The Application of Similarity Theory and Dimensional Analysis to the Study of Centrifugal-Rotary Chopper of Forage Grain

Abstract

:1. Introduction

2. Materials and Methods

Let there exista physical law, expressed in the form based on some dimension, generally speaking, the values of the dimensional governing parameters the same. This dependence can be represented as a dependence of a dimensionless quantity on dimensionless combinations of defining parameters. The number of these dimensionless combinations is less than the total number of dimensional defining parameters by the number of defining parameters with independent dimension.

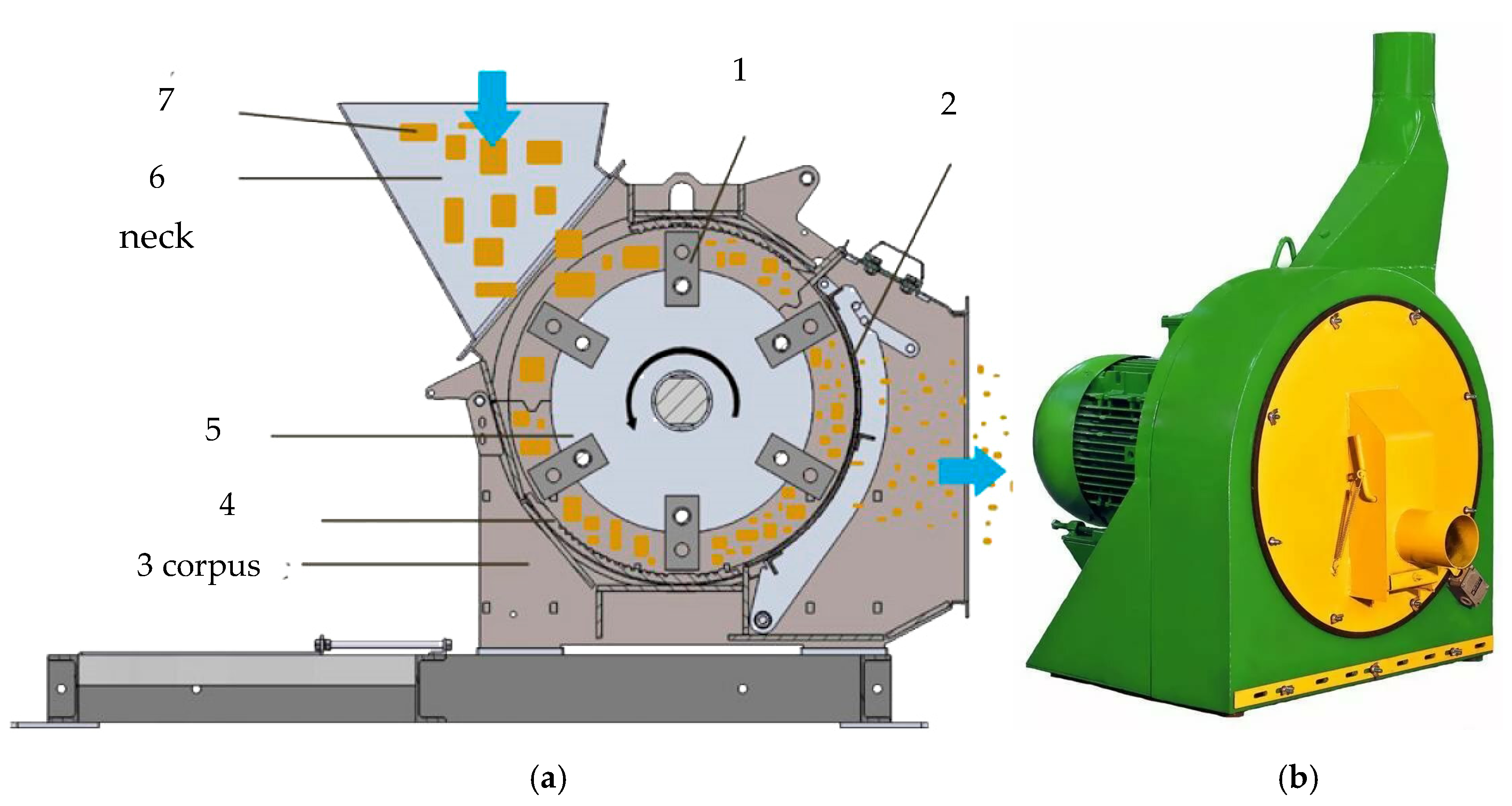

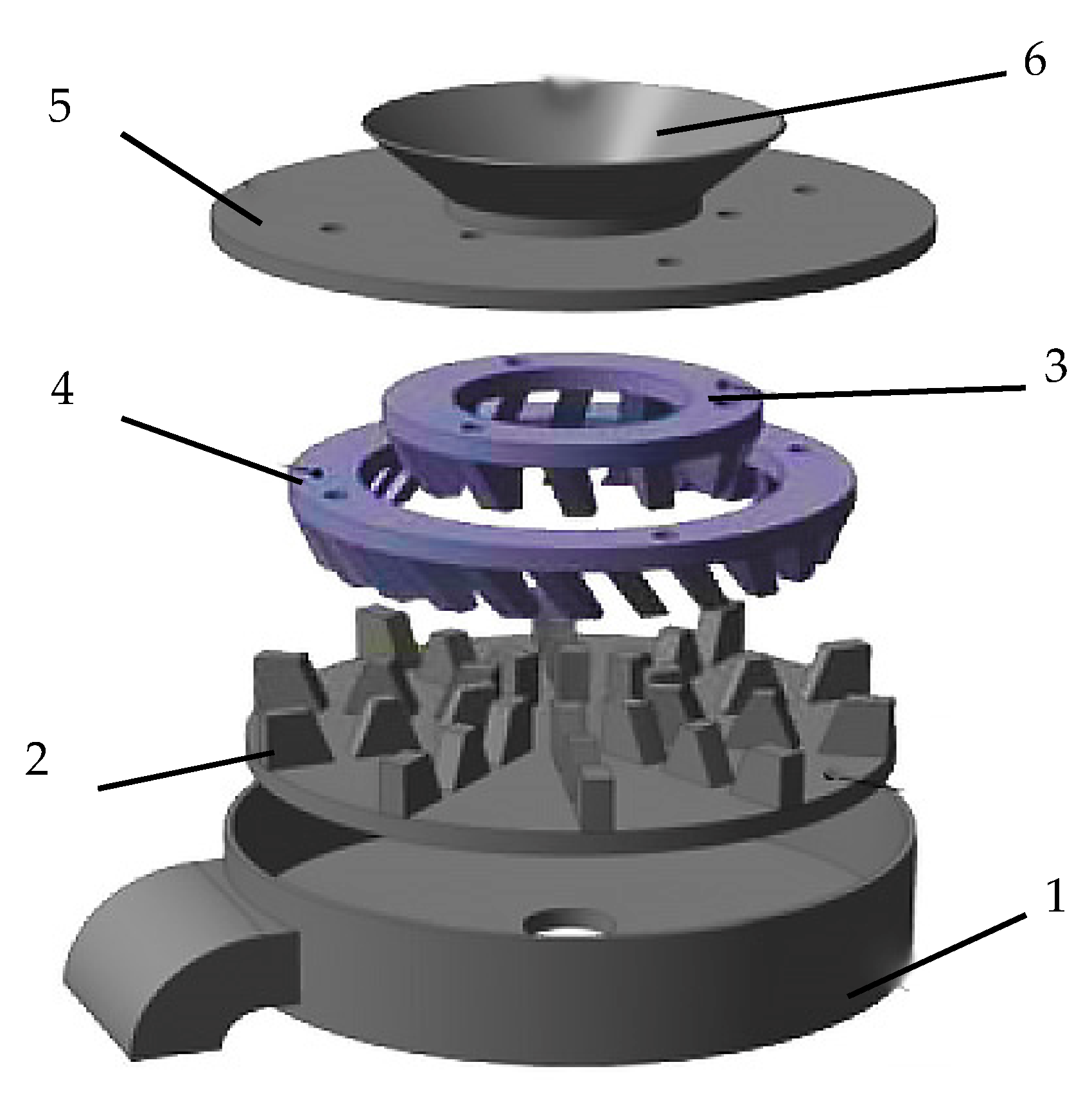

