Reliability Assessment of Passive Safety Systems for Nuclear Energy Applications: State-of-the-Art and Open Issues

Abstract

:1. Introduction

2. Approaches for the Reliability Assessment of Passive Systems

- systems/components reliability;

- physical phenomena reliability, which accounts for the physical boundary conditions and mechanisms.

2.1. The Independent Failure Modes Approach

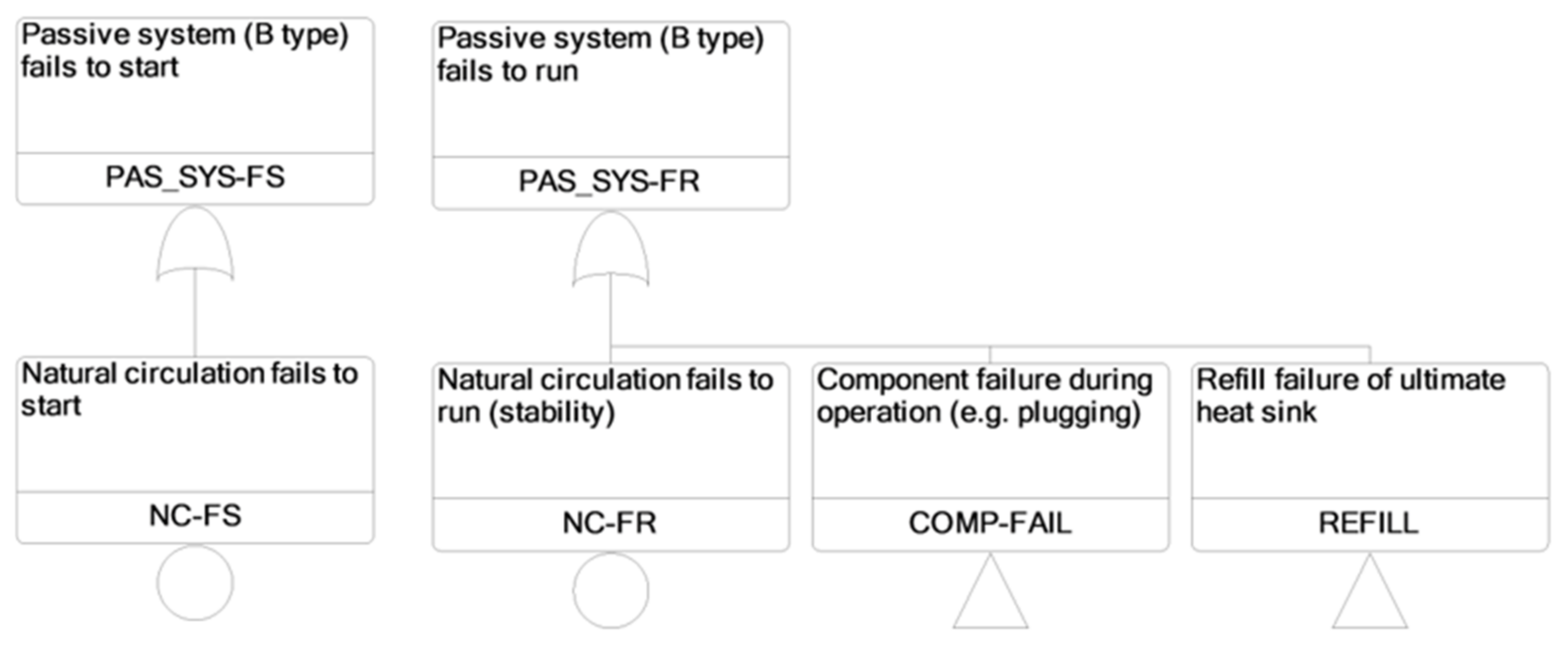

2.2. The Hardware Failure Modes Approach

2.3. The Functional Failure Approach

3. Advanced Monte Carlo Simulation Approach

- Subset Simulation (SS) is used to create an input batch from the ideal, zero-variance ISD g*(x) relying on an ANN that (i) is adaptively refined in proximity of failure region by means of the samples iteratively produced by SS, and (ii) substitutes the expensive T–H code f(x);

- The g*(x) built at step (1) is used to perform IS and calculate the probability of failure of the T–H passive system.

4. Frameworks for the Reliability Assessment of Passive Systems

5. Open Issues

5.1. Sensitivity Analysis Methods

5.2. Role of Empirical Regression Modelling

5.3. Integration of Passive Systems in PSA

5.3.1. Integration of Passive System Reliability into Static PSA

- Start-up failure: for standby active equipment (e.g., pumps, fans), the failure probability of start-up should be assessed, while for valves, the failure probability of opening and/or closing should be modelled.

- Failure during operation: the failure probability during operation of active components (e.g., pumps) should be quantified and modelled in the PSA. To this purpose, the most commonly applied reliability models employ the failure rate and the expected mission time (or functional time) of the component. For components with relatively short mission time (1–2 h), this kind of malfunction is usually modelled within the start-up failure framework.

- Separate headers for start-up failures and failures during operation;

- One header representing both types of failure.

5.3.2. Integration of Passive Systems into Dynamic PSA

6. Conclusions, Recommendations and Additional Issues

- If the estimation of the passive system functional failure probability is of interest, we suggest combining metamodels with efficient MCS techniques, for example, by constructing and adaptively refining the metamodel by means of samples generated by the advanced MCS method in proximity of the system functional failure region [78,79,80,81,82,83,84,85,86]. An example is represented by the Adaptive Metamodel-based Subset Importance Sampling (AM-SIS) method, recently proposed by some of the authors, which intelligently combines Subset Simulation (SS), Importance Sampling (IS) and iteratively trained Artificial Neural Networks (ANNs) [78,79].

