1. Introduction

Bifacial photovoltaic (PV) module technology is becoming increasingly attractive, with a market share of around 20% in 2020 expected to increase significantly to more than 70% over the next 10 years [

1,

2,

3,

4,

5]. The bifacial solar cell technology uses similar fabrication methods to monofacial PV cells and implementation only requires minor and affordable changes of the manufacturing equipment. The manufacturing of bifacial modules requires the use of transparent material at the rear side, such as a transparent backsheet or glass, which may increase slightly the cost. The alternative mounting concepts of bifacial modules offers potential benefits for applications, including building-integrated vertically mounted scenarios, etc. [

6,

7,

8].

The modeling and simulation of bifacial PV modules is a major obstacle to the bankability of bifacial PV technology. Monofacial PV performance forecasting models are well established; however, their adaption for bifacial systems is still ongoing, and their reliability needs to be proven by comparison with measured data [

9,

10]. Several studies reported that the geometrical, optical, and environmental conditions dictate the energy output of bifacial PV systems and that the synergistic effect of these factors ought to be accounted for when evaluating the performance of bifacial technologies [

11,

12,

13,

14,

15,

16]. In addition, the integration of the bifacial PV to the buildings could increase the shadowing or inhomogeneities of the received radiation on both the front and rear side of the bifacial modules.

In this work, we applied monofacial electrical models to simulate the bifacial PV module energy production: (i) The model of Eduardo et al. [

17], which uses the electrical characteristics indicated in the manufacturer datasheet at Standard Test Conditions (STC). (ii) The model of King et al. [

18], known as the Sandia Array Performance Model, in which the model’s coefficients are determined from the assessment of the measured data. In both models, we considered that the short-circuit current and the current at maximum power point vary according to the backside power gain of the bifacial modules. The performances of the models were validated using measured data from monofacial and bifacial PV arrays installed in Barcelona, Spain.

