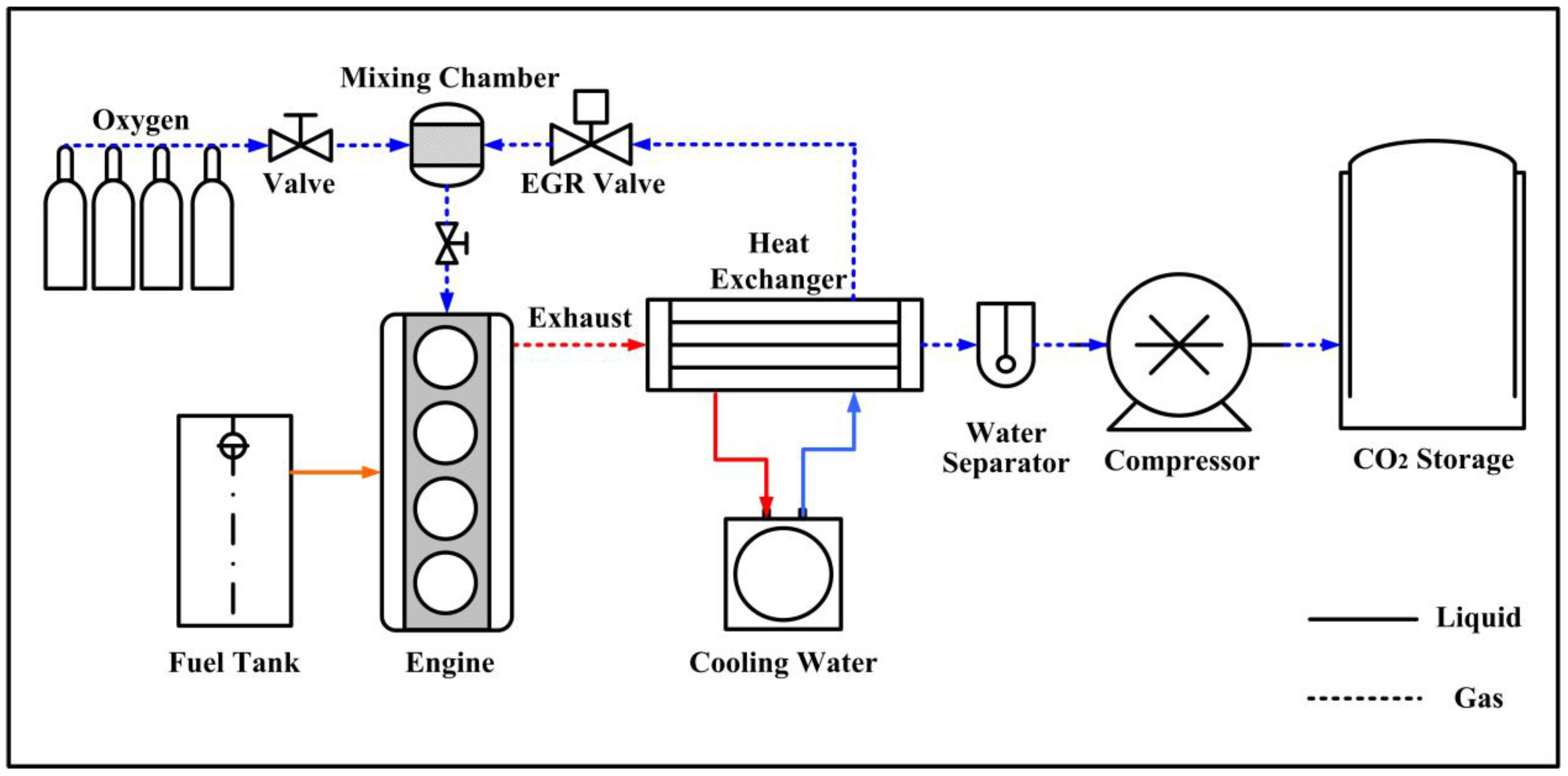

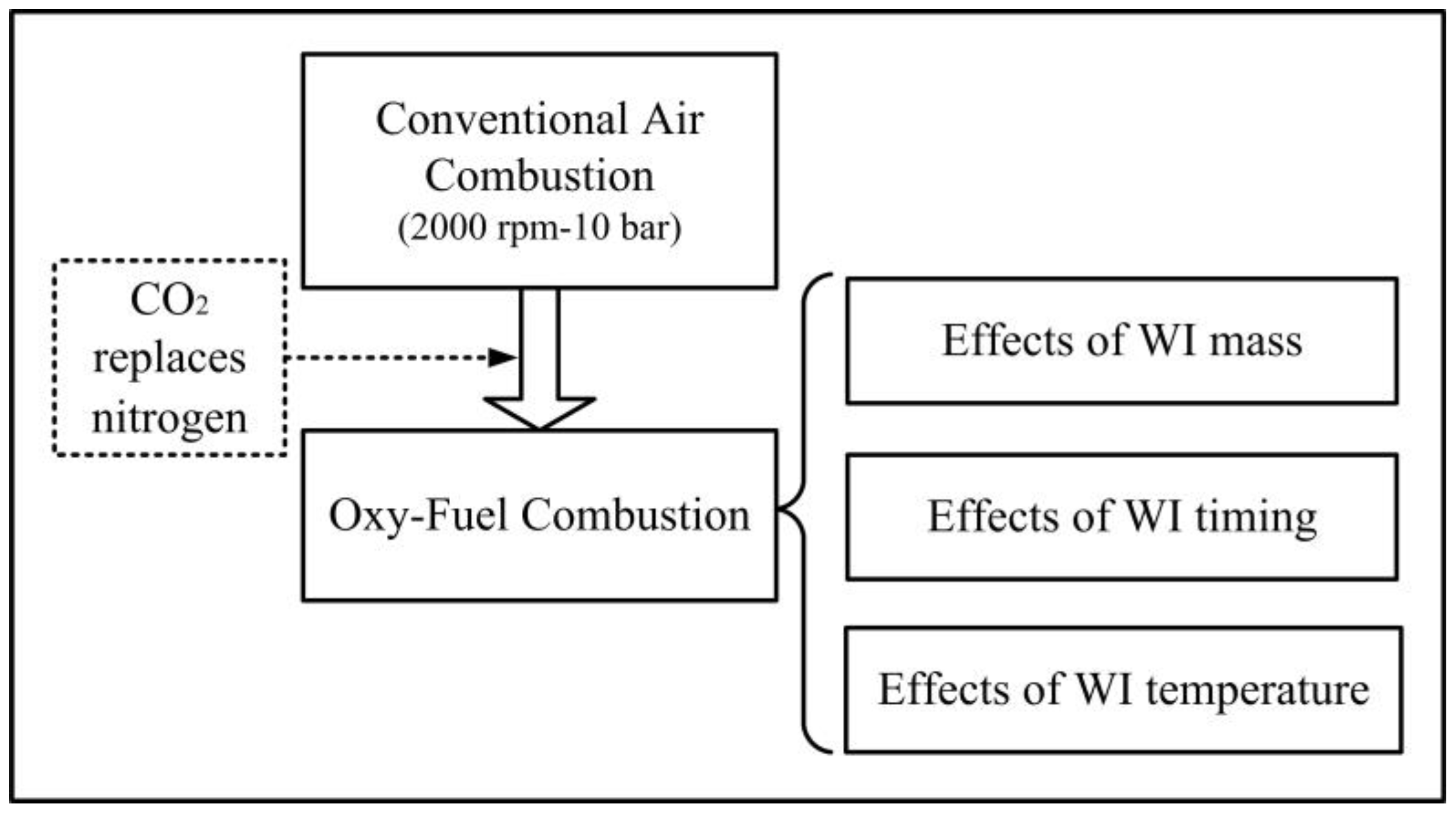

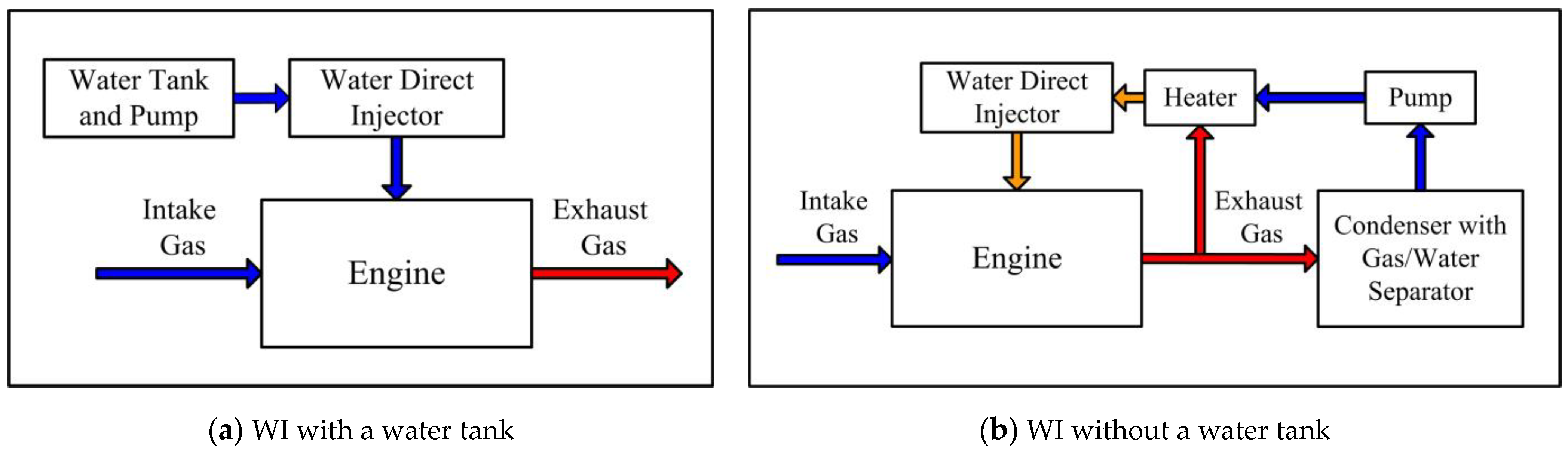

2. Research Approach and Numerical Method

2.1. Research Approach and Key Parameters

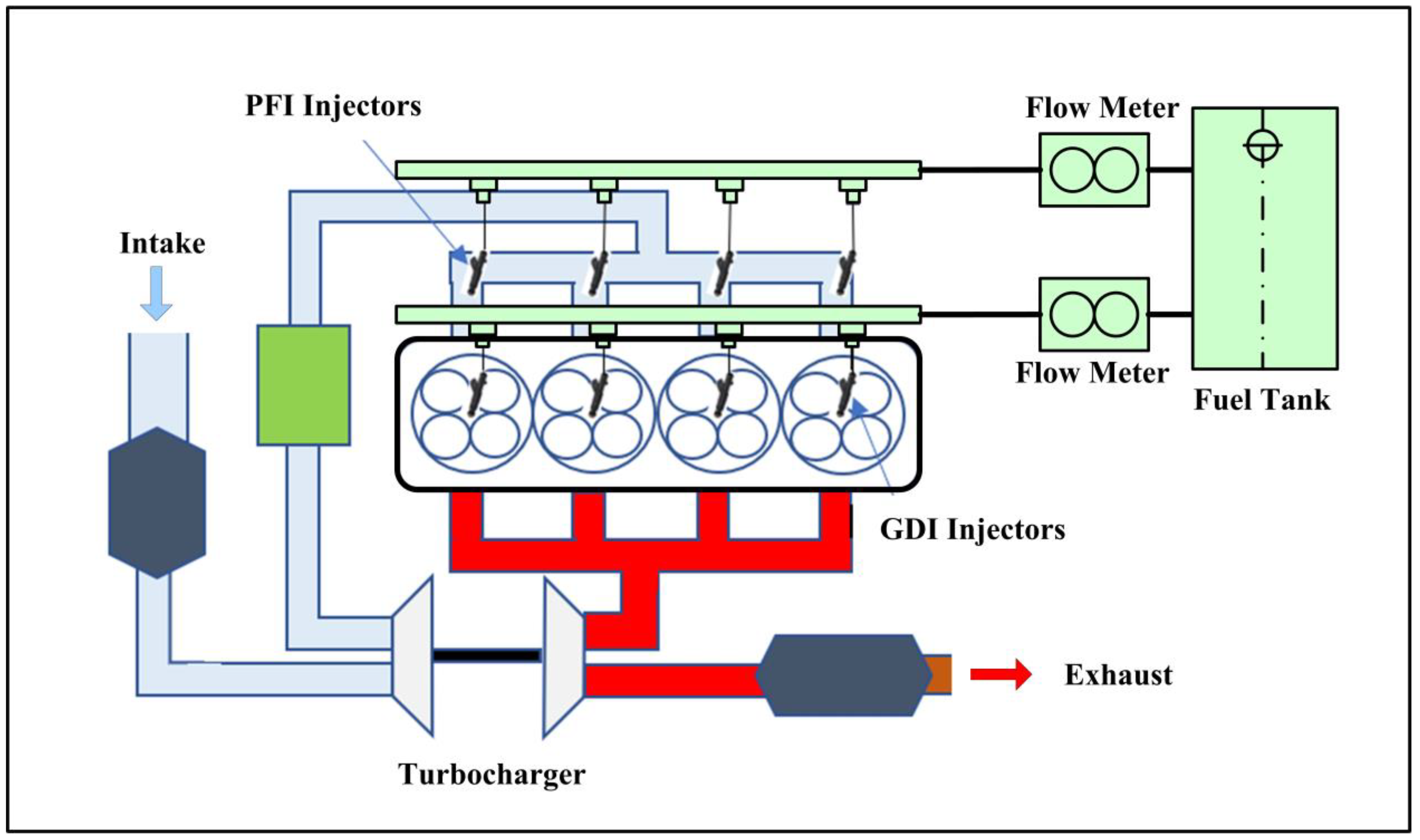

2.2. Engine and Testbed

2.3. Model Description

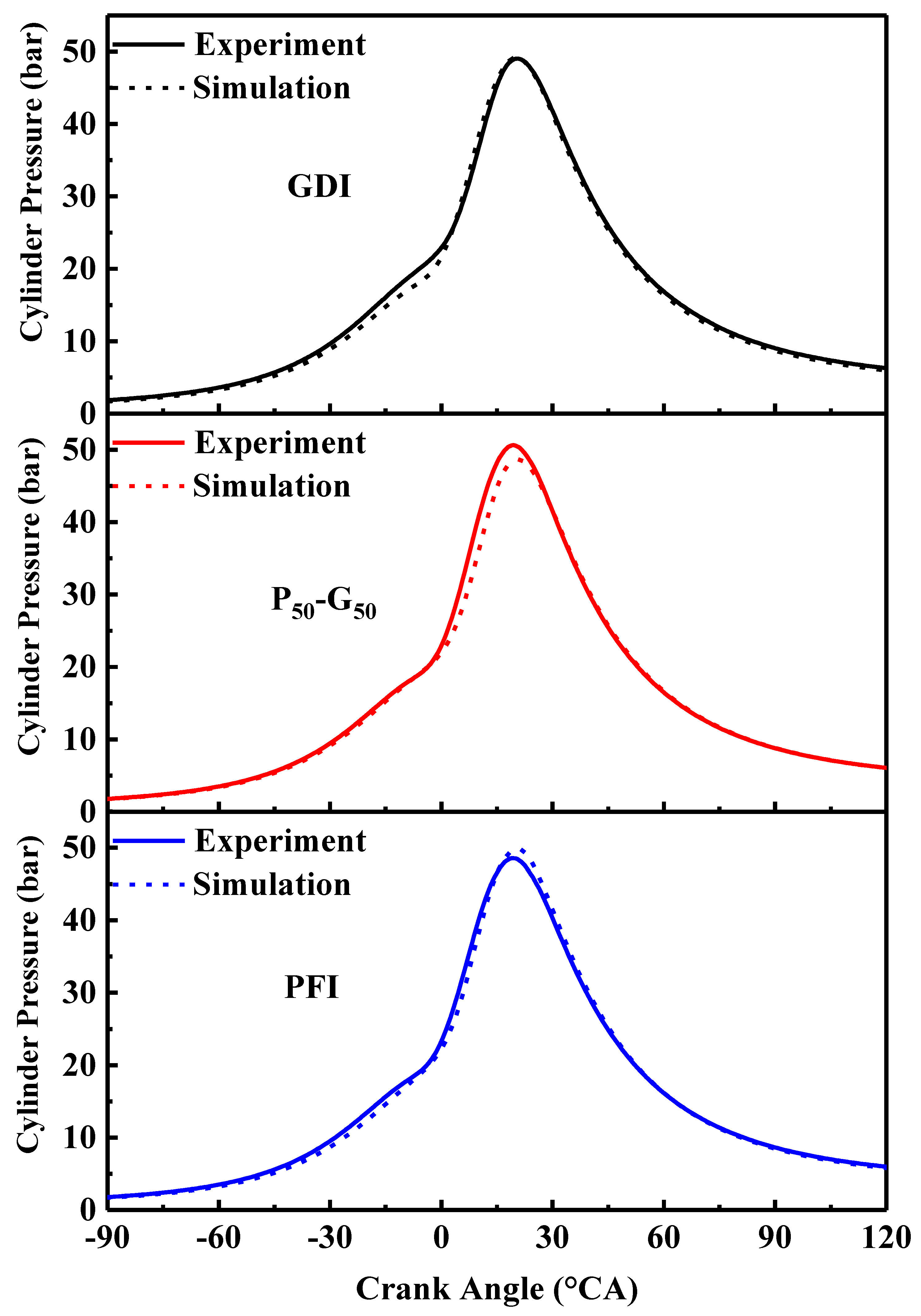

2.4. Model Validation

3. Results and Discussion

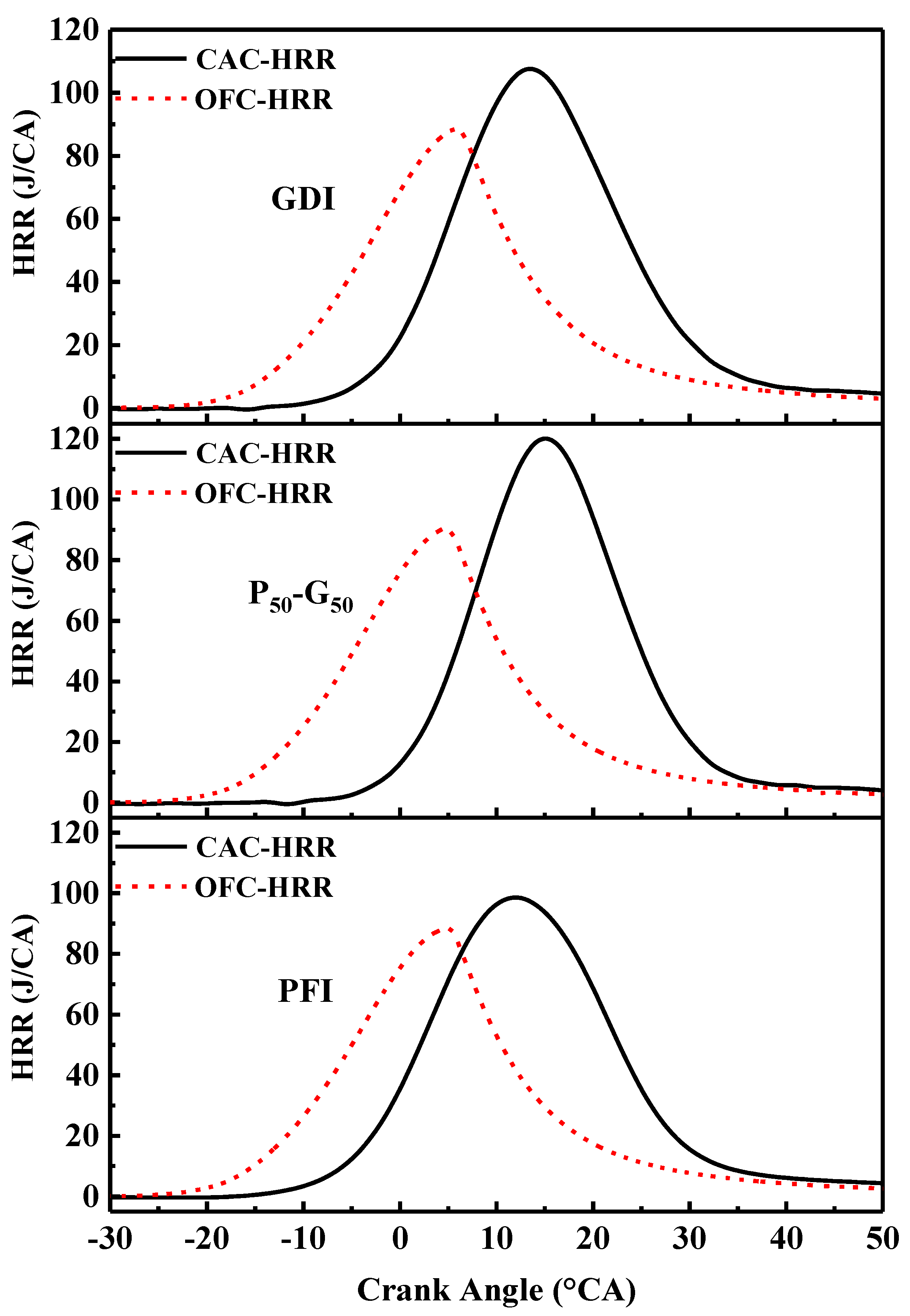

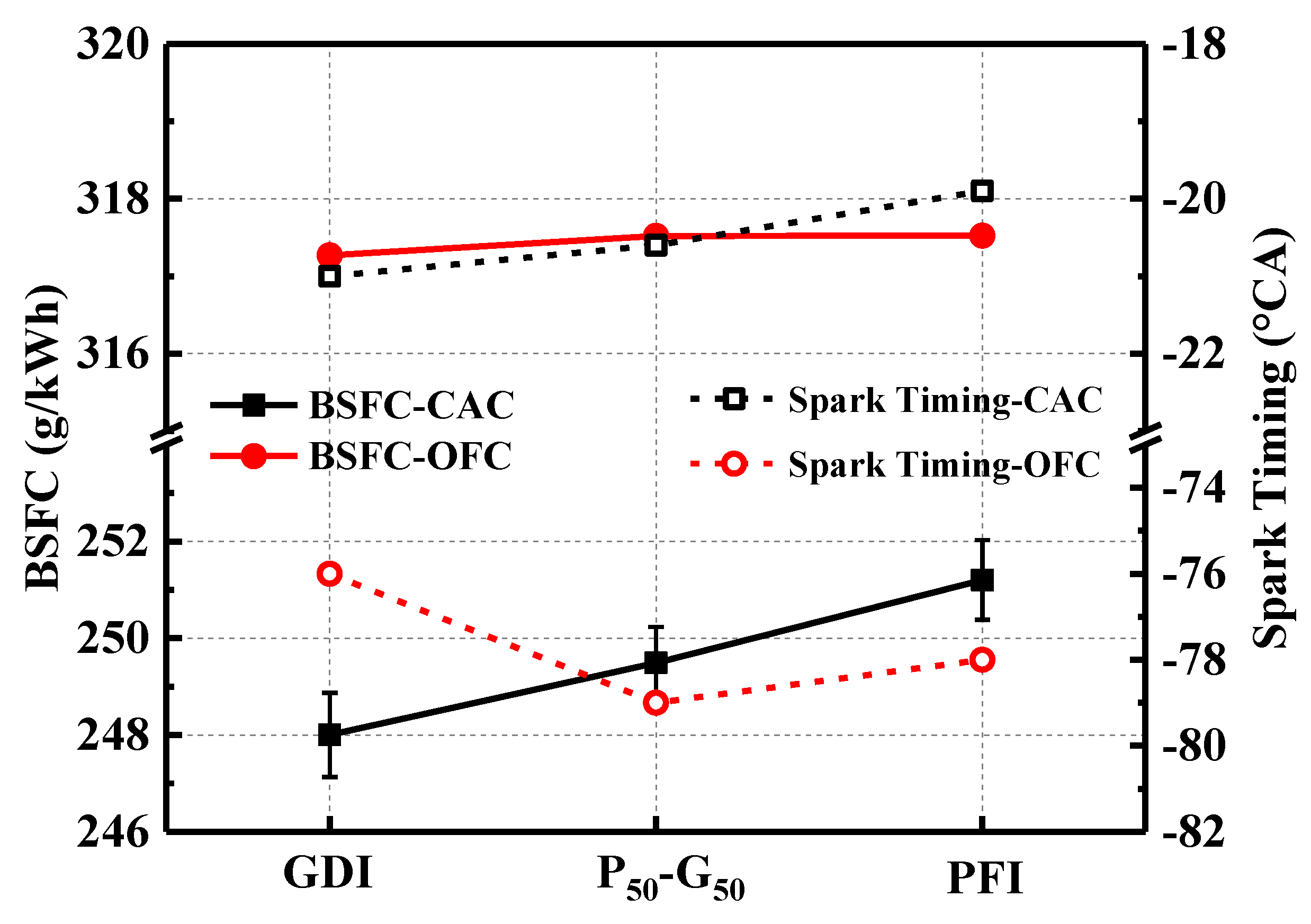

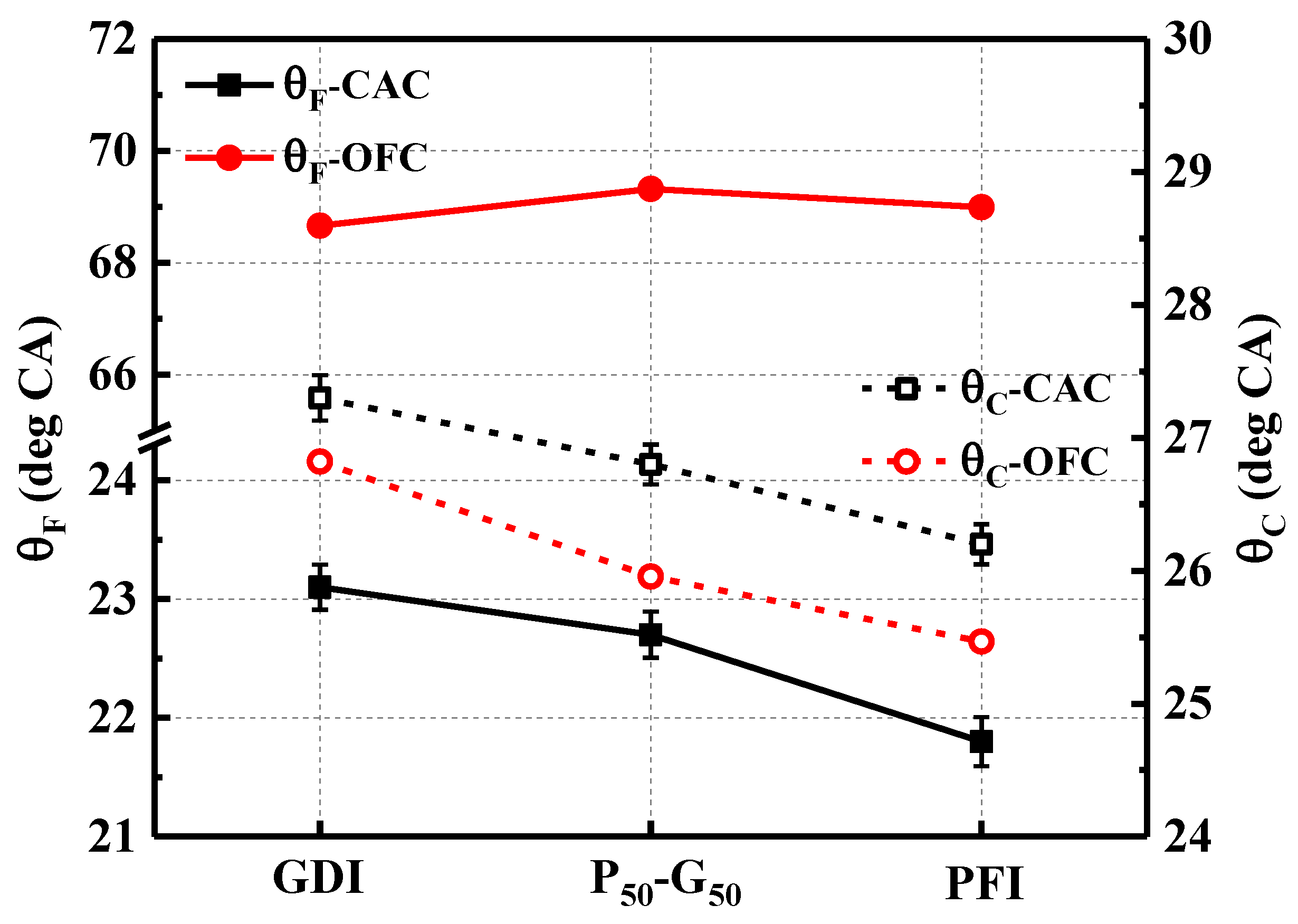

3.1. Comparison between CAC and OFC

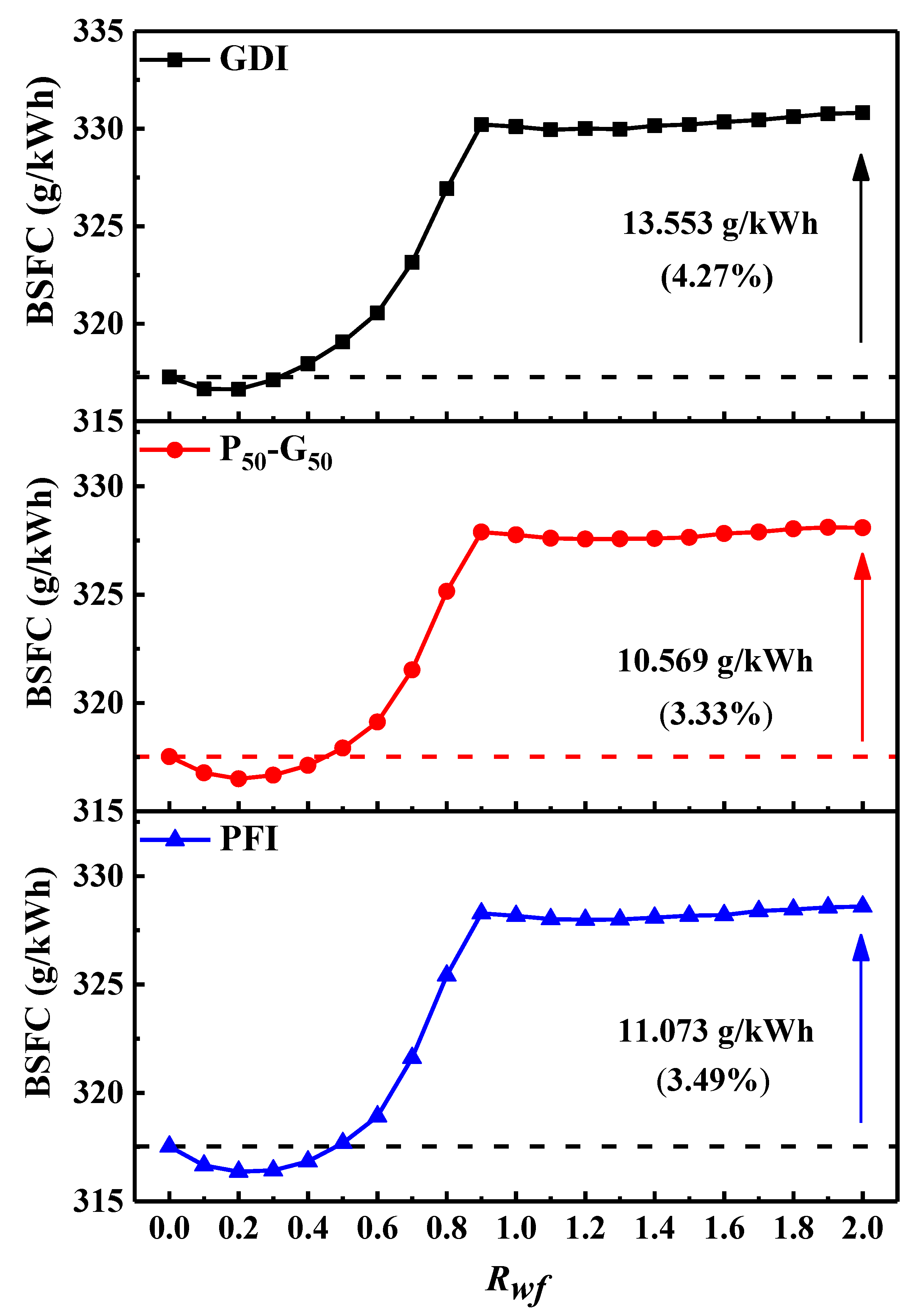

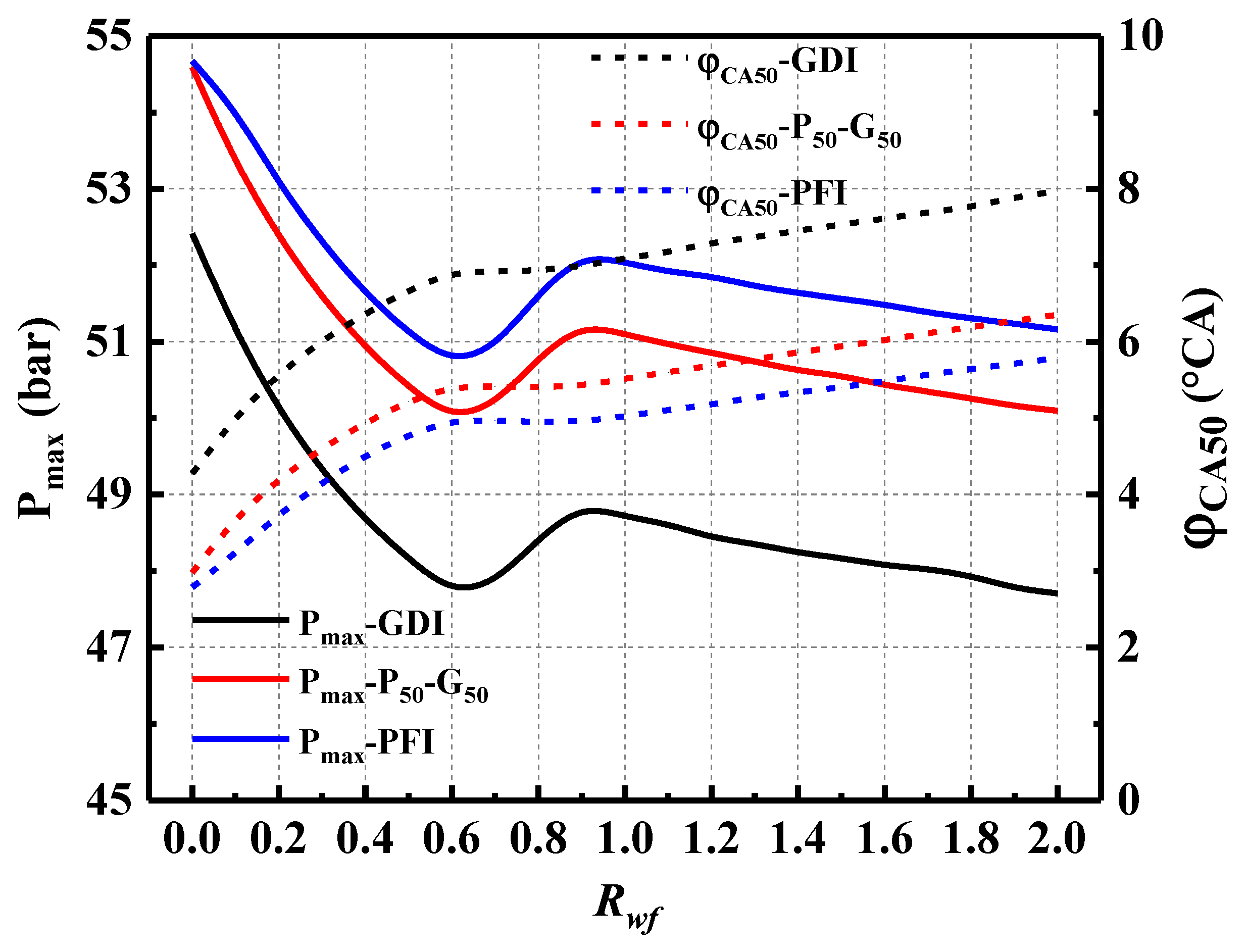

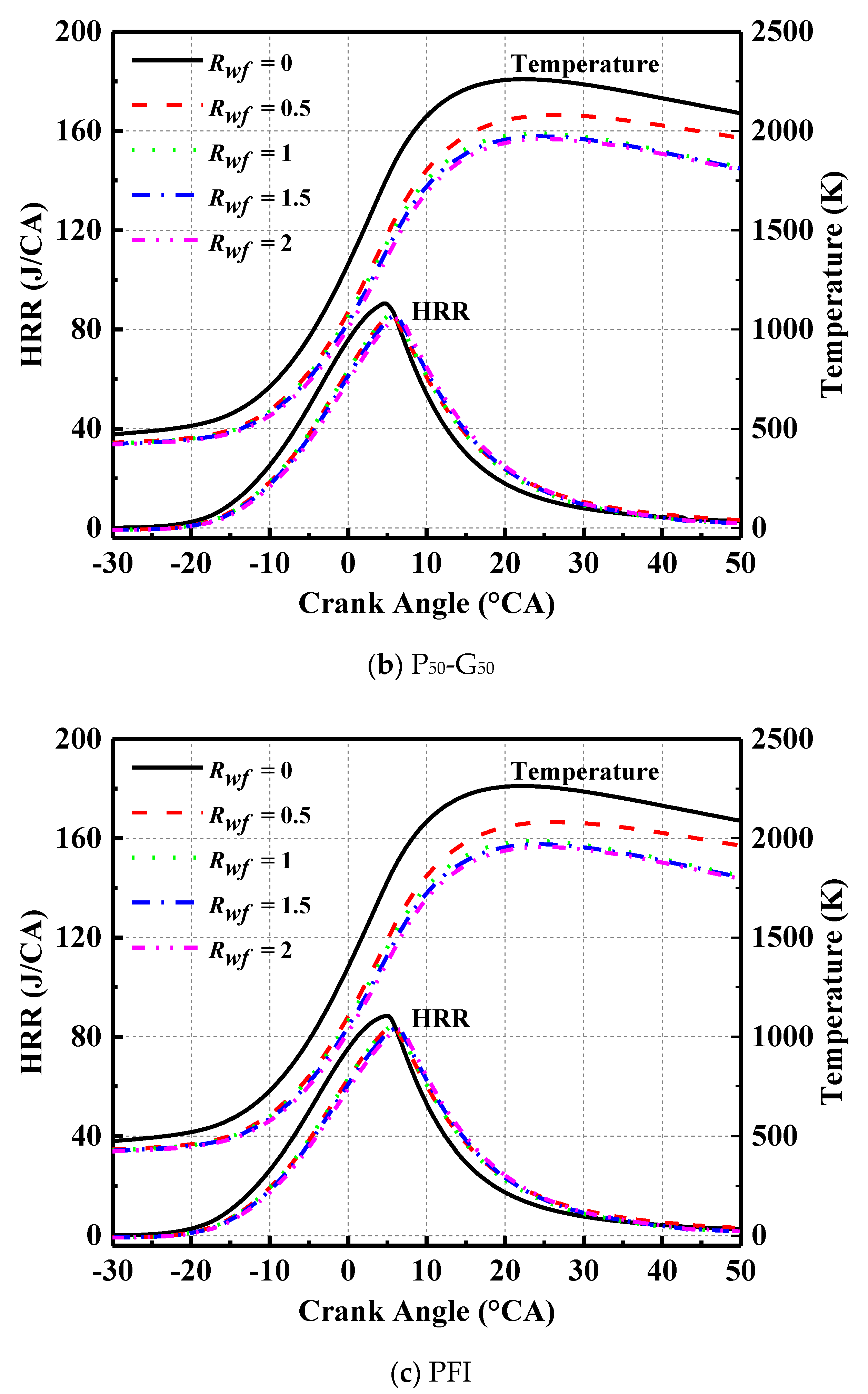

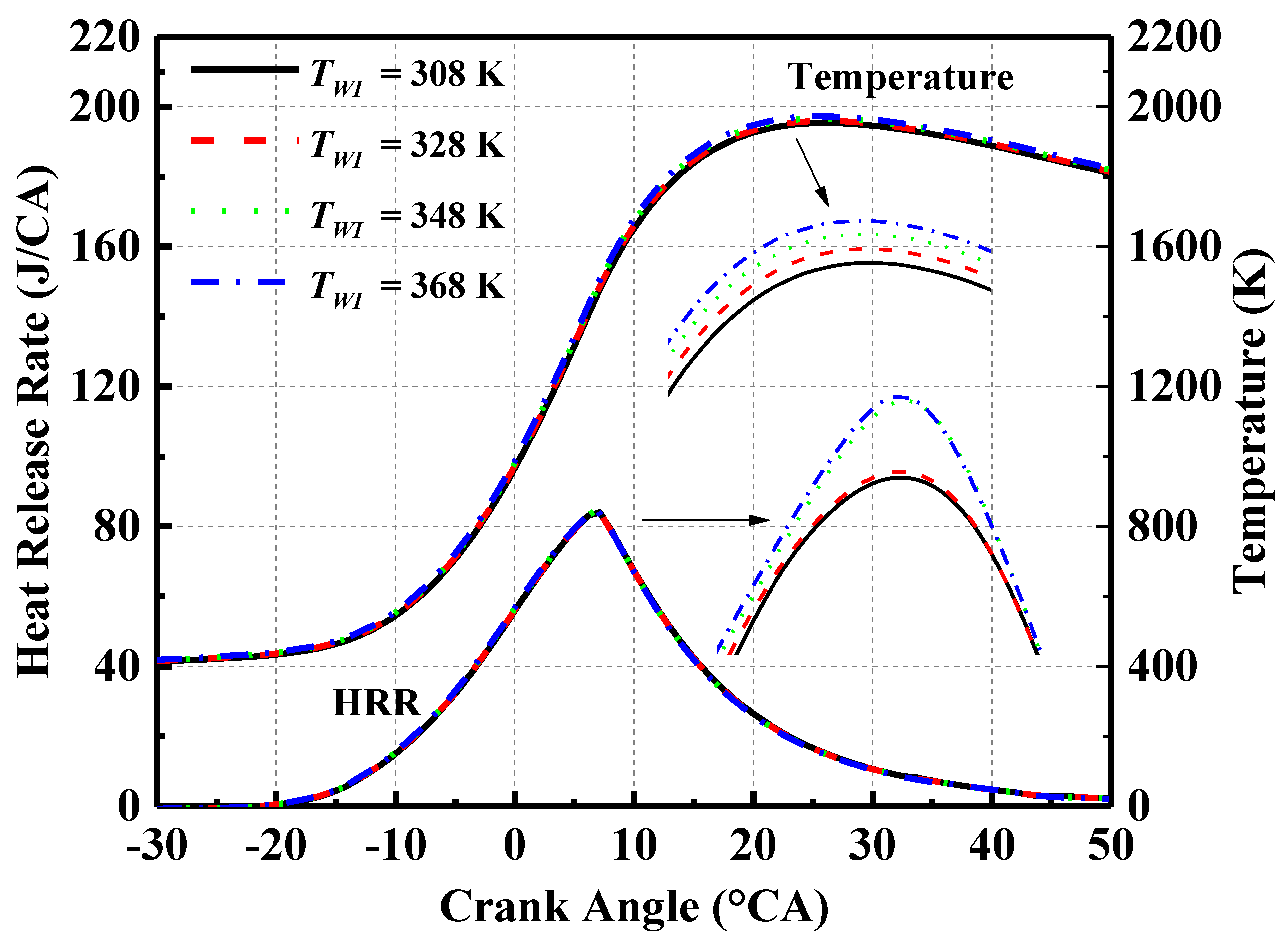

3.2. Effects of WI Mass on OFC Performance

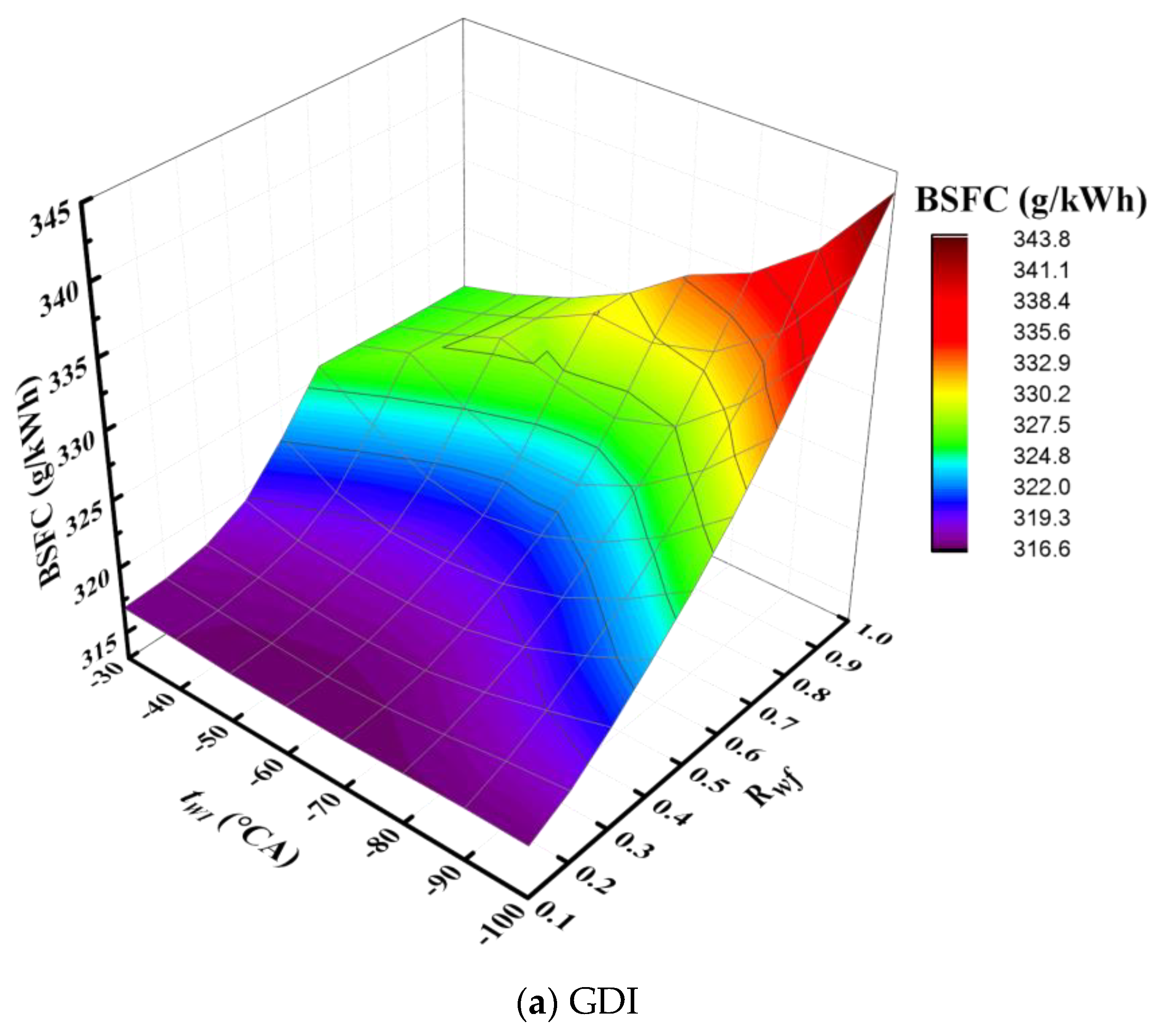

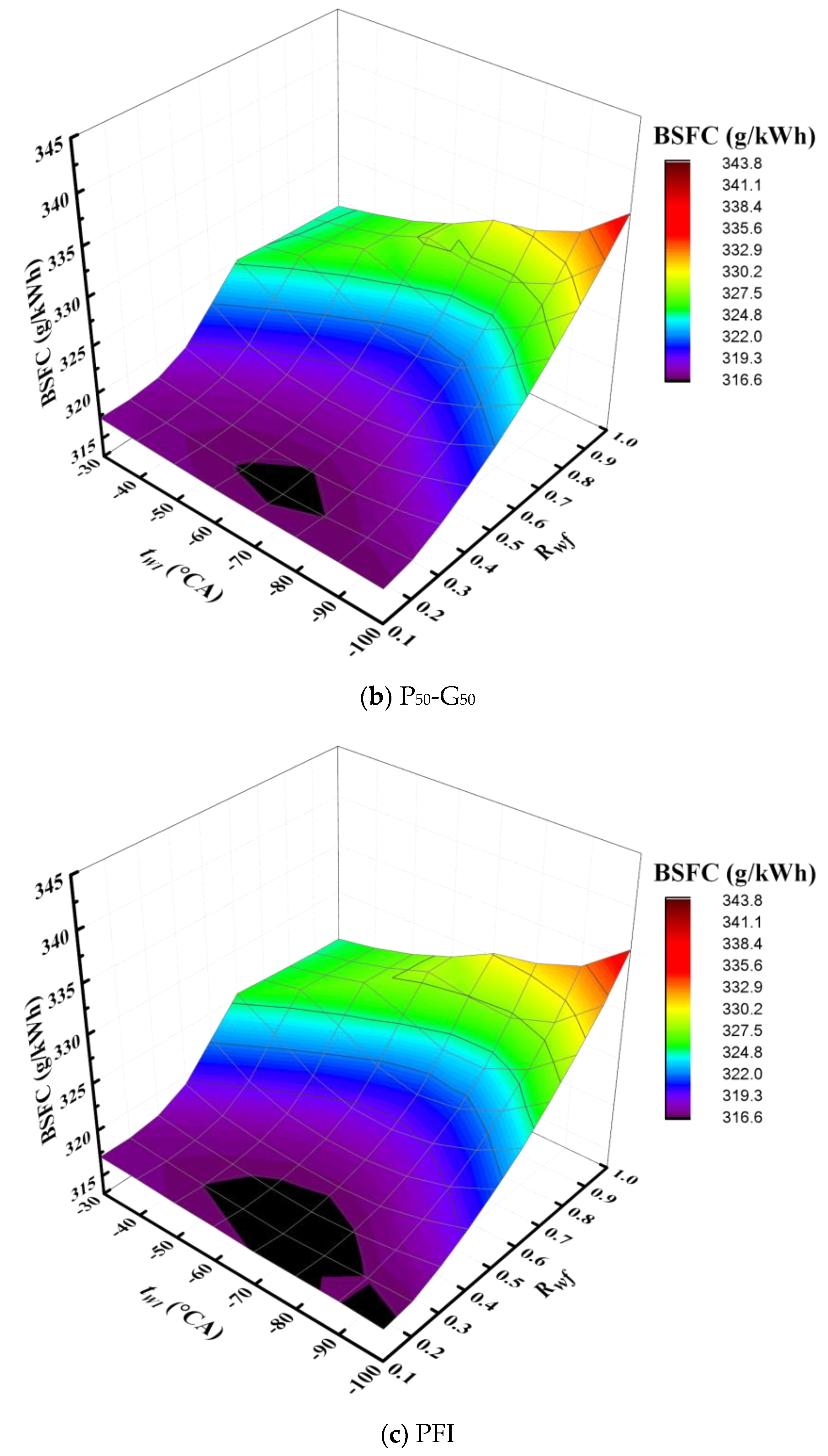

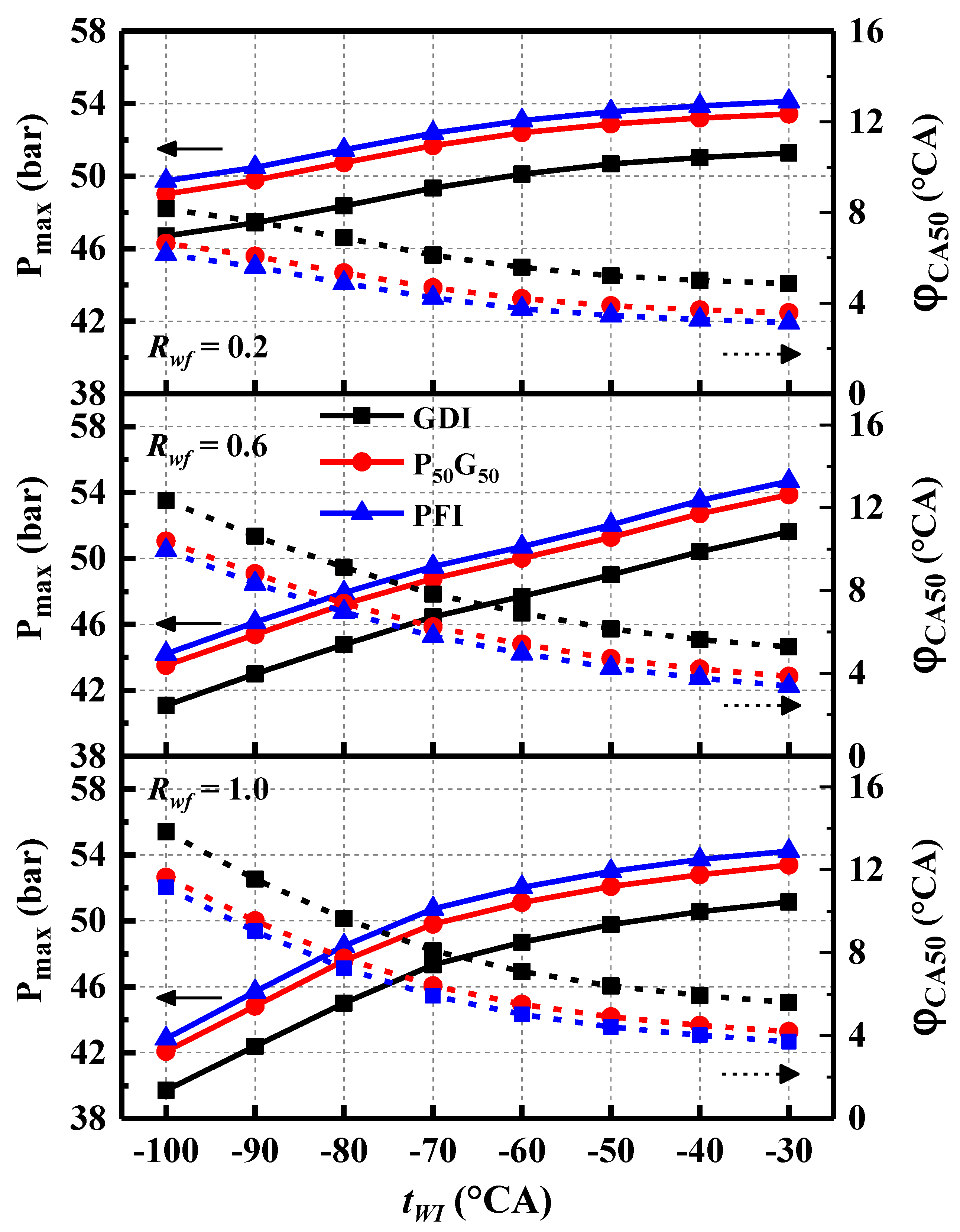

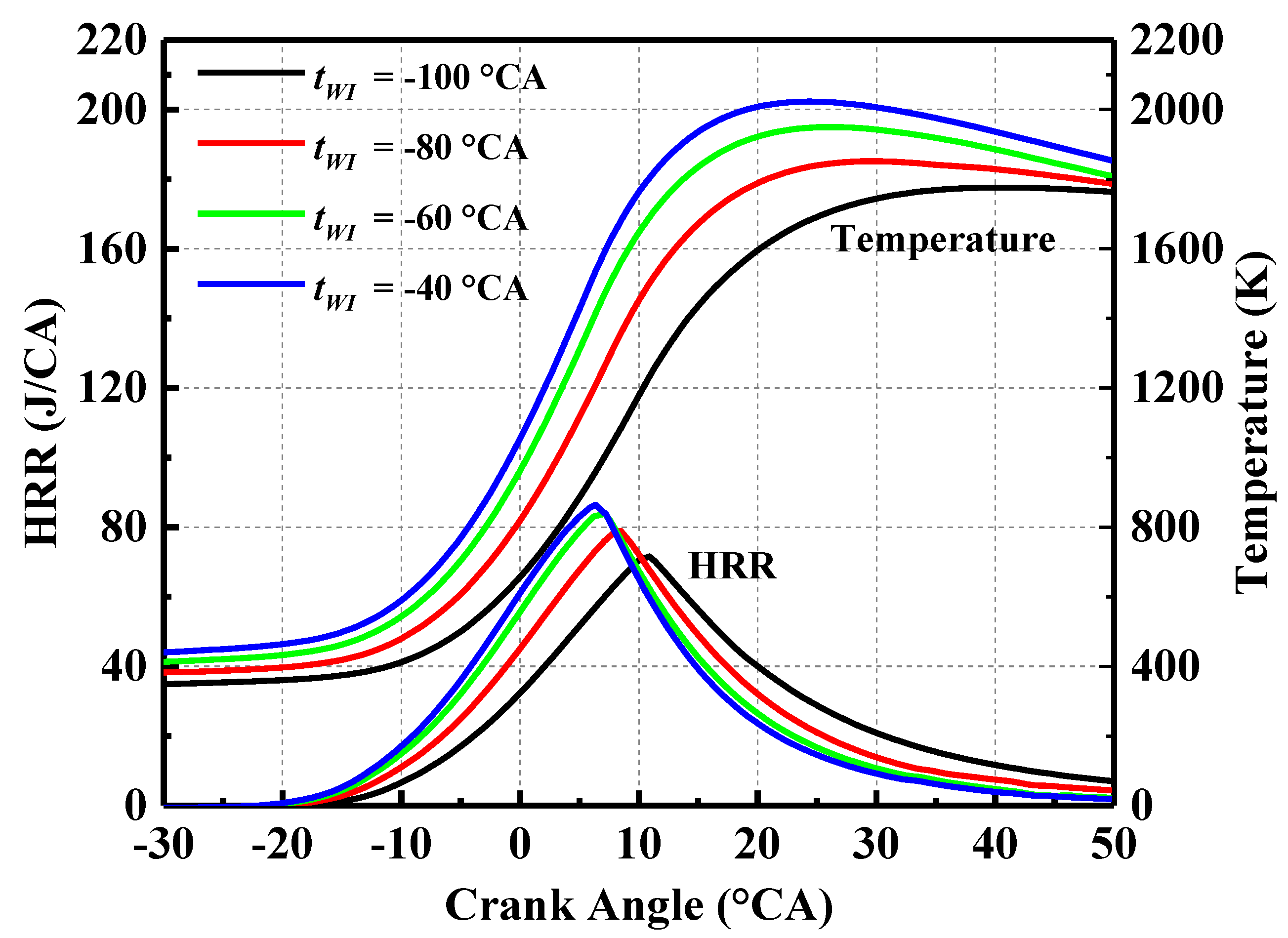

3.3. Effects of WI Timing on OFC Performance

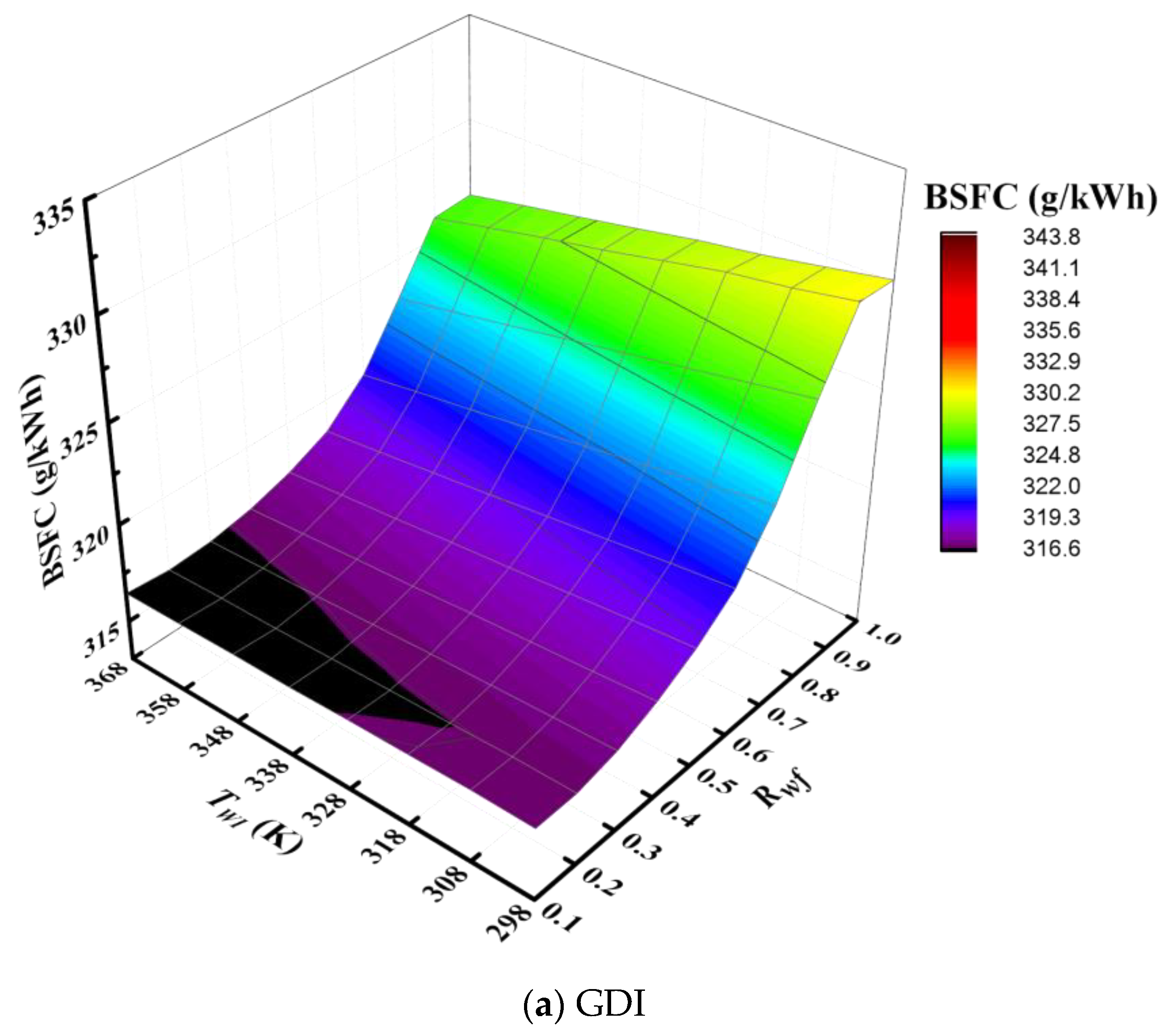

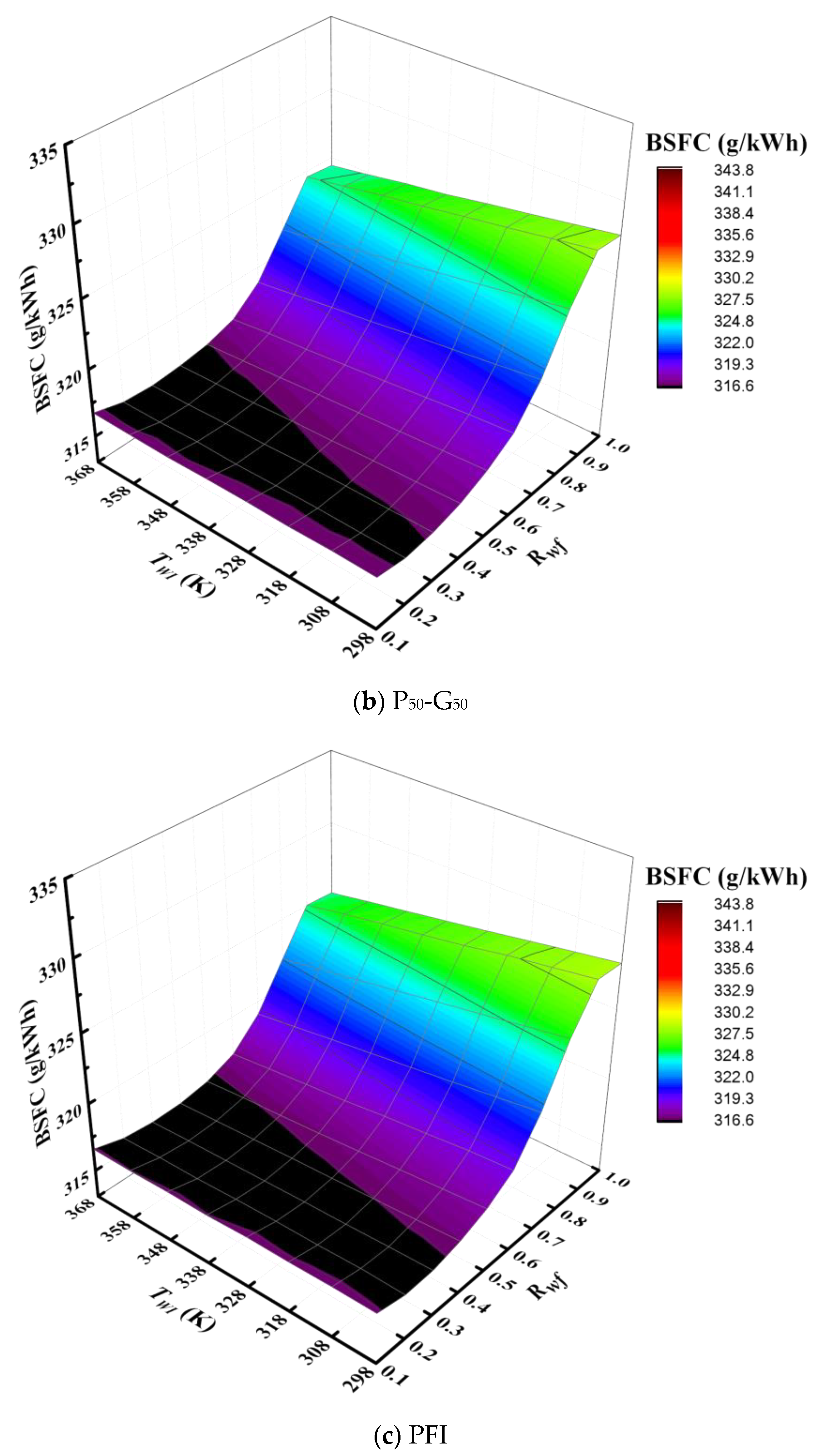

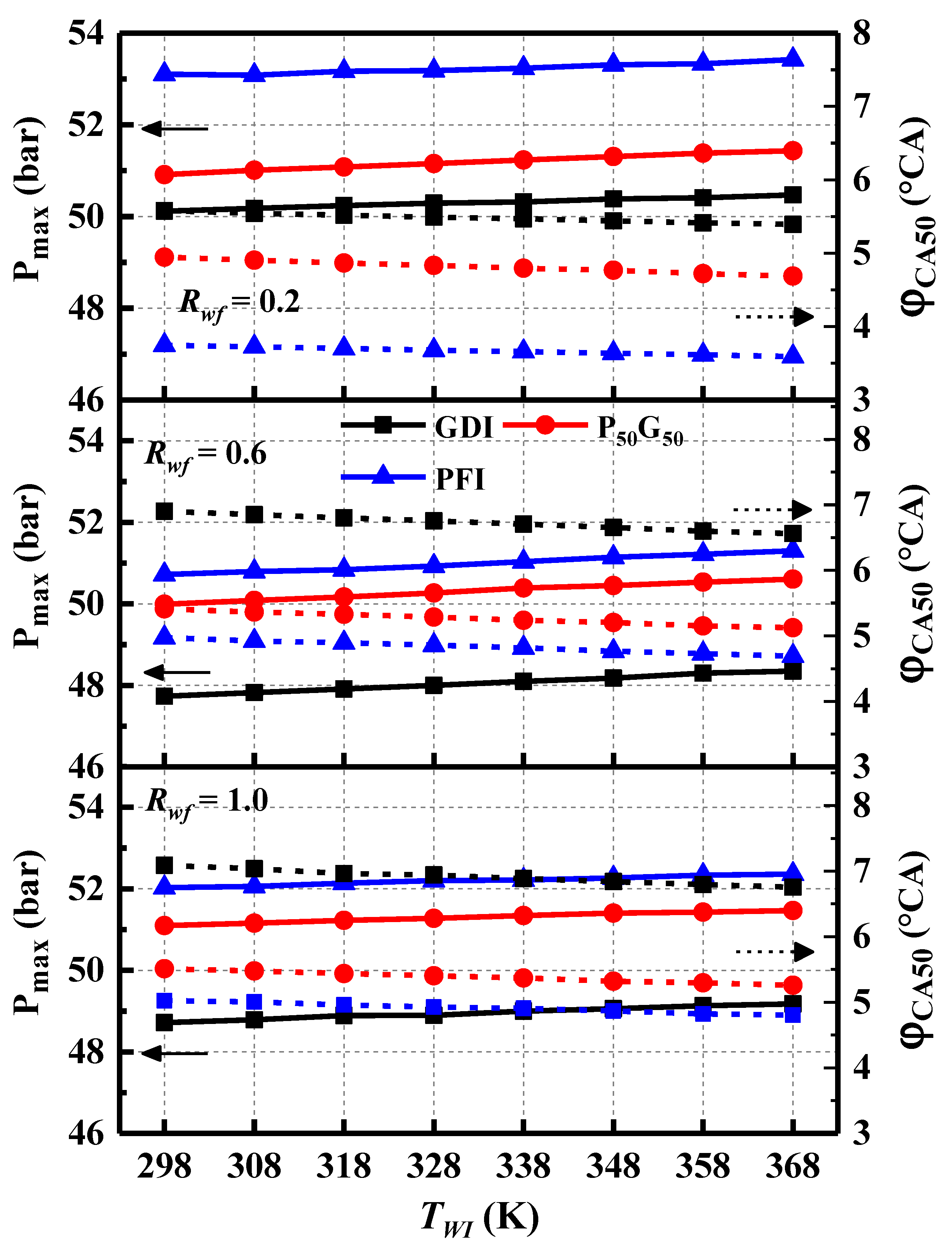

3.4. Effects of WI Temperature on OFC Performance

4. Conclusions

- Compared to CAC mode, it can be seen that the peaks of HRR under OFC are generally about 8 degrees advanced than CAC. The peaks of HRR curves decrease from around 110 J/CA of CAC to 90 J/CA of OFC. Furthermore, there is a significant increase of around 68 g/kWh in BSFC under OFC. is significantly prolonged, and the spark timing is obviously advanced. Besides, of PFI is a bit shorter than that of GDI and P50-G50.

