Efficiency of Pressurized Rock Traps for Unlined Hydropower Tunnels

Abstract

:1. Introduction

2. Sediment Problems in Hydropower Turbines

2.1. Hydroabrasion and -Erosion

2.2. Other Damage Types

3. Sources of Sediments

3.1. Sediments from Intakes

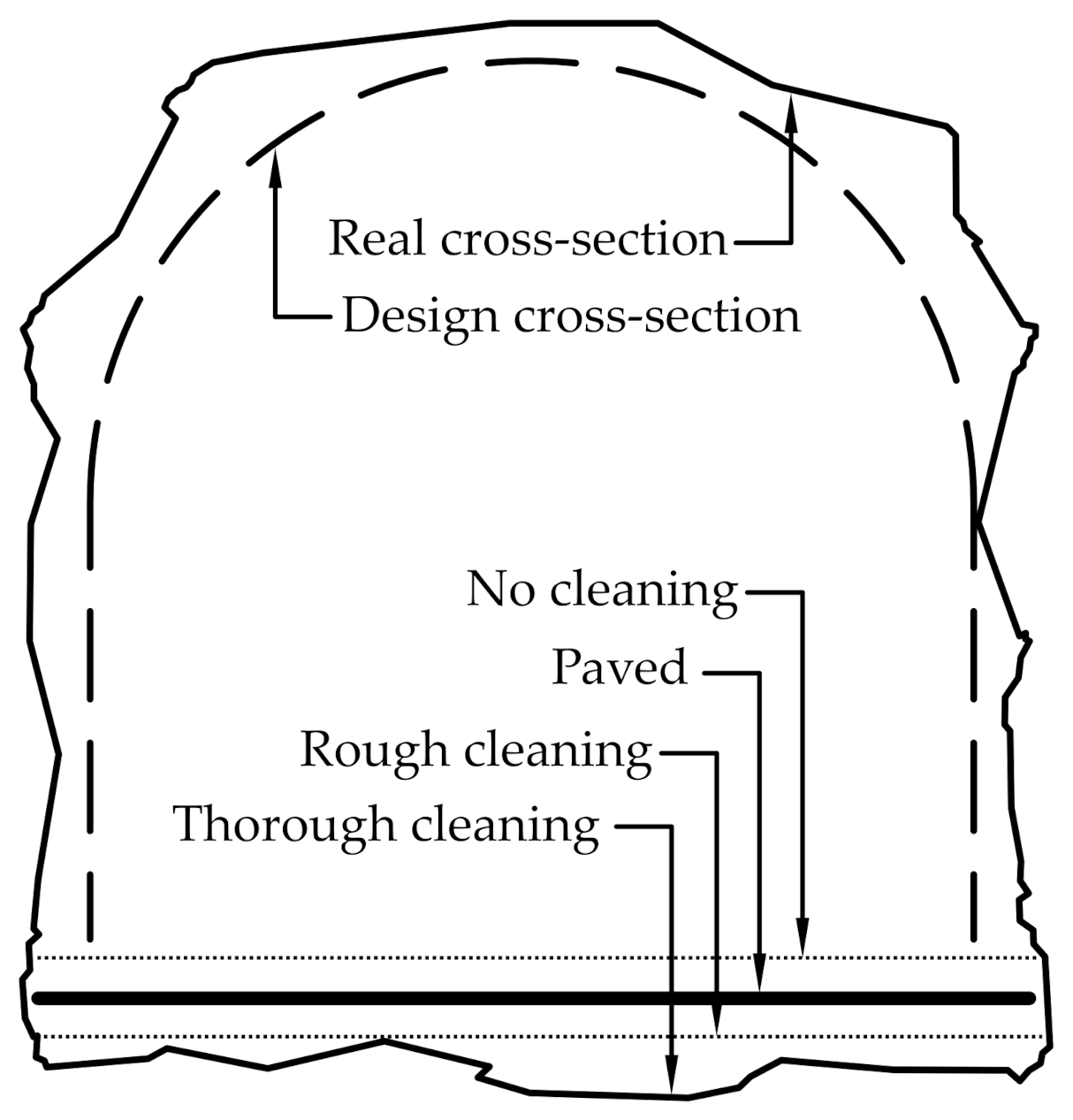

3.2. Sediments from the Tunnel

3.3. Field Measurements

3.4. Removal of Sediments in Hydropower Tunnels

- Maintenance

- Reduced efficiency

- Shortened lifetime, premature replacement

