On the Optimization of Electrical Water Heaters: Modelling Simulations and Experimentation

Abstract

:1. Introduction

- Most of the studies consider complex systems of building operation, while the present paper is focused only on water tank heating systems and their thermal behavior.

- Most of the studies develop very complex predictive optimization techniques that simultaneously treat the effect of several parameters to sort out optimized configurations, while the present manuscript constitutes simplified thermal modeling and its associated numerical tool which permits it to easily perform parametric studies of effects separately and jointly (as detailed in the manuscript).

- Most of the studies concentrate on the mathematical side of the optimization, while the present paper concentrates on the thermal-energy side towards optimization.

- Finally, the present work constitutes a solid basis for the future development of new optimization techniques by using the simulation tool presented as part of an overall optimization algorithm, especially when it comes to the water heating and the time of power utilization.

- It proposes an appropriate simplified and modular thermal modeling of electrical water heater that facilitates performing parametric studies with low computational time.

- The study presents a significant material in which the performance of electrical water heaters is investigated by undergoing a viable thermal modeling and performing parametric analysis.

- It provides useful modeling and parametric analysis for the electrical water heater community. This benefit is achieved when the conducted thermal model is utilized in investigations aimed at energy management of the operation of electrical water heaters. It also facilitates studying the effects on system performance of a large range of parameters, especially when investigating the feasibility of new concepts or configurations.

