Personalized Anti-Vibration Protection for Telematics Devices in Urban Freight Transport Vehicles

Abstract

1. Introduction

1.1. Electric Vans in City Logistics

- A high torque, available over the entire speed range;

- A low level of noise;

- No emissions during stoppages associated with the delivery;

- The easy implementation of systems with simultaneous all swivel and all driven wheels (all-wheel steer–all-wheel drive), which increases maneuverability;

1.2. Adverse Effect of Vibrations

1.3. Telematics in Road Transport

- Infrastructural;

- In-vehicle;

- Mixed.

1.4. Damping and Dampers

1.5. Additive Manufacturing (AM) and FDM Method

1.6. Polymers and Thermoplastic Elastomers

1.7. Manufacturing Process Management (MPM)

- Selection of material;

- Selection of (print) parameters;

- Printing;

- Evaluation—printability and properties;

- Pre-process, encompassing steps such as product development, design, material selection, material composition, slicing and deposition strategy;

- In-process: loading of material, liquification, pressure, extrusion, plotting, bonding and support;

- Post-process: component cooling, support removal, mechanical finish and chemical finish.

1.8. Summary—Need of the Study

2. Materials and Methods

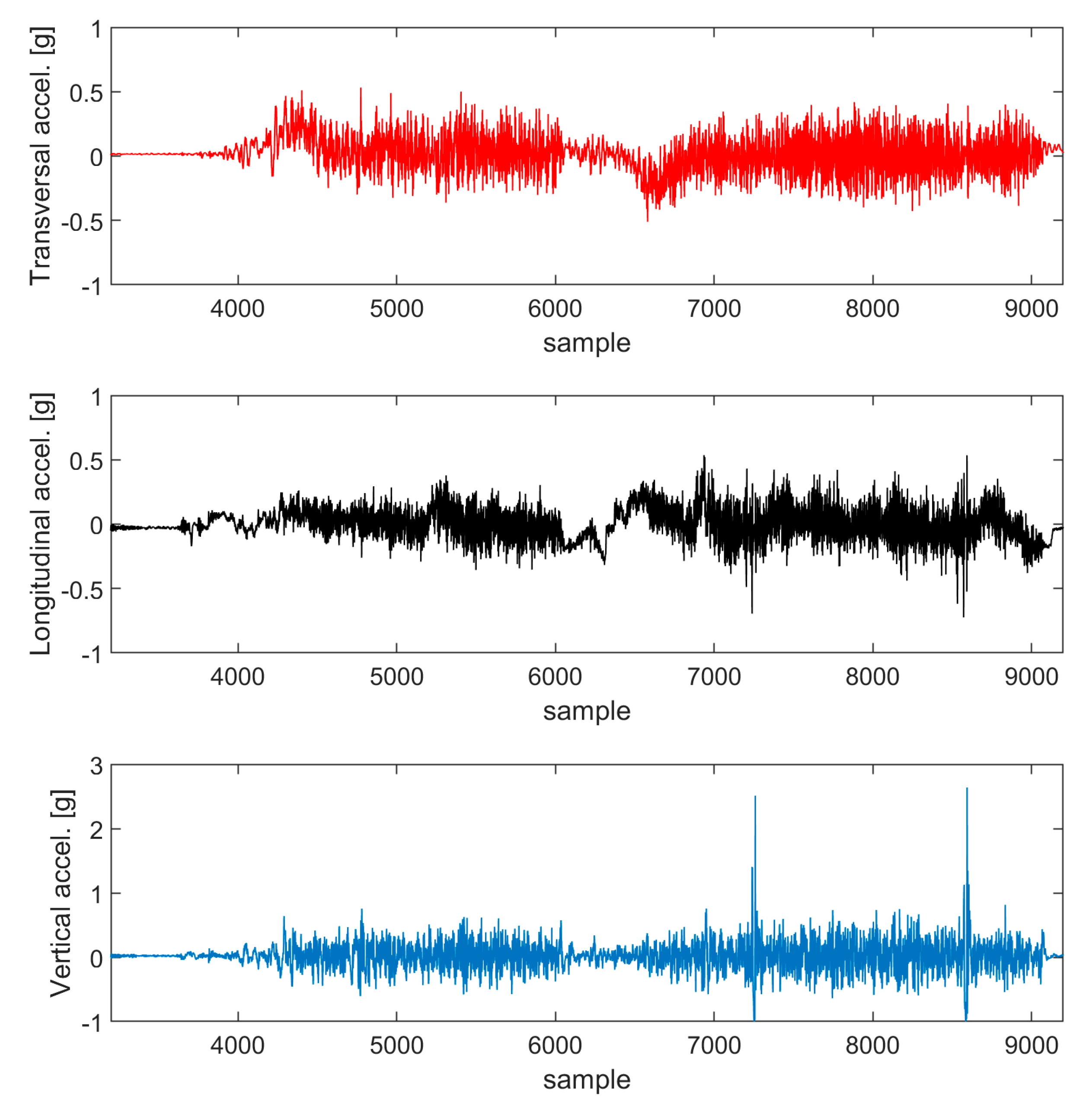

2.1. Vibration Test

2.2. Printing Parameters and Conditions

2.3. Compression Test

2.4. Criterions

3. Results and Discussion

3.1. Selection of Material

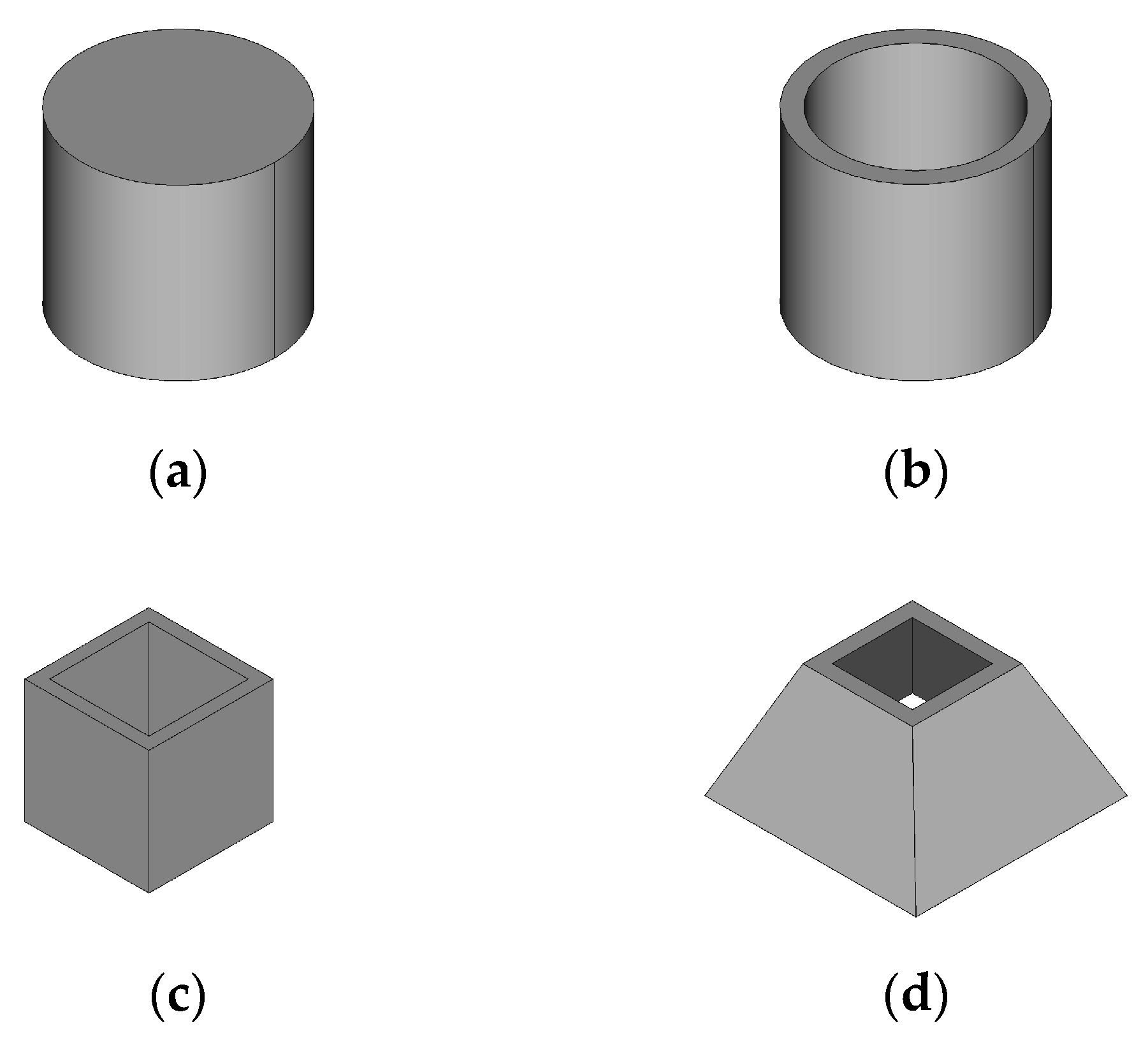

3.2. The Geometry of a Printed Part

3.3. The Effect of Printing Parameters on Damper Properties

3.4. Post-Printing Treatment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statements

Acknowledgments

Conflicts of Interest

References

- Watrobski, J.; Malecki, K.; Kijewska, K.; Iwan, S.; Karczmarczyk, A.; Thompson, R.G. Multi-Criteria Analysis of Electric Vans for City Logistics. Sustainability 2017, 9, 1453. [Google Scholar] [CrossRef]

