Abstract

This study investigates the input–output energy-flow patterns and CO2 emissions from the wheat–rice crop rotation system. In this regard, an arid region of Punjab, Pakistan was selected as the study area, comprising 4150 km2. Farmers were interviewed to collect data and information on input/output sources during the 2020 work season. The total energy from these sources was calculated using appropriate energy equivalents. Three energy indices, including energy use efficiency (ηe), energy productivity (ηp), and net energy (ρ), were defined and calculated to investigate overall energy efficiency. Moreover, the data envelopment analysis (DEA) technique was used to optimize the input energy in wheat and rice production. Finally, CO2 emissions was calculated using emissions equivalents from peer-reviewed published literature. Results showed that the average total energy consumption in rice production was twice the energy consumed in wheat production. However, the values of ηe, ηp, and ρ were higher in wheat production and calculated as 5.68, 202.3 kg/GJ, and 100.12 GJ/ha, respectively. The DEA showed the highest reduction potential in machinery energy for both crops, calculated as −42.97% in rice production and −17.48% in wheat production. The highest CO2 emissions were found in rice production and calculated as 1762.5 kg-CO2/ha. Our conclusion indicates that energy consumption and CO2 emissions from wheat–rice cropping systems can be minimized using optimized energy inputs.

1. Introduction

Wheat (Triticum aestivum) and rice (Oryza sativa) are the main cereal crops grown worldwide, constituting 54% of the total cereal production [1]. The mean annual global wheat and rice production are recorded as 646.9 and 654.8 million metric tonnes, respectively [2]. These grains are the staple food of 85% of the world population [3,4]. Pakistan is an agricultural country, having a share of 3.32% and 1.3% in the world’s wheat and rice production, respectively [2]. The demand for these grains is increasing tremendously, due to increasing growth in the world’s population. Forecasts showed an increase in world wheat demand up to 60% of the current production—by 2050 [5]. Moreover, arable land is decreasing, due to housing societies and other domestic/commercial purposes. This necessitates efficient energy use in agricultural production to enhance yields and sustain food security. Moreover, food storage and processing is also an important element of food security [6,7,8]. In this regard, energy-efficient and environment-friendly storage systems can play an important role in avoiding off-season food shortages [9,10,11].

Agriculture is an energy conversion process, in which solar energy is converted into food and fiber through photosynthesis [12]. It becomes more energy-intensive due to the use of fossil fuels, fertilizers, machinery, and electricity to enhance overall production [13]. Agricultural energy flow is classified as direct energy input and indirect energy input. Direct energy input includes energy consumed on the farm during various operations e.g., labor, fuel, machinery, water, and electricity. Indirect energy input is the energy consumed during the production process of different input sources e.g., fertilizers, machinery, seeds, and biocides [14]. These energy inputs can also be divided into renewable and non-renewable energy inputs. Renewable energy includes the energy input from machinery and labor while non-renewable energy constitutes all other input sources [15]. The amount and type of energy input in agricultural production mainly depend on the socioeconomic characteristics of the farm and farmers [16,17,18]. These characteristics include farmer’s experience and education, farm size, source of irrigation, local climate, soil and crop type, and farmer’s landholdings [15,19,20]. However, the intensive use of energy in agricultural production creates health and environmental concerns [13]. For example, the combustion of fossil fuels emits a large amount of carbon dioxide (CO2) and other greenhouse gasses (GHGs) into the atmosphere. Similarly, the production processes of fertilizers, machinery, electricity, and chemicals emit a huge amount of GHGs. Higher concentrations of these gasses in the atmosphere creates an alarming situation for the atmospheric chemistry of the globe [21]. For instance, the concentration of CO2 in the atmosphere has reached 419.05 ppm and is increasing further rapidly [22]. It leads to global warming and climate change, the most challenging issues of the current century [23], to which end the United Nations Framework Convention on Climate Change has aimed to limit global warming up to 2 °C in the current century. In this regard, the present decarbonization rate, of 1.6 percent per year, has to be increased to 6.4 percent per year, otherwise global temperatures may increase by four degrees Celsius by the end of this century [24]. Furthermore, though Pakistan is ranked seventh among countries vulnerable to climate change, per capita emissions of the country are among the lowest in the world [25]. This said, the majority GHGs emissions in Pakistan come from the energy and agriculture sectors, accounting for 46% and 41% of total emissions, respectively [26]. Therefore, efficient, and optimized energy use in agricultural production is necessary in agricultural countries like Pakistan if emissions are to be reduced further.

Several studies have been conducted worldwide on energy-use patterns and CO2 emissions from agricultural production. These studies include energy consumption analysis in wheat [27,28], maize [29], rice [30,31], and soybean [32] production in India; energy and economic analyses in the production of wheat [33,34,35], rice [13], sugar beet [36], and fruits [37,38,39] in Iran; energy modeling and CO2 emissions assessment for wheat production in New Zealand [18,40,41,42]; comparative input–output energy analysis in agricultural production in Indonesia and Thailand [43,44]; the assessment of CO2 emissions and energy flow in cotton [17,45], fruits [20,46,47], and vegetables [48] in Turkey; the effects of different fertilizer management practices on CO2 emissions from different crop production systems; energy and water footprint assessment in grain crops in Australia [16,49,50]; energy budget evaluation in wheat production in China [51]. Finally, in Pakistan, Ashraf et al. [15] and Khan et. al. [52] investigated energy consumption patterns in wheat and rice production, respectively. However, no such study was found for the wheat–rice crop rotation system in an arid region of Punjab, Pakistan.

The main objective of this study was to investigate and compare input–output energy flow and CO2 emissions in wheat–rice crop rotation systems in an arid region of Punjab, Pakistan. This study provides insights into energy-use optimization in wheat and rice production, using the data envelopment analysis (DEA) technique. Moreover, the study reveals the relationship between grain yield and energy input, using mathematical models developed from the data and information collected from farmers in the study area. The relationship between total input energy and CO2 emission is also developed to analyze the impact of energy consumption on carbon dioxide emissions. This study contributes solutions to optimizing energy use for wheat and rice production.

