Surrogate-Based Optimization of Horizontal Axis Hydrokinetic Turbine Rotor Blades

Abstract

1. Introduction

2. Methododology

2.1. Initial Geometry

2.1.1. Lifting Line Optimization

2.1.2. Initial Blade Geometry

2.2. Analysis

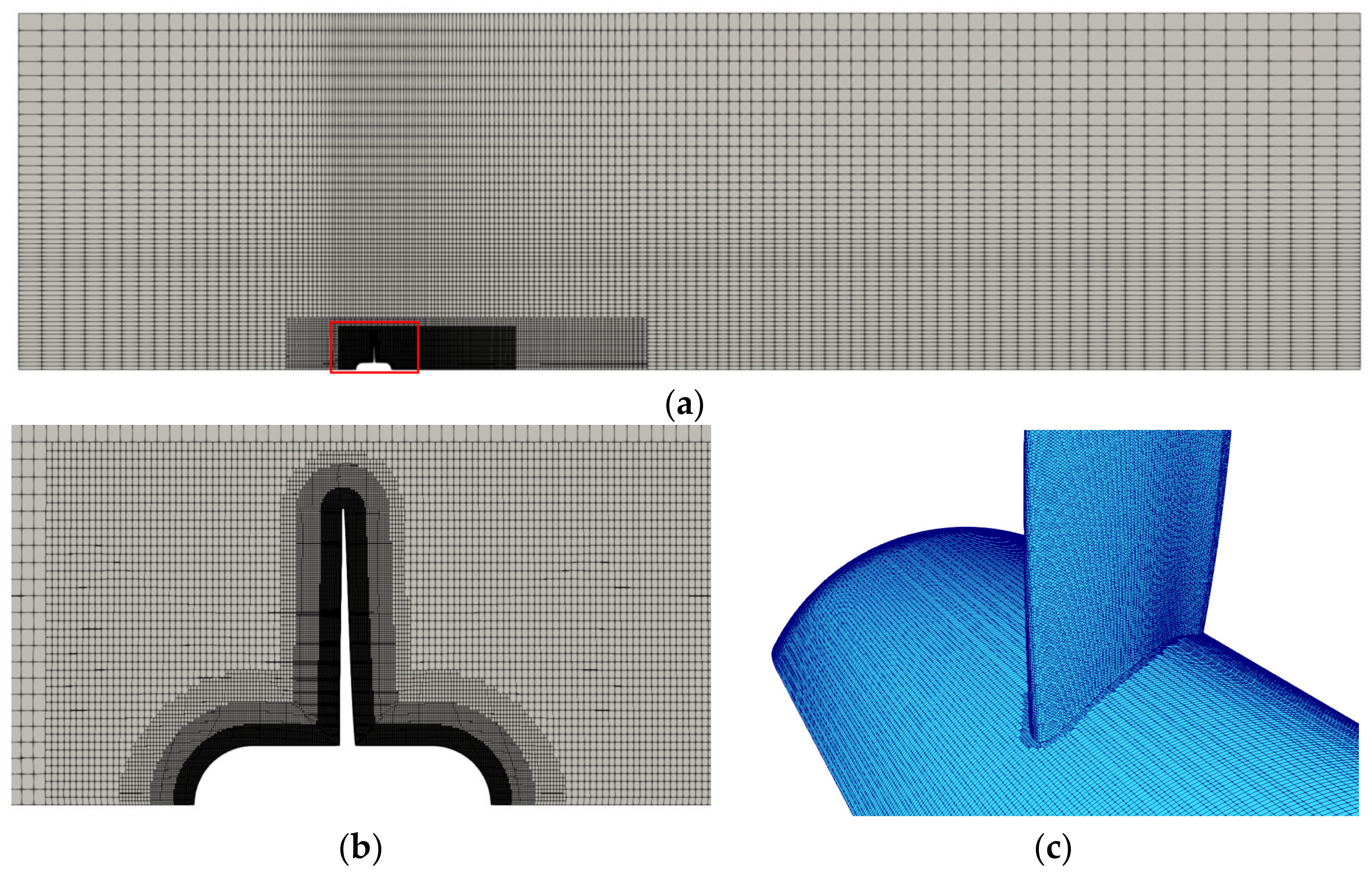

2.2.1. Model Set-Up

2.2.2. Convergence Analysis

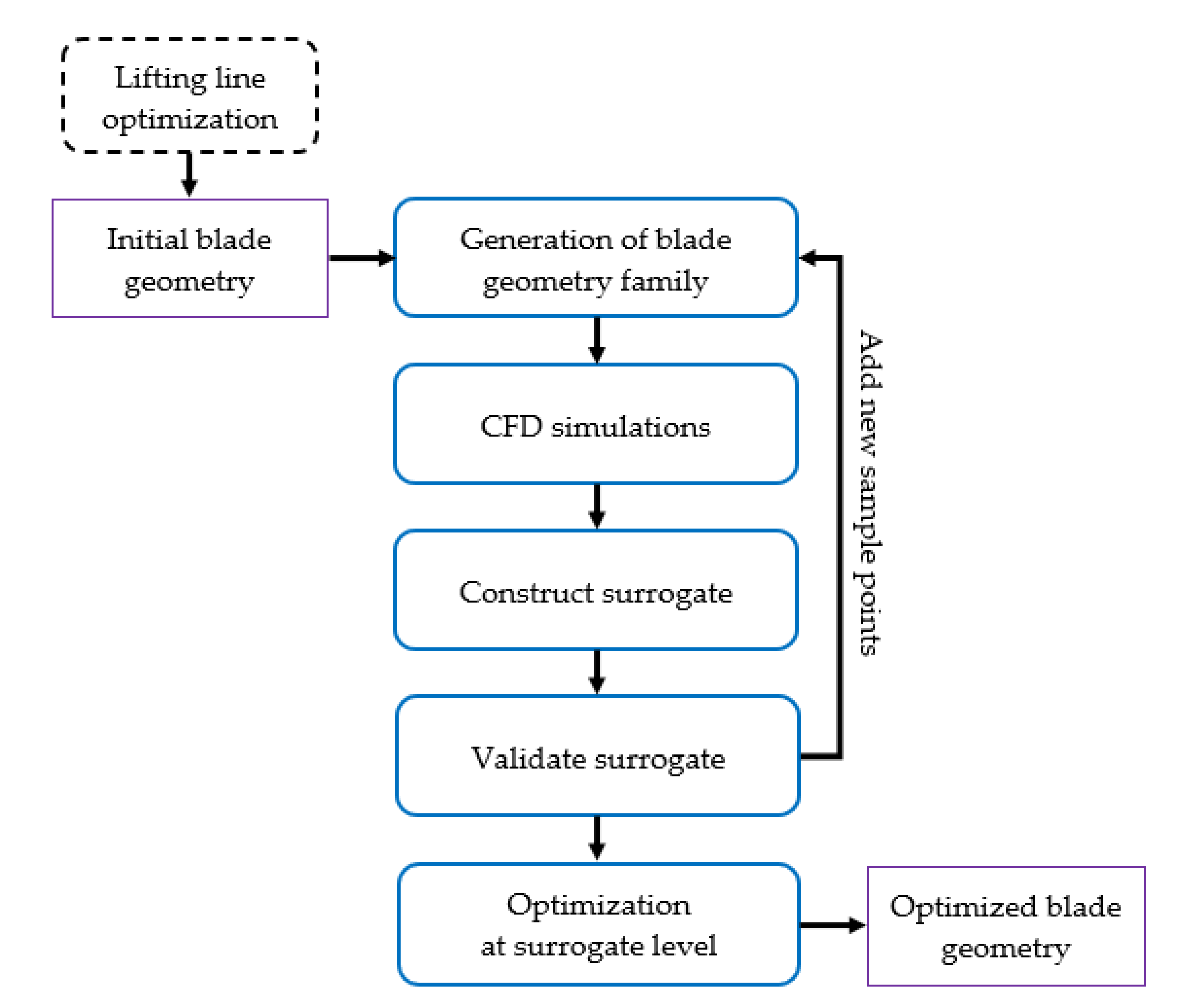

2.3. Optimization

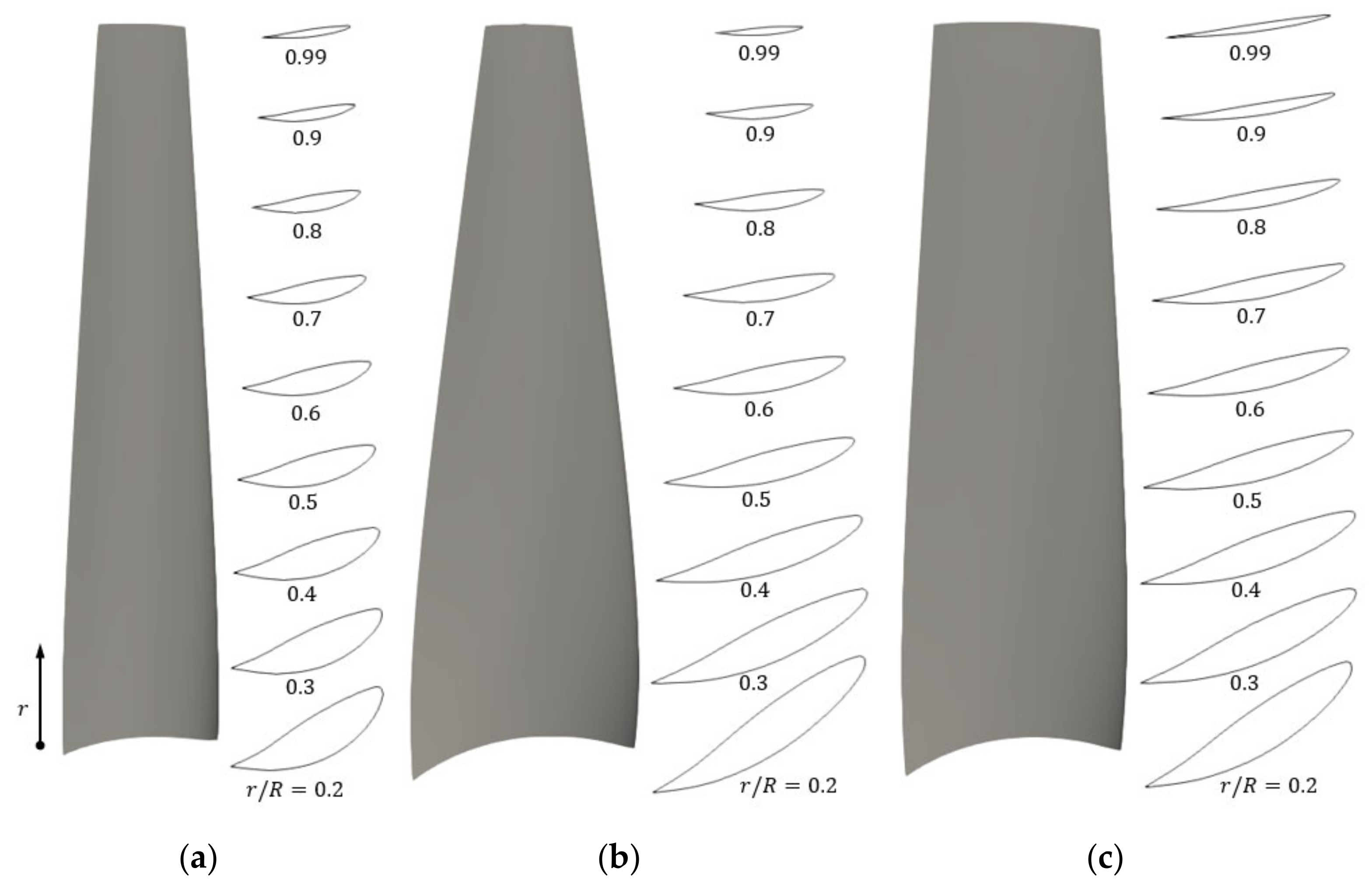

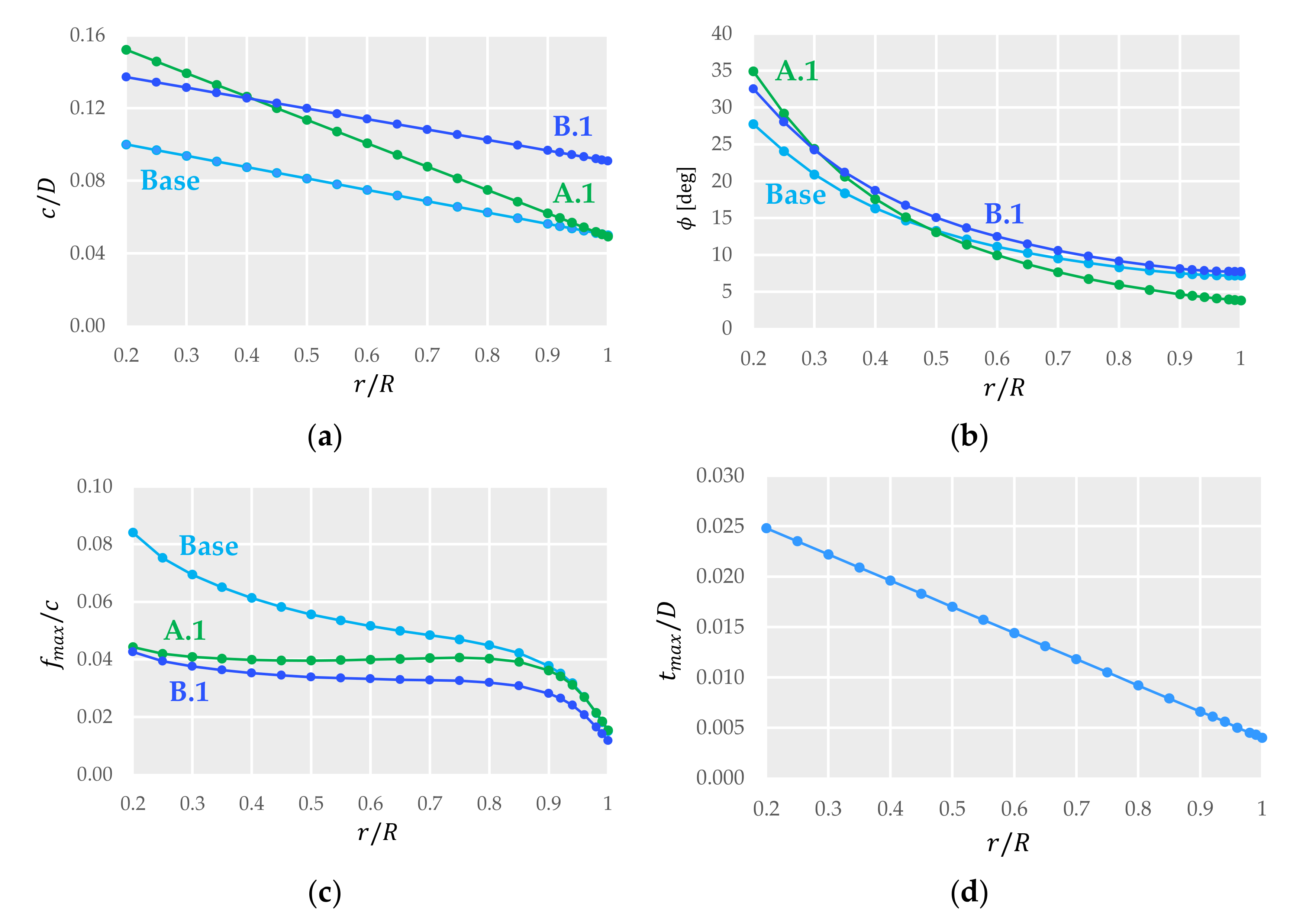

2.3.1. Blade Geometry Parametrization

2.3.2. Cavitation

2.3.3. Surrogate Model

2.3.4. Optimization Problem Set-Up

3. Results

3.1. Analysis of Design Space

3.2. Optimization Results

- Problem A: Without imposing a constraint on the minimum pressure coefficient ;

- Problem B: Imposing (cavitation constraint).

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Laws, N.D.; Epps, B.P. Hydrokinetic energy conversion: Technology, research, and outlook. Renew. Sustain. Energy Rev. 2016, 57, 1245–1259. [Google Scholar] [CrossRef]