- Iwan, S.; Kijewska, K.; Kijewski, D. Possibilities of Applying Electrically Powered Vehicles in Urban Freight Transport. In Procedia Social and Behavioral Sciences, Proceedings of the 1st International Conference on Green Cities—Green Logistics for Greener Cities, Szczecin, Poland, 19–21 May 2014; Iwan, S., Thompson, R.G., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 87–101. [Google Scholar] [CrossRef]

- Kijewska, K.; Iwan, S.; Małecki, K. Applying Multi-Criteria Analysis of Electrically Powered Vehicles Implementation in Urban Freight Transport. In Procedia Computer Science, Proceedings of the 23rd KES International Conference on Knowledge-Based and Intelligent Information and Engineering Systems (KES), Budapest, Hungary, 4–6 September 2019; Rudas, I.J., Janos, C., Toro, C., Botzheim, J., Howlett, R.J., Jain, L.C., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1558–1567. [Google Scholar] [CrossRef]

- Iwan, S.; Allesch, J.; Celebi, D.; Kijewska, K.; Hoe, M.; Klauenberg, J.; Zajicek, J. Electric mobility in European urban freight and logistics—Status and attempts of improvement. In Transportation Research Procedia, Proceedings of the 3rd International Conference on Green Cities—Green Logistics for Greener Cities, Szczecin, Poland, 13–14 September 2018; Iwan, S., Thompson, R.G., Kijewska, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 112–123. [Google Scholar] [CrossRef]

- Grzesica, D. Measurement and analysis of truck vibrations during off-road transportation. In MATEC Web of Conferences, Proceedings of the 14th International Conference on Vibration Engineering and Technology of Machinery (VETOMAC), Lisbon, Portugal, 10–13 September 2018; Maia, N., Dimitrovova, Z., Eds.; E D P Sciences: Les Ulis, France, 2018. [Google Scholar] [CrossRef][Green Version]

- Agostinacchio, M.; Ciampa, D.; Olita, S. The vibrations induced by surface irregularities in road pavements—A Matlab (R) approach. Eur. Transp. Res. Rev. 2014, 6, 267–275. [Google Scholar] [CrossRef]

- Reina, G.; Leanza, A.; Messina, A. On the vibration analysis of off-road vehicles: Influence of terrain deformation and irregularity. J. Vib. Control. 2018, 24, 5418–5436. [Google Scholar] [CrossRef]

- Amy, R.A.; Aglietti, G.S.; Richardson, G. Reliability analysis of electronic equipment subjected to shock and vibration—A review. Shock Vib. 2009, 16, 45–59. [Google Scholar] [CrossRef]

- Al-Yafawi, A.; Yu, D.; Park, S.; Pitarresi, J.; Chung, S. Reliability assessment of electronic components under random vibration loading. In Proceedings of the 59th Electronic Components and Technology Conference, San Diego, CA, USA, 26–29 May 2009; IEEE: New York, NY, USA, 2009; Volume 1–4. [Google Scholar] [CrossRef]

- Ham, S.J.; Lee, S.B. Experimental study for reliability of electronic packaging under vibration. Exp. Mech. 1996, 36, 339–344. [Google Scholar] [CrossRef]

- U.S. Department of Defence. Test Method Standard 750D; Semiconductor Devices: Washington, DC, USA, 1995. [Google Scholar]

- U.S. Department of Defence. Test Method Standard 883E; Microcircuits: Washington, DC, USA, 1996. [Google Scholar]

- Kiciński, J. Dynamika wirników i łożysk ślizgowych. In Maszyny Przepływowe; Burka, E.S., Ed.; Wydawnictwo IMP PAN: Gdańsk, Poland, 2005; p. 28. [Google Scholar]

- Solecki, L. Assessment of annual exposure of private farmers to the whole-body mechanical vibration on selected family farms of animal production profile. Med. Pr. 2010, 61, 143–154. [Google Scholar]

- Kubo, M.; Terauchi, F.; Aoki, H.; Matsuoka, Y. An investigation into a synthetic vibration model for humans: An investigation into a mechanical vibration human model constructed according to the relations between the physical, psychological and physiological reactions of humans exposed to vibration. Int. J. Ind. Ergon. 2001, 27, 219–232. [Google Scholar] [CrossRef]

- Iwan, S.; Małecki, K.; Korczak, J. Impact of Telematics on Efficiency of Urban Freight Transport. In Activities of Transport Telematics, Proceedings of the 13th International Conference on Transport Systems Telematics (TST), Katowice, Poland, 23–26 October 2013; Mikulski, J., Ed.; Springer: New York, NY, USA, 2013. [Google Scholar]

- Symans, M.D.; Constantinou, M.C. Semi-active control systems for seismic protection of structures: A state-of-the-art review. Eng. Struct. 1999, 21, 469–487. [Google Scholar] [CrossRef]