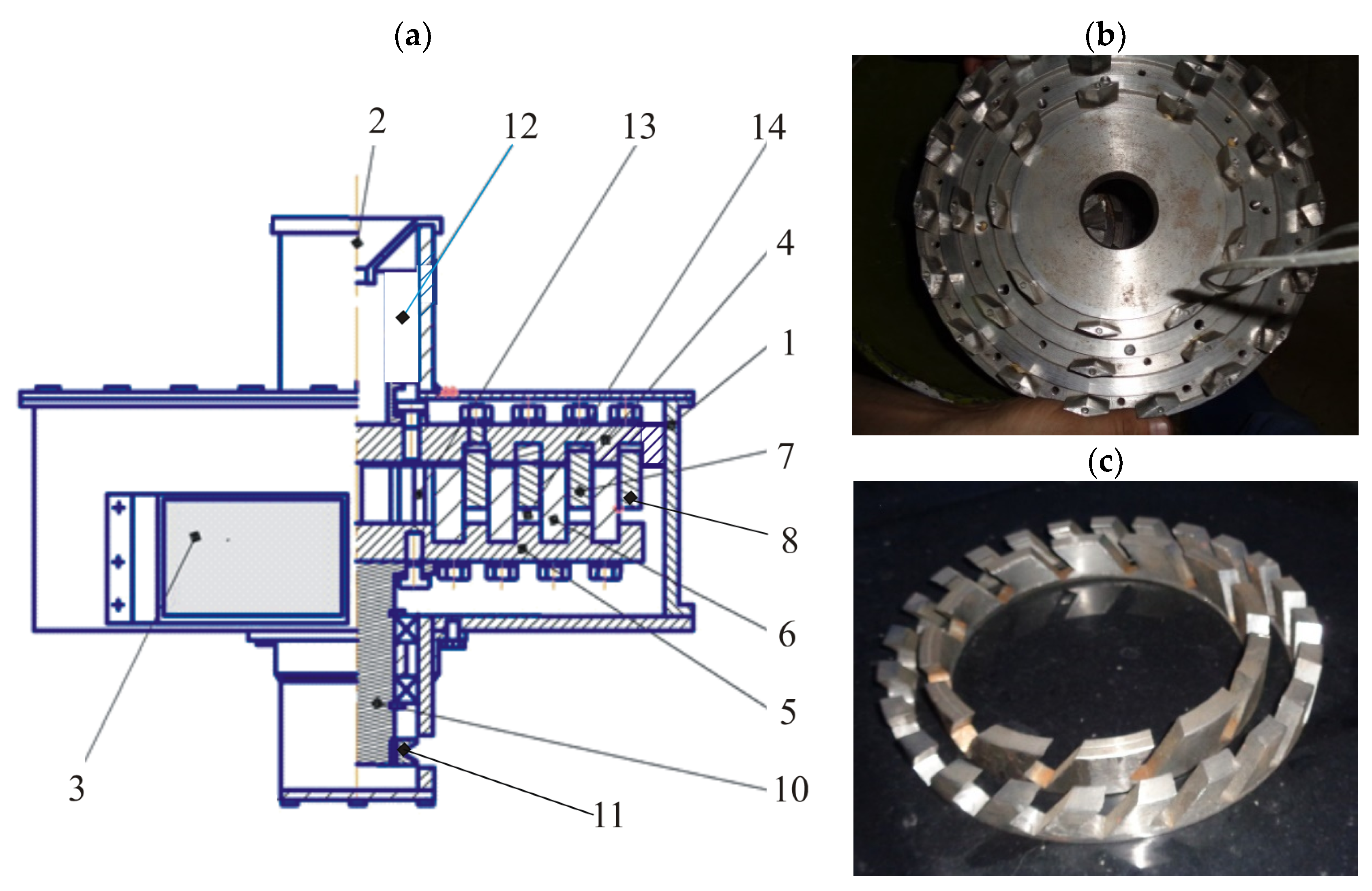

2.1. Experimental Stand

2.2. Scope and Research Mehodology

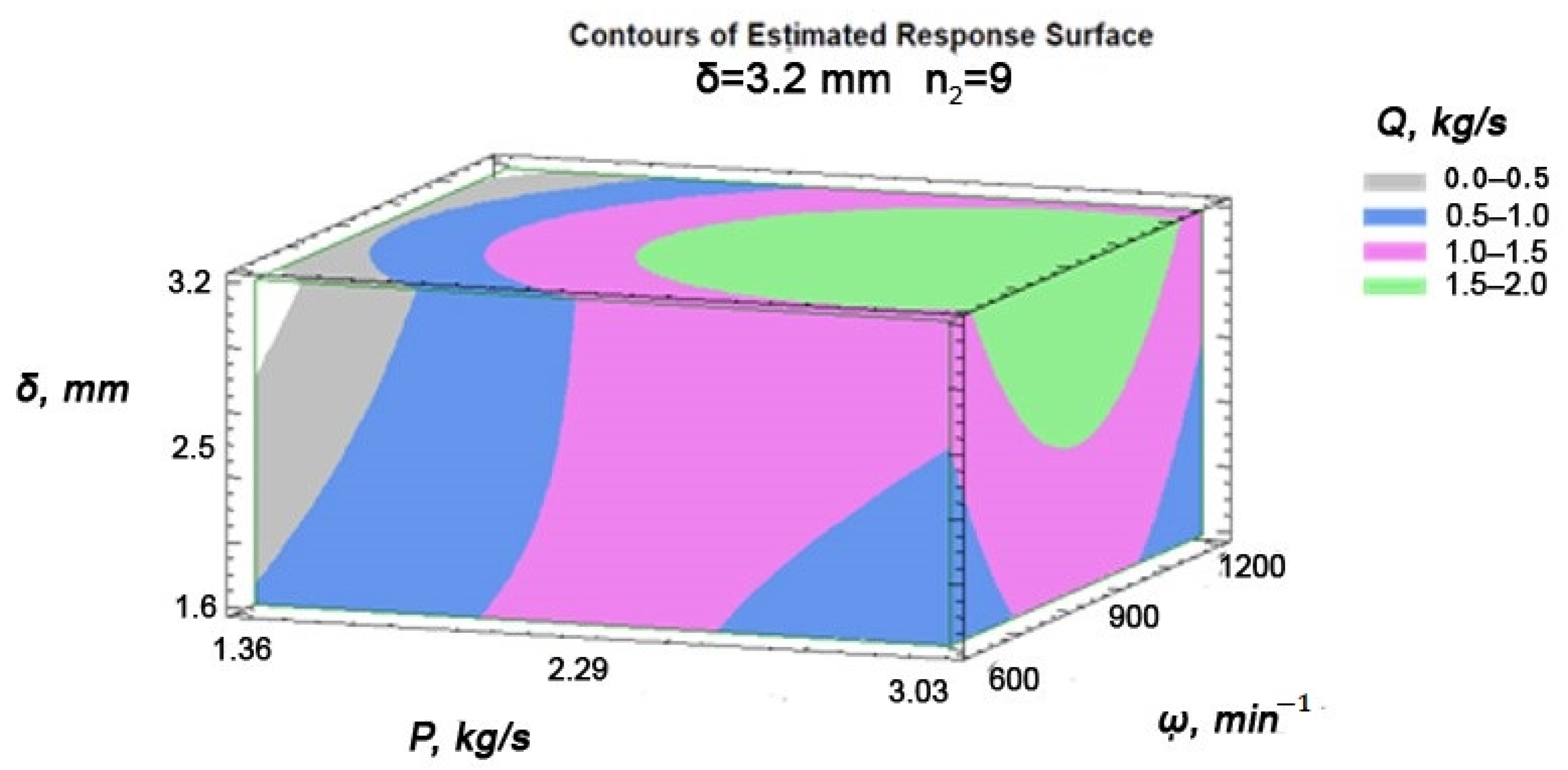

3. Results and Discussion

- −

- Dimensionless ratio that characterizes the ratio of the output to the incoming grain material for grinding, Equation (14a):

- −

- Dimensionless criterion that determines the angle at which the grain material moves non-stop at the selected knife installation radius, Equation (14b):

- −

- Dimensionless ratio describing the ratio of the output to the separation of the crushed grain material, Equation (15a):

- −

- Dimensionless geometric criterion, Equation (15b):

4. Conclusions

- (1)

- The use of similarity theory and dimension analysis allowed us to obtain an empirical dependence for calculating the performance of a centrifugal-rotary grain shredder of the considered design. Thus, this method makes it possible to solve the problem of establishing the relationship between different parameters with a minimum amount of experimental work with sufficient confidence. Therefore, at the next stage of our research work, we should consider a more complex problem—the relationship of energy costs in a centrifugal-rotor type chopper with a knife working body. Thus, in this case, the shape and sharpness of the blade of knives and counter-cuts, the size of the grain material coming to the grinding, its radial and circumferential speed, the degree of grinding, the angle of installation of knives, and other parameters will be of great importance to those already considered earlier (1);

- (2)

- Using similarity criteria, dimensionless complexes were obtained that allow us to determine the importance of the parameters selected at the initial stage on the performance of the shredder;

- (3)

- The use of similarity theory and dimension analysis will allow you to scale the results of experimental data and get a centrifugal-rotary type chopper with greater productivity while maintaining the quality of the resulting product. Moreover, this technique can be used to determine the energy costs of the grinding process, which can used to choose the ratio of parameters in the shredder that would ensure a minimum amount of energy is consumed.