2. Thermal Modeling

2.1. Energy Balance and Governing Equations

2.2. Experimental Determination of the Overall Heat Transfer Coefficient

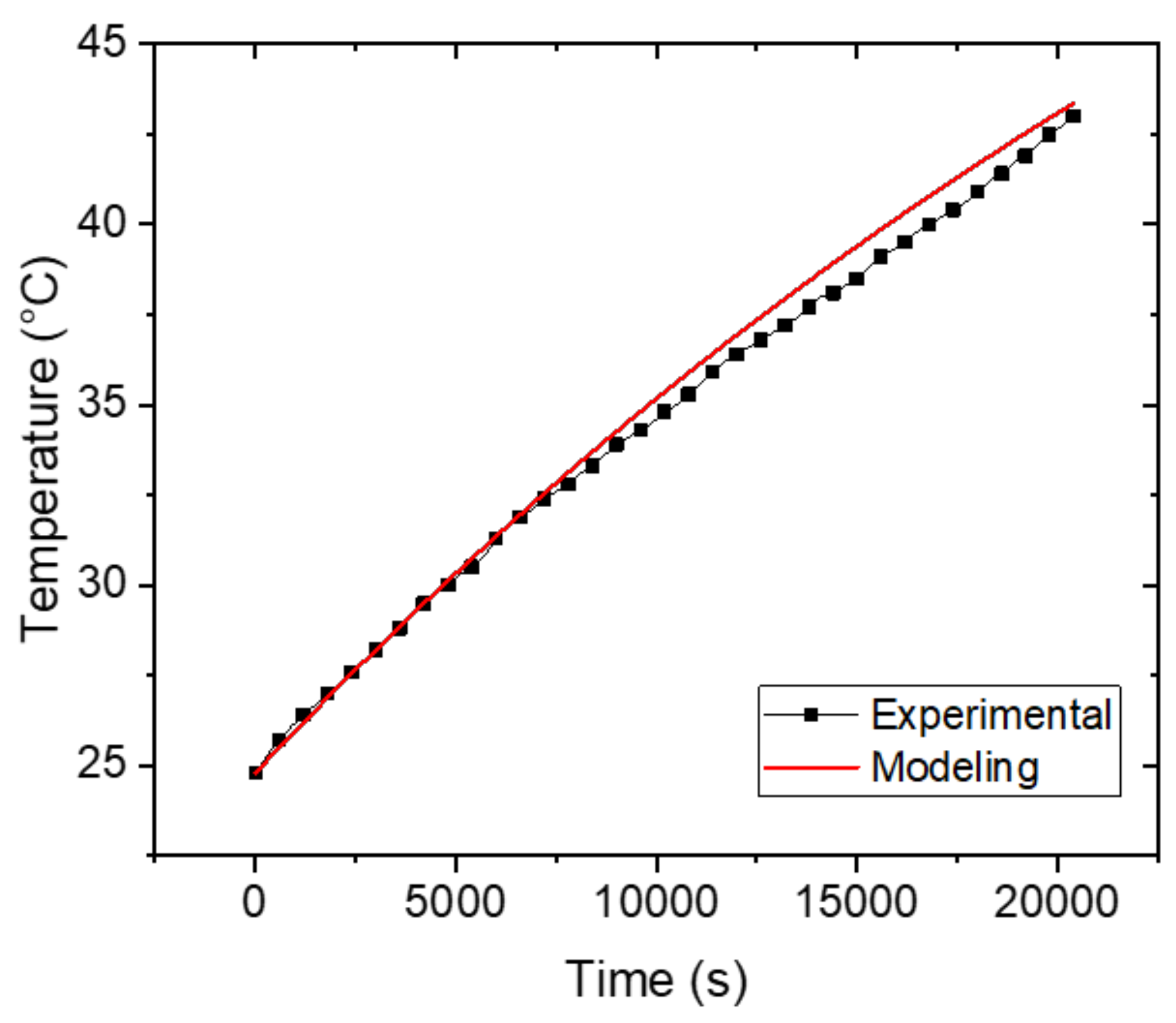

2.3. Experimental Validation

3. Parametric Study

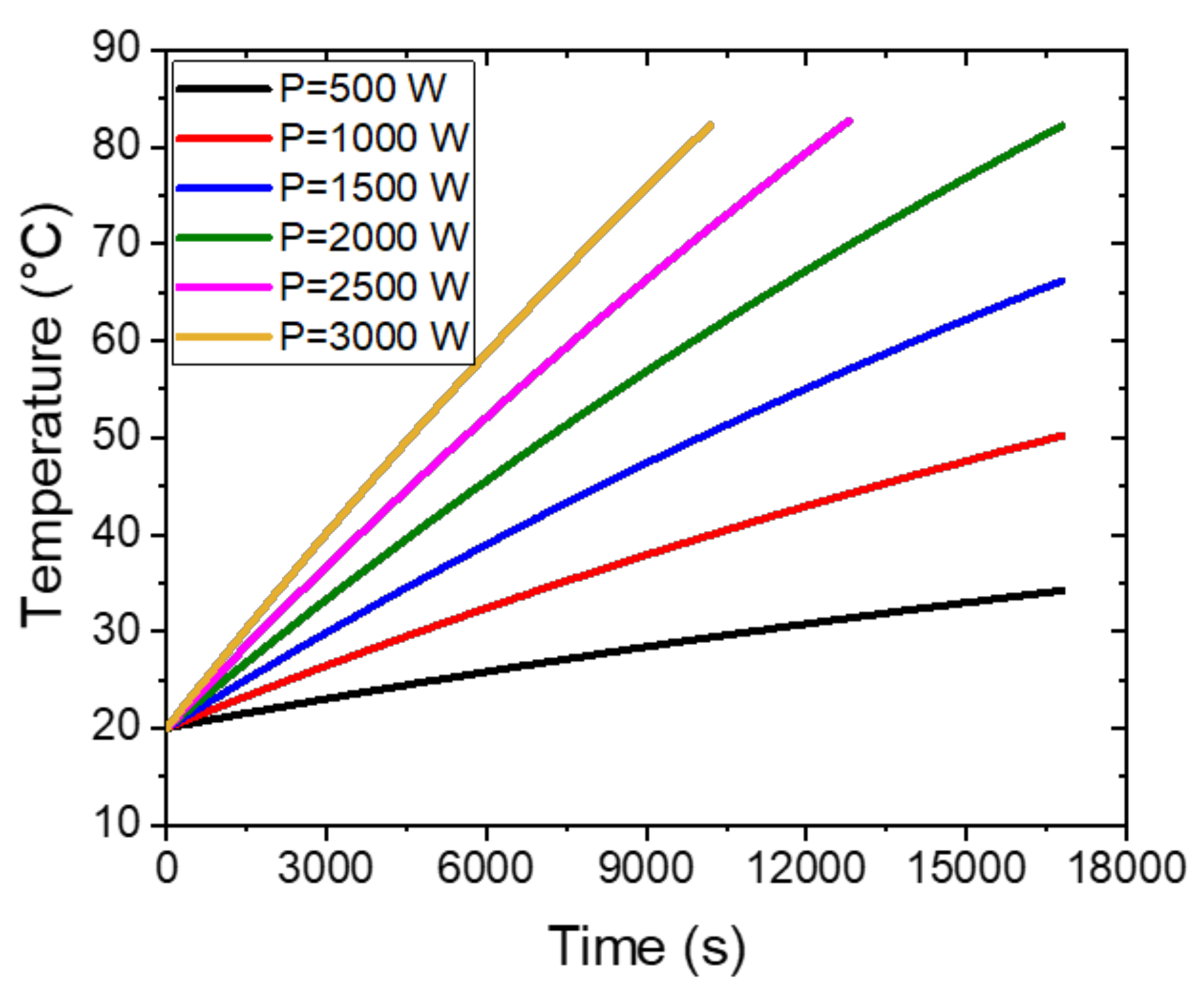

- The first simulation was achieved with six different electric powers (500, 1000, 1500, 2000, 2500 and 3000 W). The tank had a fixed volume of 100 L with a height of 1050 mm. This choice was made to simulate a typical size of commercial heaters.

