Hydraulic Conductivity of Rock Masses Surrounding Water Curtain Boreholes for Underground Oil Storage Caverns

Abstract

:1. Introduction

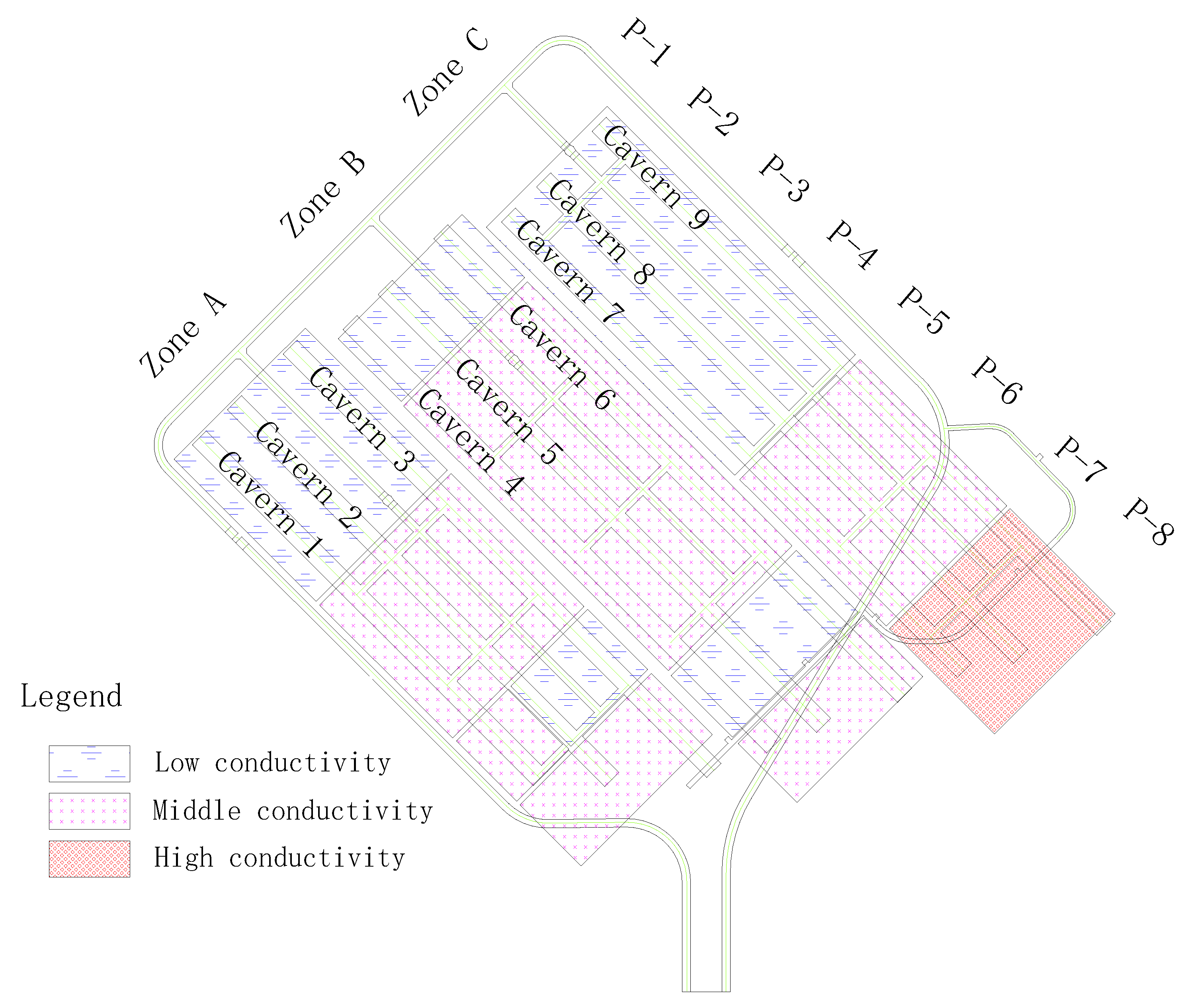

2. Hydro-Geological Tests of the Water Curtain System in the Huangdao Project