- Shiu, H.; van Dam, C.P.; Johnson, E.; Barone, M.; Phillips, R.; Straka, W.; Fontaine, A.; Jonson, M. A Design of a Hydrofoil Family for Current-Driven Marine-Hydrokinetic Turbines. In Proceedings of the 2012 20th International Conference on Nuclear Engineering and the ASME 2012 Power Conference, Anaheim, CA, USA, 30 July–3 August 2012; 2012. [Google Scholar] [CrossRef]

- Walker, J.M.; Flack, K.A.; Lust, E.E.; Schultz, M.P.; Luznik, L. Experimental and numerical studies of blade roughness and fouling on marine current turbine performance. Renew. Energy 2014, 66, 257–267. [Google Scholar] [CrossRef]

- Hansen, M.O.L. Aerodynamics of Wind Turbines, 3rd ed.; Routledge: London, UK, 2015. [Google Scholar] [CrossRef]

- Vogel, C.R.; Willden, R.H.J.; Houlsby, G.T. Blade element momentum theory for a tidal turbine. Ocean Eng. 2018, 169, 215–226. [Google Scholar] [CrossRef]

- Togneri, M.; Pinon, G.; Carlier, C.; Bex, C.C.; Masters, I. Comparison of synthetic turbulence approaches for blade element momentum theory prediction of tidal turbine performance and loads. Renew. Energy 2020, 145, 408–418. [Google Scholar] [CrossRef]