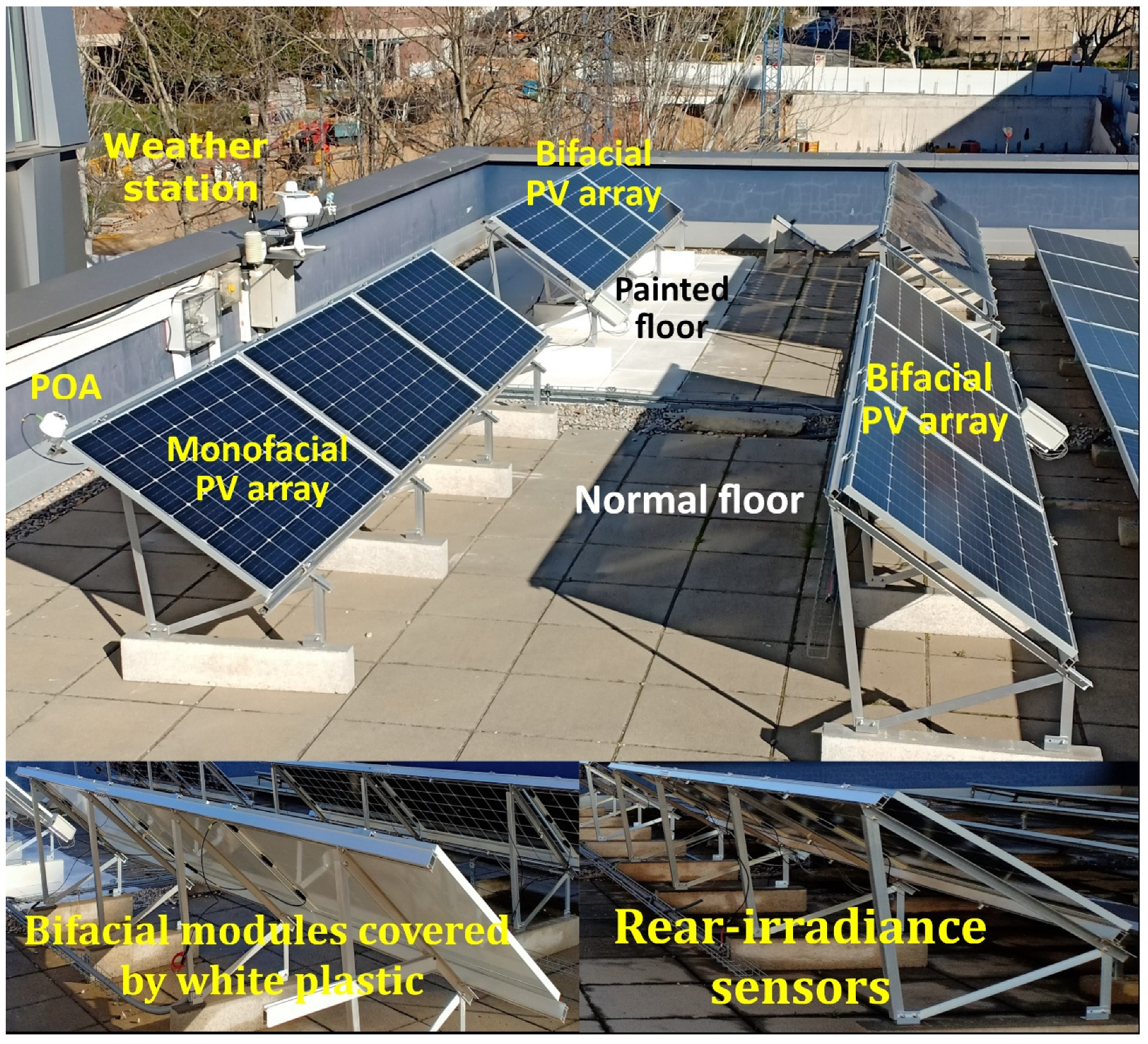

The experimental setup was built up using the same commercial bifacial modules arranged in three PV arrays with the same configuration, such as the orientation, tilt, ground clearance, etc. However, the PV arrays were installed with different rear-side conditions; the backside of the first PV array was coated with a thin white plastic layer to provide data for monofacial operation. This was also considered as the reference PV array to allow an equivalent and direct evaluation of the advantage of the bifacial modules. The bifacial PV modules of the second and the third PV arrays were installed over normal and high albedos, respectively. The albedo of a surface corresponds to the ratio between the reflected light and the incident light. The albedo represents the amount of light reflected off of a surface. A dark body that absorbs light has low albedo, and a bright reflective body has high albedo [

19].

Electrical, weather, and environmental conditions were measured by the installation of a number of sensors, such as pyranometers, thermocouples, current and voltage transducers, and others. We point out here that five irradiance sensors to measure the rear irradiance distribution of each albedo were installed. The developed monitoring program enabled the acquisition of all necessary data, the creation of daily XLS report files, and the visualization of all such data. The simulation results were compared with measurement data in order to evaluate the accuracy of models for bifacial applications.

2. Measurement Set-Up

The measurement set-up involved the design and installation of three bifacial PV arrays with a monitoring system capable of collecting weather, environmental, and electrical parameters. In order to provide comparative data under different rear-side conditions, we used the same bifacial PV module to form the PV arrays.

The arrays were installed on the flat roof of the Polytechnic University of Catalonia (UPC) in Terrassa (coordinates: 41°33′45.1″ N 2°1′15.5″ E), Spain. This setup belongs to the KETsupply pilot plant developed in the framework of the Sudoket Project, devoted to foster the application of Key Enabling Technologies (KET’s) in Intelligent Buildings [

9,

20]. The Azimuth of the building is 163°, which means it is rotated by 17° south-southeast. The bifacial PV module consists of 60 bifacial PERC cells (Passivated Emitter Rear Cell) encapsulated with EVA (Ethylene Vinyl Acetate) polymer and a front glass and rear glass. The nominal front side power is 320 Wp with a bifaciality of 70 ± 5%.

