Evaluation of New PCM/PV Configurations for Electrical Energy Efficiency Improvement through Thermal Management of PV Systems

Abstract

:1. Introduction

2. Methodology

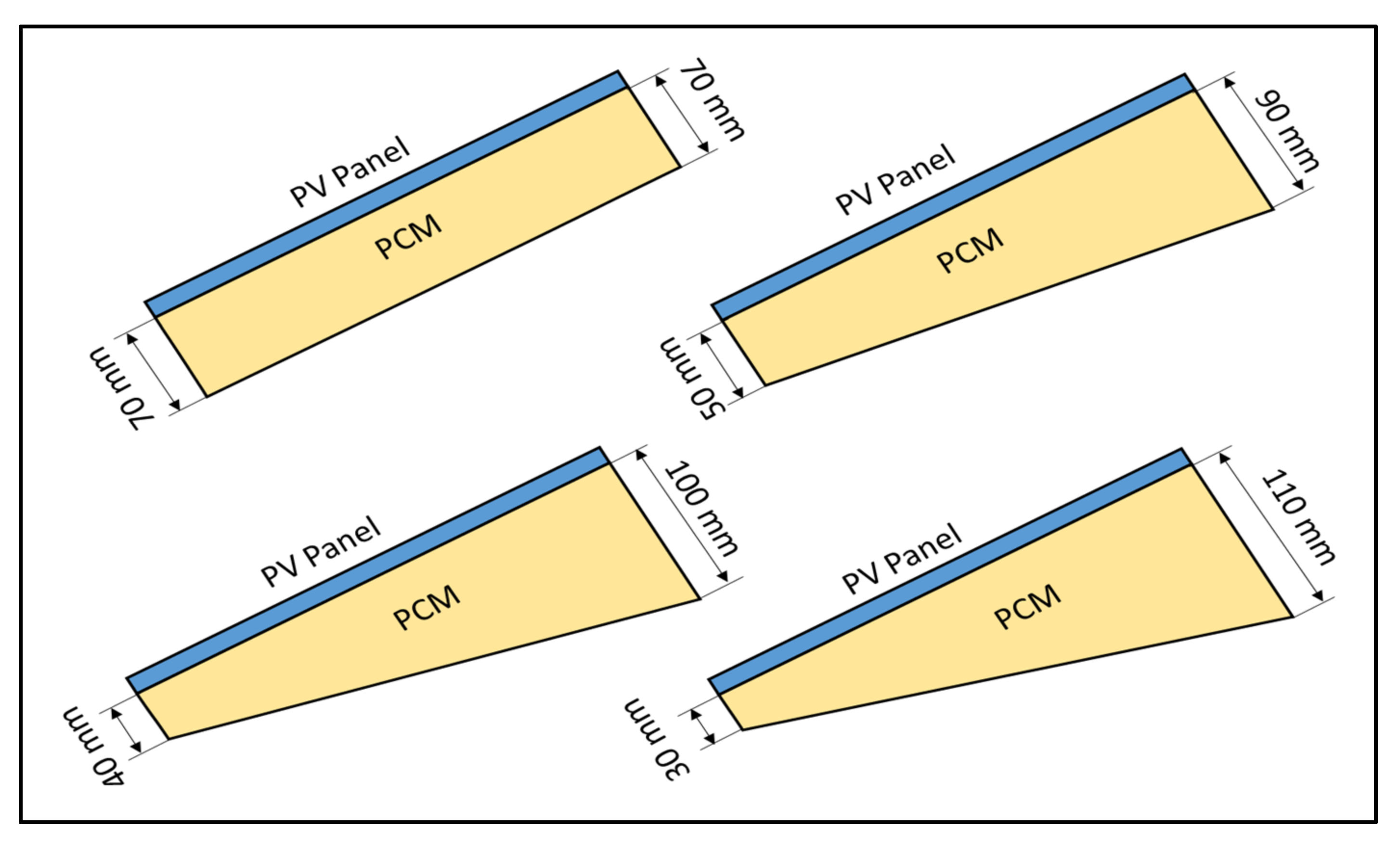

2.1. System Design

2.2. PV/PCM System Model

- The thermal resistance between the PV layers is negligible.

- There is a uniform heat flux distribution on the PV surface.

- Heat leaks/gains through the insulation are negligible.