- The methods proposed rely on the assessment of the uncertainty (both aleatory and epistemic) in the quantitative description provided by models of the phenomena pertaining to the functions of the passive systems. This requires a systematic, sound and rigorous Inverse Uncertainty Quantification (IUQ) approaches to find a characterization of the input parameters uncertainty that is consistent with the experimental data, while limiting the associated computational burden. Approaches have been already proposed in the open literature, but not yet in the field of passive system reliability assessment [131,132,133,134,135,136].

- If we resort to empirical metamodels for estimating passive systems failure probabilities and carrying out uncertainty and SA, the following problems should be considered:

- the regression error should be carefully quantified (and possibly controlled) throughout the process, in order to reduce its impact on the entire reliability assessment [81];

- the higher the input dimensionality (e.g., in the presence of time series data), the higher the size of the training dataset should be to obtain metamodel accuracy. Rigorous (linear or nonlinear) approaches to reduce the input dimensionality (e.g., Principal Component Analysis, PCA, or Stacked Sparse Autoencoders) should be sought, with increased metamodel performances [137];

- the quality of metamodel training can be negatively affected by noisy data. Data filtering, carried out on the model code predictions, may impact on the metamodel predictive performance [138].

- The introduction of passive safety systems in the framework of PSA deserves particular attention, in particular, when accident scenarios are generated in a dynamic fashion. The reasons are the following:

- it is difficult to define the state of passive systems along an accident sequence only in the classical binary terms of ‘success/failure’; rather, ‘intermediate’ modes of operation or degraded performances states should be considered, where the passive system might still be capable of providing a functional level sufficient for the mitigation of the accident progression;

- the amount of accident scenarios to be handled is consistently larger than that associated with the traditional static fault/event tree techniques. Thus, the “a posteriori” retrieval of information can be quite burdensome and difficult. In this view, artificial intelligence techniques could be embraced to address the problem [125,126,127];

- the thorough exploration of the dynamic state-space of the passive safety system is impracticable by standard (sampling) methods: advanced exploration schemes should be sought to intelligently drive the search towards ‘interesting’ scenarios (e.g., extreme unexpected events), while reducing the computational effort [139,140].

Author Contributions

Funding

Conflicts of Interest

References

- Pagani, L.P.; Apostolakis, G.E.; Hejzlar, P. The Impact of Uncertainties on the Performance of Passive Systems. Nucl. Technol. 2005, 149, 129–140. [Google Scholar] [CrossRef]

- Marquès, M.; Pignatel, J.; Saignes, P.; D’Auria, F.; Burgazzi, L.; Müller, C.; Bolado-Lavin, R.; Kirchsteiger, C.; La Lumia, V.; Ivanov, I. Methodology for the reliability evaluation of a passive system and its integration into a Probabilistic Safety Assessment. Nucl. Eng. Des. 2005, 235, 2612–2631. [Google Scholar] [CrossRef]

- Jafari, J.; D’Auria, F.; Kazeminejad, H.; Davilu, H. Reliability evaluation of a natural circulation system. Nucl. Eng. Des. 2003, 224, 79–104. [Google Scholar] [CrossRef]

- Thunnissen, D.P.; Au, S.-K.; Tsuyuki, G.T. Uncertainty Quantification in Estimating Critical Spacecraft Component Temperatures. J. Thermophys. Heat Transf. 2007, 21, 422–430. [Google Scholar] [CrossRef]

- Fong, C.J.; Apostolakis, G.E.; Langewisch, D.R.; Hejzlar, P.; Todreas, N.E.; Driscoll, M.J. Reliability analysis of a passive cooling system using a response surface with an application to the flexible conversion ratio reactor. Nucl. Eng. Des. 2009, 239, 2660–2671. [Google Scholar] [CrossRef] [Green Version]

- Bousbia Salah, A.; Auria, F. Insights into Natural Circulation—Phenomena, Models, and Issues; LAP Lambert Academic Publishing: Saarbrücken, Germany, 2010. [Google Scholar]

- Aksan, N.; D’Auria, F. Relevant Thermal Hydraulic Aspects of Advanced Reactor Design-Status Report. NEA/CSNI/R. 1996. Available online: https://www.oecd-nea.org/jcms/pl_16144/relevant-thermal-hydraulic-aspects-of-advanced-reactors-design-status-report-1996?details=true (accessed on 3 May 2021).

- Aksan, N.; Boado, R.; Burgazzi, L.; Choi, J.H.; Chung, Y.J.; D’Auria, F.S.; De La Rosa, F.C.; Gimenez, M.O.; Ishii, M.; Khartabil, H.; et al. Natural Circulation Phenomena and Modeling for Advanced Water Cooled Reactors. IAEA-TECDOC-1677 978-92-0-127410-6. 2012. Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/TE-1677_web.pdf (accessed on 3 May 2021).

- Aksan, N.; D’Auria, F.S.; Marques, M.; Saha, D.; Reyes, J.; Cleveland, J. Natural Circulation in Water-Cooled Nuclear Power Plants Phenomena, Models, and Methodology for System Reliability Assessments. IAEA-TECDOC-1474 92-0-110605-X. 2005. Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/TE_1474_web.pdf (accessed on 3 May 2021).

- Aksan, N.; Choi, J.H.; Chung, Y.J.; Cleveland, J.; D’Auria, F.S.; Fil, N.; Gimenez, M.O.; Ishii, M.; Khartabil, H.; Korotaev, K.; et al. Passive Safety Systems and Natural Circulation in Water Cooled Nuclear Power Plants. IAEA-TECDOC-1624 978-92-0-111309-2. 2009. Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/te_1624_web.pdf (accessed on 3 May 2021).

