Bio-Crude Production Improvement during Hydrothermal Liquefaction of Biopulp by Simultaneous Application of Alkali Catalysts and Aqueous Phase Recirculation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Feedstock Characterization

2.2. HTL Procedure

2.3. Product Characterization

2.4. Financial Evaluation Method

3. Results

3.1. Feedstock Characterization

3.2. HTL Experiments

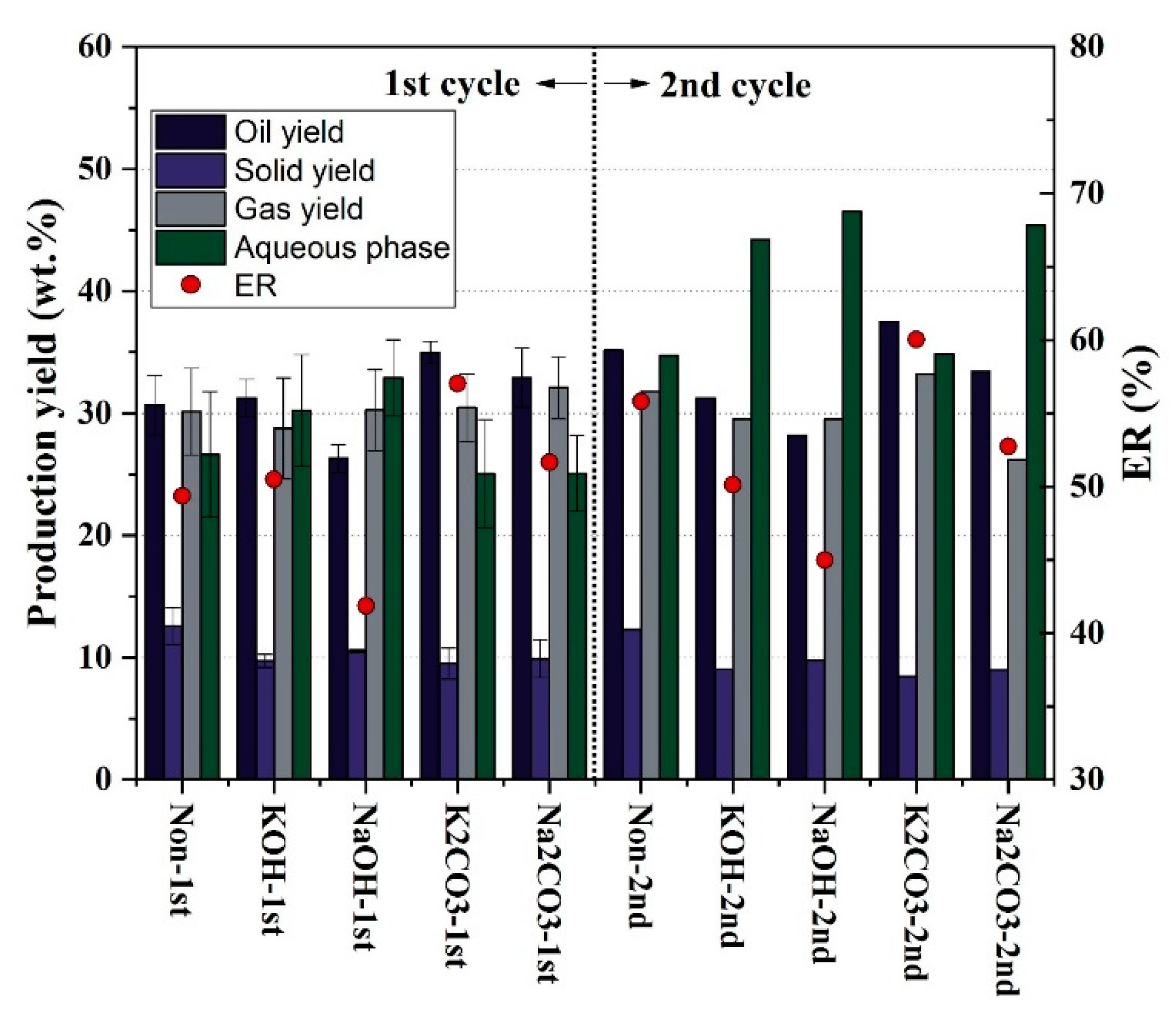

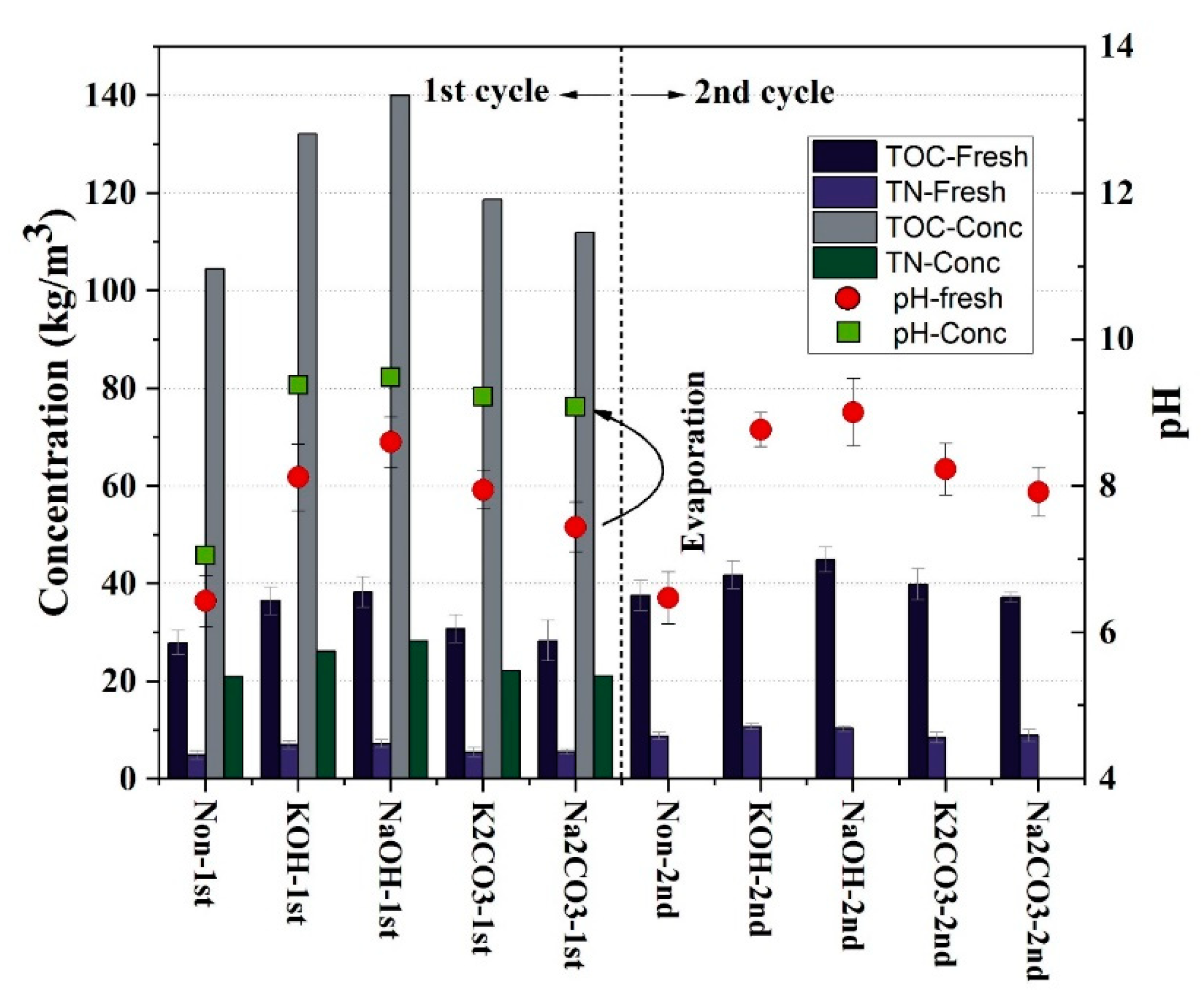

3.2.1. Effect of Catalysts and Concentrate Recirculation on HTL Products

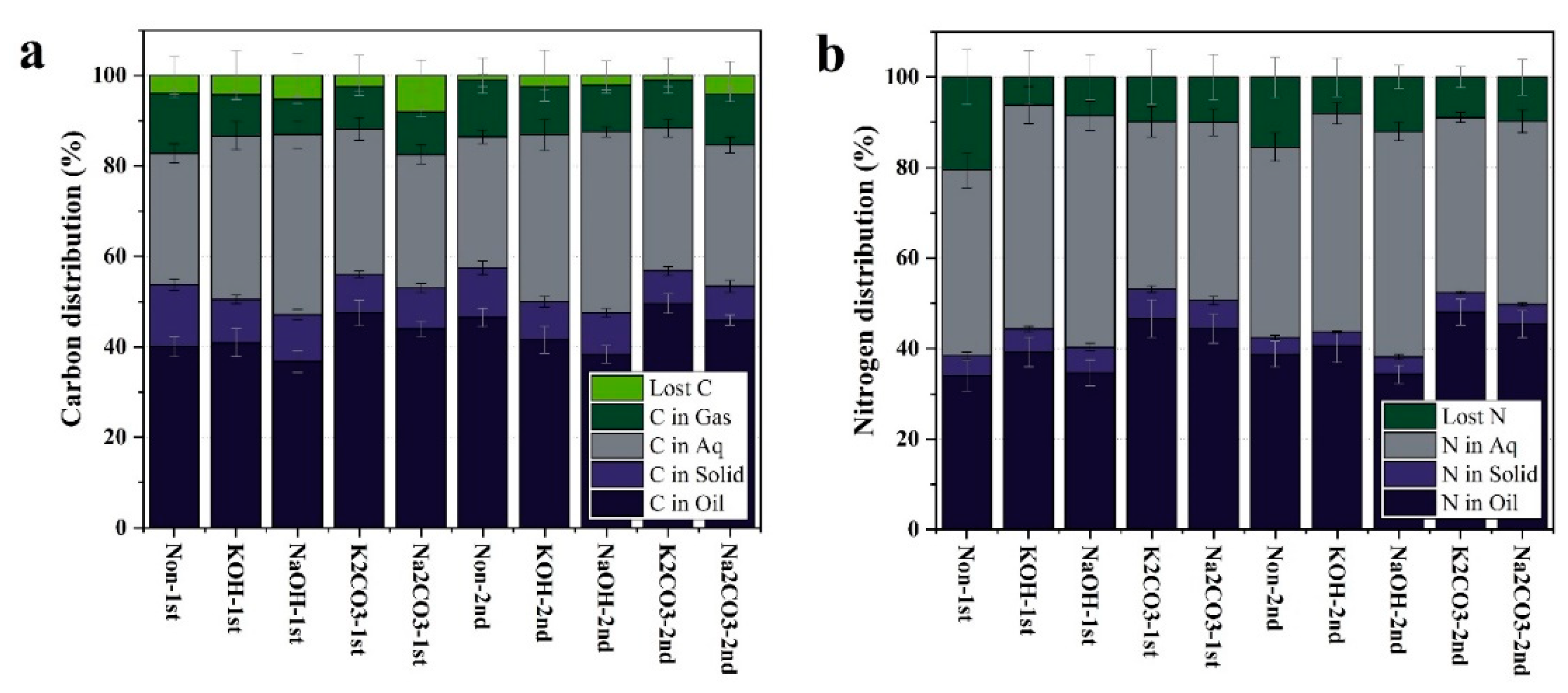

3.2.2. Carbon and Nitrogen Distribution

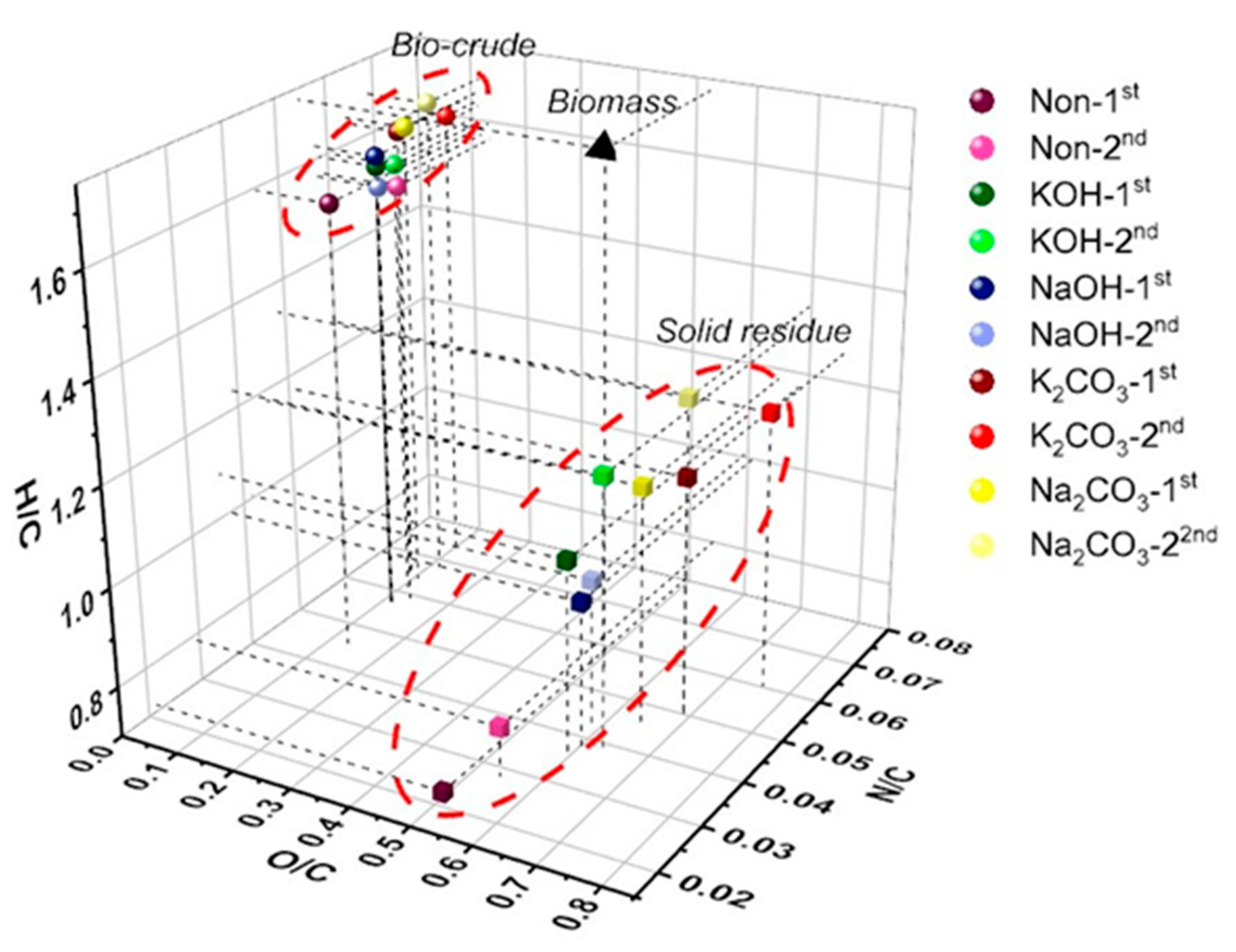

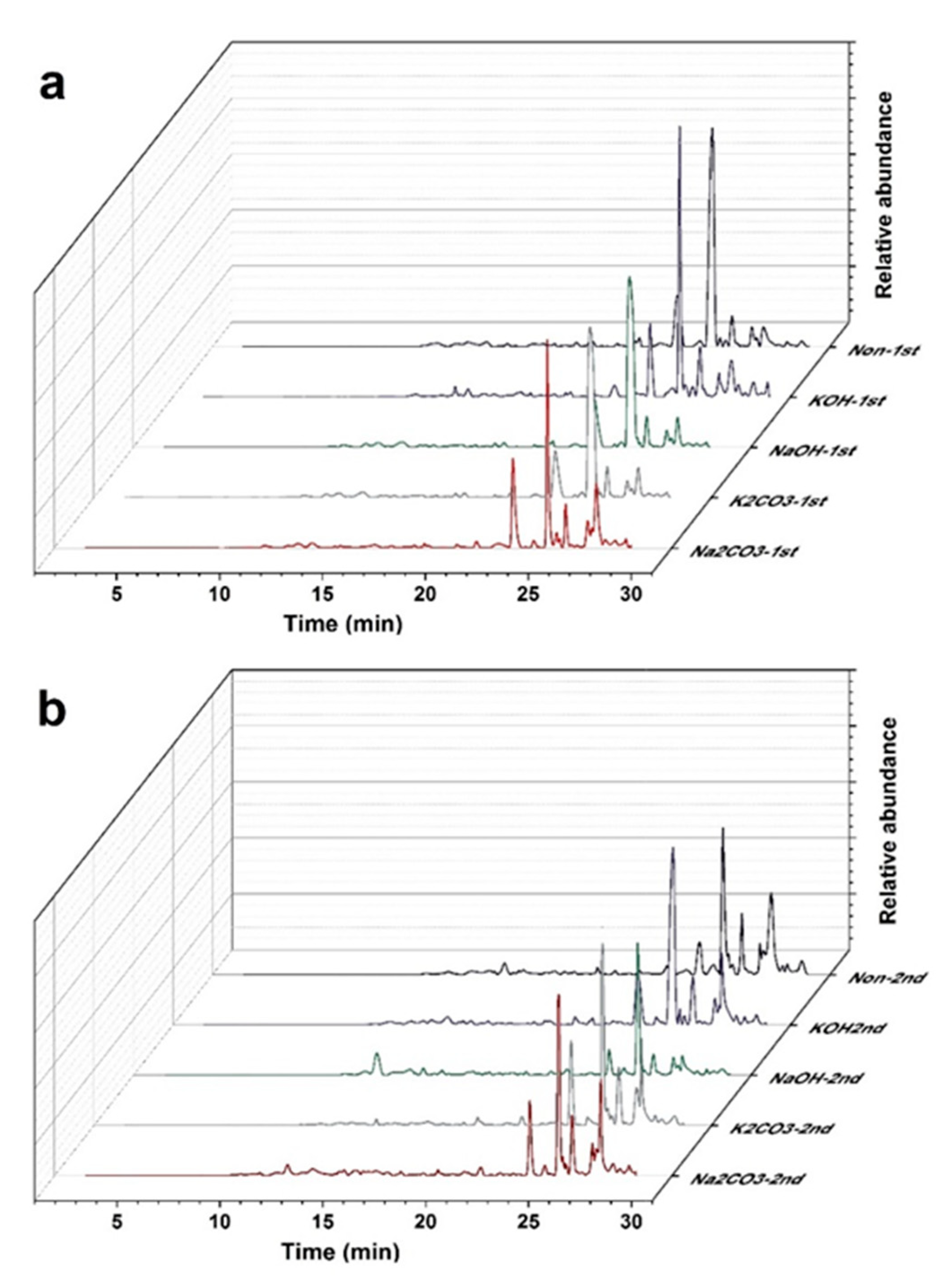

3.3. Characterization of Bio-Crude

3.3.1. Elemental Analysis

3.3.2. TG Analysis

3.3.3. GC-MS Analysis

3.3.4. Inorganic Element Distribution

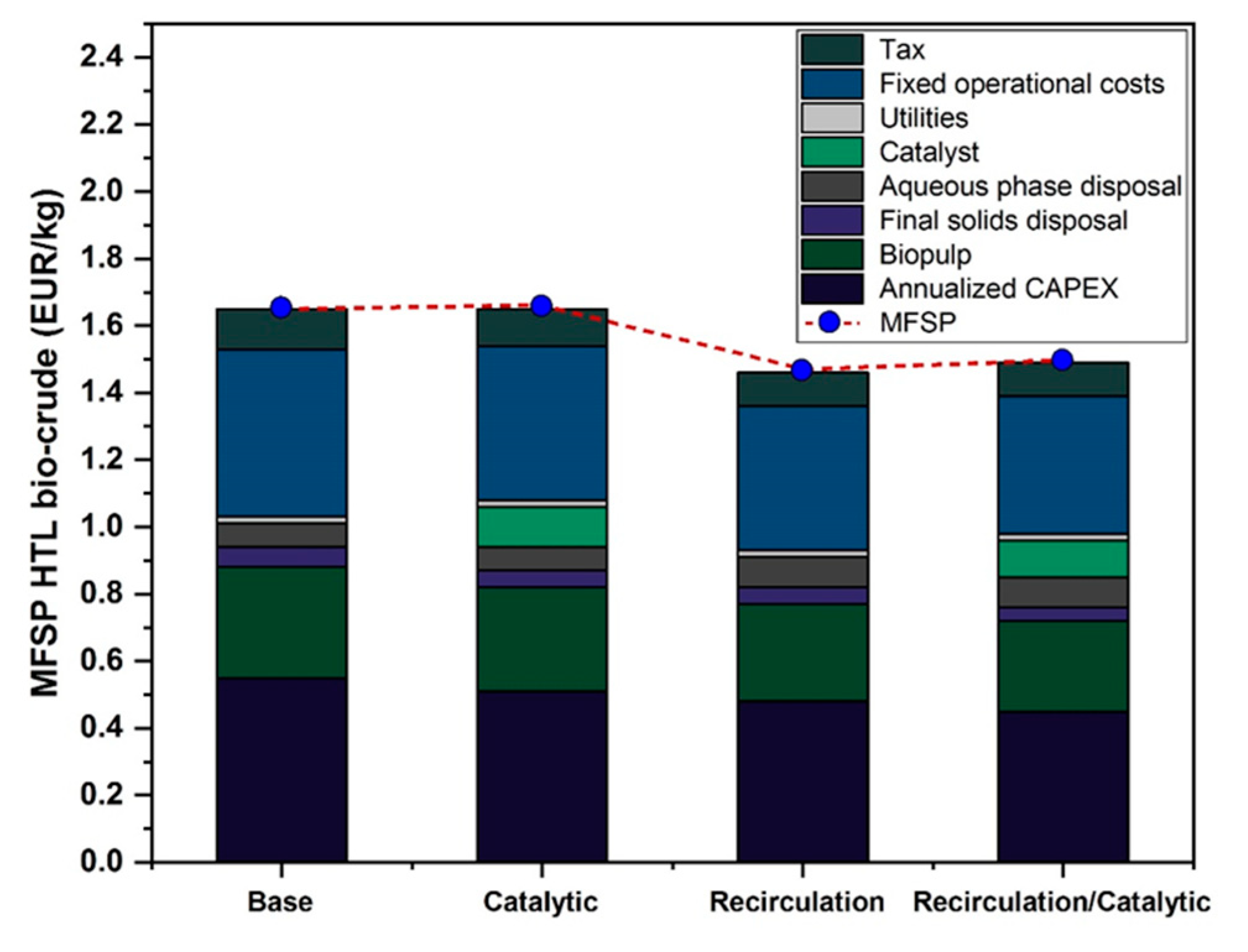

3.4. Economic Analysis

4. Conclusions

- Non-catalytic HTL yielded 30.7 wt.% of bio-crude (ER: 47.9%).

- While NaOH and KOH did not show a positive impact on the quantity of the bio-crude, all catalysts increased the HHV and ER of the bio-crude, and K2CO3 resulted in the bio-crude with the highest ER (57.2%).

