Experimental Investigations on Steam Generation in Nanofluids under Concentrated Solar Radiation

Abstract

:1. Introduction

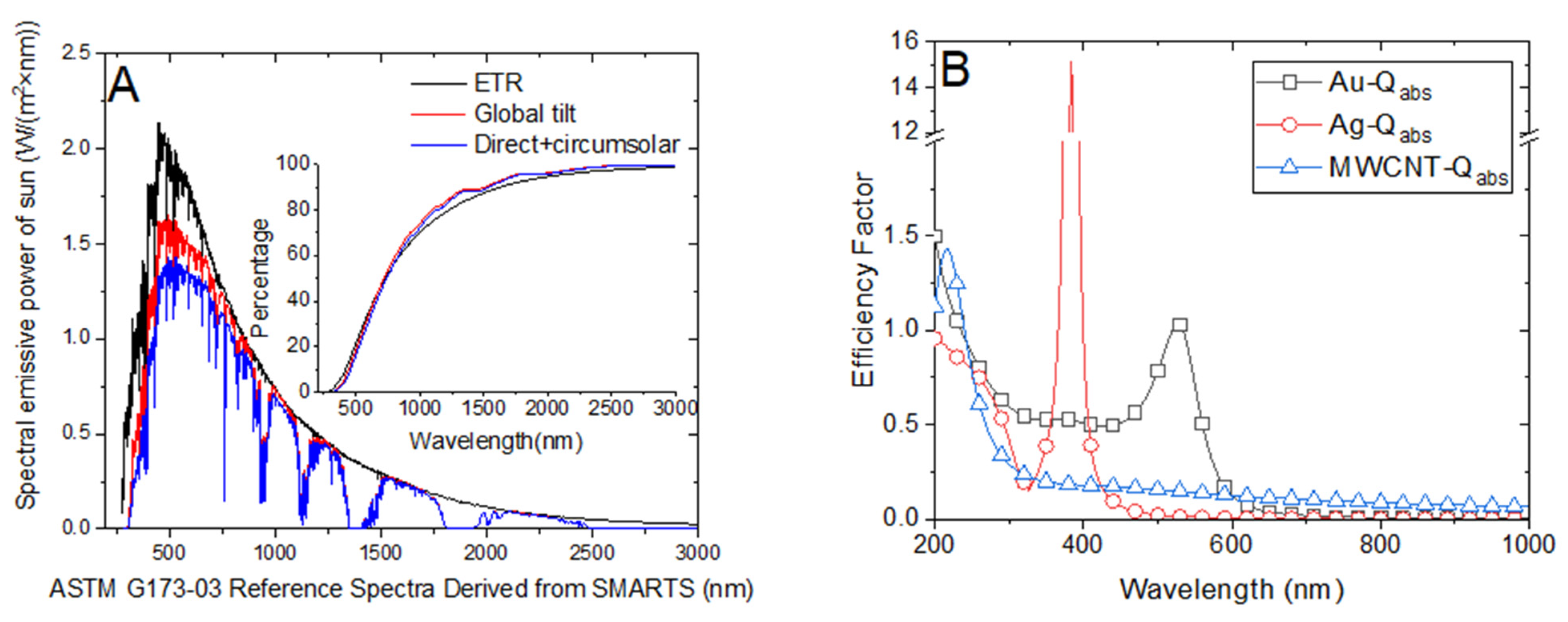

2. Materials and Methods

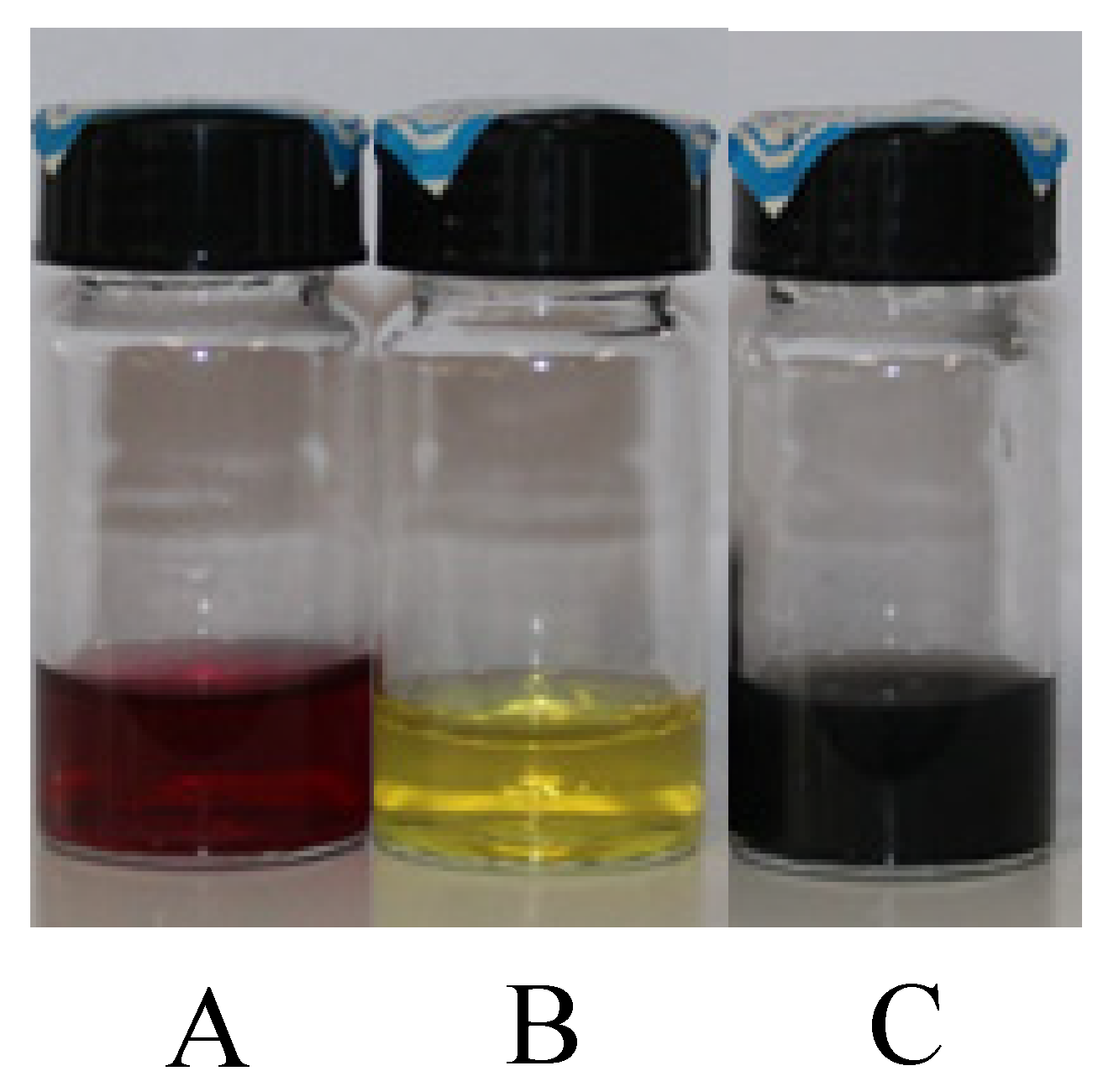

2.1. Preparation of Nanofluids

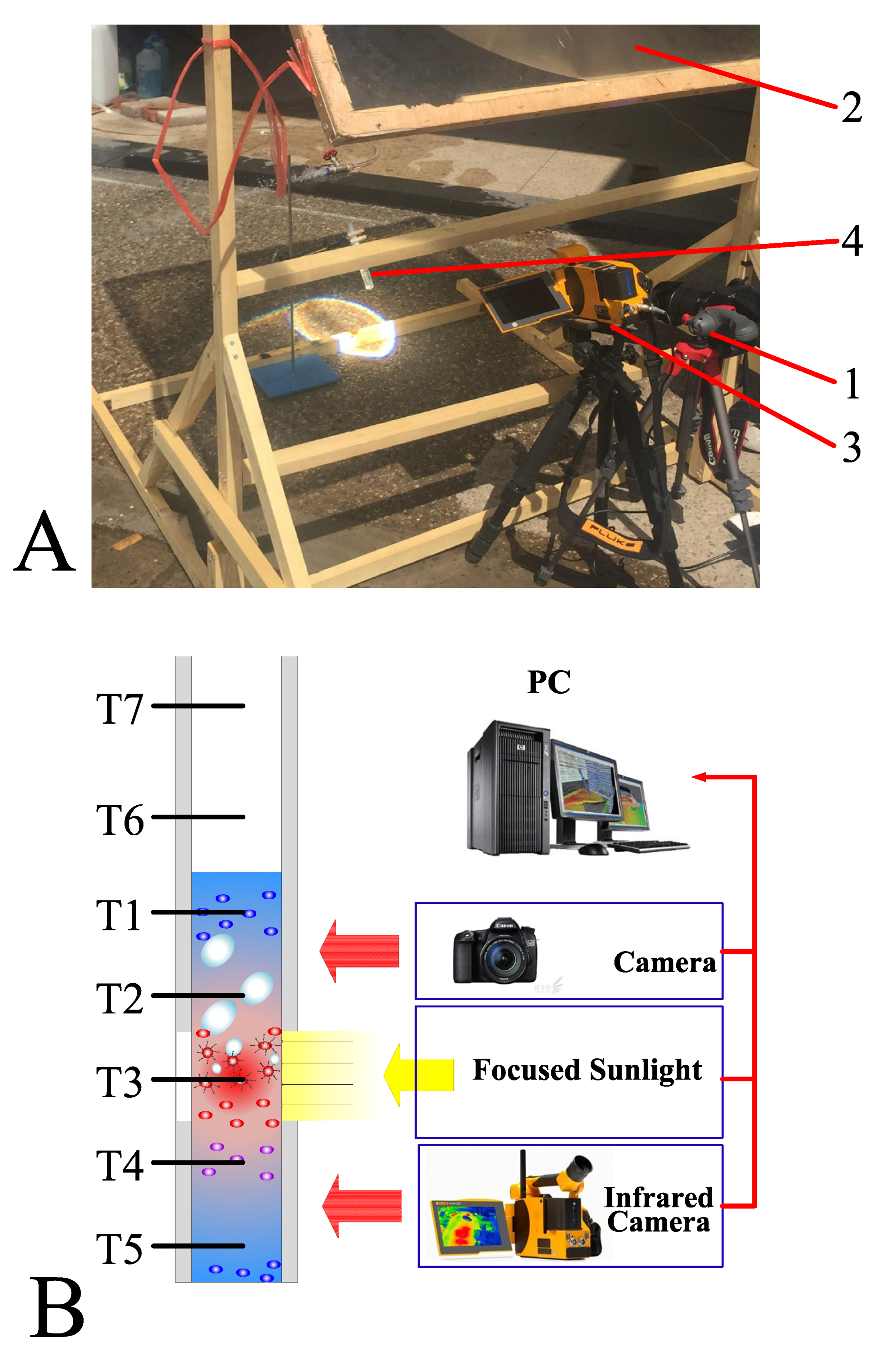

2.2. Experimental Setup

3. Results and Discussion

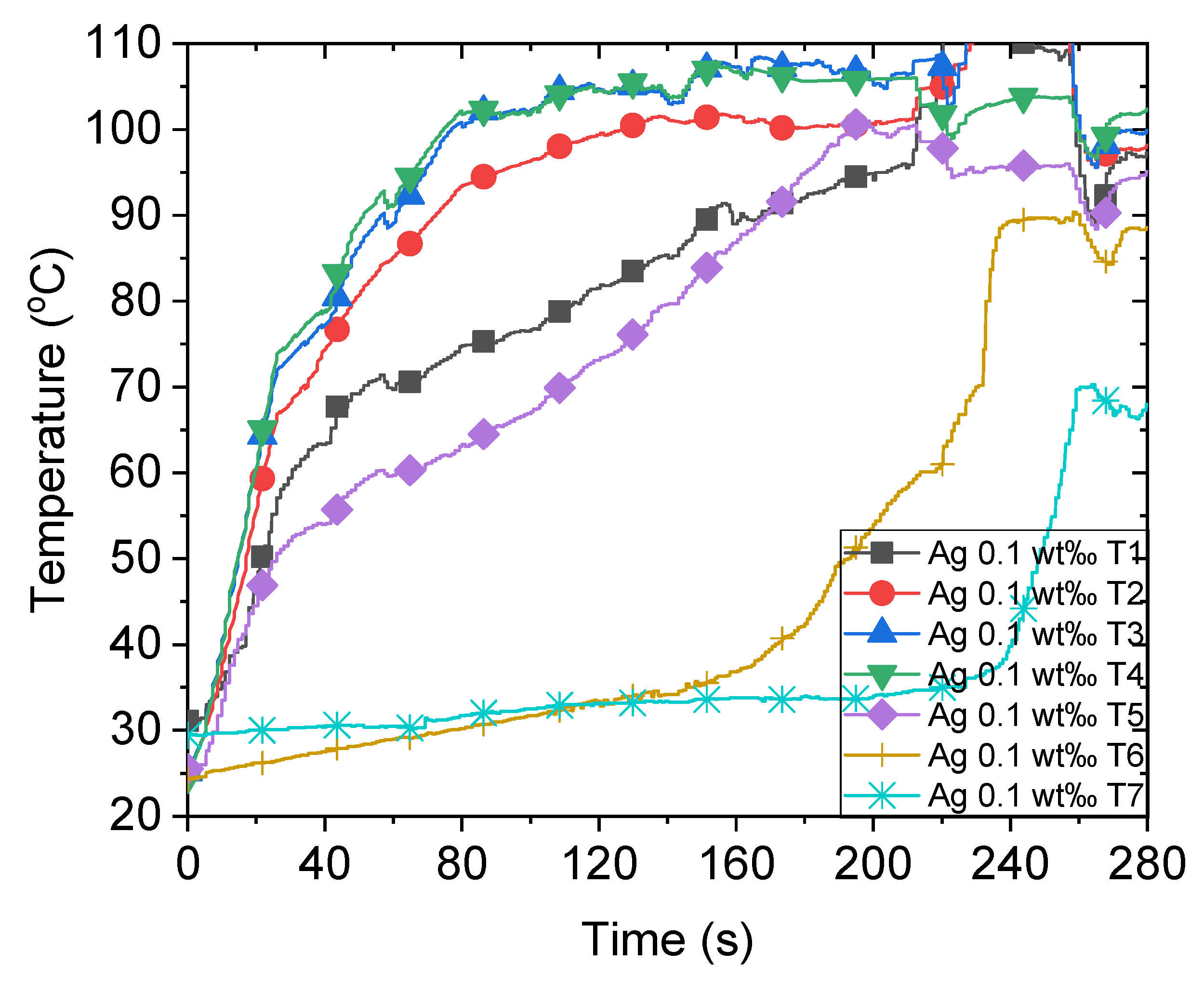

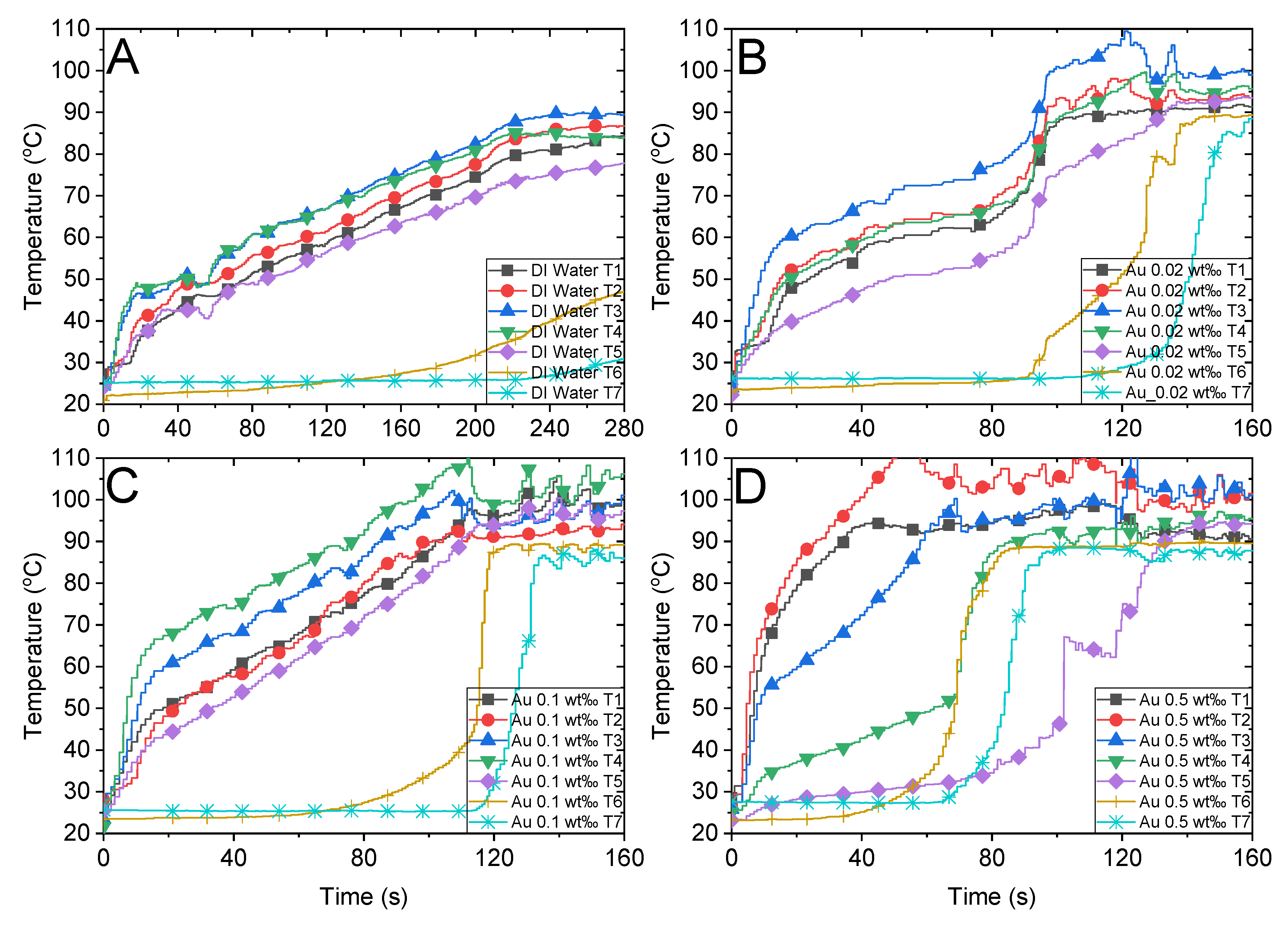

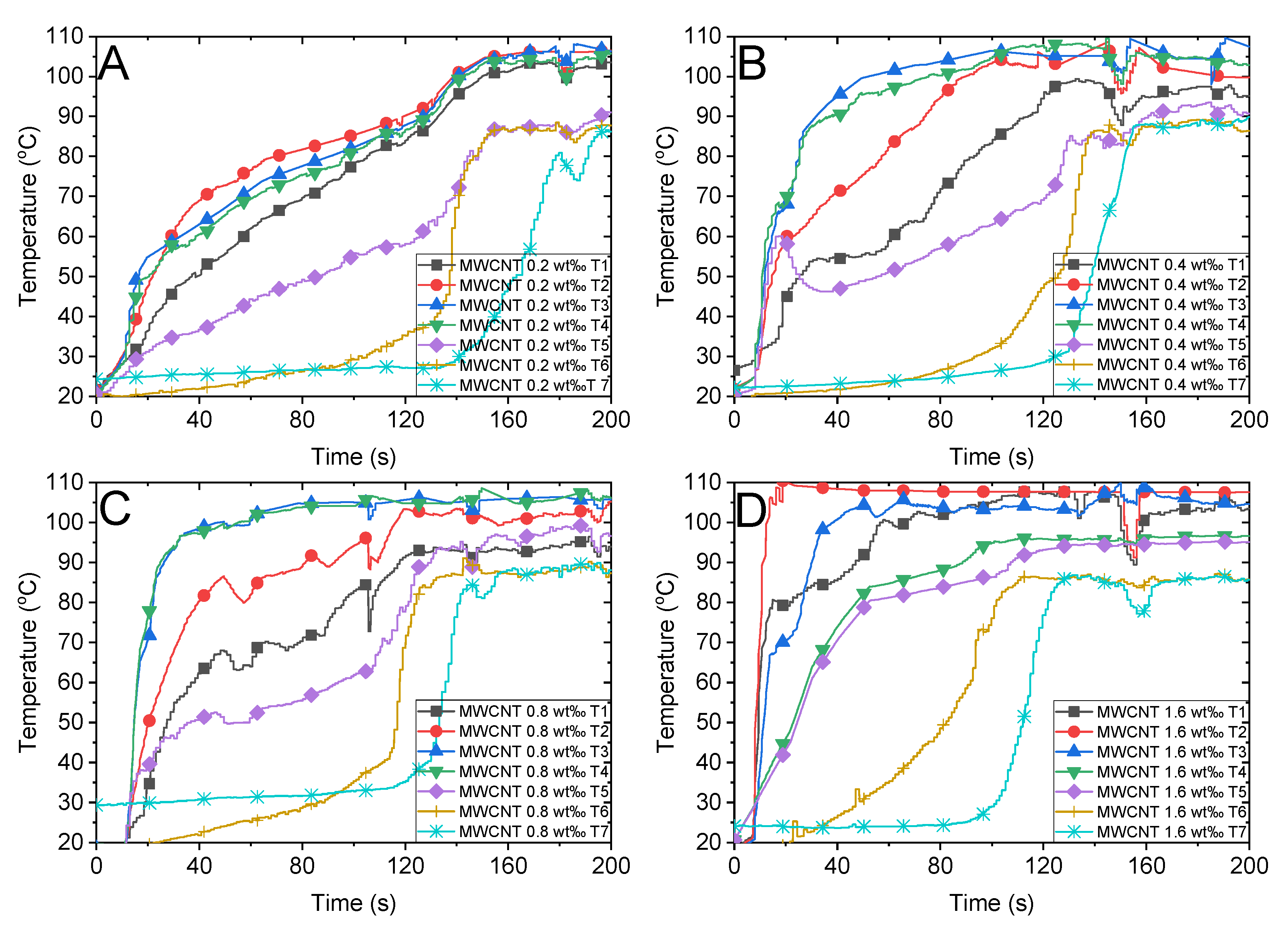

3.1. Temperature Profile of Nanofluids under Concentrated Sunlight

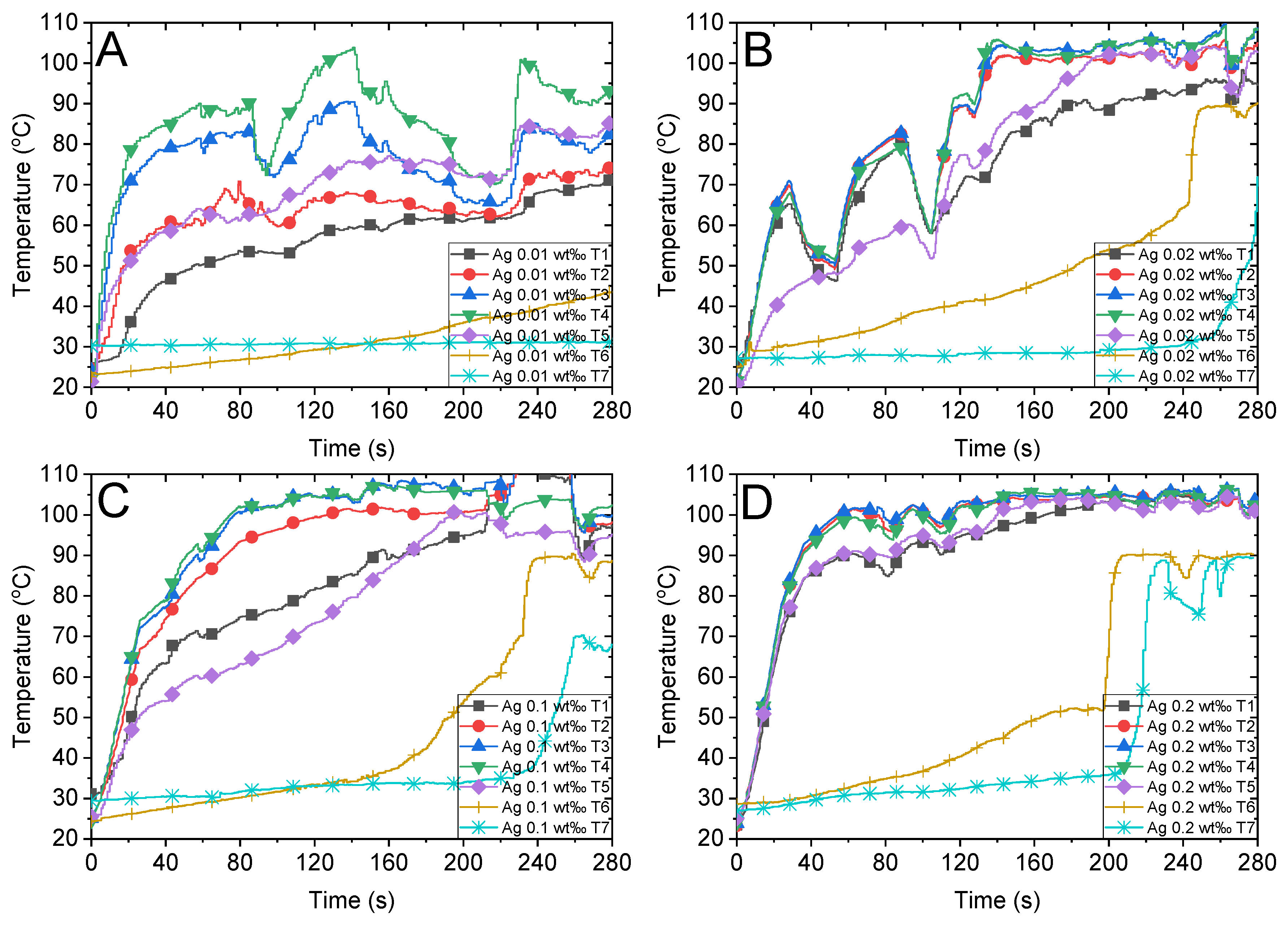