- Ricotti, M.E.; Zio, E.; D’Auria, F.; Caruso, G. Reliability Methods for Passive Systems(RMPS) Study—Strategy and Results. Unclassified NEA CSNI/WGRISK 2002, 10, 149. [Google Scholar]

- Lewis, M.J.; Pochard, R.; D’auria, F.; Karwat, H.; Wolfert, K.; Yadigaroglu, G.; Holmstrom, H.L.O. Thermohydraulics of Emergency Core Cooling in Light Water Reactors—A State of the Art Report. CSNI Rep. 1989. Available online: https://www.oecd-nea.org/upload/docs/application/pdf/2020-01/csni89-161.pdf (accessed on 3 May 2021).

- Aksan, N.; D’auria, F.; Glaeser, H.; Pochard, R.; Richards, C.; Sjoberg, A. A Separate Effects Test Matrix for Thermal-Hydraulic Code Validation: Phenomena Characterization and Selection of Facilities and Tests; OECD/GD OECD Guidance Document; OECD: Paris, France, 1993. [Google Scholar]

- Aksan, N.; D’Auria, F.; Glaeser, H.; Lillington, J.; Pochard, R.; Sjoberg, A. Evaluation of the Separate Effects Tests (SET) Validation Matrix; OECD/GD OECD Guidance Document; OECD: Paris, France, 1996. [Google Scholar]

- U.S. Nuclear Regulatory Commission. Others Compendium of ECCS Research for Realistic LOCA Analysis; NUREG-1230; Division of Systems Research, Office of Nuclear Regulatory Research, U.S. Nuclear Regulatory Commission: Washington, DC, USA, 1988.

- Burgazzi, L. Addressing the uncertainties related to passive system reliability. Prog. Nucl. Energy 2007, 49, 93–102. [Google Scholar] [CrossRef]

- Burgazzi, L. State of the art in reliability of thermal-hydraulic passive systems. Reliab. Eng. Syst. Saf. 2007, 92, 671–675. [Google Scholar] [CrossRef]

- Burgazzi, L. Thermal–hydraulic passive system reliability-based design approach. Reliab. Eng. Syst. Saf. 2007, 92, 1250–1257. [Google Scholar] [CrossRef]

- Burgazzi, L. Evaluation of uncertainties related to passive systems performance. Nucl. Eng. Des. 2004, 230, 93–106. [Google Scholar] [CrossRef]

- D’Auria, F.; Giannotti, W. Development of a Code with the Capability of Internal Assessment of Uncertainty. Nucl. Technol. 2000, 131, 159–196. [Google Scholar] [CrossRef]

- Ahn, K.-I.; Kim, H.-D. A Formal Procedure for Probabilistic Quantification of Modeling Uncertainties Employed in Phenomenological Transient Models. Nucl. Technol. 2000, 130, 132–144. [Google Scholar] [CrossRef]

- Zio, E.; Pedroni, N. Building confidence in the reliability assessment of thermal-hydraulic passive systems. Reliab. Eng. Syst. Saf. 2009, 94, 268–281. [Google Scholar] [CrossRef]

- Apostolakis, G. The concept of probability in safety assessments of technological systems. Science 1990, 250, 1359–1364. [Google Scholar] [CrossRef] [Green Version]

- Helton, J.; Oberkampf, W. Alternative representations of epistemic uncertainty. Reliab. Eng. Syst. Saf. 2004, 85, 1–10. [Google Scholar] [CrossRef]

- Zio, E. A study of the bootstrap method for estimating the accuracy of artificial neural networks in predicting nuclear transient processes. IEEE Trans. Nucl. Sci. 2006, 53, 1460–1478. [Google Scholar] [CrossRef]

- Helton, J.; Johnson, J.; Sallaberry, C.; Storlie, C. Survey of sampling-based methods for uncertainty and sensitivity analysis. Reliab. Eng. Syst. Saf. 2006, 91, 1175–1209. [Google Scholar] [CrossRef] [Green Version]

- Zio, E.; Pedroni, N. Estimation of the functional failure probability of a thermal–hydraulic passive system by Subset Simulation. Nucl. Eng. Des. 2009, 239, 580–599. [Google Scholar] [CrossRef]

- Pourgol-Mohamad, M.; Mosleh, A.; Modarres, M. Methodology for the use of experimental data to enhance model output uncertainty assessment in thermal hydraulics codes. Reliab. Eng. Syst. Saf. 2010, 95, 77–86. [Google Scholar] [CrossRef]

- Burgazzi, L. Failure Mode and Effect Analysis Application for the Safety and Reliability Analysis of a Thermal-Hydraulic Passive System. Nucl. Technol. 2006, 156, 150–158. [Google Scholar] [CrossRef]

- Burgazzi, L. Passive System Reliability Analysis: A Study on the Isolation Condenser. Nucl. Technol. 2002, 139, 3–9. [Google Scholar] [CrossRef]

- Burgazzi, L. Reliability Evaluation of Passive Systems through Functional Reliability Assessment. Nucl. Technol. 2003, 144, 145–151. [Google Scholar] [CrossRef]

- Bassi, C.; Marques, M. Reliability Assessment of 2400 MWth Gas-Cooled Fast Reactor Natural Circulation Decay Heat Removal in Pressurized Situations. Sci. Technol. Nucl. Install. 2008, 2008, 287376. [Google Scholar] [CrossRef] [Green Version]

- Mackay, F.J.; Apostolakis, G.E.; Hejzlar, P. Incorporating reliability analysis into the design of passive cooling systems with an application to a gas-cooled reactor. Nucl. Eng. Des. 2008, 238, 217–228. [Google Scholar] [CrossRef]

- Mathews, T.S.; Ramakrishnan, M.; Parthasarathy, U.; Arul, A.J.; Kumar, C.S. Functional reliability analysis of Safety Grade Decay Heat Removal System of Indian 500MWe PFBR. Nucl. Eng. Des. 2008, 238, 2369–2376. [Google Scholar] [CrossRef]