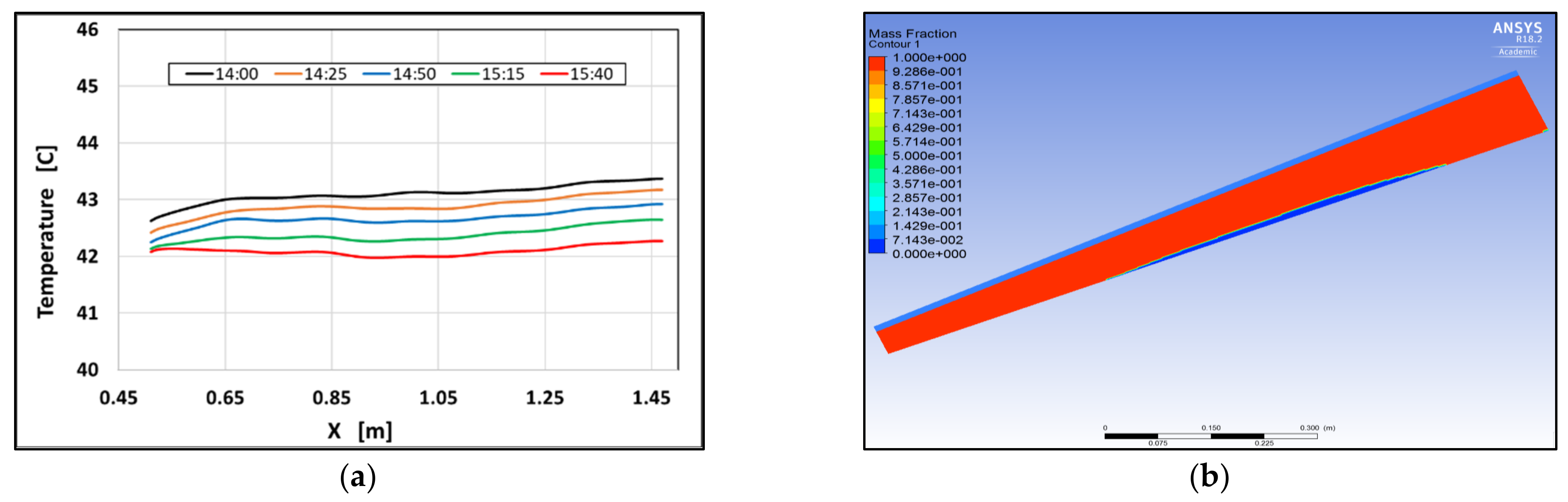

3. Model Validation

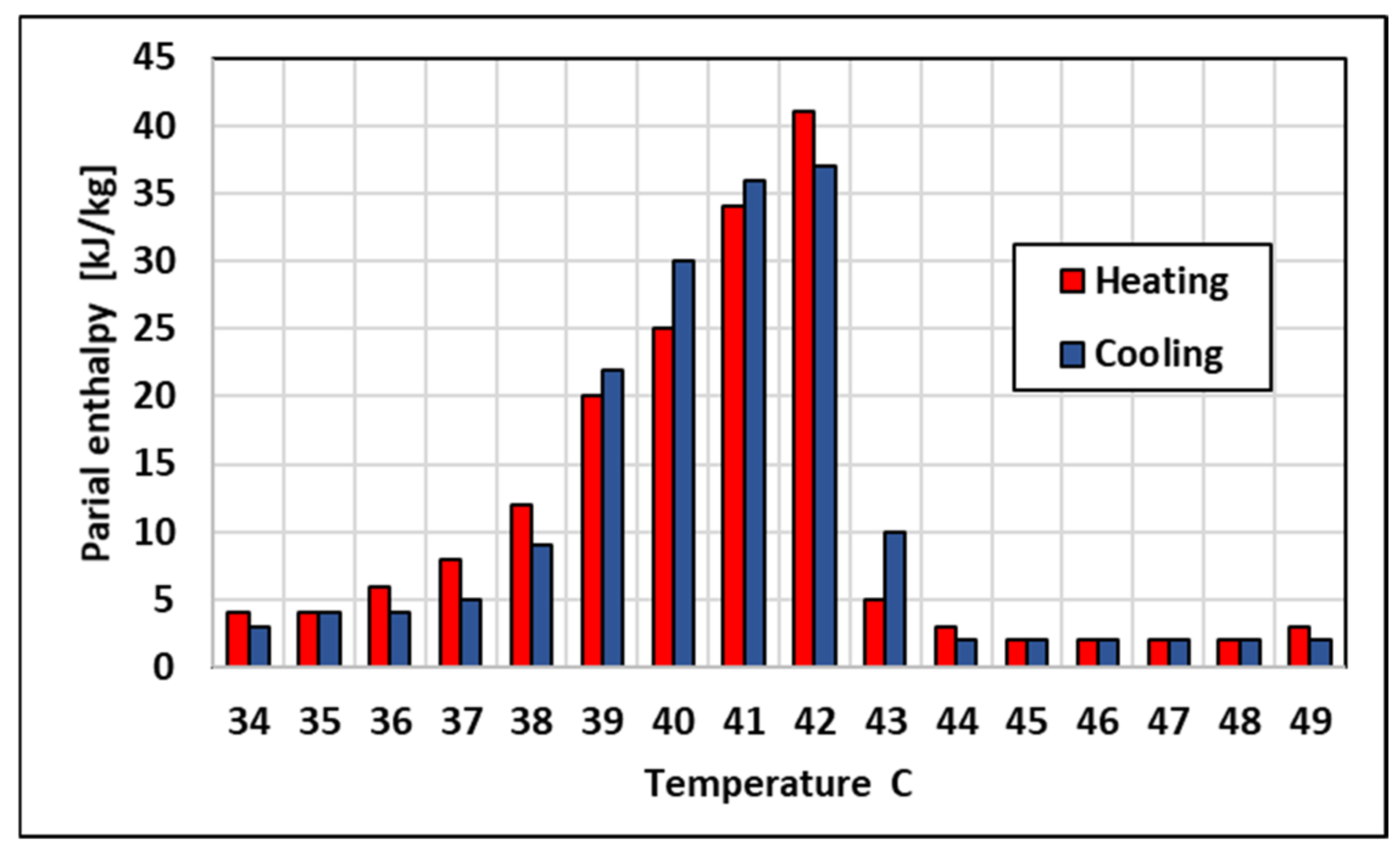

4. Result and Discussion

5. Conclusions

- The CFD model demonstrated good agreement with the experimental work found in the literature with a maximum temperature difference of less than 2 °C.