3. Method for Analyzing Equivalent Hydraulic Conductivity

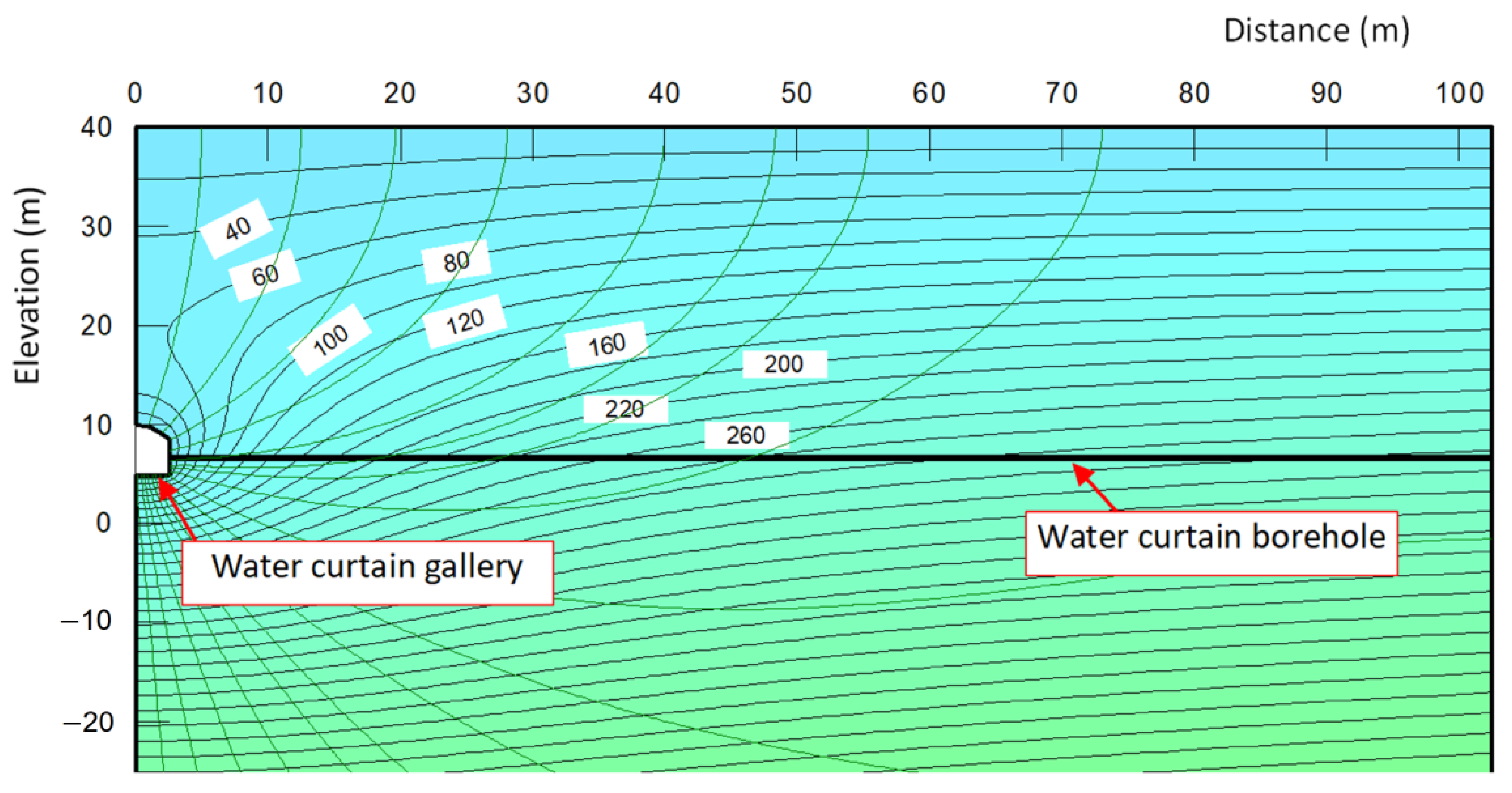

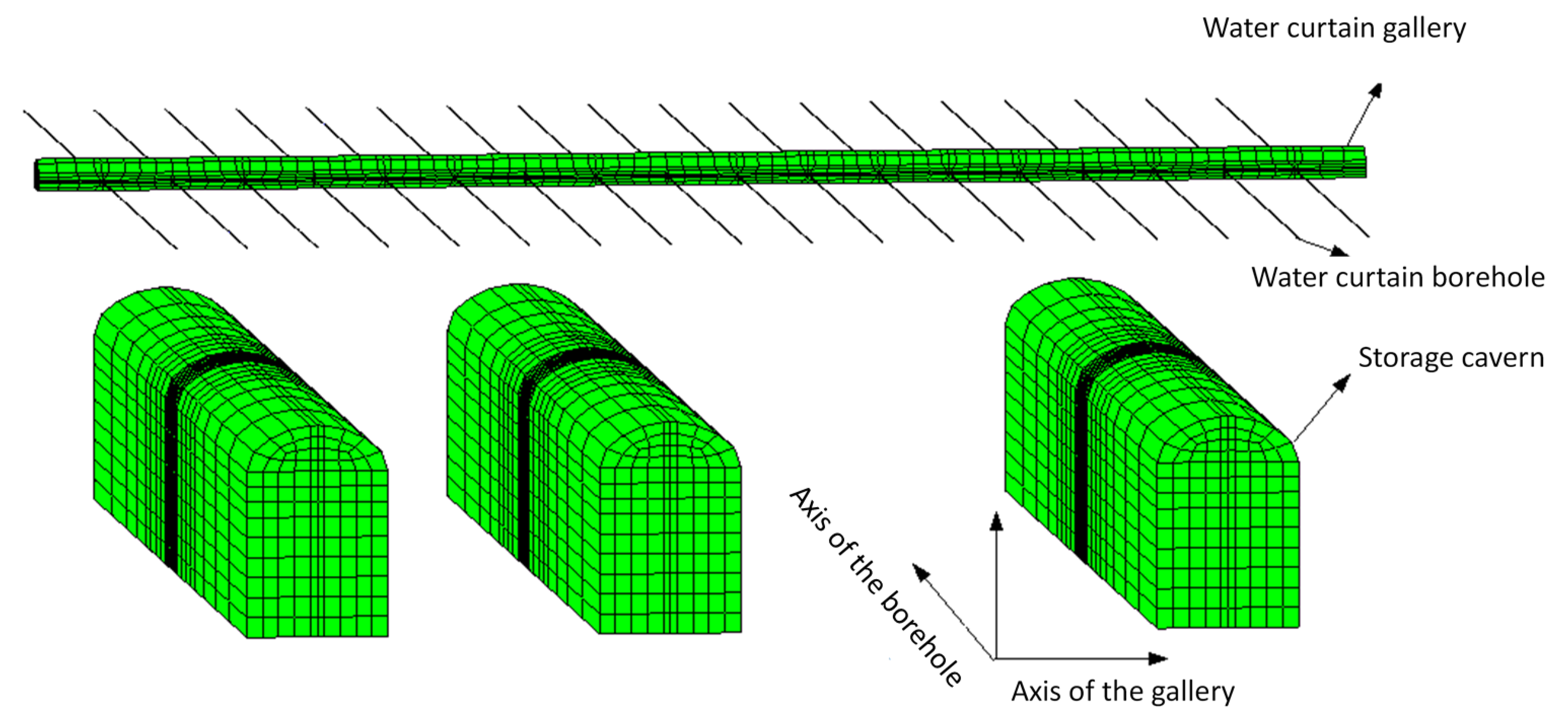

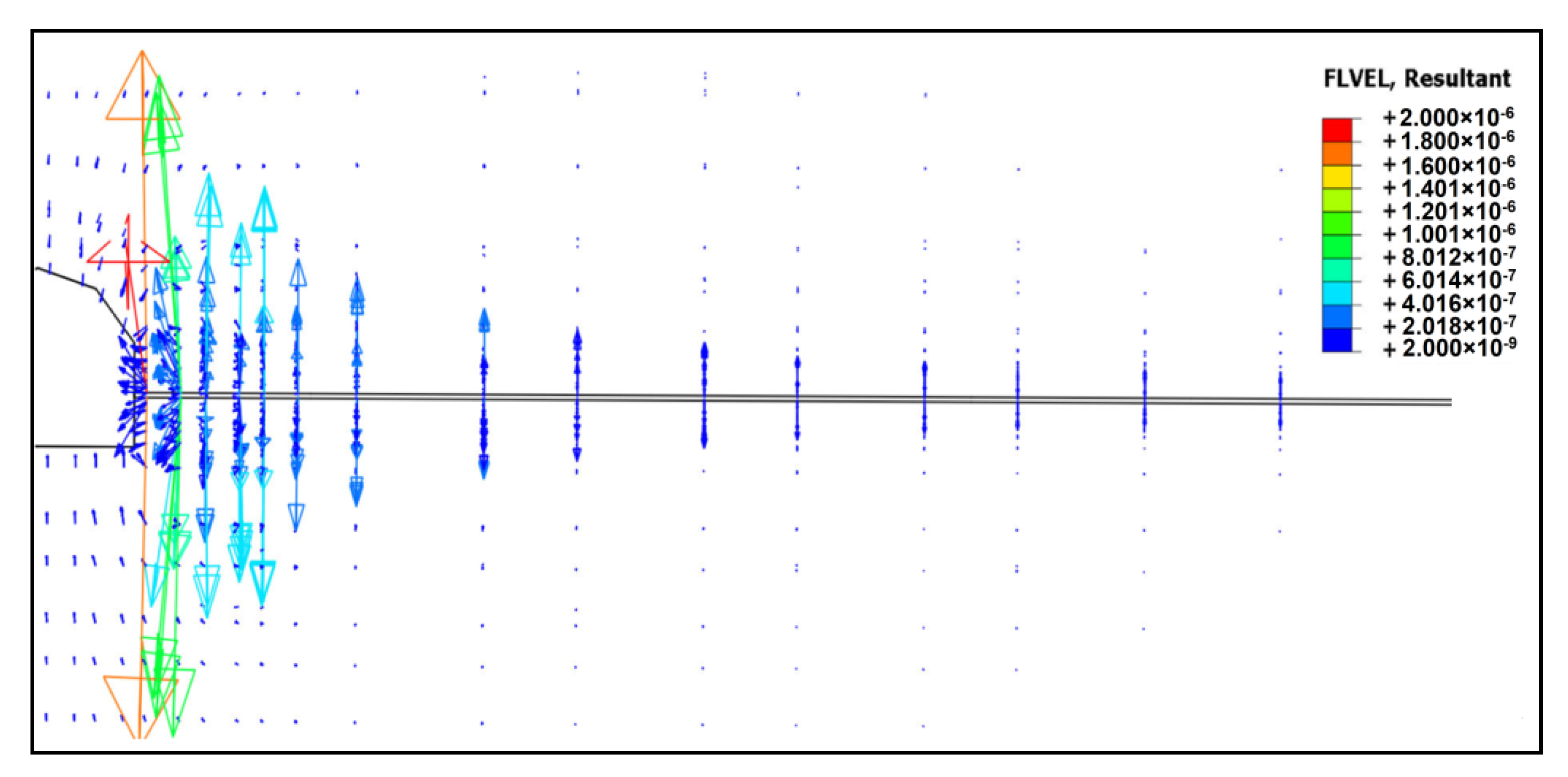

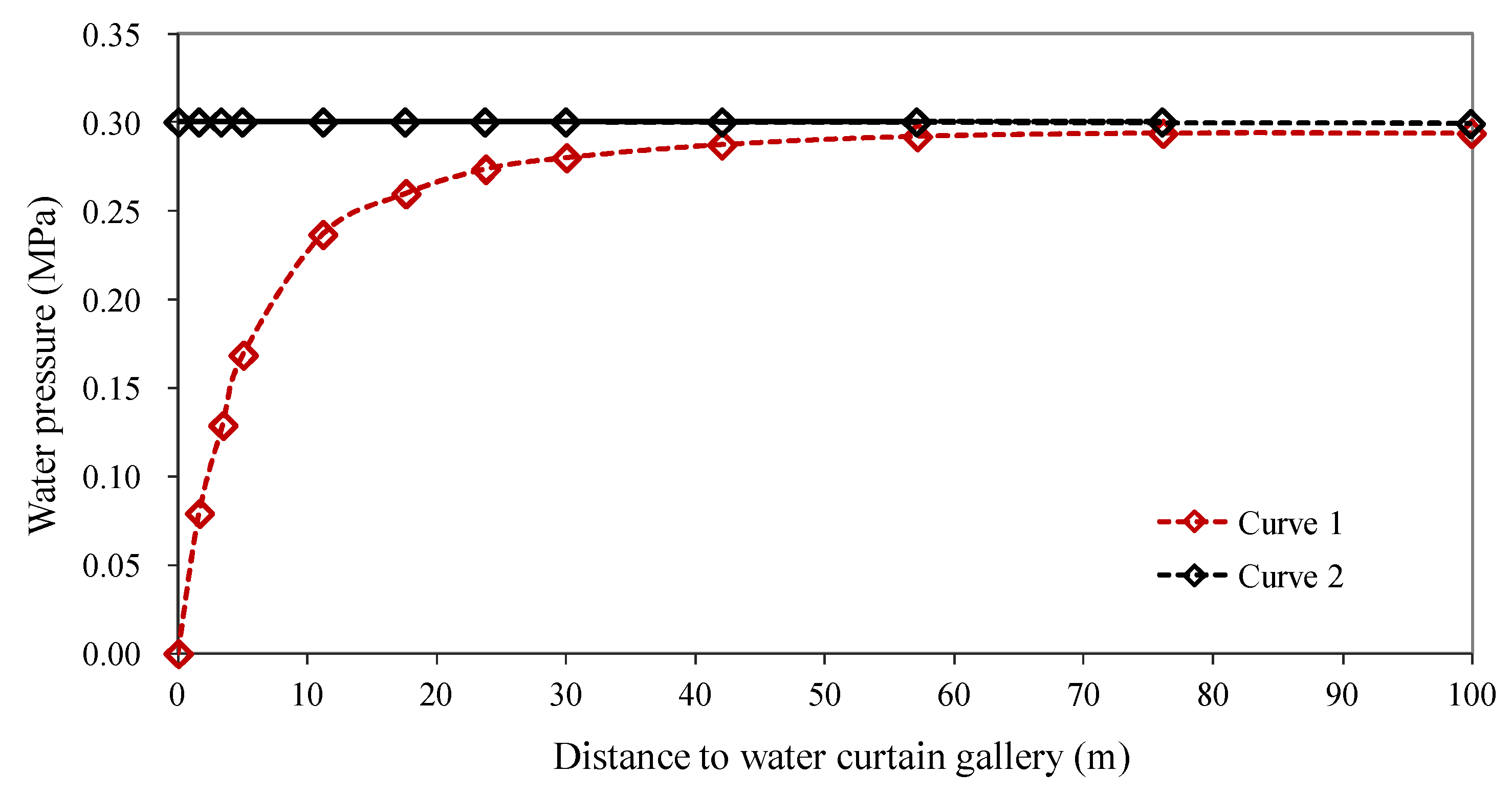

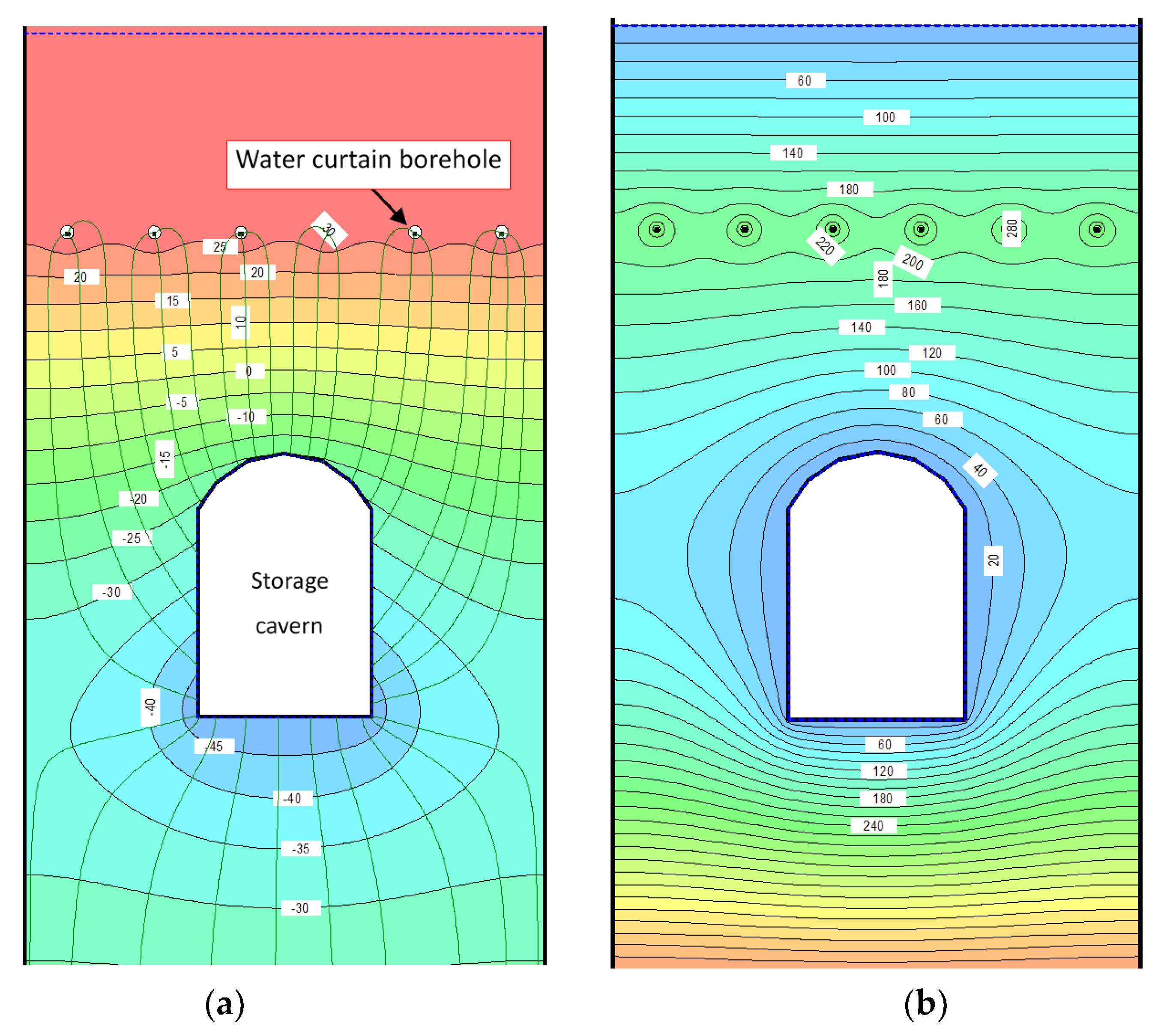

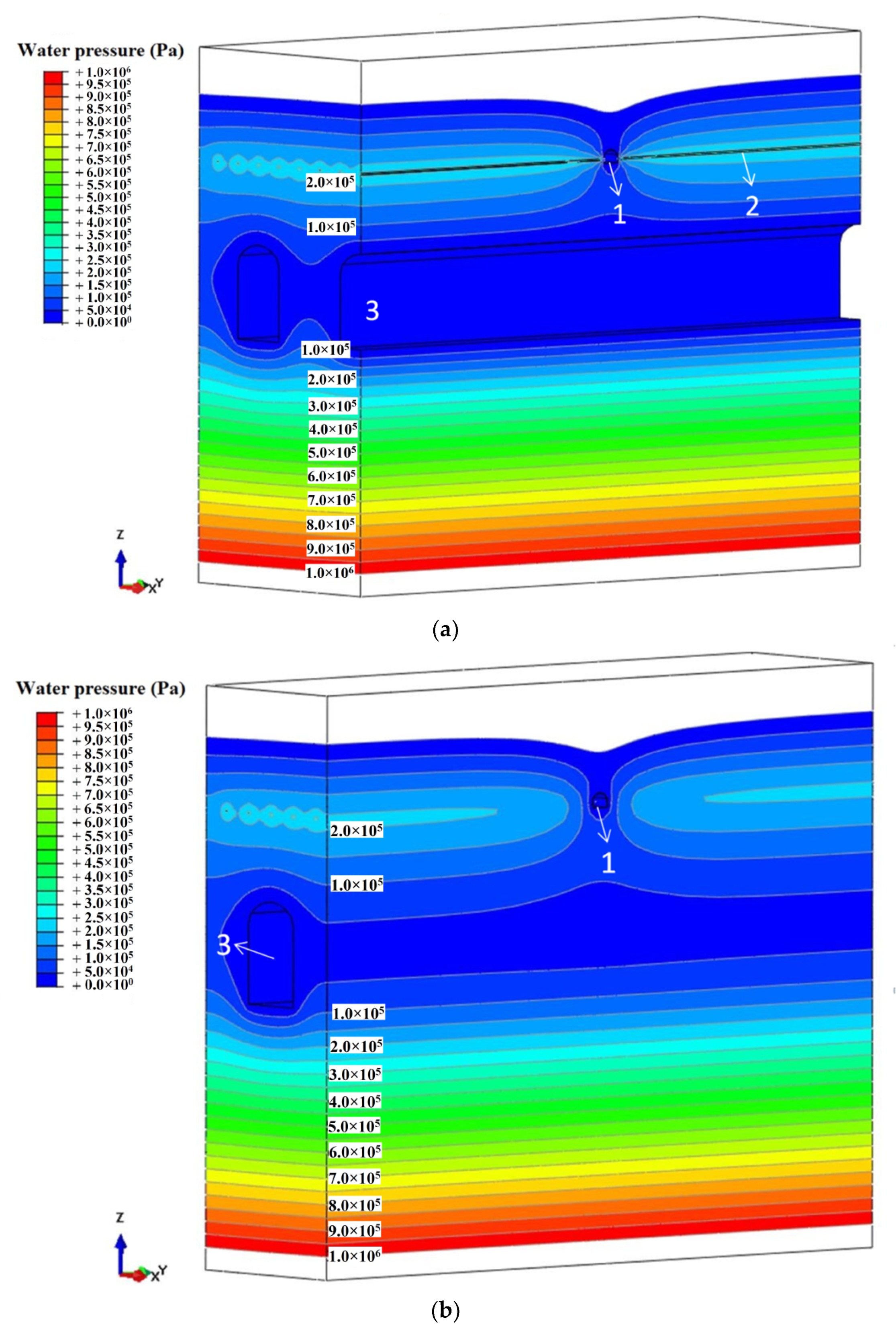

