Fabrication and Performance Evaluation of Cold Thermal Energy Storage Tanks Operating in Water Chiller Air Conditioning System

Abstract

:1. Introduction

2. Methodology

2.1. Mathematical Equations

2.2. Model Design

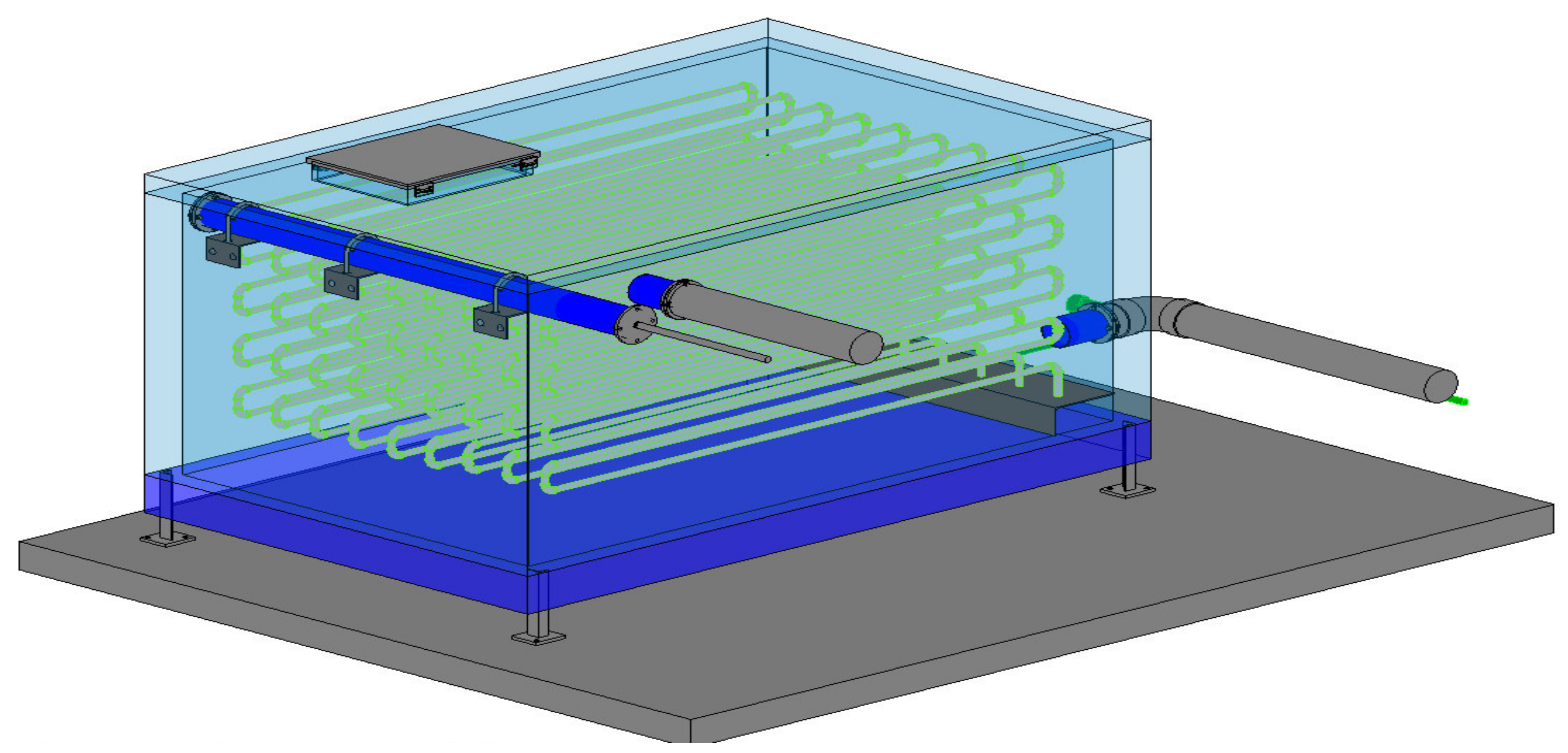

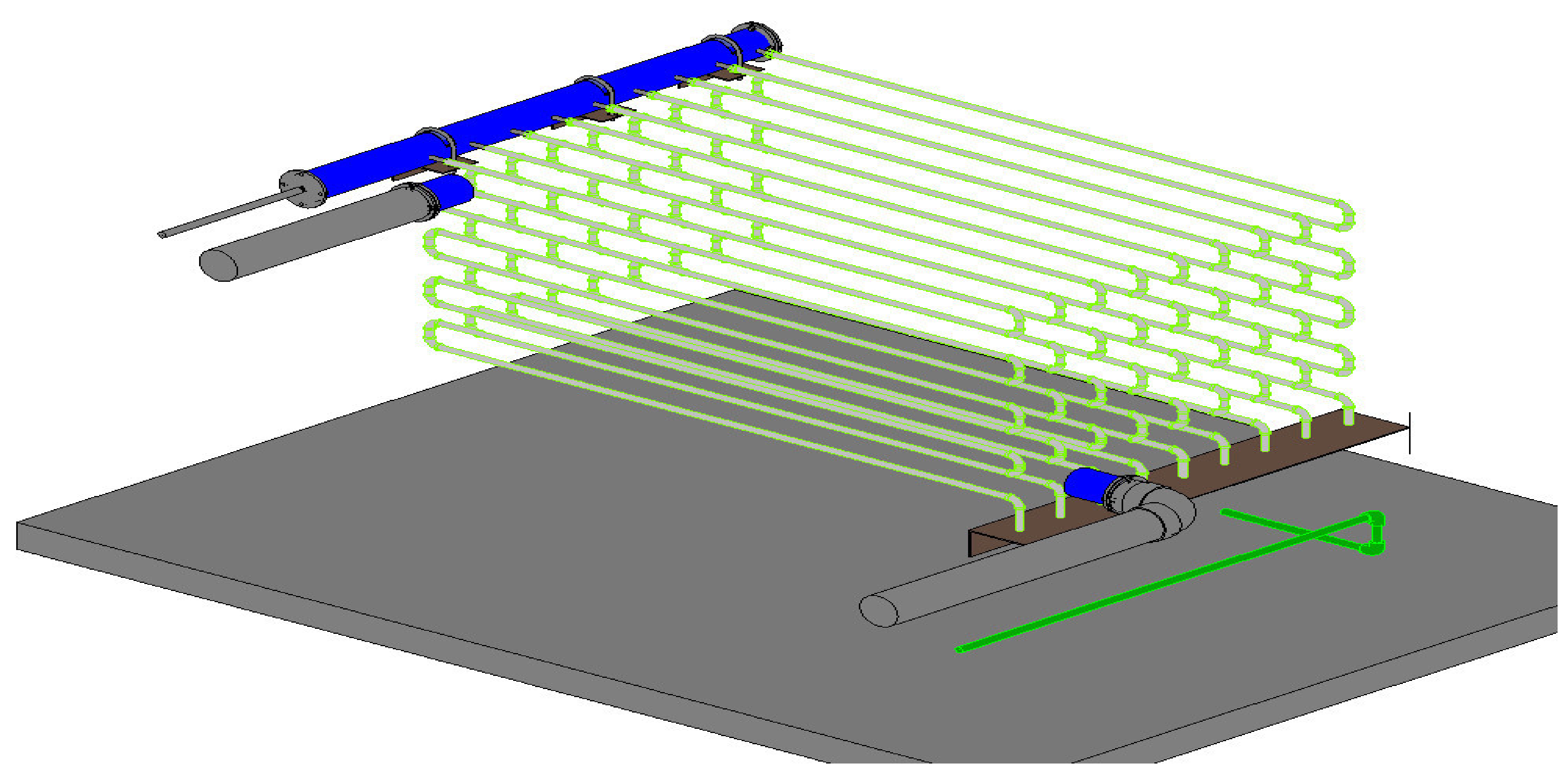

2.2.1. Cold Storage Tank

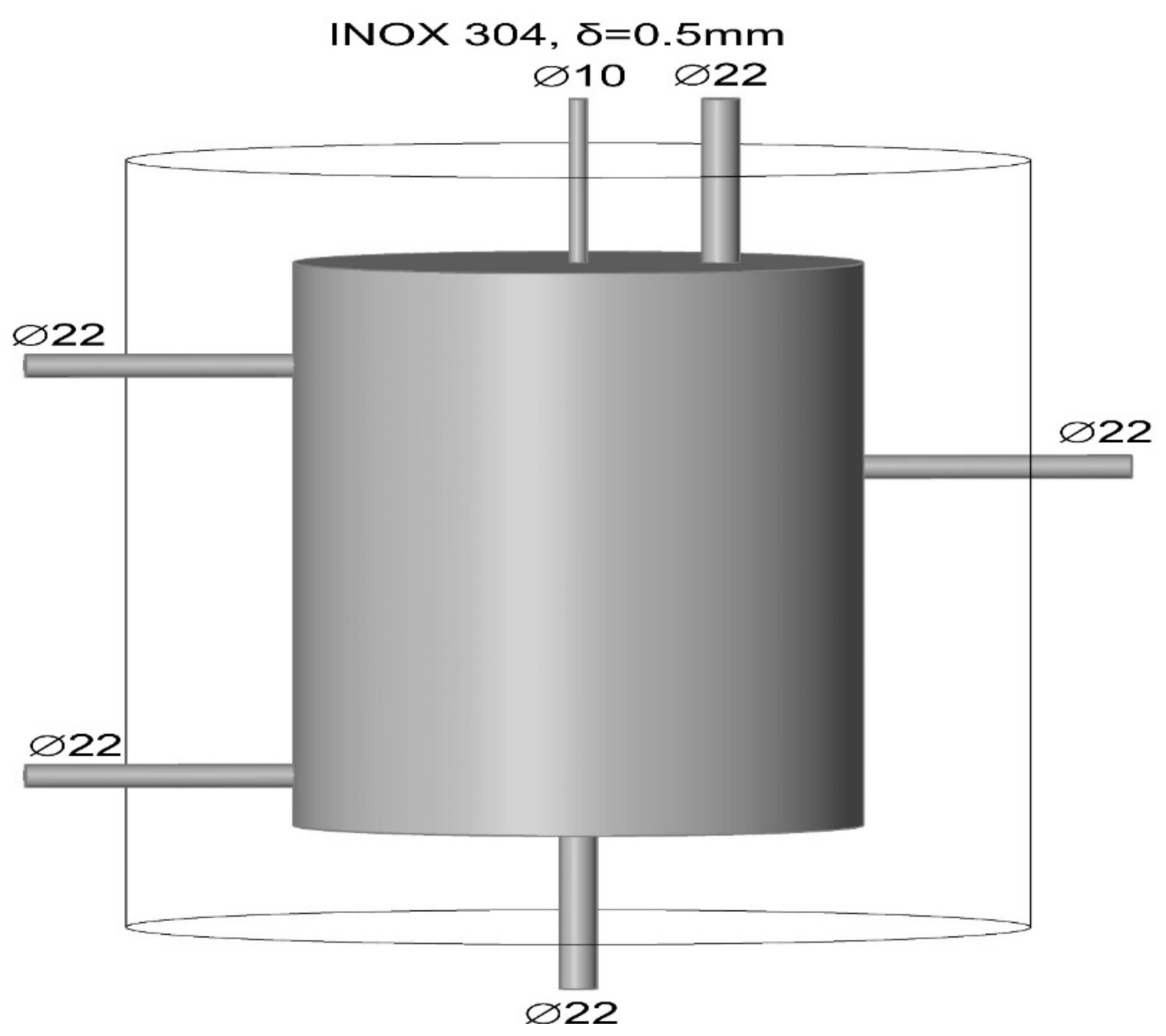

2.2.2. Thermal Storage Tank

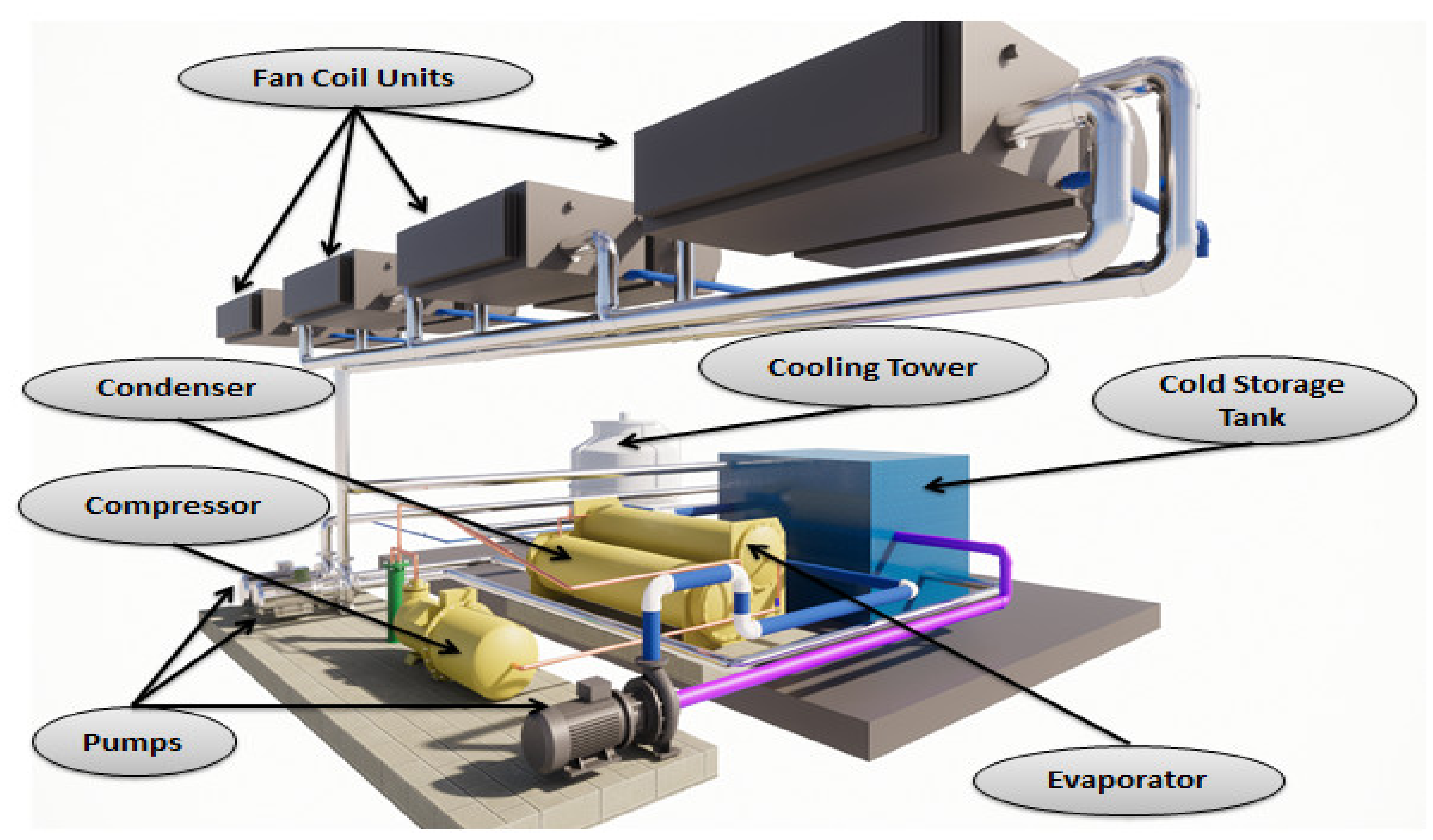

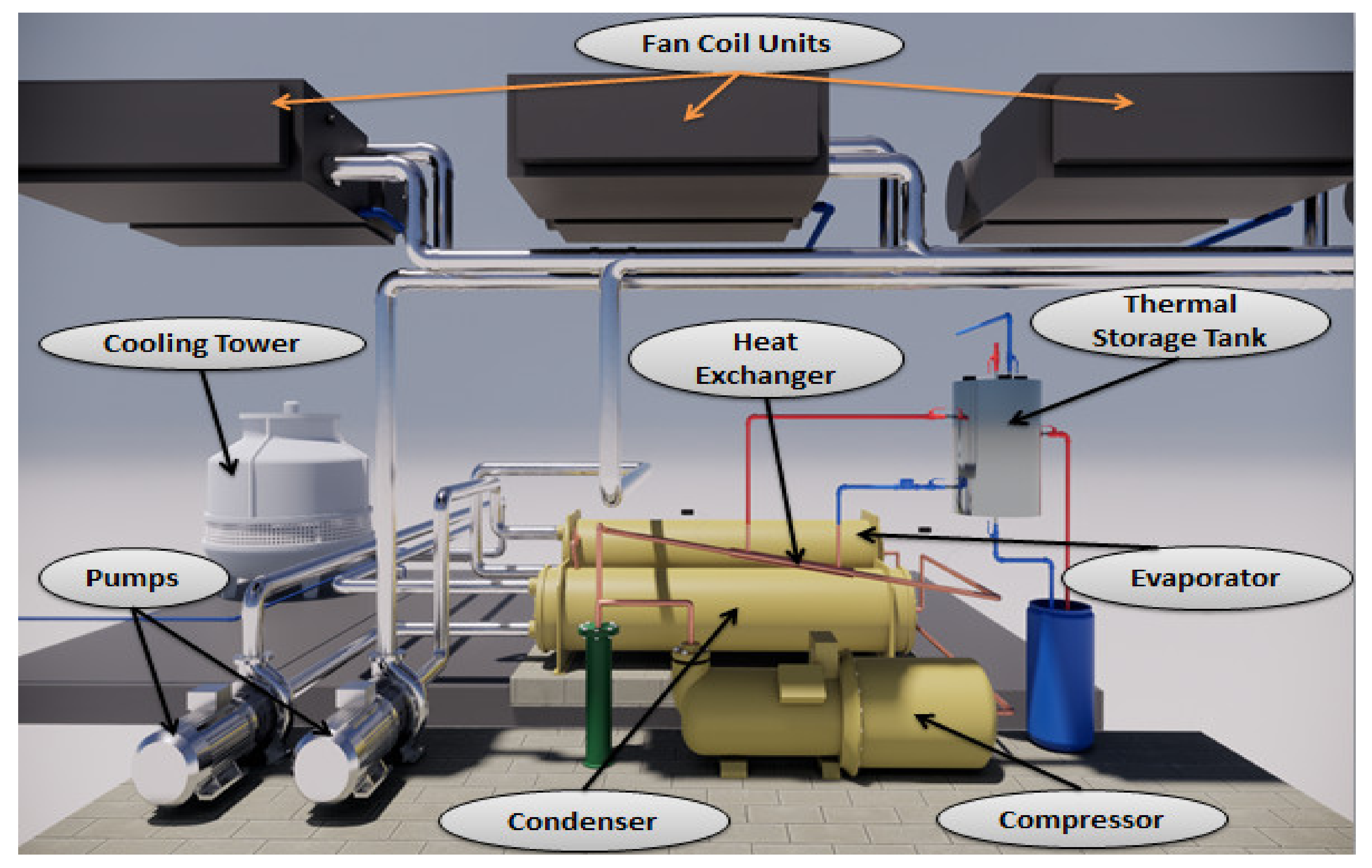