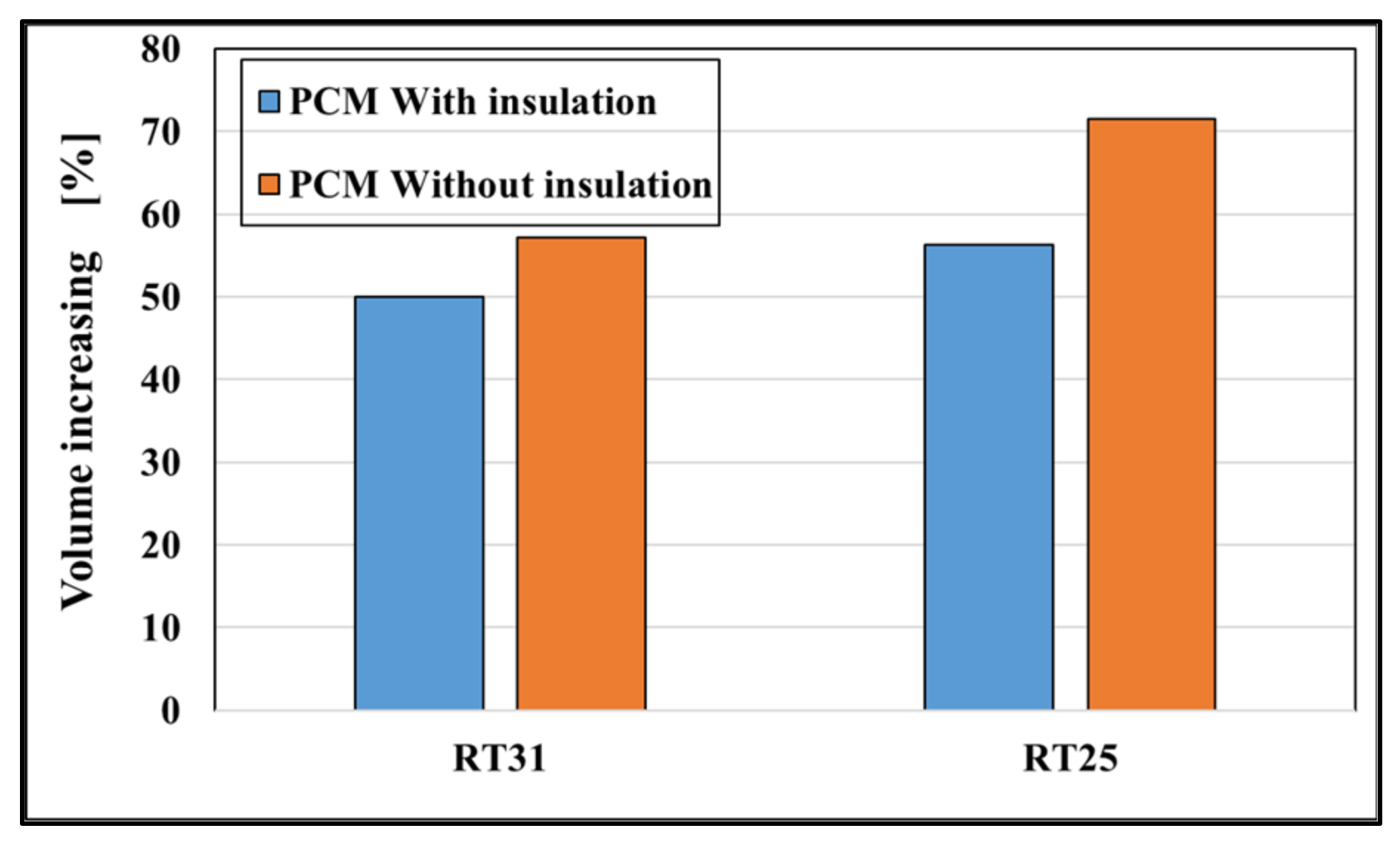

- Insulation in the PCM container will increase the required amount of the PCM, no matter the melting temperature of the PCM.

- The rectangular shape (Case 1) and the optimum depth/height of the PCM containers with a sufficient amount of PCM to meet the cooling load during the daytime were 70 mm, 110 mm, and 120 when RT42, RT31, and RT25, respectively, were used in cases without insulation. With insulation, the optimum depth/height of the PCM containers were 80 mm, 120 mm, and 125 mm, respectively.

- PCMs with a lower melting temperature require more amounts of PCM when there is no significant difference in the latent heat. Compared to RT42, RT31 and RT25 showed an increase in the PCM amount by 56% and 72%, respectively.

- Regarding the PCM container geometry, trapezoid container configurations (Cases 2, 3, and 4) showed a considerably better cooling performance due to their lower variation of PV temperature. This enhances the performance of the PV systems by reducing mismatched losses.