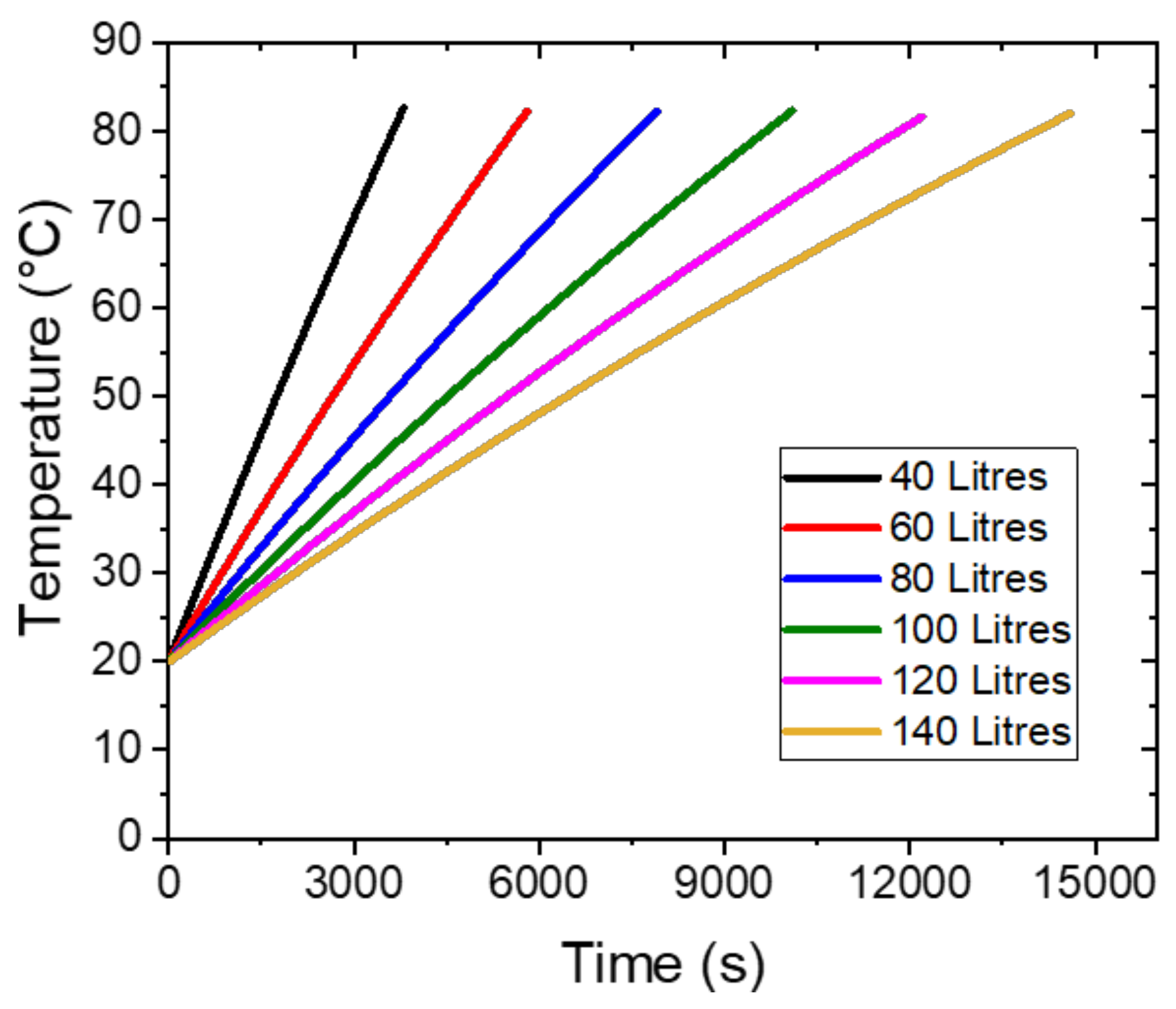

- The second parameter was the volume of the tank which was varied according to six levels: between 40 and 140 L, conserving a fixed height of 1050 mm. The electrical power was fixed at 3000 Watt. The objective of this study was to quantify the heat losses associated with the change of volume.