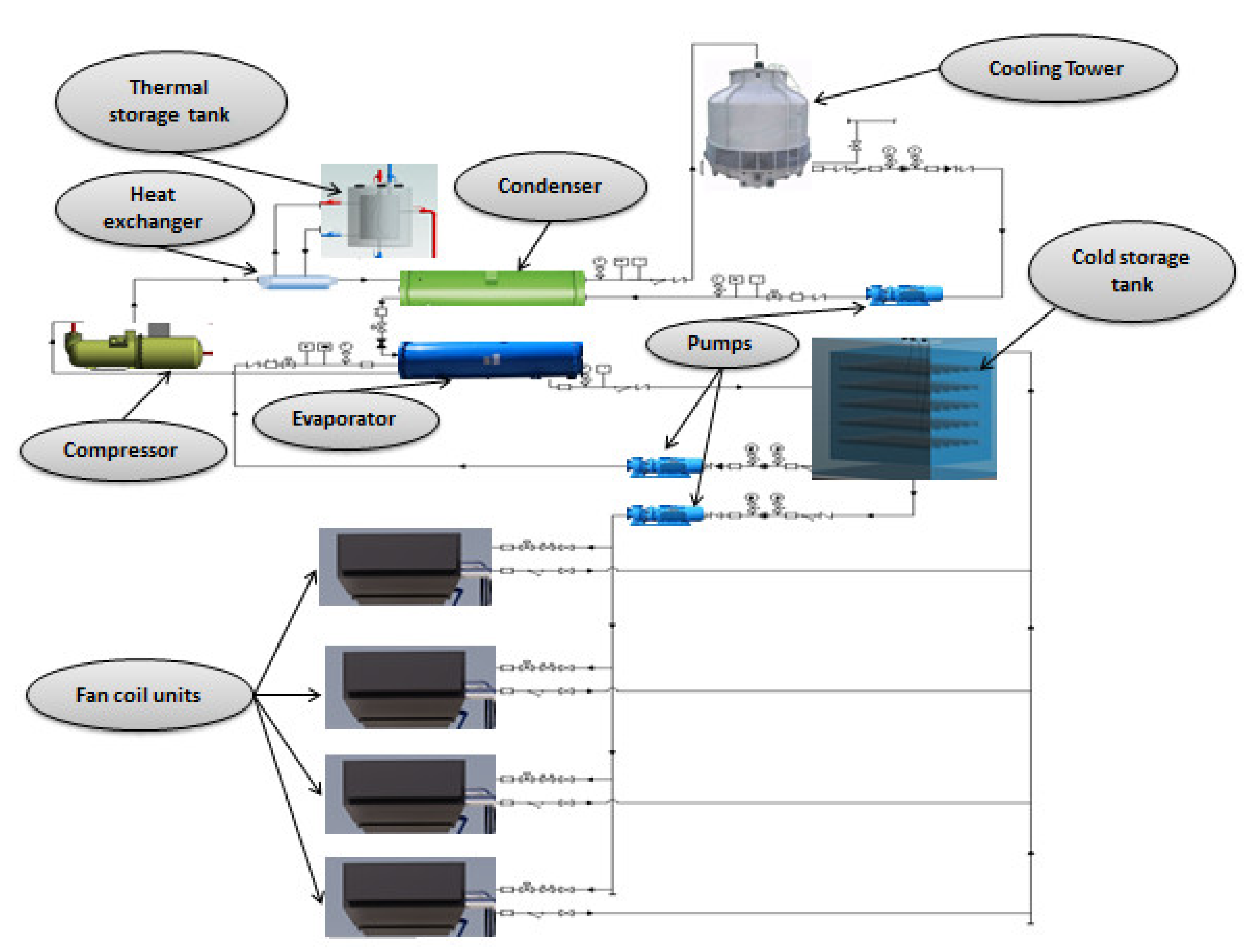

2.2.3. System Installation

2.2.4. Experimental Setup

3. Results and Discussion

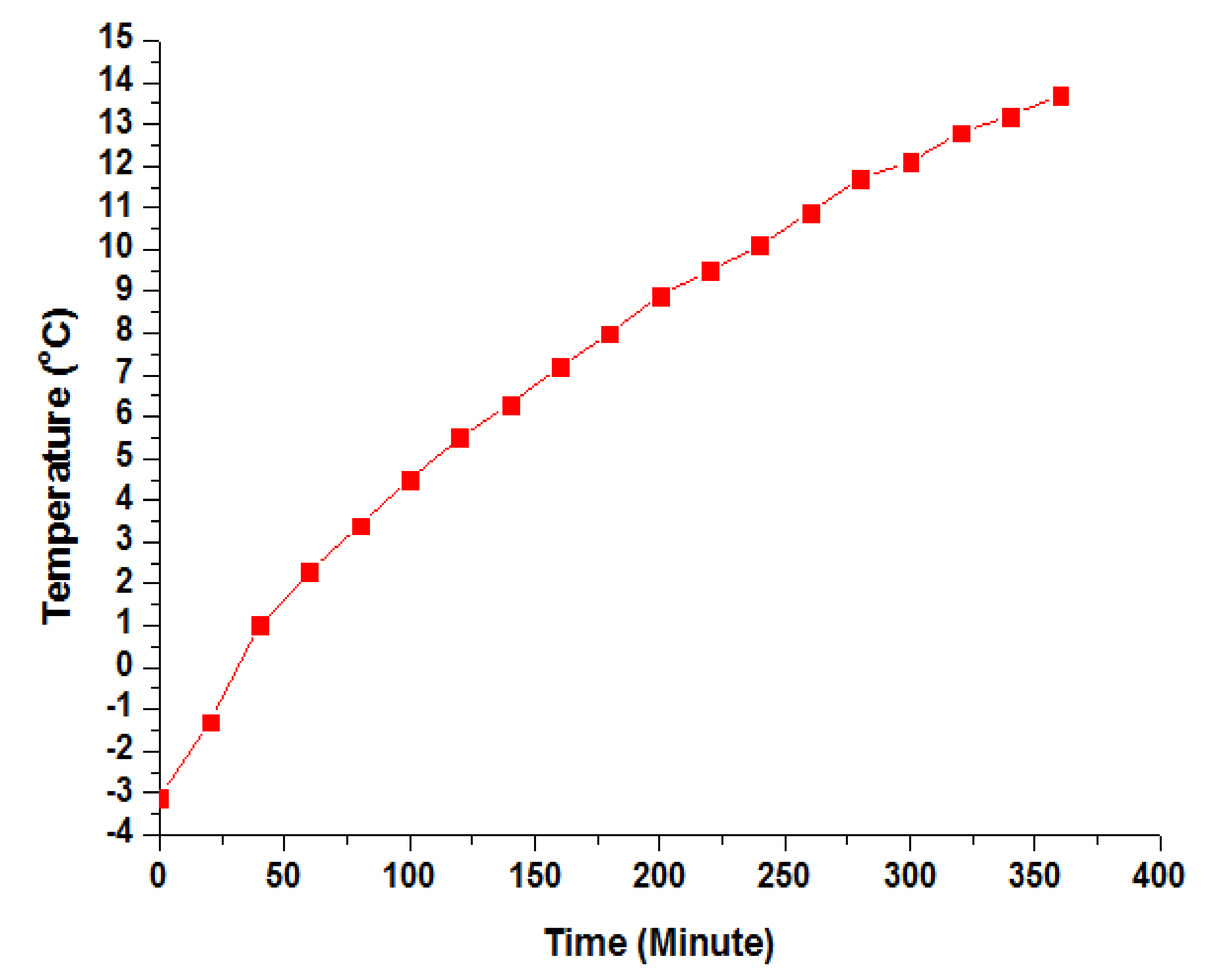

3.1. Changes in Cold Storage Material Temperature during Charging Process

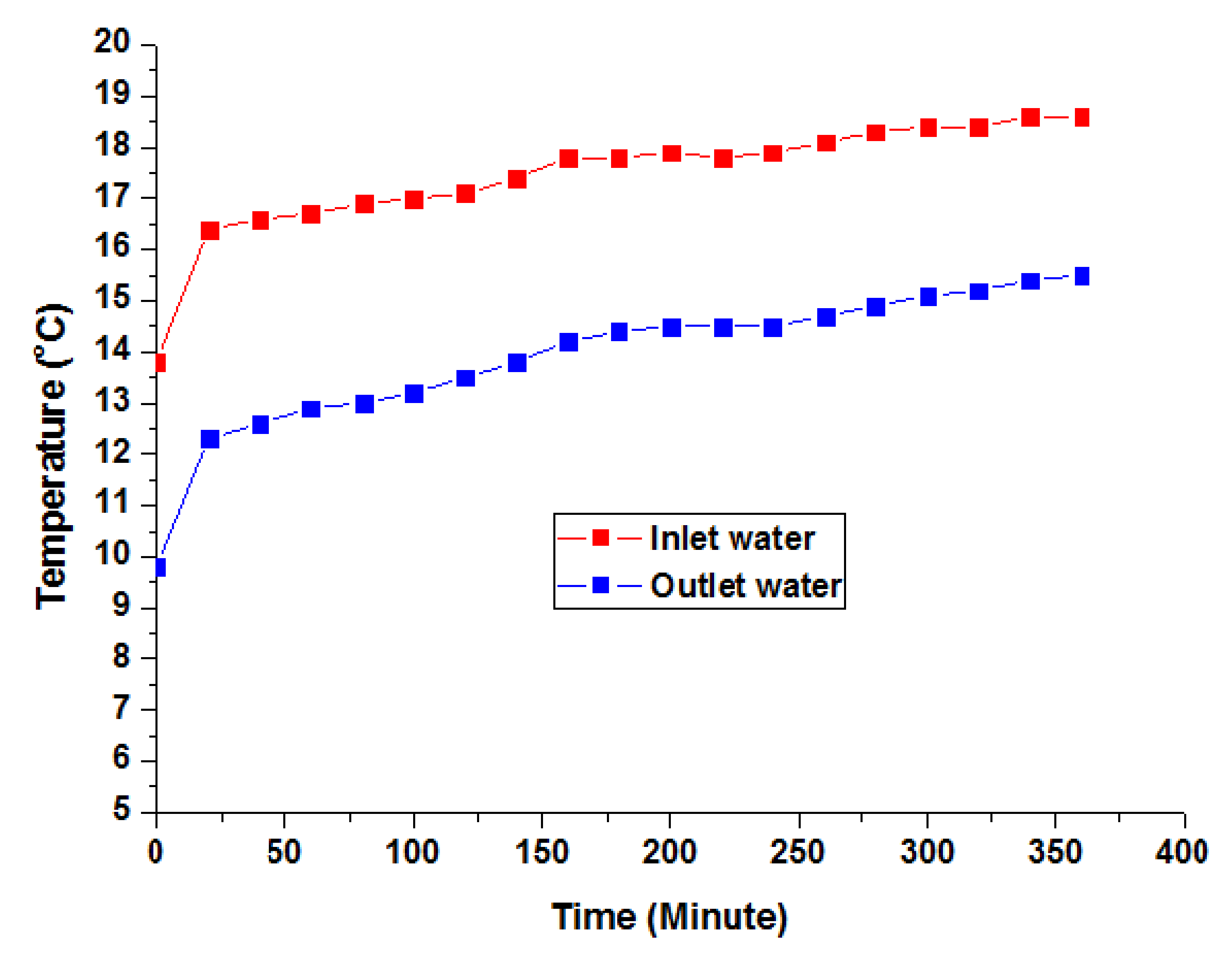

3.2. Changes in Temperatures of Heat Transfer Fluid and Cold Storage Material during Discharging Process

3.3. Changes in Air Temperature Leaving the FCU during Discharging Process

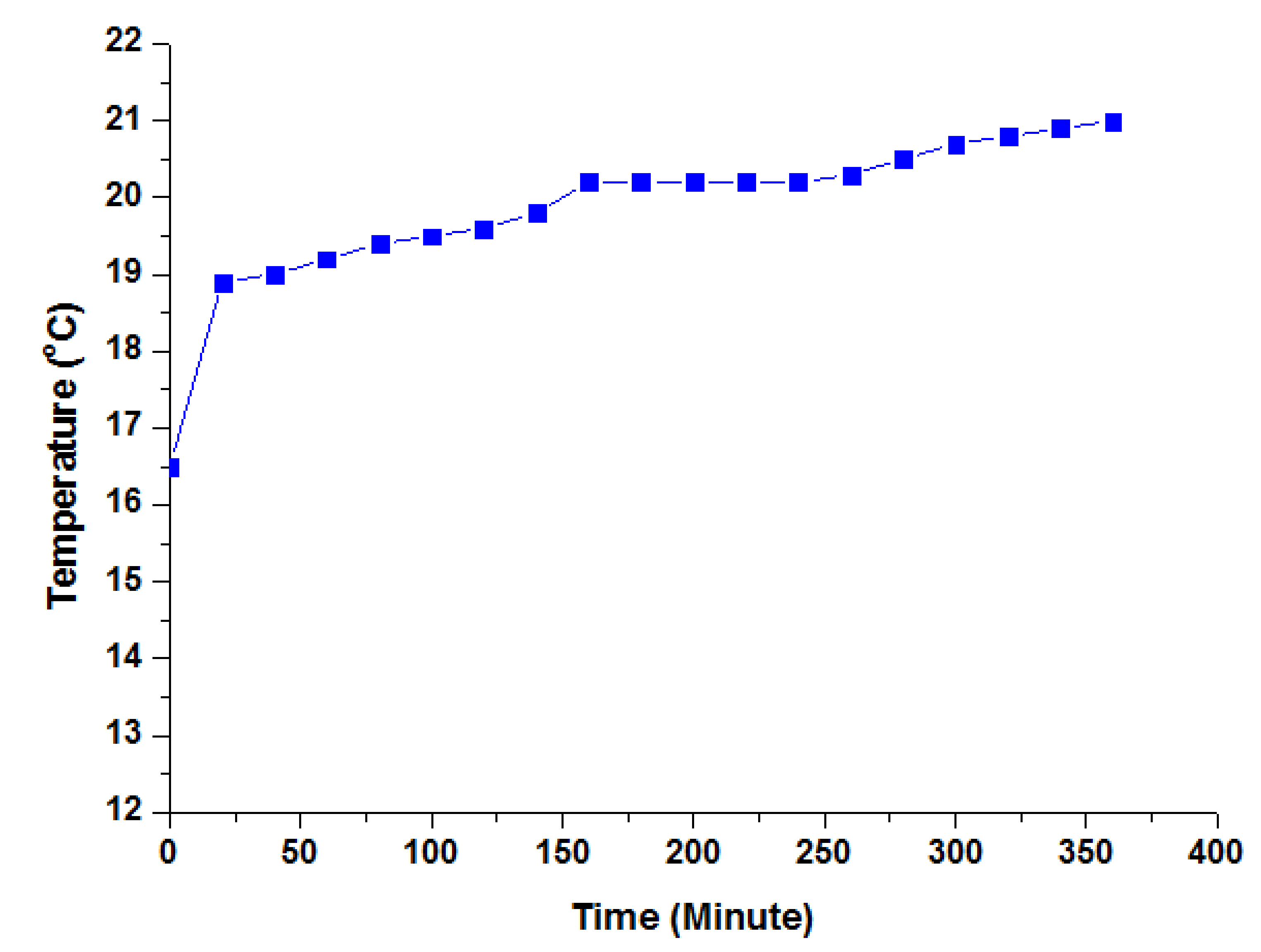