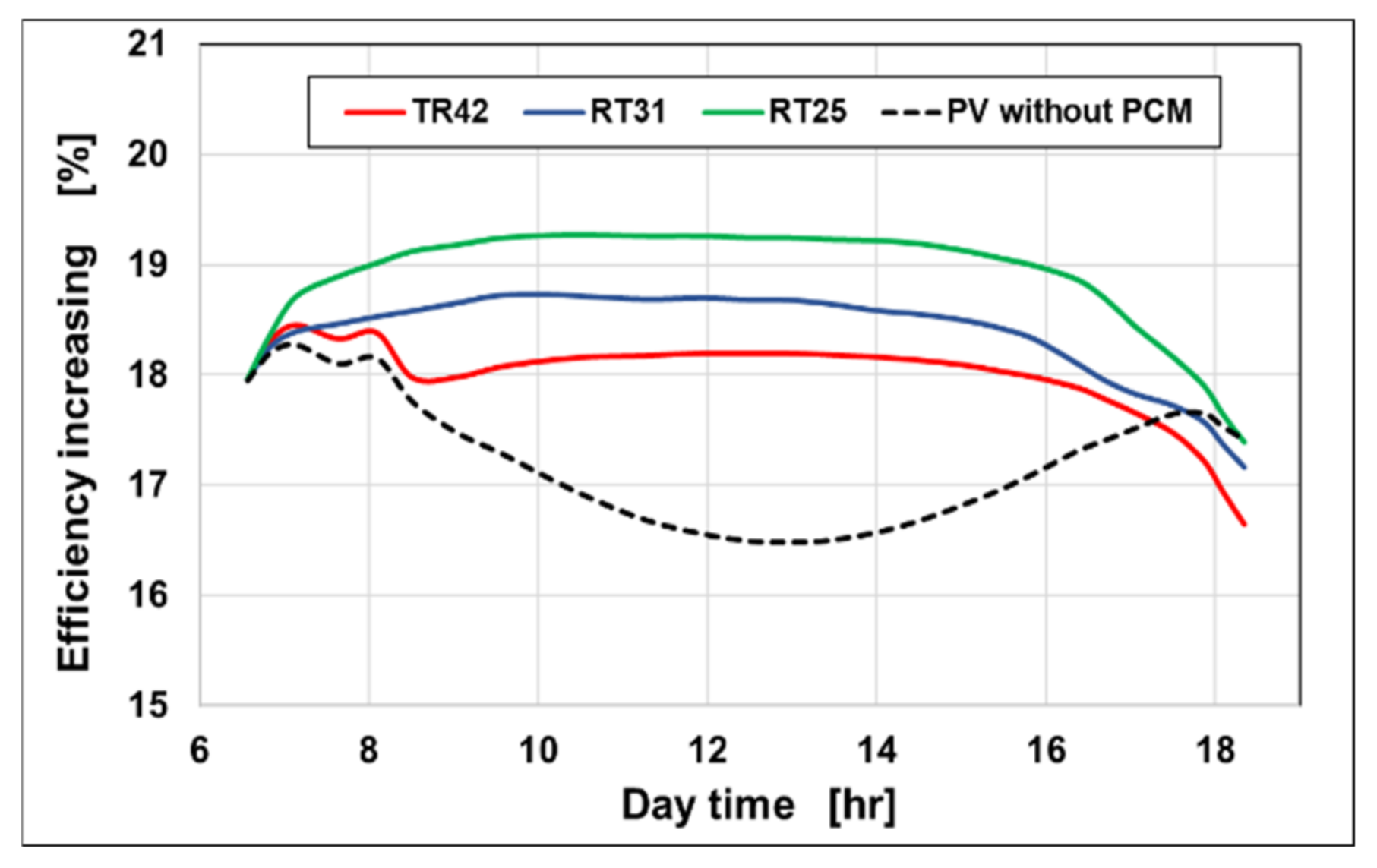

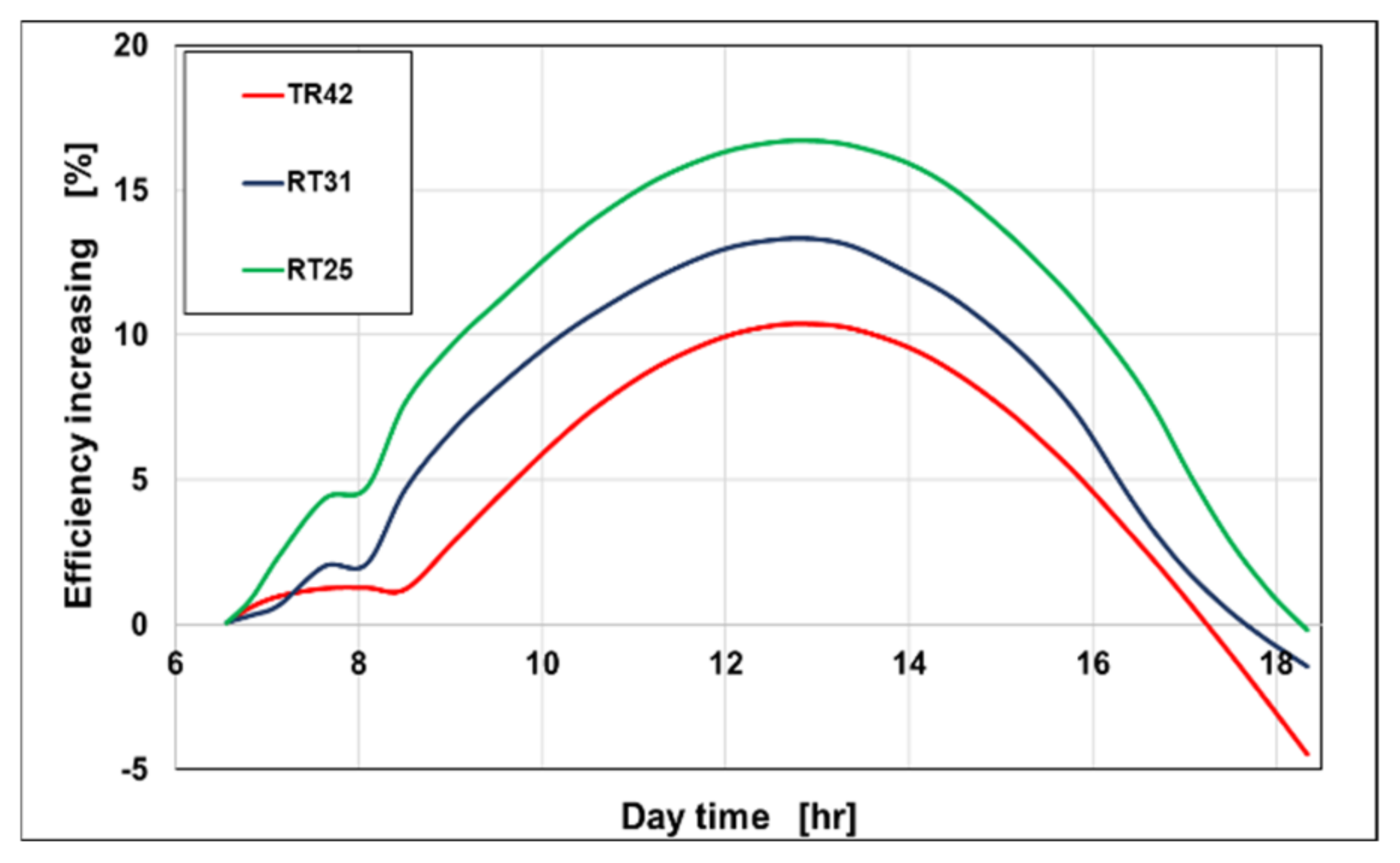

- In all investigated PCMs, the PV/PCM system showed a considerable enhancement of the PV module efficiency and maintained it at an almost constant level over the daytime. Compared with the PV-only system, the efficiency enhancement at the peak times reached 10%, 13% and 17% when RT42, RT31, and RT25 were used, respectively.