- Production stop at unfortunate times

- Loss of water

4. Theory for Design of Pressurized Rock Traps

4.1. Design Criteria

4.2. Theory of Incipient Motion

4.3. Discussion of Combination of Shields’ Criterion and Friction Formulas

4.4. Theory of Armor Layers

5. Design of Pressurized Rock Traps

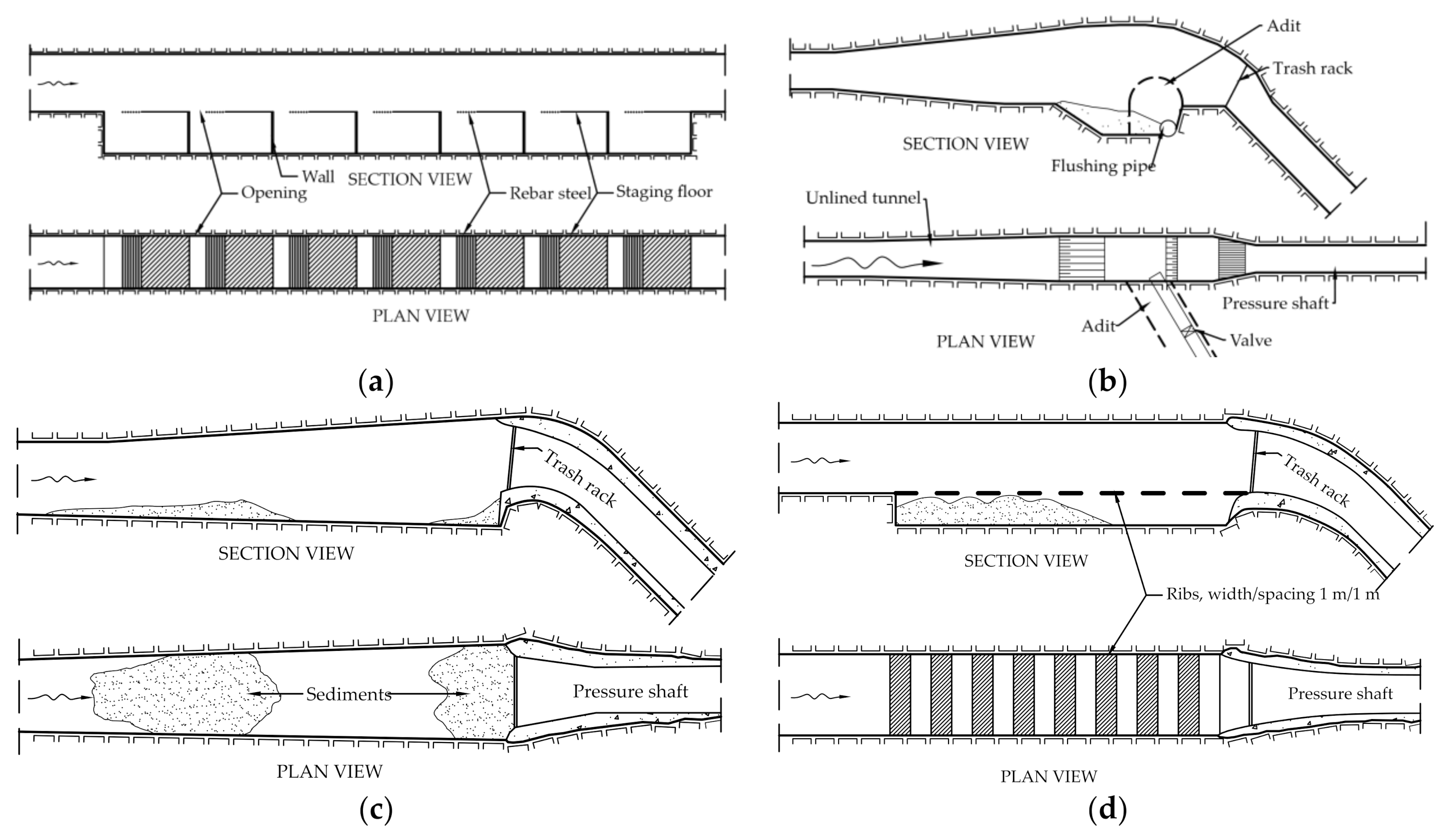

5.1. Historical Review

- No change of cross-section area for smooth and undisturbed throughflow.