3.2. Effect of Nanofluid Concentrations on Solar Energy Absorption Performance

3.3. Effect of Different Nanofluids on Solar Energy Absorption Performance

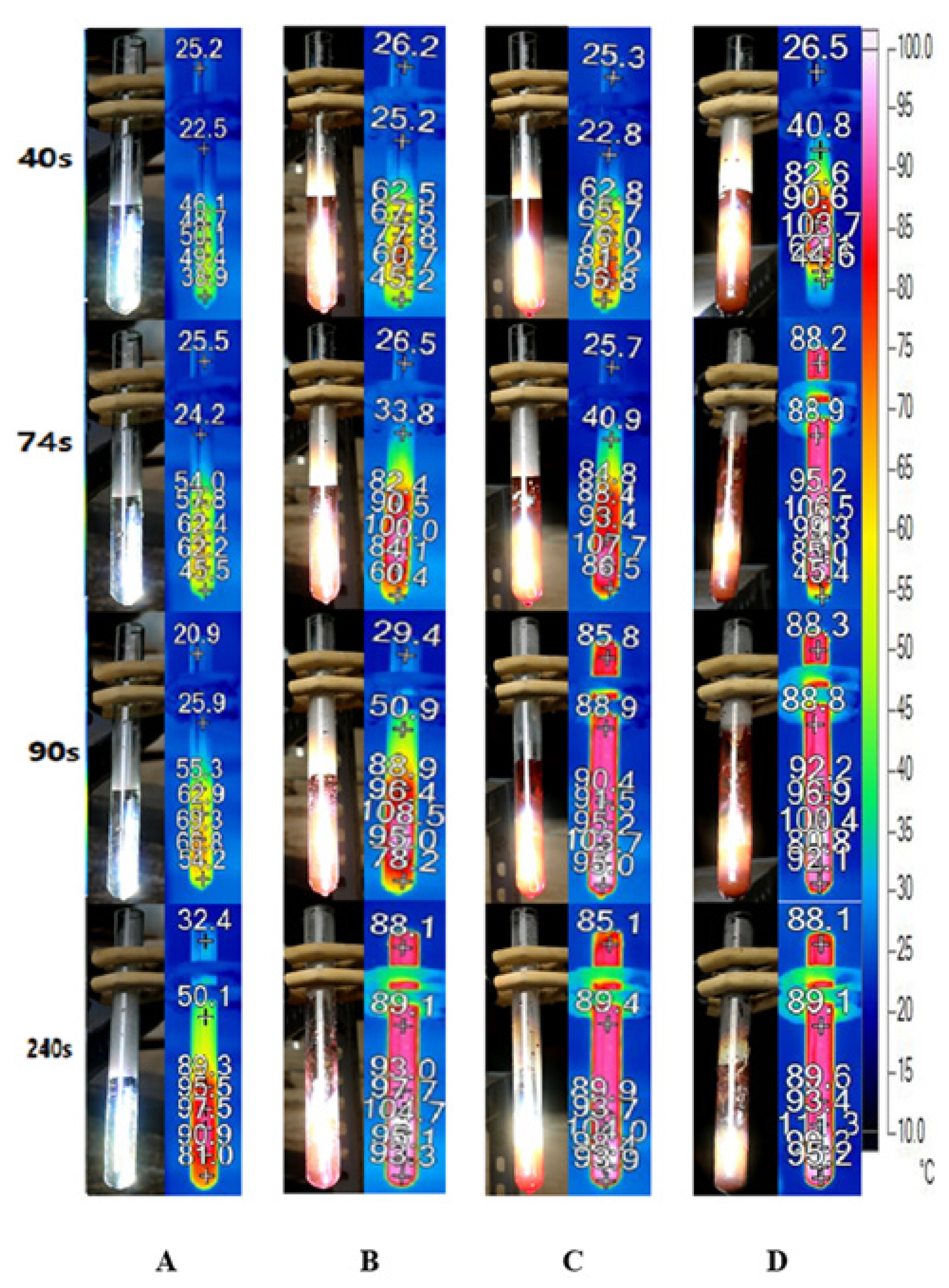

3.4. Temperature Distribution and Bubble Formation in Different Nanofluids

3.4.1. Ag Nanofluid

3.4.2. Au Nanofluid

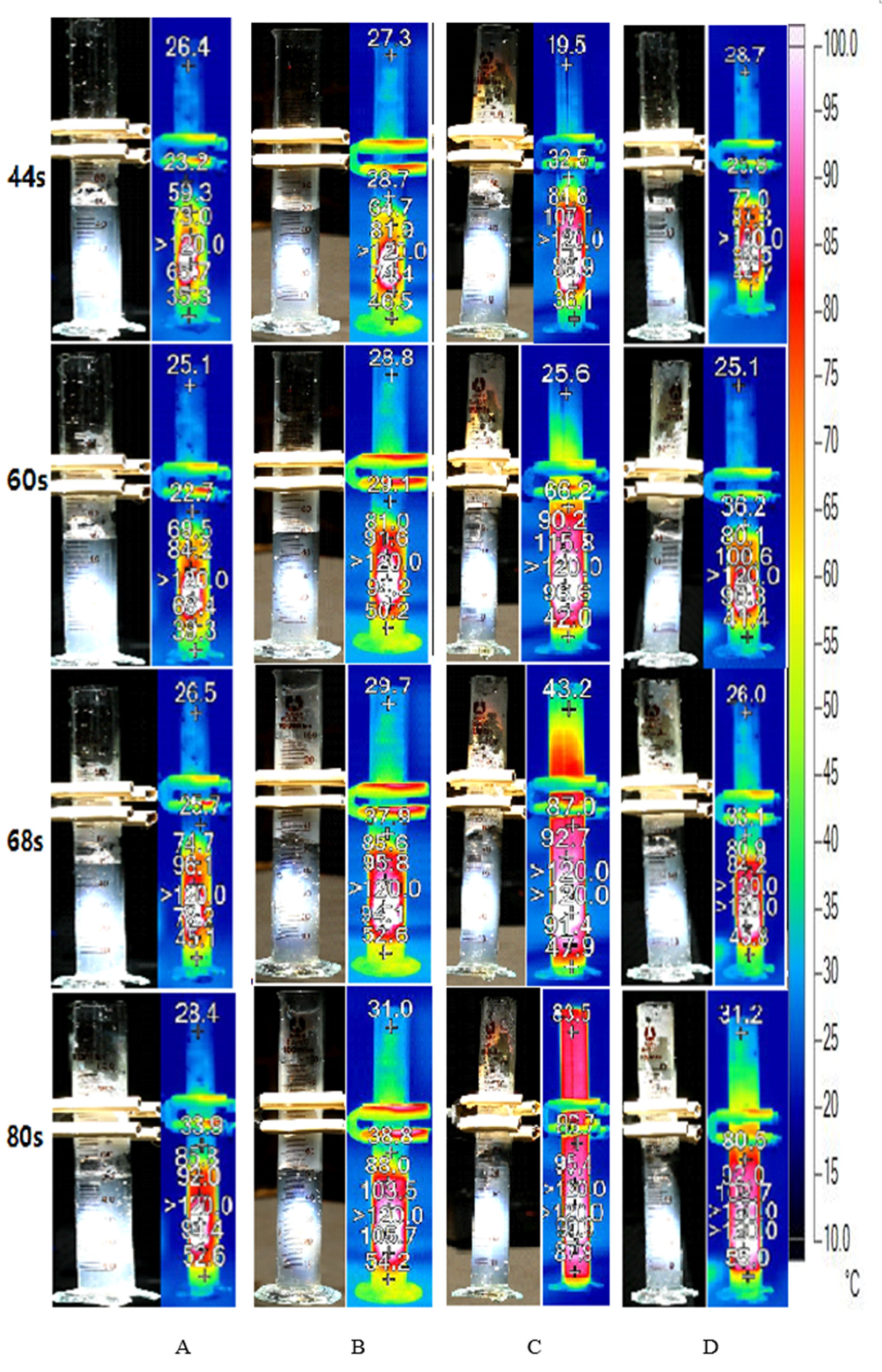

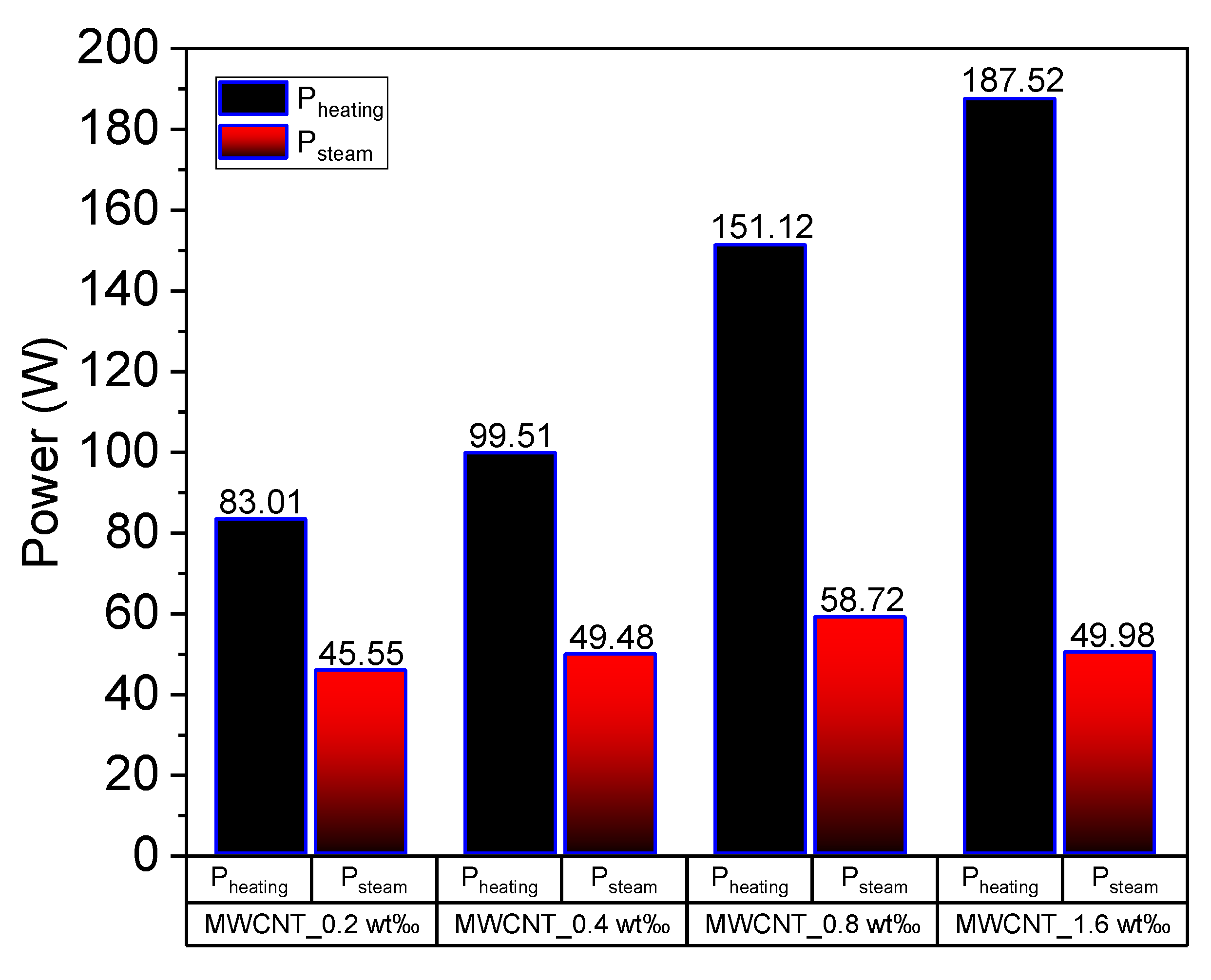

3.4.3. MWCNT Nanofluid

3.5. Energy Harvesting and Efficiency Analysis

4. Conclusions

- (1)

- The temperature increases rapidly under concentrated solar radiation when the concentration