- With the increase of , and in-cylinder temperature is reduced, while and the peak of HRR is postponed. There is a small benefit to BSFC under low . However, with the further increase of from 0.2 to 0.9, there is an increment of 4.29%, 3.6% and 3.77% in BSFC for GDI, P50-G50 and PFI, respectively.

- On the whole, the relatively lower BSFC generally appear with low . The lowest BSFC appears on the operating condition of ‘ = −70 °CA, = 0.1’, ‘ = −70 °CA, = 0.2’ and ‘ = −70 °CA, = 0.2’ for GDI, P50-G50 and PFI, respectively.

- Under the conditions of ≥ 0.8, BSFC is strongly affected by . As postpones to around −30 °CA, with the improvement in combustion performance, BSFC has a sharp decrease of more than 6 g/kWh, and this decline is more evident under GDI injection strategy.

- The variation of and is less affected by compared to the effects of or . BSFC generally has a small decline with the increase of from 298 K to 368 K regardless of the injection strategy. just presents an increase of around 0.5 bar, and whilst would be advanced by about 0.25 degrees.

- It is feasible to implement appropriate WI strategies to control OFC characteristics and performance of a dual-injection SI engine, but the benefit in fuel economy is limited.

- The findings of this study are beneficial to establish a conceptual and theoretical foundation for the implementation of OFC technology in dual-injection SI engines, as well as increasing the efficiency of this kind of engine. In future works, the engine efficiency under the OFC mode will be expected to further improve by various optimisation research, such as the effects of different kinds of fuel injection, intake charge components, variable valve actuation, etc.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| BMEP | Brake Mean Effective Pressure (bar) |

| BSFC | Brake Specific Fuel Consumption (g/kWh) |

| CA | Crank Angle (degree) |

| CAC | Conventional Air Combustion |

| CCS | Carbon Capture and Storage |

| CO2 | Carbon Dioxide |

| DI | Direct Injection |

| ECU | Electronic Control Unit |

| ERDF | European Regional Development Fund |

| GDI | Gasoline Direct Injection |

| GHG | Greenhouse Gas |

| HRR | Heat Release Rate |

| ICE | Internal Combustion Engine |

| ICRC | Internal Combustion Rankine Cycle |

| KLSA | Knock Limited Spark Advance |

| MBT | Maximum Brake Torque |

| OFC | Oxy-Fuel Combustion |

| OMF | Oxygen Mass Fraction |

| PFI | Port Fuel Injection |

| P50-G50 | 50% Port Fuel Injection and 50% Gasoline Direct Injection |

| rpm | revolutions per minute |