- (4)

- The chopper can also be used to prepare biomass by shredding the residues [26]. In that way, prepared substrate can be used in the methane fermentation process, which improves the efficiency of the process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Symbols

| half the width of the knife | m | |

| , | constant dimensionless coefficients | |

| the flow of the grain material for the separation | kg∙s−1 | |

| feed of grain material to the i-stage of grinding | kg∙s−1 | |

| feed of grain material to the first stage of grinding, which can be assumed to be equal to the feed from the storage hopper | kg∙s−1 | |

| Qc | productivity of the centrifugal-rotary type shredder on separation | kg∙s−1 |

| productivity of the centrifugal-rotary type shredder at the i-stage of grinding | kg∙s−1 | |

| radius of installation of knives forming a separating surface | m | |

| radius of installation of knives at the i -stage of grinding | m | |

| time (period) of one revolution | s | |

| time (period) of cutting at the i-stage of grinding | s | |

| s | time (period) of idling or stopping the movement of grain material as a result of overlapping the channel with the knife surface | s |

| the number of installed blades | PCs | |

| , , …, , …, | exponent | |

| degree indicator for the second stage of grinding | ||

| the gap between the knives forming the separating surface | m | |

| dimensionless ratio characterizing the loss in productivity of the grain material shredder | ||

| angular speed of rotation of the rotor | s−1 |

References

- Melnikov, S.V.; Vagin, B.I.; Andreev, P.A. Mechanization of Livestock Farms; Kolos: Moscow, Russia, 1969; p. 440. [Google Scholar]

- Sysuev, V.A.; Aleshkin, A.V.; Savinykh, P.A. Forage Preparation machines. In Theory, Development, Experiment; North-Eastern Zonal Agricultural Research&Development Institute: Kirov, Russia, 2008; Volume I, p. 640. [Google Scholar]

- Patro, M.; Zubala, T. Use of different form of retention as the condition of sustainable management of water resources in rural environment. J. Water Land Dev. 2020, 126–135. [Google Scholar] [CrossRef]

- Sergeev, N.S. Centrifugal-Rotary Feed Grain Grinders. Ph.D. Thesis, Technical Sciences, Chelyabinsk, Russia, 2008; p. 315. [Google Scholar]

- Pushkarev, A.S. Improving the Efficiency of the Grain Milling Process by Using Working Bodies with Cutting Elements of Curved Shape. Ph.D. Thesis, Cand. Technical Sciences, Barnaul, Russia, 2018; p. 22. [Google Scholar]

- Druzhinin, R.A. Improving the Working Process of a Shock-Centrifugal Chopper. Ph.D. Thesis, Voronezh State Technical University, Voronezh, Russia, 2014; p. 169. [Google Scholar]

- Fomin, V.V. Reducing Energy Consumption and Increasing the Uniformity of Grain Grinding in A Small-Sized Centrifugal-Rotary Shredder. Ph.D. Thesis, Author’s Abstract, Cand. Technical Sciences, Novosibirsk, Russia, 2010; p. 23. [Google Scholar]

- Soloviy, C.; Malovanyy, M.; Nykyforov, V.; Dihtyar, S. Critical analysis of biotechnologies on using resource potential of hydrobionts. J. Water Land Dev. 2020, 143–150. [Google Scholar] [CrossRef]

- Turubanov, N.V.; Medvedev, O.Y.; Isupov, A.Y. Investigation of the effect of installing guides in the pneumatic separation channel on the performance of a hammer crusher. In Proceedings of the XVIII all-Russian Scientific and Practical Conference, St. Petersburg, Russia, 20–21 November 2019; Volume 3, pp. 1015–1021. [Google Scholar]

- Arkhipov, V.A.; Konovalenko, A.I. Practicum on the theory of similarity and the analysis of dimensions. In Educational and Methodological Guide; Tomsk State University: Tomsk, Russia, 2016; p. 92. [Google Scholar]

- Ivanov, I.E.; Ereshchenko, V.E. Methods of Similarity of Physical Processes; MADI: Moscow, Russia, 2015; p. 144. [Google Scholar]