3.4. The Temperature Changes of Water in the Thermal Storage Tank

4. Conclusions

- The heat transfer process in the heat exchanger of the cold storage tank was acceptable. The temperature difference of heat transfer fluid between the inlet and outlet of the heat exchanger ranged from 3 °C to 4 °C.

- A cold storage system was successfully fabricated and operated, assisting the air conditioner in cooling the internship workshop space at the university with an area of 400 m2, thereby contributing to a remarkable reduction in operating costs during the daytime.

- To recover the waste heat from the compressor of the water chiller, a thermal storage system was successfully built and operated, providing 50 L of hot water at a temperature of 60 °C per hour to serve the everyday needs of school students. The aim of this study was to design and produce a waste heat recovery thermal storage system to save energy, reduce operating costs, and mitigate environmental pollution. Therefore, further research and development of the thermal storage system are essential for it to become increasingly applicable.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Cp | Specific heat at constant pressure (kJ·kg−1·K−1) |

| F | Heat transfer surface area (m2) |

| h | Convection heat transfer coefficient (W·m−2 K−1) |

| M | Mass flow rate (g·s−1) |

| p | Pressure (Pa) |

| Q | Heat transfer rate (W) |

| T | Temperature (K) |

| U | Overall heat transfer coefficient (W·m−2·K−1) |

| ΔTLM | Logarithmic mean temperature difference (K) |

| λ | Thermal conductivity (W·m−2.K) |

| a | Thermal diffusivity (m2/s) |

| Re | Reynolds number |

| Pr | Prandtl number |

| Prs | Prandtl number at surface |

| Nu | Nusselt number |

| Ra | Rayleigh number |

| Gr | Grashof number |

| C | Coefficient |

| m | Exponent of Reynolds number |

| n | Exponent of Prandtl number |

| β | Volumetric coefficient of expansion (K−1) |

| Density (kg.m−3) | |

| μ | Viscosity (N.s.m−2) |

| ν | Kinematic viscosity (m2.s−1) |

| t’ | Heat transfer fluid inlet temperature |

| t’’ | Heat transfer fluid outlet temperature |

| ts2 | Outer surface temperature of pipe |

| tf2 | Cold storage material temperature |

| d1 | Inner diameter (mm) |

| d2 | Outer diameter (mm) |

References

- Martin, V.; He, B.; Setterwall, F. Direct contact PCM–water cold storage. Appl. Energy 2010, 87, 2652–2659. [Google Scholar] [CrossRef]