- Avoid abrupt transitions into the sediment chamber section.

- Horizontal steel plates and rebars for the separation of the flow.

- Walls between the cells for keeping the trapped sediments in place, horizontally.

- Sediments that deposit in the rock trap are susceptible to resuspension and erosion because of turbulence.

- Variable flow conditions based on the operation of the hydropower plant prevent utilization of the full volume of the sedimentation chamber.

- Unlined tunnels are naturally very rough because of the construction method and irregularities in the rock mass, so smooth transitions of cross-section changes are expensive, difficult, or even impossible.

- The length of the rock trap is of high importance. Longer rock traps (150 m to 200 m) give much better conditions for the settling of smaller particles than shorter rock traps (30 m to 60 m) [24].

- They should be placed at least 150 m to 200 m downstream from any bend, gate, or valve. In other words, the tunnel upstream of the rock trap should be straight and without any expansions or contractions. The flow through the rock trap is very sensitive to changes, like bends, entrance adits, or expansions. Virtually all irregularities cause turbulence which prevents sedimentation.

- To get the desired low flow velocity, a smooth transition from the small tunnel cross-section area to the larger cross-section area is vital. If this is not attained, the flow can separate from the walls, and the consequence will be twofold negative: The flow near the walls and invert will be very turbulent, and the flow in the center of the rock trap will be higher than desired, both of which will prevent sediments from settling.

- The drill and blast method of tunneling can cause very uneven surfaces, which will disturb the flow severely, causing reduced settling capability.

- The settled sediments are better guarded from the flow and are less susceptible to re-entrainment.

- The closed type is less sensitive for non-uniform flow, since it prevents large, high-energy turbulence vortices from reaching the sediments. Therefore, there are less constraints than in open rock traps on the upstream placement of bends, constrictions, and other elements that may disturb the flow.