2. Research Methodology

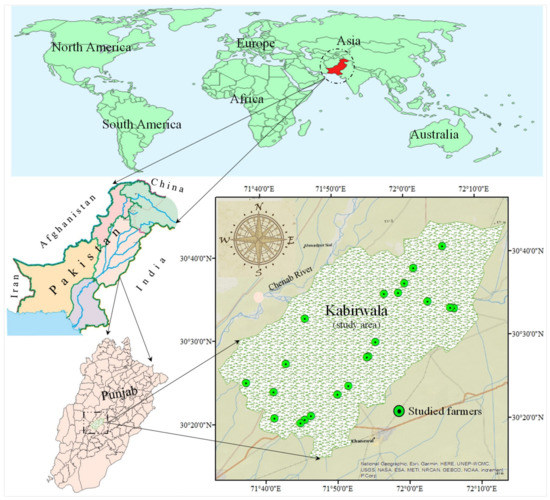

This study was conducted in Kabirwala (30°24′ N, 71°52′ E), a Tehsil of Khanewal District, Punjab, Pakistan. The map of the study area is shown in Figure 1. Kabirwala is situated at the bank of the river Chenab and has fertile lands for agricultural cultivations. The study area is comprised was 4150 km2, of which more than 80% was cultivatable land. Most of the population in the study area is engaged with the agriculture sector, indicating the economic importance of agriculture in this area. Wheat–rice is the prominent crop rotation in Tehsil. According to the Pakistan Bureau of Statistics [53], the Khanewal district has a significant share (3.9%) of Pakistan’s total wheat production, while 1.6% of total rice production was in Punjab. The mean annual minimum and maximum temperatures in the study area are 11 °C and 46 °C, respectively. The study area lies in an arid region with a mean annual rainfall of 177.4 mm. Most of the rainfall (41.5%) in the study area occurs in the monsoon season i.e., July and August. However, canal water and groundwater (pumped by tube-wells) are used for irrigation to meet crop’s water requirements throughout the year. In this regard, data on irrigation water and other energetic aspects i.e., seeds, labor, fuel, fertilizer, machinery, chemicals, and electricity were collected from farmers through face-to-face interviews and questionnaires during the 2020 work season. A total of 23 farmers were selected and visited randomly from the study area to collect data and information. The sample size was calculated using the Cochran formula given in Equation (1) [54].

where N is the required sample size, n is the number of landholdings, q is a constant taken as 1.96 for 95% reliability, E2 is the variance, and e is the margin of error.

Figure 1.

Map of the study area and distribution of the studied farmers inside the study area.

Preliminary data evaluation revealed that there were variations in energy inputs/outputs among the studied farmers. These variations were mainly due to differences in the socioeconomic characteristics of a specific farm and/or farmer. It is evident that variations in these properties of the farms/farmers affect the management practices and eventual crop yield [42]. The socioeconomic structures of the farms and farmers are given in Table 1. The table depicts minimum, maximum, and mean values of seven socioeconomic characteristics of the farm/farmers i.e., farmers’ education, farmers’ experience, farm size, number of farm laborers, number of tractors, source of irrigation, and canal-to-tube-well irrigation ratio. We reported that a farmer’s education and farm size are directly related to their energy consumption; farmers’ education and farm size vary positively with energy use [42]. In this regard, the average farmer’s education and farm size were found to be 8 years of schooling and 8.78 ha, respectively. Similarly, the number of a farm’s laborers and tractors also increases with its size. The highest number of farm laborers and tractors observed were seven and two, respectively, corresponding to the largest farm at 31.03 ha. Moreover, the farmers’ mean experience was 18.35 years, indicating the higher technical knowledge of farmers in the study area. The farmers’ greater experience also suggests that the studied farmers have been intergenerationally involved in agriculture. Additionally, sources of irrigation are also an important factor in the overall energy consumption of agricultural production [15]. Therefore, the consumption of canal water is ideal for irrigation, as it eliminates pumping energy and hence decreases overall energy usage. However, the main source of irrigation in the study area was tube-well water, due to the limited availability of canal water throughout the year. The canal-to-tube-well irrigation ratio was observed as 31:61. These socioeconomic factors were considered in the present study.

Table 1.

Socioeconomic properties of the farms and farmers in the study area.

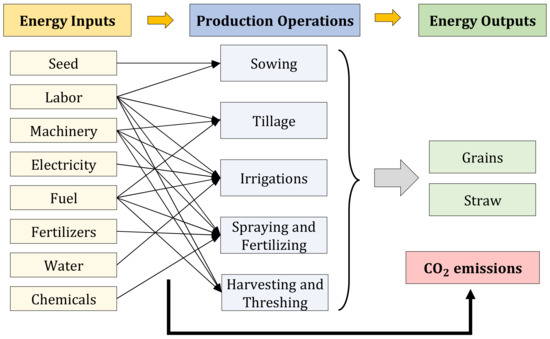

The present study evaluates input–output energy patterns for wheat–rice crop rotation systems from sowing until harvesting. The system boundaries for this study are shown in Figure 2. The figure depicts this study’s evaluation of the energy flow inside a farm and does not consider transporting outputs from the farm gate to the end consumer. Quantitative data on input sources were used to calculate total energy consumption, using energy equivalents. Energy equivalents from different studies were reviewed technically and the most appropriate equivalents were used in the present study; those used in this study are given in Table 2. However, energy consumption from farm equipment was calculated using Equation (2) [55]. Furthermore, energy efficiency in wheat–rice cropping patterns was investigated based on three indices, energy-use efficiency, energy productivity, and net energy (Equations (3)–(5)). The term energy efficiency is used to denote the overall performance of energy inputs to generate energy outputs. This performance was investigated based on the above-mentioned energy indices.

where Ee is the energy equivalent for farm implement/tractor (MJ/hr), B is a constant (MJ/kg), W refers to the weight of a tractor/implement (kg), and L refers to the economic life span of a tractor/implement (hr). The appropriate values for B, W, and L were taken from the literature [55,56,57]. ηp is energy productivity (kg/GJ), Ga is the weight of grains (kg/ha), Ei is the total input energy (GJ/ha), ηe is energy-use efficiency, Eo is the total output energy (GJ/ha), and ρ is net energy (GJ/ha).

Figure 2.

System boundaries and energy flow pattern for input–output energy analyses in a wheat–rice crop rotation system.

Table 2.

Energy equivalents used to calculate total input–output energy in wheat and rice production.