- Soong, T.T.; Spencer, B.F. Supplemental energy dissipation: State-of-the-art and state-of-the practice. Eng. Struct. 2002, 24, 243–259. [Google Scholar] [CrossRef]

- Van Krevelen, D.W.; Te Nijenhuis, K. Properties of Polymers, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Adams, R. Vibration Damping of Adhesively Bonded Joints. In Handbook of Adhesion Technology; Da Silva, L.F.M., Ochsner, A., Adams, R.D., Eds.; Springer: Berlin, Germany, 2011. [Google Scholar] [CrossRef]

- Soedel, W.; Qatu, M.S. Vibrations of Shells and Plates, 3rd ed.; Marcel Dekker, Inc.: New York, NY, USA, 2005. [Google Scholar]

- Shen, M.Y.; Chiou, Y.C.; Tan, C.M.; Wu, C.C.; Chen, W.J. Effect of Wall Thickness on Stress-Strain Response and Buckling Behavior of Hollow-Cylinder Rubber Fenders. Materials 2020, 13, 1170. [Google Scholar] [CrossRef]

- Benyoucef, A.; Leblouba, M.; Zerzour, A. Stiffness and energy dissipation of Oval Leaf Spring mounts under unidirectional line loading. Mech. Ind. 2017, 18, 4. [Google Scholar] [CrossRef]

- Vithani, K.; Goyanes, A.; Jannin, V.; Basit, A.; Gaisford, S.; Boyd, B. An Overview of 3D Printing Technologies for Soft Materials and Potential Opportunities for Lipid-based Drug Delivery Systems. Pharm. Res. 2019, 36, 1–20. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Espera, A.H.; Chen, Q.Y.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M. 3D printing with polymers: Challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef] [PubMed]

- Wohlers, T.; Gornet, T. History of Additive Manufacturing. Wohler Associates. Available online: http://www.wohlersassociates.com/history2014.pdf (accessed on 27 February 2021).

- Ligon, S.; Liska, R.; Stampfl, J.; Gurr, M.; Mulhaupt, R. Polymers for 3D printing and customized additive manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Kumar, N.; Jain, P.; Tandon, P.; Pandey, P. The effect of process parameters on tensile behavior of 3D printed flexible parts of ethylene vinyl acetate (EVA). J. Manuf. Process. 2018, 35, 317–326. [Google Scholar] [CrossRef]

- Maconachie, T.; Tino, R.; Lozanovski, B.; Watson, M.; Jones, A.; Pandelidi, C.; Alghamdi, A.; Almalki, A.; Downing, D.; Brandt, M.; et al. The compressive behaviour of ABS gyroid lattice structures manufactured by fused deposition modelling. Int. J. Adv. Manuf. Technol. 2020, 107, 4449–4467. [Google Scholar] [CrossRef]

- Rajzer, I.; Kurowska, A.; Jabłoński, A.; Jatteau, S.; Śliwka, M.; Ziąbka, M.; Menaszek, E. Layered gelatin/PLLA scaffolds fabricated by electrospinning and 3D printing for nasal cartilages and subchondral bone reconstruction. Mater. Des. 2018, 155, 297–306. [Google Scholar] [CrossRef]

- Bose, S.; Vahabzadeh, S.; Bandyopadhyay, A. Bone tissue engineering using 3D printing. Mater. Today 2018, 16, 496–504. [Google Scholar] [CrossRef]

- Jia, Y.; He, H.; Peng, X.; Meng, S.; Chen, J.; Geng, Y. Preparation of a new filament based on polyamide-6 for three-dimensional printing. Polym. Eng. Sci. 2017, 57, 1322–1328. [Google Scholar] [CrossRef]

- Pollard, D.; Ward, C.; Herrmann, G.; Etches, J. The manufacture of honeycomb cores using Fused Deposition Modeling. Adv. Manuf. Polym. Compos. Sci. 2017, 3, 21–31. [Google Scholar] [CrossRef]

- Liao, G.X.; Li, Z.X.; Cheng, Y.C.; Xu, D.D.; Zhu, D.C.; Jiang, S.L.; Guo, J.J.; Chen, X.D.; Xu, G.J.; Zhu, Y.J. Properties of oriented carbon fiber/polyamide 12 composite parts fabricated by fused deposition modeling. Mater. Des. 2018, 139, 283–292. [Google Scholar] [CrossRef]

- Morales, N.G.; Fleck, T.J.; Rhoads, J.F. The effect of interlayer cooling on the mechanical properties of components printed via fused deposition. Addit. Manuf. 2018, 24, 243–248. [Google Scholar] [CrossRef]

- Saari, M.; Galla, M.; Cox, B.; Krueger, P.; Cohen, A.; Richer, E. Additive Manufacturing of Soft and Composite Parts from Thermoplastic Elastomers. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 18 January 2015; pp. 949–958. [Google Scholar]