- Evaporation of the aqueous phase successfully removed 83.0% of the surplus water along with 14.8 to 25.3% of the total nitrogen of the water phase.

- Aqueous phase recirculation showed a positive impact on bio-crude yield regardless of the catalyst, while incorporating it with an alkali catalyst could determine the enhancement magnitude. The highest bio-crude yield (37.5 wt.%) and ER (59.4%) were achieved when simultaneously using K2CO3 and single aqueous phase recirculation.

- The high concentration of potassium (87.5 to 96.7%) and sodium (73.0 to 92.0%) in the aqueous phase after catalytic HTL envisaged a great potential in the recycling of the alkali elements to the next cycle. On the other hand, unaddressed catalyst adjustment resulted in a higher value of Na and/or K in the bio-crude obtained from the second cycle.

- Catalytic HTL (cycle 1) allowed phosphorous to selectively precipitate in the solid residue, which opens up the possibility of nutrient recovery in a highly concentrated phase.

- Catalytic HTL did not positively impact the economy of the process, while recirculation of the aqueous phase decreased the MFSP by around 11% due to the higher bio-crude yields.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Environment Agency. Managing Municipal Solid Waste—A Review Of Achievements in 32 European Countries; Office for Official Publication of the European Communities: Luxembourg, 2013. [CrossRef]