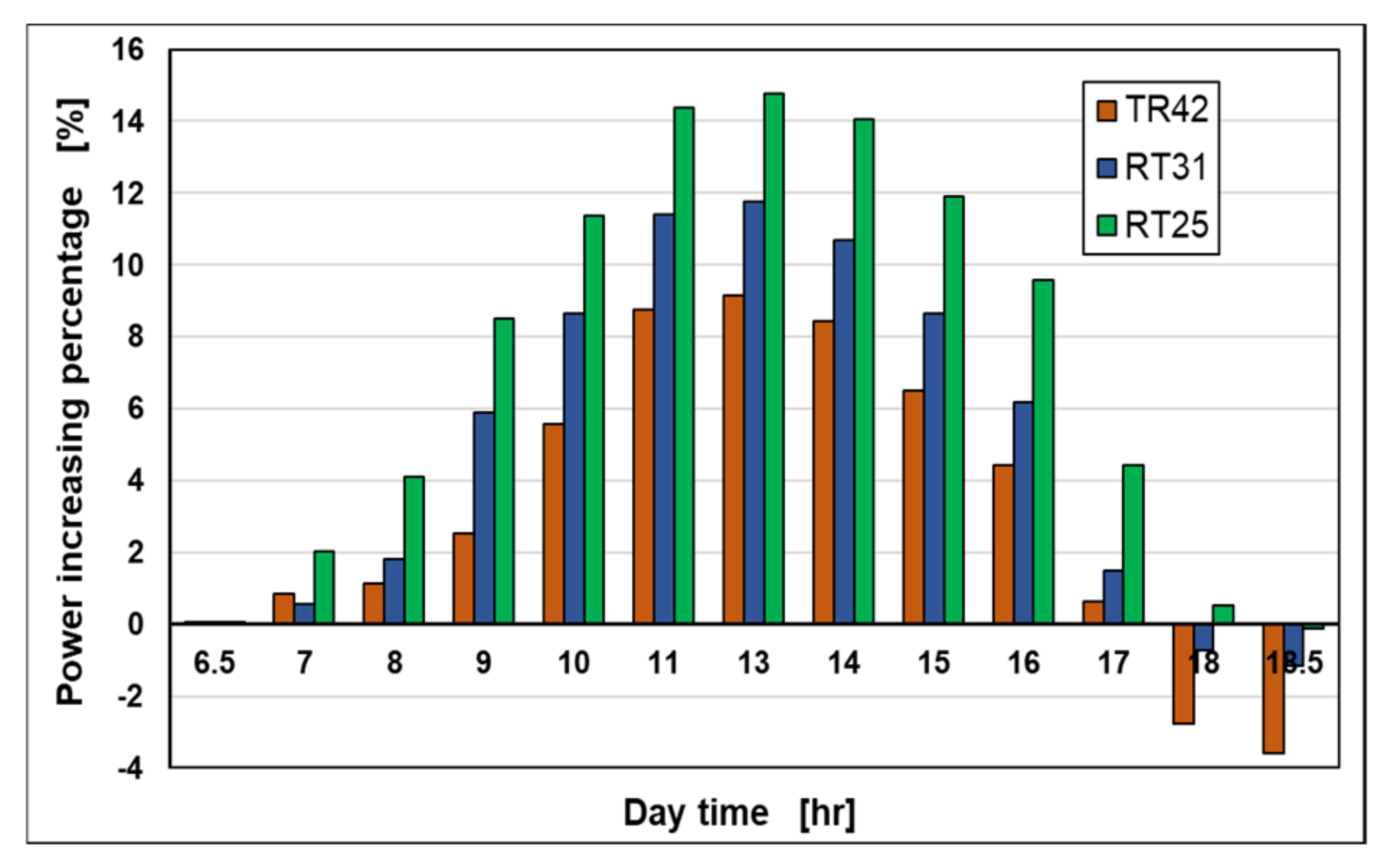

- PV/PCM systems showed a considerable power output enhancement; at the solar peak time, the power output increased by 9%, 11.5% and 14.6% when RT42, RT31, and RT25 were used, respectively, compared with the PV-only system.