| SI | Spark Ignition |

References

- Wimmer, K.; Sanz, W. Optimization and comparison of the two promising oxy-combustion cycles NET Power cycle and Graz Cycle. Int. J. Greenh. Gas Control. 2020, 99, 103055. [Google Scholar] [CrossRef]

- Mondal, M.K.; Balsora, H.K.; Varshney, P. Progress and trends in CO2 capture/separation technologies: A review. Energy 2012, 46, 431–441. [Google Scholar] [CrossRef]

- Koytsoumpa, E.I.; Bergins, C.; Kakaras, E. The CO2 economy: Review of CO2 capture and reuse technologies. J. Supercrit. Fluids 2018, 132, 3–16. [Google Scholar] [CrossRef]

- Anwar, M.N.; Fayyaz, A.; Sohail, N.F.; Khokhar, M.F.; Baqar, M.; Khan, W.D.; Rasool, K.; Rehan, M.; Nizami, A.S. CO2 capture and storage: A way forward for sustainable environment. J. Environ. Manag. 2018, 226, 131–144. [Google Scholar] [CrossRef] [PubMed]

- Zheng, G.; Peng, Z. Life Cycle Assessment (LCA) of BEV’s environmental benefits for meeting the challenge of ICExit (Internal Combustion Engine Exit). Energy Rep. 2021, 7, 1203–1216. [Google Scholar] [CrossRef]

- Huang, H.; Lei, H.; Liu, M.; Wang, T.; Li, C.; Guo, X.; Chen, Y.; Pan, M. Effect of superior mesenteric artery branch structure-based flow field on PEMFC performance. Energy Convers. Manag. 2020, 226, 113546. [Google Scholar] [CrossRef]

- Pan, M.; Li, C.; Liao, J.; Lei, H.; Pan, C.; Meng, X.; Huang, H. Design and modeling of PEM fuel cell based on different flow fields. Energy 2020, 207, 118331. [Google Scholar] [CrossRef]