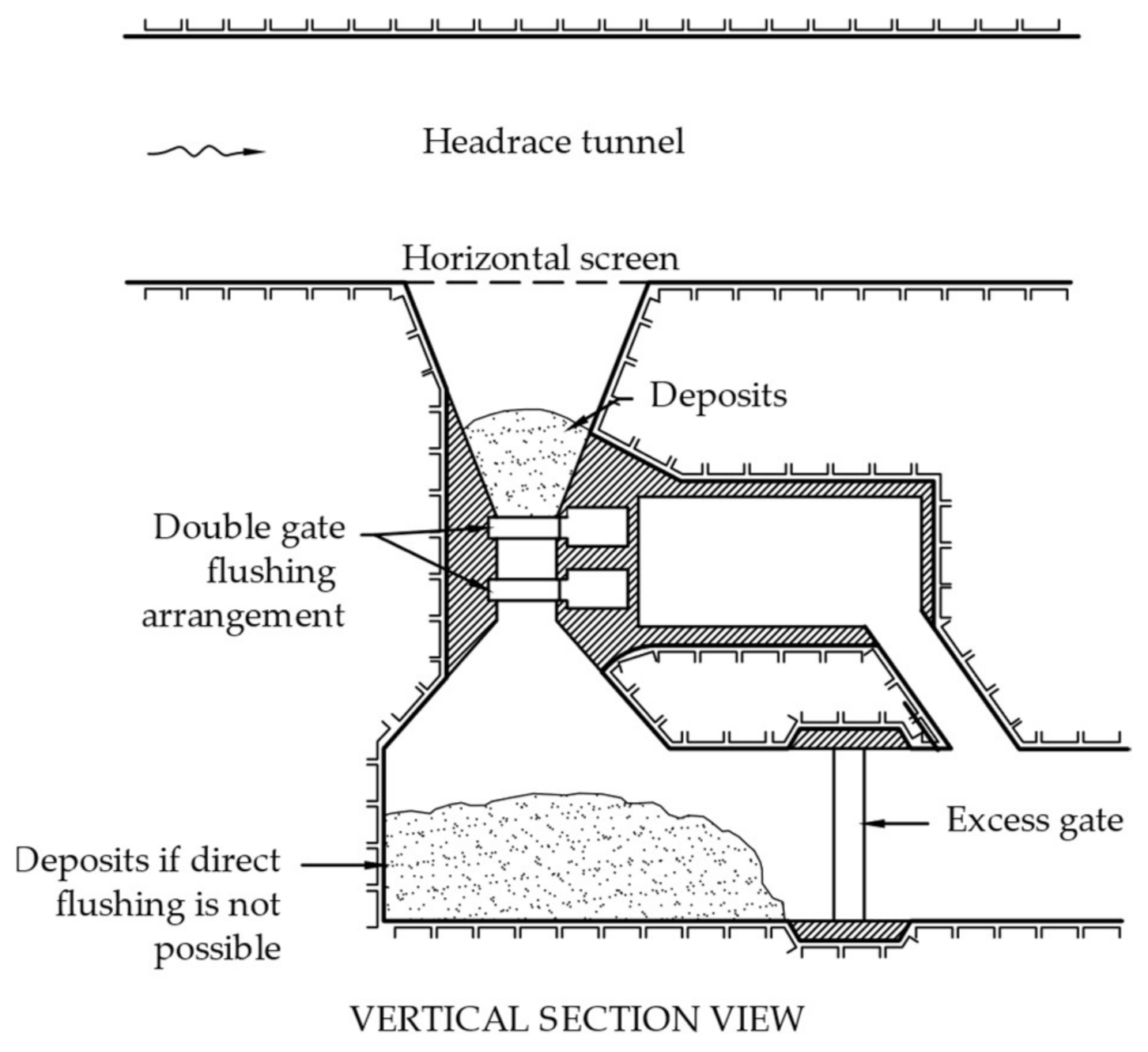

5.2. Summary of Rock Trap Designs

5.3. Emptying Procedure and Flushing Solutions

5.4. Flow Conditioners

5.5. State-of-the-Art for New Pressurized Rock Traps

5.6. State-of-the-Art for Retrofitting Pressurized Rock Traps

6. Discussion

6.1. Design Criteria

6.2. Outlook for Pressurized Rock Traps

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Duan, C.G.; Karelin, V.Y. (Eds.) Abrasive Erosion and Corrosion of Hydraulic Machinery; Series on Hydraulic Machinery; Imperial College Press: London, UK, 2002; Volume 2. [Google Scholar]

- Zhang, Z. Pelton Turbines; Springer: Zürich, Switzerland, 2016. [Google Scholar]

- Lysne, D.K. Movement of sand in tunnels. J. Hydraul. Div. 1969, 95, 1835–1846. [Google Scholar] [CrossRef]

- Camp, T.R. Studies of Sedimentation Basin Design. Sew. Ind. Wastes 1953, 25, 1–14. [Google Scholar]

- Dominy, F.E. Design of desilting works for irrigation systems. J. IRRIG. Drain. Div. 1966, 92, 1–26. [Google Scholar] [CrossRef]

- Develay, D.; Binquet, J.; Divatia, E.; Venkatesha, C.R. Desilting Basin System of the Dul Hasti Hydroelectric Project. J. Hydraul. Eng. 1996, 122, 565–572. [Google Scholar] [CrossRef]

- Ortmanns, C. Entsander von Wasserkraftanlagen. Ph.D. Thesis, Versuchsanstalt für Wasserbau, Hydrologie und Glaziologie, ETH-Zentrum, Zürich, Switzerland, 2006. [Google Scholar]

- Paschmann, C. Design Optimization of Desanding Facilities for Hydropower Schemes. Ph.D. Thesis, Versuchanstalt für Wasserbau, Hydrologie und Glaziologie, ETH Zürich, Zürich, Switzerland, 2018. [Google Scholar]

- Mosonyi, E. High-Head Power Plants, 3rd ed.; Akadémiai Kiadó: Budapest, Hungary, 1991; Volume 2a. [Google Scholar]

- Giesecke, J.; Heimerl, S.; Mosonyi, E. Wasserkraftanlagen, 6th ed.; Springer Vieweg: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Lysne, D.K.; Glover, B.; Støle, H.; Tesaker, E. Hydropower Development—Hydraulic Design; Hydropower Development, Norwegian University of Science and Technology, Department of Hydraulic and Environmental Engineering: Trondheim, Norway, 2003; Volume 8. [Google Scholar]