Data envelopment analysis (DEA) was also conducted to calculate the technical efficiencies of the farmers in the study area. Technical efficiency is the performance of an individual farmer based on the ratio of weighted outputs to weighted inputs. Data envelopment analysis (DEA) is an analytical technique that compares different decision-making units (DMUs) against their relative performances in a specific operation [58]. DMUs are the specific units that must be compared in DEA e.g., farmers, in the present study. The technical efficiencies of the DMUs were calculated by an input-oriented CCR (Charnes–Cooper-Rhodes) model [59]. In this regard, three inputs i.e., diesel, seed, and fertilizer energies were taken as inputs, and grains (kg/ha) as output, in the studied CCR model. The input-oriented CCR model works on the principle of achieving a constant output while minimizing inputs. Technically efficient and inefficient DMUs were critically studied to investigate potential improvements in inefficient DMUs (farmers). Frontier Analyst 4 was used to conduct DEA in this study. However, the mathematical interpretation of the technical efficiency of DEA is given in Equation (6) [60]. Furthermore, the grain yield (kg/ha) was also estimated by the multiple regression technique (Equation (7) and (8)). These equations were developed using grain yields as a response, while energy inputs from fertilizer, seed, and diesel as continuous predictors.

Applying linear programming to solve Equation (6):

where TEa is the technical efficiency of ath DMU, yi refers to quantity of nth output, ui and vj refer to the weights of nth output and mth input, respectively. i and j denote the number of outputs (i = 1, 2, 3,…, n) and inputs (j = 1, 2, 3,…, m), respectively. xj is the quantity of mth input, and a refers to the number of DMUs (a = 1, 2, 3,…, b). Gw and Gr are the grains yield (kg) of wheat and rice crops, respectively. F represents energy from fertilizers (GJ), S is the energy input from seed (GJ), W and D are the energy inputs (GJ) from water and diesel, respectively. The study uses the Origin software developed by the OriginLab Corporation for the regression analyses and for the development of the graphs.

In addition to the energy analyses, the carbon footprint from wheat and rice production in the study area was also assessed, by investigating carbon dioxide (CO2) emissions. In this regard, energy units were converted into kg-CO2 units using the emission equivalents given in Table 3 while considering the guidelines given by [61]. These emissions were further converted to kg-CO2/ha units using Equation (9). Other GHGs emissions, like N2O and CH4, were not considered in this study due to their minor contribution to the total emissions from agricultural production [36]. The CO2 emissions from the production processes of fertilizers, electricity, machinery, chemicals, and fuel were considered to calculate the total carbon footprint. Organic fertilizers were not considered due to their limited or absent use in wheat and rice cultivations in the study area. In the case of emissions from electricity generation, only 64% of the total electrical energy input was converted to emissions equivalence. In Pakistan, total electricity generation is generated by hydropower plants (36%) and thermal power plants (64%).

where refers to CO2 emissions in kg-CO2/ha, CE is CO2 emissions in kg-CO2/MJ and is the total input energy (MJ/ha).

Table 3.

Input energy and associated equivalent CO2 emissions used in this study to evaluate carbon footprint while considering the guidelines given by [61].

3. Results and Discussion

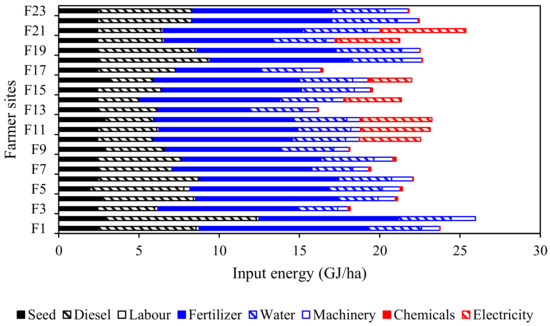

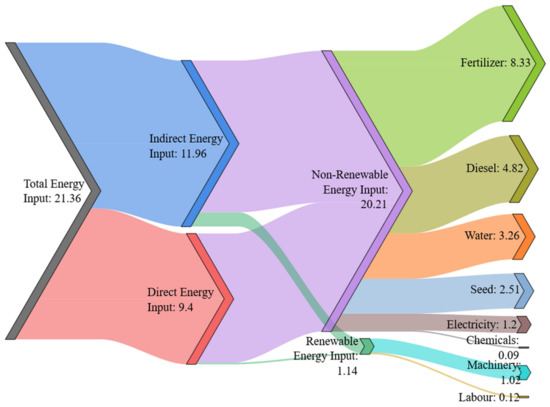

Data and information on energy sources were collected from the farmers and are given in Table 4. The table depicts the averages of consumption of different energy sources in wheat and rice production. The average labor consumption in rice production was observed as 242.698 h/ha, which was four times higher than that used in wheat production. This was due to the higher energy consumption in transplanting rice plants and the higher water requirement of this crop. Similarly, the usage of diesel, electricity, water, and machinery in rice production was much higher than their usage in wheat production. However, other inputs, i.e., fertilizers and chemicals, were used in a similar pattern to produce both crops. These inputs were converted into energy units (GJ/ha) and are exhibited in Figure 3 and Figure 4. The energy input from different sources in wheat and rice production are shown in Figure 3 and Figure 4, respectively. It is evident from the figure (Figure 3) that there are variations among the studied farmers in diesel and electrical energy inputs. The main reason for these discrepancies was the type of alternative source of irrigation. For example, some farmers used tractor-operated tube-wells for irrigation water pumping, which increased diesel energy input, while others used electricity-operated tube-wells, which increased electrical energy input. However, no major variations were found in the use of other energy inputs, hence, this study mainly focuses on the average energy consumption. The energy classifications for wheat and rice production are shown in Figure 5 and Figure 6. The average total energy input in wheat production was calculated as 21.36 GJ/ha which was further divided into direct and indirect energy inputs (Figure 5). The indirect energy input was calculated as 11.96 GJ/ha and dominated the direct energy use following the previous study [15]. The total energy was also classified as renewable and non-renewable energy inputs. The average renewable energy was found to be 1.14 GJ/ha which was lesser than non-renewable energy input i.e., 20.21 GJ/ha. Soltani et. al. [34] also reported a similar trend of energy consumption in their study on energy analysis in wheat production. However, fertilizer was the top input energy source in wheat production and accounts for 39% of the total energy consumption. Similarly, diesel was the second-highest energy source, accounting for 22.6% of total energy consumption, while energy from chemical energy was found to be the lowest (0.42% of total energy) among all the energy sources. These results are in accordance with the results of previous studies [27,41]. Singh et. al. [27] conducted a study on energy-use patterns in wheat cultivation in Punjab, India. The present study in Punjab, Pakistan, showed similar results due to comparable climatic and socioeconomic conditions. However, Gündogmus and Bayramoglu [62] reported diesel as the highest energy input source in their study on organic farming. The contradiction in these results is due to the minimum use of fertilizers in organic farming as reported in their study. On the other hand, Yuan et. al. [51] found electricity to be the highest energy input source in their study on energy flow assessment in wheat production. This is due to the use of an electricity-operated water-pumping system in their study, while tractor-operated tube-wells were mostly used for irrigation in the present study. Finally, fertilizer was found to be the main source of energy in wheat production and thus an important input source in controlling total energy consumption.