- Mathews, T.S.; Arul, A.J.; Parthasarathy, U.; Kumar, C.S.; Subbaiah, K.V.; Mohanakrishnan, P. Passive system reliability analysis using Response Conditioning Method with an application to failure frequency estimation of Decay Heat Removal of PFBR. Nucl. Eng. Des. 2011, 241, 2257–2270. [Google Scholar] [CrossRef]

- Arul, A.J.; Iyer, N.K.; Velusamy, K. Adjoint operator approach to functional reliability analysis of passive fluid dynamical systems. Reliab. Eng. Syst. Saf. 2009, 94, 1917–1926. [Google Scholar] [CrossRef]

- Arul, A.J.; Iyer, N.K.; Velusamy, K. Efficient reliability estimate of passive thermal hydraulic safety system with automatic differentiation. Nucl. Eng. Des. 2010, 240, 2768–2778. [Google Scholar] [CrossRef]

- Mezio, F.; Grinberg, M.; Lorenzo, G.; Giménez, M. Integration of the functional reliability of two passive safety systems to mitigate a SBLOCA+BO in a CAREM-like reactor PSA. Nucl. Eng. Des. 2014, 270, 109–118. [Google Scholar] [CrossRef]

- Schuëller, G.; Pradlwarter, H. Benchmark study on reliability estimation in higher dimensions of structural systems—An overview. Struct. Saf. 2007, 29, 167–182. [Google Scholar] [CrossRef]

- Schuëller, G. Efficient Monte Carlo simulation procedures in structural uncertainty and reliability analysis—Recent advances. Struct. Eng. Mech. 2009, 32, 1–20. [Google Scholar] [CrossRef]

- Zio, E.; Pedroni, N. How to effectively compute the reliability of a thermal–hydraulic nuclear passive system. Nucl. Eng. Des. 2011, 241, 310–327. [Google Scholar] [CrossRef] [Green Version]

- Zio, E.; Pedroni, N. Monte Carlo simulation-based sensitivity analysis of the model of a thermal–hydraulic passive system. Reliab. Eng. Syst. Saf. 2012, 107, 90–106. [Google Scholar] [CrossRef] [Green Version]

- Kersaudy, P.; Sudret, B.; Varsier, N.; Picon, O.; Wiart, J. A new surrogate modeling technique combining Kriging and polynomial chaos expansions—Application to uncertainty analysis in computational dosimetry. J. Comput. Phys. 2015, 286, 103–117. [Google Scholar] [CrossRef] [Green Version]

- Kartal, M.E.; Başağa, H.B.; Bayraktar, A. Probabilistic nonlinear analysis of CFR dams by MCS using Response Surface Method. Appl. Math. Model. 2011, 35, 2752–2770. [Google Scholar] [CrossRef]

- Pedroni, N.; Zio, E.; Apostolakis, G. Comparison of bootstrapped artificial neural networks and quadratic response surfaces for the estimation of the functional failure probability of a thermal–hydraulic passive system. Reliab. Eng. Syst. Saf. 2010, 95, 386–395. [Google Scholar] [CrossRef] [Green Version]

- Zio, E.; Pedroni, N. An optimized Line Sampling method for the estimation of the failure probability of nuclear passive systems. Reliab. Eng. Syst. Saf. 2010, 95, 1300–1313. [Google Scholar] [CrossRef] [Green Version]

- Babuška, I.; Nobile, F.; Tempone, R. A stochastic collocation method for elliptic partial differential equations with random input data. SIAM Rev. 2010, 52, 317–355. [Google Scholar] [CrossRef] [Green Version]

- Hurtado, J.E. Filtered importance sampling with support vector margin: A powerful method for structural reliability analysis. Struct. Saf. 2007, 29, 2–15. [Google Scholar] [CrossRef]

- Bect, J.; Ginsbourger, D.; Li, L.; Picheny, V.; Vazquez, E. Sequential design of computer experiments for the estimation of a probability of failure. Stat. Comput. 2012, 22, 773–793. [Google Scholar] [CrossRef] [Green Version]

- Rubino, G.; Tuffin, B. Rare Event Simulation Using Monte Carlo Methods; John Wiley & Sons: Hoboken, NJ, USA, 2009; ISBN 9780470772690. [Google Scholar]

- Zio, E.; Apostolakis, G.; Pedroni, N. Quantitative functional failure analysis of a thermal–hydraulic passive system by means of bootstrapped Artificial Neural Networks. Ann. Nucl. Energy 2010, 37, 639–649. [Google Scholar] [CrossRef] [Green Version]

- Helton, J.; Davis, F. Latin hypercube sampling and the propagation of uncertainty in analyses of complex systems. Reliab. Eng. Syst. Saf. 2003, 81, 23–69. [Google Scholar] [CrossRef] [Green Version]

- Cacuci, D.G.; Ionescu-Bujor, M. A Comparative Review of Sensitivity and Uncertainty Analysis of Large-Scale Systems—II: Statistical Methods. Nucl. Sci. Eng. 2004, 147, 204–217. [Google Scholar] [CrossRef]

- Morris, M.D. Three Technomefrics Experimental Design Classics. Technometrics 2000, 42, 26–27. [Google Scholar] [CrossRef]

- Helton, J.; Davis, F.; Johnson, J. A comparison of uncertainty and sensitivity analysis results obtained with random and Latin hypercube sampling. Reliab. Eng. Syst. Saf. 2005, 89, 305–330. [Google Scholar] [CrossRef]

- Sallaberry, C.; Helton, J.; Hora, S. Extension of Latin hypercube samples with correlated variables. Reliab. Eng. Syst. Saf. 2008, 93, 1047–1059. [Google Scholar] [CrossRef] [Green Version]

- Helton, J. Uncertainty and sensitivity analysis in the presence of stochastic and subjective uncertainty. J. Stat. Comput. Simul. 1997, 57, 3–76. [Google Scholar] [CrossRef]