- Kerwin, J.E.; Hadler, J.B. Propulsion; Society of Naval Architects and Marine Engineers: Jersey City, NJ, USA, 2010. [Google Scholar]

- Epps, B.P.; Kimball, R. Unified Rotor Lifting Line Theory. J. Ship Res. 2013, 57, 181–201. [Google Scholar] [CrossRef]

- Menéndez Arán, D.H.; Tian, Y.; Kinnas, S.A. Effect of wake alignment on turbine blade loading distribution and power coefficient. J. Offshore Mech. Arct. Eng. 2019, 141, 041901. [Google Scholar] [CrossRef]

- Falcão de Campos, J.A.C. Hydrodynamic Power Optimization of a Horizontal Axis Marine Current Turbine With Lifting Line Theory. In Proceedings of the 17th International Offshore and Polar Engineering Conference, Lisbon, Portugal, 1–6 July 2007. [Google Scholar]

- He, L.; Kinnas, S.A.; Xu, W. A Vortex-Lattice Method for the Prediction of Unsteady Performance of Marine Propellers and Current Turbines. Int. J. Offshore Polar Eng. 2013, 23, 210–217. [Google Scholar]

- Xu, W. Numerical Techniques for the Design and Prediction of Performance of Marine Turbines and Propellers. Master of Science Thesis, The University of Texas at Austin, Austin, TX, USA, 2010. [Google Scholar]

- Baltazar, J.; Falcão de Campos, J.A.C. Hydrodynamic Analysis of a Horizontal Axis Marine Current Turbine With a Boundary Element Method. J. Offshore Mech. Arct. Eng. 2011, 133, 041304. [Google Scholar] [CrossRef]

- Salvatore, F.; Sarichloo, Z.; Calcagni, D. Marine Turbine Hydrodynamics by a Boundary Element Method with Viscous Flow Correction. J. Mar. Sci. Eng. 2018, 6, 53. [Google Scholar] [CrossRef]

- Yang, X.; Khosronejad, A.; Sotiropoulos, F. Large-eddy simulation of a hydrokinetic turbine mounted on an erodible bed. Renew. Energy 2017, 113, 1419–1433. [Google Scholar] [CrossRef]

- Sanderse, B.; van der Pijl, S.P.; Koren, B. Review of computational fluid dynamics for wind turbine wake aerodynamics. Wind Energ. 2011, 14, 799–819. [Google Scholar] [CrossRef]