Table 4.

Description of average use of output and input energy sources for wheat and rice production in the study area.

Figure 3.

Energy input (GJ/ha) from various sources in wheat cultivation. The labels F1–F23 represent different farmers in the study area.

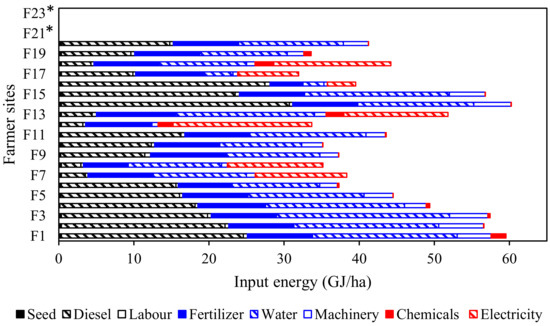

Figure 4.

Energy consumption (GJ/ha) from different input sources in rice production. The labels F1–F23 represent different farmers in the study area. * These farmers did not cultivate rice crop in the studied year.

Figure 5.

Classification of the average energy consumption (GJ/ha) in wheat production based on direct/indirect and renewable/non-renewable energy use.

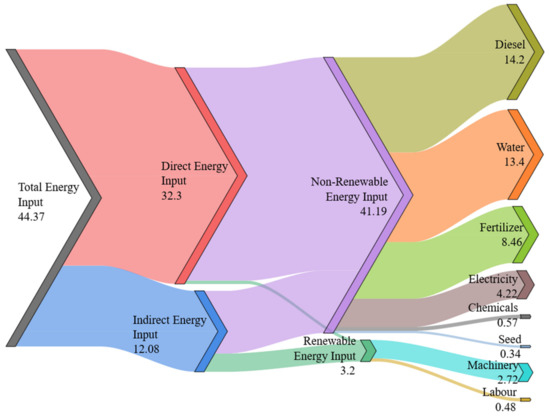

Figure 6.

Classification of the average energy consumption (GJ/ha) in rice production based on direct/indirect and renewable/non-renewable energy use.

Similarly, the energy consumption pattern in rice production is shown in Figure 6. The average total energy input was calculated as 44.37 GJ/ha, which is much higher than energy consumed in wheat production. Contrary to wheat production, direct energy consumption dominated over indirect energy use in rice production and constitutes 72.8% of total energy input. This is due to the higher water requirement of rice crops that increased the direct energy input in the form of water, diesel, and electricity. Besides, the average non-renewable energy was calculated as 41.19 GJ/ha and constitutes 92.8% of the total energy input. It is evident from the figure that diesel was the highest energy input source in rice production and constitute 32% of the total energy input. Diesel was mainly used by tractors in pumping irrigation water from tube-wells to meet the higher crop water requirement in rice production. The second highest energy source was water, contributing 30.2% to total energy consumption, and seed contributed only 0.77% to the total energy input and was found to be the lowest energy input source. Komleh et. al. [13] also found similar results in their study on the evaluation of energy consumption in rice production. However, Khan et. al. [52] found fertilizer to be the highest energy input source in their study on energy consumption analyses in rice production in Pakistan. The main reason for this contradiction in results is the difference in climatic conditions of the study areas. Their study was conducted in a comparatively humid region with lesser water-pumping requirements, while the present study was conducted in an arid region. Higher water-pumping for irrigation increases the use of machinery and thus diesel consumption in the present scenario. Ultimately, diesel and water were the main sources of energy in rice production and total energy input can be controlled by optimizing these input energies.

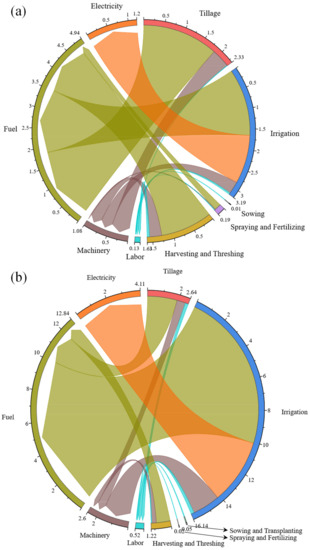

Operational energy is the energy from input sources consumed in management operations i.e., sowing, tillage, irrigation, harvesting and threshing, and spraying and fertilizing. The operational energy distribution in wheat and rice cultivation is shown in Figure 7. The average operational energy in rice production was calculated as 20.07 GJ/ha which is 2.7 times higher than that of wheat production. This was due to the higher energy input in irrigating rice production. The average irrigation energy input in rice production was found to be 16.14 GJ/ha and was the highest among all the management operations. Similarly, irrigation was also the highest energy-consuming operation in wheat production, however, the magnitude of irrigation energy in wheat production was almost five times lower than that of rice production, due to the higher water requirement of rice crops over wheat. Tillage was the second-highest energy-consuming operation in both crops. The average tillage energy in wheat production was 2.34 GJ/ha (31.8% of the total operational energy) while the average tillage energy in rice production was found to be 2.6 GJ/ha, which is 13% of the total operational energy. Due to the similarity in the cultivation process, there were no significant differences in the magnitude of tillage energies in both crops. On the other hand, sowing was the lowest energy-consuming operation in wheat cultivation, while energy input in spraying and fertilizing was the lowest in rice production. The average sowing energy in wheat production was 0.00129 GJ/ha, constituting 0.02% of total operational energy, while the average spraying and fertilizing energy in rice production was 0.02 GJ/ha. These results are in accordance with the previous literature [13,15,41]. Ashraf et. al. [15] conducted a study on energy evaluation of wheat crops in the same province and found similar trends in energy consumption between management operations. Similarly, Safa et. al. [41] and Komleh et. al. [13] also found similar results in their studies on wheat and rice production, respectively. Finally, irrigation is the crucial operation in terms of energy consumption in wheat and rice production, and more attention is needed to optimize the energy use in this operation.

Figure 7.

Distribution of energy consumption from different sources in different management operations in (a) wheat production and (b) rice production.