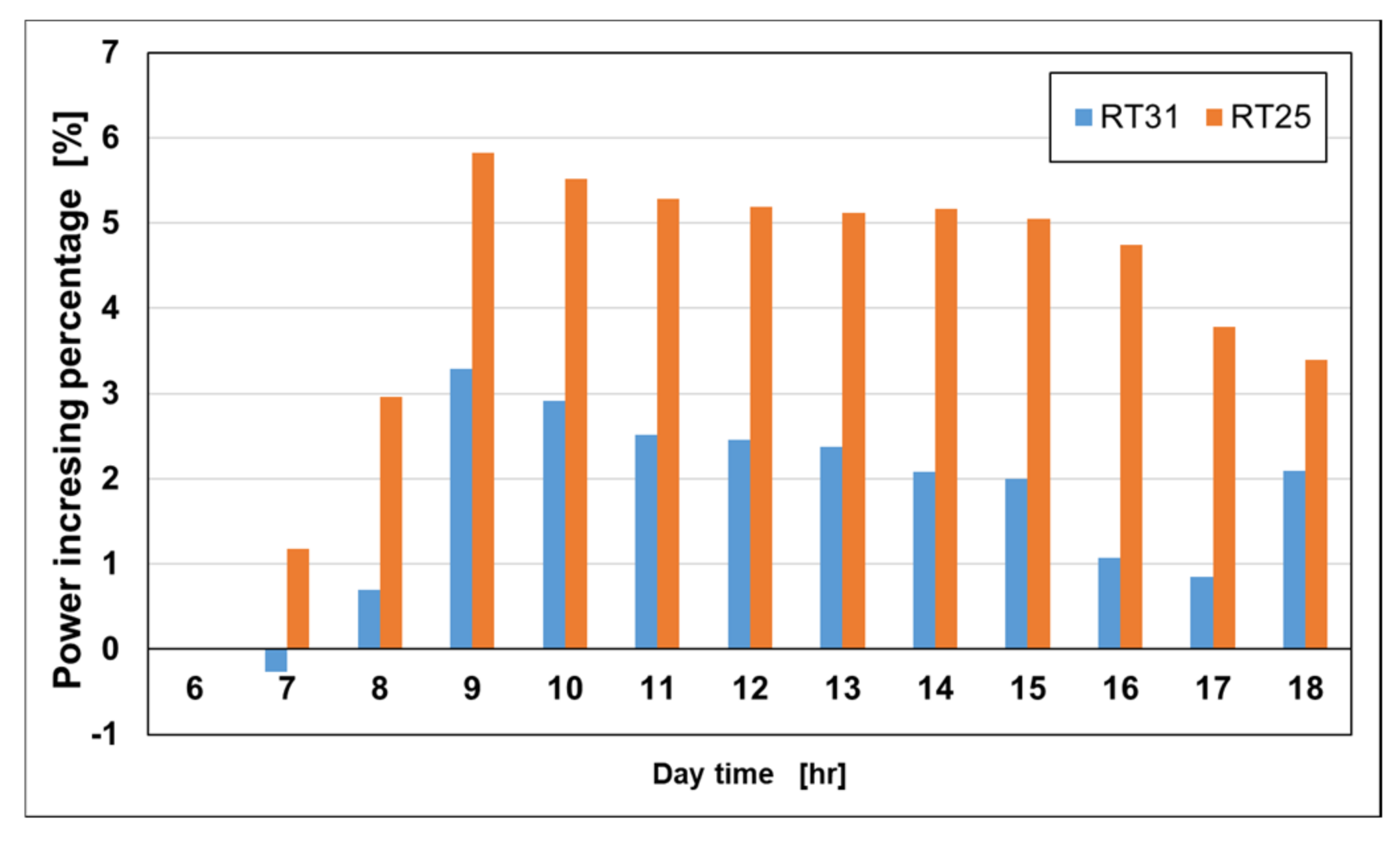

- Although RT42 showed the lowest efficiency and power enhancement, it showed a significant reduction in the amount of PCM by 36% and 14.6% compared with RT31 and RT25, respectively. Moreover, the power output from RT31 and RT25 cases showed a maximum increase of 3% and 5.5%, respectively, compared with RT42, indicating that using a PCM with a melting temperature higher than the average ambient temperature will lead to a cost-effective system without a significant reduction in the power output.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Module surface area | |

| Specific heat capacity at constant pressure | |

| Solar irradiance on PV surface (W/m2) | |

| Solar irradiance at standard reporting condition | |

| Fill factor | |

| Total enthalpy | |

| Sensible heat | |

| Latent heat | |

| Reference enthalpy | |

| Lowest current in the module | |

| Incident solar radiation absorbed by PV cells | |

| Isc | Short circuit current |

| Total solar incident | |

| Thermal conductivity | |

| Mismatch loss fraction | |

| n | Number of cells in the module |

| nr | Number of cells in one row |

| Power output | |

| Cell power generation | |

| Maximum power output | |

| PV module output power | |

| Power output of one row | |

| Source term | |

| Portion of the solar irradiance converted to heat | |

| Temperature | |

| Cell temperature | |

| PV temperature that drops the module electrical efficiency to Zero | |

| Liquidus temperature | |

| Solidification temperature | |

| Reference temperature | |

| Cell temperature at standard reporting condition | |

| Velocity | |

| Voc | Open circuit voltage |

| Open circuit voltage at standard reporting condition | |

| Open voltage of one row | |

| Greek letters | |

| Effective glass layer transmissivity and PV cell absorptivity | |

| Cell conversion efficiency. | |

| Density | |

| Cell/module electrical efficiency at standard conditions | |

| Current correction coefficient | |

| Constant varies from 0 at solid state to 1 at liquid state | |

| Voltage correction coefficient | |

| Temperature coefficient | |

| Solar radiation correction coefficient | |

References

- Gielen, D.; Gorini, R.; Wagner, N.; Leme, R.; Gutierrez, L.; Prakash, G.; Asmelash, E.; Janeiro, L.; Gallina, G.; Vale, G.; et al. Global Energy Transformation: A Roadmap to 2050; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2018; ISBN 978-92-9260-059-4. [Google Scholar]

- Abdelrazik, A.S.; Al-Sulaiman, F.; Saidur, R.; Ben-Mansour, R. A review on recent development for the design and packaging of hybrid photovoltaic/thermal (PV/T) solar systems. Renew. Sustain. Energy Rev. 2018, 95, 110–129. [Google Scholar] [CrossRef]

- Hussain, F.; Othman, M.Y.H.; Sopian, K.; Yatim, B.; Ruslan, H.; Othman, H. Design development and performance evaluation of photovoltaic/thermal (PV/T) air base solar collector. Renew. Sustain. Energy Rev. 2013, 25, 431–441. [Google Scholar] [CrossRef]

- Fouad, M.M.; Shihata, L.A.; Morgan, E.I. An integrated review of factors influencing the perfomance of photovoltaic panels. Renew. Sustain. Energy Rev. 2017, 80, 1499–1511. [Google Scholar] [CrossRef]

- Ma, T.; Li, Z.; Zhao, J. Photovoltaic panel integrated with phase change materials (PV-PCM): Technology overview and materials selection. Renew. Sustain. Energy Rev. 2019, 116, 109406. [Google Scholar] [CrossRef]

- Islam, M.M.; Pandey, A.K.; Hasanuzzaman, M.; Rahim, N.A. Recent progresses and achievements in photovoltaic-phase change material technology: A review with special treatment on photovoltaic thermal-phase change material systems. Energy Convers. Manag. 2016, 126, 177–204. [Google Scholar] [CrossRef]

- Pandey, A.K.; Tyagi, V.V.; Selvaraj, J.A.; Rahim, N.A.; Tyagi, S.K. Recent advances in solar photovoltaic systems for emerging trends and advanced applications. Renew. Sustain. Energy Rev. 2016, 53, 859–884. [Google Scholar] [CrossRef]