- ASCE. Sedimentation Engineering: Processes, Measurements, Modeling, and Practice; ASCE Manuals and Reports on Engineering Practice; García, M.H., Ed.; ASCE Task Committee for the Preparation of the Manual on Sedimentation: Reston, VA, USA, 2008; Volume 110. [Google Scholar]

- Dey, S. Fluvial Hydrodynamics: Hydrodynamic and Sediment Transport Phenomena; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Eltvik, M. Sediment Erosion in Francis Turbines. Ph.D. Thesis, Institutt for Energi-og Prosessteknikk, NTNU, Trondheim, Norway, 2013. [Google Scholar]

- Singh, G.; Kumar, A. Performance evaluation of desilting basins of small hydropower projects. ISH J. Hydraul. Eng. 2016, 22, 135–141. [Google Scholar] [CrossRef]

- Winkler, K. Hydro-abrasive erosion: Problems and solutions. IOP Conf. Ser. Earth Environ. Sci. 2014, 22, 052022. [Google Scholar] [CrossRef] [Green Version]

- Bitter, J.G.A. A study of erosion phenomena part I. Wear 1963, 6, 5–21. [Google Scholar] [CrossRef]

- Felix, D. Experimental Investigation on Suspended Sediment, Hydro-Abrasive erosion and Efficiency Reductions of Coated Pelton Turbines. Ph.D. Thesis, Versuchanstalt für Wasserbau, Hydrologie und Glaziologie, ETH Zürich, Zürich, Switzerland, 1996. [Google Scholar]

- VR. Sandslitasje på Vannkraftturbiner—Kilder og Tiltak. In Sandslitasje på Vannkraftturbiner; Pettersen, S., Ed.; Vassdragsregulantenes Forening: Asker, Norway, 1984. [Google Scholar]

- Jacobsen, T.; Luzuriaga, G.A. South American sediments. Int. Water Power Dam Constr. 2014, 66, 30–32. [Google Scholar]

- Broch, E.; Palmström, A. The design of unlined hydropower tunnels and shafts: 100 years of Norwegian experience. Int. J. Hydropower Dams 2017, 24, 72–79. [Google Scholar]

- VR. Sandslitasje på Vannkraftturbiner—Hovedrapport. In Sandslitasje på Vannkraftturbiner; Pettersen, S., Ed.; Vassdragsregulantenes Forening: Asker, Norway, 1984. [Google Scholar]

- Lysne, D.K. Sandtransport i Tunneler—Laboratorieundersøkelser; The River and Harbour Research Laboratory: Trondheim, Norway, 1968. [Google Scholar]

- Eggen, A. Sandtransport og Sandfang i Kraftverkstunneler; Vassdrags- og havnelaboratoriet: Trondheim, Norway, 1973. [Google Scholar]

- VR. Sandslitasje på vannkraftturbiner—Evanger kraftverk. In Sandslitasje på Vannkraftturbiner; Pettersen, S., Ed.; Vassdragsregulantenes Forening: Asker, Norway, 1982. [Google Scholar]

- Rønn, P.E. Konvensjonell Drift av Tunneler. Ph.D. Thesis, Institutt for Bygg-og Anleggsteknikk, NTNU, Trondheim, Norway, 1997. [Google Scholar]

- Vereide, K.; Richter, W.; Lia, L.; Havrevoll, O.H.; Jakobsen, T. Upgrading of sand traps in existing hydropower plants. In Proceedings of the Hydro 2017, Seville, Spain, 9–11 October 2017. [Google Scholar]

- VHL. Gravitasjonsrensk på Tunnelen Lauvastølsvatn-Kvilldal Kraftstasjon 1981-08-27–29; Norwegian Hydrodynamic Laboratories: Trondheim, Norway, 1982. [Google Scholar]

- Dahl, T.; Tvinnereim, K. Ulla-Førreverkene—Tunnelrensk—Sandfang. In VHL-Rapport; The River and Harbour Research Laboratory: Trondheim, Norway, 1975. [Google Scholar]

- Solvik, Ø.; Tesaker, E. Floor paving in unlined hydropower tunnels. In Proceedings of the HydroPower’97: 3rd International Conference on Hydropower, Trondheim, Trondheim, Norway, 30 June–2 July 1997. [Google Scholar]