3.1. Influence of Water Curtain Gallery Drainage on the Seepage Field

3.2. Method of Estimating Hydraulic Conductivity from Steady Water Injection Test Data

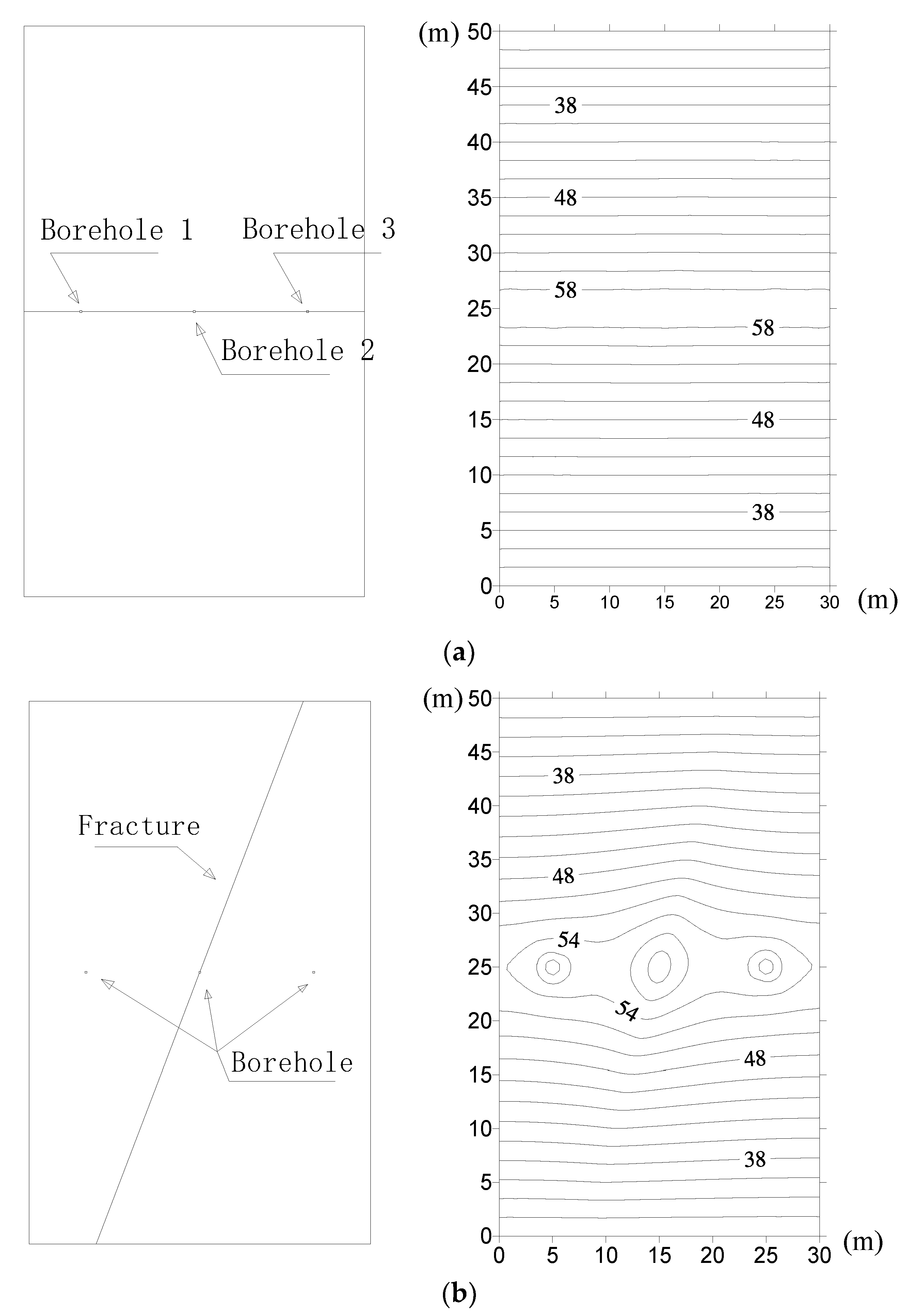

3.3. Influence of the Rock Fracture Configuration on the Equivalent Hydraulic Conductivity