- Chattopadhyay, S.; Dutta, A.K.; Ray, S. Municipal solid waste management in Kolkata, India—A review. Waste Manag. 2009, 29, 1449–1458. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0.: A Global Snapshot of Solid Management to 2050; World Bank Publications: Washington, DC, USA, 2018. [Google Scholar]

- Okoro-Shekwaga, C.K.; Ross, A.; Camargo-Valero, M.A. Enhancing bioenergy production from food waste by in situ biomethanation: Effect of the hydrogen injection point. Food Energy Secur. 2021, e288. [Google Scholar] [CrossRef]

- Sharma, K.D.; Jain, S. Municipal solid waste generation, composition, and management: The global scenario. Soc. Responsib. J. 2020, 16, 917–948. [Google Scholar] [CrossRef]

- He, P.; Chen, L.; Shao, L.; Zhang, H.; Lü, F. Municipal solid waste (MSW) landfill: A source of microplastics?—Evidence of microplastics in landfill leachate. Water Res. 2019, 159, 38–45. [Google Scholar] [CrossRef]

- Farrell, M.; Jones, D. Critical evaluation of municipal solid waste composting and potential compost markets. Bioresour. Technol. 2009, 100, 4301–4310. [Google Scholar] [CrossRef]

- Borja, R. Biogas Production. Compr. Biotechnol. 2011, 2, 785–798. [Google Scholar] [CrossRef]

- Sipra, A.T.; Gao, N.; Sarwar, H. Municipal solid waste (MSW) pyrolysis for bio-fuel production: A review of effects of MSW components and catalysts. Fuel Process. Technol. 2018, 175, 131–147. [Google Scholar] [CrossRef]

- Raikova, S.; Smith-Baedorf, H.; Bransgrove, R.; Barlow, O.; Santomauro, F.; Wagner, J.L.; Allen, M.J.; Bryan, C.G.; Sapsford, D.; Chuck, C.J. Assessing hydrothermal liquefaction for the production of bio-oil and enhanced metal recovery from microalgae cultivated on acid mine drainage. Fuel Process. Technol. 2016, 142, 219–227. [Google Scholar] [CrossRef] [Green Version]

- Katakojwala, R.; Kopperi, H.; Kumar, S.; Mohan, S.V. Hydrothermal liquefaction of biogenic municipal solid waste under reduced H2 atmosphere in biorefinery format. Bioresour. Technol. 2020, 310, 123369. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.-T.; Zhang, Y.; Lee, T.H.; Wu, Z.; Si, B.; Lee, C.-F.F.; Lin, A.; Sharma, B.K. Renewable diesel blendstocks produced by hydrothermal liquefaction of wet biowaste. Nat. Sustain. 2018, 1, 702–710. [Google Scholar] [CrossRef]