- Yaverbaum, L. Fluidized Bed Combustion of Coal and Waste Materials; Noyes Data Corp.: Park Ridge, NJ, USA, 1977. [Google Scholar]

- Kimura, N.; Omata, K.; Kiga, T.; Takano, S.; Shikisima, S. The characteristics of pulverized coal combustion in O2/CO2 mixtures for CO2 recovery. Energy Convers. Manag. 1995, 36, 805–808. [Google Scholar] [CrossRef]

- Nozaki, T.; Takano, S.-I.; Kiga, T.; Omata, K.; Kimura, N. Analysis of the flame formed during oxidation of pulverized coal by an O2 CO2 mixture. Energy 1997, 22, 199–205. [Google Scholar] [CrossRef]

- Chui, E.; Majeski, A.; Douglas, M.; Tan, Y.; Thambimuthu, K. Numerical investigation of oxy-coal combustion to evaluate burner and combustor design concepts. In Greenhouse Gas Control Technologies-6th International Conference; Gale, J., Kaya, Y., Eds.; Pergamon: Oxford, UK, 2003; pp. 87–93. [Google Scholar]

- Stanger, R.; Wall, T.; Spörl, R.; Paneru, M.; Grathwohl, S.; Weidmann, M.; Scheffknecht, G.; McDonald, D.; Myöhänen, K.; Ritvanen, J.; et al. Oxyfuel combustion for CO2 capture in power plants. Int. J. Greenh. Gas Control. 2015, 40, 55–125. [Google Scholar] [CrossRef]

- Stephen, R. An Introduction to Combustion: Concepts and Applications; McGraw-Hill: New York, NY, USA, 1996. [Google Scholar]