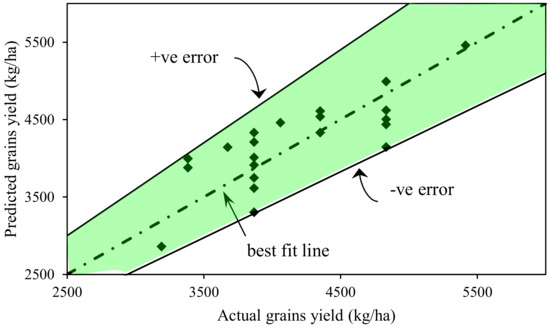

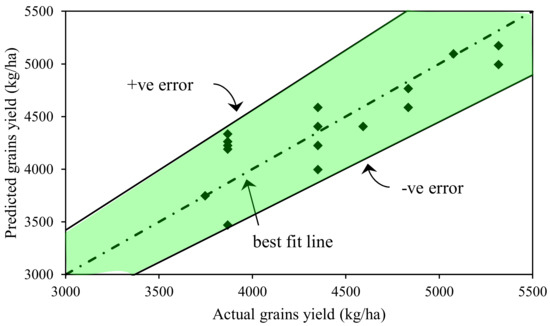

The overall energy efficiency in the studied crops was determined using three energy indices i.e., energy use efficiency (ηe), energy productivity (ηp), and net energy (ρ). The average values of these indices are exhibited in Table 5. The values of ηe, ηp, and ρ for the wheat crop were calculated as 5.68, 202.3 kg/GJ, and 100.12 kg/ha, respectively. In rice production, these values were found to be 1.71, 100.71 kg/GJ, and 31.13 GJ/ha, respectively. These results show the higher overall energy efficiency of the wheat crops compared to rice. There are two main reasons for the higher energy efficiency of wheat crops i.e., higher input energy in rice production and energy from rice-crop residue is not considered in this study, which ultimately decreases the total energy output from rice crops. However, total rice-grain yields per hectare is higher than wheat-grain yields and recorded as 4441.24 kg/ha. Finally, the wheat crop was found to be more energy-efficient and the rice crop was more productive in terms of grain yields. Furthermore, a multiple regression model was developed to predict grain yield for both crops. The comparison between actual and predicted grain yields for wheat and rice crops is shown in Figure 8 and Figure 9, respectively. It is evident that the developed model can predict wheat yield with a coefficient of regression (R2) value of 0.7733, while the R2 value for rice yield was 0.7299. These equations might be helpful for the farmers in the study area to predict the response of a specific energy input towards total grain yield before the actual application of that input in the field.

Table 5.

Description of average energy consumption, energy outputs, and energy indices in wheat and rice production in the study area.

Figure 8.

Comparison between actual and predicted grain yields of the studied farms based on the developed multiple regression model for wheat production.

Figure 9.

Comparison between actual and predicted grain yields of the studied farms based on the developed multiple regression model for rice production.

Data envelopment analysis (DEA) was also conducted to optimize the energy inputs. Four major energy sources (i.e., diesel, water, fertilizer, and machinery) were considered as controlled inputs while grain yield was taken as output in a CCR-based DEA function. Table 6 exhibits the energy optimization pattern for wheat and rice crops in the study area. The highest reduction potential was observed for machinery energy in both crops i.e., wheat and rice, calculated as −17.48% and −42.97%, respectively. It shows that lower machining operations e.g., minimum/zero tillage can also maintain the same level of output while reducing the total input energy. Moreover, it can enhance the overall energy efficiency/productivity in the wheat–rice crop rotation system. The minimum reduction potential was found in water energy (−2.76%) for wheat crop while diesel energy (−17.25%) in rice production. The lower reduction potential in water energy shows the importance of water for wheat crop in an arid region. Similarly, the reduction potential in water energy for rice crop was also among the lowest and calculated as −17.65%. These results are in accordance with the previous literature [15,38]. Ashraf et. al. [15] conducted DEA in wheat production in similar climatic conditions and found that water energy had the least reduction potential. However, they did not consider machinery energy in their study hence no information was found related to reduction potential in machining operations. Mousavi-Avval et. al. [38] also found similar results in their studies on apple production in Iran. Finally, optimizing the energy use in agricultural production can increase energy use efficiency, energy productivity, and net energy. This would help in reducing energy input while maintaining output, i.e., grain yields, in the current scenario.

Table 6.

Energy-use optimization and average technical efficiencies of the studied farmers, calculated by a CCR-based DEA optimization function.

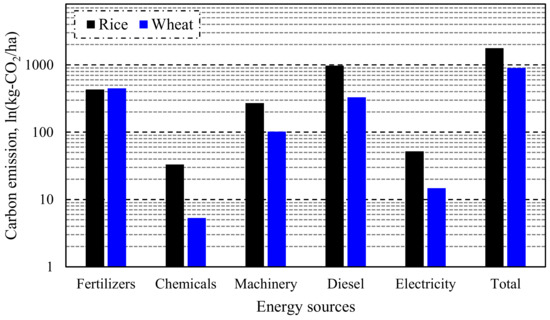

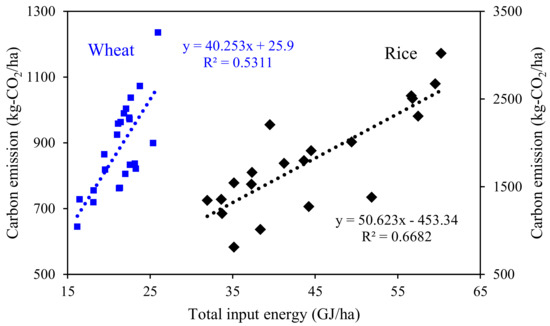

Carbon dioxide (CO2) emissions are a byproduct of the production processes of energy sources i.e., machinery, fertilizer, electricity, and chemicals, while on-farm combustion of diesel also emits a large amount of the gas. Figure 10 shows the average total and source-wise CO2 emissions in kg-CO2/ha units. The average total emissions in wheat and rice production were calculated as 900.9 kg-CO2/ha and 1762.5 kg-CO2/ha, respectively. Diesel was the highest emissions source in rice production, constituting 55.34% of total CO2 emissions. On the other hand, fertilizer was found to be the highest CO2 emissions source in wheat production, at 49.7% of total emissions. The higher emissions from diesel, in rice production, were due to the higher use of diesel in pumping irrigation water from tractor-operated tube-wells. The lowest emissions calculation belonged to chemical sources, for both crops. The average CO2 emissions from chemicals in rice and wheat production was recorded as 33.2 kg-CO2/ha and 5.3 kg-CO2/ha, respectively. These results are in accordance with the results of previous literature [15,34]. Ashraf et. al. [15] and Soltani et. al. [34] found similar results in their studies on wheat production in Pakistan and Iran, respectively. Their findings also revealed that CO2 emissions increase with total input energy. In this regard, a relationship was developed between total input energy and CO2 as shown in Figure 11. The figure shows that CO2 emissions increase linearly with total energy input in wheat and rice cultivations. Therefore, emissions from rice production are higher than that from wheat production. To reduce these emissions, there is a need to reduce the total input energy. In this regard, the above-discussed DEA approach can play an important role in reducing the total input energy and, eventually, CO2 emissions, while maintaining grain yields.