Table 1 provides the bifacial module specifications under the STC with different levels of the backside power gain, these values were used to model the bifacial modules, see

Section 3.

The bifacial PV modules were arranged in three PV arrays with 34° tilt, ground clearance height of 50 cm, and row-to-row distance of 3 m, see

Figure 1. Each PV array was composed of three bifacial modules installed in a landscape position and connected in series; the rated power per array was 960 Wp. The landscape position reduced the non-homogeneity of the rear irradiance and provided a power gain. This landscape gain is defined as the power in landscape compared to portrait [

21]. As shown in

Figure 1, the bifacial modules were installed on the rooftop, where the natural floor provides a normal albedo for the bifacial modules, and the high reflectance floor provides a higher albedo due to paint with high solar reflectance index (SRI) of 105. The albedo is the reflected irradiance of the floor divided by the incident irradiance [

22].

Before mounting the bifacial PV modules, three pyranometers were installed to measure the ground albedo: first, installed facing the sky, measuring the front incident irradiance, and the others facing the ground to measure the reflective irradiance of the normal and painted floors. We found that the albedo was 15% for the normal floor and only 32% for the painted floor, which was much lower than expected. As reported in [

18], the albedo for concrete was 16%, and the addition of white paint increased the albedo to 62%. The same reported 23% for greenfield and 27% for white gravel. The albedo appeared to be highly affected by the surrounding structures, such as walls, PV arrays, buildings, and others.

In order to have the equivalent monofacial PV array (reference), the backside of the bifacial modules was covered with white plastic to obstruct the rear side of the bifacial cells. The same commercial bifacial module was used to reduce the differences due to cell and module technology. In [

21], the researchers reported that the energy gain varied widely ranging from 13% to 35% and from 8.3% to 39%, respectively.

Figure 2 shows the testbed diagram developed to test and monitor the bifacial modules. The PV generation of each PV array was injected into the electrical grid by a single-phase PV inverter with a nominal power of 1.5 kW. As shown, the direct normal irradiance (

DNI), global horizontal irradiance (

GHI), plan of array irradiance (

GPOA), and rear irradiance (

Gr) for the normal and high albedos (

GrNA and

GrHA) were measured. Five sensors (EKO ML 01) were installed on the top, middle, and bottom to measure the reflective irradiance from the normal and painted floor. We also installed those for the normal albedo away from the reflection of the painted floor.

These measurements may allow us to study later the uniformity and distribution of the rear irradiance. The weather station also included sensors to measure the ambient temperature and humidity (

Tamb and

H) and an anemometer to measure the wind speed (

W). The operating temperature of the PV modules (

TC) was measured by fixing the thermocouples (type K) on the back of the central module for each PV array. The DC voltages and currents were measured by means of transducers installed at the output of each PV array; we indicate here that the inverter used had an MPPT efficiency of 99.9% and maximum efficiency of 97.1%. The information about the sensors and the measured parameters is summarized in

Table 2. The sensors were selected respecting the standard to monitor the performance of the PV system [

23].

In order to ensure robust, reliable, and continuous measurement of the indoor and outdoor parameters, we designed the data acquisition system with two DAQs connected to the lab PC with Ethernet cables in a line topology. Then, using LabVIEW, we achieved a monitoring program that managed the DAQs to synchronize all the measured data from the sensors installed outside and inside the building. This system was also programmed to perform the calibration of the signals to the corresponding units, the real-time display of the measured and derived parameters, and the creation of the daily excel report files.

For the latter, a sub-program that saved all the measured parameters to an excel file at 30 s intervals was developed. At midnight, the sub-program reset all the energy meters, save and sent the daily excel file to a dedicated Dropbox, and created a new excel file for the next day. We directly saved the data to the Dropbox, which shared the files with the project team’s PCs; this prevented any data loss and full remote access to the database.