- Kumar, N.; Jain, P.; Tandon, P.; Pandey, P. Additive manufacturing of flexible electrically conductive polymer composites via CNC-assisted fused layer modeling process. J. Braz. Soc. Mech. Sci. 2018, 40, 1–13. [Google Scholar] [CrossRef]

- Achillas, C.; Aidonis, D.; Iakovou, E.; Thymianidis, M.; Tzetis, D. A methodological framework for the inclusion of modern additive manufacturing into the production portfolio of a focused factory. J. Manuf. Syst. 2015, 37, 328–339. [Google Scholar] [CrossRef]

- Drobny, J.G. Handbook of Thermoplastic Elastomers, 1st ed.; William Andrew Publishing: Norwich, NY, USA, 2007. [Google Scholar]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Abbott, A.C.; Tandon, G.P.; Bradford, L.P.; Koerner, H.; Baur, J.W. Process-structure-property effects on ABS bond strength in fused filament fabrication. Addit. Manuf. 2018, 19, 29–38. [Google Scholar] [CrossRef]

- Przybytek, A.; Kucińska-Lipka, J.; Janik, H. Thermoplastic elastomer filaments and their application in 3D printing. Elastomery 2016, 20, 32–39. [Google Scholar]

- Domingo-Espin, M.; Puigoriol-Forcada, J.M.; Garcia-Granada, A.A.; Lluma, J.; Borros, S.; Reyes, G. Mechanical property characterization and simulation of fused deposition modeling polycarbonate parts. Mater. Des. 2015, 83, 670–677. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Adel, M.; Abdelaal, O.; Gad, A.; Nasr, A.B.; Khalil, A. Polishing of fused deposition modeling products by hot air jet: Evaluation of surface roughness. J. Mater. Process. Technol. 2018, 251, 73–82. [Google Scholar] [CrossRef]

- Hamidi, A.; Tadesse, Y. Single step 3D printing of bioinspired structures via metal reinforced thermoplastic and highly stretchable elastomer. Compos. Struct. 2019, 210, 250–261. [Google Scholar] [CrossRef]

- Kumar, N.; Jain, P.K.; Tandon, P.; Pandey, P.M. Extrusion-based additive manufacturing process for producing flexible parts. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 1–12. [Google Scholar] [CrossRef]

- Lathers, S.; Mousa, M.; La Belle, J. Additive manufacturing Fused Filament Fabrication three-dimensional printed pressure sensor for prosthetics with low elastic modulus and high filler ratio filament composites. 3D Print. Addit. Manuf. 2017, 4, 30–40. [Google Scholar] [CrossRef]

- Korger, M.; Bergschneider, J.; Lutz, M.; Mahltig, B.; Finsterbush, K.; Rabe, M. Possible Applications of 3D Printing Technology on Textile Substrates. In Proceedings of the 48th Conference of the International Federation of Knitting Technologists (IFKT), Moenchengladbach, Germany, 8–11 June 2016; Aumann, S., Ehrmann, A., Weber, M.O., Eds.; IOP Publishing Ltd.: Bristol, UK, 2016. [Google Scholar] [CrossRef]

- Kannan, S.; Ramamoorthy, M. Mechanical characterization and experimental modal analysis of 3D Printed ABS, PC and PC-ABS materials. Mater. Res. Express 2020, 7, 1–11. [Google Scholar] [CrossRef]

- Jiang, S.L.; Liao, G.X.; Xu, D.D.; Liu, F.H.; Li, W.; Cheng, Y.C.; Li, Z.X.; Xu, G.J. Mechanical properties analysis of polyetherimide parts fabricated by fused deposition modeling. High. Perform. Polym. 2018, 31, 97–106. [Google Scholar] [CrossRef]

- Fu, W.H.; Chung, D.D.L. Vibration reduction ability of polymers, particularly polymethylmethacrylate and polytetrafluoroethylene. Polym. Polym. Compos. 2001, 9, 423–426. [Google Scholar] [CrossRef]

- Hudnut, S.W.; Chung, D.D.L. Use of submicron diameter carbon filaments for reinforcement between continuous carbon fiber layers in a polymer-matrix composite. Carbon 1995, 33, 1627–1631. [Google Scholar] [CrossRef]

- Luo, X.C.; Chung, D.D.L. Vibration damping using flexible graphite. Carbon 2000, 38, 1499–1524. [Google Scholar] [CrossRef]

- Elkins, K.; Nordby, H.; Janak, C.; Gray, R.W.; Bohn, J.H.; Baird, D.G. Soft elastomers for fused deposition modelling. In Solid Freeform Fabrication Proceedings (Series), Proceedings of the 8th Solid Freeform Fabrication (SFF) Symposium, Austin, TX, USA, 11–13 August 1997; Bourell, D.L., Beaman, J.J., Crawford, R.H., Marcus, H.L., Barlow, J.W., Eds.; Univ. Texas Austin: Austin, TX, USA, 1997; pp. 441–448. [Google Scholar]