- Shah, A.A.; Toor, S.S.; Seehar, T.H.; Sadetmahaleh, K.K.; Pedersen, T.H.; Nielsen, A.H.; Rosendahl, L.A. Bio-crude production through co-hydrothermal processing of swine manure with sewage sludge to enhance pumpability. Fuel 2021, 288, 119407. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, H.; Hu, Y.; Gao, J.; Zhao, G.; Ray, M.B.; Xu, C.C. Hydrothermal Co-Liquefaction of Lignite and Lignocellulosic Biomass with the Addition of Formic Acid: Study on Product Distribution, Characteristics, and Synergistic Effects. Ind. Eng. Chem. Res. 2020, 59, 21663–21675. [Google Scholar] [CrossRef]

- Kohansal, K.; Tavasoli, A.; Bozorg, A. Using a hybrid-like supported catalyst to improve green fuel production through hydrothermal liquefaction of Scenedesmus obliquus microalgae. Bioresour. Technol. 2019, 277, 136–147. [Google Scholar] [CrossRef]

- Gollakota, A.; Kishore, N.; Gu, S. A review on hydrothermal liquefaction of biomass. Renew. Sustain. Energy Rev. 2018, 81, 1378–1392. [Google Scholar] [CrossRef]

- Jindal, M.K.; Jha, M.K. Hydrothermal liquefaction of wood: A critical review. Rev. Chem. Eng. 2016, 32, 459–488. [Google Scholar] [CrossRef]

- Kaur, R.; Biswas, B.; Kumar, J.; Jha, M.K.; Bhaskar, T. Catalytic hydrothermal liquefaction of castor residue to bio-oil: Effect of alkali catalysts and optimization study. Ind. Crop. Prod. 2020, 149, 112359. [Google Scholar] [CrossRef]

- Koley, S.; Khadase, M.S.; Mathimani, T.; Raheman, H.; Mallick, N. Catalytic and non-catalytic hydrothermal processing of Scenedesmus obliquus biomass for bio-crude production – A sustainable energy perspective. Energy Convers. Manag. 2018, 163, 111–121. [Google Scholar] [CrossRef]

- Jindal, M.; Jha, M. Catalytic Hydrothermal Liquefaction of Waste Furniture Sawdust to Bio-oil. Indian Chem. Eng. 2015, 58, 157–171. [Google Scholar] [CrossRef]

- Klemmer, M.; Madsen, R.B.; Houlberg, K.; Mørup, A.J.; Christensen, P.S.; Becker, J.; Glasius, M.; Iversen, B.B. Effect of Aqueous Phase Recycling in Continuous Hydrothermal Liquefaction. Ind. Eng. Chem. Res. 2016, 55, 12317–12325. [Google Scholar] [CrossRef]

- Déniel, M.; Haarlemmer, G.; Roubaud, A.; Weiss-Hortala, E.; Fages, J. Bio-oil Production from Food Processing Residues: Improving the Bio-oil Yield and Quality by Aqueous Phase Recycle in Hydrothermal Liquefaction of Blackcurrant (Ribes nigrum L.) Pomace. Energy Fuels 2016, 30, 4895–4904. [Google Scholar] [CrossRef] [Green Version]

- Posmanik, R.; Martinez, C.M.; Cantero-Tubilla, B.; Cantero, D.; Sills, D.; Cocero, M.J.; Tester, J.W. Acid and Alkali Catalyzed Hydrothermal Liquefaction of Dairy Manure Digestate and Food Waste. ACS Sustain. Chem. Eng. 2017, 6, 2724–2732. [Google Scholar] [CrossRef]

- Pedersen, T.; Grigoras, I.; Hoffmann, J.; Toor, S.; Daraban, I.; Jensen, C.; Iversen, S.; Madsen, R.; Glasius, M.; Arturi, K.R.; et al. Continuous hydrothermal co-liquefaction of aspen wood and glycerol with water phase recirculation. Appl. Energy 2016, 162, 1034–1041. [Google Scholar] [CrossRef] [Green Version]

- Conti, F.; Toor, S.S.; Pedersen, T.H.; Seehar, T.H.; Nielsen, A.H.; Rosendahl, L.A. Valorization of animal and human wastes through hydrothermal liquefaction for biocrude production and simultaneous recovery of nutrients. Energy Convers. Manag. 2020, 216, 112925. [Google Scholar] [CrossRef]

- Mariotti, F.; Tomé, D.; Mirand, P.P. Converting Nitrogen into Protein—Beyond 6.25 and Jones’ Factors. Crit. Rev. Food Sci. Nutr. 2008, 48, 177–184. [Google Scholar] [CrossRef] [PubMed]

- Kohansal, S.K.; Toor, K.; Sharma, R.; Chand, L.; Rosendahl, T.H. Pedersen, Hydrothermal liquefaction of pre-treated municipal solid waste (biopulp) with recirculation of concentrated aqueous phase. Biomass and Bioenergy 2021, 148, 106032. [Google Scholar] [CrossRef]

- Aierzhati, A.; Stablein, M.J.; Wu, N.E.; Kuo, C.-T.; Si, B.; Kang, X.; Zhang, Y. Experimental and model enhancement of food waste hydrothermal liquefaction with combined effects of biochemical composition and reaction conditions. Bioresour. Technol. 2019, 284, 139–147. [Google Scholar] [CrossRef]

- Watson, J.; Lu, J.; de Souza, R.; Si, B.; Zhang, Y.; Liu, Z. Effects of the extraction solvents in hydrothermal liquefaction processes: Biocrude oil quality and energy conversion efficiency. Energy 2019, 167, 189–197. [Google Scholar] [CrossRef]

- Seehar, T.H.; Toor, S.S.; Shah, A.A.; Nielsen, A.H.; Pedersen, T.H.; Rosendahl, L.A. Catalytic hydrothermal liquefaction of contaminated construction wood waste for biocrude production and investigation of fate of heavy metals. Fuel Process. Technol. 2021, 212, 106621. [Google Scholar] [CrossRef]

- Taghipour, A.; Hornung, U.; Ramirez, J.A.; Brown, R.J.; Rainey, T.J. Aqueous phase recycling in catalytic hydrothermal liquefaction for algal biomass and the effect on elemental accumulation and energy efficiency. J. Clean. Prod. 2021, 289, 125582. [Google Scholar] [CrossRef]

- Conti, F.; Toor, S.S.; Pedersen, T.H.; Nielsen, A.H.; Rosendahl, L.A. Biocrude production and nutrients recovery through hydrothermal liquefaction of wastewater irrigated willow. Biomass Bioenergy 2018, 118, 24–31. [Google Scholar] [CrossRef]

- Shah, A.A.; Toor, S.S.; Seehar, T.H.; Nielsen, R.S.; Nielsen, A.H.; Pedersen, T.H.; Rosendahl, L.A. Bio-Crude Production through Aqueous Phase Recycling of Hydrothermal Liquefaction of Sewage Sludge. Energies 2020, 13, 493. [Google Scholar] [CrossRef] [Green Version]