- Chen, L.; Yong, S.Z.; Ghoniem, A.F. Oxy-fuel combustion of pulverized coal: Characterization, fundamentals, stabilization and CFD modeling. Prog. Energy Combust. Sci. 2012, 38, 156–214. [Google Scholar] [CrossRef]

- Bilger, R.W. Zero release combustion technologies and the oxygen economy. In Proceedings of the Fifth International Conference on Technologies and Combustion for a Clean Environment, Lisbon, Portugal, 12–15 July 1999. [Google Scholar]

- Bilger, R.W.; Wu, Z. Carbon capture for automobiles using internal combustion Rankine cycle engines. J. Eng. Gas Turbines Power 2009, 131, 034502. [Google Scholar] [CrossRef]

- Yu, X.; Wu, Z.; Fu, L.; Deng, J.; Hu, Z.; Li, L. Study of Combustion Characteristics of a Quasi Internal Combustion Rankine Cycle Engine. In SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Fu, L.Z.; Wu, Z.J.; Yu, X.; Deng, J. Experimental study of effect of water injection on combustion stability in internal combustion Rankine cylinder engine. Chin. Intern. Combust. Engine Eng. 2014, 35, 38–45. (In Chinese) [Google Scholar]

- Fu, L.-Z.; Wu, Z.; Li, L.; Yu, X. Effect of Water Injection Temperature on Characteristics of Combustion and Emissions for Internal Combustion Rankine Cycle Engine. In SAE Technical Paper; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- Wu, Z.J.; Yu, X.; Fu, L.Z.; Deng, J.; Hu, Z.J.; Li, L.G. A high efficiency oxyfuel internal combustion engine cycle with water direct injection for waste heat recovery. Energy 2014, 70, 110–120. [Google Scholar] [CrossRef]