- Ruddell, B.L.; Salamanca, F.; Mahalov, A. Reducing a semiarid city’s peak electrical demand using distributed cold thermal energy storage. Appl. Energy 2014, 134, 35–44. [Google Scholar] [CrossRef]

- Wang, X.; Dennis, M. Characterisation of thermal properties and charging performance of semi-clathrate hydrates for cold storage applications. Appl. Energy 2016, 167, 59–69. [Google Scholar] [CrossRef]

- Xie, Y.; Li, G.; Liu, D.; Liu, N.; Qi, Y.; Liang, D.; Guo, K.; Fan, S. Experimental study on a small scale of gas hydrate cold storage apparatus. Appl. Energy 2010, 87, 3340–3346. [Google Scholar] [CrossRef]

- Zhai, X.Q.; Wang, X.L.; Wang, T.; Wang, R.Z. A review on phase change cold storage in air-conditioning system: Materials and applycation. Renew. Sustain. Energy Rev. 2013, 22, 108–120. [Google Scholar] [CrossRef]

- Cheng, X.; Zhai, X. Thermal performance analysis and optimization of a cascaded packed bed cool thermal energy storage unit using multiple phase change materials. Appl. Energy 2018, 215, 566–576. [Google Scholar] [CrossRef]

- Melone, L.; Altomare, L.; Cigada, A.; De Nardo, L. Phase change material cellulosic composites for the cold storage of perishable products: From material preparation to computational evaluation. Appl. Energy 2012, 89, 339–346. [Google Scholar] [CrossRef]

- Vitorino, N.; Abrantes, J.C.; Frade, J.R. Gelled graphite/gelatin composites for latent heat cold storage. Appl. Energy 2013, 104, 890–897. [Google Scholar] [CrossRef]

- Murphy, M.D.; O’Mahony, M.J.; Upton, J. Comparison of control systems for the optimisation of ice storage in a dynamic real time electricity pricing environment. Appl. Energy 2015, 149, 392–403. [Google Scholar] [CrossRef]

- Pu, J.; Liu, G.; Feng, X. Cumulative exergy analysis of ice thermal storage air conditioning system. Appl. Energy 2012, 93, 564–569. [Google Scholar] [CrossRef]

- Wang, C.; He, Z.; Li, H.; Wennerstern, R.; Sun, Q. Evaluation on performance of a phase change material based cold storage house. Energy Procedia 2017, 105, 3947–3952. [Google Scholar] [CrossRef]

- Lee, W.S.; Chen, Y.T.; Wu, T.H. Optimization for ice-storage air conditioning system using particle swarm algorithm. Appl. Energy 2009, 86, 1589–1595. [Google Scholar] [CrossRef]

- Alekseiko, L.N.; Slesarenko, V.V.; Yudakov, A.A. Combination of wastewater treatment plants and heat pumps. Pac. Sci. Rev. 2014, 16, 36–39. [Google Scholar] [CrossRef] [Green Version]

- Cipolla, S.S.; Maglionico, M. Heat recovery from urban wastewater: Analysis of the variability of flow rate and temperature in the sewer of Bologna, Italy. Energy Procedia 2014, 45, 288–297. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Fan, X.; Zhang, W.; Wang, Z. Utilization Potential and Economic Feasibility Analysis of Bathing Sewage and its Heat Generated in Colleges and Universities. Energy Procedia 2017, 142, 1244–1250. [Google Scholar] [CrossRef]

- Culha, O.; Gunerhan, H.; Biyik, E.; Ekren, O.; Hepbasli, A. Heat exchanger applications in wastewater source heat pumps for buildings: A key review. Energy Build. 2015, 104, 215–232. [Google Scholar] [CrossRef]

- Hepbasli, A.; Biyik, E.; Ekren, O.; Gunerhan, H.; Araz, M. A key review of wastewater source heat pump (WWSHP) systems. Energy Convers. Manag. 2014, 88, 700–722. [Google Scholar] [CrossRef]

- Thulukkanam, K. Heat Exchanger Design Handbook, 2nd ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2013. [Google Scholar]

- Kutz, M. Heat Transfer Calculations; MCGraw-Hill: New York, NY, USA, 2005. [Google Scholar]

- Turns, S.R. Thermal Fluid Sciences: An Intergrated Approach; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, X.V. Fabrication and Performance Evaluation of Cold Thermal Energy Storage Tanks Operating in Water Chiller Air Conditioning System. Energies 2021, 14, 4159. https://doi.org/10.3390/en14144159

Nguyen XV. Fabrication and Performance Evaluation of Cold Thermal Energy Storage Tanks Operating in Water Chiller Air Conditioning System. Energies. 2021; 14(14):4159. https://doi.org/10.3390/en14144159

Chicago/Turabian StyleNguyen, Xuan Vien. 2021. "Fabrication and Performance Evaluation of Cold Thermal Energy Storage Tanks Operating in Water Chiller Air Conditioning System" Energies 14, no. 14: 4159. https://doi.org/10.3390/en14144159

APA StyleNguyen, X. V. (2021). Fabrication and Performance Evaluation of Cold Thermal Energy Storage Tanks Operating in Water Chiller Air Conditioning System. Energies, 14(14), 4159. https://doi.org/10.3390/en14144159