- Westine, P.S.; Dodge, F.T.; Baker, W.E. Similarity Methods in Engineering Dynamics: Theory and Practice of Scale Modeling; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Palitsyn, A.V.; Ivanov, I.I. Development and Search Results of Research of a Rotary-Centrifugal Type Feed Grain Shredder for Farms. In Proceedings of the Current Issues of Improving the Technology of Production and Processing of Agricultural Products: Maslovskie Readings: Materials of International Scientific-Practical Conference, Yoshkar-Ola, Russia, 23–24 March 2017; pp. 284–289. [Google Scholar]

- Gabryszuk, M.; Barszczewski, J.; Kuźnicka, E.; Sakowski, T. Effect of long-term fertilization of the permanent dry meadow on the zinc content in soil and meadow sward. J. Water Land Dev. 2020, X–XII, 61–65. [Google Scholar] [CrossRef]

- Savinykh, P.A.; Isupov, A.Y.; Kuznetsov, N.N.; Ivanov, I.I. Assessment of the influence of various modes of operation of a rotary-centrifugal type grain shredder on the quality of the resulting product. In Energy-Saving Agricultural Technologies and Equipment for Northern Agriculture and Animal Husbandry: Monograph; Sysuev, V.A., Ed.; OOO “Kirov Regional Printing House”: Kirov, Russia, 2018; pp. 269–274. [Google Scholar]

- Ivanov, I.I.; Palitsyn, A.V.; Savinykh, P.A.; Isupov, A.Y. Results of practical research of experimental feed grain shredder of rotary-centrifugal type. In Problems of Intensification of Animal Husbandry Taking into Account Environmental Protection and Production of Alternative Energy Sources; Romaniuk, V., Ed.; Monograph under the Scientific; Publishing ITP: Falenty-Warsaw, Poland, 2018; pp. 55–60. [Google Scholar]

- Savinykh, P.A.; Isupov, A.Y.; Ivanov, I.I. Results of research of a centrifugal-rotary grain shredder. Bull. NGIEI 2019, 8, 18–33. [Google Scholar]

- Savinykh, P.A.; Saitov, V.E.; Sukhlyaev, V.A.; Ivanov, I.I.; Palitsyn, A.V.; Kuznetsov, N.N. Device for Crushing Bulk Materials. Russian Patent Application Submitted 17 October 2016. Obtained Russian Patent No. 2656619, 6 June 2018. [Google Scholar]

- Shagdyrov, I.B. Substantiation of Parameters of a Multistage Feed Grain Crusher. Ph.D. Thesis, Dis. Cand. Chelyabinsk Insitute of Agricultural Mechanization and Electrification, Chelyabinsk, Russia, 1988; p. 220. [Google Scholar]

- Salman, A.D.; Ghadiri, M.; Hounslow, M. Particle Breakdown; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Melnikov, S.V.; Aleshkin, V.R.; Roshchin, P.M. Planning an Experiment in Research of Agricultural Processes; Kolos: Leningrad, Russia, 1980; p. 168. [Google Scholar]

- Johnson, N.; Lyon, F. Statistics and Experiment Planning in Engineering and Science: Methods of Experiment Planning; Mir: Moscow, Russia, 1981; p. 520. [Google Scholar]

- Herrera-Barros, A.; Tejada-Tovar, C.; Gonzalez-Delgado, A.D. Comparative assessment of Al2O3-modified biomasses from agricultural residues for nickel and cadmium removal. J. Water Land Dev. 2021, IV–VI, 29–34. [Google Scholar] [CrossRef]

- Roman, K.; Roman, M.; Szadkowska, D.; Szadkowski, J.; Grzegorzewska, E. Evaluation of Physical and Chemical Parameters According to Energetic Willow (Salix viminalis L.) Cultivation. Energies 2021, 14, 2968. [Google Scholar] [CrossRef]

- Roman, M.; Roman, K. Innowacyjne Wykorzystanie Biomasy Stałej w Gospodarstwach Agroturystycznych, Innovative Use of Solid Biomass in Agritourism Farms, Studia KPZK; Polska Akademia Nauk Komitet Przestrzennego Zagospodarowania Kraju: Warszawa, Poland, 2016; pp. 33–40. [Google Scholar]