- Christ, J.F.; Aliheidari, N.; Potschke, P.; Ameli, A. Bidirectional and Stretchable Piezoresistive Sensors Enabled by Multimaterial 3D Printing of Carbon Nanotube/Thermoplastic Polyurethane Nanocomposites. Polymers 2019, 11, 11. [Google Scholar] [CrossRef]

- Noorani, R. Materials for 3D printing. In 3D Printing: Technology, Applications, and Selection; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Bahr, F.; Westkamper, E. Correlations between influencing parameters and quality properties of components produced by Fused Deposition Modeling. In Procedia CIRP, Proceedings of the 51st CIRP Conference on Manufacturing Systems (CIRP CMS), Stockholm, Sweden, 16–18 May 2018; Wang, L., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1214–1219. [Google Scholar] [CrossRef]

- Konatowski, S.; Golgowski, M. Road surface hazard warning system for vehicle drivers. In Proceedings of the 2018 14th International Conference on Advanced Trends in Radioelectronics, Telecommunications and Computer Engineering (TCSET), Lviv, Ukraine, 20–24 February 2018; IEEE: New York, NY, USA, 2018; pp. 421–425. [Google Scholar]

- Bittel, A.; Elazzazi, A.; Bittel, D. Accuracy and Precision of an Accelerometer-Based Smartphone App Designed to Monitor and Record Angular Movement over Time. Telemed. E-Health 2016, 22, 302–309. [Google Scholar] [CrossRef]

- Mobark, M.; Chuprat, S.; Mantoro, T. Improving the accuracy of complex activities recognition using accelerometer-embedded mobile phone classifiers. In Proceedings of the 2017 Second International Conference on Informatics and Computing (ICIC), Jayapura, Indonesia, 1–3 November 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Alberts, J.; Hirsch, J.; Koop, M.; Schindler, D.; Kana, D.; Linder, S.; Campbell, S.; Thota, A. Using Accelerometer and Gyroscopic Measures to Quantify Postural Stability. J. Athl. Train. 2015, 50, 578–588. [Google Scholar] [CrossRef] [PubMed]

- Allmendinger, R.; Siron, C.; Scott, C. Structural data collection with mobile devices: Accuracy, redundancy, and best practices. J. Struct. Geol. 2017, 102, 98–112. [Google Scholar] [CrossRef]

- Ibrahim, A.; Eltawil, A.; Na, Y.; El-Tawil, S. Accuracy Limits of Embedded Smart Device Accelerometer Sensors. IEEE Trans. Instrum. Meas. 2020, 69, 5488–5496. [Google Scholar] [CrossRef]

- Google Play Store. BOSCH iNVH. Available online: https://play.google.com/store/apps/details?id=com.bosch.nvh_analysis&hl=pl&gl=US (accessed on 5 June 2021).

- Phyphox Sensor Database. Available online: https://phyphox.org/sensordb/ (accessed on 5 June 2021).

- Szymczyk, A.; Nastalczyk, J.; Sablong, R.J.; Roslaniec, Z. The influence of soft segment length on structure and properties of poly(trimethylene terephthalate)-block-poly(tetrametylene oxide) segmented random copolymers. In Proceedings of the 10th International Conference on Polymers for Advanced Technologies (PAT 2009), Jerusalem, Israel, 11–14 October 2009; Wiley: Hoboken, NJ, USA, 2009; pp. 72–83. [Google Scholar] [CrossRef]

- Gorce, J.N.; Hellgeth, J.W.; Ward, T.C. Mechanical hysteresis of a polyether polyurethane thermoplastic elastomer. Polym. Eng. Sci. 1993, 33, 1170–1176. [Google Scholar] [CrossRef]

- Adams, D.J.; Topham, P.D. Assembly of Block Copolymers. In Supramolecular Chemistry: From Molecules to Nanomaterials; Steed, J.W., Gale, P.A., Eds.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; Volume 7, pp. 3235–3253. [Google Scholar]

- Piesowicz, E.; Paszkiewicz, S.; Szymczyk, A. Phase Separation and Elastic Properties of Poly(Trimethylene Terephthalate)-block-poly(Ethylene Oxide) Copolymers. Polymers 2016, 8, 237. [Google Scholar] [CrossRef]

- Sperling, L.H. Introduction to Physical Polymer Science, 4th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Helal, E.; Demarquette, N.R.; Amurin, L.G.; David, E.; Carastan, D.J.; Frechette, M. Styrenic block copolymer-based nanocomposites: Implications of nanostructuration and nanofiller tailored dispersion on the dielectric properties. Polymer 2015, 64, 139–152. [Google Scholar] [CrossRef]

- Naskar, K.; Gohs, U.; Wagenknecht, U.; Heinrich, G. PP-EPDM thermoplastic vulcanisates (TPVs) by electron induced reactive processing. Express Polym. Lett. 2009, 3, 677–683. [Google Scholar] [CrossRef]