- Storlie, C.B.; Swiler, L.P.; Helton, J.C.; Sallaberry, C.J. Implementation and evaluation of nonparametric regression procedures for sensitivity analysis of computationally demanding models. Reliab. Eng. Syst. Saf. 2009, 94, 1735–1763. [Google Scholar] [CrossRef]

- Olsson, A.; Sandberg, G.; Dahlblom, O. On Latin hypercube sampling for structural reliability analysis. Struct. Saf. 2003, 25, 47–68. [Google Scholar] [CrossRef]

- Pebesma, E.J.; Heuvelink, G.B. Latin Hypercube Sampling of Gaussian Random Fields. Technometrics 1999, 41, 303–312. [Google Scholar] [CrossRef]

- Au, S.-K.; Beck, J.L. Estimation of small failure probabilities in high dimensions by subset simulation. Probabilistic Eng. Mech. 2001, 16, 263–277. [Google Scholar] [CrossRef] [Green Version]

- Au, S.-K.; Beck, J.L. Subset Simulation and its Application to Seismic Risk Based on Dynamic Analysis. J. Eng. Mech. 2003, 129, 901–917. [Google Scholar] [CrossRef]

- Au, S.-K.; Wang, Y. Engineering Risk Assessment with Subset Simulation; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Koutsourelakis, P.-S.; Pradlwarter, H.; Schuëller, G. Reliability of structures in high dimensions, part I: Algorithms and applications. Probabilistic Eng. Mech. 2004, 19, 409–417. [Google Scholar] [CrossRef]

- Pradlwarter, H.; Pellissetti, M.; Schenk, C.; Schuëller, G.; Kreis, A.; Fransen, S.; Calvi, A.; Klein, M. Realistic and efficient reliability estimation for aerospace structures. Comput. Methods Appl. Mech. Eng. 2005, 194, 1597–1617. [Google Scholar] [CrossRef]

- Zio, E.; Pedroni, N. Functional failure analysis of a thermal–hydraulic passive system by means of Line Sampling. Reliab. Eng. Syst. Saf. 2009, 94, 1764–1781. [Google Scholar] [CrossRef]

- Metropolis, N.; Rosenbluth, A.W.; Rosenbluth, M.N.; Teller, A.H.; Teller, E. Equation of State Calculations by Fast Computing Machines. J. Chem. Phys. 1953, 21, 1087–1092. [Google Scholar] [CrossRef] [Green Version]

- Schuëller, G.; Pradlwarter, H.; Koutsourelakis, P.-S. A critical appraisal of reliability estimation procedures for high dimensions. Probabilistic Eng. Mech. 2004, 19, 463–474. [Google Scholar] [CrossRef]

- Lu, Z.; Song, S.; Yue, Z.; Wang, J. Reliability sensitivity method by line sampling. Struct. Saf. 2008, 30, 517–532. [Google Scholar] [CrossRef]

- Valdebenito, M.; Pradlwarter, H.; Schuëller, G. The role of the design point for calculating failure probabilities in view of dimensionality and structural nonlinearities. Struct. Saf. 2010, 32, 101–111. [Google Scholar] [CrossRef]

- Wang, B.; Wang, N.; Jiang, J.; Zhang, J. Efficient estimation of the functional reliability of a passive system by means of an improved Line Sampling method. Ann. Nucl. Energy 2013, 55, 9–17. [Google Scholar] [CrossRef]

- De Boer, P.-T.; Kroese, D.P.; Mannor, S.; Rubinstein, R.Y. A Tutorial on the Cross-Entropy Method. Ann. Oper. Res. 2005, 134, 19–67. [Google Scholar] [CrossRef]

- Hutton, D.M. The Cross-Entropy Method: A Unified Approach to Combinatorial Optimisation, Monte-Carlo Simulation and Machine Learning. Kybernetes 2005, 34, 903. [Google Scholar]

- Botev, Z.I.; Kroese, D. An Efficient Algorithm for Rare-event Probability Estimation, Combinatorial Optimization, and Counting. Methodol. Comput. Appl. Probab. 2008, 10, 471–505. [Google Scholar] [CrossRef] [Green Version]

- Au, S.-K.; Beck, J. A new adaptive importance sampling scheme for reliability calculations. Struct. Saf. 1999, 21, 135–158. [Google Scholar] [CrossRef]

- Morio, J. Extreme quantile estimation with nonparametric adaptive importance sampling. Simul. Model. Pract. Theory 2012, 27, 76–89. [Google Scholar] [CrossRef]

- Botev, Z.I.; L’Ecuyer, P.; Tuffin, B. Markov chain importance sampling with applications to rare event probability estimation. Stat. Comput. 2011, 23, 271–285. [Google Scholar] [CrossRef]

- Asmussen, S.; Glynn, P.W. Stochastic Simulation: Algorithms and Analysis; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Pedroni, N.; Zio, E. An Adaptive Metamodel-Based Subset Importance Sampling approach for the assessment of the functional failure probability of a thermal-hydraulic passive system. Appl. Math. Model. 2017, 48, 269–288. [Google Scholar] [CrossRef] [Green Version]

- Echard, B.; Gayton, N.; Lemaire, M. AK-MCS: An active learning reliability method combining Kriging and Monte Carlo Simulation. Struct. Saf. 2011, 33, 145–154. [Google Scholar] [CrossRef]

- Echard, B.; Gayton, N.; Lemaire, M.; Relun, N. A combined Importance Sampling and Kriging reliability method for small failure probabilities with time-demanding numerical models. Reliab. Eng. Syst. Saf. 2013, 111, 232–240. [Google Scholar] [CrossRef]

- Bourinet, J.-M.; Deheeger, F.; Lemaire, M. Assessing small failure probabilities by combined subset simulation and Support Vector Machines. Struct. Saf. 2011, 33, 343–353. [Google Scholar] [CrossRef]