- Kang, Z.; Chen, S.; Wu, Z.; Deng, J.; Hu, Z.; Li, L. Simulation Study of Water Injection Strategy in Improving Cycle Efficiency Based on a Novel Compression Ignition Oxy-Fuel Combustion Engine. SAE Int. J. Engines 2018, 11, 935–945. [Google Scholar] [CrossRef]

- Yu, X.; Wu, Z.; Wang, C.; Deng, J.; Hu, Z.; Li, L. Study of the Combustion and Emission Characteristics of a Quasi ICRC Engine under Different Engine Loads. In SAE Technical Paper; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- Wu, Z.-J.; Yu, X.; Fu, L.-Z.; Deng, J.; Li, L.-G. Experimental study of the effect of water injection on the cycle performance of an internal-combustion Rankine cycle engine. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2014, 228, 580–588. [Google Scholar] [CrossRef]

- Fu, L.; Wu, Z.; Yu, X.; Deng, J.; Hu, Z.; Li, L. Experimental Investigation of Combustion and Emission Characteristics for Internal Combustion Rankine Cycle Engine under Different Water Injection Laws. Energy Procedia 2015, 66, 89–92. [Google Scholar] [CrossRef][Green Version]

- Wu, J.; Kang, Z.; Zhang, Z.; Li, Z.; Deng, J.; Wu, Z. Effects of Vessel and Water Temperatures on Direct Injection in Internal Combustion Rankine Cycle Engines. Automot. Innov. 2018, 1, 331–341. [Google Scholar] [CrossRef]