- Lynch, C.E. Advanced CFD Methods for Wind Turbine Analysis. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2011. [Google Scholar]

- Lawson, M.J.; Li, Y.; Sale, D.C. Development and Verification of a Computational Fluid Dynamics Model of a Horizontal-Axis Tidal Current Turbine. In Proceedings of the ASME 2011 30th International Conference on Ocean, Offshore and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, S.; Kim, D.H.; Rhee, S.H.; Kim, M. Computational methods for performance analysis of horizontal axis tidal stream turbines. Appl. Energy 2012, 98, 512–523. [Google Scholar] [CrossRef]

- Mukherji, S.S.; Kolekar, N.; Banerjee, A.; Mishra, R. Numerical investigation and evaluation of optimum hydrodynamic performance of a horizontal axis hydrokinetic turbine. J. Renew. Sustain. Energy. 2011, 3, 063105. [Google Scholar] [CrossRef]

- OpenFOAM Web Page. Available online: http://openfoam.com (accessed on 1 June 2021).

- Forrester, A.; Sobester, A.; Keane, A. Engineering Design via Surrogate Modelling: A Practical Guide; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2008. [Google Scholar] [CrossRef]

- Dakota Web Page. Available online: https://dakota.sandia.gov (accessed on 1 June 2021).

- Thelen, A.S. Surrogate-based design optimization of dual-rotor wind turbines using steady RANS equations. Master of Science Thesis, Iowa State University, Ames, IA, USA, 2016. [Google Scholar] [CrossRef]

- Kumar, M.; Nam, G.W.; Oh, S.J.; Seo, J.; Samad, A.; Rhee, S.H. Design optimization of a horizontal axis tidal stream turbine blade using CFD. In Proceedings of the 5th International Symposium on Marine Propulsors, Espoo, Finland, 12–15 June 2017. [Google Scholar]

- Pholdee, N.; Bureerat, S.; Nuantong, W. Kriging Surrogate-Based Genetic Algorithm Optimization for Blade Design of a Horizontal Axis Wind Turbine. Comput. Model Eng. Sci. 2021, 126, 261–273. [Google Scholar] [CrossRef]

- Karthikeyan, T.; Avital, E.J.; Venkatesan, N.; Samad, A. Optimization of a horizontal axis marine current turbine via surrogate models. Ocean Syst. Eng. 2019, 9, 111–133. [Google Scholar] [CrossRef]

- OpenProp Web Page. Available online: https://engineering.dartmouth.edu/openprop/ (accessed on 1 June 2021).

- Moreu, J.; Epps, B.P.; Valle, J.; Taboada, M.; Bueno, P. Variational optimization of hydrokinetic turbines and propellers operating in a non-uniform flow field. Ocean Eng. 2017, 135, 207–220. [Google Scholar] [CrossRef]

- Kinnas, S.; Xu, W.; Yu, Y.H.; Lei, H. Computational methods for the design and prediction of performance of tidal turbines. J. Offshore Mech. Arct. Eng. 2012, 134, 011101-1. [Google Scholar] [CrossRef]

- Melo, D.B.; Baltazar, J.; Falcão de Campos, J.A.C. A numerical wake alignment method for horizontal axis wind turbines with the lifting line theory. J. Wind. Eng. Ind. Aerodyn. 2018, 174, 382–390. [Google Scholar] [CrossRef]

- Abbott, I.H.; von Doenhoff, A.E. Theory of Wing Sections; Dover Publications: New York, NY, USA, 1959. [Google Scholar]

- Weller, H.G.; Tabor, G.; Jasak, H.; Fureby, C. A tensorial approach to computational continuum mechanics using object-oriented techniques. Comput. Phys. 1998, 12, 620–631. [Google Scholar] [CrossRef]

- Menter, F.R. Two-Equation Eddy-Viscosity Turbulence Models for Engineering Applications. AIAA J. 1994, 32, 269–289. [Google Scholar] [CrossRef]

- Roache, P.J. Verification and Validation in Computational Science and Engineering; Hermosa: Albuquerque, NM, USA, 1998. [Google Scholar]

- Wang, D.; Atlar, M.; Sampson, R. An experimental investigation on cavitation, noise, and slipstream characteristics of ocean stream turbines. In Proceedings of the Institution of Mechanical Engineers, Part A. J. Power Energy 2007, 221, 219–231. [Google Scholar] [CrossRef]

- Díaz-Manríquez, A.; Toscano-Pulido, G.; Gómez-Flores, W. On the selection of surrogate models in evolutionary optimization algorithms. In Proceedings of the 2011 IEEE Congress of Evolutionary Computation (CEC), New Orleans, LA, USA, 5–8 June 2011; pp. 2155–2162. [Google Scholar] [CrossRef]

- Giunta, A.A.; Swiler, L.P.; Brown, S.L.; Eldred, M.S.; Richards, M.D.; Cyr, E.C. The Surfpack Software Library for Surrogate Modeling of Sparse Irregularly Spaced Multidimensional Data. In Proceedings of the 11th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Portsmouth, VA, USA, 6–8 September 2006. AIAA Paper 2006-7049. [Google Scholar] [CrossRef]