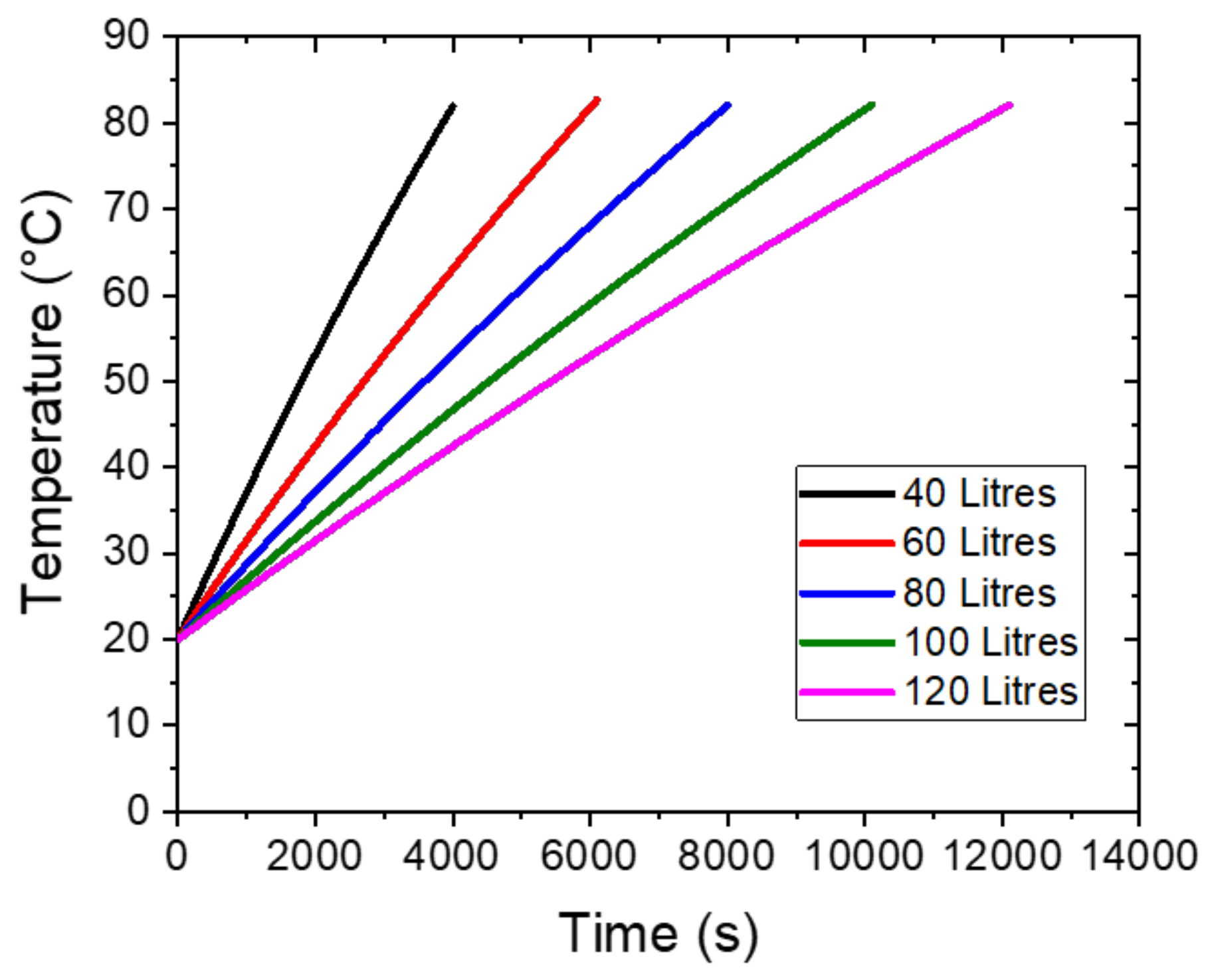

- The third simulation was designed later and was inspired by the results of the second study which are presented and analyzed in the next paragraph. However, the simulation was based on a variable volume with a constant area of the tank which was fixed at 1.35 m2. This value corresponds to the area of the commercial tank simulated in the first study.