- Jensen, C.U.; Rosendahl, L.; Olofsson, G. Impact of nitrogenous alkaline agent on continuous HTL of lignocellulosic biomass and biocrude upgrading. Fuel Process. Technol. 2017, 159, 376–385. [Google Scholar] [CrossRef]

- Snowden-Swan, L.J.; Zhu, Y.; Jones, S.B.; Elliott, D.C.; Schmidt, A.J.; Hallen, R.T.; Billing, J.; Hart, T.R.; Fox, S.P.; Maupin, G.D. Hydrothermal Liquefaction and Upgrading of Municipal Wastewater Treatment Plant Sludge: A Preliminary Techno-Economic Analysis, Rev.1; Pacific Northwest National Laboratory: Richland, WA, USA, 2016. [CrossRef]

- De Jong, S.A. Green Horizons: On the Production Costs, Climate Impact and Future Supply of Renewable Jet Fuels. Ph.D. Thesis, Utrecht University, Utrecht, The Netherlands, 2018. [Google Scholar]

- Ghaffour, N.; Missimer, T.M.; Amy, G.L. Technical review and evaluation of the economics of water desalination: Current and future challenges for better water supply sustainability. Desalination 2013, 309, 197–207. [Google Scholar] [CrossRef] [Green Version]

- Lozano, E.; Pedersen, T.; Rosendahl, L. Modeling of thermochemically liquefied biomass products and heat of formation for process energy assessment. Appl. Energy 2019, 254, 113654. [Google Scholar] [CrossRef]

- Wei, X.; Jie, D. Optimization to Hydrothermal Liquefaction of Low Lipid Content Microalgae Spirulina sp. Using Response Surface Methodology. J. Chem. 2018, 2018, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Elliott, D.C.; Hallen, R.T.; Sealock, L.J. Aqueous catalyst systems for the water-gas shift reaction. 2. Mechanism of basic catalysis. Ind. Eng. Chem. Prod. Res. Dev. 1983, 22, 431–435. [Google Scholar] [CrossRef]

- Karagöz, S.; Bhaskar, T.; Muto, A.; Sakata, Y.; Oshiki, T.; Kishimoto, T. Low-temperature catalytic hydrothermal treatment of wood biomass: Analysis of liquid products. Chem. Eng. J. 2005, 108, 127–137. [Google Scholar] [CrossRef]

- Yin, S.; Dolan, R.; Harris, M.; Tan, Z. Subcritical hydrothermal liquefaction of cattle manure to bio-oil: Effects of conversion parameters on bio-oil yield and characterization of bio-oil. Bioresour. Technol. 2010, 101, 3657–3664. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.J.; Um, B.H. Biocrude production from Korean native kenaf through subcritical hydrothermal liquefaction under mild alkaline catalytic conditions. Ind. Crop. Prod. 2020, 145, 112001. [Google Scholar] [CrossRef]

- Zhu, Z.; Rosendahl, L.; Toor, S.S.; Yu, D.; Chen, G. Hydrothermal liquefaction of barley straw to bio-crude oil: Effects of reaction temperature and aqueous phase recirculation. Appl. Energy 2015, 137, 183–192. [Google Scholar] [CrossRef]

- Zhu, Z.; Toor, S.S.; Rosendahl, L.; Yu, D.; Chen, G. Influence of alkali catalyst on product yield and properties via hydrothermal liquefaction of barley straw. Energy 2015, 80, 284–292. [Google Scholar] [CrossRef]

- Hardi, F.; Furusjö, E.; Kirtania, K.; Imai, A.; Umeki, K.; Yoshikawa, K. Catalytic hydrothermal liquefaction of biomass with K2CO3 for production of gasification feedstock. Biofuels 2018, 12, 149–160. [Google Scholar] [CrossRef]

- Kruse, A.; Maniam, A.P.; Spieler, F. Influence of Proteins on the Hydrothermal Gasification and Liquefaction of Biomass. 2. Model Compounds. Ind. Eng. Chem. Res. 2007, 46, 87–96. [Google Scholar] [CrossRef]

- Onwudili, J.; Williams, P.T. Hydrothermal reactions of sodium formate and sodium acetate as model intermediate products of the sodium hydroxide-promoted hydrothermal gasification of biomass. Green Chem. 2010, 12, 2214–2224. [Google Scholar] [CrossRef]

- Hao, B.; Xu, D.; Jiang, G.; Sabri, T.A.; Jing, Z.; Guo, Y. Chemical reactions in the hydrothermal liquefaction of biomass and in the catalytic hydrogenation upgrading of biocrude. Green Chem. 2021, 23, 1562–1583. [Google Scholar] [CrossRef]

- Fan, Y.; Hornung, U.; Dahmen, N.; Kruse, A. Hydrothermal liquefaction of protein-containing biomass: Study of model compounds for Maillard reactions. Biomass Convers. Biorefinery 2018, 8, 909–923. [Google Scholar] [CrossRef]

- Sun, Y.; Frenkel-Pinter, M.; Liotta, C.L.; Grover, M.A. The pH dependent mechanisms of non-enzymatic peptide bond cleavage reactions. Phys. Chem. Chem. Phys. 2019, 22, 107–113. [Google Scholar] [CrossRef]

- Zimmermann, J.; Raffelt, K.; Dahmen, N. Sequential Hydrothermal Processing of Sewage Sludge to Produce Low Nitrogen Biocrude. Processes 2021, 9, 491. [Google Scholar] [CrossRef]

- Rezagama, P.A.; Hibbaan, M.; Budihardjo, M.A. Ammonia-Nitrogen (NH3-N) and Ammonium-Nitrogen (NH4+-N) Equi-librium on The Process of Removing Nitrogen By Using Tubular Plastic Media. J. Mater. Environ. Sci. 2017, 8, 4915–4922. [Google Scholar]

- Bayat, H.; Cheng, F.; Dehghanizadeh, M.; Soliz, N.; Brewer, C.E.; Jena, U. Hydrothermal liquefaction of food waste: Bio-crude oil Characterization, Mass and Energy Balance. In Proceedings of the 2019 ASABE Annual International Meeting, Boston, MA, USA, 7–10 July 2019. [Google Scholar] [CrossRef]

- Aierzhati, A.; Watson, J.; Si, B.; Stablein, M.; Wang, T.; Zhang, Y. Development of a mobile, pilot scale hydrothermal liquefaction reactor: Food waste conversion product analysis and techno-economic assessment. Energy Convers. Manag. X 2021, 10, 100076. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, J.; Zhu, Z.; Zhang, Y.; Zhao, Y.; Li, R.; Watson, J.; Li, B.; Liu, Z. Simultaneous production of biocrude oil and recovery of nutrients and metals from human feces via hydrothermal liquefaction. Energy Convers. Manag. 2017, 134, 340–346. [Google Scholar] [CrossRef] [Green Version]