- Li, X.; Pei, Y.; Peng, Z.; Ajmal, T.; Rana, K.-J.; Aitouche, A.; Mobasheri, R. Numerical study on the effects of intake charge on oxy-fuel combustion in a dual-injection spark ignition engine at economical oxygen-fuel ratios. Int. J. Engine Res. 2021. [Google Scholar] [CrossRef]

- An, Y.; Teng, S.; Li, X.; Qin, J.; Zhao, H.; Zhan, Z.S.; Hu, T.G.; Liu, B.; Zhong, J. Study of Polycyclic Aromatic Hydrocarbons Evolution Processing in GDI Engines Using TRF-PAH Chemical Kinetic Mechanism. In SAE Technical Paper; SAE International: Warrendale, PA, USA, 2016. [Google Scholar] [CrossRef]

- Wu, M.; Pei, Y.; Qin, J.; Li, X.; Zhou, J.; Zhan, Z.S.; Guo, Q.-Y.; Liu, B.; Hu, T.G. Study on Methods of Coupling Numerical Simulation of Conjugate Heat Transfer and In-Cylinder Combustion Process in GDI Engine. In SAE Technical Paper; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Li, X.; Pei, Y.-Q.; Qin, J.; Zhang, D.; Wang, K.; Xu, B. Effect of ultra-high injection pressure up to 50 MPa on macroscopic spray characteristics of a multi-hole gasoline direct injection injector fueled with ethanol. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2017, 232, 1092–1104. [Google Scholar] [CrossRef]

- Ma, H.; Li, Z.; Tayarani, M.; Lu, G.; Xu, H.; Yao, X. Model-based computational intelligence multi-objective optimization for gasoline direct injection engine calibration. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2019, 233, 1391–1402. [Google Scholar] [CrossRef]

- Raut, A.A.; Mallikarjuna, J.M. Effects of direct water injection and injector configurations on performance and emission characteristics of a gasoline direct injection engine: A computational fluid dynamics analysis. Int. J. Engine Res. 2020, 21, 1520–1540. [Google Scholar] [CrossRef]

- Frommater, S.; Neumann, J.; Hasse, C. A phenomenological modelling framework for particle emission simulation in a direct-injection gasoline engine. Int. J. Engine Res. 2021, 22, 1166–1179. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, H. Effect of piston shape design on the scavenging performance and mixture preparation in a two-stroke boosted uniflow scavenged direct injection gasoline engine. Int. J. Engine Res. 2021, 22, 1484–1499. [Google Scholar] [CrossRef]

- Shi, H.; Uddeen, K.; An, Y.; Pei, Y.; Johansson, B. Multiple spark plugs coupled with pressure sensors: A new approach for knock mechanism study on SI engines. Energy 2021, 227, 120382. [Google Scholar] [CrossRef]

- Larsson, T.; Mahendar, S.; Christiansen-Erlandsson, A.; Olofsson, U. The Effect of Pure Oxygenated Biofuels on Efficiency and Emissions in a Gasoline Optimised DISI Engine. Energies 2021, 14, 3908. [Google Scholar] [CrossRef]

- Ikoma, T.; Abe, S.; Sonoda, Y.; Suzuki, H.; Suzuki, Y.; Basaki, M. Development of V-6 3.5-liter Engine Adopting New Direct Injection System. In SAE Technical Paper; SAE International: Warrendale, PA, USA, 2006. [Google Scholar] [CrossRef]

- Wu, X.; Daniel, R.; Tian, G.; Xu, H.; Huang, Z.; Richardson, D. Dual-injection: The flexible, bi-fuel concept for spark-ignition engines fuelled with various gasoline and biofuel blends. Appl. Energy 2011, 88, 2305–2314. [Google Scholar] [CrossRef]

- Daniel, R.; Xu, H.; Wang, C.; Richardson, D.; Shuai, S. Gaseous and particulate matter emissions of biofuel blends in dual-injection compared to direct-injection and port injection. Appl. Energy 2013, 105, 252–261. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Z.; Long, Y.; Xiang, S.; Wang, J.; Fatouraie, M. Comparative study on alcohol–gasoline and gasoline–alcohol Dual-Fuel Spark Ignition (DFSI) combustion for engine particle number (PN) reduction. Fuel 2015, 159, 250–258. [Google Scholar] [CrossRef]

- Zhuang, Y.; Zhu, G.; Gong, Z.; Wang, C. Experimental and numerical investigation of performance of an ethanol-gasoline dual-injection engine. Energy 2019, 186, 115835. [Google Scholar] [CrossRef]

- Li, J.; Liu, C.; Kang, R.; Zhou, L.; Wei, H. Effects of the injection timing on knock and combustion characteristics in dual-fuel dual-injection engines. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2020, 234, 2578–2591. [Google Scholar] [CrossRef]

- Huang, Y.; Surawski, N.C.; Zhuang, Y.; Zhou, J.L.; Hong, G. Dual injection: An effective and efficient technology to use renewable fuels in spark ignition engines. Renew. Sustain. Energy Rev. 2021, 143, 110921. [Google Scholar] [CrossRef]

- Liu, K.; Li, Y.; Yang, J.; Deng, B.; Feng, R.; Huang, Y. Comprehensive study of key operating parameters on combustion characteristics of butanol-gasoline blends in a high speed SI engine. Appl. Energy 2018, 212, 13–32. [Google Scholar] [CrossRef]

- Teodosio, L.; Pirrello, D.; Berni, F.; De Bellis, V.; Lanzafame, R.; D’Adamo, A. Impact of intake valve strategies on fuel consumption and knock tendency of a spark ignition engine. Appl. Energy 2018, 216, 91–104. [Google Scholar] [CrossRef]

- Tornatore, C.; Bozza, F.; De Bellis, V.; Teodosio, L.; Valentino, G.; Marchitto, L. Experimental and numerical study on the influence of cooled EGR on knock tendency, performance and emissions of a downsized spark-ignition engine. Energy 2019, 172, 968–976. [Google Scholar] [CrossRef]

- Tian, Z.; Zhen, X.; Wang, Y.; Liu, D.; Li, X. Combustion and emission characteristics of n-butanol-gasoline blends in SI direct injection gasoline engine. Renew. Energy 2020, 146, 267–279. [Google Scholar] [CrossRef]

- Woschni, G. A Universally Applicable Equation for the Instantaneous Heat Transfer Coefficient in the Internal Combustion Engine. In SAE Technical Paper; SAE International: Warrendale, PA, USA, 1967. [Google Scholar] [CrossRef]

- Shayler, P.J.; May, S.A.; Ma, T. Heat Transfer to the Combustion Chamber Walls in Spark Ignition Engines. In SAE Technical Paper; SAE International: Warrendale, PA, USA, 1995. [Google Scholar]

- Heywood, J.B. Internal Combustion Engine Fundamentals, 2nd ed.; McGraw-Hill: New York, NY, USA, 2018. [Google Scholar]

- Shaddix, C.R.; Molina, A. Particle imaging of ignition and devolatilization of pulverized coal during oxy-fuel combustion. Proc. Combust. Inst. 2009, 32, 2091–2098. [Google Scholar] [CrossRef]

- Molina, A.; Shaddix, C.R. Ignition and devolatilization of pulverized bituminous coal particles during oxygen/carbon dioxide coal combustion. Proc. Combust. Inst. 2007, 31, 1905–1912. [Google Scholar] [CrossRef]

- Mazas, A.N.; Fiorina, B.; Lacoste, D.A.; Schuller, T. Effects of water vapor addition on the laminar burning velocity of oxygen-enriched methane flames. Combust. Flame 2011, 158, 2428–2440. [Google Scholar] [CrossRef]

| Property | CO2 | Nitrogen | Ratio (CO2/Nitrogen) |

|---|---|---|---|

| Molecular weight | 44 | 28 | 1.57 |

| Density (kg/m3) | 0.5362 | 0.3413 | 1.57 |

| Kinematic viscosity (m2/s) | 7.69 × 10−5 | 1.2 × 10−4 | 0.631 |

| Specific heat capacity (kJ/kg K) | 1.2343 | 1.1674 | 1.06 |

| Thermal conductivity (W/m K) | 7.057 × 10−2 | 6.599 × 10−2 | 1.07 |

| Thermal diffusivity (m2/s) | 1.1 × 10−4 | 1.7 × 10−4 | 0.644 |

| Mass diffusivity of O2 (m2/s) | 9.8 × 10−5 | 1.3 × 10−4 | 0.778 |

| Prandtl number | 0.7455 | 0.7022 | 1.06 |

| Emissivity and absorptivity | >0 | ~0 | - |

| Items | Content |

|---|---|

| Engine type | Four-cylinder; Four-stroke |

| Bore × Stroke (mm) | 82.5 × 92 |

| Displacement (L) | 2.0 |

| Injection type | Dual-injection (PFI plus GDI) |

| Intake type | Turbocharged |

| Compression ratio | 9.6:1 |

| Rated speed (rpm) | 5500 |

| Rated power (kW) | 160 |

| Maximum Torque (N·m) | 320 |

| Items | Content |

|---|---|

| Fuel type | Gasoline |

| Chemical formula | C5-C12 |

| Relative molecular mass | 95–120 |

| Gravimetric carbon content (%) | 86.4 |

| Gravimetric hydrogen content (%) | 13.6 |

| Gravimetric oxygen content (%) | <0.1 |

| Research octane number | 95 |

| Density (20 °C) (kg/L) | 0.73 |

| Dynamic viscosity (20 °C) (mPa·s) | 0.52 |

| Kinematic viscosity (20 °C) (mm2/s) | 0.71 |

| Surface tension (20 °C) (N/m) | 22 |

| Boiling range (°C) | 30–200 |

| Low heating value (kJ/kg) | 44,300 |

| Latent heat of vaporisation (kJ/kg) | 370 |

| Laminar flame speed (20 °C) (m/s) | 0.33 |

| Stoichiometric air-fuel ratio | 14.7 |

| Measured Parameters | Uncertainty (%) |

|---|---|

| Engine speed | ±0.1 |

| BMEP | ±0.1 |

| BSFC | ±0.2 |

| Pressure | ±0.1 |

| Crank angle | ±0.1 |

| Lambda | ±0.3 |

| Coolant temperature | ±0.4 |

| Intercooler output temperature | ±0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Pei, Y.; Li, D.; Ajmal, T.; Rana, K.-J.; Aitouche, A.; Mobasheri, R.; Peng, Z. Effects of Water Injection Strategies on Oxy-Fuel Combustion Characteristics of a Dual-Injection Spark Ignition Engine. Energies 2021, 14, 5287. https://doi.org/10.3390/en14175287

Li X, Pei Y, Li D, Ajmal T, Rana K-J, Aitouche A, Mobasheri R, Peng Z. Effects of Water Injection Strategies on Oxy-Fuel Combustion Characteristics of a Dual-Injection Spark Ignition Engine. Energies. 2021; 14(17):5287. https://doi.org/10.3390/en14175287

Chicago/Turabian StyleLi, Xiang, Yiqiang Pei, Dayou Li, Tahmina Ajmal, Khaqan-Jim Rana, Abdel Aitouche, Raouf Mobasheri, and Zhijun Peng. 2021. "Effects of Water Injection Strategies on Oxy-Fuel Combustion Characteristics of a Dual-Injection Spark Ignition Engine" Energies 14, no. 17: 5287. https://doi.org/10.3390/en14175287

APA StyleLi, X., Pei, Y., Li, D., Ajmal, T., Rana, K.-J., Aitouche, A., Mobasheri, R., & Peng, Z. (2021). Effects of Water Injection Strategies on Oxy-Fuel Combustion Characteristics of a Dual-Injection Spark Ignition Engine. Energies, 14(17), 5287. https://doi.org/10.3390/en14175287