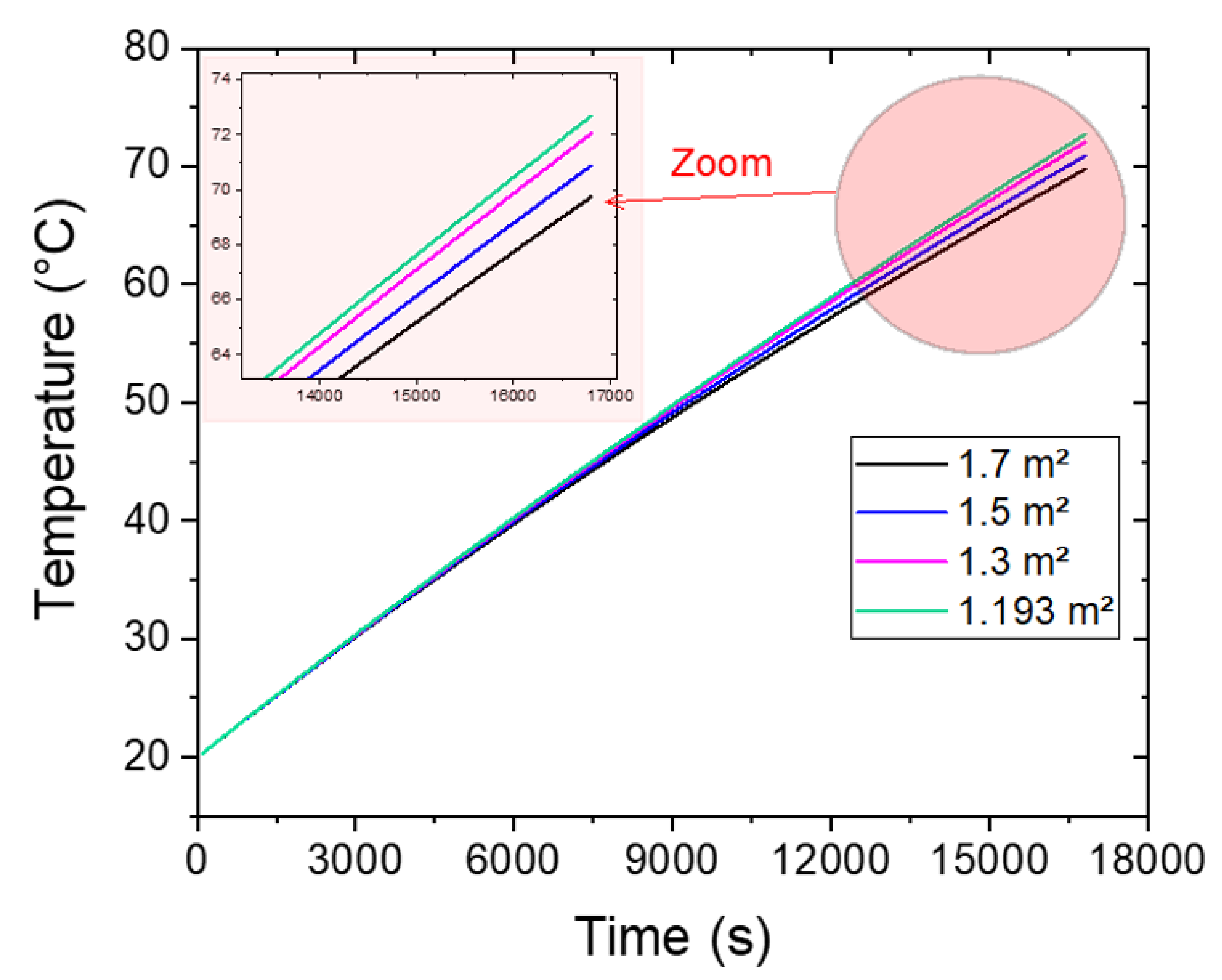

- The fourth case was done using a fixed power of 3000 W and a fixed volume of 100 L, but with different diameters and heights. The height and diameters were calculated in a manner to obtain 7 different levels of the external area of the tank which were, respectively: 1.193, 1.20, 1.25, 1.30, 1.35, 1.40 and 1.45 m2. The value of 1.193 corresponds to the minimum area which could be obtained for a cylindrical tank of 100 L capacity.

4. Results and Analysis

4.1. Effect of Power

4.2. Effect of Volume

4.3. Effect of Volume under Constant Area

4.4. Effect of Heater’s External Area

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Karacan, R.; Mukhtarov, S.; Barış, İ.; İşleyen, A.; Yardımcı, M.E. The impact of oil price on transition toward renewable energy consumption? Evidence from Russia. Energies 2021, 14, 2947. [Google Scholar] [CrossRef]

- Sun, R.; Abeynayake, G.; Liang, J.; Wang, K. Reliability and economic evaluation of offshore wind power dc collection systems. Energies 2021, 14, 2922. [Google Scholar] [CrossRef]

- Kishore, T.S.; Patro, E.R.; Harish, V.S.K.V.; Haghighi, A.T. A comprehensive study on the recent progress and trends in development of small hydropower projects. Energies 2021, 14, 2882. [Google Scholar] [CrossRef]

- Korkeakoski, M. Towards 100% renewables by 2030: Transition alternatives for a sustainable electricity sector in Isla de la Juventud, Cuba. Energies 2021, 14, 2862. [Google Scholar] [CrossRef]

- Mehta, K.; Ehrenwirth, M.; Trinkl, C.; Zörner, W.; Greenough, R. The energy situation in Central Asia: A comprehensive energy review focusing on rural areas. Energies 2021, 14, 2805. [Google Scholar] [CrossRef]

- Lourenço, J.M.; Aelenei, L.; Sousa, M.; Facão, J.; Gonçalves, H. Thermal behavior of a BIPV combined with water storage: An experimental analysis. Energies 2021, 14, 2545. [Google Scholar] [CrossRef]

- Elmouatamid, A.; Ouladsine, R.; Bakhouya, M.; El Kamoun, N.; Khaidar, M.; Zine-Dine, K. Review of control and energy management approaches in micro-grid systems. Energies 2021, 14, 168. [Google Scholar] [CrossRef]

- Nall, D. An engineering approach to evaluating energy technology. ASHREA J. 2019, 61, 60–68. [Google Scholar]