4. Results and Discussion

The power outputs of the monofacial and bifacial PV arrays were simulated using the analytical and empirical models in which we introduced the ratio of Gr to GPOA (BGg) to integrate the behavior of the bifacial modules. The simulation results were compared to the measured data, we performed daily and monthly comparisons to discuss the precision of the models over different skies. Furthermore, we discussed the daily errors over the monitored period—six-months—to discuss the performance of the proposed models for bifacial applications with different albedos.

4.1. Daily Comparison

The PV output of the PV modules depends on the local climatic conditions; therefore, two typical weather conditions namely sunny-day and overcast-day, were considered for hourly simulation.

Figure 5 and

Figure 6 show the irradiances and temperatures over two days characterized by clear (07/03/20) and overcast (16/03/20) skies. During the sunny day, we observed that white paint greatly increased the rear irradiance of the bifacial modules installed above high albedo (

GrHA) compared to the bifacial modules installed above normal albedo (

GrNA). At noon, the

GrHA max (89 W/m

2) was three times the

GrNA max (27 W/m

2), see

Figure 5a. The instantaneous

BGg was close to 9% for high albedo and less than 3% for normal albedo, see

Figure 5b. With the exception of low

BGg values, the white paint greatly increased the solar irradiance on the backside of the bifacial modules.

Clearly, the operating temperature of the bifacial modules above high albedo was slightly higher than that of the others, which were superimposed as shown in

Figure 5c. The max PV module temperature for high albedo was approximately 48 versus 42 °C for both monofacial and bifacial with normal albedo. These values were close to the NOCT of the PV module (45 °C) but are expected to be higher when the ambient temperature rises; the ambient temperature values were below 20 °C.

Instantaneous

BGg values were particularly higher during the overcast day compared to the sunny day, as shown in

Figure 6b.

BGg values were higher than 5% and 10% for normal and high albedo, respectively, and were much higher during very low irradiance periods. This is due to the fact that the diffuse fraction (the ratio of diffuse irradiance and global irradiance) is high under low irradiance, which means that the available rear irradiance is more dominant in the total received irradiance compared to the clear sky [

29].

As a result, the high

BGg values will incorrectly amplify the simulated power output and, thus, reduce the accuracy of the proposed models under low irradiance conditions. However, the amount of energy received under overcast conditions was very low compared to sunny conditions. The operating temperature curves of all the PV modules were superimposed and ranged from 10 to 16 °C, see

Figure 6c.

Figure 7 and

Figure 8 show the simulation results of the analytical and empirical models applied to the monofacial modules and bifacial modules with different albedos. The models allow the dynamic behavior simulation of the monofacial and bifacial PV modules using the irradiances and PV module temperatures measurements. The comparison between the models shows that, for bifacial modules, the analytical model showed more accuracy than the empirical model. However, for monofacial modules, the empirical model showed better accuracy for sunny and overcast days, see

Figure 7a and

Figure 8a.

During the sunny day, the comparison results show that both models achieved good performance in terms of simulating the instantaneous power output of the PV arrays. The relative error of the models was calculated for the daily energy (measured and simulated); the errors on the sunny-day were much less than the overcast-day. Excluding the shading errors during the sunrise, shown in

Figure 7a,c, we assume that the daily error of both models were found to be less than 1% for the sunny-day. The pyranometer was less affected than the PV arrays by the shading from the surrounding building.

During the overcast day, the relative errors were higher for both models, see

Figure 8a–c. We can explain this for a number of reasons: First, we modeled the effect of the rear irradiance using the linear relationship between the

Isc/

Imp and the

BGg (Equations (12) and (13)); therefore, the

BGg caused a certain overestimation of the production of the bifacial modules under overcast conditions, as shown in

Figure 8b,c. Second, the intense fluctuation of instantaneous solar irradiance (under overcast and cloudy conditions) also resulted in a relatively large measurement error (≥4%) between different instruments [

30], and it could be interesting to assess the monitored data to correct the mismatches of the models.