- Roman, K.; Barwicki, J.; Hryniewicz, M.; Szadkowska, D.; Szadkowski, J. Production of Electricity and Heat from Biomass Wastes Using a Converted Aircraft Turbine AI-20. Processes 2021, 9, 364. [Google Scholar] [CrossRef]

| No. | p, kg/s | ω, min−1 | δc, mm | n2, pcs | Q, kg/min |

|---|---|---|---|---|---|

| 1 | 0.038167 | 900 | 2.5 | 12 | 0.0362 |

| 2 | 0.022667 | 1200 | 2.5 | 12 | 0.014783 |

| 3 | 0.038167 | 900 | 2.5 | 12 | 0.0362 |

| 4 | 0.038167 | 1200 | 2.5 | 18 | 0.022917 |

| 5 | 0.022667 | 900 | 1.6 | 12 | 0.015133 |

| 6 | 0.038167 | 1200 | 2.5 | 9 | 0.013367 |

| 7 | 0.0505 | 900 | 2.5 | 18 | 0.0272 |

| 8 | 0.038167 | 900 | 1.6 | 9 | 0.03635 |

| 9 | 0.022667 | 900 | 2.5 | 18 | 0.015 |

| 10 | 0.038167 | 1200 | 1.6 | 12 | 0.024 |

| 11 | 0.038167 | 900 | 3.2 | 9 | 0.028317 |

| 12 | 0.038167 | 600 | 3.2 | 12 | 0.02595 |

| 13 | 0.038167 | 900 | 2.5 | 12 | 0.0362 |

| 14 | 0.038167 | 600 | 2.5 | 18 | 0.019233 |

| 15 | 0.022667 | 600 | 2.5 | 12 | 0.01145 |

| 16 | 0.0505 | 900 | 3.2 | 12 | 0.05095 |

| 17 | 0.0505 | 1200 | 2.5 | 12 | 0.015183 |

| 18 | 0.038167 | 900 | 3.2 | 18 | 0.020133 |

| 19 | 0.0505 | 900 | 1.6 | 12 | 0.025667 |

| 20 | 0.0505 | 600 | 2.5 | 12 | 0.014167 |

| 21 | 0.038167 | 600 | 1.6 | 12 | 0.0211 |

| 22 | 0.0505 | 900 | 2.5 | 9 | 0.02725 |

| 23 | 0.038167 | 600 | 3.2 | 12 | 0.0288 |

| 24 | 0.038167 | 600 | 2.5 | 9 | 0.0204 |

| 25 | 0.022667 | 900 | 3.2 | 12 | 0.014333 |

| 26 | 0.038167 | 900 | 1.6 | 18 | 0.01685 |

| 27 | 0.022667 | 900 | 2.5 | 9 | 0.014133 |

| Transformation | Model d.f. | p-Value | Error d.f. | Stnd. Error | R-Squared | Adj. R-Squared |

|---|---|---|---|---|---|---|

| 5 | 0.0001 | 21 | 0.3642 | 67.43 | 59.68 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romaniuk, W.; Savinykh, P.; Borek, K.; Roman, K.; Isupov, A.Y.; Moshonkin, A.; Wałowski, G.; Roman, M. The Application of Similarity Theory and Dimensional Analysis to the Study of Centrifugal-Rotary Chopper of Forage Grain. Energies 2021, 14, 4501. https://doi.org/10.3390/en14154501

Romaniuk W, Savinykh P, Borek K, Roman K, Isupov AY, Moshonkin A, Wałowski G, Roman M. The Application of Similarity Theory and Dimensional Analysis to the Study of Centrifugal-Rotary Chopper of Forage Grain. Energies. 2021; 14(15):4501. https://doi.org/10.3390/en14154501

Chicago/Turabian StyleRomaniuk, Wacław, Petr Savinykh, Kinga Borek, Kamil Roman, Alexey Y. Isupov, Aleksandr Moshonkin, Grzegorz Wałowski, and Michał Roman. 2021. "The Application of Similarity Theory and Dimensional Analysis to the Study of Centrifugal-Rotary Chopper of Forage Grain" Energies 14, no. 15: 4501. https://doi.org/10.3390/en14154501

APA StyleRomaniuk, W., Savinykh, P., Borek, K., Roman, K., Isupov, A. Y., Moshonkin, A., Wałowski, G., & Roman, M. (2021). The Application of Similarity Theory and Dimensional Analysis to the Study of Centrifugal-Rotary Chopper of Forage Grain. Energies, 14(15), 4501. https://doi.org/10.3390/en14154501