- Dubourg, V.; Sudret, B.; Deheeger, F. Metamodel-based importance sampling for structural reliability analysis. Probabilistic Eng. Mech. 2013, 33, 47–57. [Google Scholar] [CrossRef] [Green Version]

- Fauriat, W.; Gayton, N. AK-SYS: An adaptation of the AK-MCS method for system reliability. Reliab. Eng. Syst. Saf. 2014, 123, 137–144. [Google Scholar] [CrossRef]

- Cadini, F.; Santos, F.; Zio, E. Passive systems failure probability estimation by the meta-AK-IS 2 algorithm. Nucl. Eng. Des. 2014, 277, 203–211. [Google Scholar] [CrossRef]

- Cadini, F.; Gioletta, A.; Zio, E. Improved metamodel-based importance sampling for the performance assessment of radioactive waste repositories. Reliab. Eng. Syst. Saf. 2015, 134, 188–197. [Google Scholar] [CrossRef]

- Liel, A.B.; Haselton, C.B.; Deierlein, G.G.; Baker, J. Incorporating modeling uncertainties in the assessment of seismic collapse risk of buildings. Struct. Saf. 2009, 31, 197–211. [Google Scholar] [CrossRef]

- Gavin, H.P.; Yau, S.C. High-order limit state functions in the response surface method for structural reliability analysis. Struct. Saf. 2008, 30, 162–179. [Google Scholar] [CrossRef]

- Lorenzo, G.; Zanocco, P.; Giménez, M.; Marques, M.; Iooss, B.; Lavín, R.B.; Pierro, F.; Galassi, G.; D’Auria, F.; Burgazzi, L. Assessment of an Isolation Condenser of an Integral Reactor in View of Uncertainties in Engineering Parameters. Sci. Technol. Nucl. Install. 2010, 2011, 827354. [Google Scholar] [CrossRef]

- Bucknor, M.; Grabaskas, D.; Brunett, A.J.; Grelle, A. Advanced Reactor Passive System Reliability Demonstration Analysis for an External Event. Nucl. Eng. Technol. 2017, 49, 360–372. [Google Scholar] [CrossRef]

- Chandrakar, A.; Nayak, A.K.; Gopika, V. Development of the APSRA+ Methodology for Passive System Reliability Analysis and Its Application to the Passive Isolation Condenser System of an Advanced Reactor. Nucl. Technol. 2016, 194, 39–60. [Google Scholar] [CrossRef]

- Nayak, A.; Jain, V.; Gartia, M.; Prasad, H.; Anthony, A.; Bhatia, S.; Sinha, R. Reliability assessment of passive isolation condenser system of AHWR using APSRA methodology. Reliab. Eng. Syst. Saf. 2009, 94, 1064–1075. [Google Scholar] [CrossRef]

- Zio, E.; Di Maio, F.; Tong, J. Safety margins confidence estimation for a passive residual heat removal system. Reliab. Eng. Syst. Saf. 2010, 95, 828–836. [Google Scholar] [CrossRef] [Green Version]

- Di Maio, F.; Nicola, G.; Zio, E.; Yu, Y. Ensemble-based sensitivity analysis of a Best Estimate Thermal Hydraulics model: Application to a Passive Containment Cooling System of an AP1000 Nuclear Power Plant. Ann. Nucl. Energy 2014, 73, 200–210. [Google Scholar] [CrossRef]

- Zuber, N.; Wilson, G.E.; (Lanl), B.B.; (Ucla), I.C.; (Inel), R.D.; (Mit), P.G.; (Inel), K.K.; (Sli), G.L.; (Sli), S.L.; (Bnl), U.R.; et al. Quantifying reactor safety margins Part 5: Evaluation of scale-up capabilities of best estimate codes. Nucl. Eng. Des. 1990, 119, 97–107. [Google Scholar] [CrossRef]

- Guba, A.; Makai, M.; Pál, L. Statistical aspects of best estimate method—I. Reliab. Eng. Syst. Saf. 2003, 80, 217–232. [Google Scholar] [CrossRef]

- Secchi, P.; Zio, E.; Di Maio, F. Quantifying uncertainties in the estimation of safety parameters by using bootstrapped artificial neural networks. Ann. Nucl. Energy 2008, 35, 2338–2350. [Google Scholar] [CrossRef]

- Di Maio, F.; Nicola, G.; Zio, E.; Yu, Y. Finite mixture models for sensitivity analysis of thermal hydraulic codes for passive safety systems analysis. Nucl. Eng. Des. 2015, 289, 144–154. [Google Scholar] [CrossRef]

- McLachlan, G.; Peel, D. Finite Mixture Models; John Wiley & Sons: Hoboken, NJ, USA, 2000. [Google Scholar]

- Law, M.H.C.; Figueiredo, M.; Jain, A.K. Simultaneous feature selection and clustering using mixture models. IEEE Trans. Pattern Anal. Mach. Intell. 2004, 26, 1154–1166. [Google Scholar] [CrossRef] [Green Version]

- Diaconis, P.; Zabell, S.L. Updating Subjective Probability. J. Am. Stat. Assoc. 1982, 77, 822–830. [Google Scholar] [CrossRef]

- Gibbs, A.L.; Su, F.E. On Choosing and Bounding Probability Metrics. Int. Stat. Rev. 2002, 70, 419–435. [Google Scholar] [CrossRef] [Green Version]

- Cummins, W.E.; Vijuk, R.P.; Schulz, T.L. Westinghouse AP1000 advanced passive plant. In Proceedings of the American Nuclear Society—International Congress on Advances in Nuclear Power Plants 2005 (ICAPP05), Seoul, Korea, 15–19 May 2005. [Google Scholar]