Third, the DC voltage dropped by half during low irradiance periods, see

Figure 9, which could be due to the maximum power point tracking (MPPT) algorithm of the PV inverters (SOLAX X1–1.5 kW). This was not considered in our model due to the lack of information on the PV inverter control strategy. Finally, the DC operating voltage (

Vmp) of the PV arrays was close to 100 V during high irradiation and close to 50 V during low irradiance, which is much lower than the nominal DC operating voltage of the inverter (360 V). This may have an impact on the efficiency of the PV inverters, particularly during low irradiance periods.

4.2. Monthly Comparison

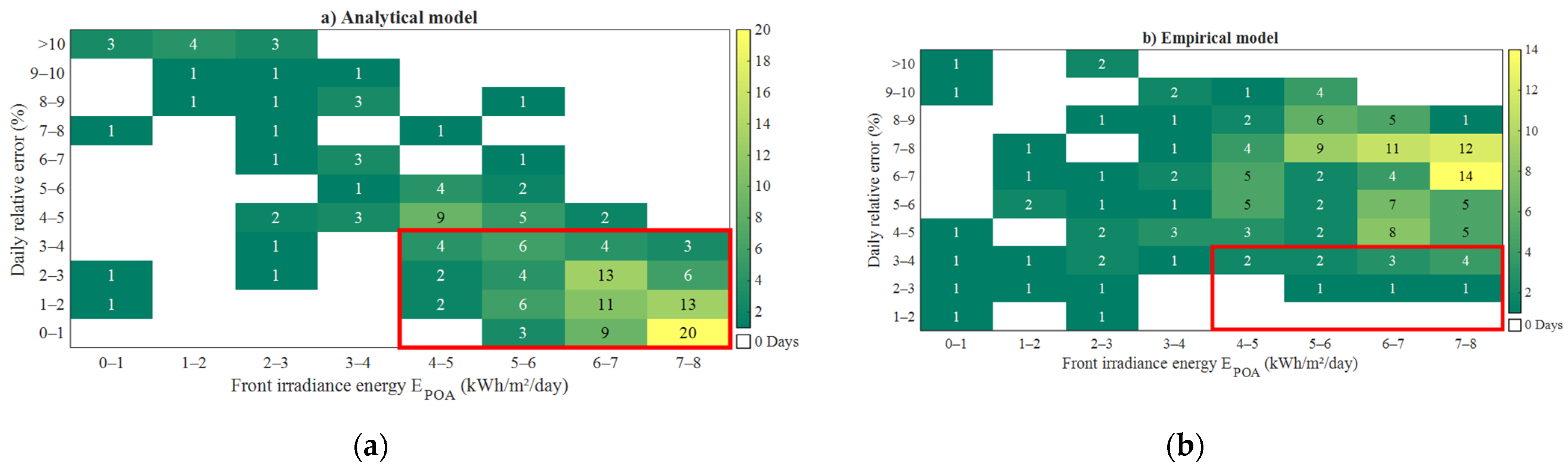

To evaluate the performance of the proposed models based on the heatmap visualization technique, we compared and evaluated the precision of the models (the difference between the measured and the simulated energy) using 166 days of measured data, from 1 March to 31 August 2020, which included spring and summer seasons.

Figure 10 shows the relative distribution of the rear irradiance energy (

EGr) and the front irradiance energy (

EPOA) of all monitored days on a heatmap. The map shows the distribution of days considering the normal and high albedos, the painted floor clearly increased the received irradiance (at the back of the bifacial modules) twofold; the distribution of the days on the map was more or less the same for both albedos. The heatmap can help to identify shading issues on both sides of the modules. As the building is south-southeast-facing, the backside of the bifacial modules could receive sunlight in the evening during the summer period. This is not the case due to the building located behind the bifacial PV arrays.