- Rajput, U.J.; Yang, J. Comparison of heat sink and water type PV/T collector for polycrystalline photovoltaic panel cooling. Renew. Energy 2018, 116, 479–491. [Google Scholar] [CrossRef]

- Abdullah, A.L.; Misha, S.; Tamaldin, N.; Rosli, M.A.M.; Sachit, F.A. Photovoltaic thermal/solar (PVT) collector (PVT) system based on fluid absorber design: A review. J. Adv. Res. Fluid Mech. Therm. Sci. 2018, 48, 196–208. [Google Scholar]

- Sultan, S.M.; Ervina Efzan, M.N. Review on recent Photovoltaic/Thermal (PV/T) technology advances and applications. Sol. Energy 2018, 173, 939–954. [Google Scholar] [CrossRef]

- Prakash, J. Transient analysis of a photovoltaic-thermal solar collector for co-generation of electricity and hot air/water. Energy Convers. Manag. 1994, 35, 967–972. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.; Sopian, K.; Kazem, H.A.; Chaichan, M.T. Photovoltaic/Thermal (PV/T) systems: Status and future prospects. Renew. Sustain. Energy Rev. 2017, 77, 109–130. [Google Scholar] [CrossRef]

- Palacios, A.; Navarro, M.E.; Barreneche, C.; Ding, Y. Hybrid 3 in 1 thermal energy storage system—Outlook for a novel storage strategy. Appl. Energy 2020, 274, 115024. [Google Scholar] [CrossRef]

- Wu, S.; Xiong, C. Passive cooling technology for photovoltaic panels for domestic houses. Int. J. Low-Carbon Technol. 2014, 9, 118–126. [Google Scholar] [CrossRef] [Green Version]

- Abd-Elhady, M.S.; Serag, Z.; Kandil, H.A. An innovative solution to the overheating problem of PV panels. Energy Convers. Manag. 2018, 157, 452–459. [Google Scholar] [CrossRef]

- Khanna, S.; Reddy, K.S.; Mallick, T.K. Optimization of finned solar photovoltaic phase change material (finned pv pcm) system. Int. J. Therm. Sci. 2018, 130, 313–322. [Google Scholar] [CrossRef]

- Stropnik, R.; Stritih, U. Increasing the efficiency of PV panel with the use of PCM. Renew. Energy 2016, 97, 671–679. [Google Scholar] [CrossRef]

- Luo, Z.; Huang, Z.; Xie, N.; Gao, X.; Xu, T.; Fang, Y.; Zhang, Z. Numerical and experimental study on temperature control of solar panels with form-stable paraffin/expanded graphite composite PCM. Energy Convers. Manag. 2017, 149, 416–423. [Google Scholar] [CrossRef]

- Su, D.; Jia, Y.; Alva, G.; Liu, L.; Fang, G. Comparative analyses on dynamic performances of photovoltaic–thermal solar collectors integrated with phase change materials. Energy Convers. Manag. 2017, 131, 79–89. [Google Scholar] [CrossRef]

- Tanuwijava, A.O.; Ho, C.J.; Lai, C.-M.; Huang, C.-Y. Numerical Investigation of the Thermal Management Performance of MEPCM Modules for PV Applications. Energies 2013, 6, 3922–3936. [Google Scholar] [CrossRef] [Green Version]

- Ho, C.J.; Chou, W.-L.; Lai, C.-M. Thermal and electrical performance of a water-surface floating PV integrated with a water-saturated MEPCM layer. Energy Convers. Manag. 2015, 89, 862–872. [Google Scholar] [CrossRef]

- Huang, M.J.; Eames, P.C.; Norton, B. Thermal regulation of building-integrated photovoltaics using phase change materials. Int. J. Heat Mass Transf. 2004, 47, 2715–2733. [Google Scholar] [CrossRef]

- Klemm, T.; Hassabou, A.; Abdallah, A.; Andersen, O. Thermal energy storage with phase change materials to increase the efficiency of solar photovoltaic modules. Energy Procedia 2017, 135, 193–202. [Google Scholar] [CrossRef]

- Kumar, K.S.; Kumar, H.A.; Gowtham, P.; Kumar, S.H.S.; Sudhan, R.H. Experimental analysis and increasing the energy efficiency of PV cell with nano-PCM (calcium carbonate, silicon carbide, copper). Mater. Today Proc. 2021, 37, 1221–1225. [Google Scholar] [CrossRef]

- Moradi, K.; Ebadian, M.A.; Lin, C.-X. A review of PV/T technologies: Effects of control parameters. Int. J. Heat Mass Transf. 2013, 64, 483–500. [Google Scholar] [CrossRef] [Green Version]

- Chow, T.T. A review on photovoltaic/thermal hybrid solar technology. Appl. Energy 2010, 87, 365–379. [Google Scholar] [CrossRef]

- Shukla, A.; Kant, K.; Sharma, A.; Biwole, P.H. Cooling methodologies of photovoltaic module for enhancing electrical efficiency: A review. Sol. Energy Mater. Sol. Cells 2017, 160, 275–286. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P. Simulation and performance analysis of 110 kWp grid-connected photovoltaic system for residential building in India: A comparative analysis of various PV technology. Energy Rep. 2016, 2, 82–88. [Google Scholar] [CrossRef] [Green Version]

- PV in the UK: Early results from the UK photovoltaics field trial. Refocus 2005, 6, 36–37. [CrossRef]

- Nižetić, S.; Jurčević, M.; Čoko, D.; Arıcı, M. A novel and effective passive cooling strategy for photovoltaic panel. Renew. Sustain. Energy Rev. 2021, 145, 111164. [Google Scholar] [CrossRef]

- Ansys Fluent. Ansys Fluent Theory Guide; ANSYS Inc.: Canonsburg, PA, USA, 2013; p. 814. [Google Scholar]