Figure 10.

Average carbon dioxide (CO2) emissions from wheat and rice production in the study area. The vertical axis is the logarithmic scale of carbon emissions in the kg-CO2/ha unit.

Figure 11.

Relationship between total input energy (GJ/ha) and carbon emissions (kg-CO2/ha) in wheat and rice production. The blue-colored tick markers belong to the primary vertical axis and represent the wheat crop, while black-colored tick markers belong to the secondary vertical axis representing the rice crop.

4. Conclusions

In this study, the input–output energy relationship and CO2 emissions in a wheat–rice crop rotation system were investigated technically. The data envelopment analysis (DEA) technique was applied to optimize total energy consumption. Based on the key findings of the study, it was concluded that socioeconomic characteristics greatly affect total energy input in agricultural production. For example, an irrigation source could be a key factor influencing total input energy. In this regard, canal-water irrigation was found to be less energy-expensive than tractor-operated and electrical turbine-operated tube-wells. Furthermore, the average total energy consumption in rice production was higher than that of wheat production. It was mainly due to the greater number of irrigations in rice production to meet the higher crop water requirement. It resulted in lowering the energy efficiency/productivity in rice production than that of wheat. However, the data envelopment analysis (DEA) was found to be an efficient approach in reducing the total energy input while maintaining grain yield. This technique is also helpful in reducing total CO2 emissions by optimized use of energy sources.

Finally, the optimized use of energy sources could increase the overall energy efficiency in the rice–wheat crop-rotation system. In this regard, minimum tillage and high-efficiency irrigation systems could be the best alternatives to conventional management practices. The results of this study showed that irrigation was the highest energy-consuming operation. Therefore, it is important to control energy consumption in this operation to enhance overall energy efficiency.

Author Contributions

Conceptualization, M.N.A. and M.H.M.; methodology, M.N.A.; software, M.N.A.; validation, M.H.M., M.S. and R.R.S.; formal analysis, M.N.A. and M.H.M.; investigation, M.H.M., S.M.I. and M.S.; resources, M.S., R.R.S. and S.M.I.; data curation, M.N.A. and M.H.M.; writing—original draft preparation, M.N.A.; writing—review and editing, M.H.M., M.S. and R.R.S.; visualization, M.S., R.R.S. and S.M.I.; supervision, M.H.M. and M.S.; project administration, M.H.M.; funding acquisition, M.H.M., M.S., S.M.I. and R.R.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Researchers Supporting Project number (RSP-2021/100), King Saud University, Riyadh, Saudi Arabia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are contained within the article.

Acknowledgments

The authors acknowledge the help in data collection by Muhammad Imran. This research work has been carried out in the Department of Agricultural Engineering, Bahauddin Zakariya University, Multan-Pakistan. This work was supported by Researchers Supporting Project number (RSP-2021/100), King Saud University, Riyadh, Saudi Arabia. The authors acknowledge the financial support by the Open Access Publication Fund of the Leibniz Association, Germany.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cereals Production Quantity. Knoema n.d. Available online: https://knoema.com/atlas/topics/Agriculture/Crops-Production-Quantity-tonnes/Cereals-production (accessed on 24 May 2021).

- Crops Data. FAOSTAT n.d. Available online: http://www.fao.org/faostat/en/#data/QC/visualize (accessed on 24 May 2021).

- Giraldo, P.; Benavente, E.; Manzano-Agugliaro, F.; Gimenez, E. Worldwide research trends on wheat and barley: A bibliometric comparative analysis. Agronomy 2019, 9, 352. [Google Scholar] [CrossRef] [Green Version]

- Lizette, K. Food Security & Staple Crops Staple Food Around the World. IAEA Bull. 2012, 53, 11. [Google Scholar]

- Lucas, H. Breakout session P1.1 National Food Security-The Wheat Initiative-an International Research Initiative for Wheat Improvement context–the problems being addressed. In Proceedings of the GCARD-Second Global Conference on Agricultural Research for Development, Punta del Este, Uruguay, 29 October–1 November 2012; pp. 1–3. [Google Scholar]

- Mahmood, M.H.; Sultan, M.; Miyazaki, T. Significance of Temperature and Humidity Control for Agricultural Products Storage: Overview of Conventional and Advanced Options. Int. J. Food Eng. 2019, 15. [Google Scholar] [CrossRef]

- Muhammad, H. Mahmood, Muhammad Sultan, Takahiko Miyazaki SK. Study on desiccant air-conditioning system for agricultural product storage in Pakistan. Intellect. Exch. Innov. Conf. Eng. Sci. 2015, 1, 13–14. [Google Scholar] [CrossRef]

- Sultan, M.; El-sharkawy, I.I.; Miyazaki, T.; Baran, B.; Koyama, S. An overview of solid desiccant dehumidification and air conditioning systems. Renew. Sustain. Energy Rev. 2015, 46, 16–29. [Google Scholar] [CrossRef]

- Sultan, M.; El-Sharkawy, I.I.; Miyazaki, T.; Saha, B.B.; Koyama, S.; Maruyama, T.; Maeda, S.; Nakamura, T. Insights of water vapor sorption onto polymer based sorbents. Adsorption 2015, 21, 205–215. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Mahmood, M.H.; Khan, Z.M. Solar assisted evaporative cooling based passive air-conditioning system for agricultural and livestock applications. J. Eng. Sci. Technol. 2018, 13, 693–703. [Google Scholar]

- Ashraf, H.; Sultan, M.; Shamshiri, R.R.; Abbas, F.; Farooq, M.; Sajjad, U.; Md-Tahir, H.; Mahmood, M.H.; Ahmad, F.; Taseer, Y.R.; et al. Dynamic Evaluation of Desiccant Dehumidification Evaporative Cooling Options for Greenhouse Air-Conditioning Application in Multan (Pakistan). Energies 2021, 14, 1097. [Google Scholar] [CrossRef]