4. Application of the Proposed Method to Assess Hydraulic Conductivity

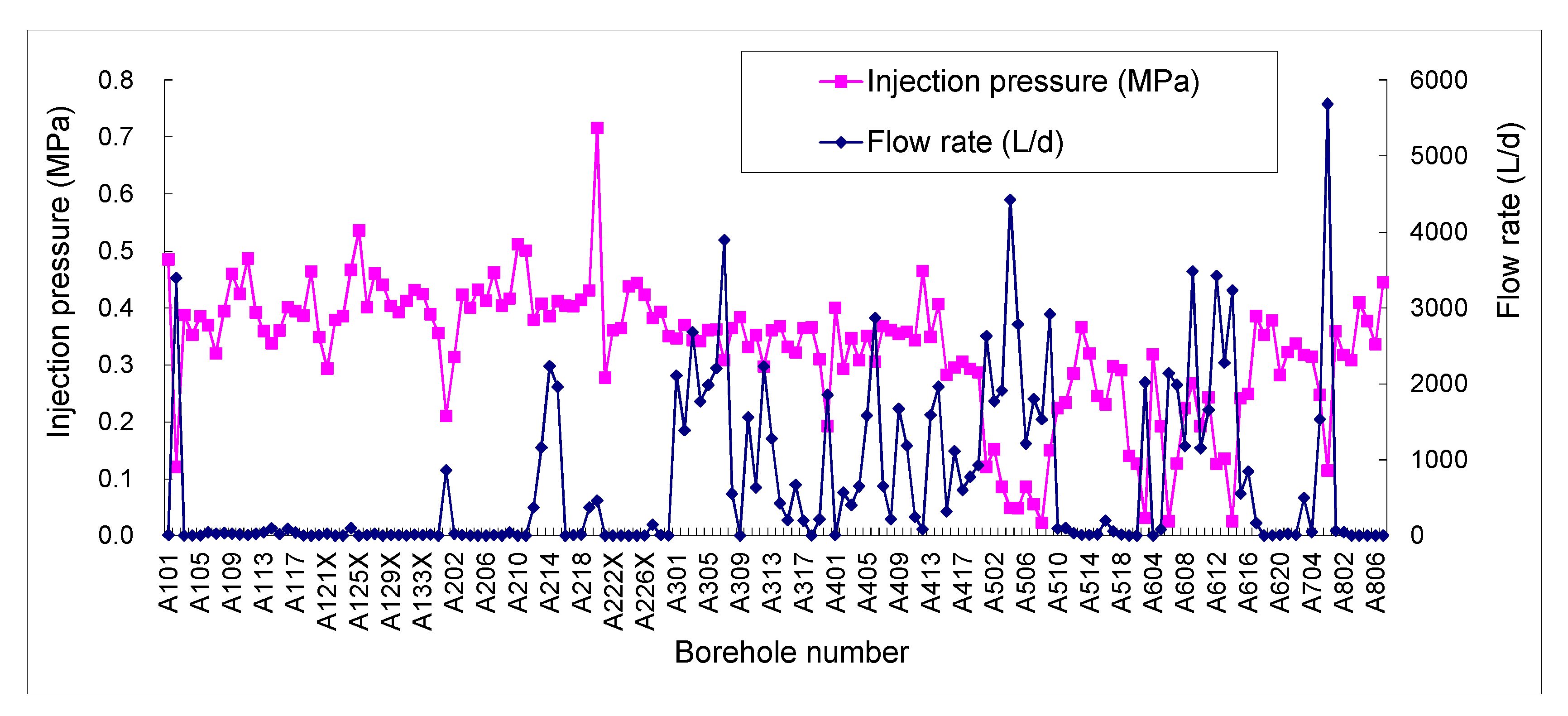

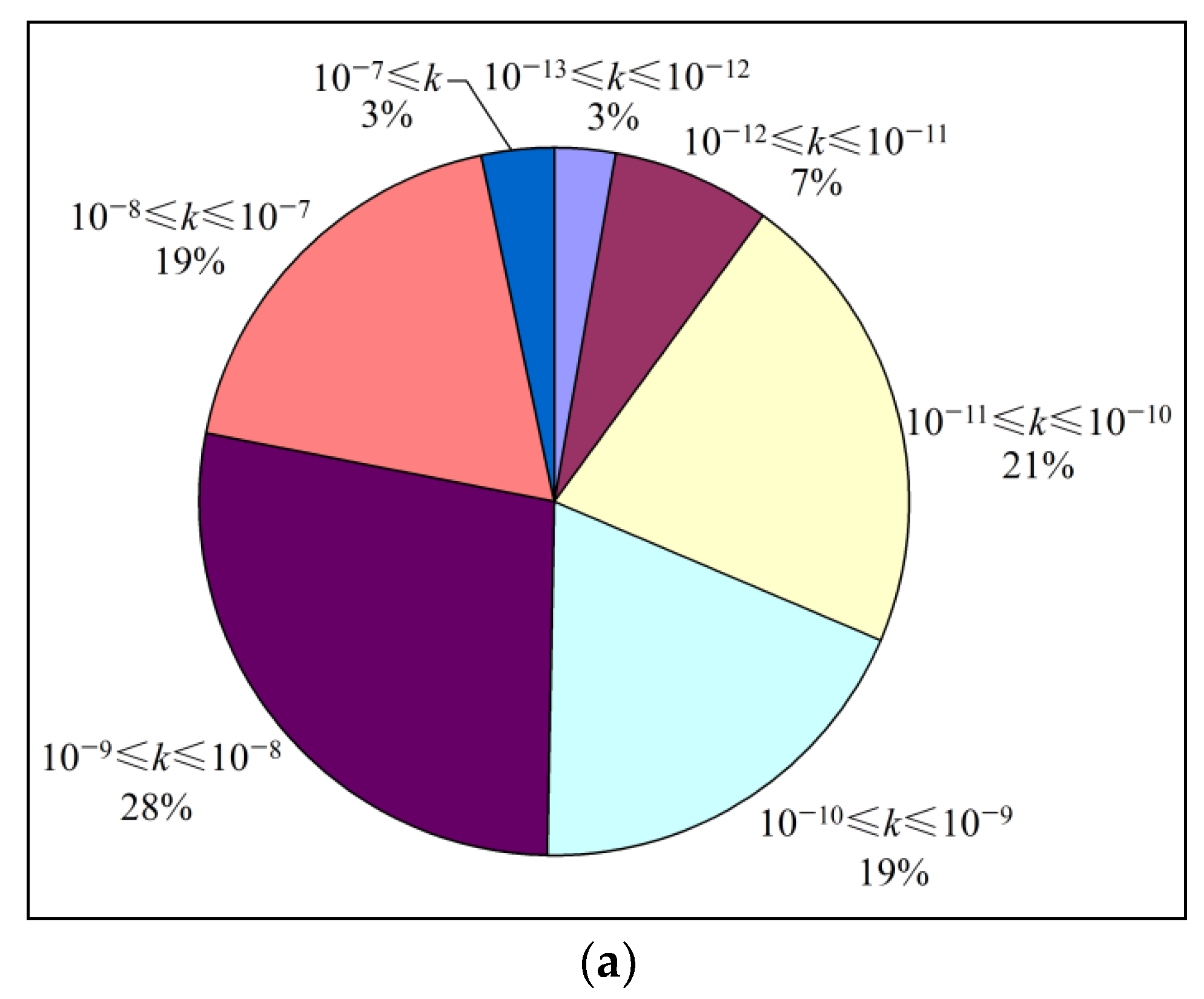

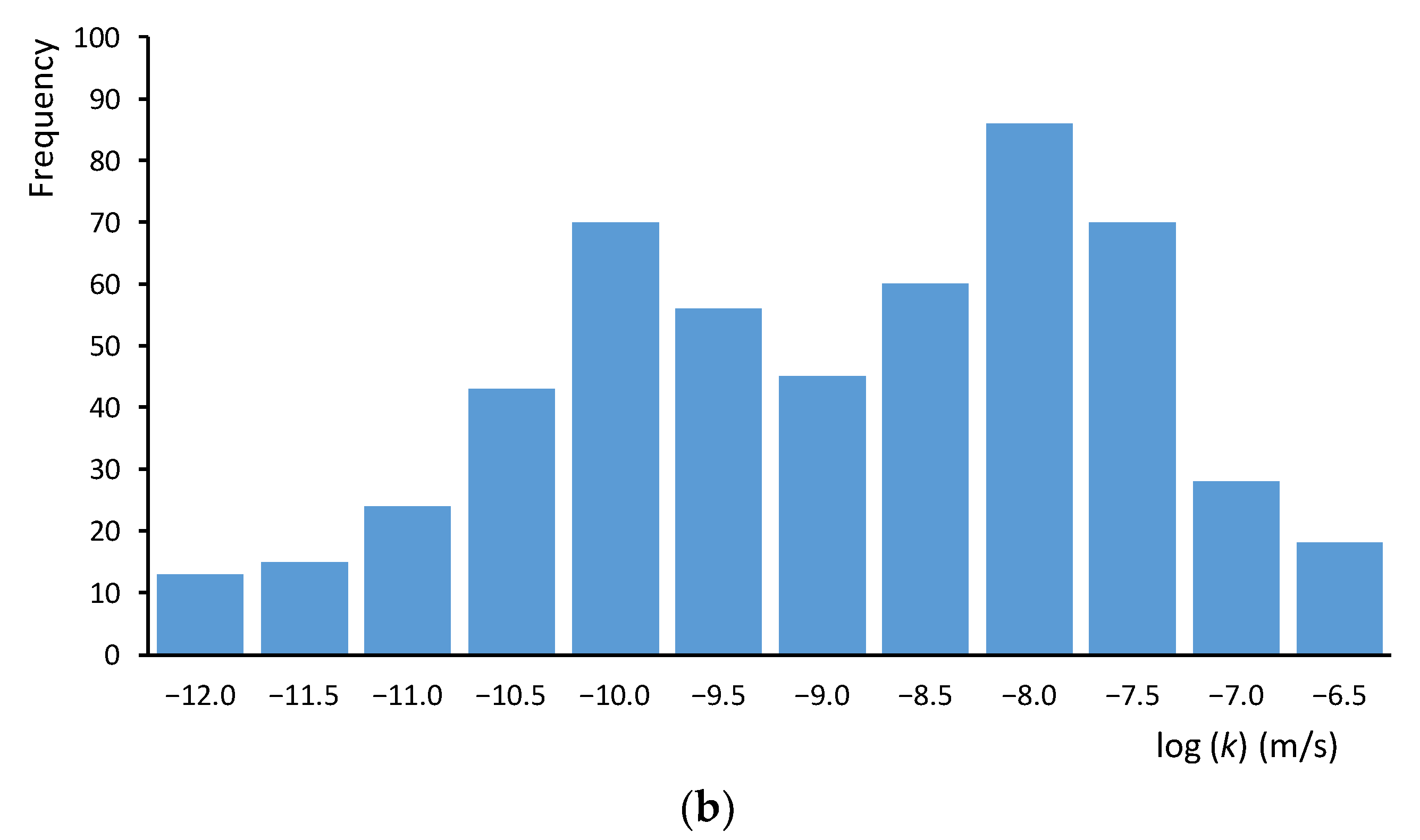

4.1. Statistical Analysis of Water Injection Test Data

4.2. Assessment of the Hydraulic Conductivity of Host Rocks

5. Conclusions and Further Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kjørholt, H.; Broch, E. The water curtain—A successful means of preventing gas leakage from high-pressure, unlined rock caverns. Tunn. Undergr. Space Technol. 1992, 7, 127–132. [Google Scholar] [CrossRef]

- Åberg, B. Prevention of gas leakage from unlined reservoirs in rock. In Proceedings of the First International Symposium on Storage in Excavated Rock Caverns, Stockholm, Sweden, 5–8 September 1977; pp. 399–413. [Google Scholar]