- Adams, B.M.; Bohnhoff, W.J.; Dalbey, K.R.; Ebeida, M.S.; Eddy, J.P.; Eldred, M.S.; Hooper, R.W.; Hough, P.D.; Hu, K.T.; Jakeman, J.D.; et al. A Multilevel Parallel Object-Oriented Framework for Design Optimization, Parameter Estimation, Uncertainty Quantification, and Sensitivity Analysis: Version 6.13 User’s Manual; Sandia Technical Report SAND2020-12495; Sandia National Laboratories,: Albuquerque, NM, USA, 2020. [Google Scholar]

- Guerrero, J.; Cominetti, A.; Pralits, J.; Villa, D. Surrogate-Based Optimization Using an Open-Source Framework: The Bulbous Bow Shape Optimization Case. Math. Comput. Appl. 2018, 23, 60. [Google Scholar] [CrossRef]

- Guerrero, J.; Mantelli, L.; Naqvi, S.B. Cloud-Based CAD Parametrization for Design Space Exploration and Design Optimization in Numerical Simulations. Fluids 2020, 5, 36. [Google Scholar] [CrossRef]

- Aseyev, A.S.; Cal, R.B. Vortex identification in the wake of a model wind turbine array. J. Turbul. 2015, 17, 357–378. [Google Scholar] [CrossRef]