- Di Maio, F.; Nicola, G.; Borgonovo, E.; Zio, E. Invariant methods for an ensemble-based sensitivity analysis of a passive containment cooling system of an AP1000 nuclear power plant. Reliab. Eng. Syst. Saf. 2016, 151, 12–19. [Google Scholar] [CrossRef] [Green Version]

- Di Maio, F.; Bandini, A.; Zio, E.; Alberola, S.C.; Sanchez-Saez, F.; Martorell, S. Bootstrapped-ensemble-based Sensitivity Analysis of a trace thermal-hydraulic model based on a limited number of PWR large break loca simulations. Reliab. Eng. Syst. Saf. 2016, 153, 122–134. [Google Scholar] [CrossRef] [Green Version]

- Perez, M.; Reventos, F.; Batet, L.; Guba, A.; Tóth, I.; Mieusset, T.; Bazin, P.; de Crécy, A.; Borisov, S.; Skorek, T.; et al. Uncertainty and sensitivity analysis of a LBLOCA in a PWR Nuclear Power Plant: Results of the Phase V of the BEMUSE programme. Nucl. Eng. Des. 2011, 241, 4206–4222. [Google Scholar] [CrossRef]

- Wilks, S.S. Statistical Prediction with Special Reference to the Problem of Tolerance Limits. Ann. Math. Stat. 1942, 13, 400–409. [Google Scholar] [CrossRef]

- Makai, M.; Pál, L. Best estimate method and safety analysis II. Reliab. Eng. Syst. Saf. 2006, 91, 222–232. [Google Scholar] [CrossRef]

- Nutt, W.T.; Wallis, G.B. Evaluation of nuclear safety from the outputs of computer codes in the presence of uncertainties. Reliab. Eng. Syst. Saf. 2004, 83, 57–77. [Google Scholar] [CrossRef]

- Bucher, C.; Most, T. A comparison of approximate response functions in structural reliability analysis. Probabilistic Eng. Mech. 2008, 23, 154–163. [Google Scholar] [CrossRef]

- Deng, J. Structural reliability analysis for implicit performance function using radial basis function network. Int. J. Solids Struct. 2006, 43, 3255–3291. [Google Scholar] [CrossRef] [Green Version]

- Cardoso, J.B.; Almeida, J.; Dias, J.S.; Coelho, P. Structural reliability analysis using Monte Carlo simulation and neural networks. Adv. Eng. Softw. 2008, 39, 505–513. [Google Scholar] [CrossRef]

- Volkova, E.; Iooss, B.; Van Dorpe, F. Global sensitivity analysis for a numerical model of radionuclide migration from the RRC “Kurchatov Institute” radwaste disposal site. Stoch. Environ. Res. Risk Assess. 2006, 22, 17–31. [Google Scholar] [CrossRef]

- Marrel, A.; Iooss, B.; Laurent, B.; Roustant, O. Calculations of Sobol indices for the Gaussian process metamodel. Reliab. Eng. Syst. Saf. 2009, 94, 742–751. [Google Scholar] [CrossRef] [Green Version]

- International Atomic Energy Agency. Safety Related Terms for Advanced Nuclear Plants; Terminos Relacionados con la Seguridad para Centrales Nucleares Avanzadas; International Atomic Energy Agency (IAEA): Vienna, Austria, 1995. [Google Scholar]

- Zio, E.; Baraldi, P.; Cadini, F. Basics of Reliability and Risk Analysis: Worked Out Problems and Solutions; World Scientific: Singapore, 2011; ISBN 9814355038. [Google Scholar]

- Marseguerra, M.; Zio, E. Monte Carlo approach to PSA for dynamic process systems. Reliab. Eng. Syst. Saf. 1996, 52, 227241. [Google Scholar] [CrossRef]

- Di Maio, F.; Vagnoli, M.; Zio, E. Risk-Based Clustering for Near Misses Identification in Integrated Deterministic and Probabilistic Safety Analysis. Sci. Technol. Nucl. Install. 2015, 2015, 693891. [Google Scholar] [CrossRef]

- Hakobyan, A.; Denning, R.; Aldemir, T.; Dunagan, S.; Kunsman, D. A Methodology for Generating Dynamic Accident Progression Event Trees for Level-2 PRA. In Proceedings of the PHYSOR-2006—American Nuclear Society’s Topical Meeting on Reactor Physics, Vancouver, BC, Canada, 10–14 September 2006. [Google Scholar]

- Coyne, K.; Mosleh, A. Nuclear plant control room operator modeling within the ADS-IDAC, Version 2, Dynamic PRA Environment: Part 1—General description and cognitive foundations. Int. J. Perform. Eng. 2014, 10, 691–703. [Google Scholar]

- Devooght, J.; Smidts, C. Probabilistic Reactor Dynamics—I: The Theory of Continuous Event Trees. Nucl. Sci. Eng. 1992, 111, 229–240. [Google Scholar] [CrossRef]

- Kopustinskas, V.; Augutis, J.; Rimkevičius, S. Dynamic reliability and risk assessment of the accident localization system of the Ignalina NPP RBMK-1500 reactor. Reliab. Eng. Syst. Saf. 2005, 87, 77–87. [Google Scholar] [CrossRef]

- Kloos, M.; Peschke, J. MCDET: A Probabilistic Dynamics Method Combining Monte Carlo Simulation with the Discrete Dynamic Event Tree Approach. Nucl. Sci. Eng. 2006, 153, 137–156. [Google Scholar] [CrossRef]

- Kumar, R.; Bechta, S.; Kudinov, P.; Curnier, F.; Marquès, M.; Bertrand, F. A PSA Level-1 method with repairable components: An application to ASTRID Decay Heat Removal systems. In Proceedings of the Safety and Reliability: Methodology and Applications—European Safety and Reliability Conference, ESREL 2014, Wroclaw, Poland, 14–18 September 2014; CRC Press/Balkema: Leiden, The Netherlands, 2015; pp. 1611–1617. [Google Scholar]