- Goodall, D.C.; Åberg, B.; Brekke, T.L. Fundamental of gas containment in unlined rock caverns. Rock Mech. Rock Eng. 1988, 21, 235–258. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, Q.; He, G. Reexamining the necessity of adding water curtain borehole with improved understanding of water sealing criterion. Rock Mech. Rock Eng. 2020, 53, 4623–4638. [Google Scholar] [CrossRef]

- Li, Z.; Wang, K.; Wang, A.; Liu, H. Experimental study of water curtain performance for gas storage in an underground cavern. J. Rock Mech. Geotech. Eng. 2009, 1, 89–96. [Google Scholar] [CrossRef] [Green Version]

- Kurose, H.; Ikeya, S.; Chang, C.S.; Maejima, T.; Shimaya, S.; Tanaka, T.; Aoki, K. Construction of Namikata underground LPG storage cavern in Japan. Int. J. JCRM. 2014, 10, 15–24. [Google Scholar]

- Rehbinder, G.; Karlsson, R.; Dahlkild, A. A study of a water curtain around a gas store in rock. Appl. Sci. Res. 1988, 45, 107–127. [Google Scholar] [CrossRef]

- Lee, Y.N.; Yun, S.P.; Kim, D.Y.; Nam, H.K. Design and construction aspects of unlined oil storage caverns in rock. In Proceedings of the South East Asian Symposium on Tunneling and Underground Space Development, (SEASTUD), Bangkok, Thailand, 18–19 January 1995; pp. 18–19. [Google Scholar]

- Park, J.J.; Jeon, S.; Chung, Y.S. Design of Pyongtaek LPG storage terminal underneath Lake Namyang: A case study. Tunn. Undergr. Space Technol. 2005, 20, 463–478. [Google Scholar] [CrossRef]

- Ivars, D.M. Water inflow into excavations in fractured rock—A three-dimensional hydro-mechanical numerical study. Int. J. Rock Mech. Min. Sci. 2006, 43, 705–725. [Google Scholar] [CrossRef]

- Yu, C.; Deng, S.C.; Li, H.B.; Li, J.C.; Xia, X. The anisotropic seepage analysis of water-sealed underground oil storage caverns. Tunn. Undergr. Space Technol. 2013, 38, 26–37. [Google Scholar] [CrossRef]

- Li, S.; Wang, Z.; Ping, Y.; Zhou, Y.; Zhang, L. Discrete element analysis of hydro-mechanical behavior of a pilot underground crude oil storage facility in granite in China. Tunn. Undergr. Space Technol. 2014, 40, 75–84. [Google Scholar] [CrossRef]

- Lin, F.; Ren, F.; Luan, H.; Ma, G.; Chen, S. Effectiveness analysis of water-sealing for underground LPG storage. Tunn. Undergr. Space Technol. 2016, 51, 270–290. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Zhang, G.; Liu, Y.; Zhou, C. A numerical procedure for modeling the seepage field of water-sealed underground oil and gas storage caverns. Tunn. Undergr. Space Technol. 2017, 66, 56–63. [Google Scholar] [CrossRef]

- Ravandi, E.G.; Rahmannejad, R.; Karimi-Nasab, S.; Sarrafi, A.; Raoof, A. Water curtain system pre-design for crude oil storage URCs: A numerical modeling and genetic programming approach. Geotech. Geol. Eng. 2018, 36, 813–826. [Google Scholar] [CrossRef]

- Lindblom, U. Design criteria for the Brooklyn gas storage caverns at JFK airport, New York. Int. J. Rock Mech. Min. Sci. 1997, 34, 179–195. [Google Scholar] [CrossRef]

- Makita, T.; Miyanaga, Y.; Iguchi, K.; Hatano, T. Underground oil storage facilities in Japan. Eng. Geol. 1993, 35, 191–198. [Google Scholar] [CrossRef]

- Liang, J.; Lindblom, U. Analyses of gas storage capacity in unlined rock caverns. Rock Mech. Rock Eng. 1994, 27, 115–134. [Google Scholar] [CrossRef]

- Kim, T.; Lee, K.-K.; Ko, K.S.; Chang, H.W. Groundwater flow system inferred from hydraulic stresses and heads at an underground LPG storage cavern site. J. Hydrol. 2000, 236, 165–184. [Google Scholar] [CrossRef]

- Benardos, A.G.; Kaliampakos, D.G. Hydrocarbon storage in unlined rock caverns in Greek limestone. Tunn. Undergr. Space Technol. 2005, 20, 175–182. [Google Scholar] [CrossRef]

- Shi, L.; Zhang, B.; Wang, L.; Wang, H.; Zhang, H. Functional efficiency assessment of the water curtain system in an underground water-sealed oil storage cavern based on time-series monitoring data. Eng. Geol. 2018, 239, 79–95. [Google Scholar] [CrossRef]

- Lemieux, A.; Sharp, K.; Shkarupin, A. Preliminary assessment of underground hydrogen storage sites in Ontario, Canada. Int. J. Hydrogen Energ. 2019, 44, 15193–15204. [Google Scholar] [CrossRef]

- The National Standard of the People’s Republic of China. Code for Design of Underground Oil Storage in Rock Caverns (GB50455-2008); China Planning Press: Beijing, China, 2009. (In Chinese) [Google Scholar]

- The National Standard of the People’s Republic of China. Code for Design of Underground Oil Storage in Rock Caverns (GB50455-2020); China Planning Press: Beijing, China, 2020. (In Chinese) [Google Scholar]

- Neuman, S.P. Trends, prospects and challenges in quantifying flow and transport through fractured rocks. Hydrogeol. J. 2005, 13, 124–147. [Google Scholar] [CrossRef]

- Allen, D.M.; Michel, F.A. Evaluation of multi-well test data in a faulted aquifer using linear and radial flow models. Ground Water 2010, 36, 938–948. [Google Scholar] [CrossRef]

- Tsang, Y.W.; Tsang, C.F.; Hale, F.V.; Dverstorp, B. Tracer transport in a stochastic continuum model of fractured media. Water Resour. Res. 1996, 32, 3077–3092. [Google Scholar] [CrossRef]

- Chen, G.; Illman, W.A.; Thompson, D.L.; Vesselinov, V.V.; Neuman, S.P. Geostatistical, type curve and inverse analyses of pneumatic injection tests in unsaturated fractured tuffs at the Apache Leap Research Site near Superior, Arizona. In Dynamics of Fluids in Fractured Rocks. Geophysical Monograph Series; Faybishenko, B., Witherspoon, P.A., Benson, S.M., Eds.; AGU: Washington, DC, USA, 2000; Volume 122, pp. 73–98. [Google Scholar]

- Park, B.Y.; Kim, K.S.; Kwon, S.; Kim, C.; Bae, D.S.; Hartley, L.J.; Lee, H.K. Determination of the hydraulic conductivity components using a three-dimensional fracture network model in volcanic rock. Eng. Geol. 2002, 66, 127–141. [Google Scholar] [CrossRef]

- Voeckler, H.; Allen, D.M. Estimating regional-scale fractured bedrock hydraulic conductivity using discrete fracture network (DFN) modeling. Hydrogeol. J. 2012, 20, 1081–1100. [Google Scholar] [CrossRef]