- Lysne, D.K. Sand transport and sand traps in hydro power tunnels. In International Conference on Pumped Storage Development and Its Environmental Effects; American Water Resources Association: Milwaukee, WI, USA, 1971. [Google Scholar]

- Tvinnereim, K. Sandtransport og sandfang i kraftverkstunneler. In EEU-Kurs: Hydromekanikk i Praksis; NTH: Trondheim, Norway, 1980. [Google Scholar]

- Yalin, M.S. Mechanics of Sediment Transport, 2nd ed.; Pergamon Press: Oxford, UK, 1977. [Google Scholar]

- Shields, A. Anwendung der Aehnlichkeitsmechanik und der Turbulenzforschung auf die Geschiebebewegung. Ph.D. Thesis, Preussischen Versuchsanstalt für Wasserbau, Technical University Berlin, Berlin, Germany, 1936. [Google Scholar]

- Lysne, D.K. Sand in tunnels. In Senior Course in Hydropower Engineering; NTH: Beijing, China, 1986. [Google Scholar]

- Brevik, O. 3D-Numerisk Modellering av Deler av Vannvegen til Tonstad Kraftverk. Master’s Thesis, Institutt for Vann-og Miljøteknikk, NTNU, Trondheim, Norway, 2013. [Google Scholar]

- Camp, T.R. Grit Chamber Design. Sew. Works J. 1942, 14, 368–381. [Google Scholar]

- Patt, H.; Gonsowski, P. Wasserbau; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Vereide, K.; Svingen, B.; Guddal, R. Case study: Damaging effects of increasing the installed capacity in an existing hydropower plant. In Proceedings of the 12th International Conference on Pressure Surges, Fluid Transients and Water Hammer, Dublin, Ireland, 18–20 November 2015. [Google Scholar]

- Cooke, J.B. Haas hydroelectric power project. Trans. ASCE 1959, 124, 989–1026. [Google Scholar]

- Mattimoe, J.J.; Tinney, E.R.; Wolcott, W.W. Rock trap experience in unlined tunnels. J. Power Div. 1964, 90, 29–45. [Google Scholar] [CrossRef]

- Blevins, R.D. Applied Fluid Dynamics Handbook; Krieger Publishing: Malabar, FL, USA, 2003. [Google Scholar]

- Vereide, K.; Richter, W.; Havrevoll, O.H.; Belete, K.; Shrestha, U.; Navaratnam, U.; Mauko, G.; Leif, L. Flexible Sandtraps. In HydroCen Reports; NTNU: Trondheim, Norway, 2021. [Google Scholar]

- Lysne, D.K. Summary of Laboratory Investigation on Sand Trap Arrangements in Power Plant Tunnels. In Bulletins of the River and Harbour Research Laboratory; River and Harbour Research Laboratory at the Technical University of Norway: Trondheim, Norway, 1967. [Google Scholar]

- Tvinnereim, K. Blåfalli II kraftstasjon—Sandfang. In VHL-Rapport; The River and Harbour Research Laboratory: Trondheim, Norway, 1971. [Google Scholar]

- Lysne, D.K.; Tvinnereim, K.; Eggen, A. Om sandtransport i kraftverkstunneler. Bygg særtrykk nr. 3342 1972, 1–4. [Google Scholar]

- Electrowatt. Karahnjukar Waterway Design Report; Unpublished report; Electrowatt: Iceland, 2010. [Google Scholar]

- Griffiths, P.T.A.; Brett, T.M. A scouring rock trap in Lemonthyne power tunnel. In Proceedings of the 5th Australasian Conference on Hydraulics and Fluid Mechanics; Civil Design Division, Hydro-Electric Commission, Christchurch, New Zealand, 9–13 December 1974. [Google Scholar]

- Balcı, H.H.; Eröz, M.; Pamuk, R. Design and construction of the Çamabşı unlined headrace tunnel. Int. J. Hydropower Dams 2014, 21, 86–89. [Google Scholar]

- Lysne, D.K.; Olsen, N.R.; Støle, H.; Jacobsen, T. Sediment control: Recent developments for headworks. Int. J. Hydropower Dams 1995, 2, 46–49. [Google Scholar]

- Solvik, Ø. Modellforsøk av Silosandfang; NHL: Trondheim, Norway, 1975. [Google Scholar]