- Conway, R.K.; Stout, B.A. Handbook of Energy for World Agriculture. London and New York: Elsevier, Applied Science, 1990, 504 pp., \$@@-@@135.00. Am. J. Agric. Econ. 1991, 73, 1302. [Google Scholar] [CrossRef]

- Pishgar-Komleh, S.H.; Sefeedpari, P.; Rafiee, S. Energy and economic analysis of rice production under different farm levels in Guilan province of Iran. Energy 2011, 36, 5824–5831. [Google Scholar] [CrossRef]

- Kardoni, F.; Ahmadi, J.A.; Bakhshi, M.R. Energy Efficiency Analysis and Modeling the Relationship between Energy Inputs and Wheat Yield in Iran. Int. J. Agric. Manag. Dev. 2015, 5, 321–330. [Google Scholar]

- Ashraf, M.N.; Mahmood, M.H.; Sultan, M.; Banaeian, N.; Usman, M.; Ibrahim, S.M.; Butt, M.U.B.U.; Waseem, M.; Ali, I.; Shakoor, A.; et al. Investigation of Input and Output Energy for Wheat Production: A Comprehensive Study for Tehsil Mailsi (Pakistan). Sustainability 2020, 12, 6884. [Google Scholar] [CrossRef]

- Maraseni, T.; Chen, G.; Banhazi, T.; Bundschuh, J.; Yusaf, T. An Assessment of Direct on-Farm Energy Use for High Value Grain Crops Grown under Different Farming Practices in Australia. Energies 2015, 8, 13033–13046. [Google Scholar] [CrossRef] [Green Version]

- Ozkan, B.; Akcaoz, H.; Fert, C. Energy input-output analysis in Turkish agriculture. Renew. Energy 2004, 29, 39–51. [Google Scholar] [CrossRef]

- Safa, M.; Samarasinghe, S.; Mohssen, M. Determination of fuel consumption and indirect factors affecting it in wheat production in Canterbury, New Zealand. Energy 2010, 35, 5400–5405. [Google Scholar] [CrossRef]

- Fami, H.S.; Ghasemi, J.; Malekipoor, R.; Rashidi, P.; Nazari, S.; Mirzaee, A. Renewable energy use in smallholder farming systems: A case study in tafresh township of Iran. Sustainability 2010, 2, 702–716. [Google Scholar] [CrossRef] [Green Version]

- Esengun, K.; Gündüz, O.; Erdal, G. Input-output energy analysis in dry apricot production of Turkey. Energy Convers. Manag. 2007, 48, 592–598. [Google Scholar] [CrossRef]

- Singh, G.; Lee, J.; Karakoti, A.; Bahadur, R.; Yi, J.; Zhao, D.; AlBahilyc, K.; Vinu, A. Emerging trends in porous materials for CO2 capture and conversion. Chem. Soc. Rev. 2020, 49, 4360–4404. [Google Scholar] [CrossRef]

- US Department of Commerce, NOAA GML. Global Monitoring Laboratory—Carbon Cycle Greenhouse Gases n.d. Available online: https://gml.noaa.gov/ccgg/trends/mlo.html (accessed on 5 April 2021).

- Snoeckx, R.; Bogaerts, A. Plasma technology—A novel solution for CO2 conversion? Chem. Soc. Rev. 2017, 46, 5805–5863. [Google Scholar] [CrossRef] [Green Version]

- Grant, J.; Low, L.P.; Unsworth, S.; Hornwall, C.; Davies, M. The Low Carbon Economy Index 2018—Time to Get on with It. Available online: https://www.pwc.co.uk/lowcarboneconomy (accessed on 5 April 2021).

- Eckstein, D.; Künzel, V.; Schäfer, L.; Winges, M. Global Climate Rate Index 2020; Germanwatch e.V., Germany. 2020. Available online: www.germanwatch.org/en/cri (accessed on 5 April 2021).

- USAID. Greenhouse Gas Emissions Factsheet: Pakistan | Global Climate Change. 2018. Available online: https://www.climatelinks.org/resources/greenhouse-gas-emissions-factsheet-pakistan (accessed on 5 April 2021).

- Singh, H.; Singh, A.K.; Kushwaha, H.L.; Singh, A. Energy consumption pattern of wheat production in India. Energy 2007, 32, 1848–1854. [Google Scholar] [CrossRef]

- Saad, A.A.; Das, T.K.; Rana, D.S.; Sharma, A.R.; Bhattacharyya, R.; Lal, K. Energy auditing of a maize–wheat–greengram cropping system under conventional and conservation agriculture in irrigated north-western Indo-Gangetic Plains. Energy 2016, 116, 293–305. [Google Scholar] [CrossRef]

- Mani, I.; Kumar, P.; Panwar, J.S.; Kant, K. Variation in energy consumption in production of wheat-maize with varying altitudes in hilly regions of Himachal Pradesh, India. Energy 2007, 32, 2336–2339. [Google Scholar] [CrossRef]

- Chaudhary, V.P.; Gangwar, B.; Pandey, D.K.; Gangwar, K.S. Energy auditing of diversified rice-wheat cropping systems in Indo-gangetic plains. Energy 2009, 34, 1091–1096. [Google Scholar] [CrossRef]

- Singh, H.; Mishra, D.; Nahar, N.M.; Ranjan, M. Energy use pattern in production agriculture of a typical village in arid zone India: Part II. Energy Convers. Manag. 2003, 44, 1053–1067. [Google Scholar] [CrossRef]

- Singh, K.P.; Prakash, V.; Srinivas, K.; Srivastva, A.K. Effect of tillage management on energy-use efficiency and economics of soybean (Glycine max) based cropping systems under the rainfed conditions in North-West Himalayan Region. Soil Tillage Res. 2008, 100, 78–82. [Google Scholar] [CrossRef]

- Tabatabaeefar, A.; Emamzadeh, H.; Varnamkhasti, M.G.; Rahimizadeh, R.; Karimi, M. Comparison of energy of tillage systems in wheat production. Energy 2009, 34, 41–45. [Google Scholar] [CrossRef]

- Soltani, A.; Rajabi, M.H.; Zeinali, E.; Soltani, E. Energy inputs and greenhouse gases emissions in wheat production in Gorgan, Iran. Energy 2013, 50, 54–61. [Google Scholar] [CrossRef]