The maximum EGr values were measured during April and May, at more than 0.2 kWh/m2/day for the normal albedo and more than 0.4 kWh/m2/day for the high albedo. During June, July, and August, the sunlight was obstructed in the evening by the rear building, which affected the Gr received by the backside of the modules. The maximum EGr values were less than 0.1 kWh/m2/day for the normal albedo and less than 0.2 kWh/m2/day for the high albedo. The results showed that installation conditions, such as the azimuth angles of the sun and the surrounding obstacles, could have a strong impact on the energy received from the back of the modules.

Figure 11 shows the heatmap visualization of the daily relative errors for the monofacial modules; the simulation error results corresponding to the

EPOA. As can be seen, most errors were less than 3% for the empiric model, and more than half were greater than 3% for the analytical model. The empiric model showed better precision for simulating the power output of the monofacial modules.

Figure 12 shows the heatmap visualization of the daily errors for the bifacial modules with normal albedo and the simulation error results corresponding to the

EPOA. Unlike the monofacial modules, the maps show that the distribution of the daily errors was better for the analytical model. Within the highlighted area limited to

EPOA more than 4 kWh/m

2/day and relative errors less than 4%, the number of days for the analytical model and the empirical model were 125 and 114, respectively. In addition, there were 72 days with less than 2% error for the analytical model compared to 38 days for the empiric model.

Figure 13 shows the heatmap visualization of the daily errors for the bifacial modules with high albedo; the simulation error results corresponding to the

EPOA. The distribution of the errors confirms the previous results. Within the same area (limited to >4 kWh/m

2/day and <4%), the number of the days for the analytical model and the empirical model were 106 and 14, respectively. Under high albedo, the comparison between the maps shows the clear advantage to simulate the bifacial power output using the analytical model.

The bifacial energy gain was calculated by the ratio of the energy generated by the monofacial and bifacial PV arrays. As shown in

Table 3, the bifacial energy gain values for normal and high albedo were 4.18% and 9.56%, respectively. The results are approximately close to the values of the instantaneous

BGg (bifacial gain of irradiance) under clear sky (9% for high albedo and less than 3% for normal albedo, see

Figure 5). The average daily errors of the proposed models, given in

Table 3, validate that the analytical model was more precise to simulate the bifacial PV production, with the daily average errors at 0.51% and 2.82% for normal and high albedos, respectively. However, the empirical model provided better accuracy to simulate the monofacial PV production, whose average daily error was 0.43%.

5. Conclusions

The simulation tools for bifacial PV generation are still under development, and their reliability needs to be demonstrated by comparison with the measured data. In this paper, we adapted two monofacial electrical PV models to simulate the power output of bifacial PV modules with different rear conditions. An experimental setup was built to demonstrate the feasibility of this approach by installing identical bifacial PV arrays with different albedos plus one monofacial PV array as a reference. Analytical and empiric models were used to simulate the instantaneous bifacial output of the modules by integrating the bifaciality of the modules (light capture from both front- and rear- sides) using the measured rear irradiance. The comparison with the monitored data showed that monofacial models could be a good way to monitor bifacial production.

The results showed very good agreement between the measured and the simulated results of the monofacial and bifacial modules under clear sky conditions. We found that the analytical model was more accurate and easier to implement compared to the empirical model. The latter was more accurate for monofacial simulation. As the models provide information on healthy operation using the measured solar irradiances and operating temperatures, we found that more than 2% of the differences under clear skies were due to the shading of the surrounding buildings.

These models integrated into the monitoring system could be an effective tool for assessing shading and soiling losses in real time. However, the accuracy of both models decreased under low solar irradiance conditions; thus, further work is planned to include the measurement of diffuse solar irradiance in the models. The assessment of the models over six months using the heatmap visualization technique confirmed the same results obtained from the instantaneous comparisons and provides us with a very powerful tool to show the effect of the albedo, the azimuth angles of the sun, and the surrounding obstacles.

The average daily errors for the analytical model were found to be less than 1% and 3% for normal and high albedos, respectively. This was achieved by accurate measurement of the solar irradiance and temperature, although further work could include other techniques/algorithms to avoid the expensive sensors and investigate the predictability of the bifacial production using monofacial models.