- Di Maio, F.; Rossetti, R.; Zio, E. Postprocessing of Accidental Scenarios by Semi-Supervised Self-Organizing Maps. Sci. Technol. Nucl. Install. 2017, 2017, 2709109. [Google Scholar] [CrossRef] [Green Version]

- Di Maio, F.; Baronchelli, S.; Vagnoli, M.; Zio, E. Determination of prime implicants by differential evolution for the dynamic reliability analysis of non-coherent nuclear systems. Ann. Nucl. Energy 2017, 102, 91–105. [Google Scholar] [CrossRef] [Green Version]

- Di Maio, F.; Picoco, C.; Zio, E.; Rychkov, V. Safety margin sensitivity analysis for model selection in nuclear power plant probabilistic safety assessment. Reliab. Eng. Syst. Saf. 2017, 162, 122–138. [Google Scholar] [CrossRef] [Green Version]

- Zio, E. The future of risk assessment. Reliab. Eng. Syst. Saf. 2018, 177, 176–190. [Google Scholar] [CrossRef] [Green Version]

- Di Maio, F.; Zio, E. Dynamic accident scenario generation, modeling and post-processing for the integrated deterministic and probabilistic safety analysis of nuclear power plants. In Advanced Concepts in Nuclear Energy Risk Assessment and Management; World Scientific: Singapore, 2018; Volume 1, pp. 477–504. ISBN 9813225629. [Google Scholar]

- Burgazzi, L. About time-variant reliability analysis with reference to passive systems assessment. Reliab. Eng. Syst. Saf. 2008, 93, 1682–1688. [Google Scholar] [CrossRef]

- Shrestha, R.; Kozlowski, T. Inverse uncertainty quantification of input model parameters for thermal-hydraulics simulations using expectation–maximization under Bayesian framework. J. Appl. Stat. 2015, 43, 1011–1026. [Google Scholar] [CrossRef]

- Hu, G.; Kozlowski, T. Inverse uncertainty quantification of trace physical model parameters using BFBT benchmark data. Ann. Nucl. Energy 2016, 96, 197–203. [Google Scholar] [CrossRef]

- Faes, M.; Broggi, M.; Patelli, E.; Govers, Y.; Mottershead, J.; Beer, M.; Moens, D. A multivariate interval approach for inverse uncertainty quantification with limited experimental data. Mech. Syst. Signal Process. 2019, 118, 534–548. [Google Scholar] [CrossRef] [Green Version]

- Kennedy, M.C.; O’Hagan, A. Bayesian calibration of computer models. J. R. Stat. Soc. Ser. B 2001, 63, 425–464. [Google Scholar] [CrossRef]

- Wu, X.; Kozlowski, T.; Meidani, H. Kriging-based inverse uncertainty quantification of nuclear fuel performance code BISON fission gas release model using time series measurement data. Reliab. Eng. Syst. Saf. 2018, 169, 422–436. [Google Scholar] [CrossRef]

- Wu, X.; Kozlowski, T.; Meidani, H.; Shirvan, K. Inverse uncertainty quantification using the modular Bayesian approach based on Gaussian process, Part 1: Theory. Nucl. Eng. Des. 2018, 335, 339–355. [Google Scholar] [CrossRef] [Green Version]

- Baccou, J.; Zhang, J.; Fillion, P.; Damblin, G.; Petruzzi, A.; Mendizábal, R.; Reventos, F.; Skorek, T.; Couplet, M.; Iooss, B.; et al. SAPIUM: A Generic Framework for a Practical and Transparent Quantification of Thermal-Hydraulic Code Model Input Uncertainty. Nucl. Sci. Eng. 2020, 194, 721–736. [Google Scholar] [CrossRef]

- Nagel, J.B.; Rieckermann, J.; Sudret, B. Principal component analysis and sparse polynomial chaos expansions for global sensitivity analysis and model calibration: Application to urban drainage simulation. Reliab. Eng. Syst. Saf. 2020, 195, 106737. [Google Scholar] [CrossRef] [Green Version]

- Roma, G.; Di Maio, F.; Bersano, A.; Pedroni, N.; Bertani, C.; Mascari, F.; Zio, E. A Bayesian framework of inverse uncertainty quantification with principal component analysis and Kriging for the reliability analysis of passive safety systems. Nucl. Eng. Des. 2021, 379, 111230. [Google Scholar] [CrossRef]

- Turati, P.; Pedroni, N.; Zio, E. An Adaptive Simulation Framework for the Exploration of Extreme and Unexpected Events in Dynamic Engineered Systems. Risk Anal. 2016, 37, 147–159. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Maio, F.; Pedroni, N.; Tóth, B.; Burgazzi, L.; Zio, E. Reliability Assessment of Passive Safety Systems for Nuclear Energy Applications: State-of-the-Art and Open Issues. Energies 2021, 14, 4688. https://doi.org/10.3390/en14154688

Di Maio F, Pedroni N, Tóth B, Burgazzi L, Zio E. Reliability Assessment of Passive Safety Systems for Nuclear Energy Applications: State-of-the-Art and Open Issues. Energies. 2021; 14(15):4688. https://doi.org/10.3390/en14154688

Chicago/Turabian StyleDi Maio, Francesco, Nicola Pedroni, Barnabás Tóth, Luciano Burgazzi, and Enrico Zio. 2021. "Reliability Assessment of Passive Safety Systems for Nuclear Energy Applications: State-of-the-Art and Open Issues" Energies 14, no. 15: 4688. https://doi.org/10.3390/en14154688

APA StyleDi Maio, F., Pedroni, N., Tóth, B., Burgazzi, L., & Zio, E. (2021). Reliability Assessment of Passive Safety Systems for Nuclear Energy Applications: State-of-the-Art and Open Issues. Energies, 14(15), 4688. https://doi.org/10.3390/en14154688