- Shahan, S.; Jafari, A.; Mobli, H.; Rafiee, S.; Karimi, M. Effect of Farm Size on Energy Ratio for Wheat Production: A Case Study from Ardabil Province of Iran. Energy 2008, 3, 604–608. [Google Scholar]

- Yousefi, M.; Khoramivafa, M.; Mondani, F. Integrated evaluation of energy use, greenhouse gas emissions and global warming potential for sugar beet (Beta vulgaris) agroecosystems in Iran. Atmos. Environ. 2014, 92, 501–505. [Google Scholar] [CrossRef]

- Ra, S.; Hashem, S.; Avval, M.; Mohammadi, A. Modeling and sensitivity analysis of energy inputs for apple production in Iran. Energy 2010, 35, 3301–3306. [Google Scholar] [CrossRef]

- Mousavi-Avval, S.H.; Ra, S.; Mohammadi, A. Optimization of energy consumption and input costs for apple production in Iran using data envelopment analysis. Energy 2011, 36, 909–916. [Google Scholar] [CrossRef]

- Khoshroo, A.; Mulwa, R.; Emrouznejad, A.; Arabi, B. A non-parametric Data Envelopment Analysis approach for improving energy ef fi ciency of grape production. Energy 2013, 63, 189–194. [Google Scholar] [CrossRef]

- Safa, M.; Samarasinghe, S. CO2 emissions from farm inputs “case study of wheat production in Canterbury, New Zealand”. Environ. Pollut. 2012, 171, 126–132. [Google Scholar] [CrossRef]

- Safa, M.; Samarasingh, S.; Mohssen, M. A field study of energy consumption in wheat production in Canterbury, New Zealand. Energy Convers. Manag. 2011, 52, 2526–2532. [Google Scholar] [CrossRef]

- Safa, M.; Samarasinghe, S. Determination and modelling of energy consumption in wheat production using neural networks: “A case study in Canterbury province, New Zealand”. Energy 2011, 36, 5140–5147. [Google Scholar] [CrossRef] [Green Version]

- Kuswardhani, N.; Soni, P.; Shivakoti, G.P. Comparative energy input-output and financial analyses of greenhouse and open field vegetables production in West Java, Indonesia. Energy 2013, 53, 83–92. [Google Scholar] [CrossRef]

- Soni, P.; Taewichit, C.; Salokhe, V.M. Energy consumption and CO2 emissions in rainfed agricultural production systems of Northeast Thailand. Agric. Syst. 2013, 116, 25–36. [Google Scholar] [CrossRef]

- Yilmaz, I.; Akcaoz, H.; Ozkan, B. An analysis of energy use and input costs for cotton production in Turkey. Renew. Energy 2005, 30, 145–155. [Google Scholar] [CrossRef]

- Erdal, G.; Esengün, K.; Erdal, H.; Gündüz, O. Energy use and economical analysis of sugar beet production in Tokat province of Turkey. Energy 2007, 32, 35–41. [Google Scholar] [CrossRef]

- Ozkan, B.; Fert, C.; Karadeniz, C.F. Energy and cost analysis for greenhouse and open-field grape production. Energy 2007, 32, 1500–1504. [Google Scholar] [CrossRef]

- Canakci, M.; Topakci, M.; Akinci, I.; Ozmerzi, A. Energy use pattern of some field crops and vegetable production: Case study for Antalya Region, Turkey. Energy Convers. Manag. 2005, 46, 655–666. [Google Scholar] [CrossRef]

- Snyder, C.S.; Bruulsema, T.W.; Jensen, T.L.; Fixen, P.E. Review of greenhouse gas emissions from crop production systems and fertilizer management effects. Agric. Ecosyst. Environ. 2009, 133, 247–266. [Google Scholar] [CrossRef]

- Khan, S.; Hanjra, M.A. Footprints of water and energy inputs in food production—Global perspectives. Food Policy 2009, 34, 130–140. [Google Scholar] [CrossRef]

- Yuan, S.; Peng, S.; Wang, D.; Man, J. Evaluation of the energy budget and energy use efficiency in wheat production under various crop management practices in China. Energy 2018, 160, 184–191. [Google Scholar] [CrossRef]

- Khan, M.A.; Awan, I.U.; Zafar, J. Energy requirement and economic analysis of rice production in western part of Pakistan. Soil Environ. 2009, 28, 60–67. [Google Scholar]

- Khan, S.B.; Khan, F.; Sadaf, S.; Kashif, R.H. Crops Area and Production (By Districts) (1981–82 To 2008–09); Pakistan Bureau of Statistics: Islamabad, Pakistan, 2009; p. 214. [Google Scholar]

- Banaeian, N.; Omid, M.; Ahmadi, H. Energy and economic analysis of greenhouse strawberry production in Tehran province of Iran. Energy Convers. Manag. 2011, 52, 1020–1025. [Google Scholar] [CrossRef]

- Kitani, O.; Jungbluth, T.; Peart, R.M.; Ramdani, A. CIGR Handbook of Agricultural Engineering (Energy and Biomass Engineering); ASAE Publication: St. Joseph, MI, USA, 1999; Volume 5. [Google Scholar]

- ASAE. Agricultural Machinery Management Data; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2011. [Google Scholar]

- Wells, D. Total Energy Indicators of Agricultural Sustainability: Dairy Farming Case Study; Technical Paper; Ministry of Agriculture and Forestry: Wellington, New Zealand, 2001; ISBN 0-478-07968-0. [Google Scholar]

- Singh, P.; Singh, G.; Sodhi, G.P.S. Applying DEA optimization approach for energy auditing in wheat cultivation under rice-wheat and cotton-wheat cropping systems in north-western India. Energy 2019, 181, 18–28. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Cooper, W.W.; Seiford, L.M.; Tone, K. Data Envelopment Analysis: A Comprehensive Text with Models, Applications, References and DEA-Solver Software, 2nd ed.; Springer: New York, NY, USA, 2007. [Google Scholar] [CrossRef] [Green Version]

- Saunders, C.; Barber, A.; Taylor, G. Food Miles - Comparative Energy/emissions Performance of New Zealand’s Agriculture Industry; Agribusiness & Economics Research Unit, Lincoln University: Lincoln, New Zealand, 2006. [Google Scholar]

- Gündogmus, E.; Bayramoglu, Z. Energy input use on organic farming: A comparative analysis on organic versus conventional farms in Turkey. J. Agron. 2006, 5, 16–22. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).