- Agll, A.A.A.; Hamad, Y.M.; Hamad, T.A.; Sheffield, J.W. Study of energy recovery and power generation from alternative energy source. Case Stud. Therm. Eng. 2014, 4, 92–98. [Google Scholar] [CrossRef] [Green Version]

- Chiemchaisri, C.; Juanga, J.P.; Visvanathan, C. Municipal solid waste management in Thailand and disposal emission inventory. Environ. Monit. Assess. 2007, 135, 13–20. [Google Scholar] [CrossRef] [PubMed]

- Khaled, M.; Ramadan, M. Heating fresh air by hot exhaust air of HVAC systems. Case Stud. Therm. Eng. 2016, 8, 398–402. [Google Scholar] [CrossRef] [Green Version]

- Ramadan, M.; Gad El Rab, M.; Khaled, M. Parametric analysis of air-water heat recovery concept applied to HVAC systems: Effect of mass flow rates. Case Stud. Therm. Eng. 2015, 6, 61–68. [Google Scholar] [CrossRef] [Green Version]

- Khaled, M.; Ramadan, M.; Chahine, K.; Assi, A. Prototype implementation and experimental analysis of water heating using recovered waste heat of chimneys. Case Stud. Therm. Eng. 2015, 5, 127–133. [Google Scholar] [CrossRef] [Green Version]

- Wannagosit, C.; Sakulchangsatjatai, P.; Kammuang-Lue, N.; Terdtoon, P. Validated mathematical models of a solar water heater system with thermosyphon evacuated tube collectors. Case Stud. Therm. Eng. 2018, 12, 528–536. [Google Scholar] [CrossRef]

- Teo, H.G.; Lee, P.S.; Hawlader, M.N.A. An active cooling system for photovoltaic modules. Appl. Energy 2012, 90, 309–315. [Google Scholar] [CrossRef]

- Kelly, N.; Strachan, P.A. Modeling enhanced performance inte-grated PV modules. In Proceedings of the 16th European PV SolarEnergy Conference, Glasgow, UK, 1–5 May 2000. [Google Scholar]

- Arnaout, M.; Salameh, W.; Assi, A. Impact of solar radiation and temperature levels on the variation of the series and shunt resistors in photovoltaic modules. Int. J. Res. Eng. Technol. 2016, 5, 295–301. [Google Scholar]

- Sowmy, D.S.; Prado, R.T.A. Assessment of energy efficiency in electric storage water heaters. In Energy and Buildings; Elsevier B.V.: Amsterdam, The Netherlands, 2008; Volume 40, pp. 2128–2132. [Google Scholar]

- Maghami, M.R.; Hizam, H.; Gomes, C.; Radzi, M.A.; Rezadad, M.I.; Hajighorbani, S. Power loss due to soiling on solar panel: A review. Renew. Sustain. Energy Rev. 2016, 59, 1307–1316. [Google Scholar] [CrossRef] [Green Version]

- Booysen, M.J.; Engelbrecht, J.A.A.; Molinaro, A. Proof of concept: Large-scale monitor and control of household water heating in near real-time. In Proceedings of the International Conference on Applied Energy, Pretoria, South Africa, 1–4 July 2013. [Google Scholar]

- Sateikis, I. Determination of the amount of thermal energy in the tanks of buildings heating systems. In Energy and Buildings; Elsevier: Amsterdam, The Netherlands, 2002; Volume 34, pp. 357–361. [Google Scholar]

- Cupelli, L.; Schumacher, M.; Monti, A.; Mueller, D.; De Tommasi, L.; Kouramas, K. Simulation tools and optimization algorithms for efficient energy management in neighborhoods. In Energy Positive Neighborhoods and Smart Energy Districts; Academic Press: Cambridge, MA, USA, 2017; pp. 57–100. [Google Scholar]

- Ma, Y.; Kelman, A.; Daly, A.; Borrelli, F. Predictive control for energy efficient buildings with thermal storage: Modeling, stimulation, and experiments. IEEE Control Syst. Mag. 2012, 32, 44–64. [Google Scholar]