- Ovsyannikova, E.; Kruse, A.; Becker, G.C. Feedstock-Dependent Phosphate Recovery in a Pilot-Scale Hydrothermal Liquefaction Bio-Crude Production. Energies 2020, 13, 379. [Google Scholar] [CrossRef] [Green Version]

- Deng, Y.; Zhang, T.; Clark, J.; Aminabhavi, T.; Kruse, A.; Tsang, D.C.W.; Sharma, B.K.; Zhang, F.; Ren, H. Mechanisms and modelling of phosphorus solid–liquid transformation during the hydrothermal processing of swine manure. Green Chem. 2020, 22, 5628–5638. [Google Scholar] [CrossRef]

- Dai, L.; Tan, F.; Wu, B.; He, M.; Wang, W.; Tang, X.; Hu, Q.; Zhang, M. Immobilization of phosphorus in cow manure during hydrothermal carbonization. J. Environ. Manag. 2015, 157, 49–53. [Google Scholar] [CrossRef] [PubMed]

| Analysis Name | Value |

|---|---|

| Ultimate Analysis (wt.%) | |

| C | 52.3 ± 0.5 |

| H | 7.1 ± 0.2 |

| N | 3.5 ± 0.1 |

| O a | 37.1 ± 0.7 |

| HHV (MJ/kg) | 23.2 ± 0.02 |

| Proximate analysis (wt.%) | |

| Moisture | 83.1 |

| Ash | 9.7 |

| Volatile matter b | 71.9 |

| Fixed carbon b | 18.4 |

| Biochemical analysis (wt.%) | |

| Crude fats | 19.2 |

| Crude proteins | 21.8 |

| Carbohydrate a | 49.3 |

| Inorganic Element | Concentration | Relative Concentration |

|---|---|---|

| Unit | (µg/g Biopulp) | (%) a |

| K | 285.94 | 2.96 |

| Na | 493.63 | 0.86 |

| Mg | 83.07 | 5.11 |

| Ca | 721.60 | 7.47 |

| Al | 94.67 | 0.98 |

| Fe | 42.50 | 0.44 |

| Mn | 2.90 | 0.03 |

| P | 234.74 | 2.43 |

| S | 85.97 | 0.89 |

| Si | 105.29 | 1.09 |

| Sr | 2.90 | 0.03 |

| Total | 2153.21 | 22.29 |

| Sample | Elemental Analysis | O/C | H/C | N/C | Ash | HHVdaf | Yield | ER | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | H | N | O | ||||||||

| Unit | wt.% | wt.% | wt.% | wt.% a | - | - | - | % b | MJ/kg c | wt.% d | % |

| Oil-Non-1st | 73.86 ± 0.23 | 9.82 ± 0.12 | 3.36 ± 0.18 | 12.96 ± 0.53 | 0.13 | 1.60 | 0.045 | 0.49 | 36.23 | 30.66 | 47.88 |

| Oil-KOH-1st | 75.13 ± 0.45 | 10.03 ± 0.07 | 4.37 ± 0.31 | 10.47 ± 0.83 | 0.10 | 1.60 | 0.058 | 4.30 | 37.20 | 31.25 | 50.10 |

| Oil-NaOH-1st | 74.44 ± 0.20 | 10.10 ± 0.10 | 4.25 ± 0.26 | 11.21 ± 0.56 | 0.11 | 1.63 | 0.057 | 1.12 | 36.97 | 26.30 | 41.91 |

| Oil-K2CO3-1st | 75.73 ± 0.65 | 10.34 ± 0.08 | 4.90 ± 0.14 | 9.03 ± 0.87 | 0.09 | 1.64 | 0.065 | 1.54 | 37.98 | 34.96 | 57.24 |

| Oil-Na2CO3-1st | 74.32 ± 0.33 | 10.24 ± 0.24 | 4.76 ± 0.28 | 10.68 ± 0.77 | 0.11 | 1.65 | 0.064 | 1.58 | 37.13 | 32.91 | 52.68 |

| Oil-Non-2nd | 73.10 ± 0.58 | 9.53 ± 0.25 | 4.32 ± 0.23 | 13.05 ± 1.13 | 0.14 | 1.56 | 0.059 | 1.66 | 35.41 | 35.18 | 53.70 |

| Oil-KOH-2nd | 74.65 ± 0.30 | 9.90 ± 0.17 | 4.59 ± 0.13 | 10.86 ± 0.60 | 0.11 | 1.59 | 0.061 | 7.60 | 36.76 | 31.26 | 49.53 |

| Oil-NaOH-2nd | 74.34 ± 0.42 | 9.73 ± 0.24 | 4.23 ± 0.07 | 11.70 ± 0.73 | 0.12 | 1.57 | 0.057 | 4.06 | 36.33 | 28.19 | 44.15 |

| Oil-K2CO3-2nd | 74.00 ± 0.41 | 10.08 ± 0.18 | 5.43 ± 0.09 | 10.49 ± 0.68 | 0.11 | 1.63 | 0.073 | 3.78 | 36.73 | 37.51 | 59.39 |

| Oil-Na2CO3-2nd | 73.38 ± 0.22 | 10.3 ± 0.09 | 5.00 ± 0.14 | 11.32 ± 0.45 | 0.12 | 1.68 | 0.068 | 2.83 | 36.77 | 33.41 | 52.95 |

| Solid-Non-1st | 57.12 ± 0.17 | 3.40 ± 0.13 | 1.22 ± 0.20 | 38.26 ± 0.50 | 0.50 | 0.71 | 0.021 | 34.05 | 17.90 | 12.59 | 9.71 |

| Solid-KOH-1st | 51.98 ± 0.45 | 4.72 ± 0.31 | 1.85 ± 0.21 | 41.45 ± 0.97 | 0.60 | 1.09 | 0.036 | 59.23 | 17.48 | 9.74 | 7.34 |

| Solid-NaOH-1st | 51.64 ± 0.53 | 4.32 ± 0.22 | 1.90 ± 0.07 | 42.14 ± 0.82 | 0.61 | 1.00 | 0.037 | 56.49 | 16.68 | 10.53 | 7.57 |

| Solid-K2CO3-1st | 48.49 ± 0.36 | 4.74 ± 0.17 | 2.45 ± 0.18 | 44.32 ± 0.71 | 0.69 | 1.17 | 0.050 | 58.96 | 15.81 | 9.51 | 6.48 |

| Solid-Na2CO3-1st | 49.77 ± 0.78 | 4.89 ± 0.09 | 2.26 ± 0.30 | 43.08 ± 1.17 | 0.65 | 1.18 | 0.045 | 58.01 | 16.67 | 9.90 | 7.11 |

| Solid-Non-2nd | 54.99 ± 0.51 | 3.67 ± 0.11 | 1.55 ± 0.12 | 39.79 ± 0.74 | 0.54 | 0.80 | 0.028 | 37.54 | 17.29 | 12.32 | 9.18 |

| Solid-KOH-2nd | 50.10 ± 0.37 | 5.21 ± 0.20 | 1.89 ± 0.08 | 42.80 ± 0.65 | 0.64 | 1.24 | 0.037 | 70.08 | 17.33 | 9.07 | 6.76 |