of the nanofluids increase. Typically, steam generates excessively when the bulk temperature attains the boiling point in the case of different nanofluids.

- (2)

- The volume heating and steam generation efficiency vary for different nanofluids with identical concentrations, which can be attributed to the efficiency factor of different nanoparticles. The absorbed solar energy for heating the volume and generating steam is 6 and 40 times higher than those of pure water, respectively, when the Au nanofluid concentration is 0.5 wt‰.

- (3)

- The bubble formation initiates at the focal point under concentrated solar radiation, indicating the localized boiling that causes the rapid steam generation of nanofluids.

- (4)

- The heating power and steam generation power of different nanofluids increase with concentration. However, an extremely high concentration of MWCNT nanofluids is not recommended for efficient steam generation owing to the volume expansion, which requires further investigations in the future.

Author Contributions

Funding

Conflicts of Interest

References

- Tian, Y.; Zhao, C.Y. A review of solar collectors and thermal energy storage in solar thermal applications. Appl. Energy 2013, 104, 538–553. [Google Scholar] [CrossRef] [Green Version]

- Elimelech, M.; Phillip, W.A. The Future of Seawater Desalination: Energy, Technology, and the Environment. Science 2011, 333, 712–717. [Google Scholar] [CrossRef]

- Shannon, M.A.; Bohn, P.W.; Elimelech, M.; Georgiadis, J.G.; Marinas, B.J.; Mayes, A.M. Science and technology for water purification in the coming decades. Nature 2008, 452, 301–310. [Google Scholar] [CrossRef]

- Tiwari, G.N.; Singh, H.N.; Tripathi, R. Present status of solar distillation. Solar Energy 2003, 75, 367–373. [Google Scholar] [CrossRef]

- Gupta, M.K.; Kaushik, S.C. Exergy analysis and investigation for various feed water heaters of direct steam generation solar-thermal power plant. Renew. Energy 2010, 35, 1228–1235. [Google Scholar] [CrossRef]

- Yu, S.; Zhang, Y.; Duan, H.; Liu, Y.; Quan, X.; Tao, P.; Shang, W.; Wu, J.; Song, C.; Deng, T. The impact of surface chemistry on the performance of localized solar-driven evaporation system. Sci. Rep. 2015, 5, 13600. [Google Scholar] [CrossRef]

- Shannon, M.A. Water desalination Fresh for less. Nat. Nanotechnol. 2010, 5, 248–250. [Google Scholar] [CrossRef]