- Khanna, S.; Reddy, K.S.; Mallick, T.K. Performance analysis of tilted photovoltaic system integrated with phase change material under varying operating conditions. Energy 2017, 133, 887–899. [Google Scholar] [CrossRef]

- Chamberlin, C.E.; Lehman, P.; Zoellick, J.; Pauletto, G. Effects of mismatch losses in photovoltaic arrays. Sol. Energy 1995, 54, 165–171. [Google Scholar] [CrossRef]

- Savvakis, N.; Tsoutsos, T. Phase Change Materials in Photovoltaics: The Assessment of System Performance in the Present Mediterranean Climate Conditions. In Power Systems, Energy Markets and Renewable Energy Sources in South-Eastern Europe; (Engineering and Industry Series Volume); Trivent Publishing: Budapest, Hungary, 2016. [Google Scholar] [CrossRef]

- GmbH, R.T. Technical Data Sheet RT 42. Available online: https://www.rubitherm.eu/en/index.php/productcategory/organische-pcm-rt (accessed on 5 July 2021).

- Caluianu, I.-R.; Băltăreţu, F. Thermal modelling of a photovoltaic module under variable free convection conditions. Appl. Therm. Eng. 2012, 33, 86–91. [Google Scholar] [CrossRef]

- Hasan, M.I.; Tbena, H.L. Using of phase change materials to enhance the thermal performance of micro channel heat sink. Eng. Sci. Technol. Int. J. 2018, 21, 517–526. [Google Scholar] [CrossRef]

- Karlsson, L. The Dynamics of Drops Freezing on Cold Surfaces; Luleå University of Technology: Luleå, Sweden, 2013. [Google Scholar]

- Muhammad, M.D.; Badr, O.; Yeung, H. Validation of a CFD Melting and Solidification Model for Phase Change in Vertical Cylinders. Numer. Heat Transf. Part A Appl. 2015, 68, 501–511. [Google Scholar] [CrossRef]

- Skoplaki, E.; Palyvos, J.A. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

| PV Module | Efficiency (%)1 |

|---|---|

| Si-Cristalline | 26.1–25.1 |

| Si-yPolycrystalline | 21.4–20.2 |

| III–V cells | 29.7–18.1 |

| Thin-film chalcogenide | 21.4–18.1 |

| Amorphous/microcrystalline Si | 11.7–9.9 |

| Dye-sensitized | 12.3–8.5 |

| Organic | 11.3–9.2 |

| Material | Properties | |||

|---|---|---|---|---|

| Cp (kJ/kg·K) | ρ (kg/m3) | K (W/m.K) | Thickness (mm) | |

| Glass | 0.5 | 3000 | 1.8 | 4 |

| Ethylene-vinyl-acetate (EVA) | 2.09 | 960 | 0.35 | 0.5 |

| Silicon | 0.677 | 2330 | 148 | 0.3 |

| Tedlar | 1.25 | 1200 | 0.2 | 0.1 |

| Aluminium | 0.903 | 2675 | 211 | 4 |

| PCM | Cp (kJ/kg-K) | K (W/m-K) | ρ (kg/m3) | Tm (°C) | Lh(kJ/kg) |

|---|---|---|---|---|---|

| RT42 | 2.00 | 0.20 | 832 | 41 | 135 |

| RT31 | 2.00 | 0.20 | 820 | 31 | 140 |

| RT25 | 1.99/2.11 | 0.19/0.18 | 830830 | 26.6 | 180 |

| Module Characteristic | Value |

|---|---|

| Rated Power | 340 W |

| TC of open circuit voltage | −0.28%/°C |

| TC of short circuit current | 0.057%/°C |

| TC of power | −0.40%/°C |

| Short circuit current Isc of PV cell/module | 9.3 A |

| Open circuit voltage Voc of module | 46.6 V |

| Open circuit voltage Voc of cell | 0.6472 V |

| Maximum current Imp | 8.77 A |

| Maximum voltage Vmp of module | 38.8 V |

| Row | Temperature (°C) | Current (A) | Voltage (V) | Power (W) |

|---|---|---|---|---|

| 1 | 48 | 7.108 | 6.050 | 43.005 |

| 2 | 45 | 7.096 | 6.105 | 43.318 |

| 3 | 42 | 7.084 | 6.159 | 43.629 |

| 4 | 39 | 7.072 | 6.213 | 43.939 |

| 5 | 36 | 7.060 | 6.267 | 44.248 |

| 6 | 33 | 7.048 | 6.322 | 44.556 |

| Minimum current (7.048) | Total voltage (37.116) | Total power (262.696) | ||

| Actual power | 7.048 * 37.116 | 261.594 | ||

| Mismatch loss | 1.102 | |||

| Mismatch loss fraction | 0.421% | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, A.; Navarro, H.; Ghosh, S.; Ding, Y.; Roy, J.N. Evaluation of New PCM/PV Configurations for Electrical Energy Efficiency Improvement through Thermal Management of PV Systems. Energies 2021, 14, 4130. https://doi.org/10.3390/en14144130

Ahmad A, Navarro H, Ghosh S, Ding Y, Roy JN. Evaluation of New PCM/PV Configurations for Electrical Energy Efficiency Improvement through Thermal Management of PV Systems. Energies. 2021; 14(14):4130. https://doi.org/10.3390/en14144130

Chicago/Turabian StyleAhmad, Abdalqader, Helena Navarro, Saikat Ghosh, Yulong Ding, and Jatindra Nath Roy. 2021. "Evaluation of New PCM/PV Configurations for Electrical Energy Efficiency Improvement through Thermal Management of PV Systems" Energies 14, no. 14: 4130. https://doi.org/10.3390/en14144130

APA StyleAhmad, A., Navarro, H., Ghosh, S., Ding, Y., & Roy, J. N. (2021). Evaluation of New PCM/PV Configurations for Electrical Energy Efficiency Improvement through Thermal Management of PV Systems. Energies, 14(14), 4130. https://doi.org/10.3390/en14144130