- Støle, H. Split and Settle—A new Concept for Underground desanders. In Proceedings of the Hydropower’97: 3rd International Conference on Hydropower, Trondheim, Norway, 30 June–2 July 1997. [Google Scholar]

- Jacobsen, T. Sediment Problems in Reservoirs. Ph.D. Thesis, Department of Hydraulic and Environmental Engineering, NTNU, Trondheim, Norway, 1997. [Google Scholar]

- Ivarson, M.M.; Trivedi, C.; Vereide, K. Investigations of Rake and Rib Structures in Sand Traps to Prevent Sediment Transport in Hydropower Plants. Energies 2021, 14, 3882. [Google Scholar] [CrossRef]

- Dann, H.E.; Hartwig, W.P.; Hunter, J.R. Unlined tunnels of the Snowy Mountains Hydro-Electric Authority, Australia. J. Power Div. 1964, 90, 47–79. [Google Scholar] [CrossRef]

- Brekke, T.L.; Ripley, B.D. Design Guidelines for Pressure Tunnels and Shafts; University of California, Berkeley, Electric Power Research Institute: Palo Alto, CA, USA, 1987; p. 184. [Google Scholar]

- Brox, D. Design and Functional Requirements for Rock Traps for Hydropower Pressure Tunnels. Int. J. Hydropower Dams 2016, 23, 4386–4396. [Google Scholar]

- Richter, W.; Mauko, G.; Zenz, G. Hydraulic Investigation, Numerical and Physical Model Test, Flexible Sandtrap (FlekS) 2.0; TU Graz: Graz, Austria, 2020. [Google Scholar]

- Belete, K.; Shrestha, U.; Vereide, K. Physical Model Study of Tonstad Sand Trap III; NTNU: Trondheim, Norway, 2020. [Google Scholar]

- Raju, K.R.; Kothyari, U.C.; Srivastav, S.; Saxena, M. Sediment Removal Efficiency of Settling Basins. J. Irrig. Drain. Eng. 1999, 125, 308–314. [Google Scholar] [CrossRef]

- Ruiz, L. Evaluation of Operational Changes in Norwegian Hydropower. Master’s Thesis, Department of Civil and Environmental Engineering, NTNU, Trondheim, Norway, 2019. [Google Scholar]

| CELSEP [41] | Obsolete [44] | Open [19] | Closed [19] | |

|---|---|---|---|---|

| Length | >40 m | 10–20 m | 40–200 m | >15 m |

| Cross section area | Same as headrace tunnel | ~2–5× headrace tunnel | ~2× headrace tunnel | Same as headrace tunnel |

| Sedimentation height | 2.7 m | 1–1.5 m | ~2 m | ~2 m |

| Flushing possible? | Yes | Not working | Yes | Yes |

| Sediment/flow separation | Yes | No | No | Yes |

| Emptying procedure | Not planned for | Flushing (does not work) | Mechanical excavation or flushing | Mechanical excavation or flushing |

| Cross-section expansion | No | Yes | Yes | No |

| Cost | expensive | Low cost | Low cost | expensive |

| Sensitive to upstream flow disturbances? | Less | Yes | Yes, esp. long ones | Less |

| Headloss | Small | Small | Small | Small |

| Functioning as intended? | Yes | No | If built correctly and carefully | Yes |

| Recommended? | Yes | No | No | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Havrevoll, O.H.; Vereide, K.; Lia, L. Efficiency of Pressurized Rock Traps for Unlined Hydropower Tunnels. Energies 2021, 14, 4344. https://doi.org/10.3390/en14144344

Havrevoll OH, Vereide K, Lia L. Efficiency of Pressurized Rock Traps for Unlined Hydropower Tunnels. Energies. 2021; 14(14):4344. https://doi.org/10.3390/en14144344

Chicago/Turabian StyleHavrevoll, Ola Haugen, Kaspar Vereide, and Leif Lia. 2021. "Efficiency of Pressurized Rock Traps for Unlined Hydropower Tunnels" Energies 14, no. 14: 4344. https://doi.org/10.3390/en14144344

APA StyleHavrevoll, O. H., Vereide, K., & Lia, L. (2021). Efficiency of Pressurized Rock Traps for Unlined Hydropower Tunnels. Energies, 14(14), 4344. https://doi.org/10.3390/en14144344