- Ghasemi, H.; Ni, G.; Marconnet, A.M.; Loomis, J.; Yerci, S.; Miljkovic, N.; Chen, G. Solar steam generation by heat localization. Nat. Commun. 2014, 5, 4449. [Google Scholar] [CrossRef] [Green Version]

- Bae, K.; Kang, G.; Cho, S.K.; Park, W.; Kim, K.; Padilla, W.J. Flexible thin-film black gold membranes with ultrabroadband plasmonic nanofocusing for efficient solar vapour generation. Nat. Commun. 2015, 6, 10103. [Google Scholar] [CrossRef] [Green Version]

- Jin, H.C.; Lin, G.P.; Bai, L.Z.; Zeiny, A.; Wen, D.S. Steam generation in a nanoparticle-based solar receiver. Nano Energy 2016, 28, 397–406. [Google Scholar] [CrossRef] [Green Version]

- Jin, H.C.; Lin, G.P.; Bai, L.Z.; Amjad, M.; Bandarra, E.P.; Wen, D.S. Photothermal conversion efficiency of nanofluids: An experimental and numerical study. Solar Energy 2016, 139, 278–289. [Google Scholar] [CrossRef] [Green Version]

- Jin, H.C.; Lin, G.P.; Zeiny, A.; Bai, L.Z.; Wen, D.S. Nanoparticle-based solar vapor generation: An experimental and numerical study. Energy 2019, 178, 447–459. [Google Scholar] [CrossRef]

- Khullar, V.; Tyagi, H.; Hordy, N.; Otanicar, T.P.; Hewakuruppu, Y.; Modi, P.; Taylor, R.A. Harvesting solar thermal energy through nanofluid-based volumetric absorption systems. Int. J. Heat Mass Transf. 2014, 77, 377–384. [Google Scholar] [CrossRef]

- Ishii, S.; Sugavaneshwar, R.P.; Nagao, T. Titanium Nitride Nanoparticles as Plasmonic Solar Heat Transducers. J. Phys. Chem. C 2016, 120, 2343–2348. [Google Scholar] [CrossRef]

- Zhou, L.; Tan, Y.L.; Ji, D.X.; Zhu, B.; Zhang, P.; Xu, J.; Gan, Q.Q.; Yu, Z.F.; Zhu, J. Self-assembly of highly efficient, broadband plasmonic absorbers for solar steam generation. Sci. Adv. 2016, 2, e1501227. [Google Scholar] [CrossRef] [Green Version]

- Yeshchenko, O.A.; Kutsevol, N.V.; Naumenko, A.P. Light-Induced Heating of Gold Nanoparticles in Colloidal Solution: Dependence on Detuning from Surface Plasmon Resonance. Plasmonics 2016, 11, 345–350. [Google Scholar] [CrossRef]

- Tullius, T.K.; Bayazitoglu, Y. Temperature of a metallic nanoparticle embedded in a phase change media exposed to radiation. Int. J. Heat Mass Transf. 2016, 93, 980–990. [Google Scholar] [CrossRef]

- Otanicar, T.P.; Phelan, P.E.; Prasher, R.S.; Rosengarten, G.; Taylor, R.A. Nanofluid-based direct absorption solar collector. J. Renew. Sustain. Energy 2010, 2, 033102. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Chen, H.J.; Du, X.Z.; Wen, D.S. Photothermal conversion characteristics of gold nanoparticle dispersions. Solar Energy 2014, 100, 141–147. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, C.; Wei, W.; Xiao, G.; Ni, M. Performance improvement of a nanofluid solar collector based on direct absorption collection (DAC) concepts. Int. J. Heat Mass Transf. 2014, 75, 262–271. [Google Scholar] [CrossRef]

- Jin, X.; Lin, G.P.; Zeiny, A.; Jin, H.C.; Bai, L.Z.; Wen, D.S. Solar photothermal conversion characteristics of hybrid nanofluids: An experimental and numerical study. Renew. Energy 2019, 141, 937–949. [Google Scholar] [CrossRef]

- Neumann, O.; Urban, A.S.; Day, J.; Lal, S.; Nordlander, P.; Halas, N.J. Solar vapor generation enabled by nanoparticles. ACS Nano 2013, 7, 42–49. [Google Scholar] [CrossRef] [PubMed]

- Ni, G.; Miljkovic, N.; Ghasemi, H.; Huang, X.; Boriskina, S.V.; Lin, C.-T.; Wang, J.; Xu, Y.; Rahman, M.M.; Zhang, T.; et al. Volumetric solar heating of nanofluids for direct vapor generation. Nano Energy 2015, 17, 290–301. [Google Scholar] [CrossRef] [Green Version]

- Gan, Y.A.; Qiao, L. Optical Properties and Radiation-Enhanced Evaporation of Nanofluid Fuels Containing Carbon-Based Nanostructures. Energ. Fuel 2012, 26, 4224–4230. [Google Scholar] [CrossRef]

- Hogan, N.J.; Urban, A.S.; Ayala-Orozco, C.; Pimpinelli, A.; Nordlander, P.; Halas, N.J. Nanoparticles Heat through Light Localization. Nano Lett. 2014, 14, 4640–4645. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Neumann, O.; Feronti, C.; Neumann, A.D.; Dong, A.J.; Schell, K.; Lu, B.; Kim, E.; Quinn, M.; Thompson, S.; Grady, N.; et al. Compact solar autoclave based on steam generation using broadband light-harvesting nanoparticles. Proc. Natl. Acad. Sci. USA 2013, 110, 11677–11681. [Google Scholar] [CrossRef] [Green Version]

- Saidur, R.; Meng, T.C.; Said, Z.; Hasanuzzaman, M.; Kamyar, A. Evaluation of the effect of nanofluid-based absorbers on direct solar collector. Int. J. Heat Mass Transf. 2012, 55, 5899–5907. [Google Scholar] [CrossRef]

- Fang, Z.; Zhen, Y.R.; Neumann, O.; Polman, A.; de Abajo, F.J.G.; Nordlander, P.; Halas, N.J. Evolution of light-induced vapor generation at a liquid-immersed metallic nanoparticle. Nano Lett. 2013, 13, 1736–1742. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Govorov, A.O.; Zhang, W.; Skeini, T.; Richardson, H.; Lee, J.; Kotov, N.A. Gold nanoparticle ensembles as heaters and actuators: Melting and collective plasmon resonances. Nanoscale Res. Lett. 2006, 1, 84–90. [Google Scholar] [CrossRef] [Green Version]

- Otanicar, T.P.; Phelan, P.E.; Golden, J.S. Optical properties of liquids for direct absorption solar thermal energy systems. Solar Energy 2009, 83, 969–977. [Google Scholar] [CrossRef]

- Bandarra, E.P.; Mendoza, O.S.H.; Beicker, C.L.L.; Menezes, A.; Wen, D.S. Experimental investigation of a silver nanoparticle-based direct absorption solar thermal system. Energy Convers. Manag. 2014, 84, 261–267. [Google Scholar] [CrossRef]