- Puskas, J.E.; Antony, P.; El Fray, M.; Altstadt, V. The effect of hard and soft segment composition and molecular architecture on the morphology and mechanical properties of polystyrene-polyisobutylene thermoplastic elastomeric block copolymers. Eur. Polym. J. 2003, 39, 2041–2049. [Google Scholar] [CrossRef]

- Puskas, J.E.; Dos Santos, L.M.; Fischer, F.; Gotz, C.; El Fray, M.; Altstadt, V.; Tomkins, M. Fatigue testing of implantable specimens: Effect of sample size and branching on the dynamic fatigue properties of polyisobutylene-based biomaterials. Polymer 2009, 50, 591–597. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Inukai, S.; Noguchi, T.; Niihara, K.; Oyaizu, N.; Yamada, E.; Inagaki, S.; Takeuchi, K.; Endo, M. Properties and Interfacial Structure Analysis of MWCNT/ESBS Composites. Ind. Eng. Chem. Res. 2015, 54, 8690–8698. [Google Scholar] [CrossRef]

- Praveen, S.; Bahadur, J.; Yadav, R.; Billa, S.; Patro, T.U.; Rath, S.K.; Ratna, D.; Patri, M. Tunable viscoelastic and vibration damping properties of a segmented polyurethane synergistically reinforced with carbon black and anisotropic additives. Appl. Acoust. 2020, 170, 1–12. [Google Scholar] [CrossRef]

- Zheng, N.; Wang, Q.Z.; Cui, C.X.; Yin, F.X.; Jiao, Z.X.; Li, H.Z. Fabrication and damping behaviors of novel polyurethane/TiNiCu composites. Phys. B-Condens. Matter 2020, 582, 1–8. [Google Scholar] [CrossRef]

- Bhowmick, A.K.; Stephens, H.L. Handbook of Elastomers, 2nd ed.; Marcel Dekker, Inc.: New York, NY, USA, 2001. [Google Scholar]

- Broza, G.; Schulte, K. Melt processing and filler/matrix interphase in carbon nanotube reinforced poly(ether-ester) thermoplastic elastomer. In Polymer Engineering and Science, Proceedings of the 15th Annual Polychar World Forum on Advanced Materials, Buzios, Brazil, 16–20 April 2007; Wiley-Blackwell: Hoboken, NJ, USA, 2007; pp. 2033–2038. [Google Scholar] [CrossRef]

- Le, H.H.; Heidenreich, D.; Kolesov, I.S.; Ilisch, S.; Radusch, H.J. Effect of Carbon Black Addition and Its Phase Selective Distribution on the Stress Relaxation Behavior of Filled Thermoplastic Vulcanizates. J. Appl. Polym. Sci. 2010, 117, 2622–2634. [Google Scholar] [CrossRef]

- Zhao, Y.S.; Ning, N.Y.; Hu, X.; Li, Y.H.; Chen, F.; Fu, Q. Processing temperature dependent mechanical response of a thermoplastic elastomer with low hard segment. Polymer 2012, 53, 4310–4317. [Google Scholar] [CrossRef]

- Wang, J.; Xiang, J.Y.; Lin, H.; Wang, K.; Yao, S.; Peng, Y.; Rao, Y.N. Effects of Scanning Strategy and Printing Temperature on the Compressive Behaviors of 3D Printed Polyamide-Based Composites. Polymers 2020, 12, 1783. [Google Scholar] [CrossRef] [PubMed]

- Chaudhry, M.S.; Czekanski, A. Evaluating FDM Process Parameter Sensitive Mechanical Performance of Elastomers at Various Strain Rates of Loading. Materials 2020, 13, 3202. [Google Scholar] [CrossRef]

- Alvarez, K.L.; Lagos, R.F.; Aizpun, M. Investigating the influence of infill percentage on the mechanical properties of fused deposition modelled ABS parts. Ing. E Investig. 2016, 36, 110–116. [Google Scholar] [CrossRef]

- Kumar, A.; Verma, S.; Jeng, J.Y. Supportless Lattice Structures for Energy Absorption Fabricated by Fused Deposition Modeing. 3D Print. Addit. Manuf. 2020, 7, 85–96. [Google Scholar] [CrossRef]

- Amin, A.F.M.S.; Lion, A.; Hofer, P. Effect of temperature history on the mechanical behaviour of a filler-reinforced NR/BR blend: Literature review and critical experiments. Z. Angew. Math. Mech. 2010, 90, 347–369. [Google Scholar] [CrossRef]

- Ren, Y.M.; Zou, H.; Wang, S.J.; Liu, J.Y.; Gao, D.L.; Wu, C.J.; Zhang, S.J. Effect of annealing on microstructure and tensile properties of polypropylene cast film. Colloid. Polym. Sci. 2018, 296, 41–51. [Google Scholar] [CrossRef]