| Solid-NaOH-2nd | 52.14 ± 0.12 | 4.37 ± 0.05 | 2.17 ± 0.13 | 41.32 ± 0.30 | 0.59 | 1.00 | 0.041 | 65.86 | 17.01 | 9.78 | 7.17 |

| Solid-K2CO3-2nd | 46.03 ± 0.39 | 4.82 ± 0.15 | 2.77 ± 0.14 | 46.38 ± 0.68 | 0.76 | 1.26 | 0.060 | 69.03 | 14.73 | 8.47 | 5.38 |

| Solid-Na2CO3-2nd | 47.80 ± 0.44 | 5.34 ± 0.11 | 2.32 ± 0.10 | 44.54 ± 0.65 | 0.70 | 1.34 | 0.048 | 67.70 | 16.42 | 9.00 | 6.39 |

| Test Name | Mg | Al | Ca | Cu | Fe | K | Mn | Na | P | S | Si | Sr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit | % | % | % | % | % | % | % | % | % | % | % | % |

| Solid-Non-1st | 1.05 | 1.84 | 7.95 | <0.14 | 1.15 | 0.64 | 0.04 | 0.47 | 2.86 | 0.70 | 1.01 | 0.03 |

| Solid-KOH-1st | 0.77 | 1.24 | 7.99 | <0.14 | 1.07 | 5.02 | 0.03 | 1.81 | 4.64 | 0.30 | 1.53 | 0.02 |

| Solid-NaOH-1st | 0.97 | 1.71 | 10.46 | <0.14 | 0.79 | 0.50 | 0.04 | 8.73 | 2.91 | 0.26 | 0.56 | 0.03 |

| Solid-K2CO3-1st | 0.90 | 1.19 | 9.03 | <0.14 | 1.24 | 1.15 | 0.04 | 0.76 | 3.56 | 0.37 | 1.64 | 0.03 |

| Solid-Na2CO3-1st | 1.07 | 1.63 | 10.20 | <0.14 | 1.24 | 0.45 | 0.04 | 7.69 | 4.09 | 0.46 | 2.66 | 0.03 |

| Solid-Non-2nd | 0.82 | 1.21 | 6.59 | <0.14 | 3.00 | 0.40 | 0.04 | 0.39 | 3.93 | 0.65 | 1.06 | <0.01 |

| Solid-KOH-2nd | 0.82 | 1.28 | 9.26 | <0.14 | 0.88 | 5.09 | 0.03 | 1.86 | 3.24 | 0.32 | 2.22 | 0.03 |

| Solid-NaOH-2nd | 1.41 | 2.27 | 10.90 | <0.14 | 1.36 | 0.81 | 0.05 | 16.7 | 3.30 | 0.34 | 0.66 | 0.04 |

| Solid-K2CO3-2nd | 0.76 | 0.90 | 7.81 | <0.14 | 0.60 | 1.58 | 0.03 | 1.4 | 3.16 | <0.14 | 2.16 | 0.03 |

| Solid-Na2CO3-2nd | 1.39 | 1.25 | 11.90 | <0.14 | 0.86 | 0.34 | 0.04 | 3.24 | 3.94 | 0.50 | 0.47 | 0.04 |

| Unit | µg/cm3 | µg/cm3 | µg/cm3 | µg/cm3 | µg/cm3 | µg/cm3 | µg/cm3 | µg/cm3 | µg/cm3 | µg/cm3 | µg/cm3 | µg/cm3 |

| Aq.p-Non-1st | 68.6 | <10 | 1480 | NF | <10 | 2180 | <10 | 1530 | <10 | 76 | 76 | <10 |

| Aq.p -KOH-1st | 49.1 | NF | 74.6 | NF | <10 | 12.300 | <10 | 1640 | <20 | 114 | 114 | <10 |

| Aq.p -NaOH-1st | 21.2 | NF | 19.7 | NF | <10 | 2490 | <10 | 10.590 | <20 | 126 | 126 | <10 |

| Aq.p -K2CO3-1st | 43.4 | NF | 120.8 | NF | <10 | 12.900 | <10 | 1520 | 74.9 | 121 | 121 | <10 |

| Aq.p -Na2CO3-1st | 42.7 | NF | 77.5 | NF | <10 | 2200 | <10 | 7498 | <20 | 120 | 120 | <10 |

| Aq.p -Non-2nd | 75.7 | NF | 1498 | NF | <10 | 3410 | <10 | 2665 | <20 | 82 | 82 | <10 |

| Aq.p -KOH-2nd | 32.9 | NF | 649 | NF | <10 | 13.900 | <10 | 3385 | 37.5 | 117 | 117 | <10 |

| Aq.p -NaOH-2nd | 8.6 | NF | 24.5 | NF | NF | 3050 | <10 | 16.630 | 115.7 | 171 | 171 | <10 |

| Aq.p -K2CO3-2nd | 36.7 | NF | 128.10 | NF | <10 | 21.200 | <10 | 2596 | <20 | 143 | 143 | <10 |

| Aq.p -Na2CO3-2nd | 21.1 | NF | 28.9 | NF | <10 | 3280 | <10 | 13.220 | <20 | 110 | 110 | <10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kohansal, K.; Sharma, K.; Toor, S.S.; Sanchez, E.L.; Zimmermann, J.; Aistrup Rosendahl, L.; Pedersen, T.H. Bio-Crude Production Improvement during Hydrothermal Liquefaction of Biopulp by Simultaneous Application of Alkali Catalysts and Aqueous Phase Recirculation. Energies 2021, 14, 4492. https://doi.org/10.3390/en14154492

Kohansal K, Sharma K, Toor SS, Sanchez EL, Zimmermann J, Aistrup Rosendahl L, Pedersen TH. Bio-Crude Production Improvement during Hydrothermal Liquefaction of Biopulp by Simultaneous Application of Alkali Catalysts and Aqueous Phase Recirculation. Energies. 2021; 14(15):4492. https://doi.org/10.3390/en14154492

Chicago/Turabian StyleKohansal, Komeil, Kamaldeep Sharma, Saqib Sohail Toor, Eliana Lozano Sanchez, Joscha Zimmermann, Lasse Aistrup Rosendahl, and Thomas Helmer Pedersen. 2021. "Bio-Crude Production Improvement during Hydrothermal Liquefaction of Biopulp by Simultaneous Application of Alkali Catalysts and Aqueous Phase Recirculation" Energies 14, no. 15: 4492. https://doi.org/10.3390/en14154492

APA StyleKohansal, K., Sharma, K., Toor, S. S., Sanchez, E. L., Zimmermann, J., Aistrup Rosendahl, L., & Pedersen, T. H. (2021). Bio-Crude Production Improvement during Hydrothermal Liquefaction of Biopulp by Simultaneous Application of Alkali Catalysts and Aqueous Phase Recirculation. Energies, 14(15), 4492. https://doi.org/10.3390/en14154492