- Rahman, M.M.; Al-Mazroui, W.A.; Al-Hatmi, F.S.; Al-Lawatia, M.A.; Eltayeb, I.A. The role of a convective surface in models of the radiative heat transfer in nanofluids. Nucl. Eng. Des. 2014, 275, 382–392. [Google Scholar] [CrossRef]

- Hussain, I.; Graham, S.; Wang, Z.X.; Tan, B.; Sherrington, D.C.; Rannard, S.P.; Cooper, A.I.; Brust, M. Size-controlled synthesis of near-monodisperse gold nanoparticles in the 1–4 nm range using polymeric stabilizers. J. Am. Chem. Soc. 2005, 127, 16398–16399. [Google Scholar] [CrossRef]

- Baffou, G.; Quidant, R.; de Abajo, F.J.G. Nanoscale Control of Optical Heating in Complex Plasmonic Systems. ACS Nano 2010, 4, 709–716. [Google Scholar] [CrossRef] [PubMed]

- Lukianova-Hleb, E.; Hu, Y.; Latterini, L.; Tarpani, L.; Lee, S.; Drezek, R.A.; Hafner, J.H.; Lapotko, D.O. Plasmonic Nanobubbles as Transient Vapor Nanobubbles Generated around Plasmonic Nanoparticles. ACS Nano 2010, 4, 2109–2123. [Google Scholar] [CrossRef] [Green Version]

- Ni, G.; Li, G.; Boriskina, S.V.; Li, H.X.; Yang, W.L.; Zhang, T.J.; Chen, G. Steam generation under one sun enabled by a floating structure with thermal concentration. Nat. Energy 2016, 1, 16126. [Google Scholar] [CrossRef]

- Li, X.Q.; Xu, W.C.; Tang, M.Y.; Zhou, L.; Zhu, B.; Zhu, S.N.; Zhu, J. Graphene oxide-based efficient and scalable solar desalination under one sun with a confined 2D water path. Proc. Natl. Acad. Sci. USA 2016, 113, 13953–13958. [Google Scholar] [CrossRef] [Green Version]

- Ma, H.Y.; Bendix, P.M.; Oddershede, L.B. Large-Scale Orientation Dependent Heating from a Single Irradiated Gold Nanorod. Nano Lett. 2012, 12, 3954–3960. [Google Scholar] [CrossRef]

- Ye, E.Y.; Win, K.Y.; Tan, H.R.; Lin, M.; Teng, C.P.; Mlayah, A.; Han, M.Y. Plasmonic Gold Nanocrosses with Multidirectional Excitation and Strong Photothermal Effect. J. Am. Chem. Soc. 2011, 133, 8506–8509. [Google Scholar] [CrossRef] [PubMed]

- Baffou, G.; Bon, P.; Savatier, J.; Polleux, J.; Zhu, M.; Merlin, M.; Rigneault, H.; Monneret, S. Thermal Imaging of Nanostructures by Quantitative Optical Phase Analysis. ACS Nano 2012, 6, 2452–2458. [Google Scholar] [CrossRef] [Green Version]

- Govorov, A.O.; Richardson, H.H. Generating heat with metal nanoparticles. Nano Today 2007, 2, 30–38. [Google Scholar] [CrossRef]

- Lukianova-Hleb, E.Y.; Volkov, A.N.; Lapotko, D.O. Laser pulse duration is critical for the generation of plasmonic nanobubbles. Langmuir 2014, 30, 7425–7434. [Google Scholar] [CrossRef]

- Hou, L.; Yorulmaz, M.; Verhart, N.R.; Orrit, M. Explosive formation and dynamics of vapor nanobubbles around a continuously heated gold nanosphere. New J. Phys. 2015, 17, 13050. [Google Scholar] [CrossRef] [Green Version]

- Vera, J.; Bayazitoglu, Y. Temperature and heat flux dependence of thermal resistance of water/metal nanoparticle interfaces at sub-boiling temperatures. Int. J. Heat Mass Transf. 2015, 86, 433–442. [Google Scholar] [CrossRef]

- Wen, D. Intracellular hyperthermia: Nanobubbles and their biomedical applications. Int. J. Hyperth. 2009, 25, 533–541. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.L.; Munjiza, A.; Zhang, K.; Wen, D.S. Molecular Dynamics Simulation of Heat Transfer from a Gold Nanoparticle to a Water Pool. J. Phys. Chem. C 2014, 118, 1285–1293. [Google Scholar] [CrossRef]

- Huang, J.; He, Y.; Hu, Y.; Wang, X. Steam generation enabled by a high efficiency solar absorber with thermal concentration. Energy 2018, 165, 1282–1291. [Google Scholar] [CrossRef]

- Modest, M.F. CHAPTER 20—The Monte Carlo Method for Thermal Radiation, 2nd ed.; Modest, M.F., Ed.; Academic Press: Burlington, MA, USA, 2003; pp. 644–679. [Google Scholar]

- McPeak, K.M.; Jayanti, S.V.; Kress, S.J.P.; Meyer, S.; Iotti, S.; Rossinelli, A.; Norris, D.J. Plasmonic Films Can Easily Be Better: Rules and Recipes. ACS Photonics 2015, 2, 326–333. [Google Scholar] [CrossRef]

- Zeiny, A.; Jin, H.; Lin, G.; Song, P.; Wen, D. Solar evaporation via nanofluids: A comparative study. Renew. Energy 2018, 122, 443–454. [Google Scholar] [CrossRef] [Green Version]

| Type of Nanoparticles | Concentrations (wt‰) | Particle Size (nm) | Preparation Method | Micro-Nano Structure |

|---|---|---|---|---|

| Au | 0.02 0.1 0.5 | 20~30 | One-step |  |

| Ag | 0.01 0.02 0.1 0.2 | 20~30 | Two-step |  |

| MWCNT | 0.2 0.4 0.8 1.6 | 50 × 500 | Two-step |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, X.; Lin, G.; Jin, H. Experimental Investigations on Steam Generation in Nanofluids under Concentrated Solar Radiation. Energies 2021, 14, 3985. https://doi.org/10.3390/en14133985

Jin X, Lin G, Jin H. Experimental Investigations on Steam Generation in Nanofluids under Concentrated Solar Radiation. Energies. 2021; 14(13):3985. https://doi.org/10.3390/en14133985

Chicago/Turabian StyleJin, Xin, Guiping Lin, and Haichuan Jin. 2021. "Experimental Investigations on Steam Generation in Nanofluids under Concentrated Solar Radiation" Energies 14, no. 13: 3985. https://doi.org/10.3390/en14133985

APA StyleJin, X., Lin, G., & Jin, H. (2021). Experimental Investigations on Steam Generation in Nanofluids under Concentrated Solar Radiation. Energies, 14(13), 3985. https://doi.org/10.3390/en14133985