- El Fray, M.; Altstadt, V. Fatigue behaviour of multiblock thermoplastic elastomers. 3. Stepwise increasing strain test of poly (aliphatic/aromatic-ester) copolymers. Polymer 2004, 45, 263–273. [Google Scholar] [CrossRef]

- Jin, Y.F.; Wan, Y.; Zhang, B.; Liu, Z.Q. Modeling of the chemical finishing process for polylactic acid parts in fused deposition modeling and investigation of its tensile properties. J. Mater. Process. Technol. 2017, 240, 233–239. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Veniali, F. Finishing of Fused Deposition Modeling parts by CNC machining. Rob. Comput. Integr. Manuf. 2016, 41, 92–101. [Google Scholar] [CrossRef]

| Model Symbol | Model Geometry | Infill Density, % | Remarks |

|---|---|---|---|

| C100 | Cylinder | 100 | Infill type—linear |

| C50 | Cylinder | 50 | Infill type—linear |

| C00 | Cylinder | 00 | Printed model walls only. |

| KP | Cube | 00 | Printed model walls only. Direction parallel to side walls. |

| KD | Cube | 00 | Printed model walls only. Direction deviated by 45 degrees from side walls (diamond) |

| PP | Pyramid | 00 | Printed model walls only. Direction parallel to side walls. |

| PD | Pyramid | 00 | Printed model walls only. Direction deviated by 45 degrees from side walls (diamond) |

| Material Property | TPE-S | TPE-U | TPE-E | TPE-V |

|---|---|---|---|---|

| Density, g/ccm | 0.9 ÷ 1.1 | 1.1 ÷ 1.3 | 1.1 ÷ 1.3 | 0.94 ÷ 1.0 |

| Tg, °C | −60 ÷ −90 | −46 ÷ −100 | −40 | −60 |

| Modulus of elasticity, MPa | 1 ÷ 11 a | 60 b | 15 ÷ 710 | 5 ÷ 8 |

| Hardness | 30 ShA ÷ 75 ShD | 60 ShA ÷ 70 ShD | 60 ShA ÷ 70 ShD | 55 ShA ÷ 50 ShD |

| Tensile strength, MPa | Low | Low to high | Low to high | Fair |

| Ultimate elongation, % | 250 ÷ 1100 | 530 b | 600 b | 530 b |

| tan δ in maximum, - | 0.8 | 0.2 ÷ 0.3 | 0.25 ÷ 0.5 | 0.35 ÷ 0.4 |

| Processing temperature, °C | 140 ÷ 185 c | 170 ÷ 190 d | 180 ÷ 260 e | 204 ÷ 232 f |

| TPE Type | Damping | Processability Issues |

|---|---|---|

| TPE-S | Addition of CB or MWCNT decreases damping (tan δ) [78] NC decreases damping (tan δ) [73] | Improved by adding polystyrene (PS) or oils [40] (p. 169). Shrinkage (0.5–2%) can occur, but can be lowered by addition of a filler |

| TPE-U, PU | Addition of graphite, aramid fiber or NC decreases damping (tan δ) [79] Addition of TiNiCu + MWCNT decreases damping, but graphite increases damping [80] | To facilitate processability by injection, molding release agents are used [81] (p. 406) |

| TPE-E | Addition of MWCNT causes decrease in damping (tan δ) [82] | Shrinkage (0.5–3%) can occur. The higher the hardness, the higher shrinkage [40] (pp. 258–259) |

| TPE-V | Addition of CB decreases tan δ value. Tan δ value depends on which phase is filled [83] | Addition of filler causes a reduction in thermoplasticity. Plasticizer increases elongation at break and improves thermoplasticity (PA-NBR) [40] (p. 184) |

| TPE-O | Addition of mineral fillers increases damping [40] (p. 192) | Hydrocarbon oils lower melt viscosity [40] (p. 192) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wojnowski, J.; Chmiel, J. Personalized Anti-Vibration Protection for Telematics Devices in Urban Freight Transport Vehicles. Energies 2021, 14, 4193. https://doi.org/10.3390/en14144193

Wojnowski J, Chmiel J. Personalized Anti-Vibration Protection for Telematics Devices in Urban Freight Transport Vehicles. Energies. 2021; 14(14):4193. https://doi.org/10.3390/en14144193

Chicago/Turabian StyleWojnowski, Jacek, and Jarosław Chmiel. 2021. "Personalized Anti-Vibration Protection for Telematics Devices in Urban Freight Transport Vehicles" Energies 14, no. 14: 4193. https://doi.org/10.3390/en14144193

APA StyleWojnowski, J., & Chmiel, J. (2021). Personalized Anti-Vibration Protection for Telematics Devices in Urban Freight Transport Vehicles. Energies, 14(14), 4193. https://doi.org/10.3390/en14144193