- O’Dwyer, E.; De Tommasi, L.; Kouramas, K.; Cychowski, M.; Lightbody, G. Modelling and disturbance estimation for model predictive control in building heating systems. In Energy and Buildings; Elsevier: Amsterdam, The Netherlands, 2016; Volume 130, pp. 532–545. [Google Scholar]

- O’Dwyer, E.; De Tommasi, L.; Kouramas, K.; Cychowski, M.; Lightbody, G. Prioritised objectives for model predictive control of building heating systems. Control Eng. Pract. 2017, 63, 57–68. [Google Scholar] [CrossRef]

- Fiorentini, M.; Wall, J.; Ma, Z.; Braslavsky, J.H.; Cooper, P. Hybrid model predictive control of a residential HVAC system with on-site thermal energy generation and storage. Appl. Energy 2017, 187, 465–479. [Google Scholar] [CrossRef] [Green Version]

- Kuboth, S.; Heberle, F.; König-Haagen, A.; Brüggemann, D. Economic model predictive control of combined thermal and electric residential building energy systems. Appl. Energy 2019, 240, 372–385. [Google Scholar] [CrossRef]

| Configuration | Fixed Parameters | Varying Parameters |

| 1 | ||

| 2 | ||

| 3 | ||

| 4 |

| Power (W) | Time Needed to Reach 50 °C (Seconds) | Energy (kJ) |

|---|---|---|

| 500 | 54,900 | 27,450 |

| 1000 | 16,600 | 16,600 |

| 1500 | 10,000 | 15,000 |

| 2000 | 7200 | 14,400 |

| 2500 | 5600 | 14,000 |

| 3000 | 4600 | 13,800 |

| Volume (Liters) | Time Needed to Reach 50 °C (Seconds) | Energy (kJ) |

|---|---|---|

| 40 | 1750 | 5250 |

| 60 | 2650 | 7950 |

| 80 | 3580 | 10,950 |

| 100 | 4510 | 13,530 |

| 120 | 5490 | 16,470 |

| 140 | 6450 | 19,350 |

| Volume (Liters) | Time Needed to Reach 50 °C (Seconds) | Energy (kJ) |

|---|---|---|

| 40 | 1800 | 5400 |

| 60 | 2720 | 8160 |

| 80 | 3580 | 10,740 |

| 100 | 4530 | 13,590 |

| 120 | 5440 | 16,320 |

| Energy Required to Reach 50 °C | Energy Savings | |

|---|---|---|

| Reference configuration: P = 3000 W V = 100 L A = 1.35 m2 | 138 kJ/L | - |

| P = 500 W V = 100 L A = 1.35 m2 | 274.5 kJ/L | −98.9% (losses) |

| P = 3000 W V = 40 L A = 1.35 m2 | 135 kJ/L | 2.2% (saving) |

| P = 3000 W V = 100 L A = 1.193 m2 | 135.1 kJ/L | 2.1% (saving) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salameh, W.; Faraj, J.; Harika, E.; Murr, R.; Khaled, M. On the Optimization of Electrical Water Heaters: Modelling Simulations and Experimentation. Energies 2021, 14, 3912. https://doi.org/10.3390/en14133912

Salameh W, Faraj J, Harika E, Murr R, Khaled M. On the Optimization of Electrical Water Heaters: Modelling Simulations and Experimentation. Energies. 2021; 14(13):3912. https://doi.org/10.3390/en14133912

Chicago/Turabian StyleSalameh, Wassim, Jalal Faraj, Elias Harika, Rabih Murr, and Mahmoud Khaled. 2021. "On the Optimization of Electrical Water Heaters: Modelling Simulations and Experimentation" Energies 14, no. 13: 3912. https://doi.org/10.3390/en14133912

APA StyleSalameh, W., Faraj, J., Harika, E., Murr, R., & Khaled, M. (2021). On the Optimization of Electrical Water Heaters: Modelling Simulations and Experimentation. Energies, 14(13), 3912. https://doi.org/10.3390/en14133912