- Llopis-Albert, C.; Capilla, J.E. Stochastic inverse modelling of hydraulic conductivity fields taking into account independent stochastic structures: A 3D case study. J. Hydrol. 2010, 391, 277–288. [Google Scholar] [CrossRef]

- Illman, W.A. Hydraulic tomography offers improved imaging of heterogeneity in fractured rocks. Groundwater 2014, 52, 659–684. [Google Scholar] [CrossRef]

- Rovey, C.W., II; Cherkauer, D.S. Scale dependency of hydraulic conductivity measurements. Ground Water 1995, 33, 769–780. [Google Scholar] [CrossRef]

- Illman, W.A. Strong field evidence of directional permeability scale effect in fractured rock. J. Hydrol. 2006, 319, 227–236. [Google Scholar] [CrossRef]

- Rovey, C.W. Assessing flow systems in carbonate aquifers using scale effects in hydraulic conductivity. Environ. Geol. 1994, 24, 244–253. [Google Scholar] [CrossRef]

- Schulze-Makuch, D.; Cherkauer, D.S. Variations in hydraulic conductivity with scale of measurements during aquifer tests in heterogeneous, porous carbonate rock. Hydrogeol. J. 1998, 6, 204–215. [Google Scholar] [CrossRef]

- Vesselinov, V.V.; Neuman, S.P.; Illman, W.A. Threedimensional numerical inversion of pneumatic cross-hole tests in unsaturated fractured tuff: 2. Equivalent parameters, high-resolution stochastic imaging and scale effects. Water Resour. Res. 2001, 12, 3019–3042. [Google Scholar] [CrossRef] [Green Version]

- Quinn, P.; Cherry, J.A.; Parker, B.L. Hydraulic testing using a versatile straddle packer system for improved transmissivity estimation in fractured-rock boreholes. Hydrogeol. J. 2012, 20, 1529–1547. [Google Scholar] [CrossRef]

- Aydin, A. Theory of single-well tests in acute fracture-wellbore systems. J. Hydrol. 1997, 194, 201–220. [Google Scholar] [CrossRef]

- Wei, Z.Q.; Egger, P.; Descoeudres, F. Permeability predictions for jointed rock masses. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1995, 32, 251–261. [Google Scholar] [CrossRef]

- El-Naqa, A. The hydraulic conductivity of the fractures intersecting Cambrian sandstone rock masses, central Jordan. Environ. Geol. 2001, 40, 973–982. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, Z. Effects of anisotropic permeability of fractured rock masses on underground oil storage caverns. Tunn. Undergr. Space Technol. 2010, 25, 629–637. [Google Scholar] [CrossRef]

- Hitchmough, A.M.; Riley, M.S.; Herbert, A.W.; Tellam, J.H. Estimating the hydraulic properties of the fracture network in a sandstone aquifer. J. Contam. Hydrol. 2007, 93, 38–57. [Google Scholar] [CrossRef]

- Hu, C.; Chen, H.; Chen, G.; Liu, J. Detection of low-efficiency zones of water curtain system for underground LPG storage by a discrete fracture network model. Environ. Earth Sci. 2019, 78, 11. [Google Scholar] [CrossRef]

- The Standard for Petrochemical Industry of the People’s Republic of China. Specification of Hydrogeological Tests for Underground Oil Storage in Rock Caverns; (SH/T 3195-2017); China Petrochemical Industry Press: Beijing, China, 2018. (In Chinese) [Google Scholar]

- Wang, Z.; Li, S.; Qiao, L. Design and test aspects of a water curtain system for underground oil storage caverns in China. Tunn. Undergr. Space Technol. 2015, 48, 20–34. [Google Scholar] [CrossRef]

- Bredehoeft, J.D.; Papadopulos, S.S. A method for determining the hydraulic properties of tight formations. Water Resour. Res. 1980, 16, 233–238. [Google Scholar] [CrossRef]

- Rehbinder, G. The double packer permeameter with narrow packers. Analytical solution for non-steady flow. Appl. Sci. Res. 1996, 56, 255–279. [Google Scholar] [CrossRef]

- US Bureau of Reclamation. Permeability tests in individual drill holes and wells. In Ground Water Manual, Dept of the Interior; US Bureau of Reclamation: Washington, DC, USA, 1977; pp. 317–342. [Google Scholar]

- The Standard for Electric Power Industry of the People’s Republic of China. Code of Water Pressure Test in Borehole for Hydropower and Water Resources Engineering; (DL/T5331-2005); China Electric Power Press: Beijing, China, 2005. (In Chinese) [Google Scholar]

- Lindblom, U. The performance of water curtains surrounding rock caverns used for gas storage. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1989, 26, 85–97. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, W.; Yin, J. Two-dimensional fractured porous flow model of arbitrary fracture network and its two solution methods. Chin. J. Rock Mech. Eng. 2012, 31, 216–227. (In Chinese) [Google Scholar]

| Model Designation | Water Injection Rate (m3/s) | Hydraulic Conductivity Nearby Borehole 2 (m/s) | ||

|---|---|---|---|---|

| Borehole 1 | Borehole 2 | Borehole 3 | ||

| No. 1 | 2.27 × 10−9 | 2.14 × 10−9 | 2.27 × 10−9 | 1.34 × 10−10 |

| No. 2 | 2.87 × 10−10 | 2.09 × 10−7 | 2.81 × 10−10 | 1.31 × 10−8 |

| No. 3 | 2.26 × 10−9 | 2.09 × 10−7 | 2.26 × 10−9 | 1.31 × 10−8 |

| No. 4 | 2.79 × 10−10 | 2.09 × 10−7 | 2.14 × 10−9 | 1.31 × 10−8 |

| No. 5 | 2.94 × 10−8 | 2.75 × 10−7 | 2.93 × 10−7 | 1.72 × 10−8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.-H.; Liu, Q.-B.; Su, A.-J.; Li, Y.-J.; Zhang, Y.-H. Hydraulic Conductivity of Rock Masses Surrounding Water Curtain Boreholes for Underground Oil Storage Caverns. Energies 2021, 14, 4588. https://doi.org/10.3390/en14154588

Zhang Q-H, Liu Q-B, Su A-J, Li Y-J, Zhang Y-H. Hydraulic Conductivity of Rock Masses Surrounding Water Curtain Boreholes for Underground Oil Storage Caverns. Energies. 2021; 14(15):4588. https://doi.org/10.3390/en14154588

Chicago/Turabian StyleZhang, Qi-Hua, Qing-Bing Liu, Ai-Jun Su, Yu-Jie Li, and Yi-Hu Zhang. 2021. "Hydraulic Conductivity of Rock Masses Surrounding Water Curtain Boreholes for Underground Oil Storage Caverns" Energies 14, no. 15: 4588. https://doi.org/10.3390/en14154588

APA StyleZhang, Q.-H., Liu, Q.-B., Su, A.-J., Li, Y.-J., & Zhang, Y.-H. (2021). Hydraulic Conductivity of Rock Masses Surrounding Water Curtain Boreholes for Underground Oil Storage Caverns. Energies, 14(15), 4588. https://doi.org/10.3390/en14154588