| k | Mesh | Number of Cells | ||||

|---|---|---|---|---|---|---|

| 1 | Coarse | 1.9M | ~13 | 0.423 | ||

| 2 | Medium | 3.6M | ~8 | 0.428 | 0.012 | 0.005 |

| 3 | Fine | 7.2M | ~4 | 0.430 | 0.004 | 0.002 |

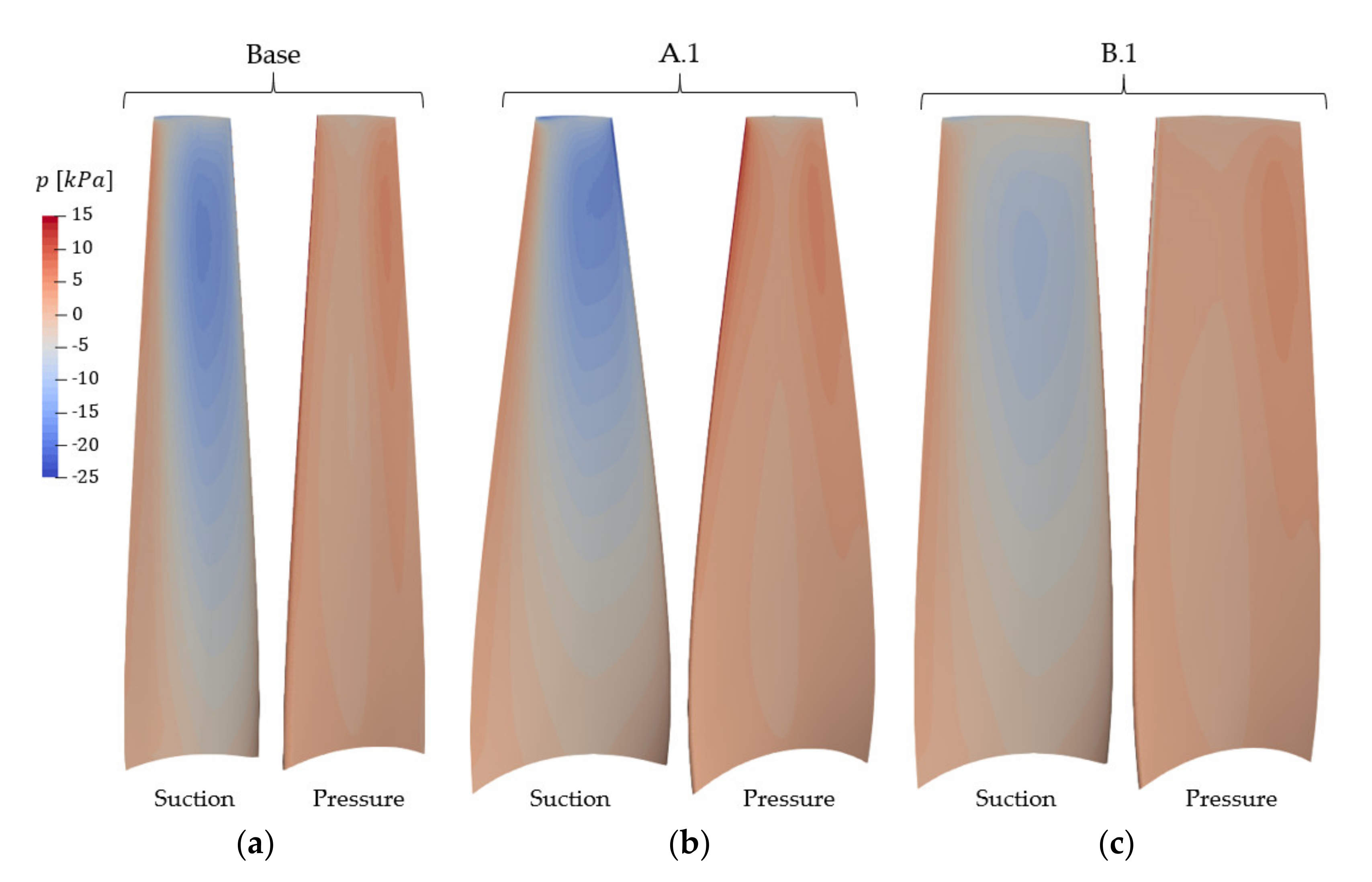

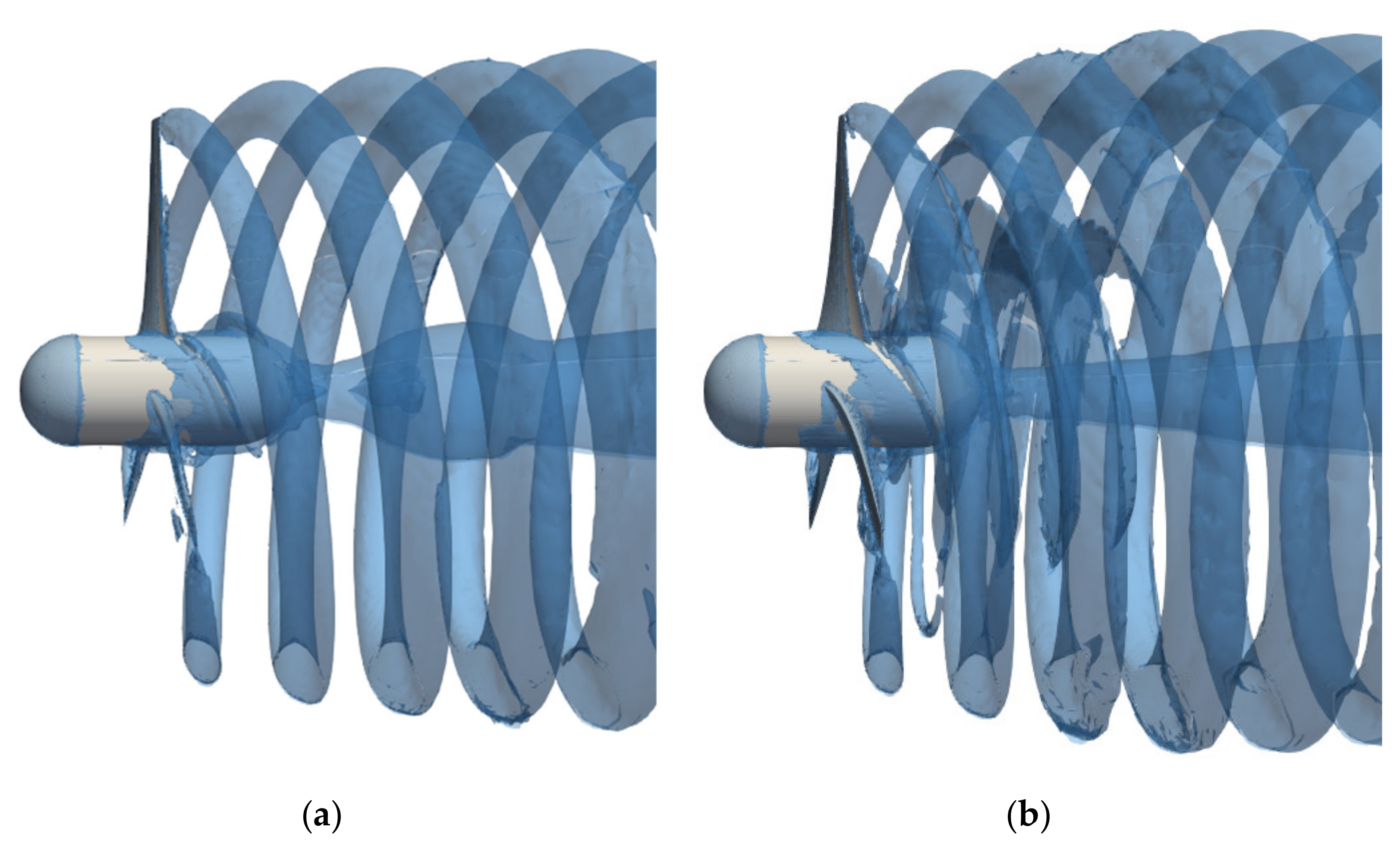

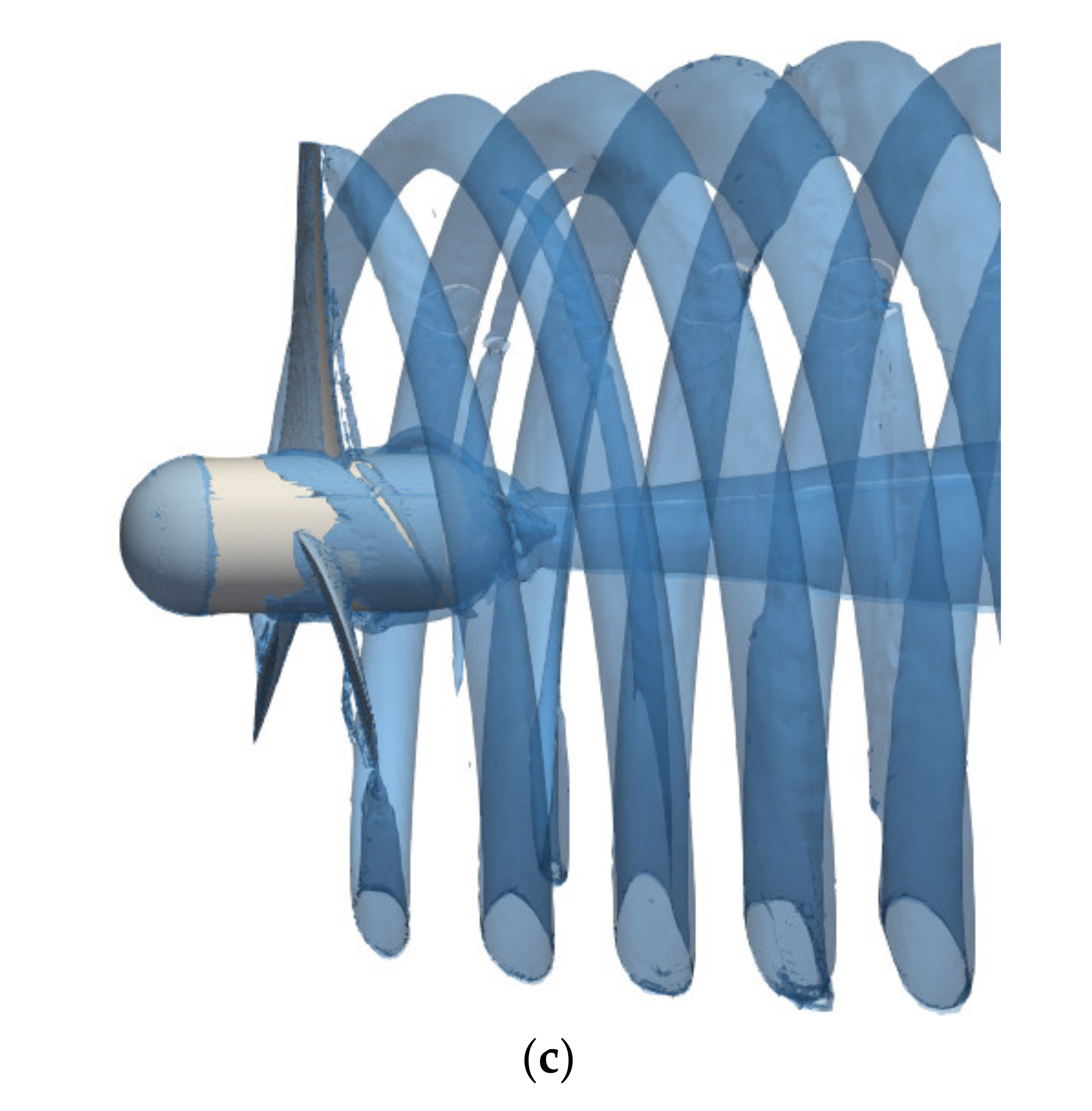

| Case | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Base | 1 | 1 | 1 | 1 | 1 | 1 | 0.428 | 0.707 | 5.756 |

| A.1 | 1.521 | 0.984 | 1.258 | 0.532 | 0.527 | 1.020 | 0.463 | 0.860 | 8.903 |

| A.2 | 1.978 | 0.582 | 1.258 | 0.848 | 0.507 | 0.780 | 0.437 | 0.705 | 7.916 |

| A.3 | 1.980 | 0.620 | 1.604 | 0.899 | 0.896 | 0.996 | 0.427 | 0.686 | 6.241 |

| B.1 | 1.371 | 1.818 | 1.172 | 1.072 | 0.567 | 0.808 | 0.437 | 0.742 | 3.407 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Menéndez Arán, D.; Menéndez, Á. Surrogate-Based Optimization of Horizontal Axis Hydrokinetic Turbine Rotor Blades. Energies 2021, 14, 4045. https://doi.org/10.3390/en14134045

Menéndez Arán D, Menéndez Á. Surrogate-Based Optimization of Horizontal Axis Hydrokinetic Turbine Rotor Blades. Energies. 2021; 14(13):4045. https://doi.org/10.3390/en14134045

Chicago/Turabian StyleMenéndez Arán, David, and Ángel Menéndez. 2021. "Surrogate-Based Optimization of Horizontal Axis Hydrokinetic Turbine Rotor Blades" Energies 14, no. 13: 4045. https://doi.org/10.3390/en14134045

APA StyleMenéndez Arán, D., & Menéndez, Á. (2021). Surrogate-Based Optimization of Horizontal Axis Hydrokinetic Turbine Rotor Blades. Energies, 14(13), 4045. https://doi.org/10.3390/en14134045